Abstract

As part of the “Waste2Energy: hybrid energy from waste as a sustainable solution for West-Africa” project, a tyre recycling plant is being constructed in Davié, north of Lomé, Togo. Understanding the tyre management chain is crucial for establishing the plant’s supply chain. This study aimed to highlight the gaps in and the importance of tyre recycling in Togo while assessing the potential of EoL tyres for the implementation of a tyre recycling plant. Togo’s vehicle fleet, predominantly concentrated in Lomé, is rapidly increasing at a rate of 6% per year, reaching an estimated 285,000 vehicles. Due to economic constraints and limited new tyre availability, most vehicle users opt for used tyres, which have a limited lifespan due to poor road conditions. An investigation of EoL tyre quantities and management chains in Togo was carried out. To evaluate the used and end-of-life tyre management chains, both direct observation and interviews with approximately 200 used-tyre dealers were conducted. The study revealed that, on average, drivers replace tyres every 7.4 months, generating between 30,525 t/a and 78,000 t/a of used tyres, 75% of which are replaced due to severe damage or wear. While the used tyre business is well organized, end-of-life tyre treatment is nearly non-existent, often involving dumping, open burning for metal recovery, or use in meat processing, causing environmental and health risks. To address these challenges, an 8 t/hr capacity tyre recycling plant is planned, based on estimated tyre availability and development opportunities for sustainable recycling in Togo.

1. Introduction

The rapid increase in motorization in Togo has sparked a surge in car ownership, resulting in a consequential rise in the generation of end-of-life tyres. This study underscores the critical necessity of comprehending the tyre use management chain to devise efficient waste management strategies in response to escalating motorization rates. In Togo as well as in most West African countries, the vehicle fleet is made of mainly used vehicles from European and American countries [1]. This increasing traffic of used vehicles to Togo leads to the distinctive feature of Togo’s tyre management chain, which is characterized by a significant contribution of imported used tyres. These tyres are often imported based on their affordability and play a pivotal role in the country’s transportation landscape. However, their widespread use exacerbates the challenges associated with tyre disposal due to their shorter lifespan and the increased likelihood of premature wear and tear.

A tyre management chain encompasses the entire process of tyre production, from raw material extraction to end-of-life disposal. Initially, natural rubber is harvested from rubber trees, while synthetic rubber is produced through chemical processes. These raw materials are then processed and combined with other components such as steel, fabric, and various chemicals to form the basic structure of a tyre [2]. The manufacturing stage involves multiple steps, including mixing, calendaring, extruding, building, and curing. During mixing, raw materials are blended to form a homogeneous rubber compound. Calendaring and extruding shape the rubber into sheets and treads, respectively. In the building phase, these components are assembled into a tyre structure, which is then vulcanized or cured to enhance durability and elasticity [2]. Once manufactured, tyres are distributed through various channels to reach consumers. This stage includes warehousing, transportation, and retail. After consumer use, worn tyres are either retreaded, recycled, or disposed of. Retreading extends the life of a tyre by replacing its tread, while recycling involves breaking down tyres into raw materials for other uses. Disposal includes incineration or landfilling and is often noted as a last resort due to its huge environmental implications [3].

In West Africa, end-of-life tyres (EoL tyres) are often disposed of in open dumps or are openly burned [4]. Dumping of EoL tyres poses a significant problem in terms of mosquito breeding due to their ability to accumulate water and create ideal artificial habitats for mosquito larvae [5]. The lack of proper legislation governing the handling and recycling of EoL tyres even exacerbates the problem. EoL tyres are not biodegradable and are expected to leach toxic chemicals when not being treated correctly [6]. Open burning of EoL tyres is highly toxic and has a serious impact on the ambient air quality [4] and the health of the population. Despite the potential for recycling of EoL tyres to create livelihoods and boost economic growth, in Togo there are no incentives put in place to support collectors and recyclers.

Sound EoL tyre management is critical for an effective circular economy and sustainable development in West Africa. EoL tyre management is broad and involves all stakeholders in the tyre industry, such as private and public companies, end-users, tyre dealers, treatment facilities, etc. [7]. Glushankova et al. [8] reported that EoL tyres should be properly treated not only because they emit pollutants but also because they constitute valuable raw materials in the context of the circular economy. Abandoned EoL tyres emit air (toxic fumes, CO2, particulate matter, etc.), water (leachates), and soil (contaminating chemical additives) pollutants [7,8]. Despite these harmful effects of EoL tyres, tons of EoL tyres are not properly disposed of in Togo. The management of EoL tyres is often the responsibility of the informal sector, which lacks proper infrastructure and regulatory oversight. This leads to inadequate recycling and disposal practises, contributing to environmental pollution [9].

Effective data collection on EoL tyres necessitates a well-established waste management system that includes collection, transportation, and disposal or recycling of tyres. However, many African countries struggle with basic waste management challenges, such as inadequate facilities and logistical issues. As a result, the systematic collection and reporting of data on EoL tyres is often not prioritized [10]. The waste management infrastructure in many African countries is not well developed and needs improvement. A comprehensive knowledge into the Togolese tyre management chain enables the identification of specific points where tyre waste is generated. By focusing and integrating these tyre waste generation points, collection and recycling efforts can be strategically targeted to maximize efficiency and effectiveness. Understanding the tyre management chain in Togo provides insights into market dynamics, including demand for recycled materials, economic factors, and regulatory considerations. This information is essential for assessing the economic viability of recycling options and identifying potential markets for recycled tyre products.

The objective of this study is to highlight the gap in and the importance of tyre recycling in Togo while assessing the potential of EoL tyres for the implementation of a tyre recycling plant. A tyre recycling plant is planned in Tsévié, located north of Lomé in Togo. This plant aims to purchase EoL tyres as feedstock for recycling rubber and metals, while also producing tyre-derived fuels (TDF) from the residual materials. By adding value to EoL tyres, which are currently regarded as waste or materials managed by open burning, this initiative will provide used tyre dealers with an additional income stream. Furthermore, it will help mitigate the environmental issues associated with open dumping and burning of EoL tyres. For the effective planning of the tyre recycling plant, several relevant research questions must be addressed: estimation of EoL tyre generation, logistics of tyre management, identifying key stakeholders involved in the handling of these tyres, and cost analysis of EoL tyres. The quantity of end-of-life (EoL) tyres in West Africa remains largely unknown, with no comprehensive data available for the region. The only documented estimate is provided by Arthur et al. [11], who developed a method to assess EoL tyre quantities in Ghana. In this study, their approach has been adapted and applied to estimate the number of EoL tyres in Togo, addressing the lack of regional data.

2. Materials and Methods

An understanding of the tyre management chain in Togo starts with the estimation of the number of tyres imported into Togo. The early steps of the tyre management chain, which are raw material extraction and tyre production, are not existent in Togo. The only country producing tyres in the African continent in 2024 is South Africa [12].

2.1. Estimation of EoL Tyre Quantities in Togo

The number of tyres which end up as end-of-life (EoL) tyres in Togo annually is not available and needs to be estimated. An estimation of the vehicle numbers in Togo has been carried out to estimate the minimum number of tyres currently being in use in Togo. Due to difficulties in accessing data on the number of imports of new and used tyres as well as vehicles, the estimation of the data on EoL tyre generation in Togo was carried out based on the estimations carried out in Ghana [11]. These estimates have been modified and matched to local country conditions of Togo. The choice of estimating the EoL tyre generation based on Ghana’s data is due to the geographical proximity of both countries, as they share a border and similar road infrastructure. The data used for estimations were also the only reliable data which has been found for the estimation on EoL tyre generation in Sub-Saharan Africa. Ref. [11]’s estimations on the generation of EoL tyres in Ghana are derived from the Ghanaian Ministry of Transport and are based on the annual numbers of vehicles in use in Ghana until 2015, derived from the International Organization of Motor Vehicle Manufacturers and the annual numbers of newly registered vehicles in Ghana until 2016. These numbers were extrapolated with medium annual growth rates until 2019 and resulted in an estimated amount of 1,092,000 vehicles in use in Ghana. These were sub-categorized into passenger vehicles (715,000 vehicles) and commercial vehicles (377,000 vehicles). The population of the neighbouring countries, Ghana and Togo, were extracted from [13], for the year 2019 and are displayed at Table 1.

Table 1.

Population of Ghana and Togo in 2019 [10].

When dividing the number of passenger vehicles through the population numbers in Ghana (see Equation (1)) for the baseline year 2019 of the study, an average of 0.0227 passenger vehicles per person were registered in Ghana and an average of 0.0120 commercial vehicles were registered per person in Ghana in 2019.

Adapting the vehicle per capita numbers to the neighbouring country Togo as of Equation (2), a very rough estimation of potential vehicle numbers in Togo in the baseline year of 2019 can be obtained.

Additional assumptions for the estimation of EoL tyre generation in Togo:

- Each passenger vehicle uses 4 tyres

- Each commercial vehicle uses 6 tyres

- Average weight of used passenger car tyre: 7 kg

- Average weight of used commercial vehicle tyre: 40 kg

The average lifetime of tyres has been researched through a set of interviews in Lomé, Togo in February 2024. The interview questions were “how often do you need to replace your tyres?” and “do you buy new or used tyres?”. The interview was split into vehicle types and the indicated number of vehicle users were interviewed as in Table 2. In total, 199 interviews were carried out.

Table 2.

Number of interviews conducted on tyre replacement frequency, depending on vehicle type.

For commercial vehicles, only buses and trucks are considered in this case. Smaller commercial vehicles such as tricycles (Abobayas) and auto-rikshaws were not able to be estimated so far. As no information is available regarding the exact numbers of buses and trucks registered in Togo so far, for estimation purposes of tyre replacement frequency, the ratio was considered to be 50/50. This assumption was based on the information received from tyre dealers regarding tyre replacement frequency. The estimation of the annually generated amounts of EoL tyres has been carried out with Equation (3) (adapted from [11]).

2.2. Evaluation of EoL Tyre Management Chain

In order to evaluate the used tyre management chain and EoL tyre management chain, two methodological approaches were adopted: (1) the empire-inductive method based on direct observation and (2) the hypothetico-deductive method based on interviews (nearly 200 used-tyre dealers).

The questions in the interviews with the tyre dealers focused on (a) understanding the demographics of tyre dealers/tyre mechanics in Togo, (b) the logistics of tyres in Togo and the organization as well as (c) the costs of tyres in Togo (see Table 3).

Table 3.

Grouped interview questions for the tyre dealers/mechanics in Lomé, Togo.

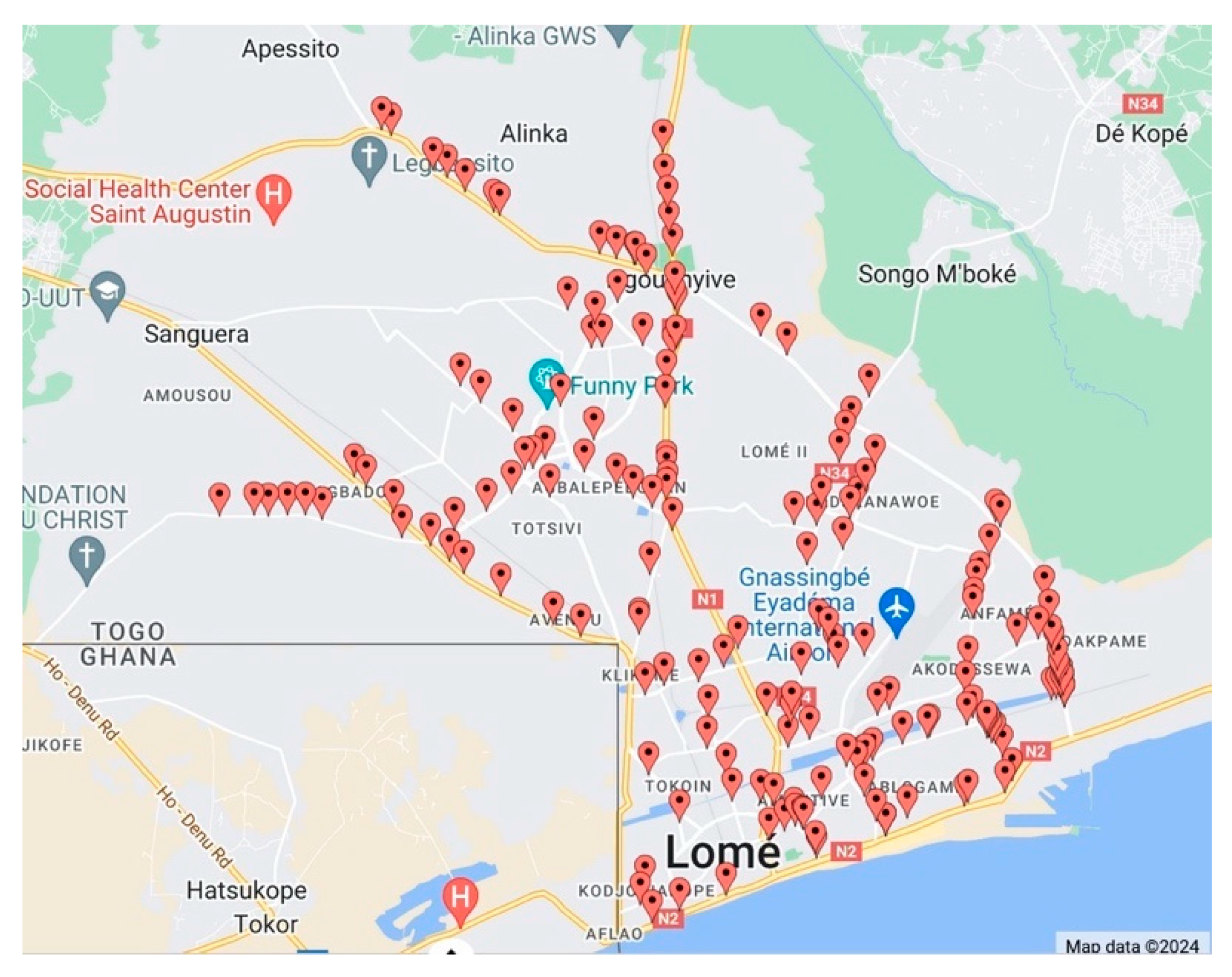

The interviews with the tyre dealers were carried out in February 2024 in Lomé, Togo and surroundings. In order to estimate how many people are doing business with tyres, we tried to gather an overview of all tyre dealers in the greater Lomé region.

For this, Lomé was travelled through by motorcycle on all paved roads, omitting sand/dust roads, and all bigger (40+ tyres) tyre dealerships were mapped. Sand/dust roads were omitted as tyre dealerships are more likely to be located at the bigger, paved roads, as higher traffic can be expected there.

The focus on medium to big tyre dealerships, which most often also offer pressured air, was because smaller tyre dealerships often change their locations and are harder to follow-up with. The tyre dealerships were approached by the interviewer with a questionnaire and asked the questions in either French or the local language, Ewé.

Questions were asked in an open-ended manner in order to not give any suggestions or answer ideas to the interviewees. Answers including multiple answers, for example, when it comes to the question regarding the treatment of the EoL tyres, were also allowed.

3. Results

3.1. End-of-Life Tyre Generation

The estimation of the annual generation of EoL tyres in Togo is based on the method from [11] and has been adapted and modified to fit the context of Togo. Further, the modified model has also been tested for other countries and can be easily applied.

Based on Equation (2), the number of vehicles in Togo for the year 2019 has been estimated (Table 4).

Table 4.

Vehicle type and estimated numbers.

Tyre durability in Togo is strongly dependent on the vehicle type and the use of the vehicle.

Commercially used vehicles, irrespective of their vehicle type, had a very short turnover of tyres. The shortest replacement frequency was given for buses, where the bus drivers reported a change of tyres every 2.4 months. Buses, as well as trucks, according to the interview results, are utilizing new tyres for replacement, but due to their heavy loads and mileage they do not last for a long time (see Table 5).

Table 5.

Average frequencies between tyre changes in Lomé, Togo.

For passenger vehicles used as taxis, the average tyre lifespan was 3 months. Taxi drivers frequently change their EoL tyres with other used tyres according to this study.

Official vehicles and private motorcycles are the vehicles with the least frequent tyre changes (31.5 months and 28.1 months respectively). Both of these vehicle users buy new tyres for their vehicles.

For the estimation of EoL tyre generation, it is important to note that taxis account for 75–80% of motorized transport in Sub-Saharan Africa [14]. For passenger vehicles, this means that approx. 75% of the overall number of vehicles have a tyre replacement frequency of 3.4 months, while all other passenger vehicles have a joint tyre replacement frequency of 19.4 months. The average tyre replacement frequency is, at this rate, at 7.4 months (0.62 years) for passenger vehicles. This is in accordance with data generated by [11].

The estimation of EoL tyres from passenger vehicles and commercial vehicles (trucks and buses) used in Togo has been carried out according to Equation (3). Table 6 shows the estimation of generated EoL tyres in 2019 for Togo.

Table 6.

Data for the estimation of generated EoL tyres in Togo 2019.

A total of 78,040.52 t/a of EoL tyres has been estimated to have been generated in Togo in 2019. Ghana’s gross domestic product (GDP) in 2019 was at $68.34 B [15], with a GDP per capita at $2168, and is thus higher than Togo’s GDP in 2019 at $6.99 B ($848 per capita) [15]. The higher GDP per capita in Ghana might lead to higher private vehicle ownership per capita in Ghana compared to Togo. The correlation between income growth and private vehicle ownership is well documented by many authors (e.g., [16,17,18]), and thus the per-capita private vehicle ownership in Togo might be well overestimated in this article and might actually be up to 2/3 smaller. This, of course, also impacts the amount of annually generated EoL tyres in the country.

To take the size of the country’s economy into account, Equation (3) has been adapted and modified through the addition of GDP value, which is displayed in Equation (4).

By correcting the total of generated EoL tyres numbers by taking the per-capita GDP into account, the total numbers of generated EoL tyres in Togo are estimated to be at a total of 30,525.11 t/a of EoL tyres in 2019 (see Table 6).

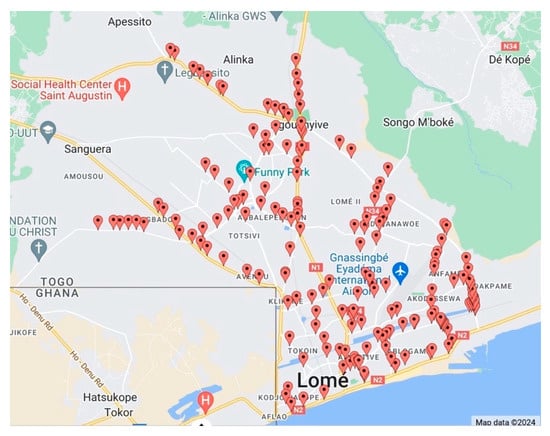

3.2. Tyre Dealerships

Through the empire-inductive method of direct observation, 188 tyre dealerships with a stock of 40+ tyres were mapped in the greater Lomé region (see Figure 1).

Figure 1.

Map of tyre dealerships in greater Lomé region, each red location pin represents a tyre dealership with more than 40 tyres (generated using Google Maps).

Attempts were made to interview every dealership with the hypothetico-deductive method, but some were closed already and many of the tyre dealers were reluctant to give out information due to fear of taxation or any unfortunate repercussions on their businesses, so the interaction was sometimes difficult and challenging. This behaviour has also been observed by [19]. Additionally, at some sites, the mechanics were busy and not available to exchange information, or their boss was away, and they could not bear the responsibility to exchange any information.

When it comes to the demographics of the tyre management chain in Togo, questions were asked on who is involved with the tyre dealerships to be able to understand the potential sellers of EoL tyres as materials for the recycling plant.

Tyre dealership services in Togo include immediate tyre fitting as well as repair and filling-up with compressed air. Tyre dealerships were 100% in male hands in Togo, with ages of the dealers/mechanics ranging between 15 and 54 years. The average age of a tyre dealer/mechanic was 28 years.

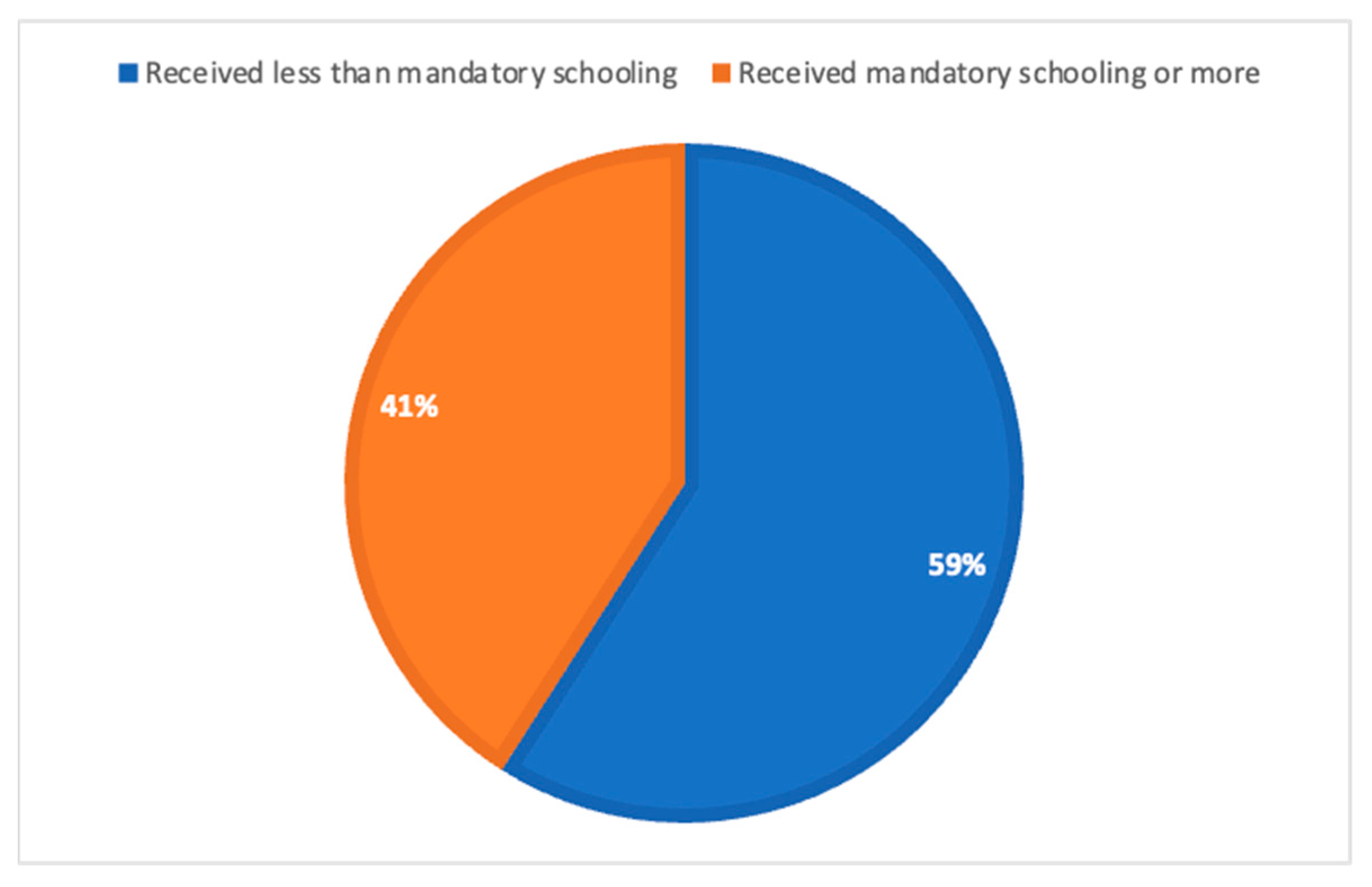

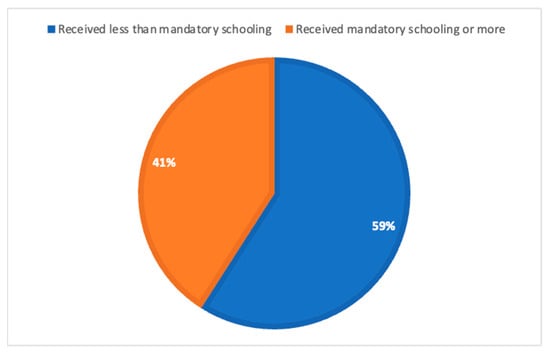

The average tyre dealer does not have a good education level. In total, 105 people answered the question about their education levels, and out of these nearly 60% have received less than the mandatory 6 years of schooling in Togo [20] (see Figure 2).

Figure 2.

Education level of tyre mechanics/dealers in Lomé, Togo in %.

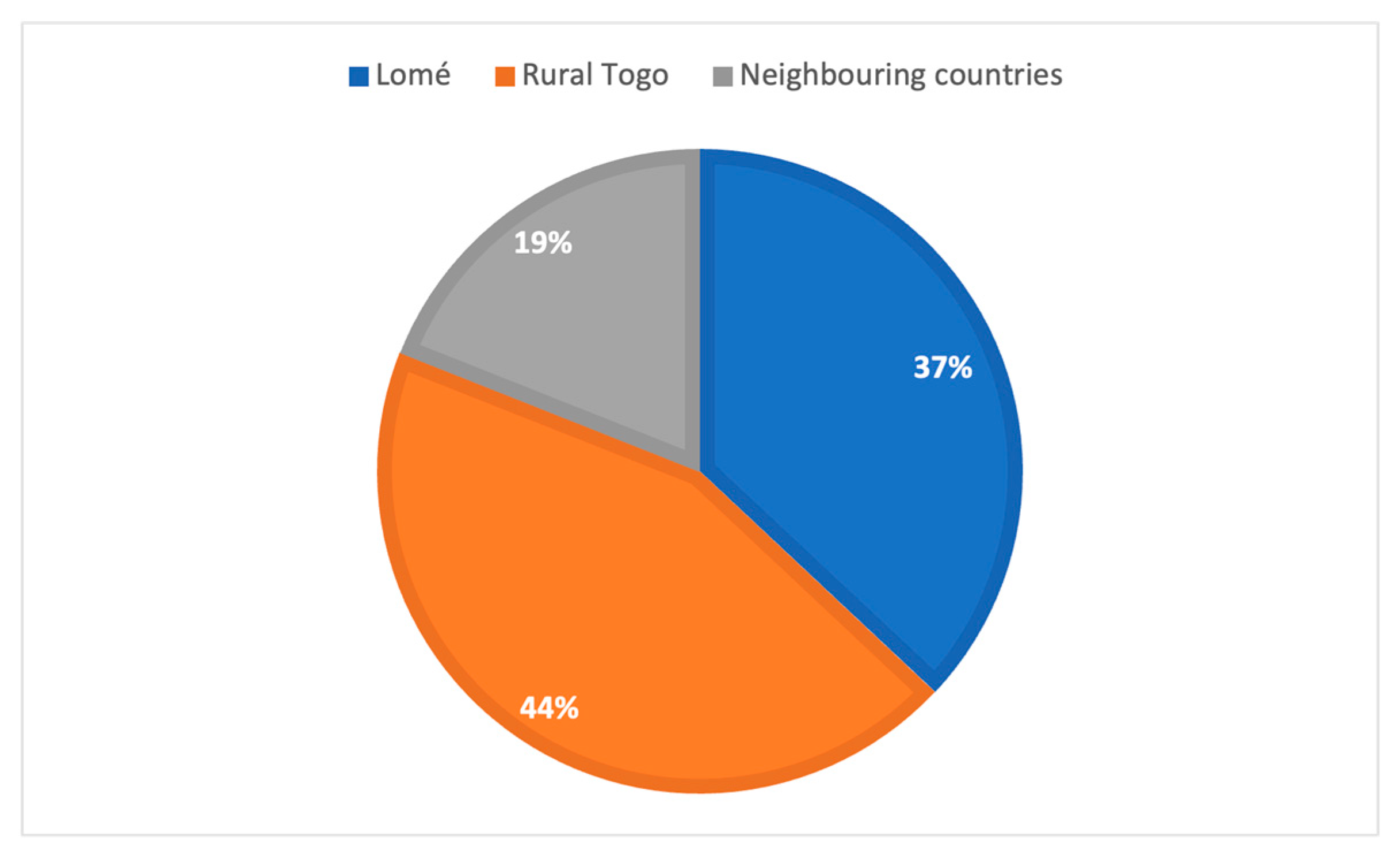

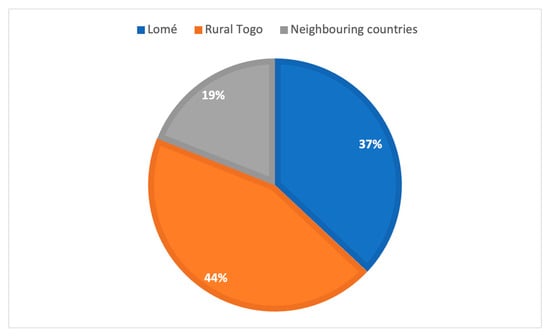

Further, nearly half of all tyre mechanics/dealers in Lomé are from rural Togo and have moved into Lomé (see Figure 3). In total, 20% of all active mechanics are from neighbouring West-African countries such as Benin, Nigeria, and Ghana.

Figure 3.

Place of origin of tyre mechanics/dealers in Lomé, Togo in percentage.

The logistics of the tyre dealers showed that all tyre dealers who gave answers to the question on where they purchased their tyres (either new or used), obtained their tyres mainly from the port. It is possible to buy tyres there in bulk and with smaller margins. Due to the close proximity of the port to Lomé, no middlemen are necessary for the distribution between the tyre dealers/mechanics and the port.

The tyre dealers/mechanics not only sell tyres, but also change and replace or repair the tyres for the customers. In this way, the tyre dealers are the people receiving the EoL tyres directly from their customers.

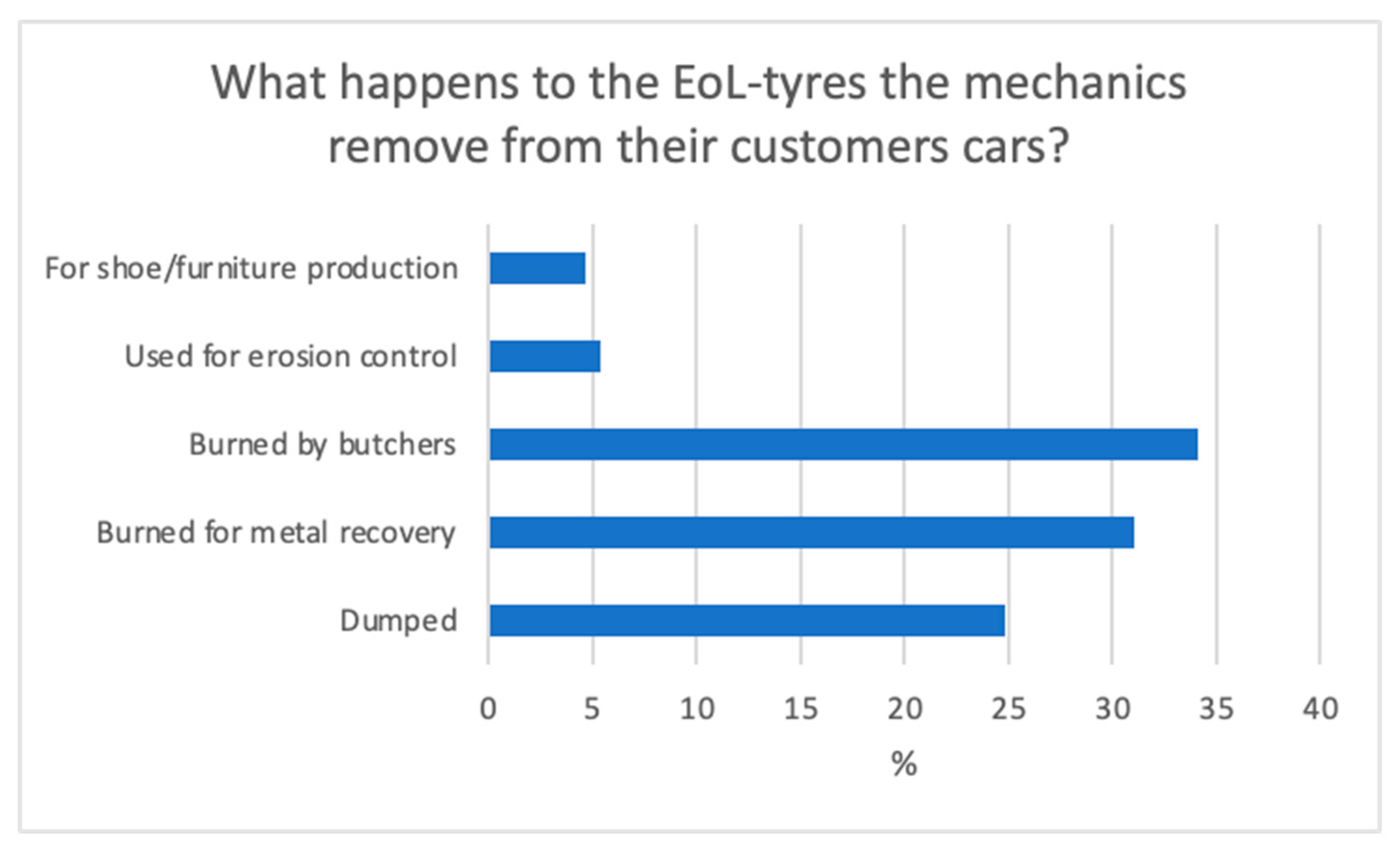

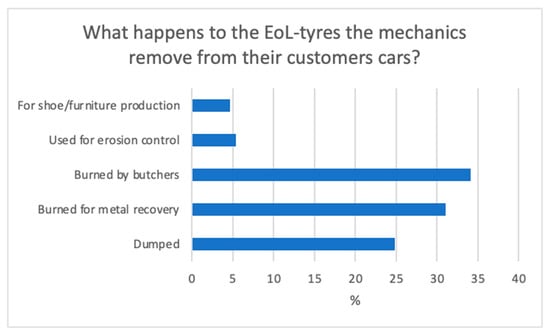

In regard to the treatment of the EoL tyres, answers were divided into five main categories, as highlighted in Figure 4. Most of the answers highlighted the fact that EoL tyres were simply dumped in a convenient location, often directly next to the tyre dealership (see Figure 5), or that they were either burned for the recovery of iron or by butchers.

Figure 4.

Treatment of EoL tyres after final use in Togo.

Figure 5.

Small-scale used tyre dealership/repair shop in Lomé with dumped EoL tyres in the foreground (Picture: M.-M. Narra).

A secondary use of EoL tyres, such as erosion control, to protect trees or to delineate football fields, was less common and EoL tyres being collected by recyclers to up-cycle them into shoes or furniture was the least frequent answer.

The tyre dealers/mechanics are well organized and have founded two professional associations, namely Syvemoto and AVT. In total, 52% of the tyre dealers/mechanics work together in these associations.

3.3. Financial Aspects

The question of the buying price of tyres from the port of Lomé was not answered by any of the tyre dealer/mechanic in this interview round.

The selling price of a tyre also differs extremely, depending on the type of tyre dealership. In real shops with a stock of several hundred tyres, a tyre for a passenger vehicle costs between 15,000 and 25,000 XOF (approx. 23–38 €). In smaller shops the prices for a tyre are between 4000 and 15,000 XOF (approx. 6–23 €), averaging at approx. 9000 XOF (ca. 13.70 €).

EoL tyres hardly yield any revenue. Most tyre dealers gave the tyres away for free or for a nominal price such as 50–300 XOF (0.08–0.46 €).

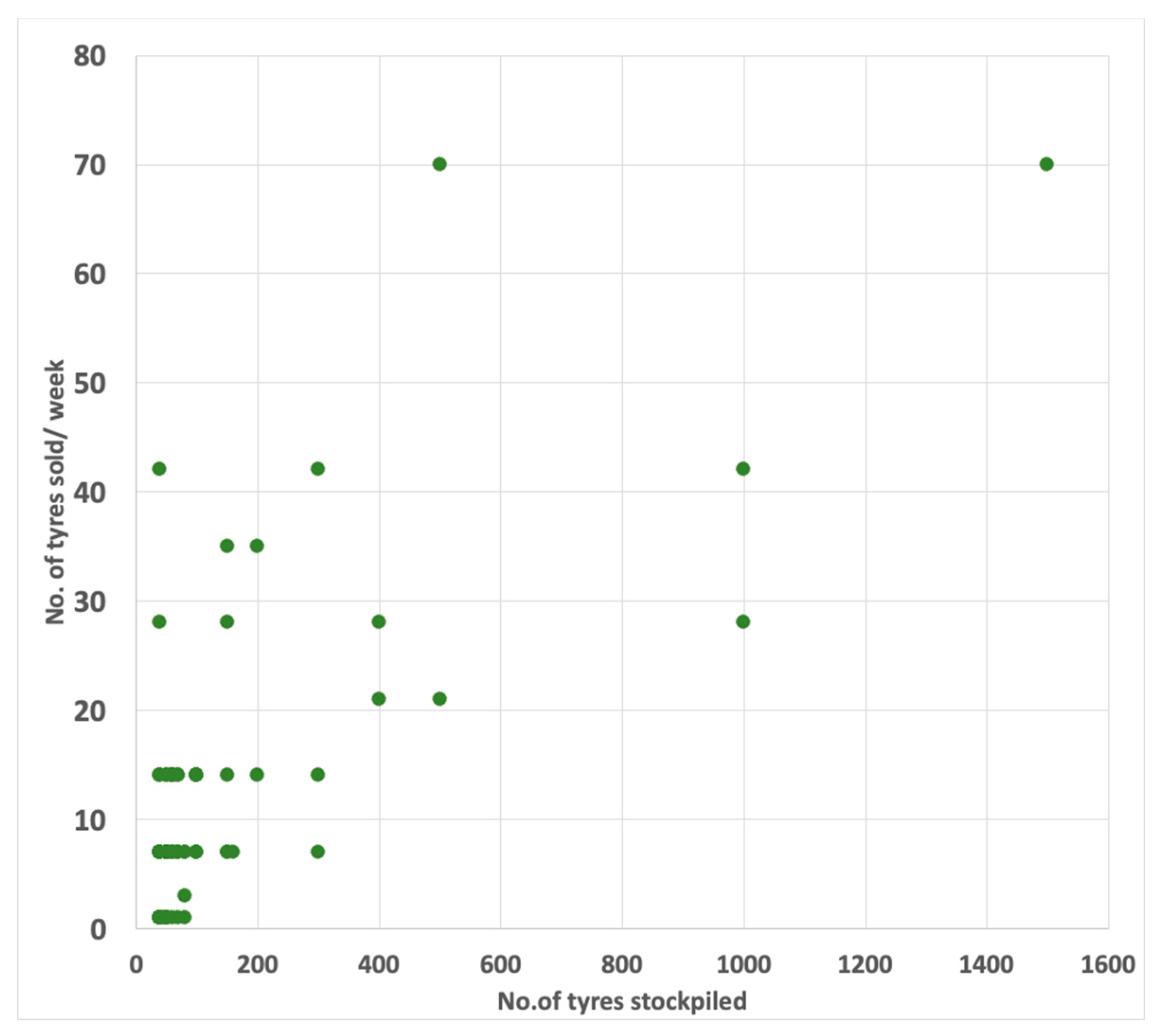

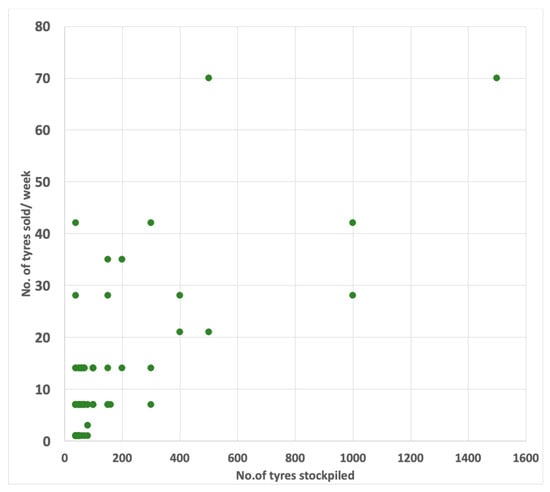

Selling tyres is not a profession which guarantees a continuous stream of income to the dealers. One hundred of the interviewed tyre dealers gave information on how many tyres they sell in a day.

As can be observed in Figure 6, most tyre dealers sell less than 20 tyres in a week. One third of all tyre dealers who offered an answer on this question, answered that they “rarely” sell a tyre. This information has been added as “1 tyre per week“ into Figure 6. The bigger tyre dealers, with an estimated stockpile of 400 tyres and more, show more success and sell more tyres weekly than the smaller tyre dealers.

Figure 6.

Vector of tyres stockpiled (e.g., size of the tyre dealership) versus numbers of tyres sold in a week.

4. Discussion

This research has been carried out in the frame of the “Waste-to-Energy as a sustainable solution for West Africa” project, in which one part is the development of a tyre recycling plant in Togo. An understanding of the tyre management chain plays a pivotal role in the decision-making process for the plant.

4.1. EoL-Quantities

The availability and accessibility of EoL tyres within Togo must be assessed as the collection phase is critical and determines the supply of raw materials to the planed recycling plant. The estimated data of 30,525.11 t/a of EoL tyre generation for Togo for 2019 gives the first indication of the plant size to be built.

The tyre recycling plant is planned to be in Davié, north of Lomé, and is under construction as of June 2024. It is planned with an hourly capacity of 8 t, being able to process all of Togo’s generated EoL tyres, when working in two shifts, in approximately 272 days. The average working days (Monday–Friday) without taking holidays, etc. into account, sum up to approx. 260 days, which means the plant will be able to process nearly all of Togo’s annually generated EoL tyres.

It is assumed that the collection of EoL tyres needs to be widened to the neighbouring countries, as collection rates of 100% will hardly be achieved throughout the country due to its high variations in urban and rural areas.

The estimated numbers also explicitly exclude smaller commercial vehicles, such as tricycles (so called Abobayas) or auto-rikshaws and motorcycles. The weight of these EoL tyres has also not been estimated yet.

The generation of EoL tyres on buses and trucks may be significantly greater, as trucks especially often have many more tyres than the 6 tyres used in this study (see Figure 7). Togo is also a transit country for countries further north, who are doing their business at the port of Lomé. This allows for a lot of truck traffic from especially Burkina Faso and Niger to travel through Togo and generate EoL tyres along the way. The EoL tyre generation amounts are thus only an estimation, and could be estimated most likely with a range between 30,525.11 and 78,040.62 t/a.

Figure 7.

Example of a truck with 20 tyres near the N1 just north of Lomé, Togo (Picture: M.-M. Narra).

For the use of EoL tyres in a tyre recycling facility, not only the annually generated EoL tyres play a role, but also the EoL tyres that have been produced in the past. These tyres were either burned in some capacity or dumped. Data on EoL tyre generation is not only lacking for Togo but for most West African countries.

Most research literature on waste tyres and waste tyre rubbers was written in China, the USA, and India, and hardly any research on EoL tyres and EoL tyre production has been published from West Africa or Africa in general, with some exemptions from notably northern Africa and South Africa [9]. A report from the World Business Council for Sustainable Development [21] reported on EoL tyre recovery rates worldwide, and only included Morocco and South Africa for the African continent. A few publications on selected countries are available, which give detailed estimations on the rate of EoL tyre generation in Ghana [12]. Similarly, [10] roughly estimated the generation of EoL tyres in Botswana, without diving deep into details. The scarcity of data on EoL tyres in African countries, excluding a few North African countries and South Africa, can be attributed to a multitude of factors. These include the lack of comprehensive waste management systems, insufficient regulatory frameworks, economic constraints, and limited research initiatives focused on EoL tyre management.

4.2. Legal Aspects and Research Gaps

The regulatory framework concerning EoL tyres is often either absent or poorly enforced in these regions. In contrast, North African countries and South Africa have implemented more stringent environmental regulations and policies that mandate the tracking and management of EoL tyres. For instance, South Africa’s Waste Tyre Regulations under the National Environmental Management such as Waste Act, enforce detailed reporting requirements on the production and disposal of tyres [22]. The absence of such regulations in other African countries leads to minimal emphasis on the need for data collection and reporting.

Economic constraints further exacerbate the issue. Many African countries face significant financial limitations that hinder their ability to invest in advanced waste management technologies and data collection systems. The high cost associated with establishing and maintaining comprehensive EoL tyre management programmes, including data collection, often competes with other economic priorities [23].

Additionally, there is a noticeable lack of research and academic interest in EoL tyre management in these regions. The focus of environmental research in many African countries tends to be on more immediate environmental concerns, such as water and air pollution, deforestation, and climate change. Consequently, EoL tyre management does not receive the same level of attention or funding, resulting in limited scholarly output and data availability.

In contrast, North African countries and South Africa have more developed economies and stronger institutional frameworks that support environmental research and data collection efforts. These countries also receive more international aid and cooperation for environmental projects, which often include components on waste management and EoL tyres [24]. The lack of data on EoL tyres in many African countries, as well as in Togo, is a result of inadequate waste management infrastructure, weak regulatory frameworks, economic constraints, and limited research focus. Addressing these issues will require concerted efforts to improve waste management systems, enforce regulatory measures, secure financial investments, and stimulate academic and policy-oriented research on EoL tyre management [9].

By investigating the number of EoL tyres in West-Africa, a data and knowledge gap can be closed, and the size of the EoL tyres waste management problem can be estimated.

4.3. Environmental and Health Aspects

The current treatment of EoL tyres in Lomé poses a serious threat to the Togolese populations and environmental health. According to the results of this study, nearly 25% of all EoL tyres are simply dumped by the tyre dealers. Approximately 65% of the generated EoL tyres are being burned for either metal recovery (31%) or by butchers (34%). Dumping of EoL tyres poses a serious threat as EoL tyres pose a significant problem in terms of mosquito breeding due to their ability to accumulate water and create ideal artificial habitats for mosquito larvae [8]. This issue is exacerbated by several factors inherent to the structure and properties of EoL tyres. EoL tyres are not biodegradable and are expected to leach toxic chemicals when not being treated correctly [9]. Landfilling EoL tyres, a step above simply dumping them randomly, is also not a preferred option, as EoL tyres occupy a large space, leaving less area for other wastes, resulting in higher need for landfilling [25].

The design of EoL tyres allows them to retain rainwater, which can remain stagnant for extended periods. This stagnant water provides a perfect breeding ground for mosquitoes, particularly species such as Aedes aegypti and Aedes albopictus, which are vectors for diseases like dengue, Zika virus, and chikungunya [8]. The impermeable nature of the rubber material prevents the water from evaporating quickly, thus extending the duration during which the water remains suitable for mosquito larvae to develop. Additionally, the dark colour of the tyres retains heat, which can accelerate the growth and development of mosquito larvae. The warmth creates a micro-environment that can support higher survival rates of mosquito larvae, leading to increased mosquito populations in areas where scrap tyres are prevalent [26].

According to the CDC-US Center for Disease Control and Prevention [27], Togo is only in sporadic risk of Dengue fever, especially in the southern parts. Further north, bordering Burkina Faso, the risk of Dengue fever is becoming continuous.

According to the interview results, most of the EoL tyres will be burnt in Togo. Burning tyres for metal recovery or other purposes has a direct impact on the ambient air quality. Studies [7] on the total suspended particulates (TSP) generated by burning tyres highlight the toxicity of burning tyres in the open environment, as a TSP of up to 1670 µg/m3 has been observed for car tyres. The maximum safe amount of TSP in the ambient air is 250 µg/m3 [28]. Excess TSP in the air can lead to respiratory and cardiovascular problems in humans [29].

Other pollutants emitted during the burning of EoL tyres are carbon monoxide, sulphur oxides, nitrogen oxides, volatile organic compounds, cyclic aromatic hydrocarbons, dioxins, furans, hydrogen chloride, benzene, polychlorinated biphenyls, arsenic, cadmium, nickel, zinc, mercury, chromium, and vanadium [30].

“The continuous exposure to gaseous and particular emissions from open burning of scrap tyres could pose major threats to human health and environment” [7], which implies the explicit threat of tyres used as fuel by butchers. This phenomenon has only been described by a few articles [19,31,32] and seems to be a local West African specialty. Ref. [32] focuses on the occupational exposure of butchers to emissions from burning tyres, whereas ref. [19] was focusing on the awareness and perceptions of Ghanaian citizens on the health implications of tyre-grilled meats for human consumption. Ref. [31] carried out some sort of meat analysis for heavy metals on the meat grilled on tyre fuels. Results showed that consumers of these kind of meats ingested high levels of Fe (iron) and Cr (Chromium), which are not safe for human consumption.

The high number of answers (34%) in this study’s interviews referring to EoL tyres being used by butchers implies that the practise of using EoL tyres for meat grilling is also common in Togo. This has been supported by informal local information. The results show that EoL tyres need to be given a value in Togo in order to discourage these harmful practises and generate another stream of income from EoL tyres.

As observed during interviews, many tyre dealers are hesitant to cooperate due to fear of taxation or negative impacts on their businesses. This reluctance poses a significant barrier to the collection of end-of-life (EoL) tyres, which are crucial for the recycling plant’s feedstock supply. Without dealer cooperation, the collection of EoL tyres could be inconsistent, limiting the plant’s ability to maintain a steady supply of materials. The tyre management chain in Togo is highly dominated by the informal sector, with no accompanying regulatory framework. This lack of formal infrastructure hinders the development of a structured and sustainable EoL tyre supply chain. Furthermore, financial challenges, both for the tyre dealers and within the broader waste management system in Togo, can also be a significant headwind.

5. Conclusions

This study aimed to highlight the gap and the importance of tyre recycling in Togo while assessing the potential of EoL tyres for the implementation of a tyre recycling plant. An estimation of EoL tyre quantities in Togo was carried out based on a similar estimation model implemented for the neighbouring country Ghana. The study also investigated the EoL tyre management chain in Togo. A total of 30,525.11 t/a of EoL tyres were estimated to have been generated in Togo in 2019. Tyre dealership services in Togo include immediate tyre fitting, repair, and refills using compressed air. The current management of EoL tyres is composed of shoe/furniture production, burning as a fuel by butchers, burning for metal recovery, dumping, and use for erosion control. EoL tyres are mostly given away for free by the tyre dealers, which renders EoL tyres economically accessible, but effectively worthless. A future research focus will be on the effects of using EoL tyres as fuel wood for meat grilling and thus highlighting the needs for giving EoL tyres a monetary value for recycling in Togo to make these highly toxic practises economically unsustainable.

In order to increase the accuracy of the estimated data on EoL tyre generation in Togo and its potential to use the equation for the estimation of EoL tyre generation potential in other West African countries, the estimated data for Togo needs to be proved with “real data” on vehicle ownership in 2019.

It is imperative to develop an extended producer responsibility (EPR) or pay-back system for tyre producers to contribute to the recycling efforts in Togo and other countries that are primarily supplied with used tyres. For this, the company who has produced each collected EoL tyre in Togo will be noted down with their DOT number to be able to understand where and when each tyre has been produced. This information will then be used to take the main tyre producers into account for waste generation.

Currently, there is not enough research on legislation, treatments, and applications of EoL tyres management in Africa. Future studies should focus more on creating tailored models for EoL tyres. This will require the identification of key facilitators and obstacles to tyre material circularity. Legislative and governance through policies present an opportunity to improve waste management activities.

Author Contributions

Conceptualization, M.-M.N.; Methodology, M.-M.N.; Software, D.G.; Validation, M.-M.N., D.G. and S.N.; Formal analysis, M.-M.N.; Investigation, M.-M.N. and D.G.; Resources, M.-M.N.; Data curation, M.-M.N.; Writing—original draft, M.-M.N.; Writing—review & editing, M.-M.N.; Visualization, M.-M.N.; Supervision, K.A. and M.N.; Project administration, M.-M.N.; Funding acquisition, S.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry of Education and Research under the project “Verbundvorhaben Waste2Energy: Hybridenergie aus Abfall als nachhaltige Lösung für Ghana”(grant number 03SF0591A).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Doumbia, M.; Toure, N.E.; Silue, S.; Yoboue, V.; Diedhiou, A.; Hauhouot, C. Emission from the road traffic of West African cities: Assessment of vehicle fleet and fuel consumption. Energies 2018, 11, 2300. [Google Scholar] [CrossRef]

- Xiao, Z.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S. Material recovery and recycling of waste tyres: A Review. Clean. Mater. 2022, 5, 100115. [Google Scholar] [CrossRef]

- Nkosi, N.; Belaid, M.; Nhubu, T.; Muzenda; Mbohwa, C. Waste tyre environmental impacts and life cycle assessment review for reuse, material recovery, and energy recovery strategies. In Frontiers of Energy and Environmental Engineering; Wen, F., Zhu, J., Eds.; Springer Nature: Singapore, 2024; pp. 671–693. [Google Scholar]

- Jimoda, L.A.; Sulaymon, I.D.; Alade, A.O.; Adebayo, G.A. Assessment of environmental impact of open burning of scrap tyres on ambient air quality. Int. J. Environ. Sci. Technol. 2018, 15, 1323–1330. [Google Scholar] [CrossRef]

- Quezada-Yaguachi, W.E.; Alquisira-Dominguez, M.; Vaquez-Anzures, M.J.; Rebollo-Salinas, D.; Correa-Morales, F.; Gonzales-Acosta, C.; Moreno-Garcia, M. Mosquito control and scrap tires: Same old problem, no reliable strategies. Acta Biol. Colomb. 2024, 29, 16–23. [Google Scholar] [CrossRef]

- Magagula, S.I.; Lebelo, K.; Motlouong, T.; Mokhena, T.C.; Mochhane, M.J. Recent advances on waste tires: Bibliometric analysis, processes, and waste management approaches. Environ. Sci. Pollut. Res. 2023, 30, 118213–118245. [Google Scholar] [CrossRef] [PubMed]

- Dabic-Miletic, S.; Simic, V.; Karagoz, S. End-of-life tire management: A critical review. Environ. Sci. Pollut. Res. 2021, 68053–68070. [Google Scholar] [CrossRef] [PubMed]

- Glushankova, I.; Ketov, A.; Krasnovskikh, M.; Rudakova, L.; Vaisman, I. End of life tires as a possible source of toxic substances emission in the process of combustion. Resources 2019, 8, 113. [Google Scholar] [CrossRef]

- Okafor, C.; Ajaero, C.; Madu, C.; Agomuo, K.; Abu, E. Implementation of circular economy principles in management of end-of-life tyres in a developing country (Nigeria). AIMS Environ. Sci. 2020, 7, 406–433. [Google Scholar] [CrossRef]

- Mmereki, D.; Machola, B.; Mokokwe, K. Status of waste tires and management practice in Botswana. J. Air Waste Manag. Assoc. 2019, 69, 1230–1246. [Google Scholar] [CrossRef] [PubMed]

- Arthur, E.; Dorfiah, P.; Hilbert, I.; Kyere, V.N.; Ocran, P.K. Waste Tyre Management; Sustainable Recycling Industries: St. Gallen, Switzerland, 2020. [Google Scholar]

- Numfor, S.A.; Corder, G.; Halog, A.; Matsubae, K. A review of End-of-Life Tire recycling in Australia, Japan, South Africa and Cameroon. Acad. Lett. 2022, 5115. Available online: https://www.academia.edu/76377619/A_Review_of_End_of_Life_Tire_Recycling_in_Australia_Japan_South_Africa_and_Cameroon (accessed on 20 October 2024).

- United Nations. World Populations Prospects 2022. Available online: https://population.un.org/wpp/Download/Standard/MostUsed/ (accessed on 10 June 2024).

- Nagaba, T. The African Commute: City Transport Trends. Engineering for Change. Available online: https://medium.com/impact-engineered/the-african-commute-city-transport-trends-cf369e5106bd (accessed on 13 June 2024).

- Macrotrends. Togo. 2024. Available online: https://www.macrotrends.net/global-metrics/countries/TGO/togo/gdp-gross-domestic-product (accessed on 17 June 2024).

- Dargay, J.; Gately, D.; Sommer, M. Vehicle Ownership and Income Growth, Worldwide: 1960–2030. Energy J. 1997, 28, 143–170. [Google Scholar] [CrossRef]

- Lescaroux, F. Car ownership in relation to income distribution and consumers’ spending decisions. J. Transp. Econ. Policy 2010, 44, 207–230. [Google Scholar]

- Çelik, A.K.; Kabakuş, N.; Tortum, A. Influential Factors of Household Car and Vehicle Ownership in Urban Areas of Turkey. Transp. Res. Rec. 2023, 2677, 218–240. [Google Scholar] [CrossRef]

- Hill, T. Public Health Implications Associated with the Practice of Utilizing Tires to Singe Meat in Three Major CITIES in Ghana: A Concurrent Mixed Methods Study. Electronic Theses Dissertations 2015. Available online: https://digitalcommons.georgiasouthern.edu/etd/1350 (accessed on 24 June 2024).

- Hoogeveen, J.; Rossi, M. Primary Education in Togo. In Transforming Education Outcomes in Africa; Hoogeveen, J., Rossin, M., Eds.; Springer International Publishing: New York, NY, USA, 2019. [Google Scholar]

- WBCSD—World Business Council for Sustainable Development. ELT Management, A Global State of Knowledge on Collection Rates, Recovery Routes, and Management Methods. 2023. Available online: https://tireindustryproject.org/wp-content/uploads/2023/06/WBCSD_ELT_management_State_of_Knowledge_Report_January_2018.pdf (accessed on 17 June 2024).

- South Africa Department of Environmental Affairs. Waste Tyre Regulations; Government Gazette; South Africa Department of Environmental Affairs: Pretoria, South Africa, 2017.

- Ogunseitan, O.A. Green Health: An A-to-Z Guide; SAGE Publications: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- Khatib, I.; Al-Sari, M.I.; Anayah, F. Sustainable Waste Management Challenges in Developing Countries; Springer International Publishing: New York, NY, USA, 2020. [Google Scholar]

- Przydatek, G.; Budzik, G.; Janik, M. Effectiveness of selected issues related to used tyre management in Poland. Environ. Sci. Pollut. Res. 2022, 29, 31467–31475. [Google Scholar] [CrossRef] [PubMed]

- Rabi’u, H.M.; Ahmed, A. A preliminary study of the abundance and species compostion of mosquitoes breeding in discarded automobile tyres in Minna, Niger State, Nigeria. Int. J. Mosq. Research 2019, 6, 119–123. [Google Scholar]

- CDC—US Center for Disease Control and Prevention. Areas with Risk of Dengue. 2024. Available online: https://www.cdc.gov/dengue/areas-with-risk/?CDC_AAref_Val=https://www.cdc.gov/dengue/areaswithrisk/around-the-world.html (accessed on 14 June 2024).

- FMNeV—Federal Ministry of Environment Nigeria. Federal Republic of Nigeria Official Gazette. National Environmental (Air Quality Control) Regulations. 2021. Available online: https://archive.gazettes.africa/archive/ng/2021/ng-government-gazette-supplement-dated-2021-02-17-no-161.pdf (accessed on 26 June 2024).

- EPA—US Environmental Protection Agency. Air Quality Index: A guide to Air Quality and your health. 2014. Available online: https://www.airnow.gov/sites/default/files/2018-04/aqi_brochure_02_14_0.pdf (accessed on 24 June 2024).

- Kerekes, Z.; Lublóy, E.; Kopecskó, K. Behaviour of tyres in fire. J. Therm. Anal. Calorimetry 2018, 133, 279–287. [Google Scholar] [CrossRef]

- Amofo-Otu, R.; Agyenim, J.B.; Adzraku, S. Meat contamination through singeing with scrap tyres in Akropong-Akuapem abbatoir, Ghana. Appl. Res. J. 2014, 1, 12–19. [Google Scholar]

- Okonkwo, F.; Njan, A.A.; Ejike, C.; Nwodo, U.U.; Onwurah, I. Health implications of occupational exposure of butchers to emissions from burning tyres. Ann. Glob. Health 2018, 84, 387. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).