A Bottom-Up Methodology for Identifying Key Performance Indicators for Sustainability Monitoring of Unit Manufacturing Processes

Abstract

1. Introduction

1.1. Performance Indicators for Sustainable Manufacturing

1.2. Challenges in Defining Bottom-Up Indicators in Sustainable Manufacturing

1.3. Motivations for Defining Process Parameter-Based Performance Indicators

1.4. Indicator Selection Criteria

2. Materials and Methods

- The first theme that emerged from the analysis relates to the relevance of a process parameter-based indicator to a chosen environmental impact category/indicator. In other words, any change in the environmental impact indicator should be captured through a change in the chosen process parameter-based indicator. The relationship between the process parameter-based indicator and the environmental impact indicator should also be rooted in a proper scientific basis. These aspects are interpreted as the sensitivity of the process parameter-based indicator to the environmental impact indicator. The formulation of the sensitivity criterion is given in Table 1.

- The second theme relates to the measurability/quantification of the process parameter-based indicator for a unit manufacturing process. Herein, it is important to note that the measurability relates to the practical aspects of continually monitoring the process parameter for a given production setup. This includes aspects such as the feasibility, cost, and management of measurement processes, as well as the impact the measurements can have on the production process or the measurement of other indicators.

- The third theme relates to the usefulness/usability of the developed indicators to key stakeholders (i.e., technicians and engineers) from the perspective of product/process improvement. It implies that the chosen process parameters can be controlled at the product/process planning stage in order to affect the sustainability performance of the unit manufacturing process. This concept is interpreted as actionability.

- The fourth theme corresponds to the reliability of the process parameter-based indicator and its usefulness as an indicator over time. This includes any uncertainties in the measurement process, deviations in the indicator over time, and the effect of uncontrollable process parameters (e.g., ambient temperature) on the indicator.

- The fifth theme is related to the timeliness of the process parameter-based indicator and reflects the usefulness of the process parameter-based indicator as a leading indicator in the context of sustainable manufacturing. In other words, the indicator should be easily accessible by stakeholders during key decision-making activities (e.g., process planning), apart from being actionable.

- The sixth theme corresponds to the level of understanding of the process parameter-based indicator by the relevant stakeholders. Ideally, the indicator is already defined and measured in ongoing production activities, with a good understanding of its impact on other aspects of production. Finally, it is important to note the need for existing human skills in the organization to measure, monitor, and control the indicator. These aspects are collectively defined as human-centricity. The formulation of the human-centricity criterion is given in Table 1.

| Criterion Name | Interpretation | Associated Prior Criteria |

|---|---|---|

| Sensitive | Describes the sensitivity (magnitude of change) of the process parameters with respect to the chosen environmental impact indicator (for a specific impact category). A process parameter with a significant and predictable sensitivity to the selected environmental impact indicator is preferred. | Specific [9,36], relevant [9,36], strong scientific basis [37,38,39] |

| Measurable | Describes the ease of measurement of a process parameter on a specific manufacturing process. It is important to note that measurability is defined on a practical basis, specific to a production setup. For example, it is important to consider aspects such as the cost of measurement and the ability to measure the process parameter without significantly impacting established production processes and requirements. | Measurable [9,36], accessible [9,39], benefits outweigh costs [37], resource demand and operational simplicity [39] |

| Actionable | Describes the ability of the process parameter to be controlled through changes to the product and/or process. Thus, affecting the process parameter enables improving the environmental sustainability performance of a manufacturing process | Useful [9], achievable [36], manageable [38,39], |

| Reliable | Describes the reliability of measuring the process parameter over time. For example, if a process parameter is uncontrolled or if there is significant uncertainty in its measurement, monitoring this process parameter over time does not give a reliable indicator of process improvement. | Reliable/useful [9,39], long-term oriented [9], robustness and uncertainty [39] |

| Timely | Data and information collection, calculation, and evaluation for an indicator must be completed in a timely manner for informative decision-making | Time-bound [36], timely [9], anticipatory [39] |

| Human-centric | Should be defined based on aspects that process engineers and operators already consider in production planning. This should give them a good understanding of the process, how to control and monitor it, and the skills to change it if needed. | Understandable/comprehensible [9,39], user-driven [39], necessary skills [39] |

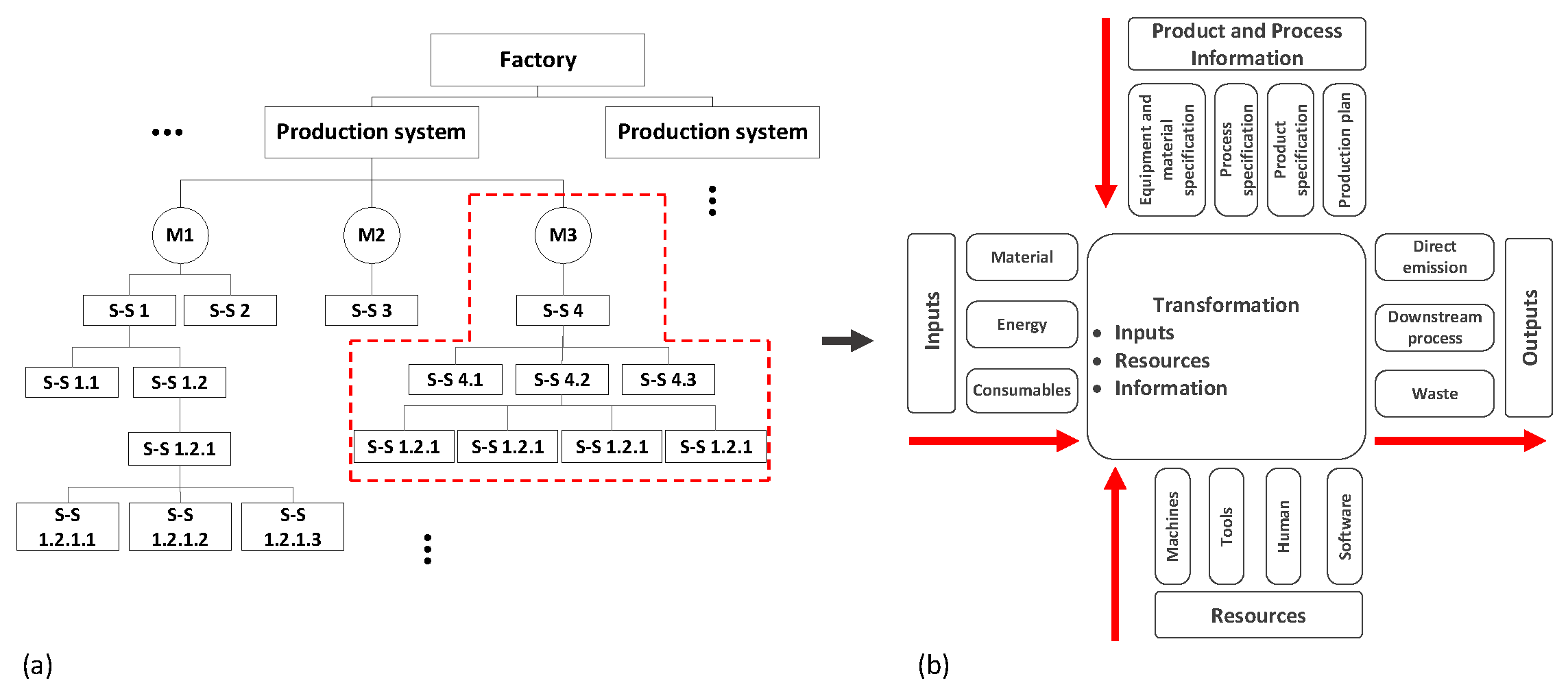

2.1. Goal and Scope Definition

2.2. Generate a Detailed Model of the Manufacturing System

2.3. Relate Inventory Flows and Process Parameters

2.4. Compute Selection Criterion for Process Parameters

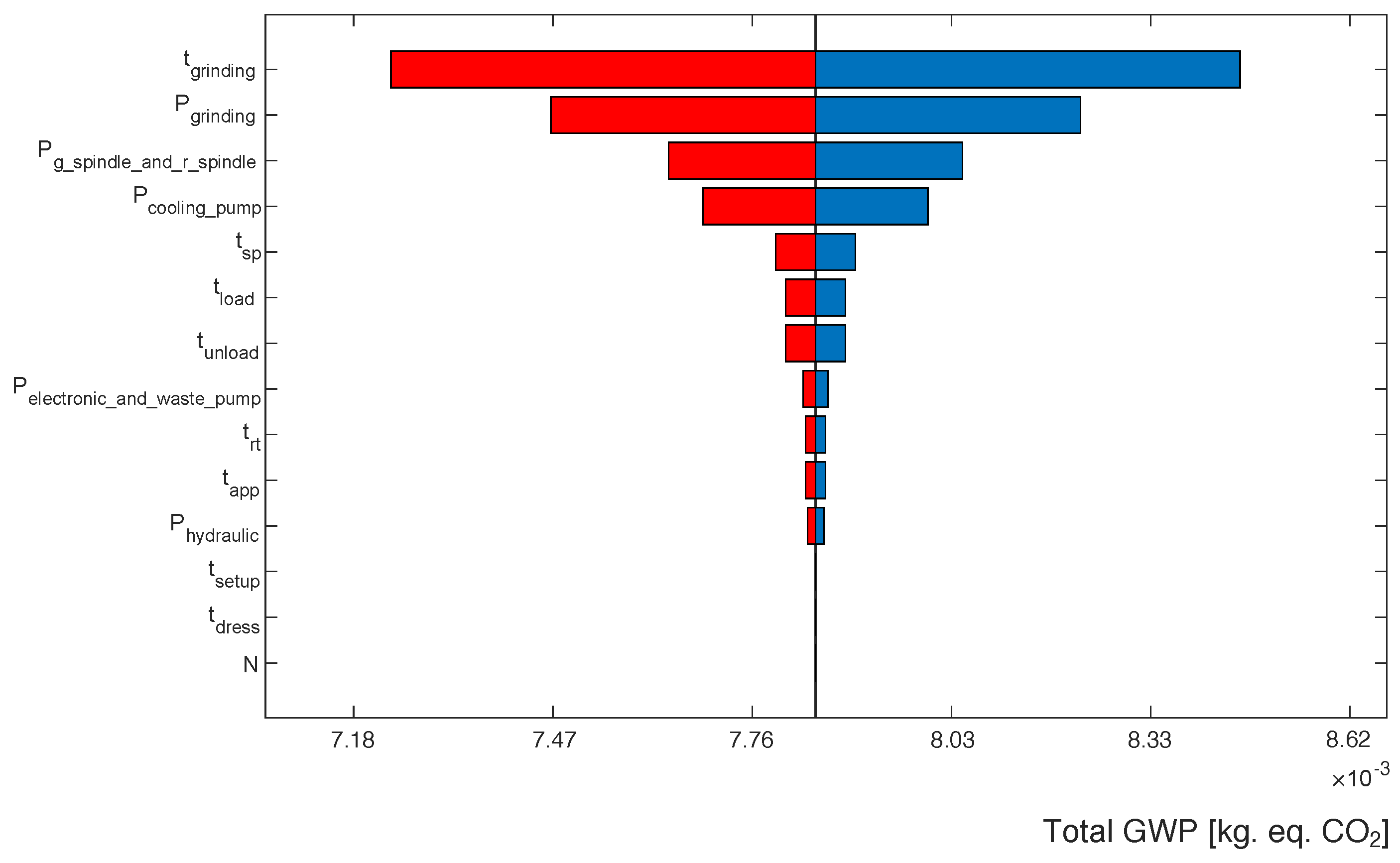

- Sensitivity assessment is based on the quantitative estimation of the sensitivity for the ith process parameter to a chosen environmental indicator . In other words, the partial rate of change in with respect to is measured in the neighborhood of the nominal value of (). The sensitivity is estimated at the nominal value for the process parameter, which is determined from empirical data for the process setup. Finally, a normalized sensitivity score () for the i process/inventory parameter from the set of all () process parameters is calculated as shown in Equation (1).

- Measurability assessment is performed through a questionnaire (see Supplementary Material S1) that evaluates five criteria describing the difficulty of measurement, adapted from the DVS framework described in the author’s previous work [43]. Supplementary Material S1 explains how to score the process parameters according to all five measurability criteria and provides a definition for each criterion. A normalized measurability score () for the ith process/inventory parameter from the set of all () process/inventory parameters is computed using the formula in Equation (2).Here, ,,… represent the difficulty-related criteria scores for the ith process parameter, established from the questionnaire.

- Actionability assessment defines whether a given process parameter is relevant for improving the environmental sustainability performance through the environmental indicator. Two aspects are evaluated on a 3-point Likert scale (High = +1, Medium = 0, Low = −1) (i) controllability of the process parameter during the production process (), (ii) degree to which the process parameter can be controlled (affected) in the product/process planning stage (), and (iii) feasibility of implementing the action the relevant controls (). An overall score (A) is computed by averaging the ratings for the above questions, as shown in Equation (3).Here, ,, represent the actionability-related criteria scores for the ith process parameter, established from the questionnaire.

- Reliability assessment is performed through a questionnaire (see Supplementary Material S1) that evaluates four criteria encoding factors that can affect the accuracy as well as the precision of process data measurements and is adapted from the DVS framework described in the author’s previous work [43]. Supplementary Material S1 explains how to score the process parameters according to all four reliability criteria and provides a definition for each criterion. The overall reliability score () for the ith process/inventory parameter from the set of all () process/inventory parameters is computed using the formula in Equation (4).Here, ,,… represent the variability-related criteria scores for the ith process parameter, established from the questionnaire.

- Timeliness assessment evaluates the ability of data collected on the process parameter to be available to decision-makers during product and process planning tasks, which could influence the environmental sustainability performance of the process. Timeliness is assessed on a 3-point Likert scale (High = +1, Medium = 0, Low = −1) and is based on the following aspects, (i) data collection and analysis for the process parameter can be conducted at a rate that is meaningful for product/process planning (), (ii) data can be archived in systems that are accessible during product/process planning (). An overall timeliness rating (T) is computed by averaging these two ratings, as shown in Equation (5).Here, and represent the timeliness-related criteria scores for the ith process parameter.

- Human-centricity is also assessed on a 3-point Likert scale (High = +1, Medium = 0, Low = −1) by the process engineers and operators participating in the analysis. The aspects addressed under human-centricity, include (i) do all relevant stakeholders have a common understanding of the process parameter (), (ii) do relevant stakeholders understand how the change in the process parameter influences the process performance () (iii) do relevant stakeholders have an understanding of how changes to the process parameters affect the sustainability aspects of the process performance (), and (iv) do relevant stakeholders have the necessary skills to control the process parameter ()? An overall score (H) is computed, as shown in Equation (6).Here, ,… represent the human-centricity related criteria scores for the ith process parameter.

2.5. Selection of Performance Indicator(s)

3. Case Study

3.1. System Description

3.2. Application of Indicator Selection Methodology

3.2.1. Manufacturing System Selection and Modeling

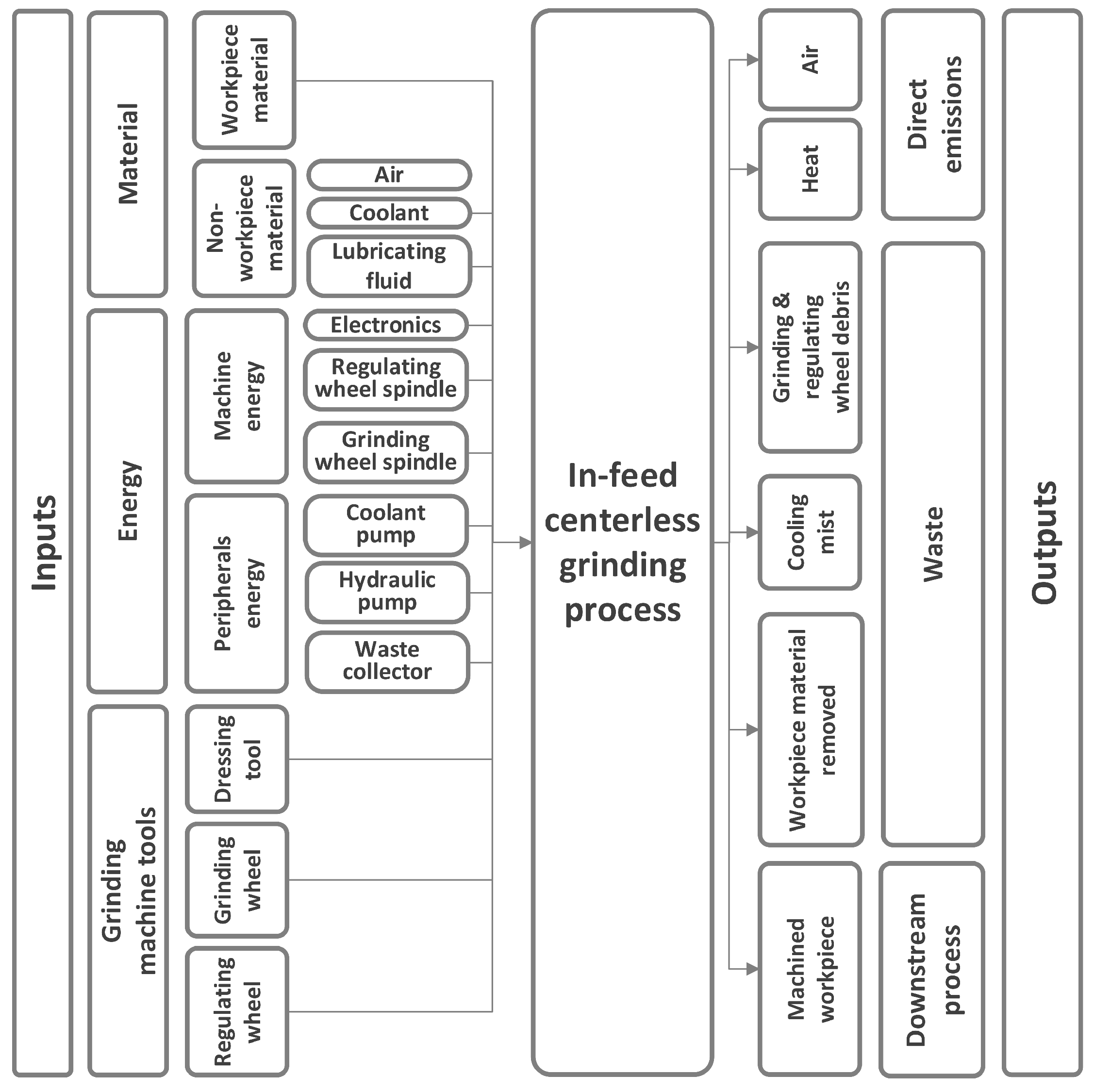

- Input materials: A workpiece (WP) that is to be ground to the required specifications while fulfilling predefined dimensional and quality requirements as well as material characteristics. Other material inputs, e.g., grinding, regulating, and dressing wheels, that have to be replaced periodically, e.g., lubricating fluid, cooling fluid, and compressed air.

- Input energy: The centerless grinding machine, peripherals, and auxiliary systems are driven by electrical energy. Significant sub-systems with regards to energy consumption are broken down in terms of the (i) main machine: electronics, regulations wheel, and grinding wheel spindles, and (ii) peripheral systems: coolant pump, hydraulic pump, and waste collector.

- Outputs emissions and wastes: These include (i) direct emissions: air, heat (ii) produced wastes: cooling mist, grinding wheel and the regulating wheel debris, and removed workpiece material.

- Output products: The ground workpiece is transferred to other downstream manufacturing processes.

3.2.2. Relate Inventory Flows and Process Parameters

3.2.3. Performance Indicator(s) Definition

4. Results and Discussion

| Criteria | |||||||

|---|---|---|---|---|---|---|---|

| Parameter | M | ||||||

| Measurability | 3 | 1 | 2 | 2 | 1 | 0.99616 | |

| 3 | 1 | 2 | 2 | 1 | 0.99616 | ||

| 3 | 1 | 2 | 1.50 | 1 | 0.99712 | ||

| 3 | 1 | 2 | 1.50 | 1 | 0.99712 | ||

| 3 | 1 | 2 | 1.50 | 1 | 0.99712 | ||

| 3 | 1 | 1.50 | 1.50 | 1 | 0.99784 | ||

| 3 | 1 | 2 | 1 | 1 | 0.99808 | ||

| 3 | 1 | 2 | 1 | 1 | 0.99808 | ||

| 3 | 1 | 2 | 1 | 1 | 0.99808 | ||

| 3 | 1 | 2 | 1 | 1 | 0.99808 | ||

| 3 | 1 | 2 | 1 | 1 | 0.99808 | ||

| 2.50 | 1 | 2 | 1 | 1 | 0.9984 | ||

| 2.50 | 1 | 2 | 1 | 1 | 0.9984 | ||

| 1 | 1 | 1 | 1 | 1 | 0.99968 | ||

| N | 1 | 1 | 1 | 1 | 1 | 0.99984 | |

| Parameter | R | ||||||

| Reliability | 3.50 | 2 | 1 | 1 | 0.9888 | ||

| 4 | 1.50 | 1 | 1 | 0.9904 | |||

| 3 | 1 | 1 | 1 | 0.9904 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| 4 | 1 | 1 | 1 | 0.9936 | |||

| N | 1 | 1 | 1 | 1 | 0.9984 | ||

| Criteria | ||||||

|---|---|---|---|---|---|---|

| Parameter | A | |||||

| Actionability | −1 | 0 | 1 | 0 | ||

| 0 | 0 | 0 | 0 | |||

| 0 | 0 | 0 | 0 | |||

| 0 | 0 | 0 | 0 | |||

| 0 | 0 | 1 | 0.3333 | |||

| 0 | 0 | 1 | 0.3333 | |||

| 0 | 1 | 1 | 0.6666 | |||

| 0 | 1 | 1 | 0.6666 | |||

| 1 | 1 | 1 | 1 | |||

| 1 | 1 | 1 | 1 | |||

| N | 1 | 1 | 1 | 1 | ||

| 1 | 1 | 1 | 1 | |||

| 1 | 1 | 1 | 1 | |||

| 1 | 1 | 1 | 1 | |||

| 1 | 1 | 1 | 1 | |||

| Parameter | T | |||||

| Timeliness | −1 | 0 | −0.5 | |||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| −1 | 0 | −0.5 | ||||

| 0 | 0 | 0 | ||||

| N | 1 | 1 | 1 | |||

| Parameter | H | |||||

| Human-centricity | 1 | 0 | −1 | 1 | 0.25 | |

| 1 | 0 | −1 | 1 | 0.25 | ||

| 1 | 0 | −1 | 1 | 0.25 | ||

| 1 | 1 | −1 | 0 | 0.25 | ||

| 1 | 1 | −1 | 0 | 0.25 | ||

| 1 | 1 | −1 | 0 | 0.25 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| 1 | 1 | −1 | 1 | 0.5 | ||

| N | 1 | 1 | 0 | 1 | 0.75 | |

| Parameter | Performance Indicator | S | M | A | R | T | H |

|---|---|---|---|---|---|---|---|

| % reduction in grinding time over the baseline value of 8.0 s | 7.8% | 0.99616 | 0.6666 | 0.9936 | −0.5 | 0.5 | |

| % reduction in grinding power consumption over the baseline value of 8.3 kW | 4.9% | 0.99616 | 0.0 | 0.9888 | −0.5 | 0.25 | |

| % reduction in cooling pump power consumption over the baseline value of 2.01 kW | 2.7% | 0.99808 | 0.3333 | 0.9936 | −0.5 | 0.25 | |

| % reduction in sparkout time over the baseline value of 2.0 s | 0.73% | 0.99968 | 1.0 | 0.9936 | 0.0 | 0.5 |

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Corresponding machine tool for identified production system | |

| Corresponding sub-systems for identified production system | |

| Normalized sensitivity score of the ith process parameter | |

| Sensitivity score of the ith process parameter | |

| Total number of process/inventory parameters | |

| Normalized measurability score of the ith process parameter | |

| Measurability criterion evaluating digitalization of the ith process parameter | |

| Measurability criterion evaluating data granularity of the ith process parameter | |

| Measurability criterion evaluating complexity of the process architecture of the ith process parameter | |

| Measurability criterion evaluating the impact of data collection on the process of the ith process parameter | |

| Measurability criterion evaluating operator/technician knowledge of the ith process parameter | |

| Overall actionability score of the ith process parameter | |

| Actionability criterion evaluating controllability of the ith process parameter during the production process | |

| Actionability criterion evaluating the degree to which ith process parameter can be controlled (affected) in the product/process planning stage | |

| Actionability criterion evaluating the possibility of implementing the action to the relevant controls of the ith process parameter | |

| Overall reliability score of the ith process parameter | |

| Reliability criterion evaluating the standard operating procedure of the ith process parameter | |

| Reliability criterion evaluating the variability of process setup for ith process parameter | |

| Reliability criterion evaluating the variability of the environmental conditions of the ith process parameter | |

| Reliability criterion evaluating the accuracy of the ith process parameter measurement | |

| Overall timeliness score of the ith process parameter | |

| Timeliness criterion evaluating if data collection and analysis for the ith process parameter can be conducted at a rate that is meaningful for product/process planning | |

| Timeliness criterion evaluating if data can be archived in systems that are accessible during product/process planning for ith process parameter | |

| Overall human-centricity score of the ith process parameter | |

| Human-centricity criterion evaluating if all relevant stakeholders have a common understanding of the ith process parameter | |

| Human-centricity criterion evaluating if all relevant stakeholders understand how the change in ith process parameter influences the process performance | |

| Human-centricity criterion evaluating if all relevant stakeholders have an understanding of how changes to ith process parameters affect the sustainability aspects of the process performance | |

| Human-centricity criterion evaluating if all relevant stakeholders have the necessary skills to control ith process parameter? | |

| Grinding power consumption | |

| Power consumption of the hydraulic system | |

| Power consumption of the cooling pump | |

| Power consumption of the grinding wheel spindle motor | |

| Power consumption of the regulating wheel spindle motor | |

| Power consumption of the electronic system and waste pump | |

| Loading time | |

| Unloading time | |

| Approaching time of the regulating wheel | |

| Retracting time of the regulating wheel | |

| Spark-out time | |

| Grinding time | |

| Setup time | |

| Dressing time | |

| N | Size of the batch |

References

- International Energy Agency. CO2 Emissions in 2022; International Energy Agency: Paris, France, 2023. Available online: https://www.iea.org/reports/co2-emissions-in-2022 (accessed on 17 September 2023).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 17 September 2023).

- Kim, D.B.; Shin, S.J.; Shao, G.; Brodsky, A. A decision-guidance framework for sustainability performance analysis of manufacturing processes. Int. J. Adv. Manuf. Technol. 2015, 78, 1455–1471. [Google Scholar] [CrossRef]

- Igos, E.; Benetto, E.; Meyer, R.; Baustert, P.; Othoniel, B. How to treat uncertainties in life cycle assessment studies? Int. J. Life Cycle Assess. 2019, 24, 794–807. [Google Scholar] [CrossRef]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A survey of unresolved problems in life cycle assessment: Part 2: Impact assessment and interpretation. Int. J. Life Cycle Assess. 2008, 13, 374–388. [Google Scholar] [CrossRef]

- Feng, S.C.; Joung, C.B.; Li, G. Development overview of sustainable manufacturing metrics. In Proceedings of the 17th CIRP International Conference on Life Cycle Engineering, Hefei, China, 19–21 May 2010; Citeseer: University Park, PA, USA, 2010; Volume 6, p. l2. [Google Scholar]

- Sarkar, P.; Joung, C.B.; Carrell, J.; Feng, S.C. Sustainable manufacturing indicator repository. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011; Volume 54792, pp. 943–950. [Google Scholar]

- Amrina, E.; Yusof, S.M. Key performance indicators for sustainable manufacturing evaluation in automotive companies. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011; pp. 1093–1097. [Google Scholar]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Calero, C.; Bertoa, M.F.; Moraga, M.Á. A systematic literature review for software sustainability measures. In Proceedings of the 2013 2nd International Workshop on Green and Sustainable Software (GREENS), San Francisco, CA, USA, 20 May 2013; pp. 46–53. [Google Scholar]

- Issa, I.I.; Pigosso, D.C.; McAloone, T.C.; Rozenfeld, H. Leading product-related environmental performance indicators: A selection guide and database. J. Clean. Prod. 2015, 108, 321–330. [Google Scholar] [CrossRef]

- Kibira, D.; Morris, K.C.; Kumaraguru, S. Methods and tools for performance assurance of smart manufacturing systems. J. Res. Natl. Inst. Stand. Technol. 2016, 121, 282. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.; Carrell, J.D.; Zhang, H.C. An investigation of indicators for measuring sustainable manufacturing. In Proceedings of the 2010 IEEE International Symposium on Sustainable Systems and Technology, Arlington, VA, USA, 17–19 May 2010; pp. 1–5. [Google Scholar]

- Bogdanski, G.; Spiering, T.; Li, W.; Herrmann, C.; Kara, S. Energy monitoring in manufacturing companies–generating energy awareness through feedback. In Proceedings of the Leveraging Technology for a Sustainable World: Proceedings of the 19th CIRP Conference on Life Cycle Engineering, University of California at Berkeley, Berkeley, CA, USA, 23–25 May 2012; Springer: Berlin/Heidelberg, Germany, 2012; pp. 539–544. [Google Scholar]

- Dorn, C.; Behrend, R.; Giannopoulos, D.; Napolano, L.; James, V.; Herrmann, A.; Uhlig, V.; Krause, H.; Founti, M.; Trimis, D. A systematic LCA-enhanced KPI evaluation towards sustainable manufacturing in industrial decision-making processes. A case study in glass and ceramic frits production. Procedia CIRP 2016, 48, 158–163. [Google Scholar] [CrossRef]

- Shahbazi, S.; Salloum, M.; Kurdve, M.; Wiktorsson, M. Material efficiency measurement: Empirical investigation of manufacturing industry. Procedia Manuf. 2017, 8, 112–120. [Google Scholar] [CrossRef]

- Mani, M.; Madan, J.; Lee, J.H.; Lyons, K.W.; Gupta, S.K. Review on Sustainability Characterization for Manufacturing Processes; Report No. NISTIR; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013; Volume 7913. [Google Scholar]

- Barbosa, E.L.; Santos Delfino, A.C.d.; Brandão, L.C. The use of alternative coolant techniques to reduce the environmental impact in the use of water in through-feed centreless grinding. Int. J. Adv. Manuf. Technol. 2017, 91, 3417–3425. [Google Scholar] [CrossRef]

- Kibira, D.; Brundage, M.P.; Feng, S.; Morris, K. Procedure for selecting key performance indicators for sustainable manufacturing. J. Manuf. Sci. Eng. 2018, 140, 011005. [Google Scholar] [CrossRef]

- Smullin, M.M.; Haapala, K.R.; Mani, M.; Morris, K.C. Using industry focus groups and literature review to identify challenges in sustainable assessment theory and practice. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 50145, p. V004T05A048. [Google Scholar]

- Garetti, M.; Taisch, M. Sustainable manufacturing: Trends and research challenges. Prod. Plan. Control 2012, 23, 83–104. [Google Scholar]

- Rakar, A.; Zorzut, S.; Jovan, V. Assessment of Production Performance by Means of KPI; In Proceedings of the Control 2004, Bath, UK, 6–9 September 2004.

- Despeisse, M.; Mbaye, F.; Ball, P.D.; Levers, A. The emergence of sustainable manufacturing practices. Prod. Plan. Control 2012, 23, 354–376. [Google Scholar] [CrossRef]

- Raman, A.S.; Haapala, K.R.; Raoufi, K.; Linke, B.S.; Bernstein, W.Z.; Morris, K. Defining near-term to long-term research opportunities to advance metrics, models, and methods for smart and sustainable manufacturing. Smart Sustain. Manuf. Syst. 2020, 4, 1–37. [Google Scholar] [CrossRef]

- Ramanujan, D.; Bernstein, W.; Diaz-Elsayed, N.; Haapala, K.R. The Role of Industry 4.0 Technologies in Manufacturing Sustainability Assessment. J. Manuf. Sci. Eng. 2022, 145, 010801. [Google Scholar] [CrossRef]

- Glišić, M.; Veluri, B.; Ramanujan, D. A reusable unit process life cycle inventory model for infeed centerless grinding. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Virtual Conference, 17–19 August 2021; American Society of Mechanical Engineers: New York, NY, USA, 2021; Volume 85413, p. V005T05A025. [Google Scholar]

- Shin, S.J.; Suh, S.H.; Stroud, I.; Yoon, S. Process-oriented life cycle assessment framework for environmentally conscious manufacturing. J. Intell. Manuf. 2017, 28, 1481–1499. [Google Scholar] [CrossRef]

- Tan, H.X.; Yeo, Z.; Ng, R.; Tjandra, T.B.; Song, B. A sustainability indicator framework for Singapore small and medium-sized manufacturing enterprises. Procedia CIRP 2015, 29, 132–137. [Google Scholar] [CrossRef]

- Contini, G.; Peruzzini, M.; Bulgarelli, S.; Bosi, G. Developing key performance indicators for monitoring sustainability in the ceramic industry: The role of digitalization and industry 4.0 technologies. J. Clean. Prod. 2023, 414, 137664. [Google Scholar] [CrossRef]

- Kellens, K.; Dewulf, W.; Overcash, M.; Hauschild, M.Z.; Duflou, J.R. Methodology for systematic analysis and improvement of manufacturing unit process life-cycle inventory (UPLCI)—CO 2 PE! initiative (cooperative effort on process emissions in manufacturing). Part 1: Methodology description. Int. J. Life Cycle Assess. 2012, 17, 69–78. [Google Scholar] [CrossRef]

- Ramanujan, D.; Bernstein, W.Z.; Totorikaguena, M.A.; Ilvig, C.F.; Ørskov, K.B. Generating contextual design for environment principles in sustainable manufacturing using visual analytics. J. Manuf. Sci. Eng. 2019, 141, 021016. [Google Scholar] [CrossRef]

- Linke, B.; Das, J.; Lam, M.; Ly, C. Sustainability indicators for finishing operations based on process performance and part quality. Procedia CIRP 2014, 14, 564–569. [Google Scholar] [CrossRef]

- Filleti, R.A.P.; Silva, D.A.L.; da Silva, E.J.; Ometto, A.R. Productive and environmental performance indicators analysis by a combined LCA hybrid model and real-time manufacturing process monitoring: A grinding unit process application. J. Clean. Prod. 2017, 161, 510–523. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating energy efficiency performance in production management–gap analysis between industrial needs and scientific literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- Hauschild, M.Z.; Huijbregts, M.A.J. Introducing Life Cycle Impact Assessment. In Life Cycle Impact Assessment; Hauschild, M.Z., Huijbregts, M.A., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 1–16. [Google Scholar]

- Schomaker, M. Development of Environmental Indicators in UNEP; FAO Land and Water Bulletin (FAO): Rome, Italy, 1997. [Google Scholar]

- National Research Council. Ecological Indicators for the Nation; National Academies Press: Washington, DC, USA, 2000. [Google Scholar]

- Hák, T.; Janoušková, S.; Moldan, B. Sustainable Development Goals: A need for relevant indicators. Ecol. Indic. 2016, 60, 565–573. [Google Scholar] [CrossRef]

- Niemeijer, D.; De Groot, R.S. A conceptual framework for selecting environmental indicator sets. Ecol. Indic. 2008, 8, 14–25. [Google Scholar] [CrossRef]

- Kristensen, P. EEA Core Set of Indicators; Technical report; European Environment Agency: Copenhagen, Denmark, 2003. [Google Scholar]

- ASTM E3012-16; Standard Guide for Characterizing Environmental Aspects of Manufacturing Processes. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/E3012-16.htm (accessed on 17 September 2023).

- Overcash, M.; Griffing, E.; Vozzola, E.; Twomey, J.; Flanagan, W.; Isaacs, J. Advancements in Unit Process Life Cycle Inventories (UPLCI) Tools. Procedia CIRP 2018, 69, 447–450. [Google Scholar] [CrossRef]

- Glišić, M.; Sarfraz, S.; Veluri, B.; Ramanujan, D. A Systematic Framework for Quantifying Production System-Specific Challenges in Life Cycle Inventory Data Collection. Procedia CIRP 2022, 105, 210–218. [Google Scholar] [CrossRef]

| Criterion | Evaluation Methodology |

|---|---|

| Sensitivity | Quantitative estimate for sensitivity estimated through experimental studies or through analytical process modeling. |

| Measurability | A normalized measurability score M is calculated, which encodes difficulties in the measuring process and relevant inventory parameters. |

| Actionability | High/medium/low evaluation encoding the controllability of process parameters. |

| Reliability | A normalized reliability score R is calculated, which encodes the accuracy and precision of process measurements. |

| Timeliness | High/medium/low evaluation encoding the the ease-of-availability of process parameters for product and process planning. |

| Human-centricity | High/medium/low evaluation based on the understandability of process parameters and their effects by the people responsible for the manufacturing process. |

| Sequence of Operation | Activation | Equipment |

|---|---|---|

| Seq 1 | Manually | Electronics |

| Air supply | ||

| Motor for workpiece waste (wear of material) | ||

| Seq 2 | Manually | Hydraulic pump - grinding wheel |

| Seq 3 | Manually | Grinding wheel and Regulating wheel |

| Seq 4 | Manually—After GW and RW are started | Coolant |

| Seq 5 | Automatically—When the tank is full | Pump for coolant |

| Seq 6 | Automatically—When the safety doors are closed | Handling system |

| Seq 7 | Manually—After everything is prepared | Master—Notify |

| Seq 8 | Automatically | A1 axis (gripper for workpiece movement within process) |

| Seq 9 | Automatically | Grinding |

| Seq 10 | 250 cycles | Lubrication of regulating wheel |

| Seq 11 | 5 cycles | Dressing of grinding wheel |

| Seq 12 | Approaching and retracting during grinding process | Z1 motor of workrest blade |

| Seq 13 | Approaching and retracting during grinding process | Z2 axis regulating wheel motor |

| Seq 14 | Grinding wheel moving along X axis | X axis grinding wheel spindle movement motor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glišić, M.; Veluri, B.; Ramanujan, D. A Bottom-Up Methodology for Identifying Key Performance Indicators for Sustainability Monitoring of Unit Manufacturing Processes. Sustainability 2024, 16, 806. https://doi.org/10.3390/su16020806

Glišić M, Veluri B, Ramanujan D. A Bottom-Up Methodology for Identifying Key Performance Indicators for Sustainability Monitoring of Unit Manufacturing Processes. Sustainability. 2024; 16(2):806. https://doi.org/10.3390/su16020806

Chicago/Turabian StyleGlišić, Marija, Badrinath Veluri, and Devarajan Ramanujan. 2024. "A Bottom-Up Methodology for Identifying Key Performance Indicators for Sustainability Monitoring of Unit Manufacturing Processes" Sustainability 16, no. 2: 806. https://doi.org/10.3390/su16020806

APA StyleGlišić, M., Veluri, B., & Ramanujan, D. (2024). A Bottom-Up Methodology for Identifying Key Performance Indicators for Sustainability Monitoring of Unit Manufacturing Processes. Sustainability, 16(2), 806. https://doi.org/10.3390/su16020806