A Modular IoT-Based Architecture for Logistics Service Performance Assessment and Real-Time Scheduling towards a Synchromodal Transport System

Abstract

1. Introduction

- Section 2 provides a brief literature review on the aforementioned research topics;

- Section 3 introduces the NEXUS Agenda aim and overall project requirements while pinpointing three associated research challenges and the authors’ proposed solutions;

- Section 4 offers a comprehensive explanation of the proposed digital architecture, where each module is clarified in its separate Section 4.1, Section 4.2 and Section 4.3;

- Section 5 introduces a simplified case study application of Module 2, starting with a short problem characterization in Section 5.1, Section 5.2 explains the case study data, followed by the MEA parameters formalization in Section 5.3, and results presentation and discussion in Section 5.4;

2. Literature Review

2.1. Data Collection in Logistics

2.2. Performance Evaluation of Logistic Services

- (D1)

- on-time delivery—is related to the ability to deliver the goods to the final logistics client within the contractualized deadline. Nowadays, with the assistance of predictive algorithms [20], logistics managers can negotiate delivery due dates more accurately to their clients. Nevertheless, when atypical events occur, e.g., worker strikes, extraordinary environmental phenomena [21], unexpected vehicle issues and equipment failure, lost or stolen goods, or documentation errors, on-time delivery may be severely affected, so as all other logistics performance dimensions;

- (D2)

- customer satisfaction—is defined as “the customer’s positive emotional response to an evaluation of perceived differences between the actual experience with a service and prior expectations of it” [22] (p. 150). Literature has shown that companies with a more customer-oriented or service quality-oriented approach have significantly higher customer retention rates and better market share of their services (an increased social/marketing image), enticing new customers into buying the service [23].

- (D3)

- “fair” prices for inputs—this dimension comprises all costs that may be associated with logistics services, from inventory, namely all expenses for storing and handling products; packaging, which is concerned with preparing goods to ensure product integrity during the logistics service; transport, and all the expenses with the vehicles fleet: fuel, maintenance, insurance, tolls, and others; taxes from governments; incorporation of technology, e.g., a tracking system placed in a vehicle and connected to a system via WiFi, where the final client can visualize where the cargo is located; to all manpower related costs.

- (D4)

- social responsibility—in logistics, social responsibility is associated with sustainable and ethical practices employed by logistics companies to reduce the negative impact their operations cause on the environment and society. It is directly concerned with the three pillars of sustainability: economic, environmental, and social [24]. More recently, green logistics (with more emphasis on the environmental aspect and overall CO2 emissions reduction) has received substantial interest from researchers, practitioners, and governments. A manifold of new and revolutionary changes in low-carbon transportation infrastructure, transportation electrification and decarbonization, and intelligent transportation systems management have been powered by governmental policies in symbiosis with emerging technologies [25].

- (D5)

- low loss and damage—this dimension is concerned with measuring and analyzing incorrectly delivered orders (or with errors), and products that have been damaged during handling or transportation. For containerized cargo, the work in [26] mentions that loss or damage of goods/assets ranks number one on the operational risk scale. Thus, exploring the root causes of these occurrences is pivotal in order not to repeat them in the future, as the condition of the order is one of the leading factors of customer satisfaction in logistics service quality [27].

2.3. From Multimodal to Synchromodal Logistics

- (C1)

- Research focusing on shipment matching and the associated operational decision-making processes under diverse and varying scenario conditions;

- (C2)

- Research related to the mapping of transport networks, considering the influence of synchromodality features. Some of the addressed problems are strategic terminal planning, transport service pricing, transport mode schedule planning, and decentralized cooperation mechanisms;

- (C3)

- Research focused on the adaptation of synchromodality within a supply chain context. The included studies aim to develop digital tools that can be applied to synchromodal transportation.

3. NEXUS Agenda Requirements, Research Challenges and Proposed Solutions

- (R1)

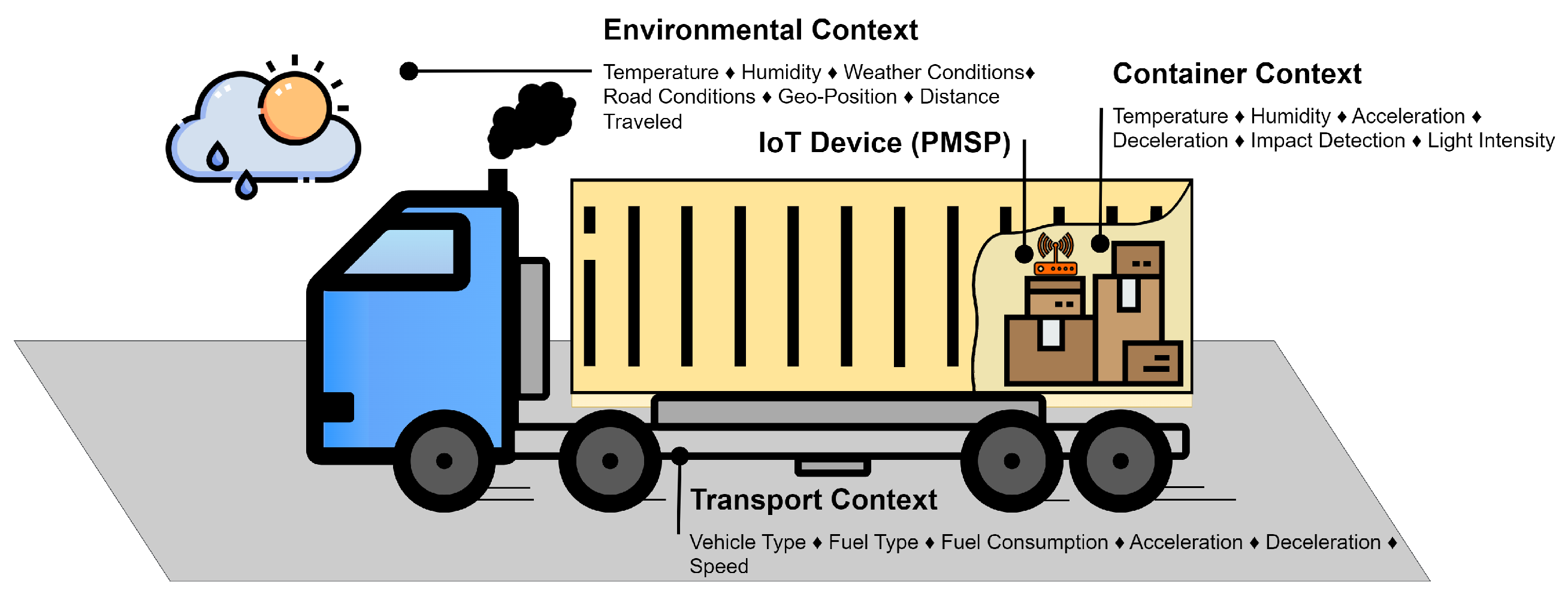

- Collection and integration of logistics data—Security, trustworthiness, and robustness challenges: In a generic sense, several IoT-based devices for data collection are available in the commercial market. Yet, these lack the advantages of the inherent higher trust given to an in-house device, with a high degree of control over hardware and software. Moreover, custom firmware further enables the application of more refined data monitoring algorithms and more robust management of data throughput. To meet this, the authors propose a so-called Predictive Maintenance Smart Probe (PMSP) device, which aims to be incorporated into a digital component (Module 1) responsible for data collection and integration with publicly available data. A detailed explanation is provided in Section 4.1.

- (R2)

- Performance assessment of multimodal transportation routes—A benchmarking-based tool for LSPs and logistics clients: As the previous literature showed, multi-criteria decision-making methods have been widely used for logistics performance assessment (see [30], a review on the topic considering more than 120 research articles published from 2010 to 2019). However, several of those methods depend on parametric choices, such as weights, that are sensible to variability and/or internally project a high-dimension to a one-dimension space, combining completely different variables units, and scales. Furthermore, several of them compute a (quasi-)optimal solution but do not allow to benchmark all the decision-making units (DMUs) involved. Although not a common method in logistics studies, DEA-based techniques and variations, blended or not with other methods, solve some of the mentioned issues and it is known as one of the most viable approaches for nonparametric benchmarking. Nevertheless, the classic DEA approach still lacks some key features relevant to meeting the aforementioned project requirements. Thus, the authors propose an optimization tool based on MEA, a further refinement of classic DEA that (1) considers all possible improvement directions for each DMU, (2) does not rely on just one specific improvement direction for ranking and (3) provides an individual inefficiency analysis per variable/KPI. Such versatility allows for diverse combinations of input-output gains and losses, as well as providing a specific analysis of which factors directly contribute to inefficient ranking scores. Compared to traditional DEA, the number of MEA applications for performance assessment of logistics and transport services is rare. Only the study of [38] was found, so the present work seeks to contribute to the literature in the field while addressing the project needs. Further details are provided in Section 4.2.

- (R3)

- Real-time scheduling and assignment towards synchromodal operations—A dynamic tool that accommodates varying system dynamics and resource availability while minimizing makespan and transportation costs: Traditionally, optimization of logistics networks has been solved using global optimization techniques. More prominently than in the intermodality field, nowadays synchromodality is a trend and need since logistics is constantly evolving with the recent adoption of I4.0 technologies, where businesses are striving more than ever to find new ways to enhance efficiency and reduce costs, pushing an urgent demand for approaches that can optimize in real-time. Optimization methods for decision-making or planning are offline by nature. Hence, one of the Module 3 requirements is to push the boundaries of optimization methods from a data batch scheme to a streaming scheme. Considering its complexity, this module is presented in this work just for completeness reasons. It requires a more detailed explanation in a future publication, not only due to the streaming concept but also because it merges two widely known NP-hard problems: a variation of the job scheduling problem and a variation of the generalized assignment problem. Although Module 2 is the core of this work, in what follows, we briefly explain some details of Module 3 and its integration into the 3-module architecture.

4. Our 3-Module Architecture

4.1. Module 1—Collection and Integration of Logistics Data

- Environmental—temperature, humidity, weather conditions, road conditions, geo-position, and distance traveled.

- Transport—vehicle type, fuel type, fuel consumption, acceleration, deceleration, speed, current gear, RPM, and GHG emissions.

- Container—temperature, humidity, acceleration, deceleration, impact detection, and light intensity.

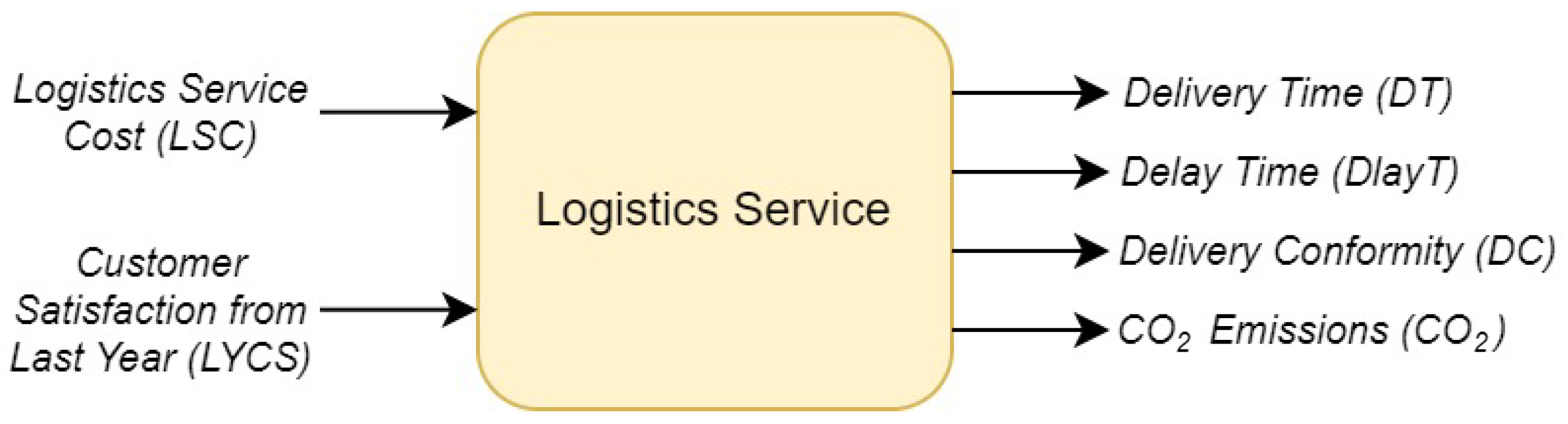

4.2. Module 2—Multimodal Transportation Routes Assessment: Performance Index Determination and Inefficiencies Analysis

4.2.1. Why MEA over DEA?

4.2.2. Mathematical Model

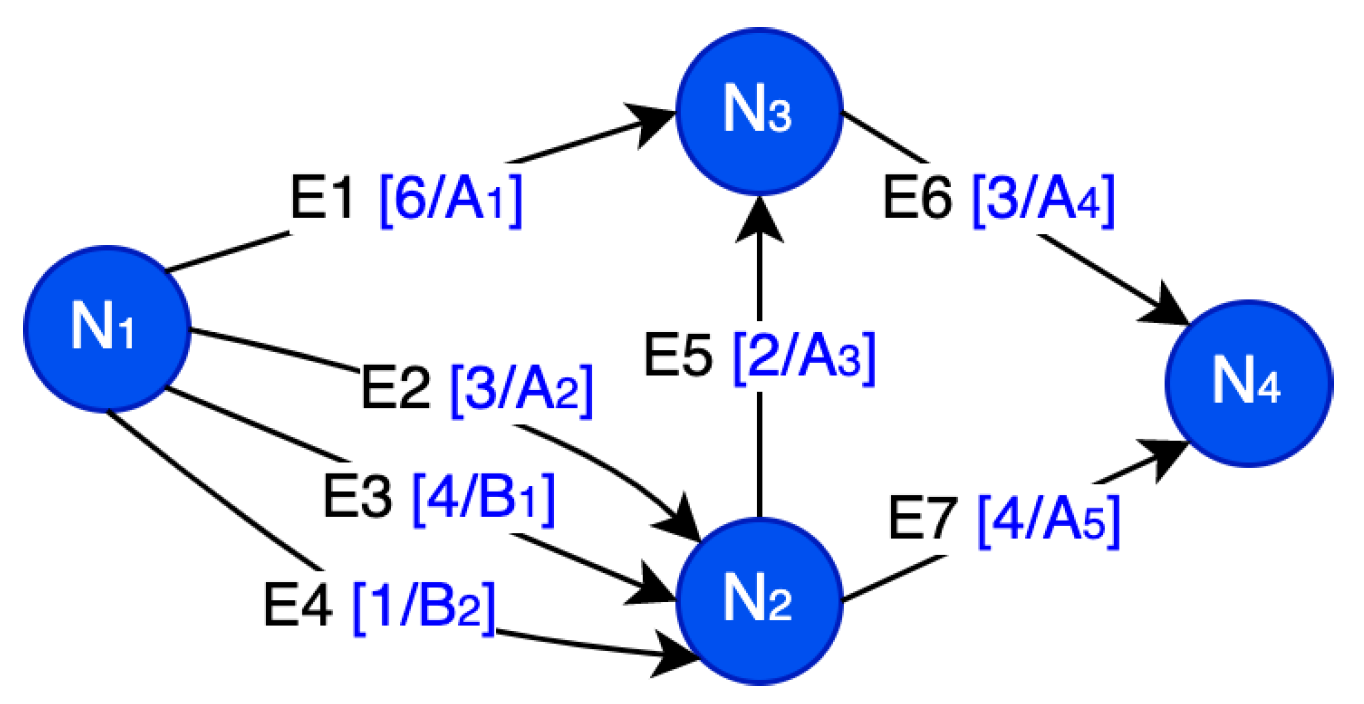

- The so-called technical efficiency index of a container , as a class partition of the MEA score , see (3),

- The technical efficiency index of a route , given by

- The technical efficiency index of a transport , given bywhere is the set of edges of a route R;

- A new directed labeled multigraph , obtained from by storing the technical efficiency index of transports in each information label value, i.e., making for all .

4.3. Module 3—Multiobjective Optimization of Routes’ Technical Efficiencies, Global Network Makespan, and Transportation Costs

4.3.1. Predicting When a Route Is Available

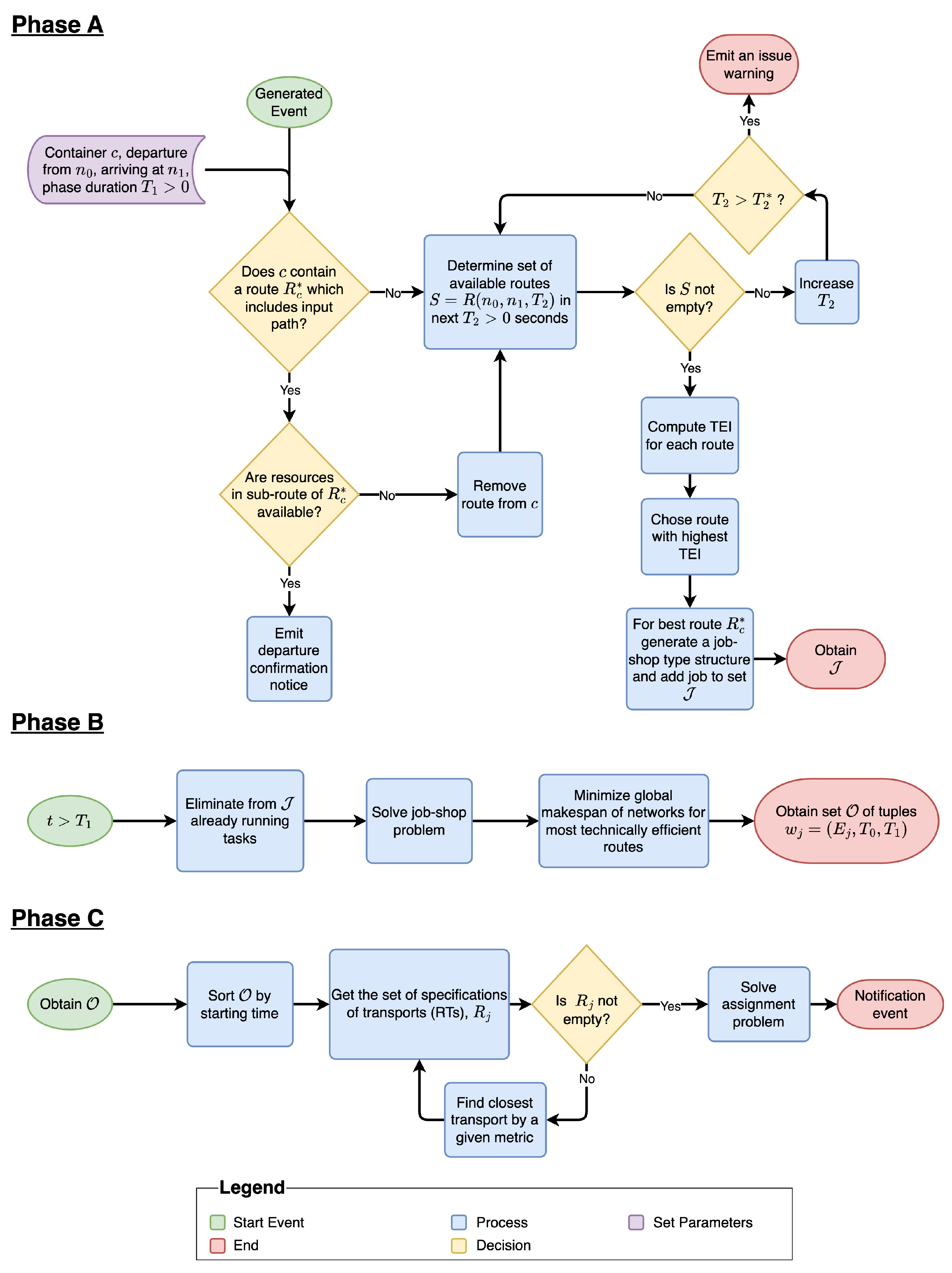

4.3.2. The Algorithm Scheme

- A.

- The first phase runs for a duration. If an event was generated for a container c to departure a node and be transported to a final destination , check if the container c have already an associated route that includes this path:

- If YES, then

- Check the availability of the assigned resources involved in the sub-route of , composed of the path between and . If the next assigned resource is available, emit a departure confirmation notice. Otherwise, remove the associated route from the container and go to , as a heuristic to implement some type of resilience to unknown disruptive events related to transports;

- If NO, then

- Determine the set of all available routes , in the next seconds. If the set is empty, recalculate by increasing the value and repeating this process until there is at least one route in the set. If is bigger than a fixed then stop processing the container and notify the issue;

- For the non-empty set obtained in A.2.1, compute the TEI for each route and choose the route with the highest TEI value;

- Suppose the best route has the edges , then generate a job-shop type structure with these edges, where jobs correspond to container transportation paths, tasks are transportation between corresponding nodes with estimated travel-times, and machines are the involved transports . Add this job to the set .

- B.

- The second phase is after finishing the duration of the first phase. Eliminate from the tasks that are already running, i.e., container-transport pairs that are currently moving between nodes, and solve the job-shop problem defined by this new configuration, so minimizing the global makespan of the network for routes chosen to be the most technically efficient.

- C.

- The third phase minimizes the costs of transport assignment to routes. Notice that, since each route edge was validated for availability, the set of potential transports is not empty. The output of phase B denoted by is a set of tuples , with an edge , transportation starting time , and an ending transportation time . Sort by starting time and then by , if some tasks start at the same time. For each task do:

- Determine the specifications of the transports (RTs) that are available at the transportation service provider and associated with the transport , by querying the logistic service provider API and retrieving their identification, characteristics, and costs. Denote the set of obtained RTs by . If the set is empty (for some unknown reason), start a process of finding the closest transport to concerning a determined metric, set , and repeat the step;

- Construct and solve the assignment problem defined by non-empty . Fix the assigned (best) resource to the task , and generate a notification event with the obtained information.

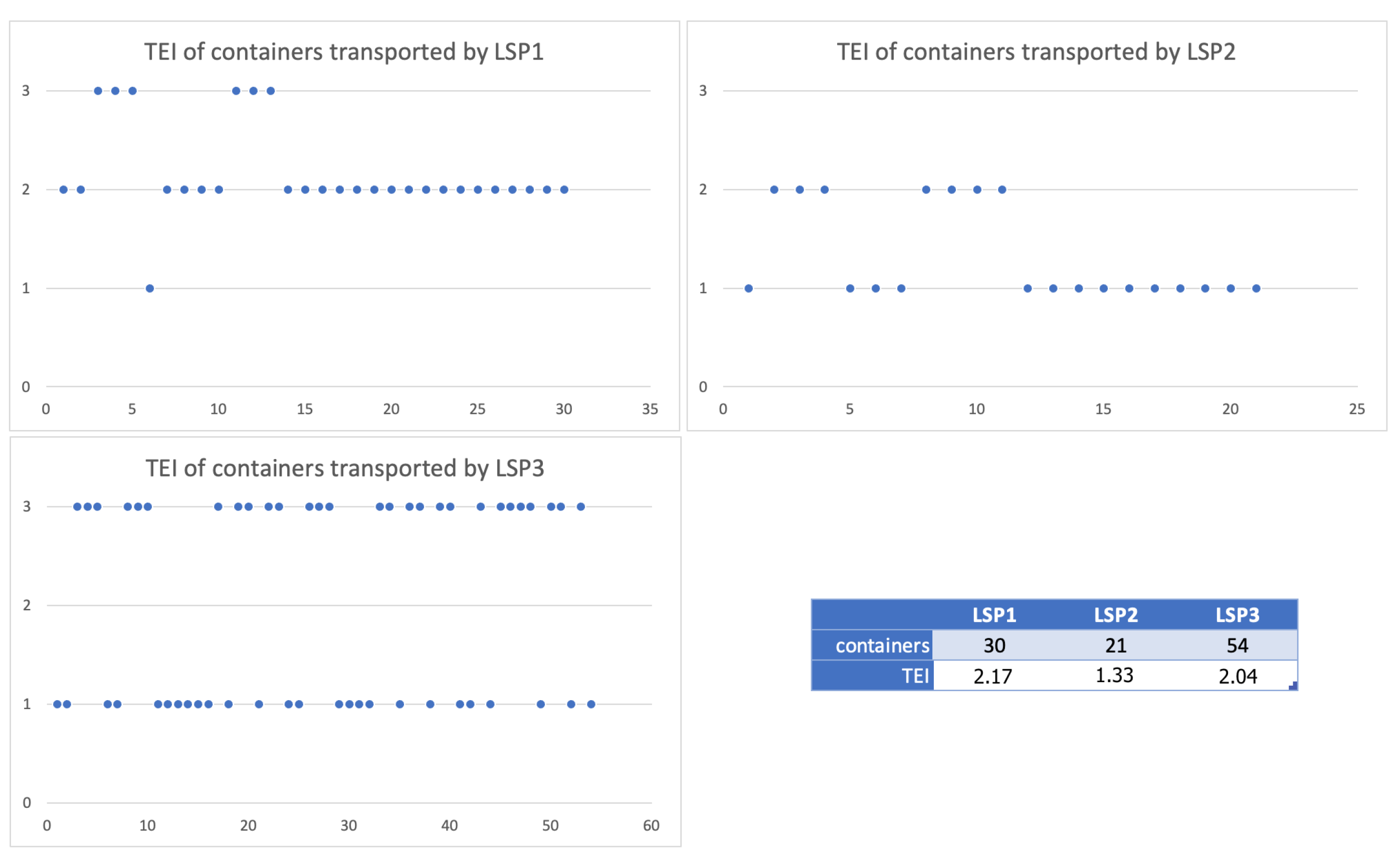

5. Case Study: Technical Efficiency Assessment of Logistics Services (Module 2 Simplified Application)

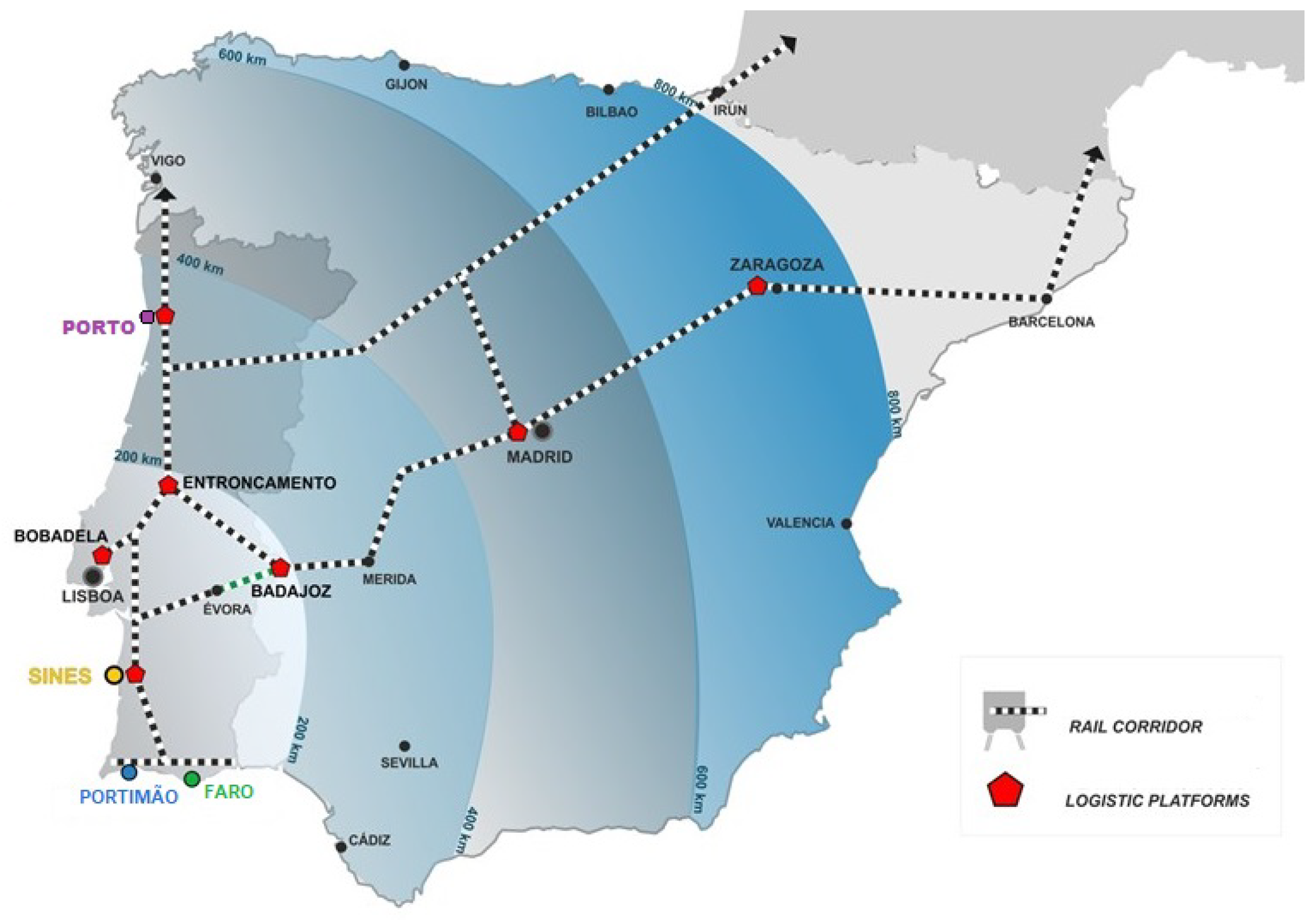

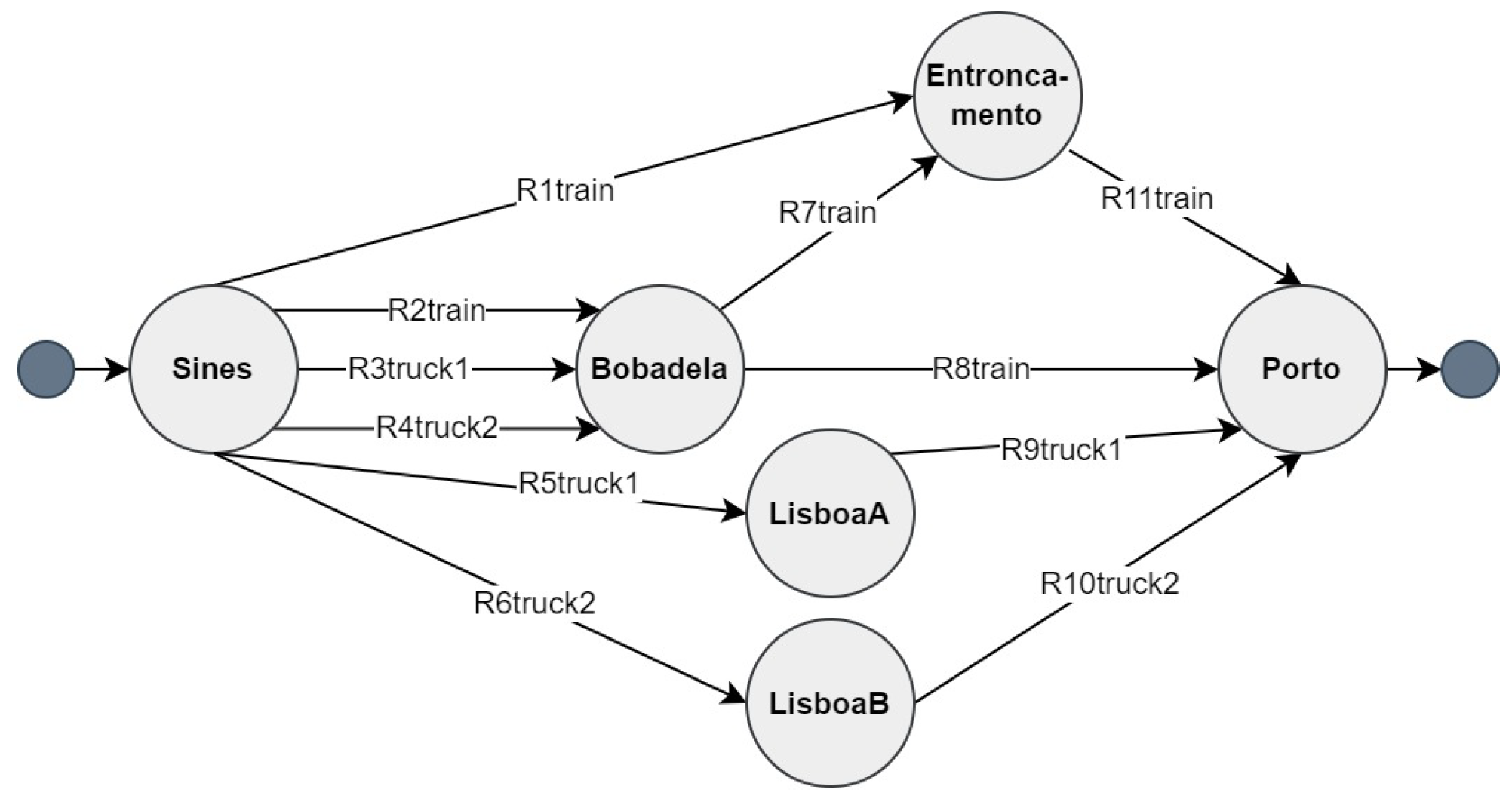

5.1. Case Study Characterization

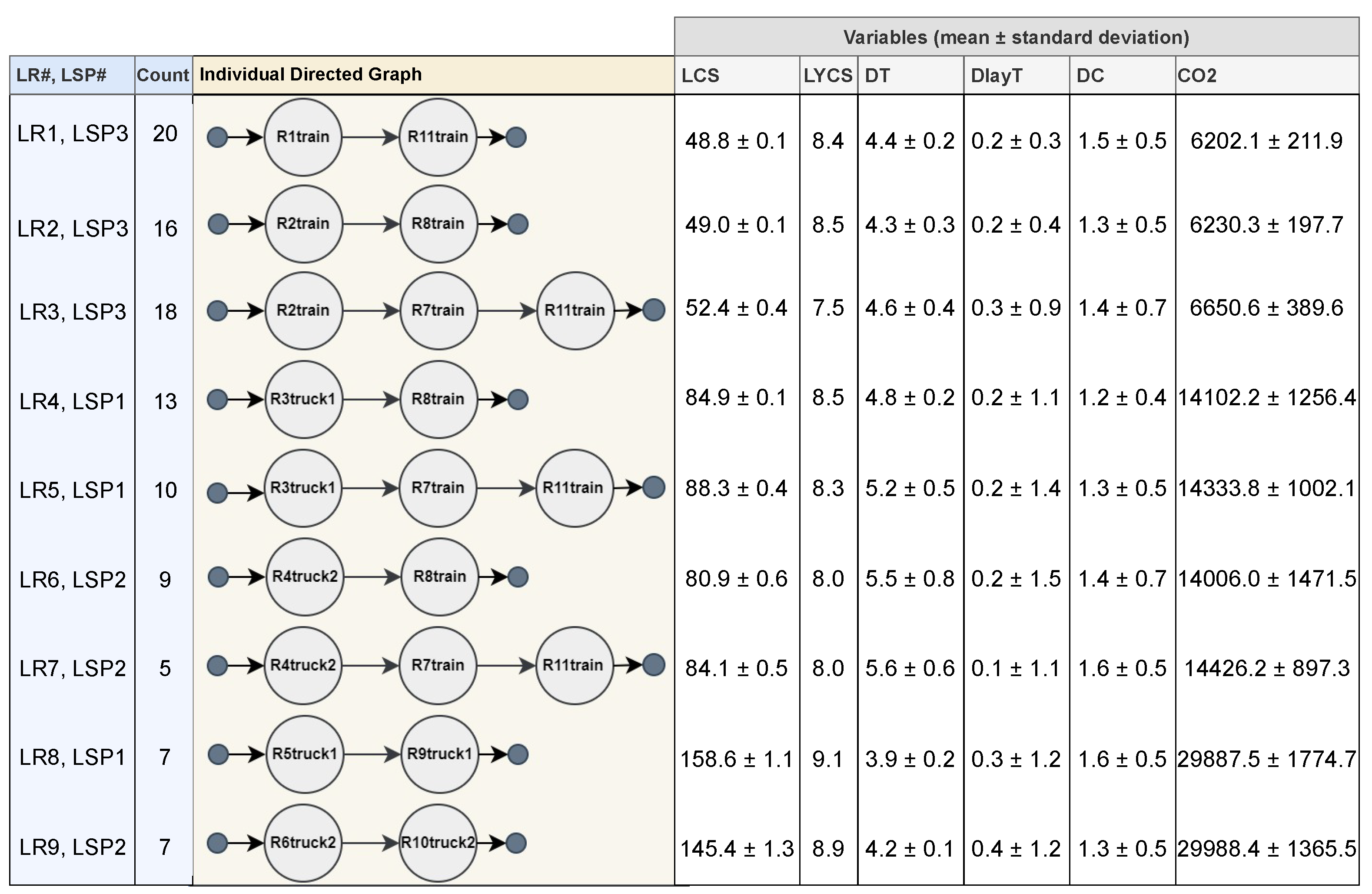

5.2. Case Study Data

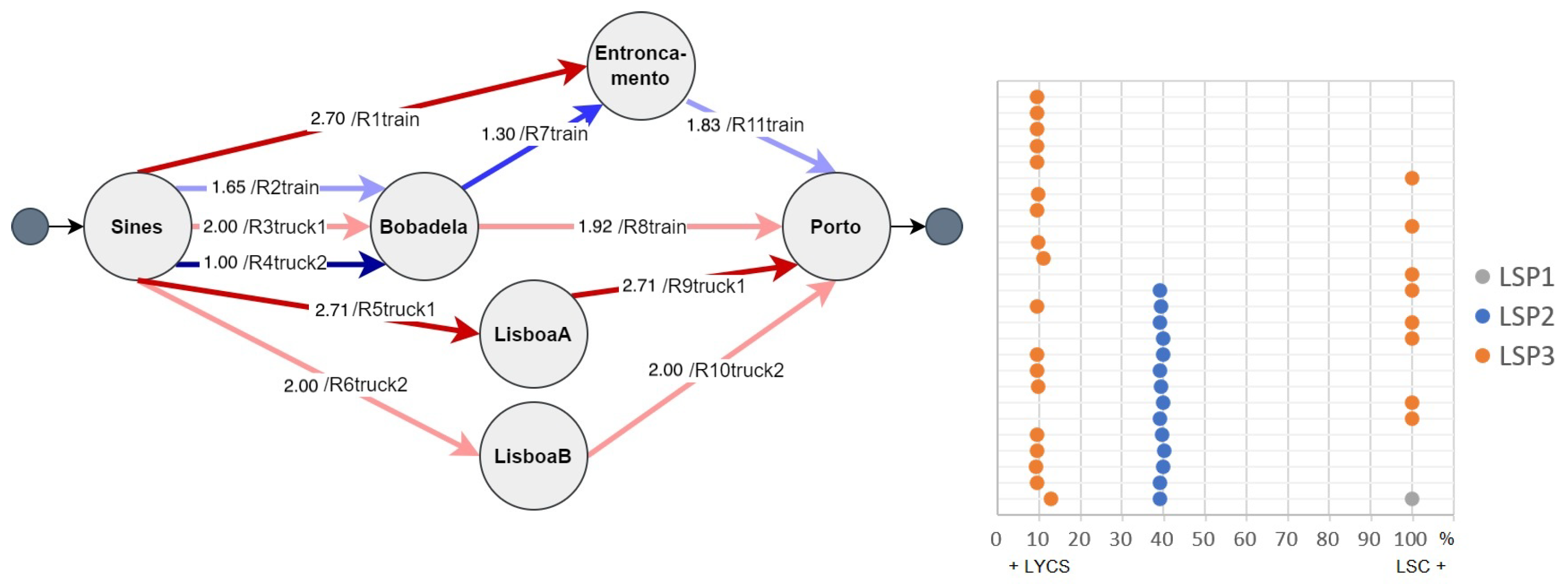

5.3. MEA Application

5.4. Results and Discussion

6. Conclusions

7. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| AP | Assignment problem |

| BLE | Bluetooth low energy |

| DEA | Data envelopment analysis |

| DMU | Decision-making unit |

| ESPs | Environmentally sensitive products |

| GHG | Green house gases |

| GPS | Global positioning system |

| ID | Identifier |

| IoT | Internet-of-things |

| JSSP | Job-shop (scheduling) problem |

| JUL | Portugal’s national logistics platform |

| KPI | Key performance indicator |

| LPI | Logistics performance index |

| LSP | Logistics service provider |

| MEA | Multi-directional efficiency analysis |

| OBD | On-board diagnostics |

| PCA | Principal component analysis |

| PI | Physical internet |

| PMSP | Predictive maintenance smart probe |

| RFID | Radio frequency identification |

| TEI | Technical efficiency index |

| WSN | Wireless sensor network |

References

- Dutch Institute for Advanced Logistics. The Logistics Data Sharing Infraestructure; Technical Report for TKI Dinalog: Breda, The Netherlands, 2020. [Google Scholar]

- Ambra, T.; Caris, A.; Macharis, C. Should I Stay or Should I Go? Assessing Intermodal and Synchromodal Resilience from a Decentralized Perspective. Sustainability 2019, 11, 1765. [Google Scholar] [CrossRef]

- Sustainable Mobility at ICLEI. The Future of Urban Freight Transport: Enabling Data Sharing to Support Decision-Making. Available online: https://sustainablemobility.iclei.org/the-future-of-urban-freight-transport-enabling-data-sharing-to-support-decision-making/ (accessed on 30 July 2023).

- Moschovou, T.; Vlahogianni, E.; Rentziou, A. Challenges for data sharing in freight transport. Adv. Transp. Stud. 2019, 48, 141–152. [Google Scholar]

- European Comission Interim Report. Data Sharing in Supply and Logistics as Commodity—The Digital Transport and Logistics Forum Second Mandate (DTLF II) Subgroup 2: Corridor Information Systems; Technical Report for European Comission: Brussels, Belgium, 2022. [Google Scholar]

- Swamy, S.N.; Kota, S.R. An empirical study on system level aspects of Internet of Things (IoT). IEEE Access 2020, 8, 188082–188134. [Google Scholar] [CrossRef]

- Tran-Dang, H.; Krommenacker, N.; Charpentier, P.; Kim, D.S. Toward the internet of things for physical internet: Perspectives and challenges. IEEE Internet Things J. 2020, 7, 4711–4736. [Google Scholar] [CrossRef]

- Rejeb, A.; Simske, S.; Rejeb, K.; Treiblmaier, H.; Zailani, S. Internet of Things research in supply chain management and logistics: A bibliometric analysis. Internet Things 2020, 12, 100318. [Google Scholar] [CrossRef]

- Montreuil, B. Toward a Physical Internet: Meeting the global logistics sustainability grand challenge. Logist. Res. 2011, 3, 71–87. [Google Scholar] [CrossRef]

- Shafique, M.N.; Rashid, A.; Bajwa, I.S.; Kazmi, R.; Khurshid, M.M.; Tahir, W.A. Effect of IoT capabilities and energy consumption behavior on green supply chain integration. Appl. Sci. 2018, 8, 2481. [Google Scholar] [CrossRef]

- Hopkins, J.; Hawking, P. Big Data Analytics and IoT in logistics: A case study. Int. J. Logist. Manag. 2018, 29, 575–591. [Google Scholar] [CrossRef]

- European Commission; Centre, J.R.; Tsiakmakis, S.; Zacharof, N.; Fontaras, G.; Ciuffo, B.; Marotta, A.; Anagnostopoulos, K.; Pavlovic, J. Review of in Use Factors Affecting the Fuel Consumption and CO2 Emissions of Passenger Cars; Publications Office: Luxembourg, 2016. [CrossRef]

- Yavari, A.; Bagha, H.; Korala, H.; Mirza, I.; Dia, H.; Scifleet, P.; Sargent, J.; Shafiei, M. ParcEMon: IoT Platform for Real-Time Parcel Level Last-Mile Delivery Greenhouse Gas Emissions Reporting and Management. Sensors 2022, 22, 7380. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, J.; Liu, M.; Yin, S.; An, Y. Green Logistics of Vehicle Dispatch under Smart IoT. Sens. Mater. 2022, 34, 3317–3338. [Google Scholar] [CrossRef]

- Huang, Y.; Ding, Z.; Lee, W.J. Charging Cost Aware Fleet Management for Shared on-Demand Green Logistic System. IEEE Internet Things J. 2022, 10, 7505–7516. [Google Scholar] [CrossRef]

- Mejjaouli, S. Internet of Things based Decision Support System for Green Logistics. Sustainability 2022, 14, 4756. [Google Scholar] [CrossRef]

- Bogataj, D.; Bogataj, M.; Hudoklin, D. Mitigating risks of perishable products in the cyber-physical systems based on the extended MRP model. Int. J. Prod. Econ. 2017, 193, 51–62. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Choy, K.L.; Wu, C.H.; Ho, G.T.; Lam, H.Y.; Koo, P.S. An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment. Int. J. Eng. Bus. Manag. 2017, 9, 1847979017749063. [Google Scholar] [CrossRef]

- Chow, G.; Heaver, T.D.; Henriks son, L.E. Logistics Performance: Definition and Measurement. Int. J. Phys. Distrib. Logist. Manag. 1994, 24, 17–28. [Google Scholar] [CrossRef]

- Tsolaki, K.; Vafeiadis, T.; Nizamis, A.; Ioannidis, D.; Tzovaras, D. Utilizing machine learning on freight transportation and logistics applications: A review. ICT Express 2022, in press. [Google Scholar] [CrossRef]

- Gong, Z.; Liu, N. Mitigative and adaptive investments for natural disasters and labor strikes in a seaport–dry port inland logistics network. Marit. Policy Manag. 2020, 47, 92–108. [Google Scholar] [CrossRef]

- Gaudenzi, B.; Confente, I.; Russo, I. Logistics service quality and customer satisfaction in B2B relationships: A qualitative comparative analysis approach. TQM J. 2021, 33, 125–140. [Google Scholar] [CrossRef]

- Lai, P.L.; Jang, H.; Fang, M.; Peng, K. Determinants of customer satisfaction with parcel locker services in last-mile logistics. Asian J. Shipp. Logist. 2022, 38, 25–30. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M. Toward Sustainable Logistics. In Springer Optimization and Its Applications; Springer: Cham, Switzerland, 2017; Volume 129, pp. 1–17. [Google Scholar]

- Li, H.; Hao, Y.; Xie, C.; Han, Y.; Wang, Z.R. Emerging technologies and policies for carbon–neutral transportation. Int. J. Transp. Sci. Technol. 2023, 12, 329–334. [Google Scholar] [CrossRef]

- Abdulahi, E.W.; Fan, L. Exploring and Validating Container Operational Risk Scale in Container Shipping: The Case of Ethiopian Shipping and Logistics Service Enterprise. Sustainability 2021, 13, 9248. [Google Scholar] [CrossRef]

- Uvet, H. Importance of Logistics Service Quality in Customer Satisfaction: An Empirical Study. Oper. Supply Chain Manag. Int. J. 2020, 13, 1–10. [Google Scholar] [CrossRef]

- The World Bank. Logistics Performance Index (LPI)—About. 2023. Available online: https://lpi.worldbank.org/about (accessed on 30 July 2023).

- Beysenbaev, R.; Dus, Y. Proposals for improving the Logistics Performance Index. Asian J. Shipp. Logist. 2020, 36, 34–42. [Google Scholar] [CrossRef]

- Chejarla, K.C.; Vaidya, O.S.; Kumar, S. MCDM applications in logistics performance evaluation: A literature review. J. Multi-Criteria Decis. Anal. 2022, 29, 274–297. [Google Scholar] [CrossRef]

- Giusti, R.; Manerba, D.; Bruno, G.; Tadei, R. Synchromodal logistics: An overview of critical success factors, enabling technologies, and open research issues. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 92–110. [Google Scholar] [CrossRef]

- Babić, D.; Kalić, M.; Janić, M.; Dožić, S.; Kukić, K. Integrated Door-to-Door Transport Services for Air Passengers: From Intermodality to Multimodality. Sustainability 2022, 14, 6503. [Google Scholar] [CrossRef]

- Tavasszy, L.; Behdani, B.; Konings, R. Intermodality and Synchromodality. In Ports and Networks—Strategies, Operations and Perspectives, 1st ed.; Routledge: London, UK, 2017; Chapter 15; pp. 251–266. [Google Scholar] [CrossRef]

- Delbart, T.; Molenbruch, Y.; Braekers, K.; Caris, A. Uncertainty in Intermodal and Synchromodal Transport: Review and Future Research Directions. Sustainability 2021, 13, 3980. [Google Scholar] [CrossRef]

- Steadieseifi, M.; Dellaert, N.P.; Nuijten, W.; Van Woensel, T.; Raoufi, R. Multimodal freight transportation planning: A literature review. Eur. J. Oper. Res. 2014, 233, 1–15. [Google Scholar] [CrossRef]

- Pfoser, S.; Treiblmaier, H.; Schauer, O. Critical Success Factors of Synchromodality: Results from a Case Study and Literature Review. Transp. Res. Procedia 2016, 14, 1463–1471. [Google Scholar] [CrossRef]

- Canale, A.; Carboni, A.; Borghetti, F.; Rentschler, J.; Elbert, R.; Weber, F. Promoting Sustainability through Synchromodal Transportation: A Systematic Literature Review and Future Fields of Research. Sustainability 2022, 14, 13269. [Google Scholar] [CrossRef]

- Lei, X.; Zhang, X.; Dai, Q.; Li, L. Dynamic evaluation on the energy and environmental performance of China’s transportation sector: A ZSG-MEA window analysis. Environ. Sci. Pollut. Res. 2020, 28, 11454–11468. [Google Scholar] [CrossRef] [PubMed]

- Chang, W.J.; Chen, L.B.; Su, J.P. Design and Implementation of Intelligent Tape for Monitoring High-Price and Fragile Cargo Shipments During Transport Procedures. IEEE Sensors J. 2020, 20, 14521–14533. [Google Scholar] [CrossRef]

- Bogetoft, P.; Hougaard, J.L. Efficiency Evaluations Based on Potential (Non-Proportional) Improvements. J. Product. Anal. 1999, 12, 233–247. [Google Scholar] [CrossRef]

- Asmild, M.; Hougaard, J.L.; Kronborg, D.; Kvist, H.K. Measuring Inefficiency via Potential Improvements. J. Product. Anal. 2003, 19, 59–76. [Google Scholar] [CrossRef]

- Bogetoft, P.; Hougaard, J.L. Super efficiency evaluations based on potential slack. Eur. J. Oper. Res. 2004, 152, 14–21. [Google Scholar] [CrossRef]

- Hahn, G.; Brandenburg, M.; Becker, J. Valuing Supply Chain Performance Within and Across Manufacturing Industries: A DEA-based Approach. Int. J. Prod. Econ. 2021, 240, 108203. [Google Scholar] [CrossRef]

- Asmild, M.; Baležentis, T.; Hougaard, J.L. Multi-directional program efficiency: The case of Lithuanian family farms. J. Product. Anal. 2016, 45, 23–33. [Google Scholar] [CrossRef]

- Manevska-Tasevska, G.; Hansson, H.; Asmild, M.; Surry, Y. Exploring the regional efficiency of the Swedish agricultural sector during the CAP reforms—Multi-directional efficiency analysis approach. Land Use Policy 2021, 100, 104897. [Google Scholar] [CrossRef]

- Farrell, M.J. The Measurement of Productive Efficiency. J. R. Stat. Society. Ser. A 1957, 120, 253. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Asmild, M.; Matthews, K. Multi-directional efficiency analysis of efficiency patterns in Chinese banks 1997–2008. Eur. J. Oper. Res. 2012, 219, 434–441. [Google Scholar] [CrossRef]

- Dyson, R.G.; Allen, R.; Camanho, A.S.; Podinovski, V.V.; Sarrico, C.S.; Shale, E.A. Pitfalls and protocols in DEA. Eur. J. Oper. Res. 2001, 132, 245–259. [Google Scholar] [CrossRef]

- Bogetoft, P.; Otto, L. Benchmarking with DEA, SFA, and R; International Series in Operations Research & Management Science; Springer: New York, NY, USA, 2011; Volume 157. [Google Scholar] [CrossRef]

- Mohan, J.; Lanka, K.; Rao, A.N. A Review of Dynamic Job Shop Scheduling Techniques. Procedia Manuf. 2019, 30, 34–39. [Google Scholar] [CrossRef]

- Li, X.; Gao, L. Review for Flexible Job Shop Scheduling. In Effective Methods for Integrated Process Planning and Scheduling. Engineering Applications of Computational Methods; Springer: Berlin/Heidelberg, Germany, 2020; Volume 2, pp. 17–45. [Google Scholar]

- Schrijver, A. On the History of Combinatorial Optimization (Till 1960). In Handbooks in Operations Research and Management Science; Aardal, K., Nemhauser, G., Weismantel, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; Volume 12, pp. 1–68. [Google Scholar] [CrossRef]

- Koehl, P.; Orland, H. Fast computation of exact solutions of generic and degenerate assignment problems. Phys. Rev. E 2021, 103, 042101. [Google Scholar] [CrossRef]

- Wang, H. Time series modeling and predicting for Highway Transport Freight. In Proceedings of the 2011 International Conference on Remote Sensing, Environment and Transportation Engineering, Nanjing, China, 24–26 June 2011; pp. 5603–5605. [Google Scholar] [CrossRef]

- Tang, J.; Liu, F.; Zou, Y.; Zhang, W.; Wang, Y. An Improved Fuzzy Neural Network for Traffic Speed Prediction Considering Periodic Characteristic. IEEE Trans. Intell. Transp. Syst. 2017, 18, 2340–2350. [Google Scholar] [CrossRef]

- Deb, B.; Khan, S.R.; Tanvir Hasan, K.; Khan, A.H.; Alam, M.A. Travel Time Prediction using Machine Learning and Weather Impact on Traffic Conditions. In Proceedings of the 2019 IEEE 5th International Conference for Convergence in Technology (I2CT), Bombay, India, 29–31 March 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Nadi, A.; Sharma, S.; Snelder, M.; Bakri, T.; van Lint, H.; Tavasszy, L. Short-term prediction of outbound truck traffic from the exchange of information in logistics hubs: A case study for the port of Rotterdam. Transp. Res. Part C Emerg. Technol. 2021, 127, 103111. [Google Scholar] [CrossRef]

- APS. Port of Sines. Available online: https://www.apsinesalgarve.pt/en/ports/port-of-sines/ (accessed on 25 May 2023).

- Slideshare - aicep Global Parques. Sines Port Hub for Logistics. Available online: https://pt.slideshare.net/aicepGlobalParques/sines-port-hub-for-logistics-243980750 (accessed on 30 July 2023).

- Bergqvist, R. Hinterland Logistics and Global Supply Chains; Kogan Page Publishers: London, UK, 2012; pp. 211–230. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brochado, Â.F.; Rocha, E.M.; Costa, D. A Modular IoT-Based Architecture for Logistics Service Performance Assessment and Real-Time Scheduling towards a Synchromodal Transport System. Sustainability 2024, 16, 742. https://doi.org/10.3390/su16020742

Brochado ÂF, Rocha EM, Costa D. A Modular IoT-Based Architecture for Logistics Service Performance Assessment and Real-Time Scheduling towards a Synchromodal Transport System. Sustainability. 2024; 16(2):742. https://doi.org/10.3390/su16020742

Chicago/Turabian StyleBrochado, Ângela F., Eugénio M. Rocha, and Diogo Costa. 2024. "A Modular IoT-Based Architecture for Logistics Service Performance Assessment and Real-Time Scheduling towards a Synchromodal Transport System" Sustainability 16, no. 2: 742. https://doi.org/10.3390/su16020742

APA StyleBrochado, Â. F., Rocha, E. M., & Costa, D. (2024). A Modular IoT-Based Architecture for Logistics Service Performance Assessment and Real-Time Scheduling towards a Synchromodal Transport System. Sustainability, 16(2), 742. https://doi.org/10.3390/su16020742