Charting the Path of Technology-Integrated Competence in Industrial Design during the Era of Industry 4.0

Abstract

1. Introduction

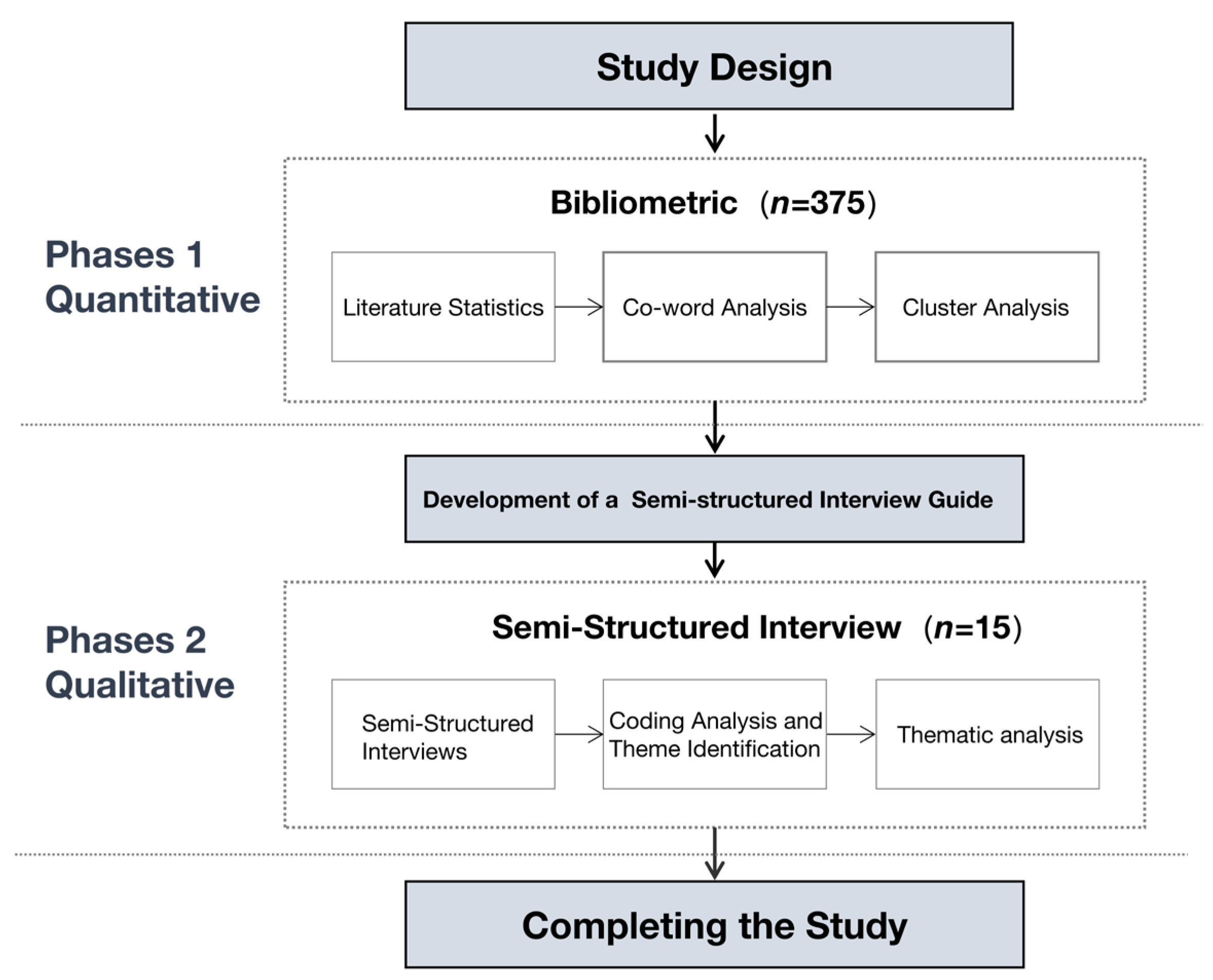

2. Methodology

2.1. Bibliometric

- (a)

- Database selection: The selection of the Web of Science (WoS) database stemmed from its publication by Thomson Reuters and its encompassing of SCIE, SSCI, and A&HCI databases, aggregating an extensive collection of approximately 2.6 million publications. Recognized as one of the most comprehensive scientific databases and citation indexing services, the WoS database stands out as a reliable resource [26]. Specifically, the ‘Science Citation Index Expanded’ (SCI-EXPANDED) within the WoS database indexes high-impact academic journals in the natural sciences, offering authoritative and referential statistical results [27]. These considerations influenced the formulation of our semi-structured interview guide and the conduct of subsequent interviews. While studies suggest comparable coverage between Scopus and WoS databases in the field of Natural Sciences and Engineering (NSE), any discrepancies in bibliometric outcomes can be deemed negligible [28]. Given these factors, our study opted for the WoS database.

- (b)

- Timeframe selection: Commencing the search from 2013 aligns with the formal introduction of the ‘Industry 4.0’ concept at the Hannover Messe in Germany, marking a pivotal milestone [27].

- (c)

- Search terms selection: The search terms were meticulously chosen to align with the research topic, incorporating terms such as ‘Industry 4.0’, ‘technology’, ‘industrial design’, and ‘capabilities’. These terms were interconnected using the ‘OR’ connector to pinpoint relevant documents.

- (d)

- Document type selection: Retaining articles featuring the search terms in their title, abstract, and keywords, alongside forthcoming articles and reviews, was integral to prevent overlooking crucial literature [29].

2.2. Semi-Structured Interview

2.2.1. Participants

2.2.2. Data Collection and Analysis Procedure

- (a)

- Crafting a semi-structured interview guide was the initial step, drawing insights from bibliometric analysis. This guide underwent iterative refinement through three rounds of pilot interviews. Comprising three sections, the guide began with demographic information encompassing participants’ age, education, workplace, position, work experience, and research areas. The second section featured four semi-open-ended questions, aligned with the identified technology clusters from the bibliometric analysis. Throughout the interviews, additional probing questions were introduced to deepen responses, such as ‘Could you describe the role of these technologies in the design process?’ and ‘What specific requirements do these technologies impose on design practitioners?’ The third section presented an open-ended question, encouraging participants to freely discuss key terms like ‘new technologies’, ‘industrial design’, and ‘capabilities’. This iterative refinement process was conducted across three rounds of pilot interviews.

- (b)

- Formal interviews were conducted with 14 participants between 20 July 2023 and 20 August 2023, a sample size typical in phenomenological research, emphasizing depth and quality over quantity [32]. Given the diverse geographical locations of the participants, a combination of online (using Zoom and Tencent Meeting) and offline methods was employed. The interview durations ranged from 40 to 95 min, with an average duration of approximately 65 min. All interviews were recorded and transcribed verbatim.

- (c)

- Employing Braun and Clarke’s six-stage analysis method [33], the researcher utilized qualitative analysis software, NVivo 12, for thematic analysis of the interview data. To ensure analysis validity, two researchers independently conducted thematic analysis and cross-verified outcomes. Ultimately, the thematic analysis revealed the trajectories of technology-integrated industrial design capabilities within the context of Industry 4.0, addressing our second research question.

3. Results

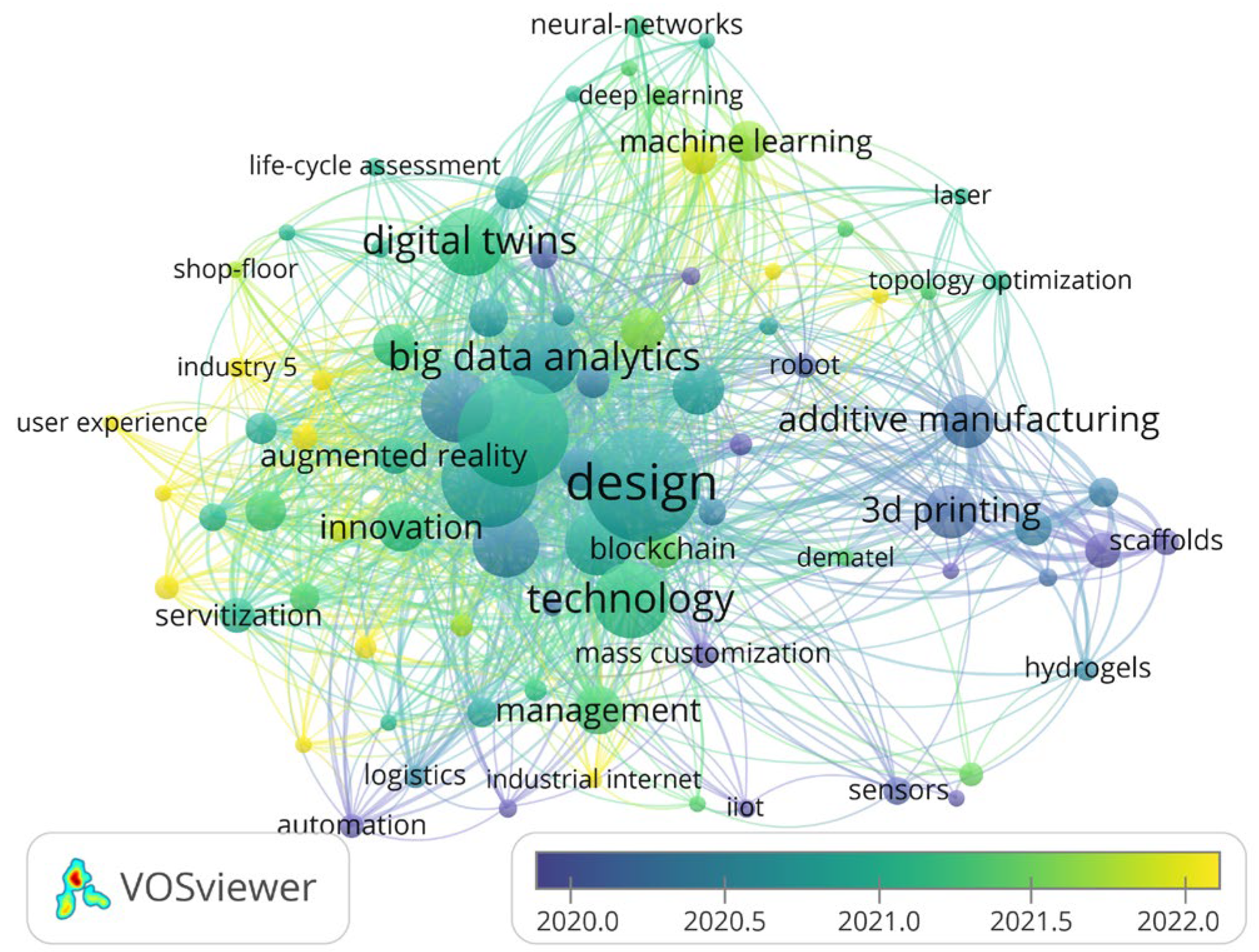

3.1. Co-Word Analysis

3.2. Cluster Analysis

3.2.1. Cluster 1: Digital Technology and Service Experience

3.2.2. Cluster 2: Smart Manufacturing and Personalization

3.2.3. Cluster 3: Additive Manufacturing and Material Processes

3.2.4. Cluster 4: Data Analysis and Artificial Intelligence

3.3. Thematic Analysis

3.3.1. Consistency Test

3.3.2. Thematic Analysis Results

Theme 1: Industrial Design Skills

- (1)

- New Technologies as Design Innovation Methods

- (2)

- New Technologies as Design Aids

Theme 2: Industrial Design Knowledge

- (1)

- Knowledge of Intelligent Manufacturing Systems

- (2)

- Interdisciplinary Knowledge

Theme 3: Ethical Considerations in Industrial Design

Theme 4: Industrial Design Industry Insights

Theme 5: Limitations Affecting Competence

4. Discussion

4.1. Research Highlights

- (1)

- Ethical Thinking in Mitigating Risks

- (2)

- Influence of Emerging Technologies on Design Tools.

- (3)

- Practical Application of New Technologies in Industrial Design

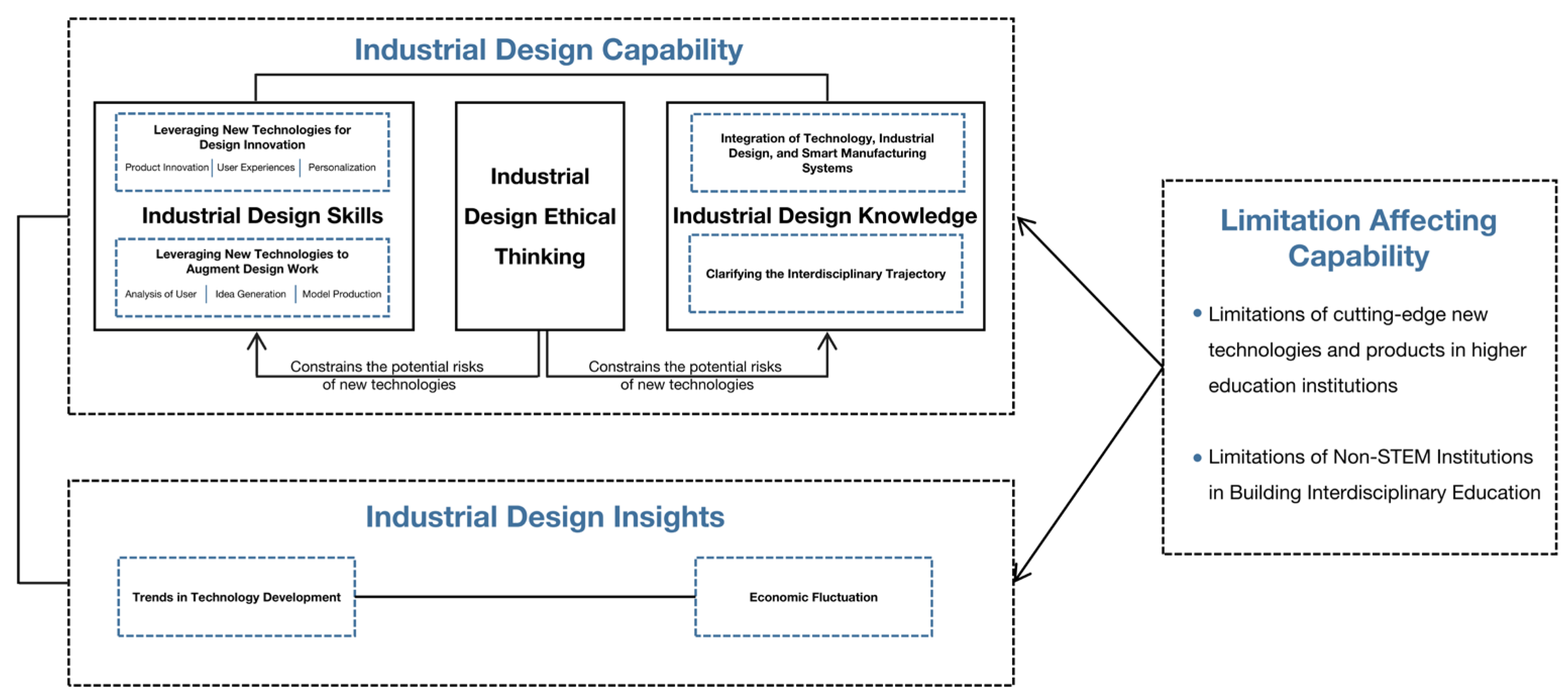

4.2. Competency Framework

4.2.1. Industrial Design Capability

- (1)

- Industrial Design Skills and Industrial Design Knowledge

- (2)

- Industrial Design Ethical Thinking

4.2.2. Industrial Design Insights

4.2.3. Limitations Affecting Competency

- (1)

- The inability to access cutting-edge new technologies and products.

- (2)

- Non-STEM institutions grapple with difficulties in establishing interdisciplinary education programs.

4.3. Limitation and Future Research

5. Conclusions

- (1)

- In the context of Industry 4.0, there are 80 new technologies closely linked to industrial design, including big data analysis, digital twins, CPS, IoT, and more. These technologies exert their influence on industrial design in four key domains: Digital Technology and Service Experience, Intelligent Manufacturing and Personalization, Additive Manufacturing and Material Processes, and Data Analysis and Artificial Intelligence.

- (2)

- The technological integration capabilities required in the Industry 4.0 era encompass four primary dimensions: Industrial Design Skills (comprising New Technologies as Design Innovation Methods and New Technologies as Design Aids), Industrial Design Knowledge (encompassing knowledge of intelligent manufacturing systems and interdisciplinary knowledge), Ethical Considerations in Industrial Design, and Industrial Design Industry Insight. The study also identifies a limitation that impacts industrial design capabilities. Furthermore, it proposes a framework for design capabilities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, C.M.; Ahn, J.; Noh, D.W.; Moon, J.S.; Kim, S.B. A Study on Core Competencies for Elementary and Secondary Education in the Era of the Fourth Industrial Revolution. J. Digit. Content Soc. 2022, 23, 2159–2170. [Google Scholar] [CrossRef]

- Prause, M.; Weigand, J. Industry 4.0 and object-oriented development: Incremental and architectural change. J. Technol. Manag. Innov. 2016, 11, 104–110. [Google Scholar] [CrossRef]

- SuDe Carolis, A.; Macchi, M.; Negri, E.; Terzi, S. A maturity model for assessing the digital readiness of manufacturing companies. In Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing, Proceedings of the IFIP WG 5.7 International Conference, APMS 2017, Hamburg, Germany, 3–7 September 2017; Proceedings, Part I; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 13–20. [Google Scholar]

- Javaid, M.; Haleem, A.; Singh, R.P.; Khan, S.; Suman, R. Sustainability 4.0 and its applications in the field of manufacturing. Internet Things Cyber-Phys. Syst. 2022, 2, 82–90. [Google Scholar] [CrossRef]

- Simonetto, M.; Peron, M.; Fragapane, G.; Sgarbossa, F. Digital assembly assistance system in Industry 4.0 era: A case study with projected augmented reality. In Advanced Manufacturing and Automation X 10; Springer: Singapore, 2021; pp. 644–651. [Google Scholar]

- Kim, K.; Lee, K.P. Two types of design approaches regarding industrial design and engineering design in product design. In Proceedings of the DS 60: Proceedings of DESIGN 2010, the 11th International Design Conference, Dubrovnik, Croatia, 17–20 May 2010. [Google Scholar]

- Macnab, M. Design by Nature: Using Universal Forms and Principles in Design; New Riders: Indianapolis, IN, USA, 2011. [Google Scholar]

- Liu, L.; Jiang, Z. Influence of technological innovation capabilities on product competitiveness. Ind. Manag. Data Syst. 2016, 116, 883–902. [Google Scholar] [CrossRef]

- Marković, B.; Đurić, A. Education 4.0 for Industry 4.0. In International Conference on Machine and Industrial Design in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2021; pp. 723–733. [Google Scholar]

- Kipper, L.M.; Iepsen, S.; Dal Forno, A.J.; Frozza, R.; Furstenau, L.; Agnes, J.; Cossul, D. Scientific mapping to identify competencies required by industry 4.0. Technol. Soc. 2021, 64, 101454. [Google Scholar] [CrossRef]

- Pahl, G.; Grote, K.H. Interdisciplinary design Knowledge and ability needed. Interdiscip. Sci. Rev. 1996, 21, 292–303. [Google Scholar] [CrossRef]

- Terkowsky, C.; Frye, S.; May, D. Online engineering education for manufacturing technology: Is a remote experiment a suitable tool to teach competences for “Working 4.0”? Eur. J. Educ. 2019, 54, 577–590. [Google Scholar] [CrossRef]

- Jeong, W.J.; Kim, S.I. A study on the role of designer in the 4th industrial revolution-focusing on design process and AI based design software. J. Digit. Converg. 2018, 16, 279–285. [Google Scholar]

- Cantamessa, M.; Montagna, F.; Altavilla, S.; Casagrande-Seretti, A. Data-driven design: The new challenges of digitalization on product design and development. Des. Sci. 2020, 6, e27. [Google Scholar] [CrossRef]

- Loy, J. The future for design education: Preparing the design workforce for additive manufacturing. Int. J. Rapid Manuf. 2015, 5, 199–212. [Google Scholar] [CrossRef]

- Hasling, K.M. Bridging understandings of materials in sustainable product design education. In Proceedings of the 10th International Conference on Design and Emotion–Duration, Amsterdam, The Netherlands, 21–23 September 2016. [Google Scholar]

- Su, H.N.; Moaniba, I.M. Investigating the dynamics of interdisciplinary evolution in technology developments. Technol. Forecast. Soc. Chang. 2017, 122, 12–23. [Google Scholar] [CrossRef]

- Frodeman, R.; Klein, J.T.; Mitcham, C.; Tuana, N. Interdisciplinary studies in science, technology, and society: “New Directions: Science, Humanities, Policy”. Technol. Soc. 2007, 29, 145–152. [Google Scholar] [CrossRef]

- Self, J.A.; Evans, M.; Jun, T.; Southee, D. Interdisciplinary: Challenges and opportunities for design education. Int. J. Technol. Des. Educ. 2019, 29, 843–876. [Google Scholar] [CrossRef]

- Umachandran, K.; Corte, V.D.; Amuthalakshmi, P.; Ferdinand-James, D.; Said, M.M.T.; Sawicka, B.; del Gaudio, G.; Roosefert, M.T.; Refugio, C.N.; Jurcic, I.; et al. Designing Learning-Skills towards Industry 4.0. World J. Educ. Technol. Curr. Issues 2019, 11, 12–23. [Google Scholar]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 12th International conference on fuzzy systems and knowledge discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; IEEE: New York City, NY, USA, 2015; pp. 2147–2152. [Google Scholar]

- Yang, G.; Zhang, J.; Zhang, J. Can central and local forces promote green innovation of heavily polluting enterprises? evidence from China. Front. Energy Res. 2023, 11, 1194543. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, G.; Ding, X.; Qin, J. Can green bonds empower green technology innovation of enterprises? Environ. Sci. Pollut. Res. 2022, 29, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Webster, J.; Watson, R.T. Analyzing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, xiii–xxiii. [Google Scholar]

- Biolchini, J.; Mian, P.G.; Natali, A.C.C.; Travassos, G.H. Systematic review in software engineering. System engineering and computer science department COPPE/UFRJ. Tech. Rep. ES 2005, 679, 45. [Google Scholar]

- Thomson Reuters. Available online: https://www.thomsonreuters.com/en/press-releases/2016/july/thomson-reuters-announces-definitive-agreement-to-sell-its-intellectual-property-science-business.html (accessed on 6 July 2023).

- Wildgaard, L. A comparison of 17 author-level bibliometric indicators for researchers in Astronomy, Environmental Science, Philosophy and Public Health in Web of Science and Google Scholar. Scientometrics 2015, 104, 873–906. [Google Scholar] [CrossRef]

- Qian, H.; Zhang, F.; Qiu, B. Deciphering the Evolution, Frontier, and Knowledge Clustering in Sustainable City Planning: A 60-Year Interdisciplinary Review. Sustainability 2023, 15, 16854. [Google Scholar] [CrossRef]

- Frewer, L.J.; van der Lans, I.A.; Fischer, A.R.; Reinders, M.J.; Menozzi, D.; Zhang, X.; den Berg, I.; Zimmermann, K.L. Public perceptions of agri-food applications of genetic modification–a systematic review and meta-analysis. Trends Food Sci. Technol. 2013, 30, 142–152. [Google Scholar] [CrossRef]

- Haustein, S.; Larivière, V. The use of bibliometrics for assessing research: Possibilities, limitations and adverse effects. In Incentives and Performance: Governance of Research Organizations; Springer International Publishing: Cham, Switzerland, 2014; pp. 121–139. [Google Scholar]

- Verdonck, M.; Wiles, L.; Broome, K. Lived experience of using assistive technology for sandy beach based leisure for Australian people with mobility limitations. Disabil. Rehabil. Assist. Technol. 2023, 32, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Starks, H.; Brown Trinidad, S. Choose your method: A comparison of phenomenology, discourse analysis, and grounded theory. Qual. Health Res. 2007, 17, 1372–1380. [Google Scholar] [CrossRef] [PubMed]

- Braun, V.; Clarke, V. Using thematic analysis in psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef]

- He, Q. Knowledge Discovery through Co-Word Analysis; University of Illinois: Champaign, IL, USA, 1999. [Google Scholar]

- Liu, J.; Wu, N.; Qiao, Y.; Li, Z. A scientometric review of research on traffic forecasting in transportation. IET Intell. Transp. Syst. 2021, 15, 1–16. [Google Scholar] [CrossRef]

- McAllister, J.T.; Lennertz, L.; Atencio Mojica, Z. Mapping a discipline: A guide to using VOSviewer for bibliometric and visual analysis. Sci. Technol. Libr. 2022, 41, 319–348. [Google Scholar] [CrossRef]

- Saniuk, S.; Grabowska, S.; Gajdzik, B. Social expectations and market changes in the context of developing the Industry 4.0 concept. Sustainability 2020, 12, 1362. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive manufacturing technologies: An overview about 3D printing methods and future prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef]

- Roscoe, S.; Cousins, P.D.; Handfield, R. Transitioning additive manufacturing from rapid prototyping to high-volume production: A case study of complex final products. J. Prod. Innov. Manag. 2023, 40, 554–576. [Google Scholar] [CrossRef]

- Blackman, N.J.M.; Koval, J.J. Interval estimation for Cohen’s kappa as a measure of agreement. Stat. Med. 2000, 19, 723–741. [Google Scholar] [CrossRef]

- Berry, K.J.; Mielke Jr, P.W. A generalization of Cohen’s kappa agreement measure to interval measurement and multiple raters. Educ. Psychol. Meas. 1988, 48, 921–933. [Google Scholar] [CrossRef]

- Ben-David, A. Comparison of classification accuracy using Cohen’s Weighted Kappa. Expert Syst. Appl. 2008, 34, 825–832. [Google Scholar] [CrossRef]

- Berrah, L.; Cliville, V.; Trentesaux, D.; Chapel, C. Industrial performance: An evolution incorporating ethics in the context of industry 4.0. Sustainability 2021, 13, 9209. [Google Scholar] [CrossRef]

- Kuys, B.; Koch, C.; Renda, G. The priority given to sustainability by industrial designers within an industry 4.0 paradigm. Sustainability 2021, 14, 76. [Google Scholar] [CrossRef]

- Atlam, H.F.; Wills, G.B. IoT security, privacy, safety and ethics. In Digital Twin Technologies and Smart Cities. Internet of Things; Springer: Cham, Switzeland, 2020; pp. 123–149. [Google Scholar]

- Chan, J.K. Design ethics: Reflecting on the ethical dimensions of technology, sustainability, and responsibility in the Anthropocene. Des. Stud. 2018, 54, 184–200. [Google Scholar] [CrossRef]

- Tu, J.; Torrente-Rodríguez, R.M.; Wang, M.; Gao, W. The era of digital health: A review of portable and wearable affinity biosensors. Adv. Funct. Mater. 2020, 30, 1906713. [Google Scholar] [CrossRef]

- Østergaard, P.A.; Duic, N.; Noorollahi, Y.; Mikulcic, H.; Kalogirou, S. Sustainable development using renewable energy technology. Renew. Energy 2020, 146, 2430–2437. [Google Scholar] [CrossRef]

- Cao, Y.; Li, S.; Liu, Y.; Yan, Z.; Dai, Y.; Yu, P.S.; Sun, L. A comprehensive survey of ai-generated content (aigc): A history of generative ai from gan to chatgpt. arXiv 2023, arXiv:2303.04226. [Google Scholar]

- Wu, J.; Gan, W.; Chen, Z.; Wan, S.; Lin, H. Ai-generated content (aigc): A survey. arXiv 2023, arXiv:2304.06632. [Google Scholar]

- Luo, Y.; Wang, L. Crisis and Responses to Design and Design Education in the AIGC Era. In Proceedings of the 4th International Conference on Education, Knowledge and Information Management, ICEKIM 2023, Nanjing, China, 26–28 May 2023. [Google Scholar]

- Guo, Z.; Zhu, Z.; Li, Y.; Cao, S.; Chen, H.; Wang, G. AI Assisted Fashion Design: A Review. IEEE Access 2023, 11, 88403–88415. [Google Scholar] [CrossRef]

- Pan, D. Research on the construction and reform of art design education from the perspective of the metaverse. Trans. Comp. Educ. 2023, 5, 22–27. [Google Scholar]

- Yin, H.; Zhang, Z.; Liu, Y. The Exploration of Integrating the Midjourney Artificial Intelligence Generated Content Tool into Design Systems to Direct Designers towards Future-Oriented Innovation. Systems 2023, 11, 566. [Google Scholar] [CrossRef]

- Lettori, J.; Raffaeli, R.; Peruzzini, M.; Schmidt, J.; Pellicciari, M. Additive manufacturing adoption in product design: An overview from literature and industry. Procedia Manuf. 2020, 51, 655–662. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R.J.P.M. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Kermavnar, T.; Shannon, A.; O’Sullivan, L.W. The application of additive manufacturing/3D printing in ergonomic aspects of product design: A systematic review. Appl. Ergon. 2021, 97, 103528. [Google Scholar] [CrossRef]

- Jung, H.; Stolterman, E. Digital form and materiality: Propositions for a new approach to interaction design research. In Proceedings of the 7th Nordic Conference on Human-Computer Interaction: Making Sense Through Design, Copenhagen Denmark, 14–17 October 2012; pp. 645–654. [Google Scholar]

- Langdon, P.; Politis, I.; Bradley, M.; Skrypchuk, L.; Mouzakitis, A.; Clarkson, J. Obtaining design requirements from the public understanding of driverless technology. In Advances in Human Aspects of Transportation: Proceedings of the AHFE 2017 International Conference on Human Factors in Transportation, The Westin Bonaventure Hotel, Los Angeles, CA, USA, 17−21 July 2017; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 749–759. [Google Scholar]

- Szalay, Z.; Tettamanti, T.; Esztergár-Kiss, D.; Varga, I.; Bartolini, C. Development of a test track for driverless cars: Vehicle design, track configuration, and liability considerations. Period. Polytech. Transp. Eng. 2018, 46, 29–35. [Google Scholar] [CrossRef]

- Berg, L.P.; Vance, J.M. Industry use of virtual reality in product design and manufacturing: A survey. Virtual Real. 2017, 21, 1–17. [Google Scholar] [CrossRef]

- Toufaily, E.; Zalan, T.; Dhaou, S.B. A framework of blockchain technology adoption: An investigation of challenges and expected value. Inf. Manag. 2021, 58, 103444. [Google Scholar] [CrossRef]

- Kim, B.; Joines, S.; Feng, J. Technology-driven design process: Teaching and mentoring technology-driven design process in industrial design education. Int. J. Technol. Des. Educ. 2023, 33, 521–555. [Google Scholar] [CrossRef]

- Olsson, T.; Lagerstam, E.; Kärkkäinen, T.; Väänänen-Vainio-Mattila, K. Expected user experience of mobile augmented reality services: A user study in the context of shopping centres. Pers. Ubiquitous Comput. 2013, 17, 287–304. [Google Scholar] [CrossRef]

- Yang, B.; Wei, L.; Pu, Z. Measuring and improving user experience through artificial intelligence-aided design. Front. Psychol. 2020, 11, 595374. [Google Scholar] [CrossRef] [PubMed]

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Chandrasegaran, S.K.; Ramani, K.; Sriram, R.D.; Horváth, I.; Bernard, A.; Harik, R.F.; Gao, W. The evolution, challenges, and future of knowledge representation in product design systems. Comput.-Aided Des. 2013, 45, 204–228. [Google Scholar] [CrossRef]

- Blanco, T.; Casas, R.; Manchado-Pérez, E.; Asensio, Á.; López-Pérez, J.M. From the islands of knowledge to a shared understanding: Interdisciplinarity and technology literacy for innovation in smart electronic product design. Int. J. Technol. Des. Educ. 2017, 27, 329–362. [Google Scholar] [CrossRef]

- Koppikar, U.; Kandakatla, R.; Mallibhat, K.; Joshi, G. Exploration of Skills Required by Engineering Faculty to Mentor Freshmen Undergraduate Students for Interdisciplinary Design Projects. IEEE Trans. Educ. 2023, 66, 450–456. [Google Scholar] [CrossRef]

| Participant | Research Field | Age | Qualification | Workplace | Qualifications for Employment | Location |

|---|---|---|---|---|---|---|

| P1 | Experience Design | 29 | Master | Experience Designer, Alibaba Group | Designer with 5 years of experience | China |

| P2 | CMF Design | 30 | Master | Product Designer, Xiaomi Group | Designer with 8 years of experience | China |

| P3 | Railway Product Design | 31 | Master | Industrial Designer, BYD Group | Designer with 6 years of experience | China |

| P4 | Innovative Experience Design | 30 | Master | Design Supervisor of European Design Team, Huawei Group | Designer with 6 years of experience | Europe |

| P5 | System Design | 30 | PhD | PhD at Tongji University and University of Barcelona | Designer with 2 years of experience | China/ Spain |

| P6 | Product Design | 30 | PhD | PhD at Hanyang University | Designer with 1 years of experience and 3 years as lecturer | South Korea |

| P7 | UX Design | 30 | Master | Senior UX Designer, Walmart Global Tech | Designer with 5 years of experience | USA |

| P8 | Product Design | 30 | Master | Industrial Designer, Midea Group | Designer with 6 years of experience | China |

| P9 | Industrial Design | 32 | PhD | PhD at China Academy of Art | Designer with 1 years of experience and 1 years as lecturer | China |

| P10 | Service Design | 28 | PhD | PhD at Hanyang University | Designer with 1 years of experience | South Korea |

| P11 | Design Management | 30 | PhD | University lecturer | Designer with 1 years of experience and 1 years as lecturer | China |

| P12 | Industrial Engineering | 33 | Master | Industrial Engineers, Huawei Group | Engineer with 8years of experience | China |

| P13 | Service Design | 27 | PhD | Experience Designer, Huawei Group | Designer with 1 years of experience | China |

| P14 | Design Methodology | 33 | PhD | University lecturer | Designer with 2 years of experience and 1 years as lecturer | China |

| P15 | Materials Science | 34 | PhD | University lecturer | Engineer with 2 years of experience and 1 years as lecturer | China |

| No. | Label | Occurrences Weight | No. | Label | Occurrences Weight |

|---|---|---|---|---|---|

| 1 | Smart Manufacturing Systems | 100 | 16 | Product-Service Systems | 18 |

| 2 | Big Data Analytics | 57 | 17 | Integration | 17 |

| 3 | Cyber-Physical System | 56 | 18 | 4D Printing | 16 |

| 4 | Digital Twins | 50 | 19 | Augmented Reality | 16 |

| 5 | Internet | 48 | 20 | Blockchain | 15 |

| 6 | Internet of Things | 46 | 21 | Artificial Intelligence | 14 |

| 7 | 3D Printing | 31 | 22 | Servitization | 14 |

| 8 | Additive Manufacturing | 31 | 23 | Smart Materials | 14 |

| 9 | Sustainability | 29 | 24 | Supply Chain | 13 |

| 10 | Innovation | 28 | 25 | Product Lifecycle Management | 12 |

| 11 | Management | 25 | 26 | Co-Creation | 11 |

| 12 | Simulation | 22 | 27 | Cloud Computing | 10 |

| 13 | Smart Factory | 21 | 28 | Digitization | 10 |

| 14 | Circular Economy | 20 | 29 | Shape-Memory Polymer | 10 |

| 15 | Machine Learning | 18 |

| Cluster | Sequences | Label | Weight |

|---|---|---|---|

| Cluster1 Digital Technology and Service Experience | 1 | Augmented Reality | 142 |

| 2 | Business Model Innovation | 134 | |

| 3 | Co-Creation | 28 | |

| 4 | Customization | 22 | |

| 5 | Digital Servitization | 17 | |

| Cluster2 Smart Manufacturing and Personalization | 1 | Smart Manufacturing Systems | 100 |

| 2 | Smart Factory | 21 | |

| 3 | Cloud Computing | 10 | |

| 4 | Sensors | 9 | |

| 5 | Mass Customization | 8 | |

| Cluster3 Additive Manufacturing and Material Processes | 1 | Additive Manufacturing | 31 |

| 2 | 3D Printing | 31 | |

| 3 | 4D Printing | 16 | |

| 4 | Smart Materials | 14 | |

| 5 | Shape-Memory Polymer | 10 | |

| Cluster4 Data Analysis and Artificial Intelligence | 1 | Big Data Analytics | 57 |

| 2 | Digital Twins | 50 | |

| 3 | Machine Learning | 18 | |

| 4 | Blockchain | 15 | |

| 5 | Artificial Intelligence | 14 |

| Thematic | Code | Frequency | Source of Data |

|---|---|---|---|

| New Technologies as Design Innovation Methods | 12 | P1. P2. P3. P4. P5. P6. P8. P10. P11. P13. P14. P15 |

| New Technologies as Design Aids | 11 | P1. P2. P3. P4. P6. P7. P8. P10. P11. P13. P15 | |

| Knowledge of Smart Manufacturing System | 7 | P2. P3. P4. P6. P10. P11. P13. P15 |

| Interdisciplinary Knowledge | 8 | P2. P4. P6. P8. P9. P13. P14. P15 | |

| Privacy | 5 | P4. P6. P7. P9. P11 |

| Equality | |||

| Social | |||

| Technology Trends | 3 | P1. P3. P4 |

| Economic Fluctuations |

| Kappa | Agreement (%) | |

|---|---|---|

| Average for all nodes and sources | 0.8126 | 97.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Zhang, X.; Chen, Z.; Wang, Z.; Liu, C.; Park, K. Charting the Path of Technology-Integrated Competence in Industrial Design during the Era of Industry 4.0. Sustainability 2024, 16, 751. https://doi.org/10.3390/su16020751

Zhang M, Zhang X, Chen Z, Wang Z, Liu C, Park K. Charting the Path of Technology-Integrated Competence in Industrial Design during the Era of Industry 4.0. Sustainability. 2024; 16(2):751. https://doi.org/10.3390/su16020751

Chicago/Turabian StyleZhang, Meng, Xi Zhang, Zibin Chen, Zhi Wang, Chenyang Liu, and Kyungjin Park. 2024. "Charting the Path of Technology-Integrated Competence in Industrial Design during the Era of Industry 4.0" Sustainability 16, no. 2: 751. https://doi.org/10.3390/su16020751

APA StyleZhang, M., Zhang, X., Chen, Z., Wang, Z., Liu, C., & Park, K. (2024). Charting the Path of Technology-Integrated Competence in Industrial Design during the Era of Industry 4.0. Sustainability, 16(2), 751. https://doi.org/10.3390/su16020751