Review of Economic, Technical and Environmental Aspects of Electric Vehicles

Abstract

1. Introduction

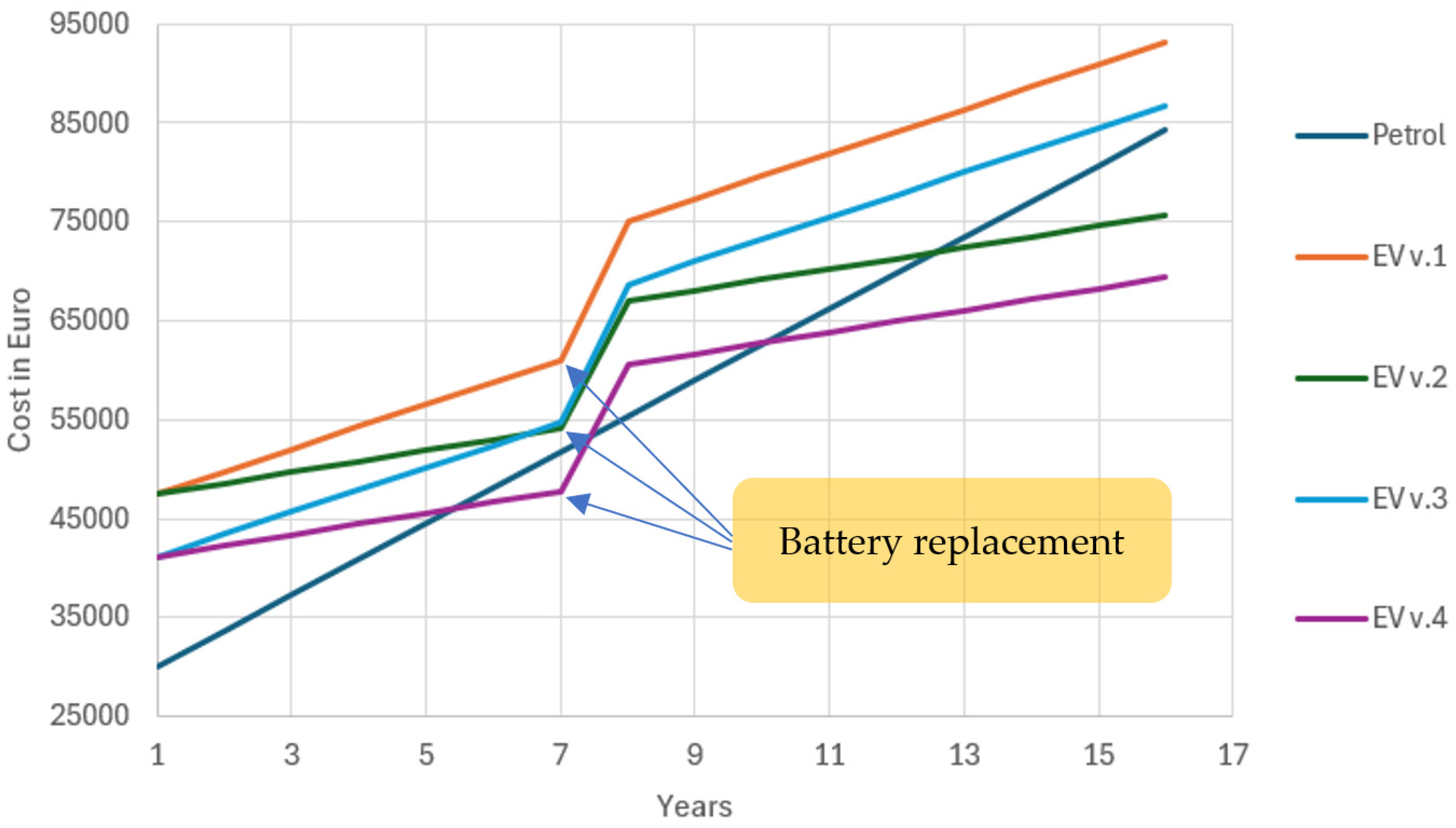

2. Economic Aspects

3. Technical Aspects

3.1. Mechanical Complexity

3.2. Energy Source

3.3. Fire Hazard

3.4. Cybersecurity

3.5. Impact on the Energy System

3.6. Battery Second Life

- As lithium-ion batteries age, changes occur at the material level, affecting their performance. One of these is the degradation of the SEI layer [69]. This layer forms on the anode during initial cycles and is passivating in nature. It helps protect it by preventing the continuous degradation of the electrolyte. Over time, however, this layer becomes thicker and more resistant. As it ages, it increases the charge transfer resistance, making it more difficult for lithium ions to move between electrodes during charge/discharge cycles. This results in lower power output and higher internal temperatures. The higher resistance also causes more pronounced voltage drops under load conditions, reducing overall usable capacitance and accelerating degradation.

- Another process that contributes to anode degradation is plating the anode with a layer of lithium [70]. The metallic lithium is deposited on the surface of the anode instead of penetrating it during charging cycles. This behaviour can result from excessively high operating currents or operations at low temperatures. Lithium coating can lead to the formation of dendrites, which are needle-like structures that grow through the electrolyte toward the cathode [71]. Dendrites can break through the separation material between the electrodes, causing internal short circuits that can result in catastrophic failures, such as uncontrolled overheating, leading to a fire. An additional effect of lithium film formation on the anode is the loss of this element from being able to actively participate in the energy storage process, leading to a reduction in capacity. Dendrite formation can also affect the voltage profiles of such damaged cells, which can affect the operation of the BMS, including the correct determination of the state of charge, which creates additional risks [72].

- Reduced vehicle range: A used battery has a reduced capacity, meaning the vehicle cannot travel the same distance on a single charge as before. This can result in more frequent charging, which is inconvenient for the user.

- Reduced charging and discharging capacity: This is due to the battery management system limiting operating currents. The increased internal resistance of the battery leads to higher losses of energy converted into heat, which further negatively affects the temperature of the energy storage. As a result, worn batteries may provide less energy, affecting vehicle performance. The car may be less dynamic, and acceleration may be reduced, affecting the overall driving experience. Charging may also be slower for the above reasons, further affecting the comfort of electric vehicles.

- Increased risk of failure: Batteries that have reached their wear limits in EVs are more prone to failure and may unexpectedly stop working, leading to unforeseen situations on the road, such as a sudden loss of power.

4. Environmental Aspects

4.1. Temperature Dependence

4.2. Lithium Acquisition

4.3. CO2 Emissions

4.4. Recycling

- Pyrometallurgy: High-temperature processes are used for smelting metals, which are then separated. This method is usually employed to recover cobalt, nickel, and copper.

- Hydrometallurgy: Chemical processes using aqueous solutions to recover metals. It is more energy-efficient than pyrometallurgy, though more complex in terms of the purification of final products.

- Mechanical Methods: Recovery of materials through mechanical crushing and separation. These are preliminary steps for further chemical treatment.

- Lithium-Cobalt Oxide (LCO) Cells: The cathode contains cobalt, and the anode contains graphite. Cobalt is a valuable material, so the priority in recycling these cells is recovering cobalt. The process involves dissolving the active materials in acids (e.g., acid leaching) and separating cobalt from other metals. Hydrometallurgical and pyrometallurgical methods are often used for this purpose.

- Lithium Iron Phosphate (LFP) Cells: The cathode contains lithium, iron, and phosphorus, and the anode contains graphite. These cells do not contain cobalt, making their recycling less financially lucrative. Hydrometallurgical techniques are used to recover lithium, iron, and phosphorus. Though the recovery process is less complex, the lower-cost materials result in less economic motivation for recycling.

- Lithium-Nickel-Manganese-Cobalt Oxide (NMC) Cells: The cathode contains nickel, manganese, and cobalt, and the anode contains graphite. Like LCO, these cells are valuable due to their cobalt and nickel content. Pyrometallurgical and hydrometallurgical processes are used to recover these metals. Due to the complex composition, the separation processes must be more advanced to recover all the valuable materials effectively.

- Lithium Titanate (LTO) Cells: The cathode is varied, and the anode contains titanium oxide. These cells are less common, and their recycling is less developed. Recovering titanium is technologically feasible, but the economic viability of this process is still under investigation. Mechanical and hydrometallurgical methods are used for separation and recovery.

- Lithium-Polymer (LiPo) Cells: The cathode can be similar to LCO, NMC, or others, and the anode contains graphite. Recycling processes depend on the specific cathode composition. These cells often require additional steps to separate polymer materials, making the process more complex. Hybrid approaches combining different recycling techniques are thus employed.

4.5. Consequences of the Fire

- Renewable Energy Sources: Wind, solar and hydroelectric energy do not emit CO2 during generation, making electric vehicles charged from such sources have a much smaller carbon footprint.

- Nuclear Power: Nuclear power also does not emit CO2 during generation, although it comes with other challenges, such as radioactive waste management.

- Fossil Fuels: Energy generated from coal, oil or natural gas is associated with high CO2 emissions, reducing the environmental benefits of electric vehicles.

5. Discussion

- -

- Developing economic models that can accurately predict long-term costs and benefits, including the potential impact of government taxes.

- -

- Advancing battery technology to improve safety, reduce costs and minimise environmental damage.

- -

- Strengthening cyber-security measures as electric vehicles are integrated into infrastructure.

- -

- Conducting life cycle assessments (LCAs) to evaluate the overall environmental impact of EVs from material extraction to recycling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Şen, M.; Yiğiter, M.S.; Özca, M. Why are consumers switching to electric vehicles? Analyzing consumers preferences for electric vehicles. Case Stud. Transp. Policy 2023, 14, 101108. [Google Scholar] [CrossRef]

- Şenyapar, H.N.D.; Murat, A. Analysis of Consumer Behavior towards Electric Vehicles: Intentions, Concerns, and Policies. Gazi Üniversitesi Fen Bilim. Derg. Part C Tasarım Teknol. 2023, 11, 161–183. [Google Scholar] [CrossRef]

- Maklár, E. Economic comparison between conventionally powered and electric cars. Acta Acad. Beregsasiensis. Econ. 2023, 3, 75–85. [Google Scholar] [CrossRef]

- Santos, G. Road fuel taxes in Europe: Do they internalize road transport externalities? Transp. Policy 2017, 53, 120–134. [Google Scholar] [CrossRef]

- How Electric Vehicles Could Affect State Transportation Budgets. Available online: https://www.pewtrusts.org/en/research-and-analysis/articles/2024/07/03/how-electric-vehicles-could-affect-state-transportation-budgets (accessed on 24 August 2024).

- Hall, D.; Lutsey, N. Emerging Best Practices for Electric Vehicle Charging Infrastructure; International Council on Clean Transportation: Washington, DC, USA, 2017. [Google Scholar]

- Putra, Y.R.P.; Sudiarno, A.; Sholihah, M.; Wikarta, A.; Pranaditya, I.; Saputra, Y.A. Comparative Economic Study of Electric Cars in Indonesia. E3S Web of Conf. 2024, 517, 05016. [Google Scholar] [CrossRef]

- Nowa KONA|Hyundai Polska. Available online: https://www.hyundai.com/pl/pl/modele/nowa-kona.html (accessed on 24 August 2024).

- Nowa KONA Electric|Hyundai Polska. Available online: https://www.hyundai.com/pl/pl/modele/nowa-kona-electric.html (accessed on 24 August 2024).

- Kłos, M.J.; Sierpiński, G. Siting of electric vehicle charging stations method addressing area potential and increasing their accessibility. J. Transp. Geogr. 2023, 109, 103601. [Google Scholar] [CrossRef]

- Hecht, C.; Figgener, J.; Sauer, D.U. Predicting Electric Vehicle Charging Station Availability Using Ensemble Machine Learning. Energies 2021, 14, 7834. [Google Scholar] [CrossRef]

- Luo, R. Deep Learning Approach for Long- Term Prediction of Electric Vehicle (EV) Charging Station Availability. In Proceedings of the 2021 IEEE International Intelligent Transportation Systems Conference (ITSC), Indianapolis, IN, USA, 19–22 September 2021; pp. 3334–3339. [Google Scholar]

- U.S. Electric Vehicle SALES Soar Into’24. Available online: https://theicct.org/us-ev-sales-soar-into-24-jan24 (accessed on 19 September 2024).

- Buchatskiy, P.; Teploukhov, S.; Onishchenko, S.; Lisov, D. Program Module for Locating Charging Stations for Electric Light Vehicles in a Settlement. In Proceedings of the 2024 International Conference on Information Processes and Systems Development and Quality Assurance (IPS), Saint Petersburg, Russia, 19 March 2024; pp. 12–16. [Google Scholar]

- Apata, O.; Bokoro, P.N.; Sharma, G. The Risks and Challenges of Electric Vehicle Integration into Smart Cities. Energies 2023, 16, 5274. [Google Scholar] [CrossRef]

- Zheng, J. Comparative Analysis of Operational Advantages and Disadvantages Between Conventional Internal Combustion Engine Vehicles and Electric Vehicles based on Tesla. Highlights Sci. Eng. Technol. 2023, 3, 208–213. [Google Scholar] [CrossRef]

- Mohammad, K.S.; Jaber, A.S. Comparison of electric motors used in electric vehicle propulsion system. Indones. J. Electr. Eng. Comput. Sci. 2022, 27, 11–19. [Google Scholar] [CrossRef]

- Dixon, J. Energy storage for electric vehicles. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Via del Mar, Chile, 14–17 March 2010; pp. 20–26. [Google Scholar]

- Jayaprabakar, J.; Aravind Kumar, J.; Parthipan, J.; Karthikeyan, A.; Anish, M.; Joy, N. Review on hybrid electro chemical energy storage techniques for electrical vehicles: Technical insights on design, performance, energy management, operating issues & challenges. J. Energy Storage 2023, 72 Pt D, 108689. [Google Scholar]

- Bencs, P.; Alktranee, M. The potential of vehicle cooling systems. J. Phys. Conf. Ser. 2021, 1935, 012012. [Google Scholar] [CrossRef]

- Tapaskar, R.P.; Revankar, P.P.; Ganachari, S.V. Advancements in Battery Management Systems for Electric Vehicles: A MATLAB-Based Simulation of 4S3P Lithium-Ion Battery Packs. World Electr. Veh. J. 2024, 15, 222. [Google Scholar] [CrossRef]

- Baczyńska, A.; Niewiadomski, W.; Gonçalves, A.; Almeida, P.; Luís, R. Li-NMC Batteries Model Evaluation with Experimental Data for Electric Vehicle Application. Batteries 2018, 4, 11. [Google Scholar] [CrossRef]

- Salgado, R.M.; Danzi, F.; Oliveira, J.E.; El-Azab, A.; Camanho, P.P.; Braga, M.H. The Latest Trends in Electric Vehicles Batteries. Molecules 2021, 26, 3188. [Google Scholar] [CrossRef] [PubMed]

- Koech, A.K.; Mwandila, G.; Mulolani, F. A review of improvements on electric vehicle battery. Heliyon 2024, 10, e34806. [Google Scholar] [CrossRef]

- Battery University. Available online: https://batteryuniversity.com/article/bu-205-types-of-lithium-ion (accessed on 24 August 2024).

- Ufine Battery. Available online: https://www.ufinebattery.com/blog/types-of-lithium-batteries/ (accessed on 24 August 2024).

- Gao, Y.; Zhang, H.; Peng, J.; Li, L.; Xiao, Y.; Li, L.; Liu, Y.; Qiao, Y.; Chou, S. A 30-year overview of sodium-ion batteries. Carbon Energy 2024, 6, 43. [Google Scholar] [CrossRef]

- Liang, K.; Zhao, H.; Li, J.; Huang, X.; Jia, S.; Chen, W.; Ren, Y. Engineering Crystal Growth and Surface Modification of Na3 V2 (PO4)2 F3 Cathode for High-Energy-Density Sodium-Ion Batteries. Small 2023, 19, e2207562. [Google Scholar] [CrossRef]

- Etukudoh, E.A.; Hamdan, A.; Daudu, C.D.; Fabuyide, A.; Sonko, S. Next-generation batteries and U.S. energy storage: A comprehensive review: Scrutinizing advancements in battery technology, their role in renewable energy, and grid stability. World J. Adv. Res. Rev. 2024, 21, 1984–1998. [Google Scholar]

- Shen, Y. Research and Development Status of Solid-State Batteries. Highlights Sci. Eng. Technol. 2024, 83, 145–152. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Yuan, Z.; Zhang, H.; Tian, S.; Zhang, Y.; Zhang, B.; Han, Y.; Zhang, J.; Cui, G. In-Situ Polymerized Solid-State Polymer Electrolytes for High-Safety Sodium Metal Batteries: Progress and Perspectives. Batteries 2023, 9, 532. [Google Scholar] [CrossRef]

- Shen, H.; Wang, H.; Li, M.; Li, C.; Zhang, Y.; Li, Y.; Yang, X.; Feng, X.; Ouyang, M. Thermal Runaway Characteristics and Gas Composition Analysis of Lithium-Ion Batteries with Different LFP and NCM Cathode Materials under Inert Atmosphere. Electronics 2023, 12, 1603. [Google Scholar] [CrossRef]

- LFP, vs. NMC Battery: Complete Comparison Guide. Available online: https://www.ecolithiumbattery.com/lfp-vs-nmc-battery (accessed on 19 September 2024).

- Bugryniec, P.J.; Resendiz, E.G.; Nwophoke, S.M.; Khanna, S.; James, C.; Brown, S.F. Review of gas emissions from lithium-ion battery thermal runaway failure—Considering toxic and flammable compounds. J. Energy Storage 2024, 87, 111288. [Google Scholar] [CrossRef]

- Amano, K.O.A.; Hahn, S.-K.; Tschirschwitz, R.; Rappsilber, T.; Krause, U. An Experimental Investigation of Thermal Runaway and Gas Release of NMC Lithium-Ion Pouch Batteries Depending on the State of Charge Level. Batteries 2022, 8, 41. [Google Scholar] [CrossRef]

- Wang, W.; He, T.; He, S.; You, T.; Khan, F. Modeling of thermal runaway propagation of NMC battery packs after fast charging operation. Process Saf. Environ. Prot. 2021, 154, 104–117. [Google Scholar] [CrossRef]

- Golubkov, A.; Scheikl, S.; Planteu, R.; Voitic, G.; Wiltsche, H.; Stangl, C.; Fauler, G.; Thaler, A.; Hacker, V. Thermal runaway of commercial 18650 Li-ion batteries with LFP and NCA cathodes—Impact of state of charge and overcharge. RSC Adv. 2015, 70, 57171–57186. [Google Scholar] [CrossRef]

- Qiu, M.; Liu, J.; Cong, B.; Cui, Y. Research Progress in Thermal Runaway Vent Gas Characteristics of Li-Ion Battery. Batteries 2023, 9, 411. [Google Scholar] [CrossRef]

- Tschirschwitz, R.; Bernardy, C.; Wagner, P.; Rappsilber, T.; Liebner, C.; Hahn, S.K.; Krause, U. Harmful effects of lithium-ion battery thermal runaway: Scale-up tests from cell to second-life modules. RSC Adv. 2023, 13, 20761–20779. [Google Scholar] [CrossRef]

- Brand, M.; Gläser, S.; Geder, J.; Menacher, S.; Obpacher, S.; Jossen, A.; Quinger, D. Electrical safety of commercial Li-ion cells based on NMC and NCA technology compared to LFP technology. World Electr. Veh. J. 2013, 6, 572–580. [Google Scholar] [CrossRef]

- Fraiji, Y.; Azzouz, L.B.; Trojet, W.; Saïdane, L.A. Cyber security issues of Internet of electric vehicles. In Proceedings of the 2018 IEEE Wireless Communications and Networking Conference (WCNC), Barcelona, Spain, 15–18 April 2018; pp. 1–6. [Google Scholar]

- Muhammad, Z.; Anwar, Z.; Saleem, B.; Shahid, J. Emerging Cybersecurity and Privacy Threats to Electric Vehicles and Their Impact on Human and Environmental Sustainability. Energies 2023, 16, 1113. [Google Scholar] [CrossRef]

- Bathla, G.; Bhadane, K.; Singh, R.K.; Kumar, R.; Aluvalu, R.; Krishnamurthi, R.; Kumar, A.; Thakur, R.; Basheer, S. Autonomous Vehicles and Intelligent Automation: Applications, Challenges, and Opportunities. Mob. Inf. Syst. 2022, 2022, 7632892. [Google Scholar] [CrossRef]

- Aghapour, R.; Zeraati, M.; Jabari, F.; Sheibani, M.; Arasteh, H. Cybersecurity and Data Privacy Issues of Electric Vehicles Smart Charging in Smart Microgrids. In Electric Vehicle Integration via Smart Charging; Springer: Berlin/Heidelberg, Germany, 2022; pp. 85–110. [Google Scholar]

- The Verge. Available online: https://www.theverge.com/2017/9/10/16283330/tesla-hurricane-irma-update-florida-extend-range-model-s-x-60-60d (accessed on 24 August 2024).

- Acharya, S.; Dvorkin, Y.; Pandžić, H.; Karri, R. Cybersecurity of Smart Electric Vehicle Charging: A Power Grid Perspective. IEEE Access 2020, 8, 214434–214453. [Google Scholar] [CrossRef]

- Hamdare, S.; Kaiwartya, O.; Aljaidi, M.; Jugran, M.; Cao, Y.; Kumar, S.; Mahmud, M.; Brown, D.; Lloret, J. Cybersecurity Risk Analysis of Electric Vehicles Charging Stations. Sensors 2023, 23, 6716. [Google Scholar] [CrossRef] [PubMed]

- Government Fleet and Public Sector Electric Vehicle Supply Equipment (EVSE) Cybersecurity Best Practices and Procurement Language Report. 2019. Available online: https://rosap.ntl.bts.gov/view/dot/43606 (accessed on 24 August 2024).

- Yilmaz, M.; Krein, P.T. Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles. IEEE Trans. Power Electron 2013, 28, 2151–2169. [Google Scholar] [CrossRef]

- Shareef, H.; Islam, M.M.; Mohamed, A. Review of the stage of the-art charging technologies, placement methodologies, and impacts of electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 403–420. [Google Scholar] [CrossRef]

- Kempton, W.; Udo, V.; Huber, K.A. Test of Vehicle-to-Grid (V2G) for Energy Storage and Frequency Regulation in the PJM System; University of Delaware: Newark, DE, USA, 2008. [Google Scholar]

- Clement-Nyns, K.; Haesen, E.; Driesen, J. The impact of vehicle-to-grid on the distribution grid. Electr. Power Syst. Res. 2011, 81, 185–192. [Google Scholar] [CrossRef]

- Pieltain Fernández, L.; Gomez San Roman, T.; Cossent, R.; Mateo Domingo, C.; Frías, P. Assessment of the impact of plug-in electric vehicles on distribution networks. IEEE Trans. Power Syst. 2011, 26, 206–213. [Google Scholar] [CrossRef]

- Wang, L.; Qin, Z.; Slangen, T.; Bauer, P.; van Wijk, T. Grid Impact of Electric Vehicle Fast Charging Stations: Trends, Standards, Issues, and Mitigation Measures—An Overview. IEEE Open J. Power Electron. 2021, 2, 56–74. [Google Scholar] [CrossRef]

- Tu, H.; Feng, H.; Srdic, S.; Lukic, S. Extreme fast charging of electric vehicles: A technology overview. IEEE Trans. Transport. Electrific. 2019, 5, 861–878. [Google Scholar] [CrossRef]

- Karmaker, A.K.; Roy, S.; Ahmed, M.R. Analysis of the Impact of Electric Vehicle Charging Station on Power Quality Issues. In Proceedings of the 2019 International Conference on Electrical, Computer, and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 7–9 February 2019; pp. 1–6. [Google Scholar]

- Yunus, K.; De LaParra, H.Z.; Reza, M. Distribution grid impact of plug-in electric vehicles charging at fast charging stations using stochastic charging model. In Proceedings of the 14th European Conference on Power Electronics and Applications, Birmingham, UK, 30 August–1 September 2011; pp. 1–11. [Google Scholar]

- Bass, R.; Zimmerman, N. Impacts of electric vehicle charging on electric power distribution systems. Transp. Res. Educ. Cent. (TREC) 2013, 7, 485–502. [Google Scholar]

- Wang, X.; Blaabjerg, F. Harmonic stability in power electronic based power systems: Concept, modeling, and analysis. IEEE Trans. Smart Grid 2019, 10, 2858–2870. [Google Scholar] [CrossRef]

- Hilshey, A.D.; Hines, P.D.H.; Rezaei, P.; Dowds, J.R. Estimating the impact of electric vehicle smart charging on distribution transformer aging. IEEE Trans. Smart Grid 2013, 4, 905–913. [Google Scholar] [CrossRef]

- Khalid, M.R.; Alam, M.S.; Sarwar, A.; Asghar, M.S.J. A Comprehensive review on electric vehicles charging infrastructures and their impacts on power-quality of the utility grid. eTransportation 2019, 1, 100006. [Google Scholar] [CrossRef]

- Coldwell, M.; Strickland, D.; Chittock, L. Impact of electric vehicles on GB electricity demand and associated benefits for system control. In Proceedings of the 2013 48th International Universities’ Power Engineering Conference (UPEC), Dublin, Ireland, 2–5 September 2013; pp. 1–6. [Google Scholar]

- Alam, M.J.E.; Muttaqi, K.M.; Sutanto, D. Effective utilization of available PEV battery capacity for mitigation of solar PV impact and grid support with integrated V2G functionality. IEEE Trans. Smart Grid 2016, 7, 1562–1571. [Google Scholar] [CrossRef]

- Salvatti, G.A.; Carati, E.G.; Cardoso, R.; da Costa, J.P.; Stein, C.M.d.O. Electric Vehicles Energy Management with V2G/G2V Multifactor Optimization of Smart Grids. Energies 2020, 13, 1191. [Google Scholar] [CrossRef]

- Yu, R.; Zhong, W.; Xie, S.; Yuen, C.; Gjessing, S.; Zhang, Y. Balancing Power Demand Through EV Mobility in Vehicle-to-Grid Mobile Energy Networks. IEEE Trans. Ind. Inform. 2016, 12, 79–90. [Google Scholar] [CrossRef]

- Sun, L.; Wang, X.; Liu, W.; Lin, Z.; Wen, F.; An, S.P.; Salam, M.A. Optimization model for power system restoration with support from electric vehicles employing battery swapping. IET Gener. Transm. Distrib. 2016, 10, 771–779. [Google Scholar] [CrossRef]

- Ma, Y.; Houghton, T.; Cruden, A.; Infield, D. Modeling the benefits of vehicle-to-grid technology to a power system. IEEE Trans. Power Syst. 2012, 27, 1012–1020. [Google Scholar] [CrossRef]

- Mrozik, M.; Merkisz-Guranowska, A. Modeling of material and energy inputs in the life cycle of a vehicle. Arch. Transp. 2024, 70, 117–136. [Google Scholar] [CrossRef]

- Wang, A.; Kadam, S.S.; Li, H.; Shi, S.; Qi, Y. Review on modeling of the anode solid electrolyte interphase (SEI) for lithium-ion batteries. Npj Comput. Mater. 2018, 4, 15. [Google Scholar] [CrossRef]

- Liu, Q.; Du, C.; Shen, B.; Zuo, P.; Cheng, X.; Ma, Y.; Yin, G.; Gao, Y. Understanding undesirable anode lithium plating issues in lithium-ion batteries. ChemInform 2016, 47, 88683–88700. [Google Scholar] [CrossRef]

- Ren, Y.; Shen, Y.; Lin, Y.; Nan, C.-W. Direct observation of lithium dendrites inside garnet-type lithium-ion solid electrolyte. Electrochem. Commun. 2015, 57, 27–30. [Google Scholar] [CrossRef]

- Aleshin, A.; Bravo, S.; Redquest, K.; Wood, K.N. Rapid Oxidation and Reduction of Lithium for Improved Cycling Performance and Increased Homogeneity. ACS Appl. Mater. Interfaces 2021, 13, 2654–2661. [Google Scholar] [CrossRef] [PubMed]

- Lacey, G.; Putrus, G.; Salim, A. The use of second life electric vehicle batteries for grid support. In Proceedings of the Eurocon 2013, Zagreb, Croatia, 1–4 July 2013; pp. 1255–1261. [Google Scholar]

- Strickland, D.; Chittock, L.; Stone, D.A.; Foster, M.P.; Price, B. Estimation of Transportation Battery Second Life for Use in Electricity Grid Systems. IEEE Trans. Sustain. Energy 2014, 5, 795–803. [Google Scholar] [CrossRef]

- Fischhaber, S.; Regett, A.; Schuster, S.F.; Hesse, H. Second-Life-Konzepte für Lithium-Ionen-Batterien aus Elektrofahrzeugen: Analyse von Nachnutzungsanwendungen, Ökonomischen und Ökologischen Potenzialen; Schaufenster Elektromobilität (BuW): Frankfurt, Germany, 2016. [Google Scholar]

- Kampker, A.; Heimes, H.H.; Offermanns, C.; Vienenkötter, J.; Frank, M.; Holz, D. Identification of Challenges for Second-Life Battery Systems—A Literature Review. World Electr. Veh. J. 2023, 14, 80. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Luque, A.; Hegedus, S. Handbook of Photovoltaic Science and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 10 0471491969/13 978-0471491965. [Google Scholar]

- Armand, M.; Axmann, P.; Bresser, D.; Copley, M.; Edström, K.; Ekberg, C.; Guyomard, D.; Lestriez, B.; Novák, P.; Petranikova, M.; et al. Lithium-ion batteries—Current state of the art and anticipated developments. J. Power Sources 2020, 479, 228708. [Google Scholar] [CrossRef]

- By 2030 EVs Represent More than 60% of Vehicles Sold Globally, and Require an Adequate Surge in Chargers Installed in Buildings. Available online: https://www.iea.org/reports/by-2030-evs-represent-more-than-60-of-vehicles-sold-globally-and-require-an-adequate-surge-in-chargers-installed-in-buildings (accessed on 19 September 2024).

- Kaunda, R.B. Potential environmental impacts of lithium mining. J. Energy Nat. Resour. Law 2020, 38, 237–244. [Google Scholar] [CrossRef]

- Karacan, R.; Kayacan, E.Y. How environmentally friendly are electric cars? The relationship between lithium usage and water resources, Chile example. Manag. Decis. Econ. 2024, 8, 5346–5358. [Google Scholar] [CrossRef]

- Wanger, T.C. The Lithium future—Resources, recycling, and the environment. Conserv. Lett. 2011, 4, 202–206. [Google Scholar] [CrossRef]

- Baspineiro, C.F.; Franco, J.; Flexer, V. Potential water recovery during lithium mining from high salinity brines. Sci. Total Environ. 2020, 720, 137523. [Google Scholar] [CrossRef] [PubMed]

- Elshamy, A.I.; Hussein, A.A.; ElBadry, S.; Elshazly, E.; Moussa, R.R.; El-Mahallawi, I. Techno-economic Evaluation and Environmental Benefit of PV-based Electric Vehicle Charging Station on University Campus. In Proceedings of the 2023 2nd International Conference on Smart Cities 4.0, Cairo, Egypt, 22–24 October 2023; pp. 49–54. [Google Scholar]

- Bodak, V. Comparison of carbon dioxide gas emissions during production, operation of an electric car and a car with an internal combustion engine. J. Mech. Eng. Transp. 2023, 17, 3–8. [Google Scholar] [CrossRef]

- Yan, Y.; Li, J. Transport carbon emissions reduction efficiency and economic growth: A perspective from nighttime lights remote sensing. Arch. Transp. 2023, 66, 21–32. [Google Scholar] [CrossRef]

- Neugebauer, M.; Żebrowski, A.; Esmer, O. Cumulative Emissions of CO2 for Electric and Combustion Cars: A Case Study on Specific Models. Energies 2022, 15, 2703. [Google Scholar] [CrossRef]

- Merkisz, J.; Pielecha, J.; Jasiński, R. Remarks about real driving emissions tests for passenger cars. Arch. Transp. 2016, 39, 51–63. [Google Scholar] [CrossRef]

- Bae, H.; Kim, Y. Technologies of lithium recycling from waste lithium ion batteries: A review. Mater. Adv. 2021, 2, 3234–3250. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Marom, R.; Amalraj, S.; Leifer, N.; Jacob, D.; Aurbach, D. A review of advanced and practical lithium battery materials. J. Mater. Chem. 2011, 21, 9938–9954. [Google Scholar] [CrossRef]

- Peng, Y.; Yang, L.; Ju, X.; Liao, B.; Ye, K.; Li, L.; Cao, B.; Ni, Y. A comprehensive investigation on the thermal and toxic hazards of large format lithium-ion batteries with LiFePO4 cathode. J. Hazard. Mater. 2020, 381, 120916. [Google Scholar] [CrossRef]

- Chen, M.; Liu, J.; He, Y.; Yuen, R.; Wang, J. Study of the fire hazards of lithium-ionbatteries at different pressures. Appl. Therm. Eng. 2017, 125, 1061–1074. [Google Scholar] [CrossRef]

- Lecocq, A.; Eshetu, G.G.; Grugeon, S.; Martin, N.; Laruelle, S.; Marlair, G. Scenario-based prediction of Li-ion batteries fire-induced toxicity. J. Power Sources 2016, 316, 197–206. [Google Scholar] [CrossRef]

- Xu, J.; Guo, P.; Duan, Q.; Yu, X.; Zhang, L.; Yujun, L.; Wang, Q. Experimental study of the effectiveness of three kinds of extinguishing agents on suppressing lithium-ion battery fires. Appl. Therm. Eng. 2020, 171, 115076. [Google Scholar] [CrossRef]

- Yuan, S.; Chang, C.; Yan, S.; Zhou, P.; Qian, X.; Yuan, M.; Liu, K. A review of fire-extinguishing agent on suppressing lithium-ion batteries fire. J. Energy Chem. 2021, 62, 262–280. [Google Scholar] [CrossRef]

- Zhang, L.; Jin, K.; Sun, J.; Wang, Q. A Review of Fire-Extinguishing Agents and Fire Suppression Strategies for Lithium-Ion Batteries Fire. Fire Technol 2024, 60, 817–858. [Google Scholar] [CrossRef]

- Russo, P.; Bari, C.D.; Mazzaro, M.; Rosa, A.D.; Morriello, I. Effective fire extinguishing systems for lithium-ion battery. Chem. Eng. Trans. 2018, 67, 727–732. [Google Scholar]

- Park, Y.J.; Kim, M.K.; Kim, H.S.; Lee, B.M. Risk assessment of lithium-ion battery explosion: Chemical leakages. J. Toxicol. Environ. Health 2018, 21 Pt B, 370–381. [Google Scholar] [CrossRef]

- Siczek, K. The Toxicity of Secondary Lithium-Sulfur Batteries Components. Batteries 2020, 6, 45. [Google Scholar] [CrossRef]

- Krol, M.; Krol, A. The Threats Related to Parking Electric Vehicle in Underground Car Parks. In Intelligent Solutions for Cities and Mobility of the Future; Springer: Cham, Switzerland, 2021; Volume 352, pp. 72–81. [Google Scholar]

- Larsson, F.; Andersson, P.; Blomqvist, P.; Mellander, B. Toxic fluoride gas emissions from lithium-ion battery fires. Sci. Rep. 2017, 7, 10018. [Google Scholar] [CrossRef]

- Vadium, I.T.; Das, R.; Wang, Y.; Putrus, G.A.; Kotter, R. Electric vehicle Carbon footprint reduction via intelligent charging strategies. In Proceedings of the 2019 8th International Conference on Modern Power Systems (MPS), Cluj Napoca, Romania, 21–23 May 2019; pp. 1–6. [Google Scholar]

- Kim, H.C.; Lee, S.; Wallington, T.J. Cradle-to-Gate and Use-Phase Carbon Footprint of a Commercial Plug-in Hybrid Electric Vehicle Lithium-Ion Battery. Environ. Sci. Technol. 2023, 57, 11834–11842. [Google Scholar] [CrossRef]

- Li, P.; Xia, X.; Guo, J. A review of the life cycle carbon footprint of electric vehicle batteries. Sep. Purif. Technol. 2022, 296, 121389. [Google Scholar] [CrossRef]

- Ghosh, A. Possibilities and Challenges for the Inclusion of the Electric Vehicle (EV) to Reduce the Carbon Footprint in the Transport Sector: A Review. Energies 2020, 13, 2602. [Google Scholar] [CrossRef]

- Ellingse, L.A.; Singh, B.; Strømman, A.H. The size and range effect: Lifecycle greenhouse gas emissions of electric vehicles. Environ. Res. Lett. 2016, 11, 054010. [Google Scholar] [CrossRef]

| Variant | Car Cost in Euros | Monthly Maintenance Cost in Euros | Battery Replacement Frequency [Years] | Battery Cost in Euros | Energy Price in Euros | Energy Consumption per 1 km [kWh] | Annual Mileage [km] |

|---|---|---|---|---|---|---|---|

| 1 | 47,505 | 35 | 8 | 11,764 | 0.49 | 0.15 | 25,000 |

| 2 | 47,505 | 35 | 8 | 11,764 | 0.18 | 0.15 | 25,000 |

| 3 | 41,153 | 35 | 8 | 11,764 | 0.49 | 0.15 | 25,000 |

| 4 | 41,153 | 35 | 8 | 11,764 | 0.18 | 0.15 | 25,000 |

| Car Cost in Euros | Monthly Maintenance Cost in Euros | Energy Price in Euros | Energy Consumption per 1 km [kWh] | Annual Mileage [km] |

|---|---|---|---|---|

| 29,976 | 70 | 1.63 | 0.068 | 25,000 |

| Aspect | Internal Combustion Vehicles | Electric Vehicles |

|---|---|---|

| Energy source | Fossil fuels | Electricity |

| Drive mechanism | Internal combustion engine | Electric motor |

| complexity | High | Low |

| Failure risk | Higher risk due to more components | Lower risk due to fewer components |

| Maintenance requirements | Higher due to complex systems | Lower due to simpler design |

| Transmission | Complex with multiple gears | Simpler, usually single-speed transmissions |

| Combustion systems | Complex with catalytic converters and exhaust systems | Less complex, no emissions systems required |

| Cooling systems | Requires sophisticated cooling mechanisms | Simpler, but battery cooling is critical |

| Moving parts | More moving parts | Fewer moving parts |

| Emissions | Produces harmful emissions, requires afterburning systems | Zero direct emissions |

| Energy efficiency | Lower efficiency due to energy loss as heat | Higher efficiency in energy conversion |

| Noise level | Higher noise levels | Lower noise levels |

| Refuelling/Charging | Quick refuelling at gas stations | Longer charging times, potential for solar-powered charging stations |

| Parameter | LFP (LiFePO4) | NMC (LiNiMnCoO2) |

|---|---|---|

| Nominal Voltage | 3.2–3.3 V per cell | 3.6–3.7 V per cell |

| Energy Density | 90–160 Wh/kg | 140–200 Wh/kg |

| Power Density | 250–670 W/kg | 150–315 W/kg |

| Cycle Life | >2000 cycles (up to 5000–10,000) | ~2000 cycles |

| Charge Time | 1–4 h | 1–3 h |

| Operating Temperature | −20 °C to 60 °C | −20 °C to 55 °C |

| Self-Discharge Rate | 1–3% per month | 1–2% per month |

| Depth of Discharge (DoD) | 80–98% | 80–90% |

| Safety | Very safe, low risk of thermal runaway | Moderate risk of thermal runaway |

| Efficiency | 92% round-trip efficiency | 85–90% round-trip efficiency |

| Temperature [°C] | Initial Voltage Drop [%] | Final Capacity [%] |

|---|---|---|

| 60 | 0 | 104 |

| 20 | 0 | 100 |

| −10 | 5 | 88 |

| −20 | 10 | 63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koniak, M.; Jaskowski, P.; Tomczuk, K. Review of Economic, Technical and Environmental Aspects of Electric Vehicles. Sustainability 2024, 16, 9849. https://doi.org/10.3390/su16229849

Koniak M, Jaskowski P, Tomczuk K. Review of Economic, Technical and Environmental Aspects of Electric Vehicles. Sustainability. 2024; 16(22):9849. https://doi.org/10.3390/su16229849

Chicago/Turabian StyleKoniak, Marcin, Piotr Jaskowski, and Krzysztof Tomczuk. 2024. "Review of Economic, Technical and Environmental Aspects of Electric Vehicles" Sustainability 16, no. 22: 9849. https://doi.org/10.3390/su16229849

APA StyleKoniak, M., Jaskowski, P., & Tomczuk, K. (2024). Review of Economic, Technical and Environmental Aspects of Electric Vehicles. Sustainability, 16(22), 9849. https://doi.org/10.3390/su16229849