Abstract

Currently, the environment and its natural resources face many issues related to the depletion of natural resources, in addition to the increase in environmental pollution resulting from uncontrolled waste disposal. Therefore, it is crucial to identify practical and effective ways to utilize these wastes, such as transforming them into environmentally friendly concrete. Artificial lightweight aggregates (ALWAs) are gaining interest because of their shift in focus from natural aggregates. Researchers have developed numerous ALWAs to eliminate the need for natural aggregates. This article explores the diverse applications of ALWAs across different industries. ALWAs are currently in the research phase due to various limitations compared to the availability of the various natural aggregates that form more durable solutions. However, researchers have discovered that certain artificial aggregates prioritize weight over strength, allowing for the effective use of ALWAs in applications like pavements. We thoroughly studied the various ALWAs discussed in this article and found that fly ash and construction waste are the most diverse sources of primary material for ALWAs. However, the production of these aggregates also presents challenges in terms of processing and optimization. This article’s case study reveals that ALWAs, consisting of 80% fly ash, 5% blast-furnace slag, and only 15% cement, can yield a sustainable solution. In the single- and double-step palletization, the aggregate proved to be less environmentally harmful. Additionally, the production of ALWAs has a reduced carbon footprint due to the recycling of various waste materials, including aggregates derived from fly ash, marble sludge, and ground granulated blast-furnace slag. Despite their limited mechanical strength, the aggregates exhibit superior performance, making them suitable for use in high-rise buildings and landscapes. Researchers have found that composition plays a key role in determining the application-based properties of aggregates. This article also discusses environmental and sustainability considerations, as well as future trends in the LWA field. Simultaneously, recycling ALWAs can reduce waste and promote sustainable construction. However, this article discusses and researches the challenges associated with the production and processing of ALWAs.

1. Introduction

Researchers and professionals in the field of artificial lightweight aggregates (ALWAs) are motivated to explore this area to provide innovative solutions that can efficiently fulfill the demands of present-day engineering. These aggregates, characterized by their unique compositions and low density, represent a significant shift in the building industry’s approach to the relationship between energy efficiency, sustainability, and the integrity of the structure [1,2,3,4]. The motivation to find lightweight alternatives arises from the need to reduce the environmental effects of construction projects while maintaining or enhancing their structural performance. Traditional aggregates, which are often larger and require more resources, have intrinsic challenges, such as higher energy usage, increased transportation costs, and added strain on the supporting infrastructure [5]. Given these difficulties, ALWAs have evolved as strategic alternatives, offering architects, engineers, and builders a promising opportunity to investigate creative solutions that are in line with the principles of sustainable development. ALWAs based on fly ash have the potential to be used on a large scale in the building industry [6,7,8]. They are frequently used in the construction industry. There is an enormous market for creating aggregates from fly ash. Fly ash is used in the concrete industry as a cement substitute, as well as in other allied industries, to produce cubes and prisms, cellular concrete, prefabricated goods, and roads [9]. The substantial economic and population increase has led to the unsustainable extraction of natural resources, resulting in direct and indirect greenhouse gas emissions that negatively affect ecosystems. The transportation of natural aggregates from extraction regions also contributes to energy consumption and greenhouse gas emissions. The analysis of energy consumption and greenhouse gas emissions associated with natural aggregate extraction requires that researchers worldwide develop alternative materials to natural aggregates. Artificial aggregates are a solution to this challenge, as they will aid the world in sustainability, resource conservation, and implementing a circular economy by utilizing waste materials from diverse industries. The constraints of availability, sustainability, and environmental issues have necessitated the adoption of artificial aggregates to fulfill the demands of the construction sector [10]. Lightweight artificial aggregates are beneficial due to their properties, such as size, shape, and porosity, which can be tailored to meet construction requirements. This modification is not feasible with natural aggregates. Additional advantages incorporate lightweight properties, enhanced thermal insulation, and durability while utilizing waste materials in its production to mitigate pollution and promote a circular economy. The production of lightweight artificial aggregates is an energy-intensive process that elevates initial costs, and the availability of raw materials such as fly ash and clay is also a concern. The characteristics of elevated porosity, water absorption, load-bearing capability, and inadequate durability during freeze–thaw conditions are significant areas for enhancement [11]. The aim of this study is to provide a comprehensive analysis of the different components that constitute ALWAs. This encompasses an exploration of their categorization, intricate structures, practical applications, and the potential path that determines their future importance in the building sector. As the details of the production processes are explored, along with the delicate impacts of material compositions and the wide spectrum of industrial uses, an effort begins to reveal the inherent revolutionary potential of these versatile materials. To understand the significance of ALWAs effectively, it is necessary to undertake a comprehensive analysis of their applications beyond their primary purpose of reducing weight. These aggregates play a crucial role in establishing the foundation for infrastructure projects and tall buildings that require optimization of their load-bearing capacity. They are employed in the fabrication of infrastructure that sustains everyday life. Further, this study aimed to illustrate the complexities and potential benefits of ALWAs [8]. It aims to provide industry professionals, researchers, and decision makers with valuable insights as they navigate the intricate relationship between sustainability, technology, and construction materials. Subsequently, a systematic analysis of the different categories of ALWAs was carried out, elucidating the intricate compositions that determine their properties, exploring their diverse applications in various industries, and offering a glimpse into prospects by summarizing ongoing research and potential advancements. In addition, this article establishes an understanding of the ability to transform ALWAs, including the examination of the potential revolutionary effects of these techniques and substances on construction progress.

2. Types of Artificial Lightweight Aggregates

ALWAs are noteworthy in the field of construction materials due to their versatility, efficiency, and environmentally friendly nature [12]. Gaining a comprehensive knowledge of the many categories of ALWAs is crucial for engineers, architects, and professionals who are looking for the most effective solutions for a wide range of projects. There are various ALWAs; for example, expanded clay is a notable form of lightweight aggregate that is produced by subjecting clay to heat and expansion [13]. This technique results in the formation of porous and lightweight pellets that are well suited for applications that necessitate insulation and drainage.

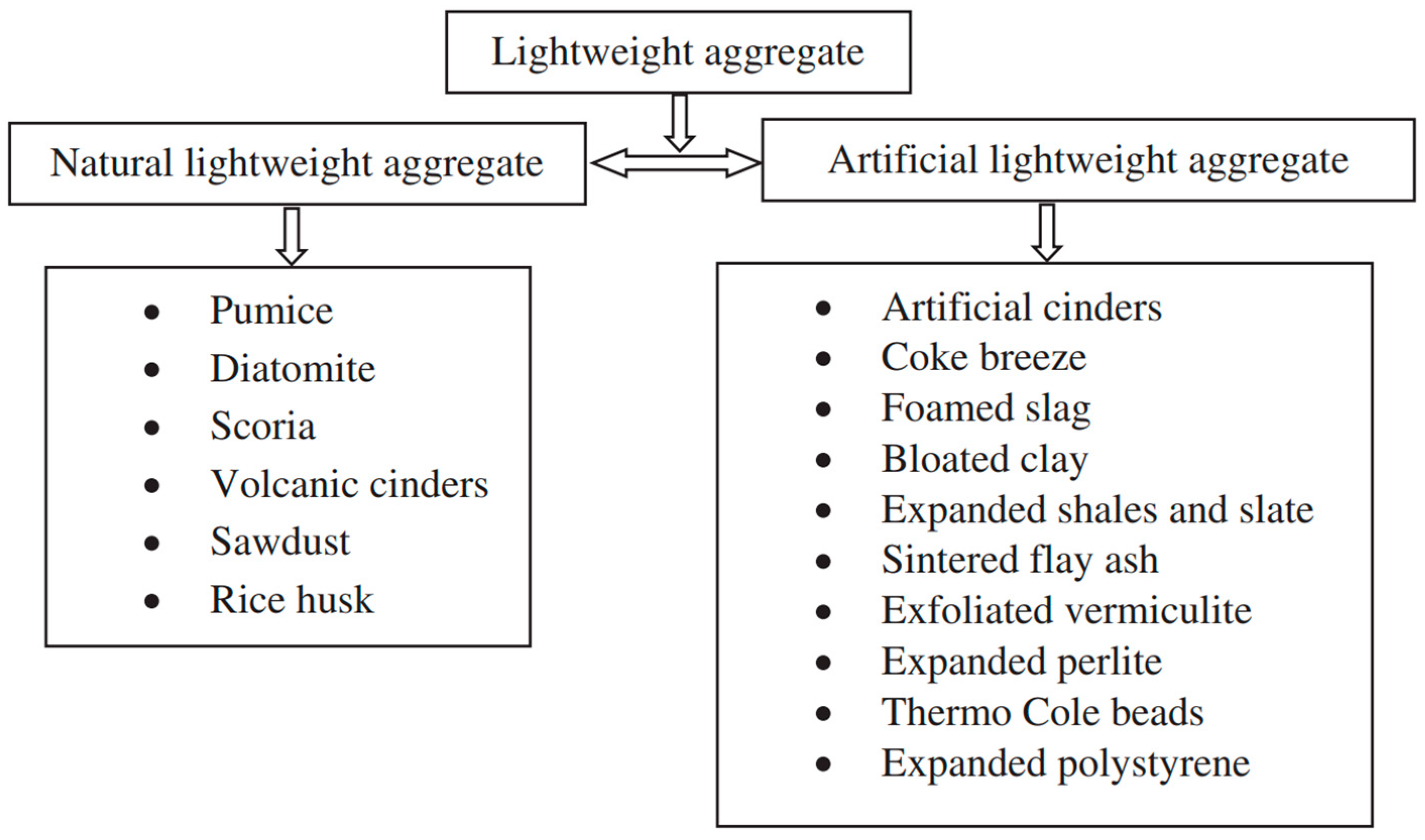

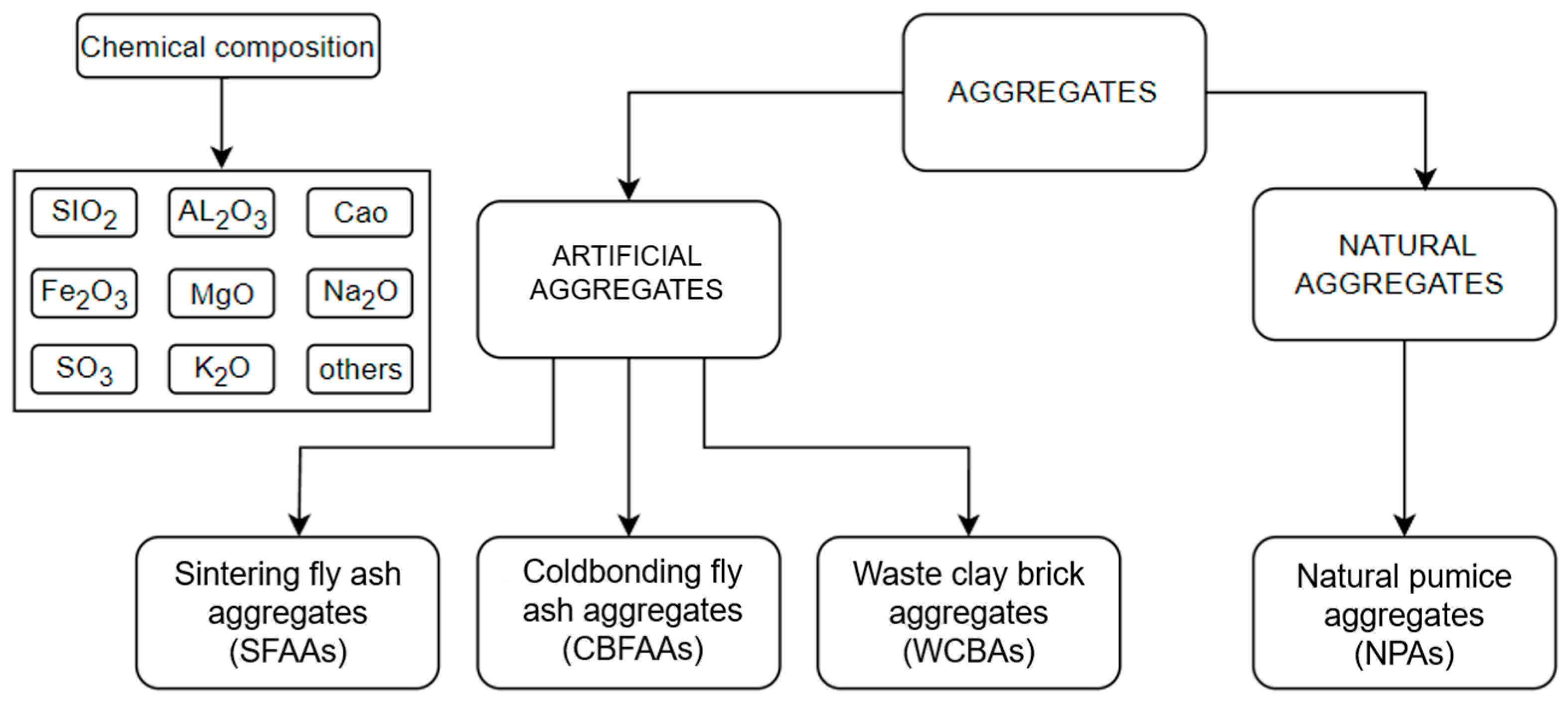

Another noteworthy variant is expanded shale, which possesses comparable attributes to expanded clay but exhibits distinct structural qualities, rendering it appropriate for construction requirements [14]. Moreover, expanded perlite, which is obtained from volcanic glass, possesses remarkable lightweight characteristics and is highly esteemed for its ability to provide thermal insulation and withstand fire. Vermiculite is a mineral composed of hydrated magnesium aluminum silicate. It is recognized as a lightweight aggregate that is highly effective in retaining moisture and providing insulation. As a result, it is highly valued in both the horticulture and building industries. Foamed slag aggregates, derived from the leftovers of steel production, offer a sustainable solution that improves both the structural strength and environmental sustainability of construction projects [15]. Every kind of lightweight aggregate possesses distinct characteristics that are well suited for a wide range of uses, including structural lightweight concrete, horticultural substrates, and insulating materials. In Figure 1, the various natural and artificial aggregates are presented. In addition to this, in Table 1, the chemical compositions and characteristics of the different LWAs are presented.

Figure 1.

ALWAs in natural and artificial form [16].

Table 1.

Chemical compositions and characterizations of LWAs.

2.1. Expanded Clay Aggregates

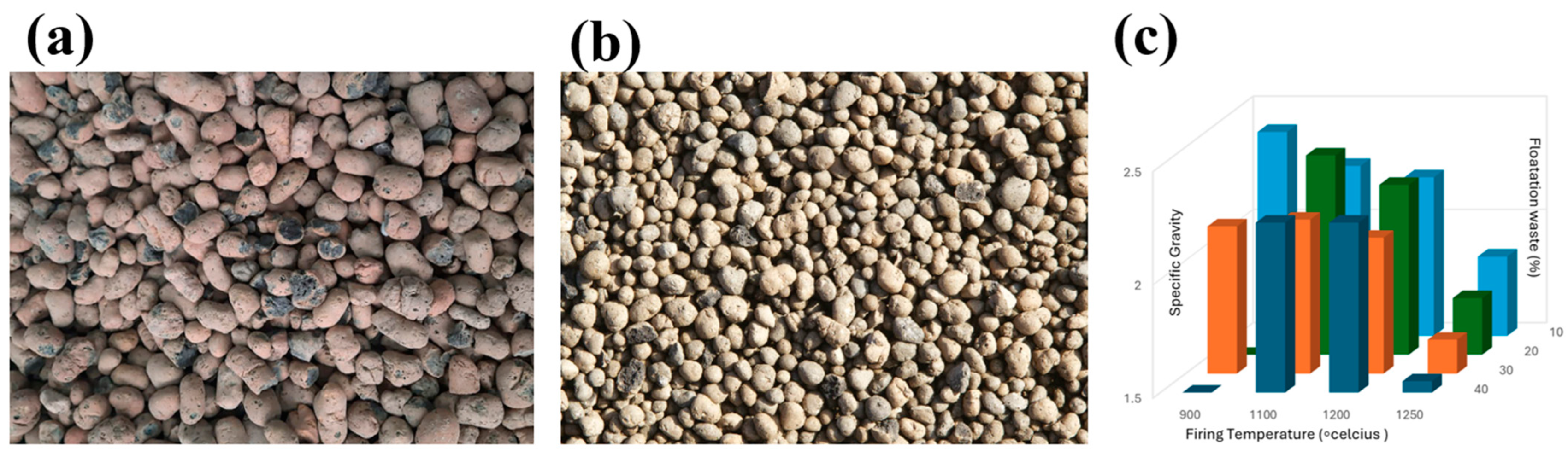

Expanded clay, a commonly utilized lightweight aggregate in the construction industry, involves a thorough manufacturing process that includes clay extraction, pellet formation, and high-temperature expansion. The following subsection provides a detailed explanation of the same [13]. The clay used to produce expanded clay aggregates is commonly obtained from natural clay deposits. The selection of these deposits is based on criteria such as mineral composition, plasticity, and proximity to manufacturing facilities. Following the process of source selection, the subsequent phase is extraction, which entails the extraction of unprocessed material from the Earth’s surface or through mining [17]. Large-scale equipment, such as excavators and bulldozers, is used to collect the clay and transfer it to manufacturing centers. After the extraction process, the manufacturing of the material is a crucial phase since it requires processing and shaping it into pellets. The clay that has been removed is subjected to a series of procedures in order to eliminate any impurities and attain the required texture. The process entails pulverizing, comminuting, and sieving the clay to achieve consistent particle dimensions and remove any impurities. After the clay has been treated, it is combined with water to create a flexible combination. Subsequently, this blend is molded into small spherical or granular forms with pelletizing machinery such as rotary cylinders or disc pelletizers. The pellets are shaped into precise dimensions according to the intended usage and market demands. Additionally, the high-temperature expansion process occurs as a subsequent stage following pellet creation, where the clay pellets are subjected to drying to eliminate any surplus moisture [18]. Figure 2a,b show the expanded aggregates that were used in the experimental study by the researchers whereas Figure 2c shows the graph with the variation in the specific gravity with respect to the firing temperature [19]. The average size of the particle was measured to be 10–20 mm. It should be noted that specific gravity is high at the firing temperatures of 1100 and 1200 degrees Celsius.

Figure 2.

(a,b) Expanded clay aggregates; 2 (c) variation in the specific gravity with respect to the firing temperature and flotation waste [19] (reproduced with permission from Elsevier, License number-5894220149618).

Industrial drying ovens or rotary dryers commonly carry out the drying process, using precise temperatures and regulated airflow to ease the process. The dehydrated clay pellets undergo exposure to elevated temperatures in kilns or rotary kilns, typically ranging from 1100 °C to 1200 °C (2000 °F to 2200 °F). The high temperature leads to the expansion of the pellets and triggers a process called sintering, in which the particles merge to create lightweight aggregates. Upon heating, the pellets undergo a process in which the water contained within them evaporates, resulting in the substantial expansion of the pellets. The process of expansion generates a porous framework inside the pellets, leading to the formation of ALWAs that possess exceptional insulating characteristics. After the pellets have expanded and acquired the desired characteristics, they are slowly cooled to reach the ambient temperature. Once the expanded clay aggregates have undergone the chilling process, they are carefully examined and organized into various sizes to fulfill specific customer specifications. Expanded clay aggregates are highly valued for their low weight, excellent thermal insulating characteristics, and strong structural integrity, which makes them a popular option for a wide range of construction purposes. The rigorous manufacturing process, which includes extracting clay, forming pellets, and subjecting them to high temperatures, guarantees the creation of outstanding aggregates that are suited for a wide range of construction projects such as lightweight concrete, precast elements, road construction, geotechnical applications, insulation and fireproofing, landscaping, and bridge decks.

2.2. Expanded Shale Aggregates

Expanded shale, a commonly used lightweight aggregate in construction, is produced by a specific manufacturing process that includes extraction, processing, and thermal treatment to achieve expansion. Furthermore, a more comprehensive explanation has been thoroughly examined in the next subsection. The first step in commencing the process of extraction of expanded shale is the selection of shale [20]. Shale formations that contain abundant minerals and possess the appropriate geological properties are chosen for exploitation. Shale is a type of sedimentary rock that is mainly made up of clay particles, quartz, and other minerals. Following the selection process, the next phase is the extraction of shale, which entails conducting mining operations to reach the shale reserves [20]. In Figure 3, some examples of the expanded shales are shown [14]. The aggregate consisted of high-strength sintered expanded shale with a continuous gradation, featuring a maximum size of 20 mm.

Figure 3.

Sintered expanded shale [14] (reproduced with permission from Elsevier, License number-5894220486544).

Different techniques, such as open-pit mining or underground mining, can be used depending on the depth and ease of access to the shale deposits [21]. After extraction, the shale rock is subjected to crushing and grinding processes. These processes take place at processing facilities, where the raw material is reduced in size. This procedure readies the shale for later thermal processing. The pulverized shale is meticulously prepared for thermal processing. It could go through further stages to eliminate impurities and obtain the required chemical composition and distribution of particle sizes. Prior to being introduced into the kiln for thermal treatment, the shale is subjected to preheating at a precise temperature in order to eliminate any residual moisture and guarantee consistent expansion throughout the subsequent heating phase. The shale that has been heated beforehand is subsequently introduced into either rotary kilns or vertical kilns, where it is exposed to elevated temperatures, often varying between 1100 °C and 1200 °C (2000 °F and 2200 °F). The high temperature induces the expansion of shale particles, leading to a mechanism analogous to that of expanded clay. Upon heating, the moisture confined within the particles of shale undergoes vaporization, leading to a substantial expansion of the shale. The process of expansion generates a structure that is both lightweight and porous within the shale particles. This leads to the formation of expanded shale aggregates that possess favorable characteristics, including low density and high strength. The enlarged shale aggregates are cooled progressively to room temperature after expansion in order to consolidate their structure. Subsequently, the materials undergo a process of examination and classification, wherein they are segregated into various dimensions according to the precise specifications of the project [14]. Expanded shale aggregates have exceptional thermal insulating characteristics, structural integrity, and long-lasting nature, rendering them highly desirable in many construction applications. The manufacturing process, which encompasses shale extraction, processing, and heat treatment for expansion, guarantees the creation of superior ALWAs that can fulfill the varied requirements of the building sector [22].

2.3. Expanded Glass Aggregates

Expanded glass, a lightweight aggregate renowned for its insulation properties and sustainability, undergoes a specialized manufacturing process involving glass cullet preparation and controlled heating for expansion. Further, the steps involved in the preparation of expanded glass have been explained in detail.

2.3.1. Glass Cullet Preparation

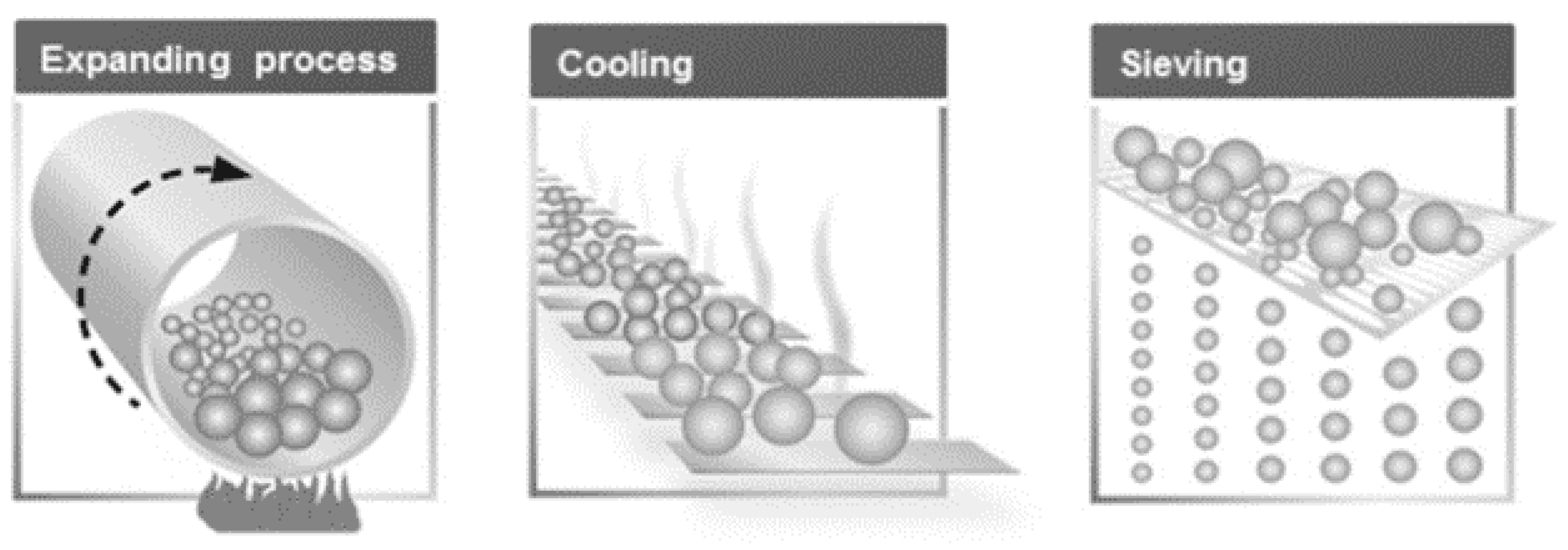

Broken or recycled glass, known as glass cullet, is used as the main raw material for producing expanded glass aggregates. The cullet is obtained from glass bottles, jars, and other glass items that have been recycled, thereby decreasing the demand for new raw materials and supporting sustainability. The gathered glass cullet undergoes meticulous sorting and cleansing procedures to eliminate impurities like metal, plastic, and organic substances. This guarantees that the cullet is devoid of any contaminants that may have an impact on the quality of the product. After undergoing the cleaning process, the glass cullet is further crushed and ground into finely fragmented particles that possess a consistent size. This technique improves the uniformity of the cullet and prepares it for the following expansion phase. In Figure 4, the process of expanding the expanded glass has been shown.

Figure 4.

Expanding process of expanded glass [23] (reproduced with permission from Elsevier, License number-5894220643132).

2.3.2. Controlled Heating for Expansion

The processed glass cullet is mixed with precise additives or fluxes to facilitate the expansion process and enhance the characteristics of the end product. These additives may comprise substances such as limestone, dolomite, or sodium carbonate. The batch mixture is introduced into a rotating kiln or furnace specifically engineered for precise heating control. Within the kiln, the cullet mixture is exposed to temperatures over 800 °C (1472 °F), approaching the glass’s softening point. During the heating process, the gases trapped within the glass particles in the cullet mixture expand, resulting in the cullet becoming inflated and forming lightweight aggregates. The regulated heating procedure guarantees consistent expansion and the creation of porous structures inside the glass aggregates. After the expansion procedure is finished, the expanded glass aggregates are slowly cooled to room temperature to stabilize their structure. Subsequently, the materials undergo a process of examination and classification, wherein they are segregated into various dimensions according to the precise specifications of the project (see Figure 5) [23].

Figure 5.

Different expanded glass bead grades (size in mm) [23] (reproduced with permission from Elsevier, License number-5894220643132).

Furthermore, expanded glass aggregates possess several benefits, such as being lightweight, providing thermal insulation, and exhibiting resistance to moisture and chemicals. The manufacturing process, which includes the preparation of glass cullet and regulated heating for expansion, enables the production of superior lightweight aggregates while also promoting sustainability through the use of recycled materials. Expanded glass aggregates are extensively utilized in building, horticulture, and other industries that require lightweight and environmentally friendly solutions [23].

2.4. Other Types of Lightweight Aggregates

Lightweight aggregates, including expanded slag and sintered fly ash, are crucial components in construction materials due to their low density, thermal insulation properties, and potential for reducing the weight of concrete structures. In the following sections, we delve into each type and their manufacturing processes:

2.4.1. Expanded Slag Aggregates

Slag is a by-product of steelmaking, commonly made by rapidly cooling molten slag with water or steam. Thermal-insulating expanded slag aggregates are lightweight and porous. Some production steps for expanded slag are listed below. First, water or steam is used to rapidly cool molten slag, forming granulated slag. Drying the granulated slag removes moisture. Preheating dried slag prepares it for expansion. A rotating kiln or sintering furnace heats preheated slag to roughly 1000 °C, releasing gasses and expanding it. To stabilize expanded slag, it is cooled slowly to room temperature. Crushed and graded expanded slag produces specified aggregate sizes [24]. One of the most important varieties of expanded slag is phase change aggregate or expanded titanium-bearing blast-furnace slag (ETS). Due to its poor hydration activity and particle strength, expanded titanium-bearing blast-furnace slag has many interconnecting pores. Researchers fully loaded paraffin into ETS’s pore system to create phase change aggregate (PCA) [25,26]. After preparing a phase change energy storage mortar (PCEM) using PCA, its mechanical, thermal, and energy-saving capabilities were assessed. The compressive strength of mortar made entirely of Portland cement admixture (PCA) reached 7.8 MPa and 8.6 MPa after 28 and 56 days, respectively. The structure saved 8.1% of energy.

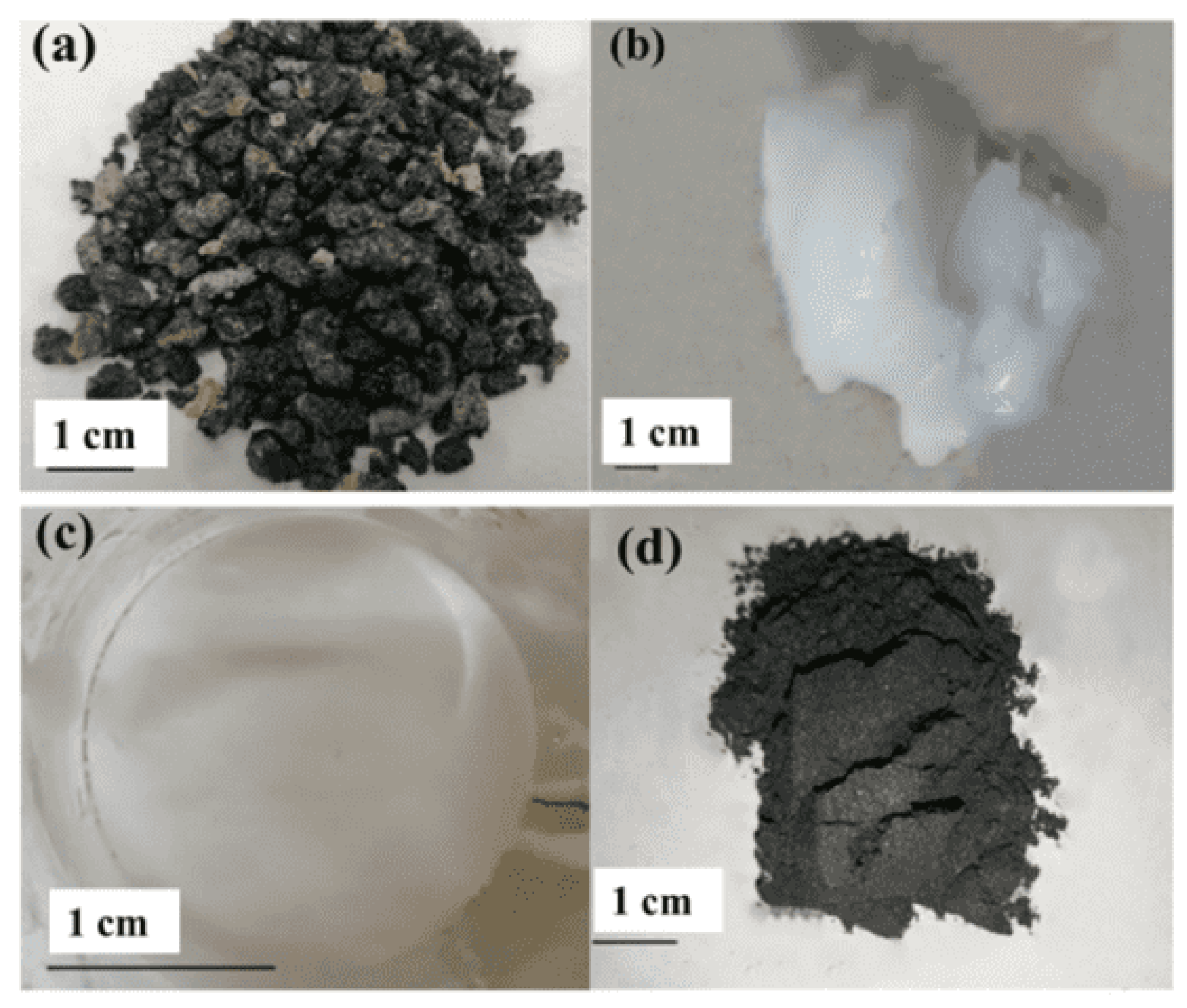

The structure’s highest inside temperature dropped 1.2 °C and 2.3 °C in spring and summer. These characteristics guarantee ETS use in energy-efficient building product manufacture [27]. Figure 6 depicts ETS, paraffin, epoxy resin, and graphite.

Figure 6.

Appearance of (a) ETS, (b) paraffin, (c) epoxy resin, and (d) graphite [27] (reproduced with permission from Elsevier, License number-5894650754025).

2.4.2. Sintered Fly Ash Aggregates

Burning pulverized coal in thermal power plants produces fine, powdery fly ash. Porous, lightweight sintered fly ash aggregates are strong and thermally efficient. The simple manufacturing process of sintered fly ash aggregates involves collecting fly ash from coal-fired power station chimneys or dust collectors [28]. Fly ash is processed to eliminate impurities and improve chemical and physical qualities. A homogeneous slurry is made from processed fly ash, water, and binders. The slurry is subsequently granulated into spherical or irregular pellets. A rotating kiln or sintering furnace heats pellets to 1100–1200 °C, forming lightweight aggregates. Sintered fly ash aggregates are cooled, crushed, and sieved to appropriate sizes (Figure 7). Fresh concrete workability is measured using the slump test, affected by self-weight and improved by lightweight aggregate (LWA) reinforcement, especially sintered aggregates. Angular aggregates require more superplasticizer than sintered fly ash aggregates for slump. Plastic and dry densities distinguish lightweight aggregate concrete (LWAC), which minimizes fresh density for efficient compaction and requires oven-dry density for structural stability. Manufacturers need aggregate and paste matrix strength for compressive strength, and LWAC competes with conventional concrete [29,30].

Figure 7.

Appearance of sintered fly ash aggregates (authors interpretation).

Split tensile strength, though typically lower in LWAC due to porous aggregates, can match or exceed regular concrete. The elastic modulus of LWAC is lower due to increased paste content and particle flexibility, impacted by LWA volume and aggregate form. Porous aggregates defy linear stress–strain relationships, complicating modulus determination [9,31,32].

2.4.3. Vermiculite and Perlite Aggregates

Vermiculite and perlite aggregates are two commonly used ALWAs known for their unique properties and wide-ranging applications in construction and horticulture. Vermiculite is a natural mineral that undergoes expansion when heated, resulting in lightweight, porous particles. Similarly, perlite is a volcanic rock that expands under high temperatures, forming lightweight, porous aggregates [33]. These aggregates are valued for their exceptional thermal insulation properties, making them ideal for applications where heat retention or resistance is crucial. In construction, vermiculite and perlite aggregates are often incorporated into lightweight concrete mixes to reduce overall density while maintaining structural integrity [34]. They are also used in insulation boards, plasters, and fireproofing materials due to their excellent fire resistance and thermal performance. In horticulture, vermiculite and perlite aggregates are popular additives to potting mixes and soil conditioners. Their lightweight nature improves soil aeration, drainage, and moisture retention, promoting healthy plant growth and root development. Additionally, these aggregates are inert and sterile, making them suitable for use in hydroponic systems and seed starting. Vermiculite and perlite aggregates offer versatility, durability, and sustainable solutions in various industries, providing lightweight and insulating properties that enhance the performance of construction materials and horticultural substrates alike [33].

2.4.4. Foamed Glass Aggregates

Foamed glass aggregates represent a remarkable innovation in the realm of lightweight construction materials. These aggregates are engineered by introducing foaming agents to crushed glass, which is then heated to high temperatures [35,36] (Figure 8). The result is a product characterized by its lightweight, cellular structure, and diverse applications across multiple industries. One of the most notable features of foamed glass aggregates is their exceptional strength-to-weight ratio. Despite their low density, foamed glass aggregates exhibit remarkable compressive strength and durability, making them suitable for a wide range of structural and non-structural applications [37,38]. In construction, they are often used as lightweight fill material in road construction, embankments, and landscaping projects. Their lightweight nature reduces the overall load on structures and minimizes settlement over time. Foamed glass aggregates also offer excellent thermal insulation properties, making them ideal for use in insulation panels, green roofs, and geotechnical applications. Their closed-cell structure effectively traps air, providing effective thermal barriers against heat transfer and reducing energy consumption in buildings. Furthermore, foamed glass aggregates are non-combustible and resistant to moisture, chemicals, and biological degradation, ensuring long-term performance and sustainability in various environments. They are environmentally friendly due to their inert nature, which allows for recycling and reuse in construction projects, thereby reducing waste and conserving resources [35].

Figure 8.

Foamed glass aggregate [35].

Foamed glass aggregates represent a versatile and sustainable solution for lightweight construction materials, offering strength, insulation, and durability across a wide range of applications in the construction, infrastructure, and environmental sectors. There are various other ALWAs that exist, such as Expanded Perlite Aggregates, Expanded Polystyrene (EPS) Beads, cellular concrete aggregates, cenospheres, expanded cork aggregates, expanded aggregates from recycled materials, and expanded wood aggregates, which constitute a diverse array of ALWAs with unique properties and applications [39]. Expanded Perlite Aggregates and EPS Beads offer exceptional thermal insulation and are widely used in construction for lightweight concrete and insulation panels. Cellular concrete aggregates, characterized by their cellular structure, are favored for their low density and high flowability, making them suitable for lightweight fill and insulation. Cenospheres, hollow spherical particles derived from fly ash, find applications as lightweight fillers in concrete and composites [40]. Expanded cork aggregates, an eco-friendly option, provide thermal and acoustic insulation and are used in construction and flooring. Similarly, expanded aggregates from recycled materials contribute to sustainability by repurposing materials like glass and plastics for lightweight concrete and insulation products. Expanded wood aggregates offer low density and good insulating properties, serving as a sustainable alternative in construction and insulation applications [41]. Each of these ALWAs presents innovative solutions for addressing the demands of modern construction while promoting environmental stewardship and resource efficiency.

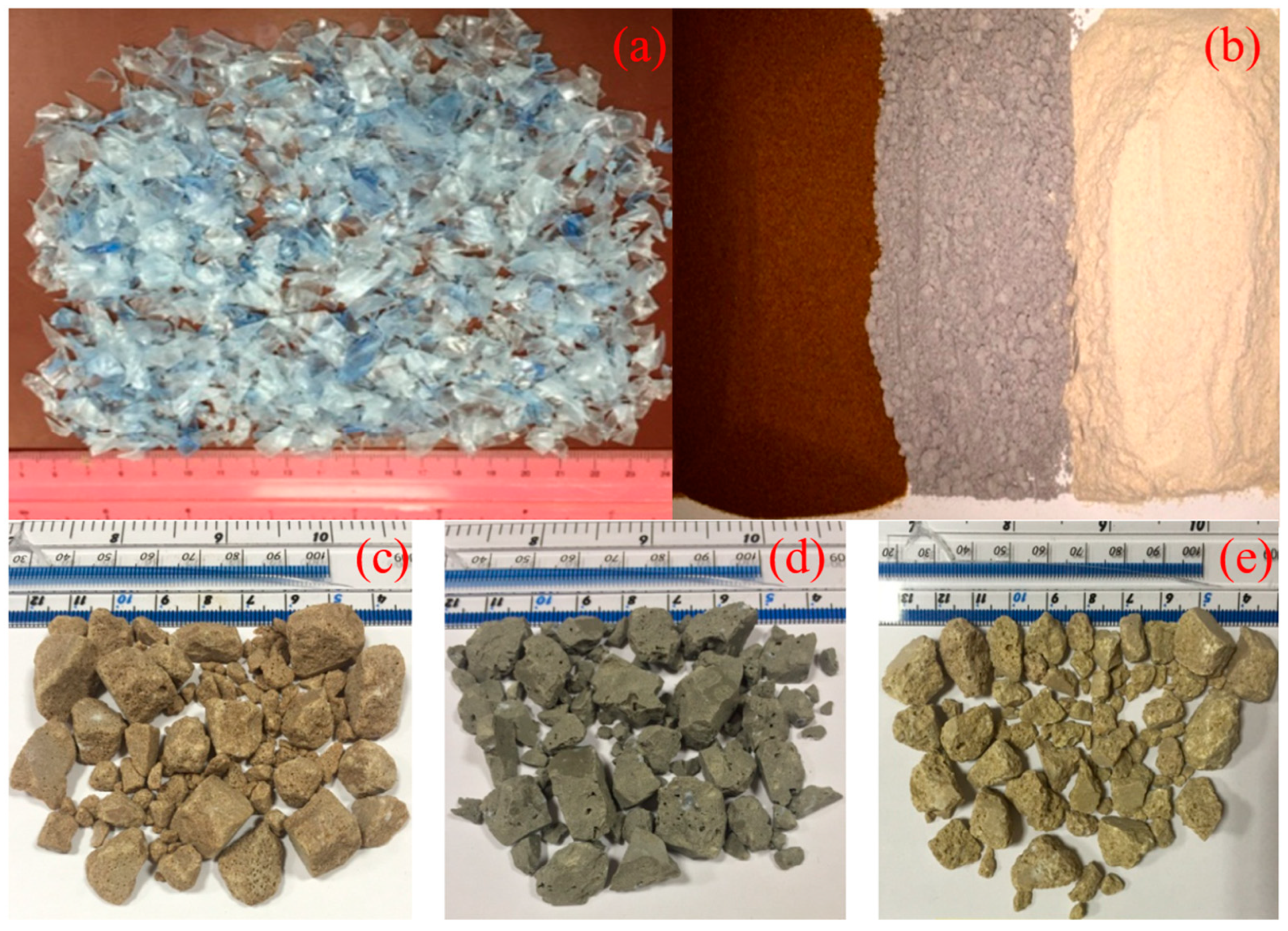

2.5. Plastic-Based Green Lightweight Aggregates

Plastic-based green ALWAs offer a novel method for sustainable construction materials by utilizing the plentiful supply of plastic waste to develop innovative solutions for building and infrastructure projects [42]. Aggregates sourced from recycled plastics, specifically polyethylene (PE) and polypropylene (PP), present a viable alternative to conventional aggregates, simultaneously mitigating environmental issues related to plastic pollution. The production process of plastic-based green ALWAs initiates with the collection and sorting of post-consumer plastic waste [43]. This waste stream comprises multiple sources, including plastic bottles, containers, packaging materials, and discarded household items. The collected plastic waste is subjected to thorough sorting and cleaning processes to eliminate impurities and contaminants, thereby ensuring the quality and purity of the raw material for aggregate production. Following sorting and cleaning, the plastic waste is shredded into smaller fragments or pellets and prepared for processing. The shredded plastic material undergoes controlled heating and melting processes, usually within a specialized extrusion or molding apparatus. Additives and modifiers may be introduced at this stage to improve the properties of the resulting aggregates, including strength, durability, and thermal insulation. The extrusion or molding of molten plastic material results in the formation of lightweight aggregate pellets or granules, achieving the specified shape and size [42]. Figure 9a illustrates the plastic waste particles, whereas Figure 9b presents various additives, including dune dust additive (DDA), fly ash additive (FAA), and quarry dust additive (QDA). Furthermore, Figure 9c–e illustrate the effects of various additives, including normal weight coarse aggregate (NCA), volcanic lightweight coarse aggregate (VLA), and lytag coarse aggregate (LYA), respectively. These aggregates experience rapid cooling and solidification, leading to lightweight, uniform, and durable construction materials appropriate for various applications. Plastic-based green ALWAs present multiple advantages compared to traditional aggregates. They contribute to reducing plastic waste accumulation in landfills and the environment, offering a sustainable solution for recycling plastic materials. Repurposing plastic waste into construction aggregates mitigates plastic pollution, conserves natural resources, and decreases the carbon footprint linked to conventional aggregate production methods [44,45]. Additionally, plastic-based ALWAs demonstrate superior lightweight characteristics, rendering them ideal for applications requiring weight reduction, including lightweight concrete, insulation panels, and green roofs. Their low density improves the energy efficiency of buildings and infrastructure projects, leading to reduced transportation costs and structural loads. Additionally, plastic-based green ALWAs present opportunities for innovation and customization, enabling manufacturers to adjust their properties to meet specific project requirements and performance standards. Advancements in technology and materials science enhance the potential for novel formulations and applications of plastic-based aggregates, promoting progress toward a sustainable and resilient built environment.

Figure 9.

Polyethylene terephthalate (PET) (a); different types of additives (b); normal weight coarse aggregate (NCA) (c); volcanic lightweight coarse aggregate (VLA) (d); and lytag coarse aggregate (LYA) (e) [42].

Plastic-based green ALWAs represent a promising paradigm shift in construction materials, harnessing the transformative potential of recycled plastics to create environmentally friendly and resource-efficient solutions for the built environment. By embracing these innovative materials, researchers can contribute to a more sustainable and circular economy while addressing the pressing challenges of plastic waste management and environmental sustainability [46].

3. Properties of Artificial Lightweight Aggregates

The composition of ALWAs encompasses a wide array of materials, each contributing unique properties and characteristics to the final product. While traditional ALWAs have been predominantly composed of natural materials such as expanded clay, shale, or slate, advancements in materials science and manufacturing techniques have led to the exploration of diverse compositions, including synthetic polymers, industrial by-products, and recycled materials. Understanding the impact of different compositions on the properties of ALWAs is essential for optimizing their performance and functionality in various applications. The impact of composition on ALWAs encompasses several key properties, including density, thermal conductivity, and mechanical strength. Understanding how different compositions influence these properties is essential for selecting the most suitable aggregates for specific applications and optimizing performance in construction and engineering projects [47].

3.1. Density

Composition significantly affects the density of lightweight aggregates, which directly influences their weight-to-volume ratio and structural characteristics. Aggregates composed of materials with low bulk density, such as expanded polystyrene (EPS) or expanded shale, exhibit lower overall densities compared to aggregates made from denser materials like expanded clay or recycled glass. Lower-density aggregates are favored for applications where weight reduction is critical, such as lightweight concrete, insulation panels, and green roofs. By utilizing lightweight aggregates, construction projects can achieve significant savings in materials, transportation costs, and structural loads while maintaining structural integrity and performance. The researchers have carried out various testing procedures to establish the physical properties of LWAC based on the densities of the various artificial aggregates, such as expanded shale aggregates (ESAs) and expanded clay aggregates (ECAs) [48]. Natural aggregates, such as gravel and crushed stone, typically have higher densities and weights compared to ALWAs. This difference in density directly impacts the overall weight of construction materials and structural loads. ALWAs, on the other hand, are specifically engineered to have lower densities, resulting in reduced structural loads, transportation costs, and construction time [49].

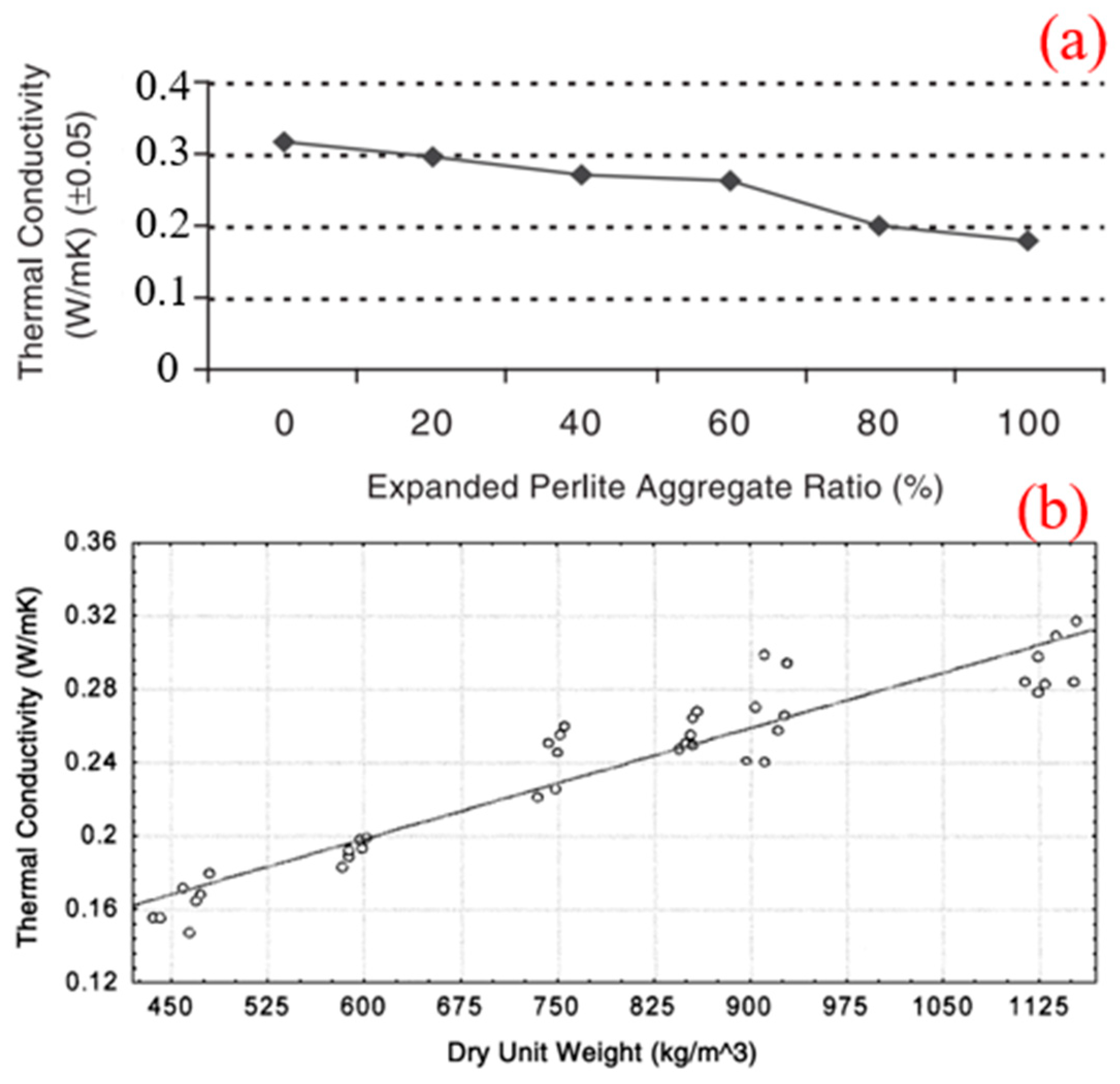

3.2. Thermal Conductivity

The thermal conductivity of ALWAs is influenced by their composition, pore structure, and density. Aggregates with high porosity and low thermal conductivity materials, such as expanded polystyrene (EPS) or polyurethane foam, exhibit excellent thermal insulation properties, making them ideal for energy-efficient building envelopes and thermal barrier applications. In research, it has been found that the thermal conductivity of concrete increases with increasing cement content and the thermal conductivity of aggregate. Silica fume (SF) causes a decrease in the thermal conductivity and an increase in the specific heat of cement paste. SF also causes an increase in electrical resistivity. However, the effect of SF and fly ash (FA) on the thermal conductivity of LWAC has not been previously reported. Further in the research, additives, such as SF and FA, are used in concrete for improving the mechanical properties, decreasing the rate of hydration, decreasing the alkali–aggregate reactivity, and decreasing the permeability of concrete. However, their effects on the thermal conductivity have received little attention. In the case of expanded perlites, it has been observed that the dry weight of concrete decreases with an increase in the percentage of perlite due to the lower specific gravity of EPA. Figure 10a) illustrates that in the case of the as the expanded perlite aggregate ratio goes on increasing the thermal conductivity tends to decrease. Further in Figure 10b) it can be seen that the relationship between dry unit weights (±0.02) and thermal conductivity (±0.05), demonstrating that as the dry unit weight of the aggregate increases, the thermal conductivity also tends to increase, indicating a correlation between the density of the material and its ability to conduct heat ALWAs excel in thermal insulation properties, offering enhanced energy efficiency and occupant comfort in buildings and infrastructure. Their low thermal conductivity helps regulate indoor temperatures, reducing heating and cooling costs. Natural aggregates, while still valuable in construction, may not provide the same level of thermal insulation as lightweight alternatives, making them less suitable for energy-efficient building designs.

Figure 10.

Relationship between (a); expanded perlite aggregates ratio (%) and thermal conductivity (±0.05), and (b); dry unit weights (±0.02) and thermal conductivity (±0.05) [50].

In this research, the relationship between thermal conductivity and silica fume with FA is established and demonstrated in the form of figures. It was observed that with an increase in the percentage of silica fume and FA, the conductivity decreases. The choice of ALWAs with optimized thermal properties is essential for achieving building code requirements, improving energy efficiency ratings, and reducing environmental impact [51].

3.3. Mechanical Strength

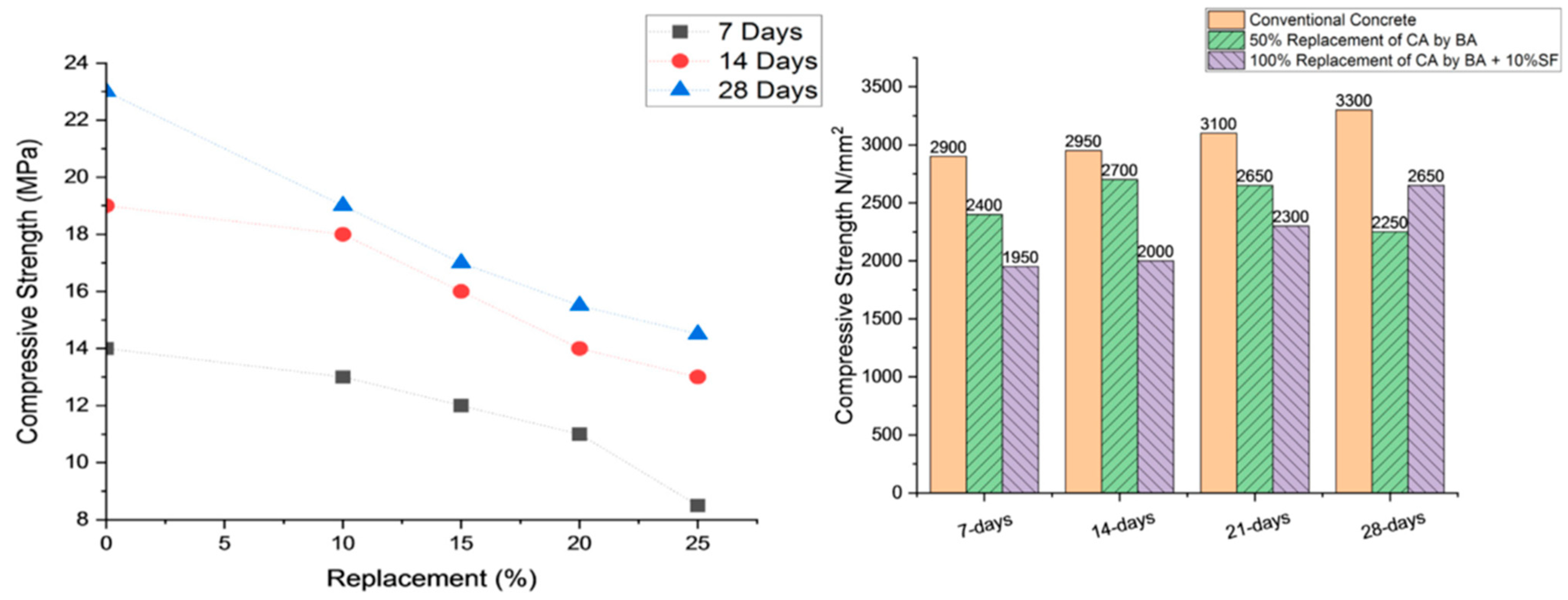

Composition plays a critical role in determining the mechanical strength and durability of ALWAs under load-bearing conditions. Aggregates composed of materials with high compressive strength, such as expanded clay or shale, exhibit superior structural performance and resistance to deformation and settlement [52]. Mechanical strength properties, including compressive strength, tensile strength, and modulus of elasticity, are essential considerations in structural design, foundation engineering, and pavement construction [53,54,55]. ALWAs with adequate strength characteristics ensure structural stability, longevity, and safety in diverse applications ranging from lightweight concrete to geotechnical reinforcement. Innovations in composition, such as the incorporation of reinforcing fibers, chemical additives, or hybrid materials, can enhance the mechanical properties of ALWAs and expand their applications in high-performance and specialty construction projects. In the case of palm kernel shell and walnut shell, the mechanical properties have been shown for the lightweight artificial aggregates. Figure 11 provides insight into how much concrete’s weight may be reduced while maintaining its strength. It can be seen that conventional concrete has better compressive strength after 7 days of maturing. Further, conventional concrete retains its compressive strength even after 28 days of maturing. When it was replaced with 50% of BA the compressive strength decreases to 2250 N/mm2.

Figure 11.

Mechanical properties in the case of lightweight artificial aggregates [29].

The impact of composition on ALWAs extends beyond individual properties to encompass a holistic understanding of material behavior, functionality, and performance. By carefully considering the interplay between density, thermal conductivity, and mechanical strength, engineers, architects, and construction professionals can optimize the selection and application of ALWAs to meet project requirements, enhance sustainability, and promote innovation in the built environment. Collaborative research, technological advancements, and sustainable practices will continue to drive progress in lightweight aggregate design and application, shaping a more resilient and resource-efficient infrastructure landscape [56]. Furthermore, natural aggregates often exhibit high compressive strength and durability, making them suitable for load-bearing applications in construction. However, their higher weight may pose challenges in certain scenarios, especially where weight reduction is critical. ALWAs offer competitive strength and durability properties while providing the additional benefit of reduced weight. This makes them particularly well suited for applications where structural integrity, thermal insulation, and energy efficiency are paramount considerations [50].

4. Applications of Artificial Lightweight Aggregates

In this section, the application of ALWAs is discussed briefly since there are numerous types of applications. The most common is in the construction industry since the use of ALWAs is the only viable sustainable solution available in this industry. Below, some of the potential application areas are discussed.

4.1. Construction Industry

ALWAs represent an indispensable component in contemporary construction methodologies, offering multifaceted advantages across diverse applications within the industry. Beyond their fundamental role in lightweight concrete formulation, these aggregates find extensive utilization in the fabrication of lightweight blocks, panels, and precast elements, thus underpinning how modern construction plays a pivotal role in reducing structural loads and enabling the design and construction of more efficient high-rise buildings and structures.

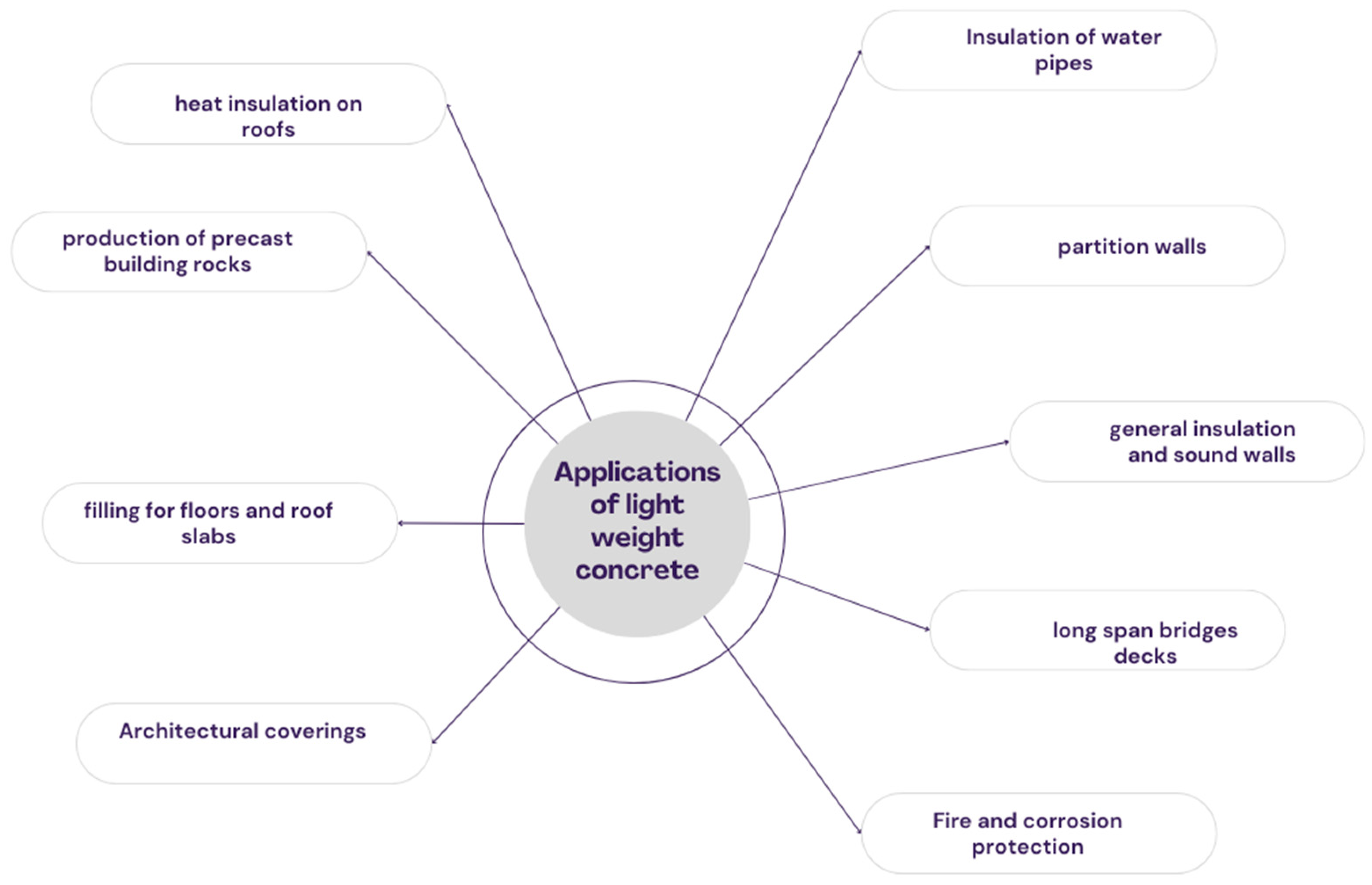

Figure 12 shows the various possible applications of the lightweight aggregates. Additionally, ALWAs contribute significantly to enhancing thermal insulation properties in buildings, leading to diminished energy consumption and heightened comfort levels for occupants. Moreover, their reduced weight facilitates expedited construction timelines and lower transportation costs, rendering them economically and environmentally advantageous compared to traditional materials. In the construction landscape, ALWAs emerge as indispensable assets, particularly in the context of high-rise building construction and the manufacturing of precast elements, marking a paradigm shift toward sustainable and efficient construction methodologies [52]. In addition to these, various other applications that have been reported to date are presented in Figure 12.

Figure 12.

Different applications of lightweight concrete prepared with lightweight aggregates (authors interpretation).

4.1.1. High-Rise Buildings

High-rise buildings stand as symbols of modern urban architecture, demanding materials and construction methodologies that balance structural integrity, efficiency, and sustainability [34,57]. ALWAs emerge as pivotal components in the construction of high-rise buildings, offering myriad advantages to address the unique challenges inherent in vertical construction. Incorporating materials like expanded clay, expanded shale, and foamed glass into lightweight concrete formulations aids in reducing structural loads, thereby enabling more efficient design and construction processes, which are particularly crucial in tall structures where weight considerations directly impact stability and foundation design. Additionally, ALWAs contribute to improved thermal insulation properties within high-rise buildings, enhancing energy efficiency and occupant comfort by regulating indoor temperatures and reducing heating and cooling costs [58]. The adoption of lightweight concrete panels, precast elements, and modular construction systems incorporating ALWAs streamlines assembly processes, reduces labor requirements, and minimizes transportation costs due to the material’s lighter weight, thereby accelerating construction cycles and yielding cost savings. Moreover, in seismic-prone regions, ALWAs bolster the seismic performance of high-rise buildings, enhancing structural resilience and mitigating the risk of damage during earthquakes. By aligning with sustainability objectives, the use of ALWAs in high-rise construction reduces carbon emissions, minimizes environmental impact, and conserves natural resources, further enhancing the eco-friendly profile of modern urban structures. In essence, ALWAs play a vital role in shaping the skylines of contemporary cities, facilitating the development of innovative, environmentally conscious, and resilient high-rise buildings that define urban landscapes worldwide [59].

4.1.2. Precast Elements

ALWAs are also integral in the production of precast elements such as panels, beams, and columns. Lightweight precast elements offer advantages in quality control, efficiency, and versatility. They contribute to sustainable construction practices by minimizing material consumption, waste generation, and transportation emissions [60,61]. Additionally, lightweight precast elements enable faster installation, reduced labor costs, and accelerated project schedules. Furthermore, these elements can be customized and engineered to meet specific project requirements, including acoustic performance, fire resistance, and thermal insulation. By integrating ALWAs into construction practices, professionals can achieve innovative designs, optimize construction workflows, and deliver high-performance building solutions that enhance the built environment [62].

4.1.3. Infrastructure Development

ALWAs assume a pivotal role in diverse infrastructure projects encompassing bridges, highways, and tunnels, where they offer enduring solutions to critical construction challenges [63]. Their integration in lightweight concrete overlays and bridge decks not only ensures durability and longevity but also reduces maintenance demands, thus enhancing the sustainability of infrastructure assets. Within road construction endeavors, ALWAs find application in embankments, subgrade stabilization, and backfill tasks, mitigating settlement issues and bolstering roadway performance, especially in regions susceptible to soil instability and differential settlement [64]. Moreover, the utilization of ALWAs underscores a commitment to sustainable infrastructure practices by minimizing environmental impact throughout construction activities and extending the operational lifespan of infrastructure assets. In the realm of infrastructure development, ALWAs emerge as indispensable elements, particularly in road embankments and as lightweight fill materials, marking a transformative shift toward resilient and eco-conscious infrastructure solutions [65].

4.1.4. Road Embankments

ALWAs play a significant role in road embankments, where stability, load-bearing capacity, and longevity are paramount considerations. By utilizing ALWAs in road embankments, engineers can mitigate settlement issues and improve the overall performance of roadways, particularly in areas prone to soil instability and differential settlement. ALWAs offer superior durability and resistance to freeze–thaw cycles and chemical corrosion, making them ideal for embankment construction in diverse environmental conditions. Additionally, ALWAs contribute to sustainable infrastructure solutions by minimizing the environmental footprint associated with construction activities and prolonging the service life of road infrastructure assets [66].

4.1.5. Lightweight Fill Materials

ALWAs serve as lightweight fill materials in various infrastructure projects, including retaining walls, embankments, and foundation support structures. Lightweight fill materials offer advantages in terms of ease of handling, installation, and structural performance. They provide stable and compressible support for retaining walls and embankments, reducing lateral loads and settlement in soft soil conditions. Additionally, lightweight fill materials contribute to sustainable construction practices by minimizing material consumption, construction time, and environmental impact. Engineers and construction professionals value the versatility and performance characteristics of lightweight fill materials, which enable efficient and cost-effective solutions for a wide range of infrastructure projects. By incorporating ALWAs into infrastructure development projects, researchers can achieve sustainable, resilient, and innovative solutions that enhance the functionality and longevity of critical infrastructure assets [67].

4.2. Geotechnical Engineering

Geotechnical engineers harness the unique properties of ALWAs to address a multitude of challenges related to soil instability, erosion, and geological hazards. Utilizing ALWAs like expanded clay and shale, engineers implement stable and erosion-resistant solutions for slope stabilization and landslide mitigation projects. Additionally, geofoam aggregates, exemplified by expanded polystyrene (EPS), serve as lightweight fill materials in applications ranging from embankments to retaining walls and foundation support structures. Their exceptional compressive strength and low density render them ideal for reducing lateral loads and settlement in soft soil conditions, thereby enhancing overall stability. Furthermore, in coastal engineering endeavors, ALWAs play a pivotal role in shoreline protection, beach nourishment, and erosion control measures. Their lightweight nature not only mitigates coastal erosion but also fosters habitat enhancement for marine ecosystems. In the realm of geotechnical engineering, the utilization of ALWAs encompasses diverse applications, including slope stabilization and land reclamation, exemplifying their versatility and indispensable role in addressing complex geological and environmental challenges [68].

4.2.1. Slope Stabilization

ALWAs play a crucial role in slope stabilization projects, where erosion control and stability are paramount concerns. By utilizing lightweight aggregates, such as expanded clay and shale, engineers can create stable and erosion-resistant solutions for mitigating slope instability and preventing landslides. ALWAs offer high stability and durability, making them ideal for reinforcing slopes and retaining walls in challenging terrain. These aggregates provide a lightweight yet effective solution for stabilizing slopes and minimizing the risk of soil erosion, particularly in environmentally sensitive areas and steep topography. Additionally, ALWAs contribute to sustainable slope stabilization practices by minimizing material consumption, construction time, and environmental impact [69].

4.2.2. Land Reclamation

In land reclamation projects, ALWAs serve as versatile and sustainable solutions for reclaiming land from water bodies and unstable terrain. ALWAs offer advantages in terms of stability, load-bearing capacity, and environmental compatibility. By utilizing lightweight aggregates, engineers can create stable and durable landfills, embankments, and foundation support structures, facilitating the development of new land areas for infrastructure and development projects. ALWAs contribute to sustainable land reclamation practices by minimizing the environmental footprint associated with construction activities and promoting ecological diversity in reclaimed land areas. Additionally, ALWAs offer cost-effective solutions for land reclamation projects, enabling efficient utilization of resources and reducing the overall environmental impact of land development activities. In summary, ALWAs play a critical role in geotechnical engineering applications, including slope stabilization and land reclamation. By incorporating ALWAs into geotechnical engineering projects, engineers and construction professionals can achieve sustainable, resilient, and innovative solutions that enhance the stability, functionality, and environmental sustainability of land and infrastructure assets [70].

4.3. Horticulture and Landscaping

In addition to their applications in construction and geotechnical engineering, ALWAs find uses in other industries such as horticulture and landscaping.

4.3.1. Horticulture and Soil Conditioning

In horticulture, ALWAs offer versatile solutions for soil conditioning and hydroponic systems. Lightweight aggregates, such as perlite and vermiculite, are commonly used in soil mixes to improve drainage, aeration, and moisture retention for plant roots. These aggregates help create optimal growing conditions by enhancing soil structure and nutrient uptake, promoting healthy plant growth and reducing compaction. Soil conditioning with ALWAs improves root development, reduces waterlogging, and minimizes the risk of root diseases, making it an essential practice in container gardening, raised beds, and landscaping projects [71].

4.3.2. Hydroponic Systems

Hydroponic systems utilize ALWAs as inert growing media for the soilless cultivation of plants. Expanded clay pellets and rockwool cubes are popular choices for hydroponic systems due to their uniformity, stability, and compatibility with nutrient solutions. ALWAs provide a stable and oxygen-rich environment for plant roots, promoting rapid growth and optimal nutrient uptake. Hydroponic systems offer advantages in water efficiency, space utilization, and crop yield, making them ideal for urban agriculture, greenhouse production, and controlled environment farming [72].

4.3.3. Lightweight Garden Structures

ALWAs serve as essential components in the construction of lightweight garden structures such as decorative planters, retaining walls, and garden borders. Expanded polystyrene (EPS) geofoam and lightweight concrete blocks offer lightweight, durable, and customizable solutions for landscaping projects. Lightweight garden structures provide versatility in design, ease of installation, and long-term durability, enhancing the aesthetic appeal and functionality of outdoor spaces. Additionally, ALWAs contribute to sustainable landscaping practices by minimizing material consumption, reducing labor costs, and promoting environmental stewardship. Lightweight garden structures offer opportunities for creative expression, plant diversity, and outdoor enjoyment, making them integral elements in residential gardens, public parks, and commercial landscapes. ALWAs play diverse roles in the horticulture and landscaping industries, offering solutions for soil conditioning, hydroponic systems, and lightweight garden structures. By incorporating ALWAs into horticultural and landscaping practices, professionals can create sustainable, resilient, and aesthetically pleasing outdoor environments that promote plant health, environmental sustainability, and community well-being [73].

5. Advantages and Challenges

ALWAs benefit building and infrastructure projects in several ways. The most important is weight loss. ALWAs lower construction material weight, which is a major benefit. Lower weight means lower structural loads, lower transportation costs, and more design freedom. ALWA structures require less structural support, saving money and allowing for inventive architecture. Thermal insulation is also significant in aggregates. The thermal insulation of ALWAs makes it perfect for energy efficiency and comfort in buildings and infrastructure. Their low thermal conductivity regulates indoor temperatures, lowering heating and cooling expenses and improving comfort. Many ALWAs have excellent compressive strength despite their low weight, making them useful for structural applications in building and engineering. A high strength-to-weight ratio enables sturdy and resilient constructions that can withstand loads and weather conditions. Aggregates absorb sound well due to their variety of materials. ALWAs absorb sound, decreasing noise and enhancing building acoustics. They are especially useful in residential, commercial, and industrial situations where noise reduction is crucial for occupant health and productivity. These versatile materials can be tweaked and designed for individual projects. They provide lightweight concrete, insulating panels, geotechnical stabilization, and horticulture substrates for building, infrastructure, and industry [74]. ALWAs reduce weight and improve thermal insulation; however, using ALWAs in construction projects is difficult. Their cost is higher than traditional aggregates, which is an issue. This higher cost can strain project budgets, especially in large projects where cost is crucial. ALWAs may also be more susceptible to freeze–thaw cycles and chemical deterioration. Long-term performance requires proper selection and maintenance. Due to their low density and friability, ALWAs require specialist handling and installation, which may raise labor costs and construction time. To satisfy performance and regulatory standards, engineers and architects must assess the compatibility of ALWAs with specific construction applications, such as those needing high structural loads or fire resistance [75].

However, ALWAs have several issues. Different cement-like industrial wastes are used to make artificial lightweight aggregates. Ash, which contains many harmful chemicals, is often used. The waste can cause respiratory issues, kidney damage, neurological diseases, and cancer. Heavy metals from garbage leech into the water, harming humans and fish. Tests and quantification of dangerous substances are needed before using industrial waste for artificial aggregates [76]. These materials must be handled with PPE to reduce exposure. Groundwater and soil pollution can be prevented by monitoring water discharge from these garbage sites. This can be avoided by checking local water and soil [77].

6. Environmental Considerations and Sustainability Aspects

- Resource Extraction: The extraction and processing of raw materials for ALWAs can have environmental impacts, including habitat destruction, land degradation, and resource depletion. Sustainable sourcing practices and responsible mining techniques are essential to minimize environmental harm and preserve natural ecosystems [78].

- Energy Consumption: Lightweight aggregate production processes, such as firing and curing, may require significant energy inputs, contributing to greenhouse gas emissions and climate change. Adopting energy-efficient technologies, utilizing renewable energy sources, and optimizing production processes can reduce energy consumption and mitigate environmental impact [73].

Recycling and Sustainability: Lightweight aggregate production using recycled materials, industrial by-products, and alternative sources reduces environmental consequences, conserves resources, and promotes circular economy principles. Researchers can improve environmental sustainability and reduce the ecological footprint of construction by promoting recycling and sustainable practices throughout the life cycle of lightweight aggregates [79]. ALWAs have several advantages in building and engineering, but tackling its problems and environmental concerns demands a holistic approach that promotes sustainability, innovation, and responsible resource management. Researchers can improve lightweight aggregate system sustainability and resilience while minimizing environmental effects and encouraging long-term environmental stewardship by using eco-friendly procedures, optimizing material utilization, and embracing circular economy principles. In Table 2, environmental sustainability factors are discussed.

Table 2.

Environmental considerations and sustainability aspects regarding LWAs.

- Waste Generation: Lightweight aggregate production produces waste that must be properly disposed of or recycled to reduce environmental effects. Recycling industrial by-products and using recycled materials in lightweight aggregate manufacturing can reduce waste and conserve resources [89].

In addition, there are various environmental impacts associated with various kinds of aggregates. Aggregates essential in construction for concrete, asphalt, and road bases exhibit differing environmental implications based on their nature and source. Natural aggregates such as gravel, sand, and crushed stone generate considerable greenhouse gas (GHG) emissions because of energy-intensive extraction, processing, and extensive transportation, while also causing ecosystem destruction, air pollution from dust, and contamination of water streams. Recycled aggregates obtained from building materials diminish greenhouse gas emissions, preserve natural resources up to some extent, and redirect materials from landfills; nevertheless, dust and noise pollution may still occur during processing. Manufactured aggregates, including blast-furnace slag or fly ash, provide reduced emissions by employing industrial wastes; yet they may harbor contaminants necessitating meticulous treatment. Lightweight aggregates, produced from materials such as clay and shale, require significant energy for manufacturing but diminish transportation emissions due to their reduced weight, despite their extraction potentially leading to land damage. Marine aggregates extracted from the seabed generate significant greenhouse gas emissions and disturb marine ecosystems, leading to ecosystem destruction, coastal erosion, and water contamination due to sediment outflows. Each aggregate type influences the environment throughout its life cycle, with recycled and manufactured materials providing more sustainable options than natural and marine sources. For better understanding, in Table 3, the types of aggregates are presented along with their environmental impacts [90,91,92,93,94].

Table 3.

Aggregates along with the associated impacts.

7. Future Trends and Innovations

As the demand for sustainable construction materials continues to rise, ongoing research and development efforts in the field of ALWAs are driving innovation and shaping future trends. These advancements encompass a wide range of areas, including materials science, manufacturing techniques, and applications in various industries.

7.1. Ongoing Research and Development

Ongoing research in ALWAs focuses on improving material properties, enhancing production processes, and exploring novel applications. Researchers are investigating alternative raw materials, such as recycled materials and industrial by-products, to reduce environmental impact and promote circular economy principles. Additionally, advancements in nanotechnology and composite materials are opening new avenues for enhancing the performance and functionality of ALWAs in construction and engineering applications [95].

7.2. Potential Advancements and Emerging Technologies

Emerging technologies, such as additive manufacturing (3D printing) and advanced computational modeling, hold promise for revolutionizing the production and design of lightweight aggregates. Additive manufacturing techniques allow for the precise control of material properties and geometries, enabling the fabrication of complex lightweight structures with customizable properties. Advanced computational modeling tools facilitate the optimization of aggregate compositions, pore structures, and mechanical properties, leading to enhanced performance and durability in diverse applications [96].

Future Applications

The future applications of ALWAs extend beyond traditional construction and engineering sectors to include emerging fields such as green infrastructure, advanced materials, and sustainable urban development. ALWAs are poised to play a crucial role in the development of resilient and energy-efficient buildings, smart cities, and infrastructure systems that mitigate climate change impacts and promote environmental sustainability. Additionally, ALWAs are finding applications in innovative areas such as 3D-printed construction, lightweight composites, and advanced manufacturing processes, where their unique properties enable novel solutions for design, performance, and functionality.

8. Role in Sustainable Development

The role of ALWAs in sustainable development is significant, encompassing resource efficiency, energy savings, and environmental challenges. ALWAs contribute to sustainable construction practices by reducing material consumption, transportation emissions, and construction waste. Their lightweight nature minimizes structural loads, conserves natural resources, and promotes energy efficiency in buildings and infrastructure. Furthermore, ALWAs facilitate the integration of renewable materials, recycled content, and eco-friendly production methods, aligning with global sustainability goals and promoting a circular economy approach to materials management. In conclusion, future trends and innovations in ALWAs are driven by ongoing research, emerging technologies, and the growing demand for sustainable construction materials. By harnessing the potential of lightweight aggregates, researchers can unlock new opportunities for innovation, sustainability, and resilience in the built environment. Collaborative research efforts, interdisciplinary approaches, and strategic partnerships will continue to shape the future of lightweight aggregates, paving the way for sustainable development and a more resilient built environment.

8.1. Comparisons with Natural Aggregates and Artificial Aggregates

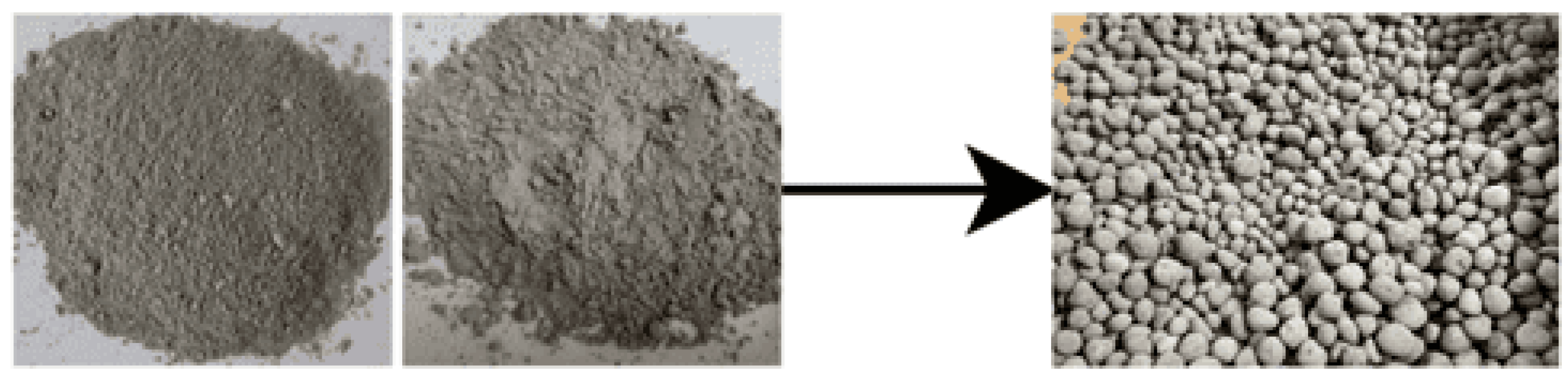

Sustainable building techniques from the ground up through optimal concrete aggregate selection can help address resource issues and solid waste problems. Shang et al. suggested a life cycle assessment-based two-level tree structure framework for ALWA sustainability evaluation [97]. Each of the four criterion groups—societal needs, financial costs, ecological impacts, and technological effectiveness—was assigned a sub-index. The target system had a quantitative calculation with eight sub-indexes and a qualitative evaluation survey with seven. The framework was utilized to evaluate and choose representative artificial and natural ALWAs, SFAAs, CBFAAs, WCBAs, and NPAs (Figure 13). The sustainability of lightweight aggregates was objectively assessed using impact and sensitivity assessments. Impact studies for waste clay brick aggregate showed better sustainability. The sensitivity assessment shows that the supply–demand relationship of raw materials considerably impacts LWA sustainability, and raw material transport range is crucial to LWA manufacturing. Artificial ALWAs are sensitive to cement binder quantity, so adding no cement or using leftover cement powder is a promising alternative. According to the sustainable life cycle evaluation, waste clay brick aggregates, sintering fly ash aggregates, and cold-bonding fly ash aggregates can replace natural pumice aggregates in ALWA concrete [97]. The results show that natural aggregates have a greater environmental impact than artificial lightweight aggregates. A considerable variation in energy use exists between natural and manufactured aggregates. Due to the substantial noise and land pollution caused by big machinery and blasting in mining, NPA production has the highest average environmental impact index scores (sound pollution and land use and ecology). However, WCBAs have lower average scores for sound pollution, land use, and environment than NPAs, showing that waste clay brick collection pollution is more tolerable.

Figure 13.

Aggregates used in the study [97] (reproduced with permission from Elsevier, License number-5894660095351).

SFAAs have greater average sound pollution, land use, and environment scores than CBFAAs. This is because the rotary kiln used in sintering causes more noise and land pollution than cold bonding. The increased environmental impact of the processes of SFAAs should lower its aggregate rating. High ratings suggest noise pollution, land use, and ecological issues. SFAAs, CBFAAs, and NPAs consume several times more energy than WCBAs. Each has different causes for high scores. Cement in raw materials is the main cause of the high energy consumption rankings of SFAAs and CBFAAs. However, the high energy consumption score of NPAs is due to their long production process and transportation distance. The energy consumption score of SFAAs is slightly greater than that of CBFAAs due to the sintering rotary kiln. Production uses a lot of energy, water, and air [98]. WCBAs obtain the greatest environmental impact index score after normalization and weight distribution. The construction materials market favors environmentally friendly production processes. Comparing ALWAs to heavier construction materials is essential for understanding their benefits and uses. This comparative analysis examines the performance and advantages of ALWAs over natural and artificial alternatives, with specific scenarios.

8.2. Specific Scenarios and Advantages

8.2.1. High-Rise Construction

In high-rise construction, where weight reduction is crucial for structural stability and design flexibility, ALWAs offer clear advantages over heavier alternatives. By reducing the overall weight of building materials, ALWAs enable taller and more slender structures while maintaining structural integrity and performance.

Although ALWAs possess a reduced load-bearing capacity relative to conventional materials such as crushed stone, their utilization in high-rise construction continues to be justified when applied correctly. ALWAs are generally unsuitable for primary load-bearing structural elements such as columns or foundations; they are more appropriate for non-load-bearing or enclosing constructions, as suggested by the reviewer. These include walls, partitions, floors, and facades, with the principal objective of minimizing the building’s deadload while maintaining structural integrity.

In such cases, these provide distinct benefits by decreasing weight, enhancing thermal insulation, and facilitating more slim and efficient designs. Nevertheless, for the essential load-bearing elements, conventional, high-strength materials remain indispensable. This distinction guarantees the preservation of structural integrity and safety while leveraging the advantages of ALWAs in high-rise construction.

8.2.2. Sustainable Building Practices

ALWAs align with sustainable building practices by reducing environmental impact, resource consumption, and carbon emissions throughout the construction life cycle. Their lightweight nature minimizes transportation costs, construction waste, and energy consumption, promoting environmental stewardship and resilience in the built environment. In summary, the comparison between ALWAs and traditional, heavier alternatives underscores the importance of understanding their unique characteristics, performance, and applications in construction and engineering. While natural aggregates continue to play a vital role in construction, ALWAs offer distinct advantages in weight reduction, thermal insulation, and sustainability, making them indispensable materials for modern building practices and infrastructure development. By leveraging the benefits of lightweight aggregates, researchers can achieve innovative designs, energy-efficient solutions, and sustainable development in the built environment [97].

9. Case Study on Manufacturing of ALWAs

One of the previous works on ALWAs has been published, and the case study from the same has been demonstrated here. In the work by Petrillo et al. (2022), a multicriteria analysis for Life Cycle Assessment and Life Cycle Costing of ALWAs from industrial waste by double-step cold bonding palletization was carried out [85]. In this research, a multicriteria model for the selection of ALWAs through experimental processes is proposed. The mechanical, environmental, and economic aspects of the ALWAs were integrated to evaluate the most sustainable, which may be appropriate for applications in the construction sector. Further, in this research work, three mixtures were prepared using cement and industrial waste: fly ash from a municipal waste incineration plant, ground granulated blast-furnace slag, and marble sludge. The fly ash content is constant (80%). By varying the blast-furnace slag (5%, 10%, and 15%) and cement content (15%, 10%, and 5%), the mechanical, environmental, and economic properties of each lightweight artificial aggregate mix were evaluated. The AHP was implemented to support the identification of preferred scenarios with reference to the three mixtures, on which there may be convergence and compliance in terms of environmental impacts (measured through LCA), economics (evaluated with the LCC), and technical–functional aspects. The results indicated that ALWAs with fly ash (80%), blast-furnace slag (5%), and a higher percentage of cement (15%) represent the optimal solution, which made the sustainable selection of ALWAs possible.

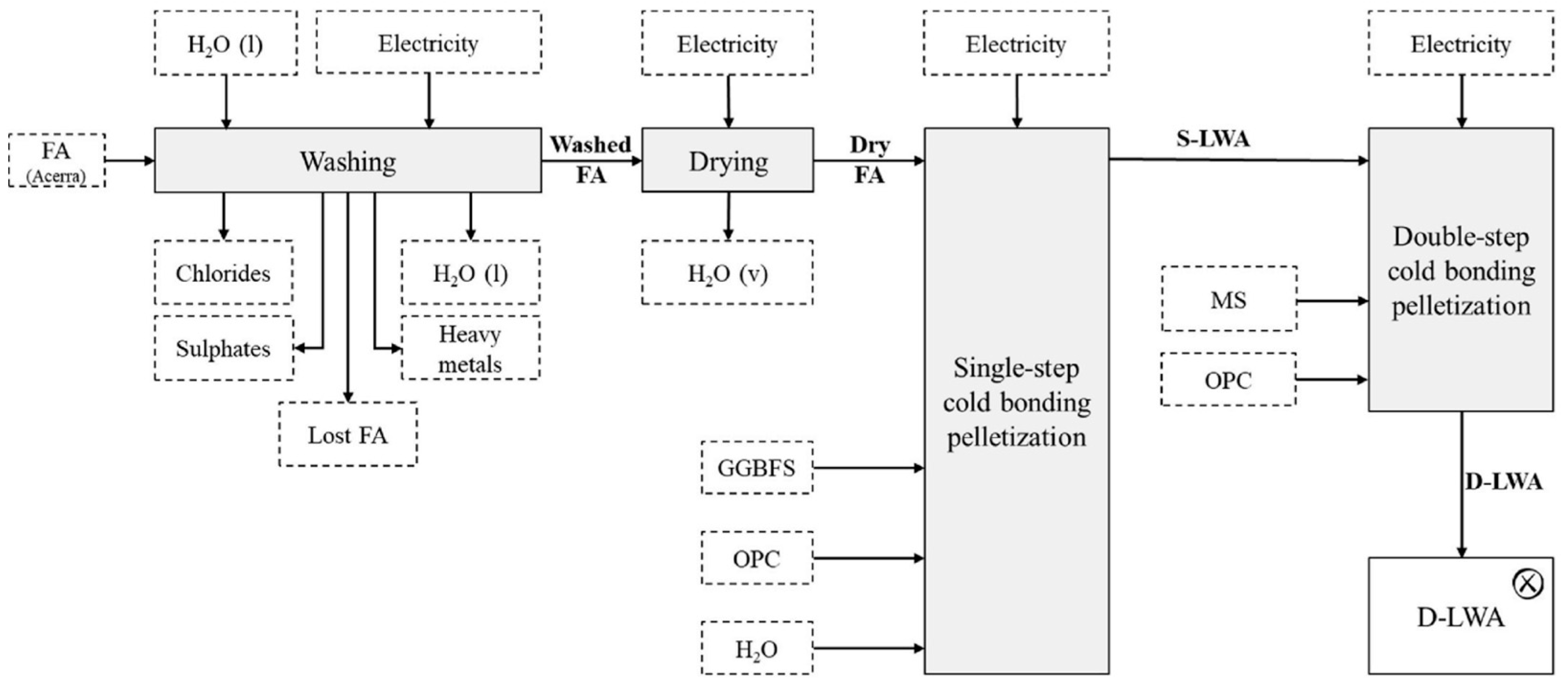

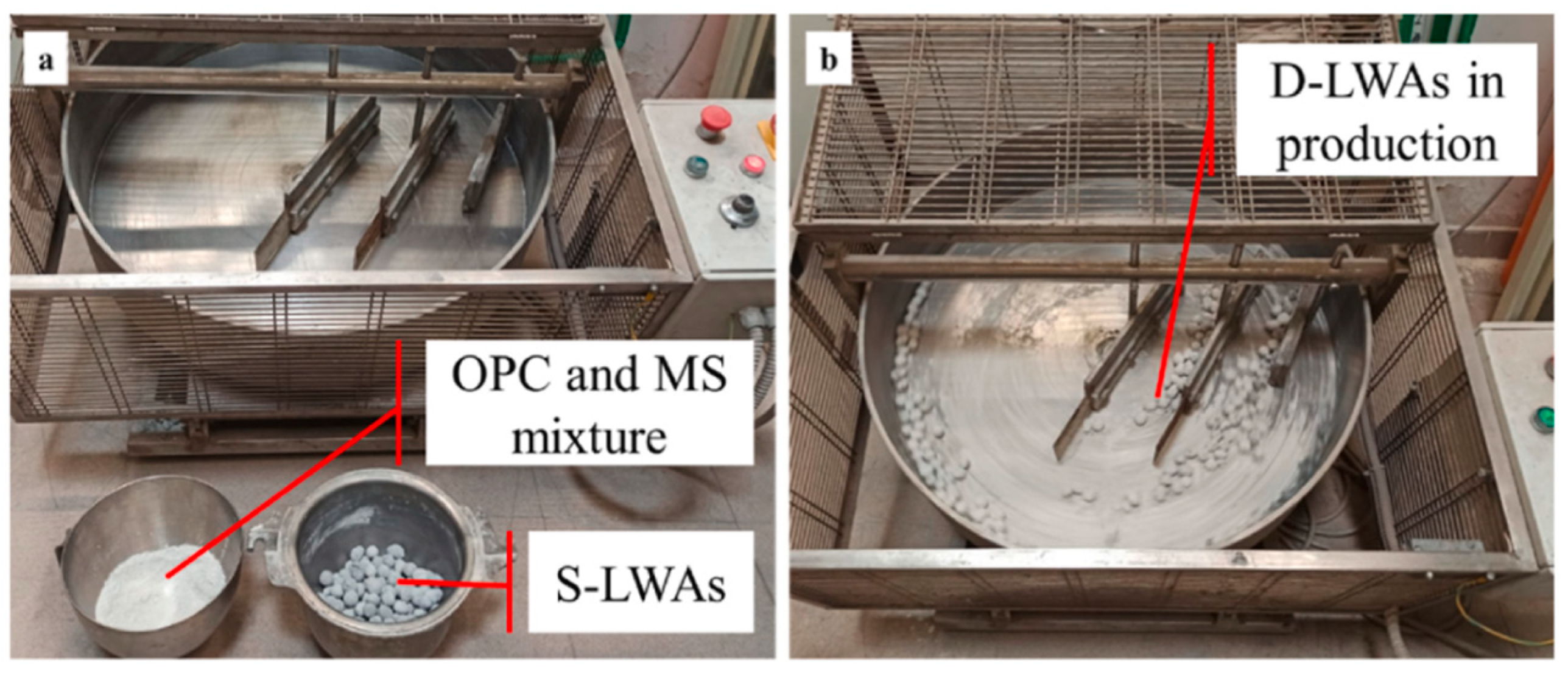

The production process involves several stages. Initially, hazardous waste, Municipal Solid Waste Ash (MSWI-FA), undergoes pre-treatment to enhance its inertization capacity and ensure suitable qualitative characteristics within a cement matrix. This pre-treatment comprises a two-phase washing with water, using a liquid/solid ratio of 2.5:1, and a retention time of 1.5 h for each phase. Following washing, the waste undergoes a drying process in a furnace set at 45 °C for 24 h. Subsequently, the production of ALWAs (LWAs) proceeds through single-step and double-step cold bonding palletization processes. In the single-step method, a mix of Portland cement (OPC), ground granulated blast-furnace slag (GGBFS), and treated MSWI-FA is used. The composition of the mix varies with a constant 80% of treated MSWI-FA, while the proportions of GGBFS (5%, 10%, and 15%) and OPC (15%, 10%, and 5%) are adjusted accordingly. On the other hand, the double-step cold bonding palletization involves the addition of more OPC (30%) and marble sludge (MS) (70%) to create D-LWAs. A graphical overview of the processes is provided in Figure 14 and Figure 15, while Table 4 outlines the specific mix designs for D-LWAs.

Figure 14.

D-LWA production process flow chart [85] (reproduced with permission from Elsevier, License number-5890820448924).

Figure 15.

Aggregate preparation process (a); Single step (S-LWAs) process, and (b); Double step (D-LWAs) process (for second layer processing) [85] (reproduced with permission from Elsevier, License number-5890820448924).

Table 4.

Mixture (wt%) of D-LWAs.

The granules prepared in the study are presented in Figure 15. Figure 15a illustrates the single step, while Figure 15b depicts the double step cold bonding process including the granules prepared. The multicriteria model evaluated various mixtures of D-LWAs, incorporating industrial waste like MSWI-FA, GGBFS, and MS stabilized by cement binder. Utilizing double-step cold bonding palletization, D-LWAs were produced, enhancing technological properties and waste reuse. AHP, integrating LCA and LCC, prioritized mechanical strength and environmental impact. Expert-engineered D-LWA C demonstrated superior mechanical performance, with 460% and 104% improvements over D-LWAs A and B, respectively. Environmentally, D-LWA B proved optimal, emitting 23 kg of CO2 eq. and consuming 0.16 m3 of water due to balanced OPC and GGBFS. Economically, D-LWA B incurred the lowest cost at approximately EUR 22, owing to optimized material usage. Integrating strength, LCA, and LCC via AHP, D-LWA C emerged as the optimal choice, boasting 11 MPa strength, 29 kg of CO2 eq. emissions, 0.197 m3 of water consumption, and EUR 30 total costs, promising superior physical, mechanical, and resistance properties.

10. Conclusions