Analytical Model for Rate Transient Behavior of Co-Production between Coalbed Methane and Tight Gas Reservoirs

Abstract

1. Introduction

2. Methodology

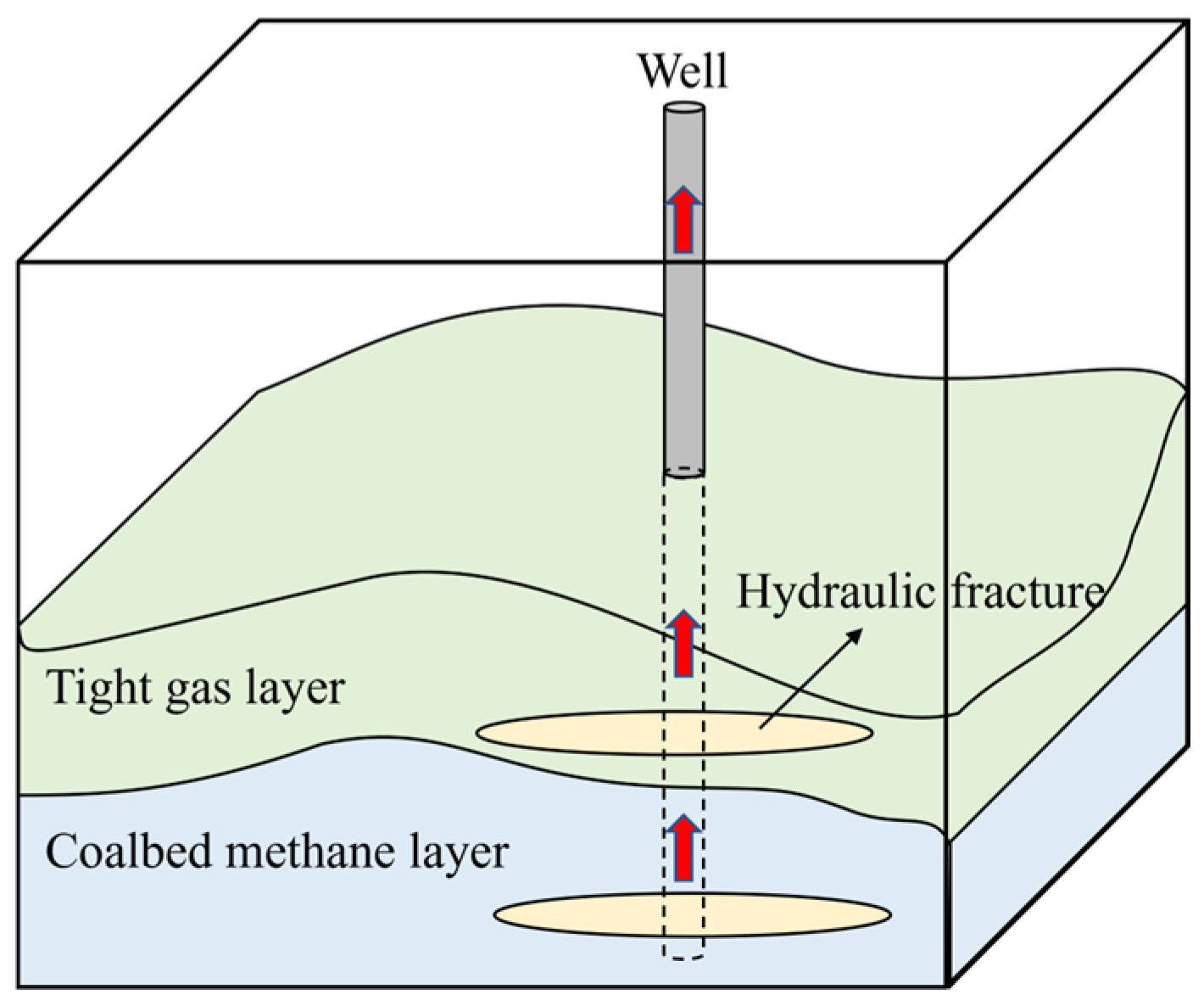

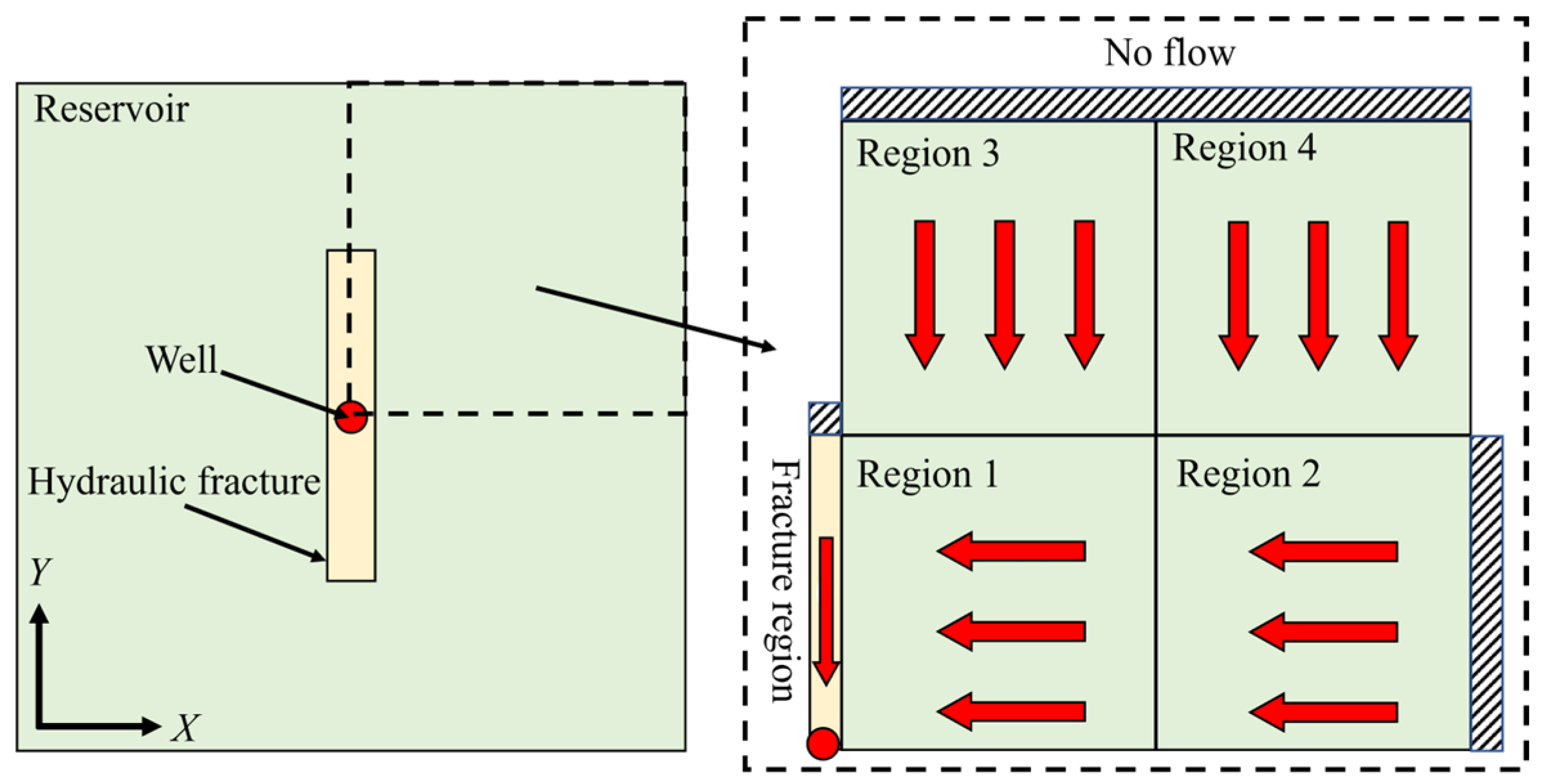

2.1. Physical Model

- The dual porosity media is considered in the tight gas reservoir;

- The effect of gas slippage and matrix shrinkage is considered in the coalbed methane;

- There are interlayers between each layer, not communicating with each other;

- The properties of tight gas and coalbed methane reservoirs are assumed to be isotropic;

- The natural gas is produced with constant pressure;

- The gravity and temperature effects are neglected in this simulation.

2.2. Mathematical Model

2.3. Solutions

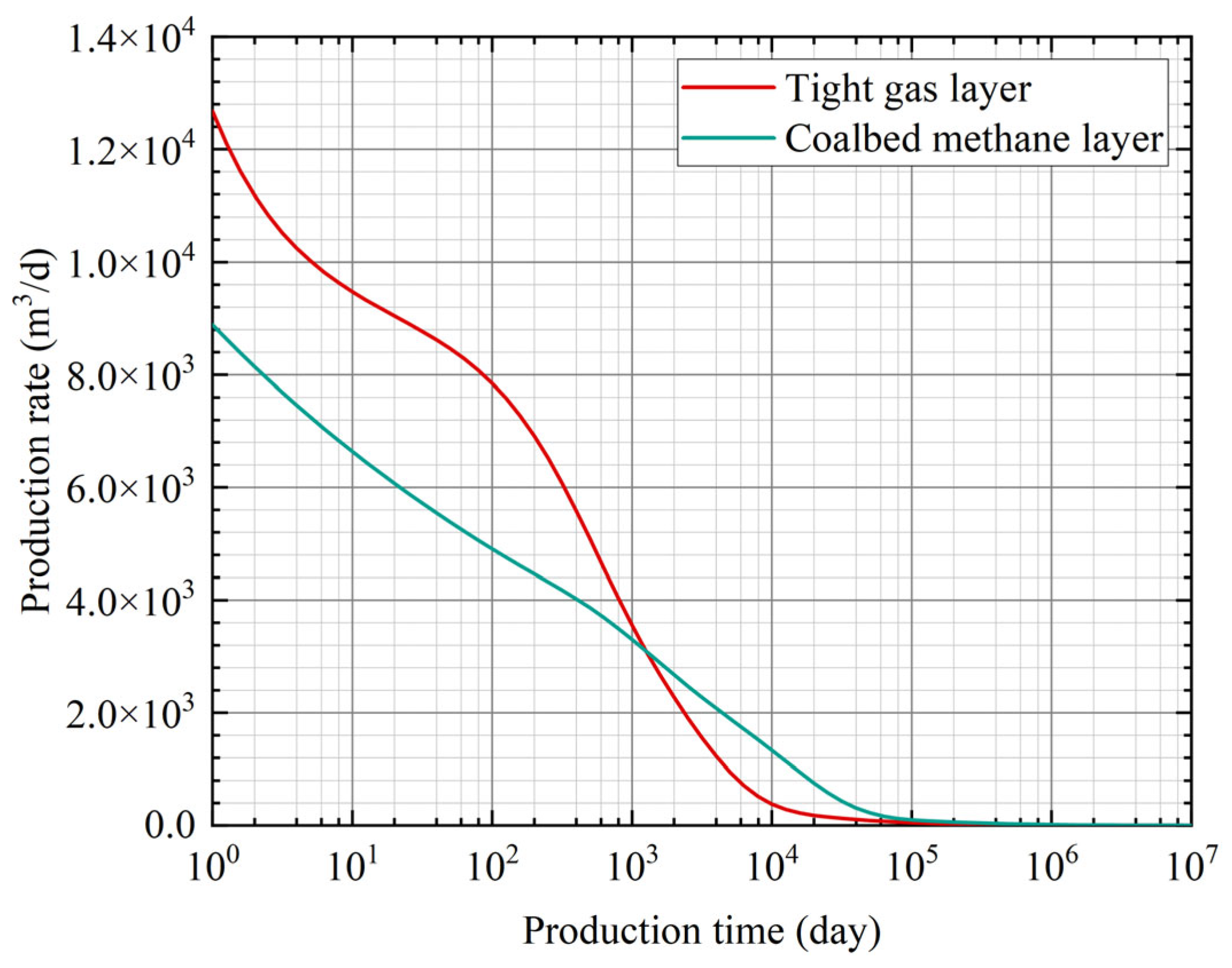

3. Results and Discussion

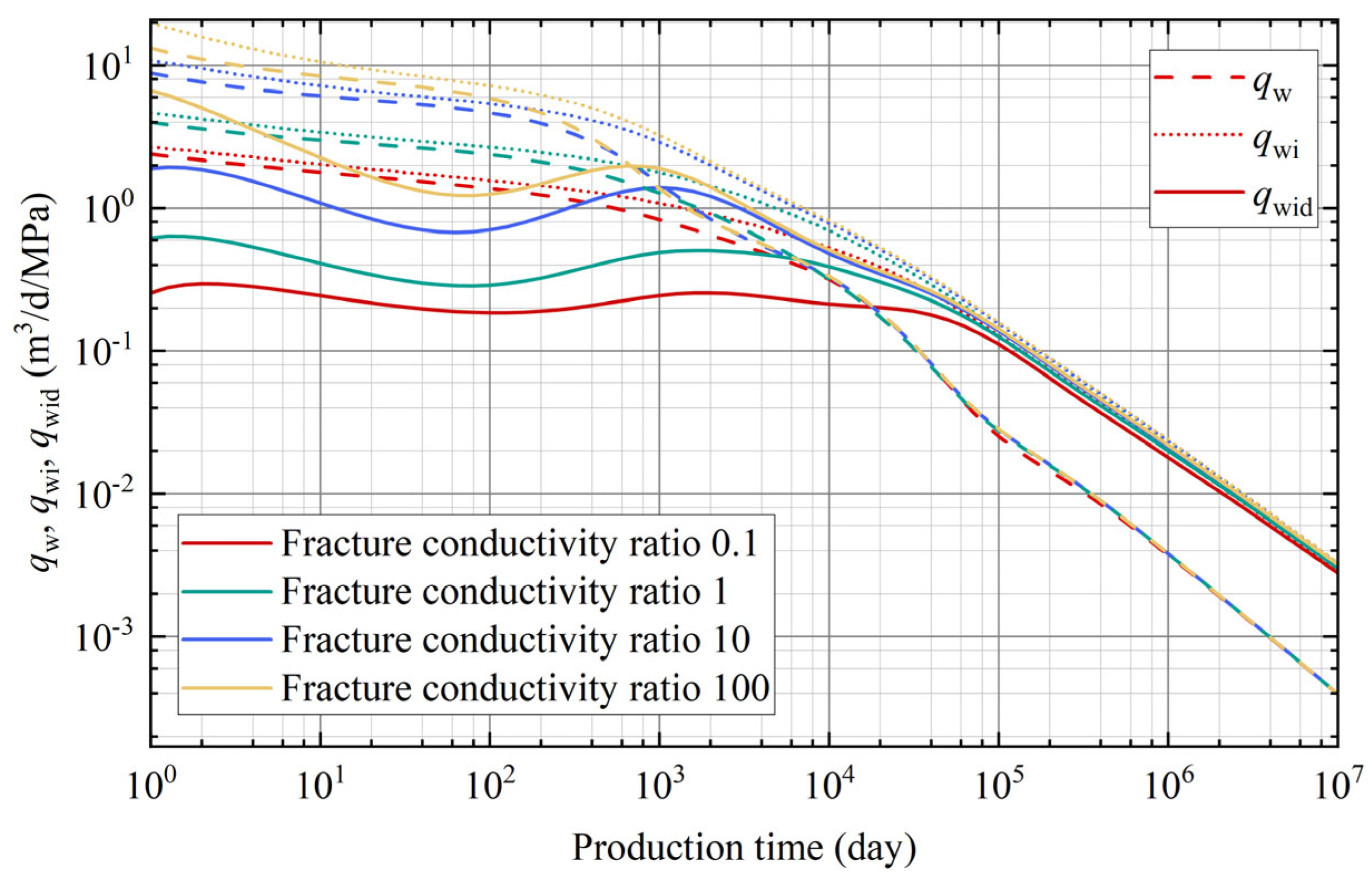

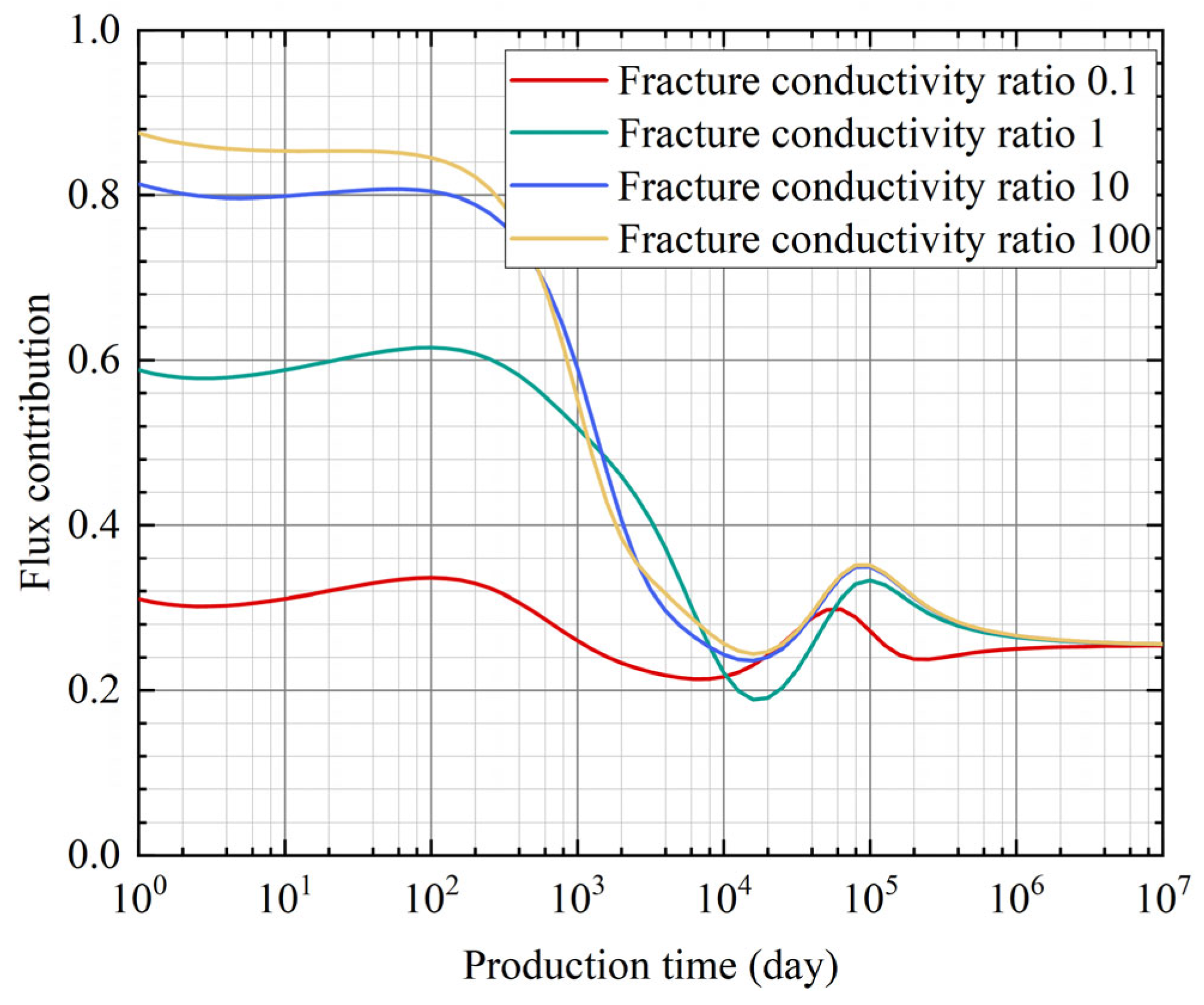

3.1. Fracture Conductivity Ratio

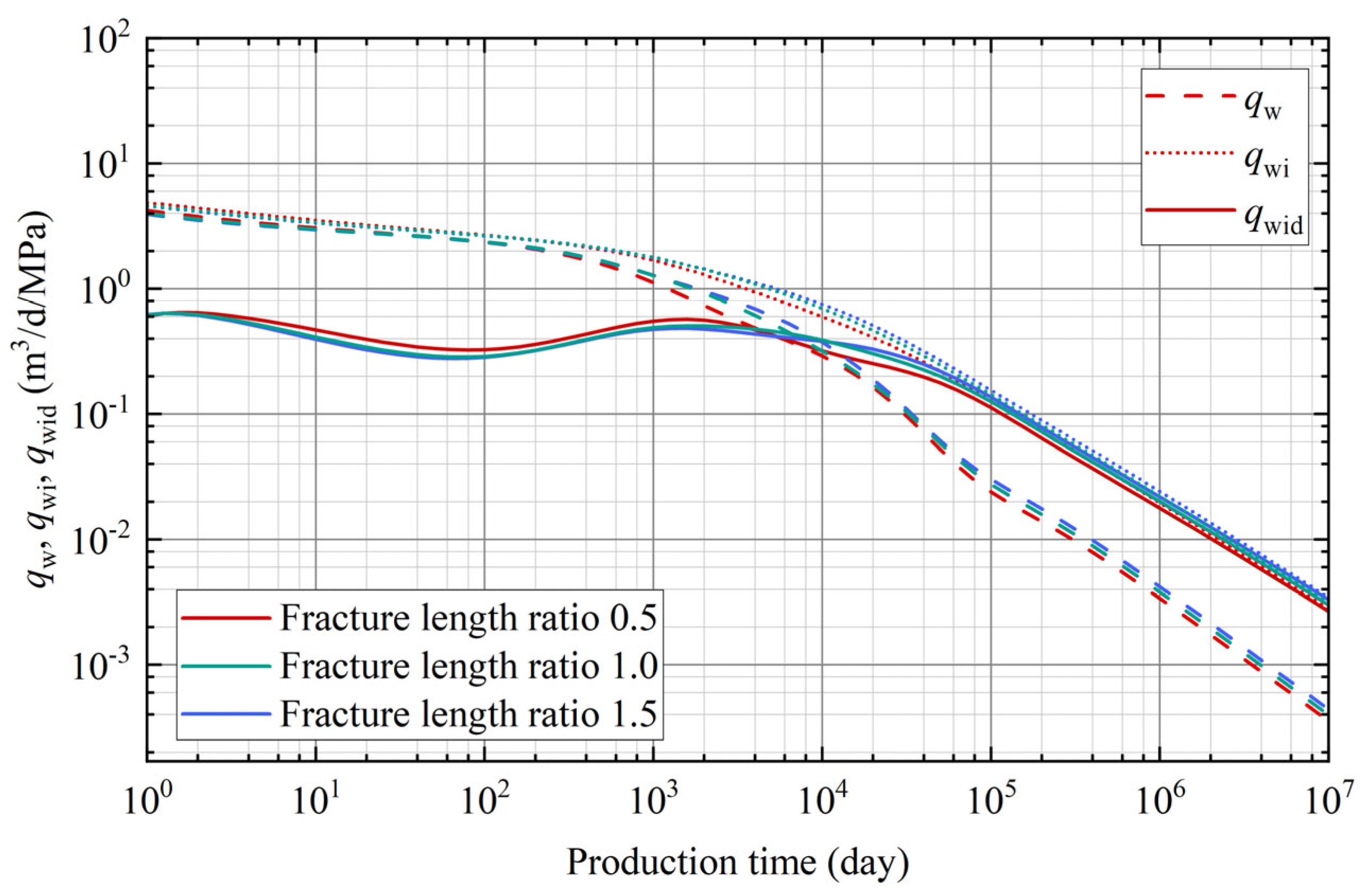

3.2. Fracture Length Ratio

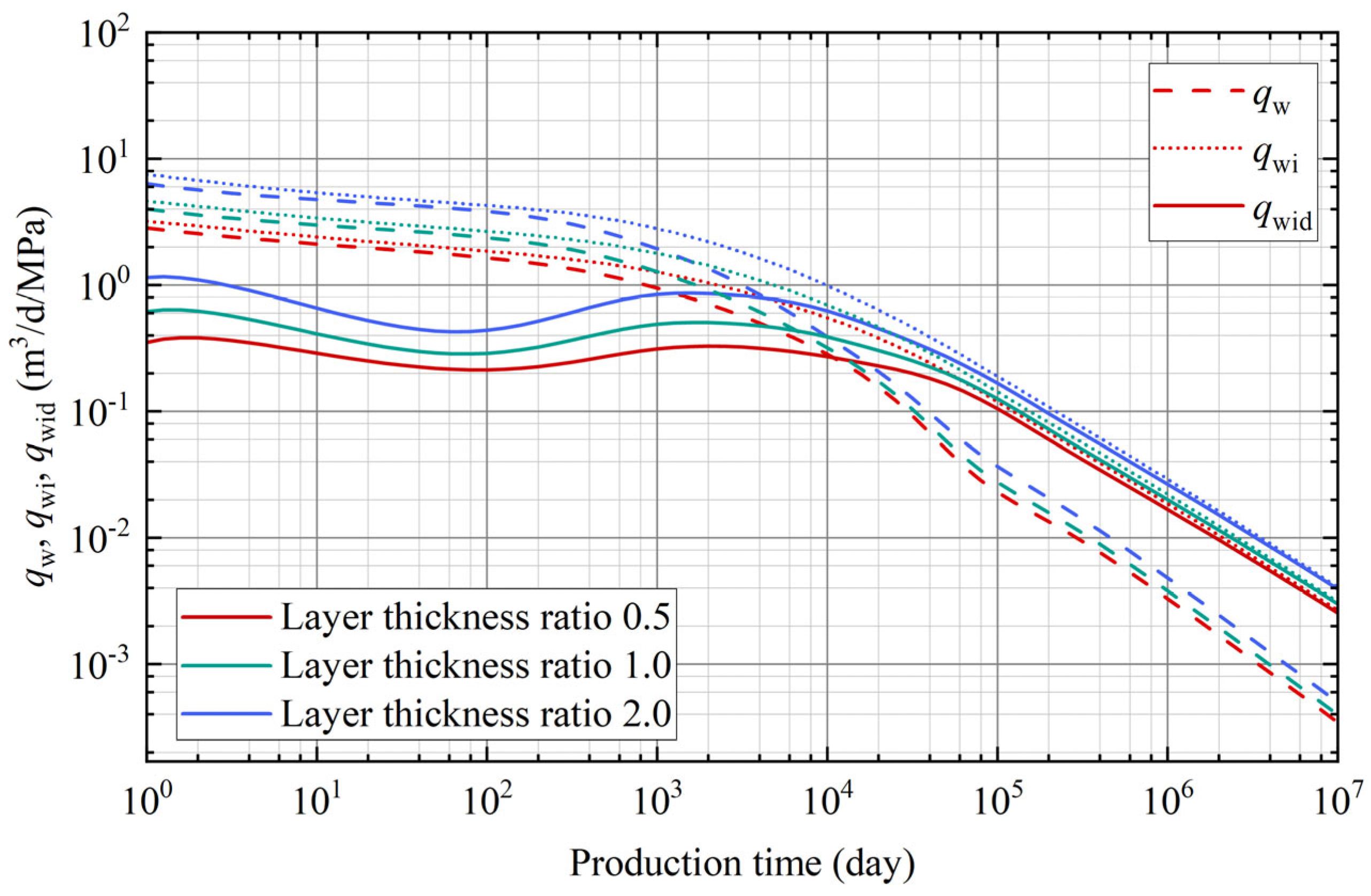

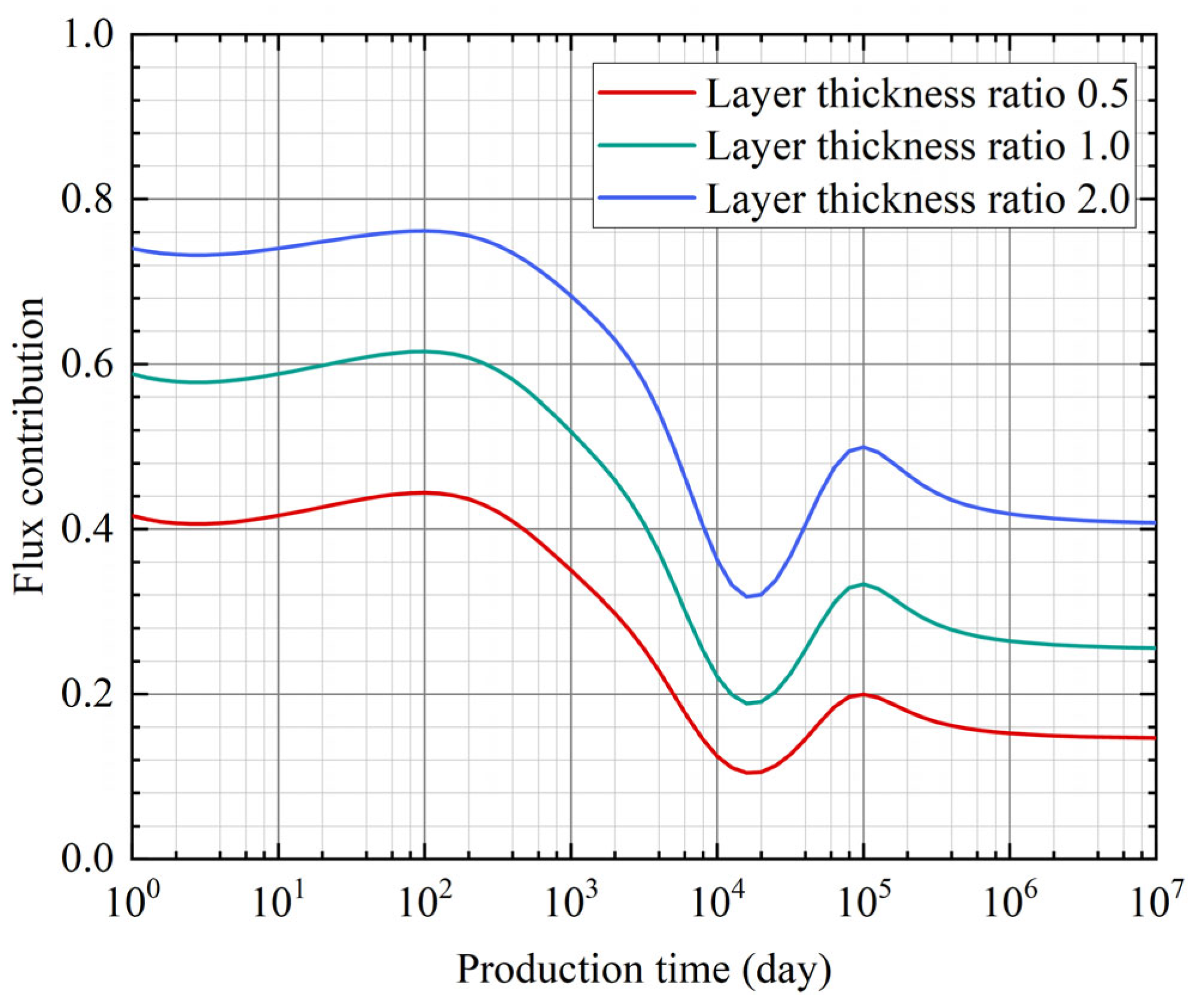

3.3. Layer Thickness Ratio

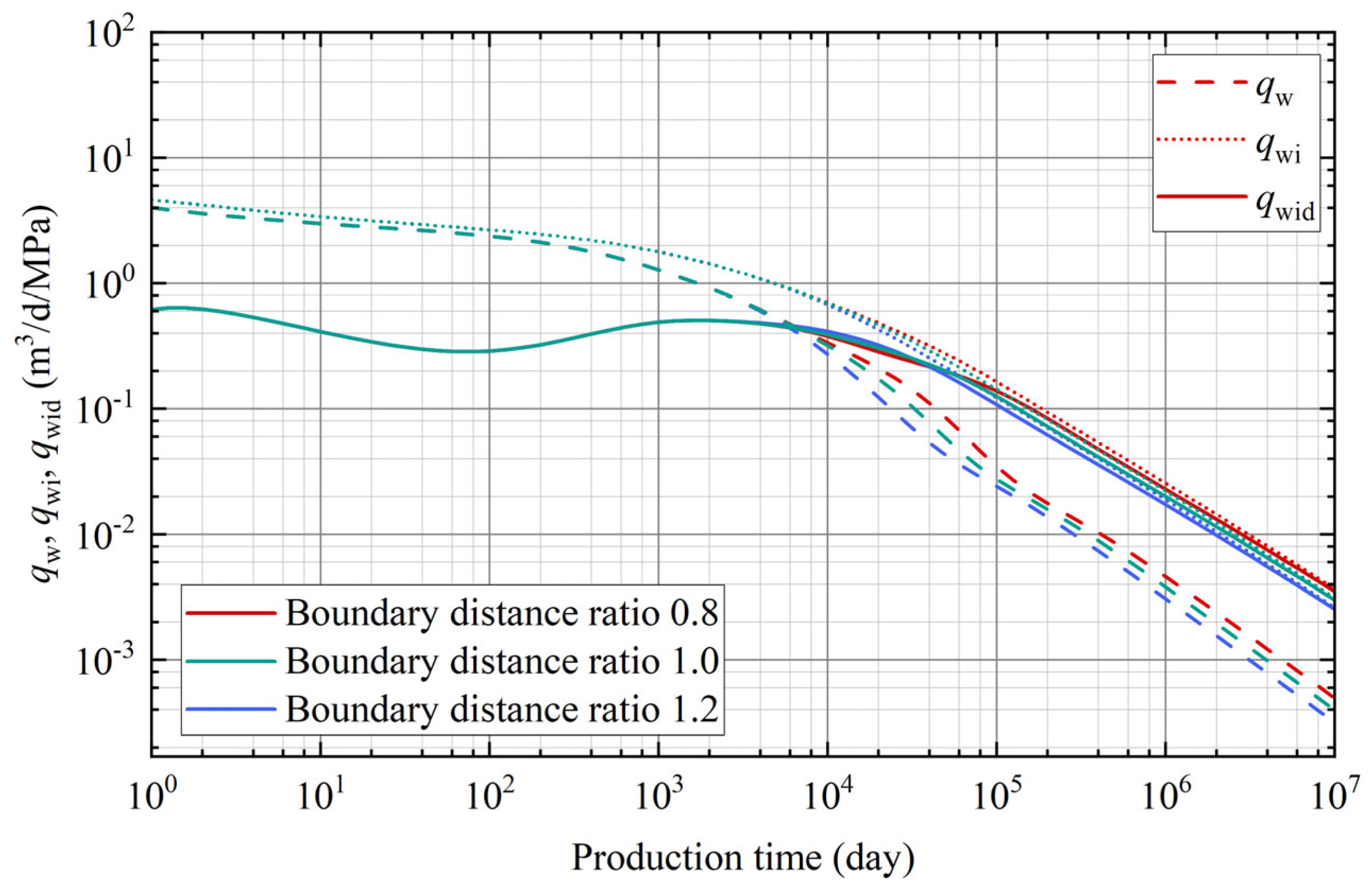

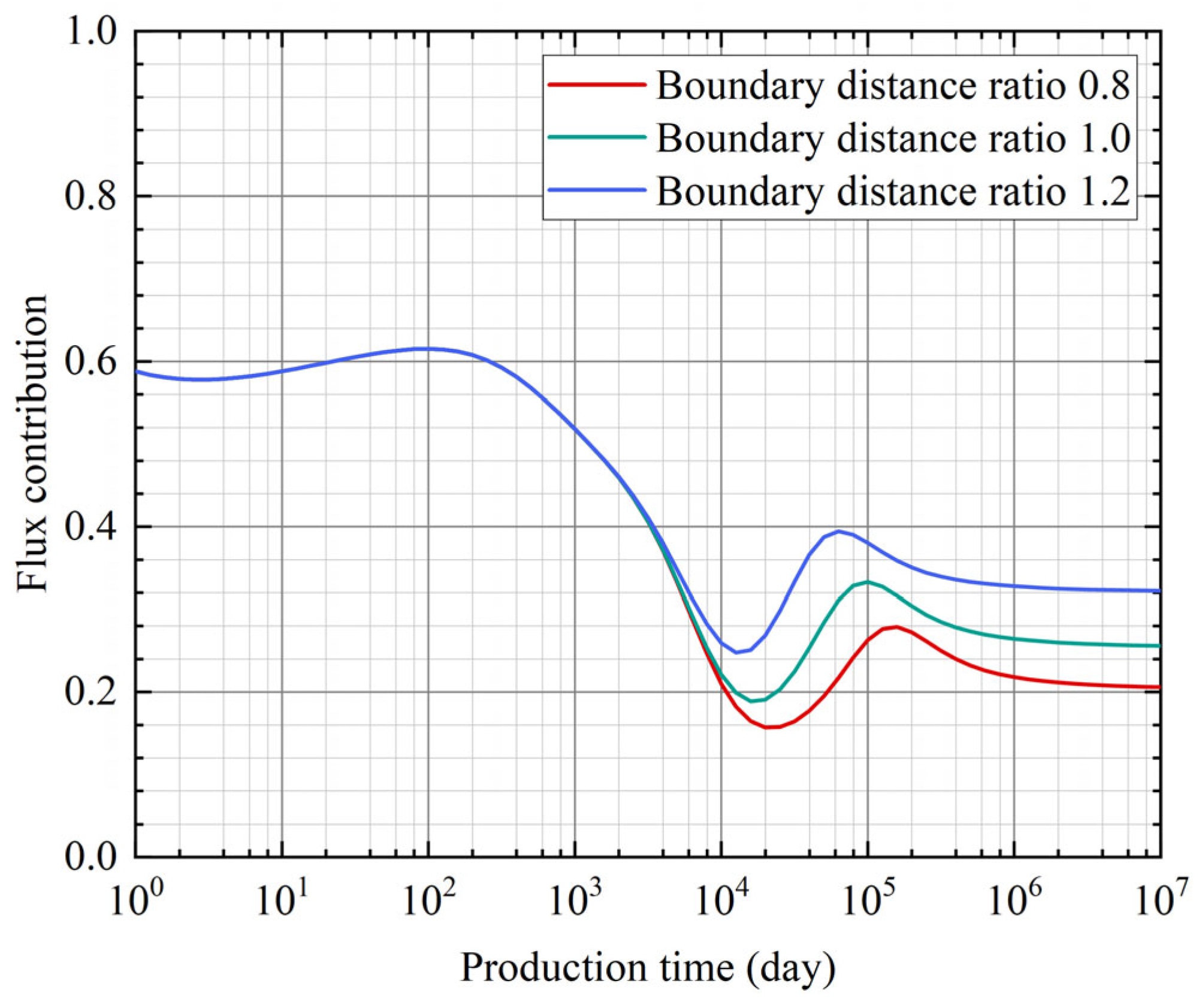

3.4. Boundary Distance Ratio

4. Conclusions

- The influence of different fracture conductivity ratios on the Blasingame decline curve and layer-specific flux contribution is particularly noticeable during the early and middle stages of production. A larger fracture conductivity reduces flow resistance, resulting in a reduced pressure drop and increased cumulative production.

- Longer fractures significantly increase the reservoir contact area, which directly boosts gas production and slows the rate of decline. This effect is especially pronounced in the middle and late production stages of the tight gas layer, where an increased fracture length helps maintain flux contribution as reservoir pressure drops.

- Layer thickness ratios significantly impact production and flux contribution. Increasing thickness boosts recoverable reserves and extends high-production phases.

- A smaller boundary distance leads to earlier boundary flow and a quicker production decline. As the boundary distance increases, higher flux contributions can be observed in the late production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Zou, C.; Yang, Z.; Huang, S.; Ma, F.; Sun, Q.; Li, F.; Pan, S.; Tian, W. Resource types, formation, distribution and prospects of coal-measure gas. Pet. Explor. Dev. 2019, 46, 451–462. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, D.; Wang, W.; Jiang, T.; Xue, Z. Development of unconventional gas and technologies adopted in China. Energy Geosci. 2020, 1, 55–68. [Google Scholar] [CrossRef]

- Liang, W.; Wang, J.; Li, P. Gas production analysis for hydrate sediment with compound morphology by a new dynamic permeability model. Appl. Energy 2022, 322, 119434. [Google Scholar] [CrossRef]

- Mastalerz, M.; Drobniak, A. Coalbed methane: Reserves, production, and future outlook. In Future Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 97–109. [Google Scholar] [CrossRef]

- Li, L.; Ma, S.; Liu, X.; Liu, J.; Lu, Y.; Zhao, P.; Kassabi, N.; Hamdi, E.; Elsworth, D. Coal measure gas resources matter in China: Review, challenges, and perspective. Phys. Fluids 2024, 36, 071301. [Google Scholar] [CrossRef]

- As, D.V.; Bottomley, W.; Furniss, J.P. The characterisation of differential depletion in a thinly layered coal seam gas reservoir using packer inflation bleed off tests PIBOTs. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, SPE, Jakarta, Indonesia, 17–19 October 2017; p. D011S006R003. [Google Scholar] [CrossRef]

- Tao, S.; Chen, S.; Pan, Z. Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci. Eng. 2019, 7, 1059–1074. [Google Scholar] [CrossRef]

- Qin, Y.; Shen, J.; Shen, Y. Joint mining compatibility of superposed gas-bearing systems: A general geological problem for extraction of three natural gases and deep CBM in coal series. J. China Coal Soc. 2016, 41, 14–23. [Google Scholar] [CrossRef]

- Wu, Y.; Pan, Z.; Zhang, D.; Lu, Z.; Connell, L.D. Evaluation of gas production from multiple coal seams: A simulation study and economics. Int. J. Min. Sci. Technol. 2018, 28, 359–371. [Google Scholar] [CrossRef]

- Wei, Y.; Jia, A.; He, D.; Wang, J.; Han, P.; Jin, Y. Comparative analysis of development characteristics and technologies between shale gas and tight gas in China. Nat. Gas Ind. 2017, 37, 43–52. [Google Scholar] [CrossRef]

- Zhang, L.; Shan, B.; Zhao, Y. Production performance laws of vertical wells by volume fracturing in CBM gas reservoirs. Nat. Gas Ind. 2017, 37, 38–45. [Google Scholar] [CrossRef]

- Wang, S.; Gao, W.; Guo, T.; Bao, S.; Jin, J.; Xu, Q. The discovery of shale gas, coalbed gas and tight sandstone gas in Permian Longtan formation, Northern Guizhou Province. Geol. China 2020, 47, 249–250. [Google Scholar] [CrossRef]

- Huang, S.; Kang, B.; Cheng, L.; Zhou, W.; Chang, S. Quantitative characterization of interlayer interference and productivity prediction of directional wells in the multilayer commingled production of ordinary offshore heavy oil reservoirs. Pet. Explor. Dev. 2015, 42, 533–540. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, Y.; Li, Y.; Wu, X.; Hu, Y.; Ni, X.; Liu, D. Co-production of tight gas and coalbed methane from single wellbore: A simulation study from northeastern Ordos Basin, China. Nat. Resour. Res. 2021, 30, 1597–1612. [Google Scholar] [CrossRef]

- Hamawand, I.; Yusaf, T.; Hamawand, S.G. Coal seam gas and associated water: A review paper. Renew. Sustain. Energy Rev. 2013, 22, 550–560. [Google Scholar] [CrossRef]

- Sang, S.; Zheng, S.; Yi, T.; Zhao, F.; Han, S.; Jia, J.; Zhou, X. Coal measures superimposed gas reservoir and its exploration and development technology modes. Coal Geol. Explor. 2022, 50, 3. [Google Scholar] [CrossRef]

- Ou, C.H.; Li, C.C.; He, J. Comprehensive evaluation of gas zone in multi-layer sandstone gas reservoir. Adv. Mater. Res. 2014, 1056, 80–83. [Google Scholar] [CrossRef]

- Guo, J.; Meng, F.; Jia, A.; Dong, S.; Yan, H.; Zhang, H.; Tong, G. Production behavior evaluation on multilayer commingled stress-sensitive carbonate gas reservoir. Energy Explor. Exploit. 2021, 39, 86–107. [Google Scholar] [CrossRef]

- Zhong, G.; Li, S.; Tang, D.; Tian, W.; Lin, W.; Feng, P. Study on Co-production compatibility evaluation method of multilayer tight gas reservoir. J. Nat. Gas Sci. Eng. 2022, 108, 104840. [Google Scholar] [CrossRef]

- Lu, J.; Rahman, M.; Yang, E.; Alhamami, M.; Zhong, H. Pressure transient behavior in a multilayer reservoir with formation crossflow. J. Pet. Sci. Eng. 2022, 208, 109376. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, B.; Zhao, Y.; Zhang, L.; Qiao, X.; Zhang, L.; Qiao, X.; Zhang, L.; Guo, J.; Thanh, H. Inter-layer interference for multi-layered tight gas reservoir in the absence and presence of movable water. Pet. Sci. 2024, 21, 1751–1764. [Google Scholar] [CrossRef]

- Huang, L.; Wang, X. Controlling factors towards co-production performance of coalbed methane and tight sandstone gas reservoirs. Arab. J. Geosci. 2021, 14, 2344. [Google Scholar] [CrossRef]

- Bumb, A.C.; McKee, C.R. Gas-well testing in the presence of desorption for coalbed methane and devonian shale. SPE Form. Eval. 1988, 3, 179–185. [Google Scholar] [CrossRef]

- Huang, S.; Yao, Y.; Ma, R.; Wang, J. Analytical model for pressure and rate analysis of multi-fractured horizontal wells in tight gas reservoirs. J. Pet. Explor. Prod. Technol. 2019, 9, 383–396. [Google Scholar] [CrossRef]

- Stalgorova, E.; Mattar, L. Analytical model for history matching and forecasting production in multifrac composite systems. In Proceedings of the SPE Canada Unconventional Resources Conference, SPE, Calgary, AB, Canada, 30 October–1 November 2012; p. SPE-162516. [Google Scholar] [CrossRef]

- Stehfest, H. Algorithm 368: Numerical inversion of Laplace transforms [D5]. Commun. ACM 1970, 13, 47–49. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Xie, S.C.; Peng, X.L.; Zhang, L.H. Transient pressure response of fractured horizontal wells in tight gas reservoirs with arbitrary shapes by the boundary element method. Environ. Earth Sci. 2016, 75, 1220. [Google Scholar] [CrossRef]

- Wei, M.Q.; Duan, Y.G.; Chen, W.; Fang, Q.T.; Li, Z.L.; Guo, X.R. Blasingame production decline type curves for analysing a multi-fractured horizontal well in tight gas reservoirs. J. Cent. South Univ. 2017, 24, 394–401. [Google Scholar] [CrossRef]

| Number | Problem Literary | Problem Literary |

|---|---|---|

| 1 | Spatial distribution problem | [4,5,6,7,8] |

| 2 | Single-layer production problem | [9,10,11] |

| 3 | Co-production challenge | [12,13,14,15,16,17,18,19,20,21,22] |

| Parameter | Value | Unit | |

|---|---|---|---|

| Tight gas layer | Fracture permeability | 1 × 104 | mD |

| Fracture porosity | 0.2 | m | |

| Fracture length | 400 | m | |

| Fracture width | 0.001 | m | |

| Natural fracture permeability | 50 | mD | |

| Natural fracture porosity | 0.01 | ||

| Permeability of region 1 | 0.02 | mD | |

| Permeability of regions 2, 3, 4 | 0.01 | mD | |

| Porosity of region 1 | 0.2 | ||

| Porosity of regions 2, 3, 4 | 0.01 | ||

| Coalbed methane layer | Fracture permeability | 1 × 104 | mD |

| Fracture porosity | 0.2 | ||

| Fracture length | 400 | m | |

| Fracture width | 0.001 | m | |

| Langmuir volume | 10 | m3/ton | |

| Langmuir pressure | 3.5 | MPa | |

| Permeability of region 1 | 0.2 | mD | |

| Permeability of regions 2, 3, 4 | 0.1 | mD | |

| Porosity of region 1 | 0.2 | ||

| Porosity of regions 2, 3, 4 | 0.1 | ||

| Reservoir | Formation thickness | 5 | m |

| x-coordinate of the boundary of region 1 | 400 | m | |

| x-coordinate of the boundary of region 2 | 800 | m | |

| y-coordinate of the boundary of region 3 | 400 | m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.; Zhao, L.; Wu, N.; Huang, L.; Du, Y.; Cai, H.; Zhou, W.; Liang, Y.; Teng, B. Analytical Model for Rate Transient Behavior of Co-Production between Coalbed Methane and Tight Gas Reservoirs. Sustainability 2024, 16, 9505. https://doi.org/10.3390/su16219505

Shi S, Zhao L, Wu N, Huang L, Du Y, Cai H, Zhou W, Liang Y, Teng B. Analytical Model for Rate Transient Behavior of Co-Production between Coalbed Methane and Tight Gas Reservoirs. Sustainability. 2024; 16(21):9505. https://doi.org/10.3390/su16219505

Chicago/Turabian StyleShi, Shi, Longmei Zhao, Nan Wu, Li Huang, Yawen Du, Hanxing Cai, Wenzhuo Zhou, Yanzhong Liang, and Bailu Teng. 2024. "Analytical Model for Rate Transient Behavior of Co-Production between Coalbed Methane and Tight Gas Reservoirs" Sustainability 16, no. 21: 9505. https://doi.org/10.3390/su16219505

APA StyleShi, S., Zhao, L., Wu, N., Huang, L., Du, Y., Cai, H., Zhou, W., Liang, Y., & Teng, B. (2024). Analytical Model for Rate Transient Behavior of Co-Production between Coalbed Methane and Tight Gas Reservoirs. Sustainability, 16(21), 9505. https://doi.org/10.3390/su16219505