Properties of Sustainable Earth Construction Materials: A State-of-the-Art Review

Abstract

1. Introduction

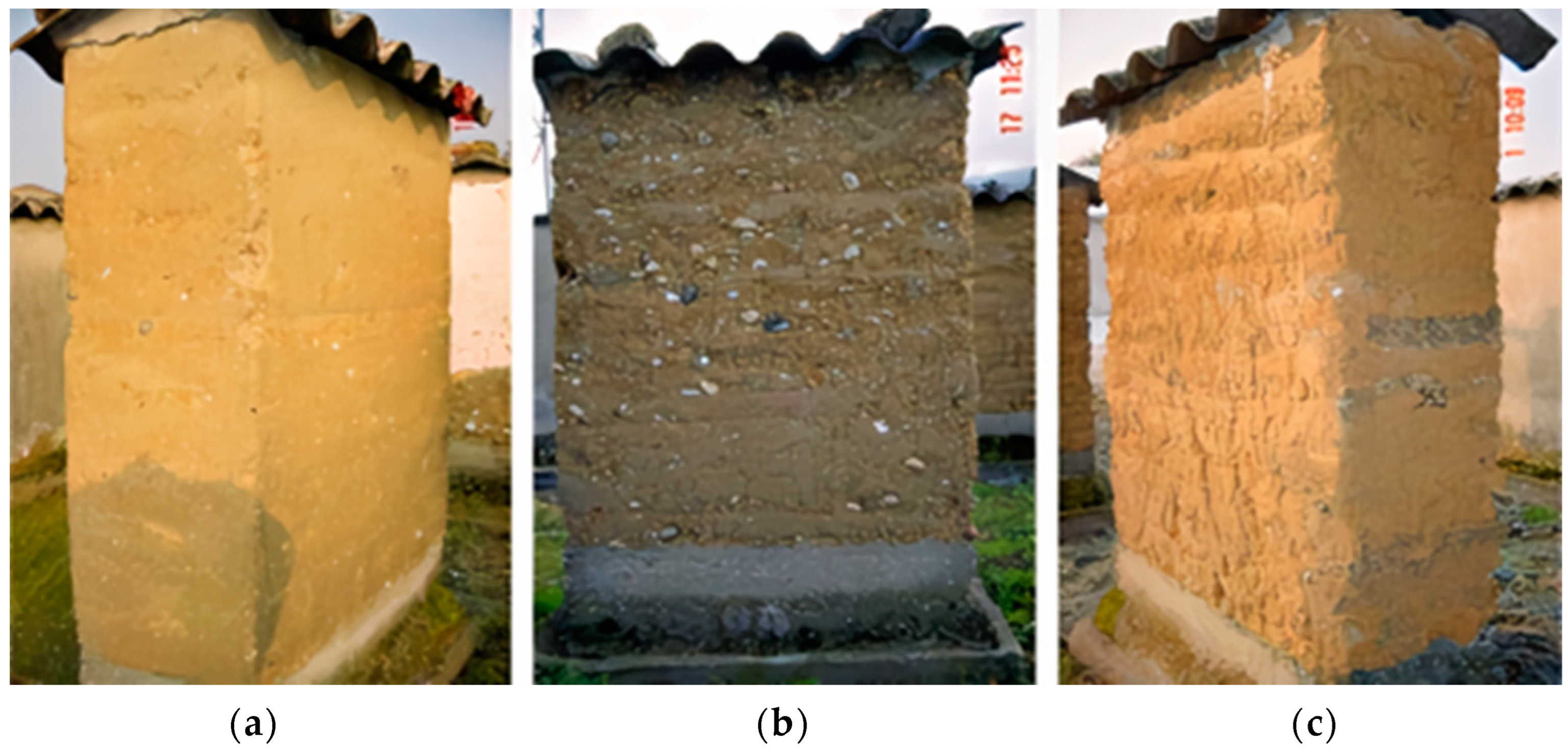

2. Development History of Earth Construction

2.1. Ancient and Glorious History

2.2. Challenges Posed by Industrialization

2.3. Revival in the Era of Ecological Civilization

3. Performance Characteristics of Earth Construction Materials

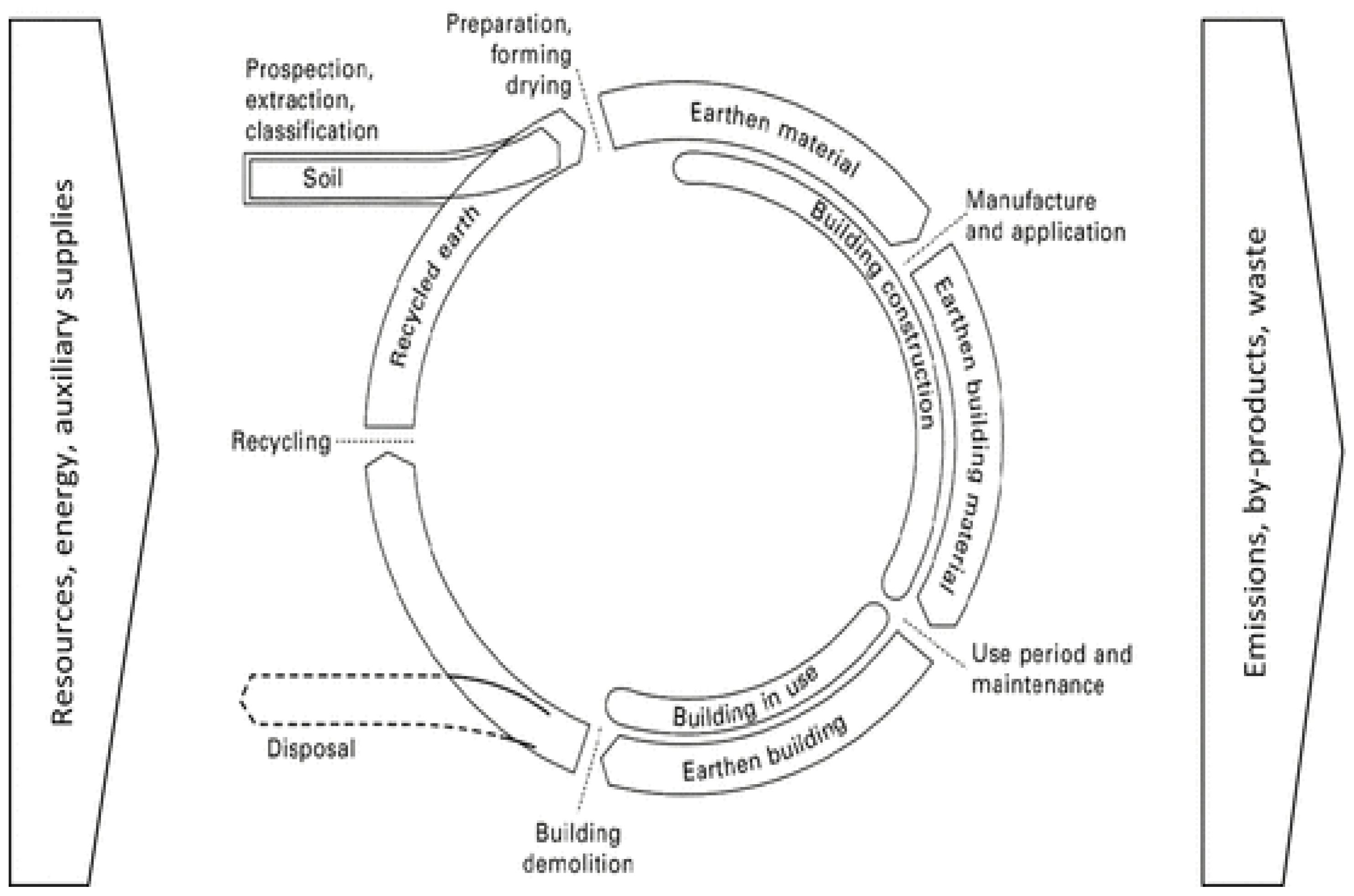

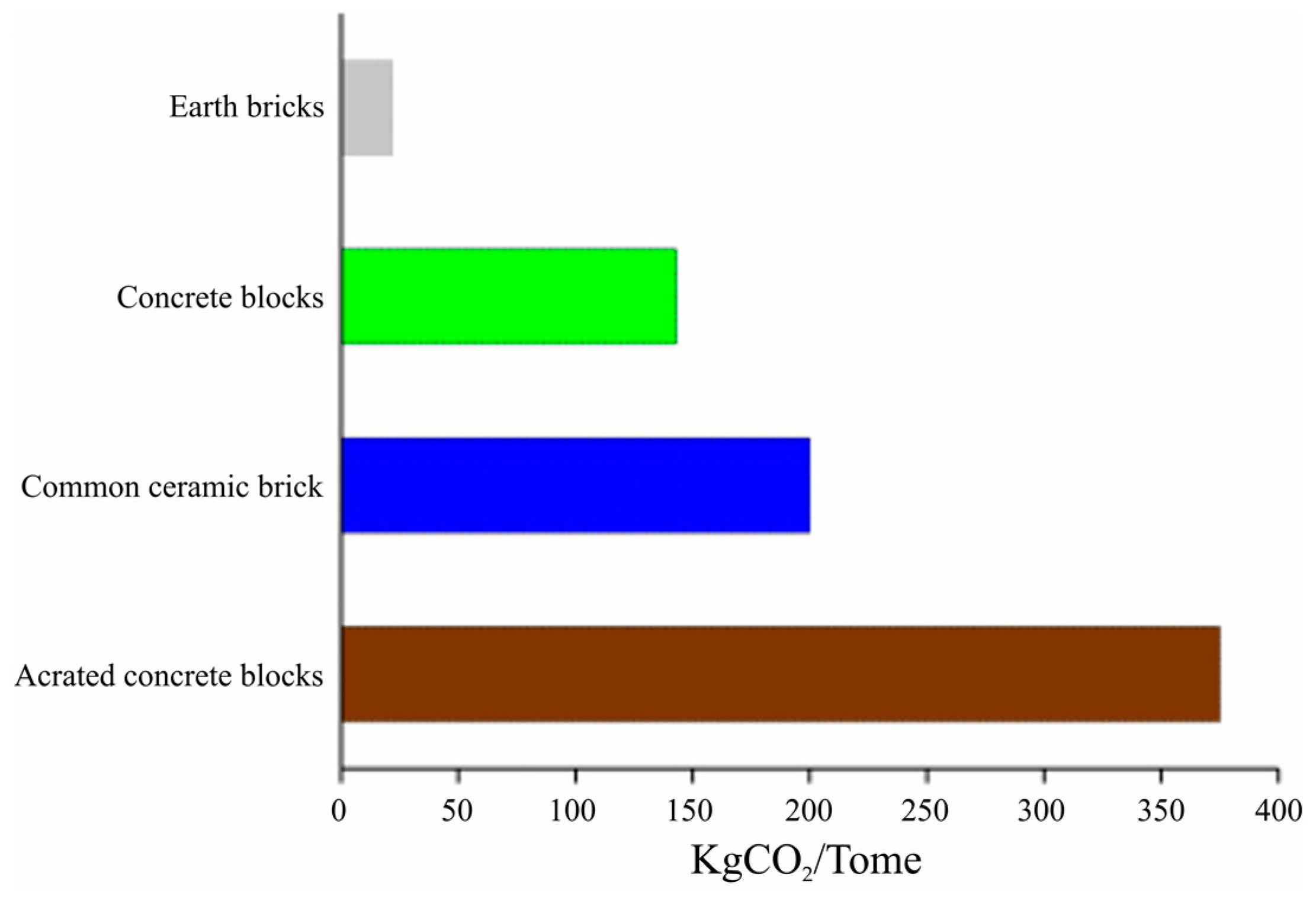

3.1. Economy and Environmental Protection

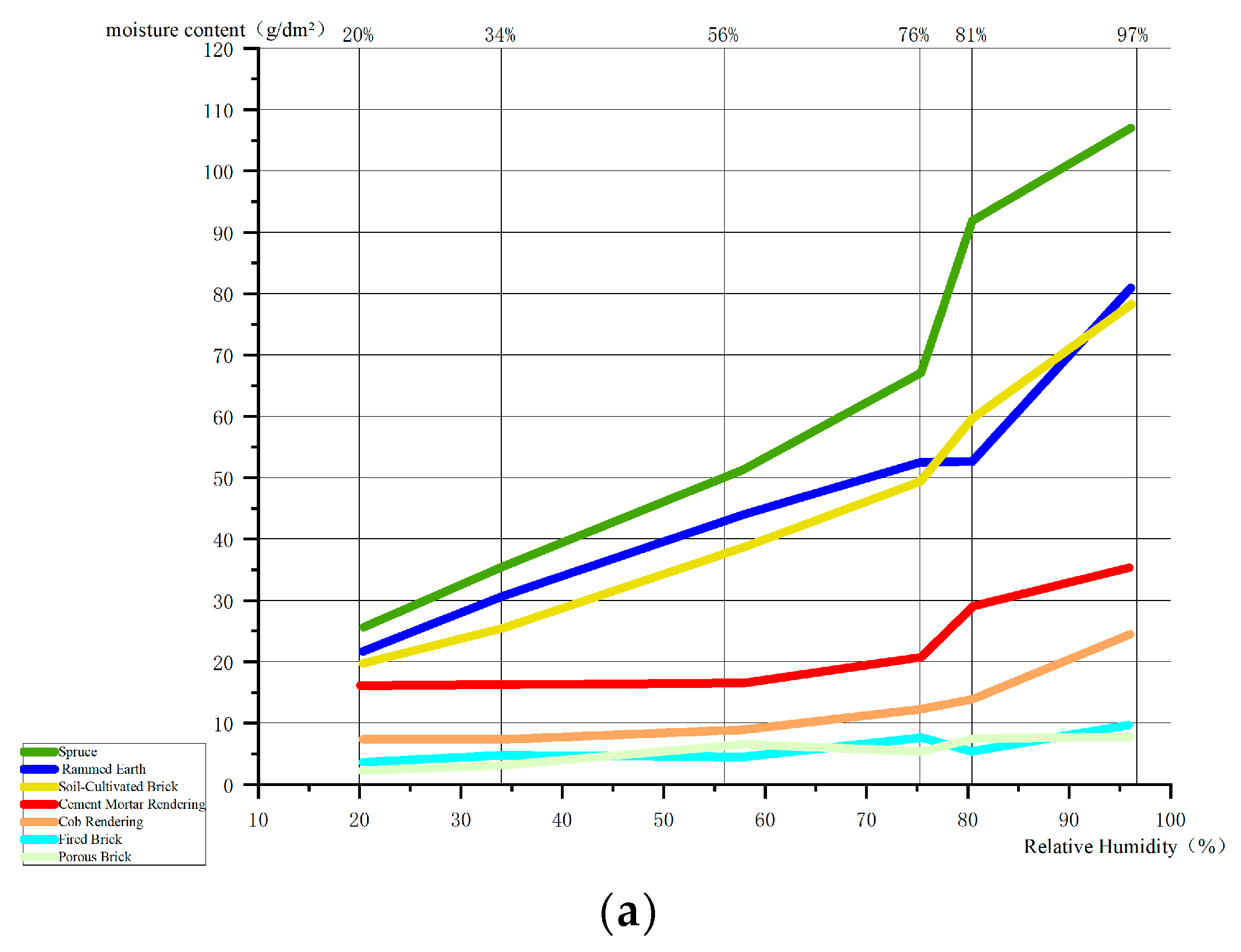

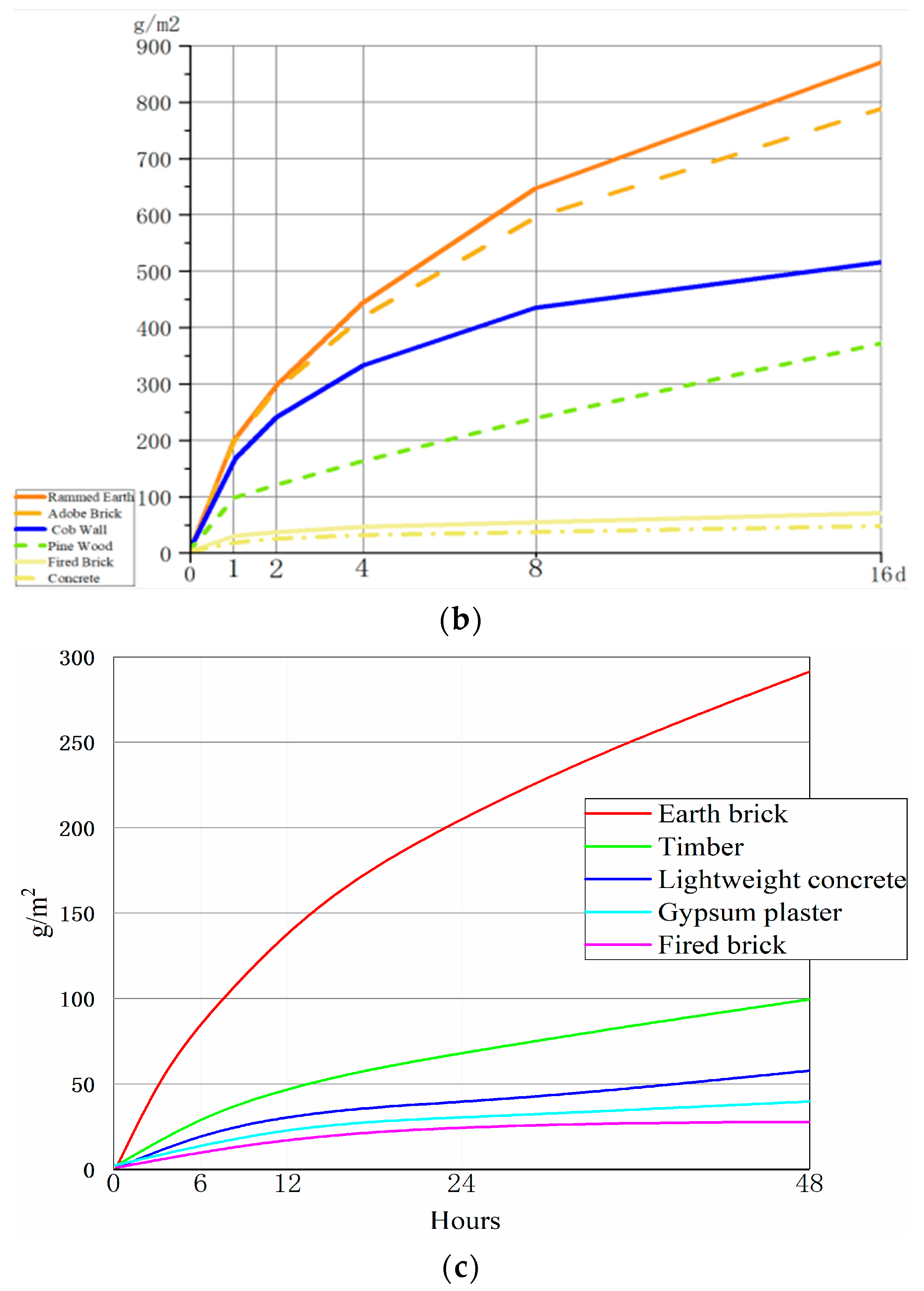

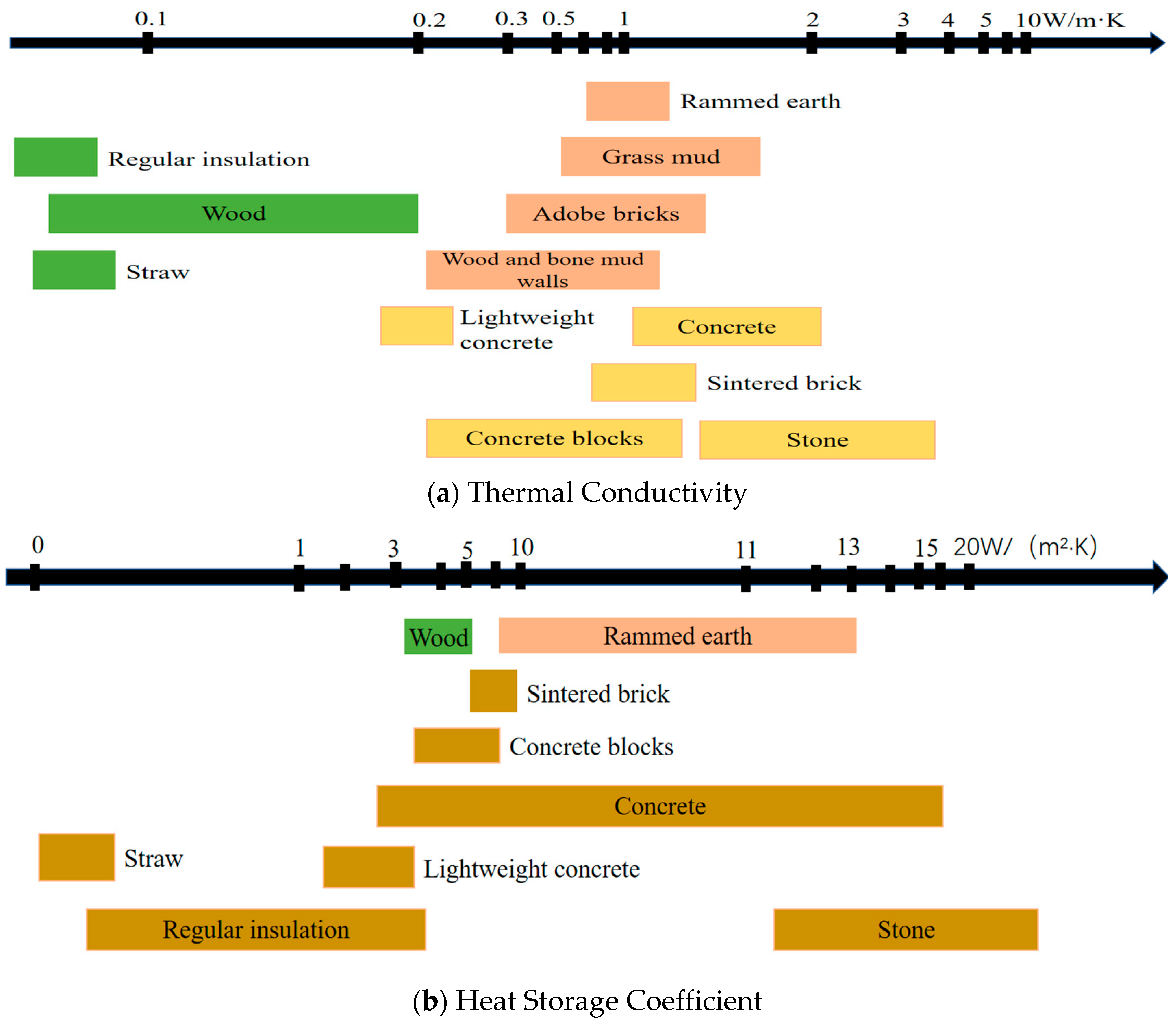

3.2. Moisture Absorption and Heat Storage

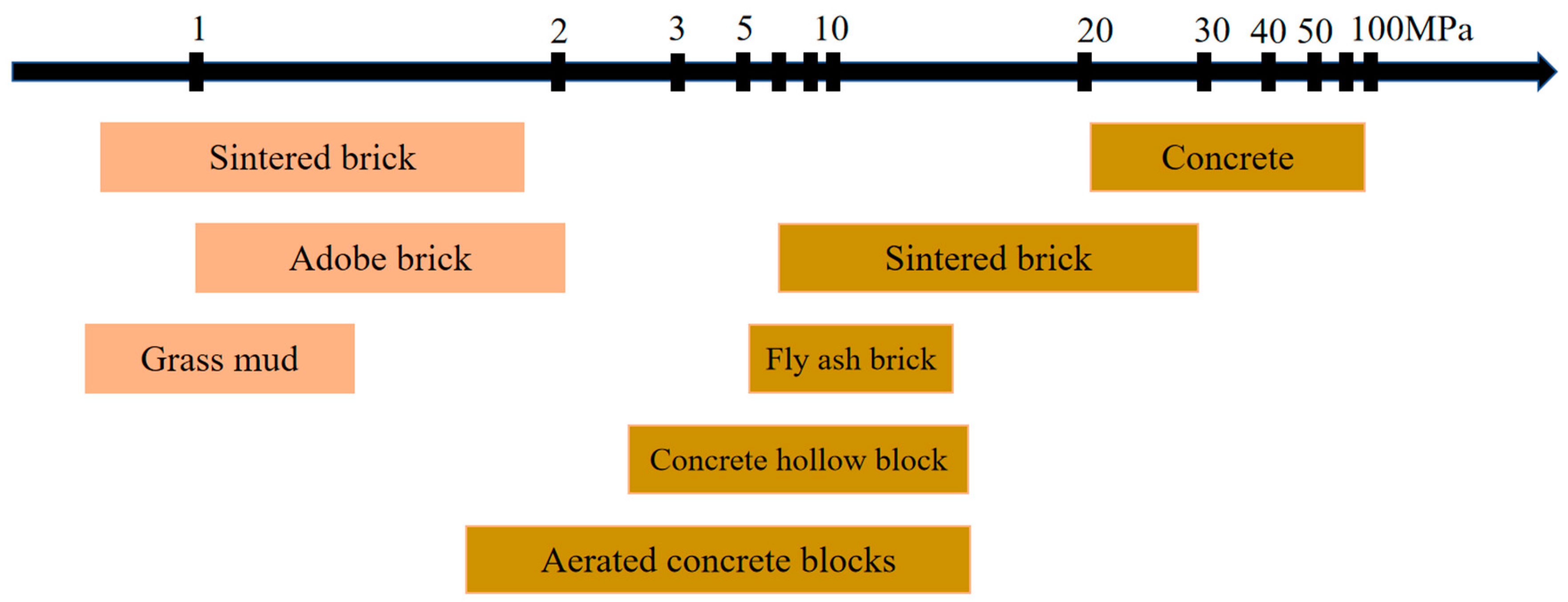

3.3. Mechanics and Durability Performance

4. Research Status of Modification of Earthen Materials

4.1. Chemical Modification

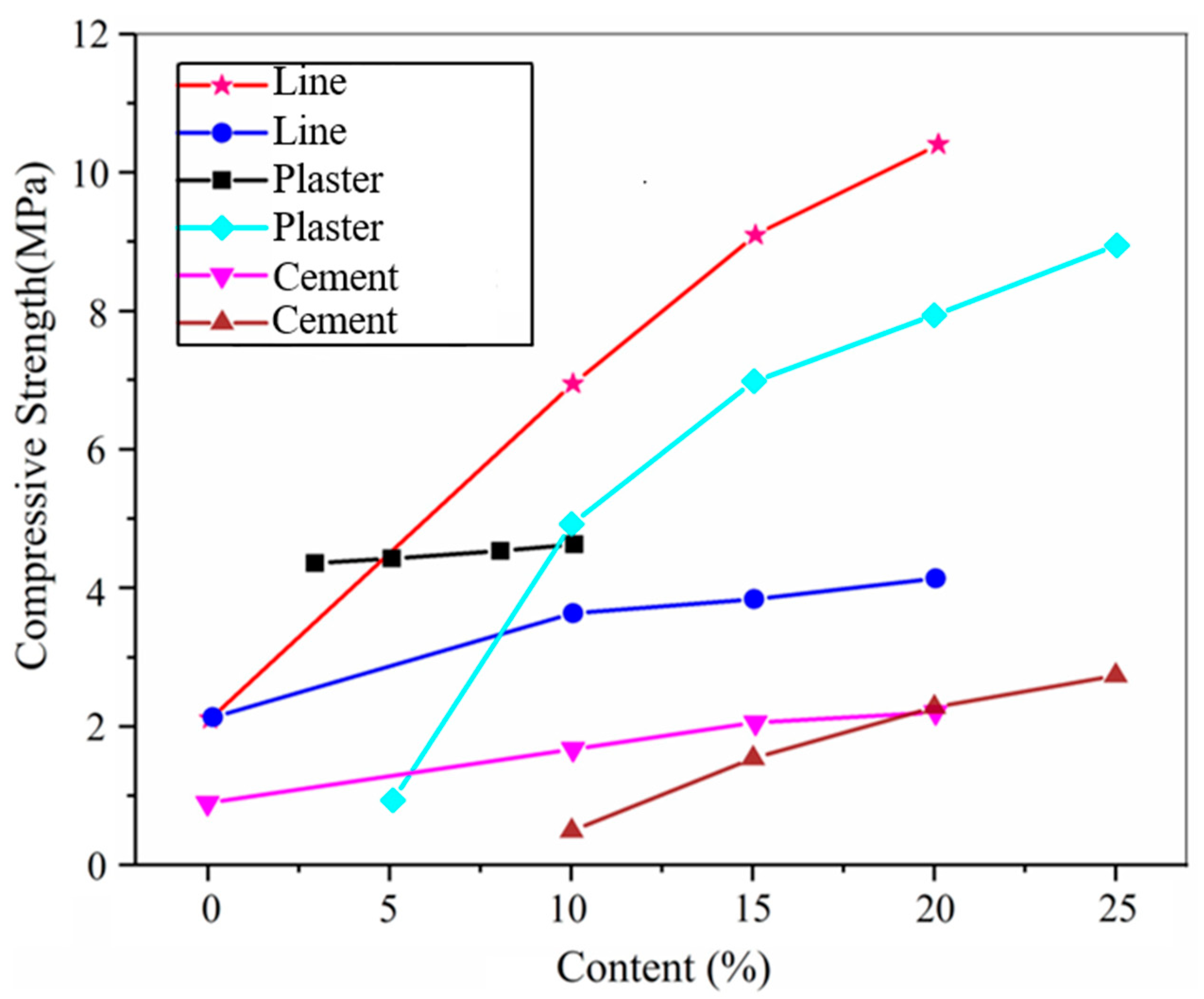

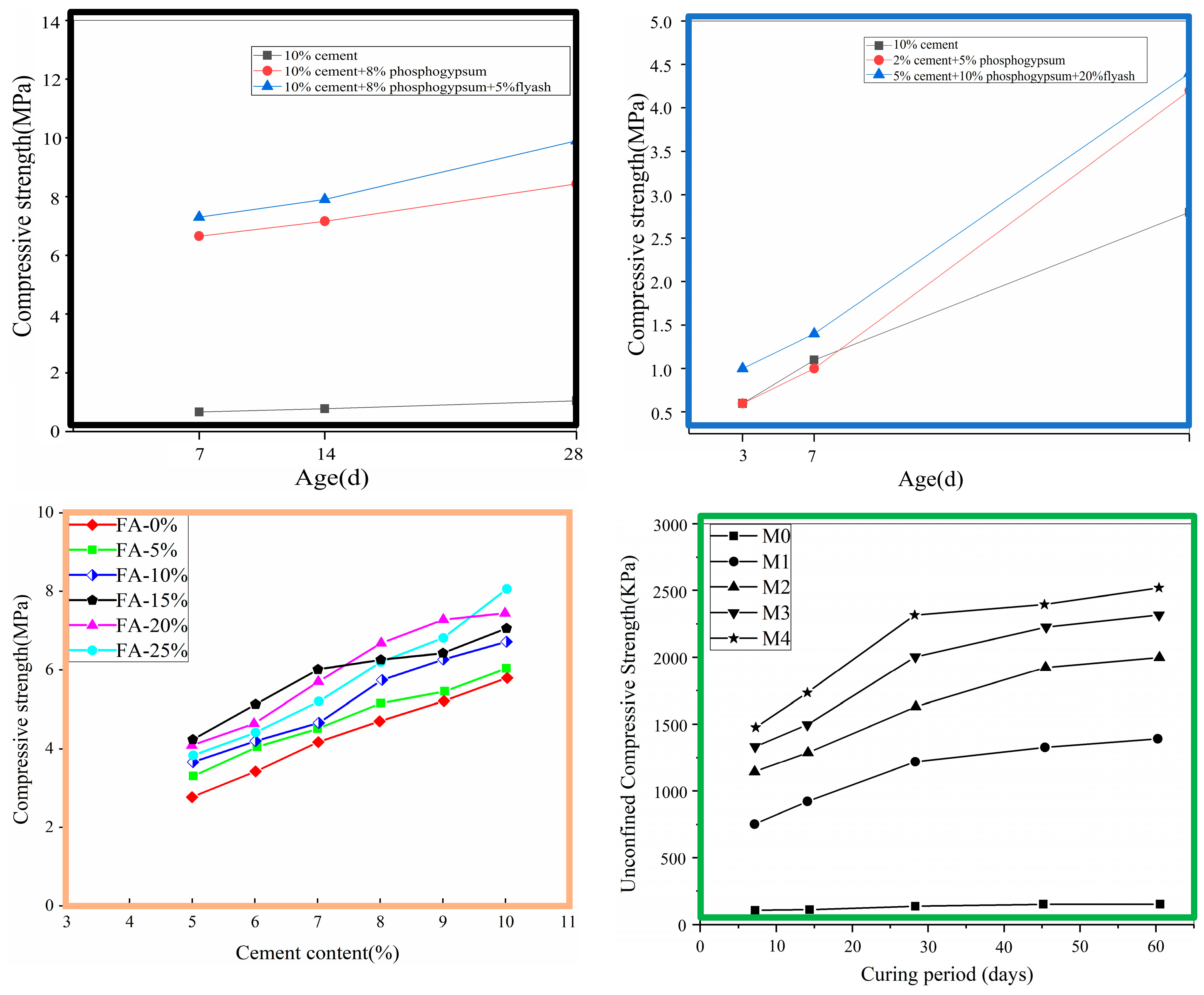

4.1.1. Impact of Chemical Modification on Strength

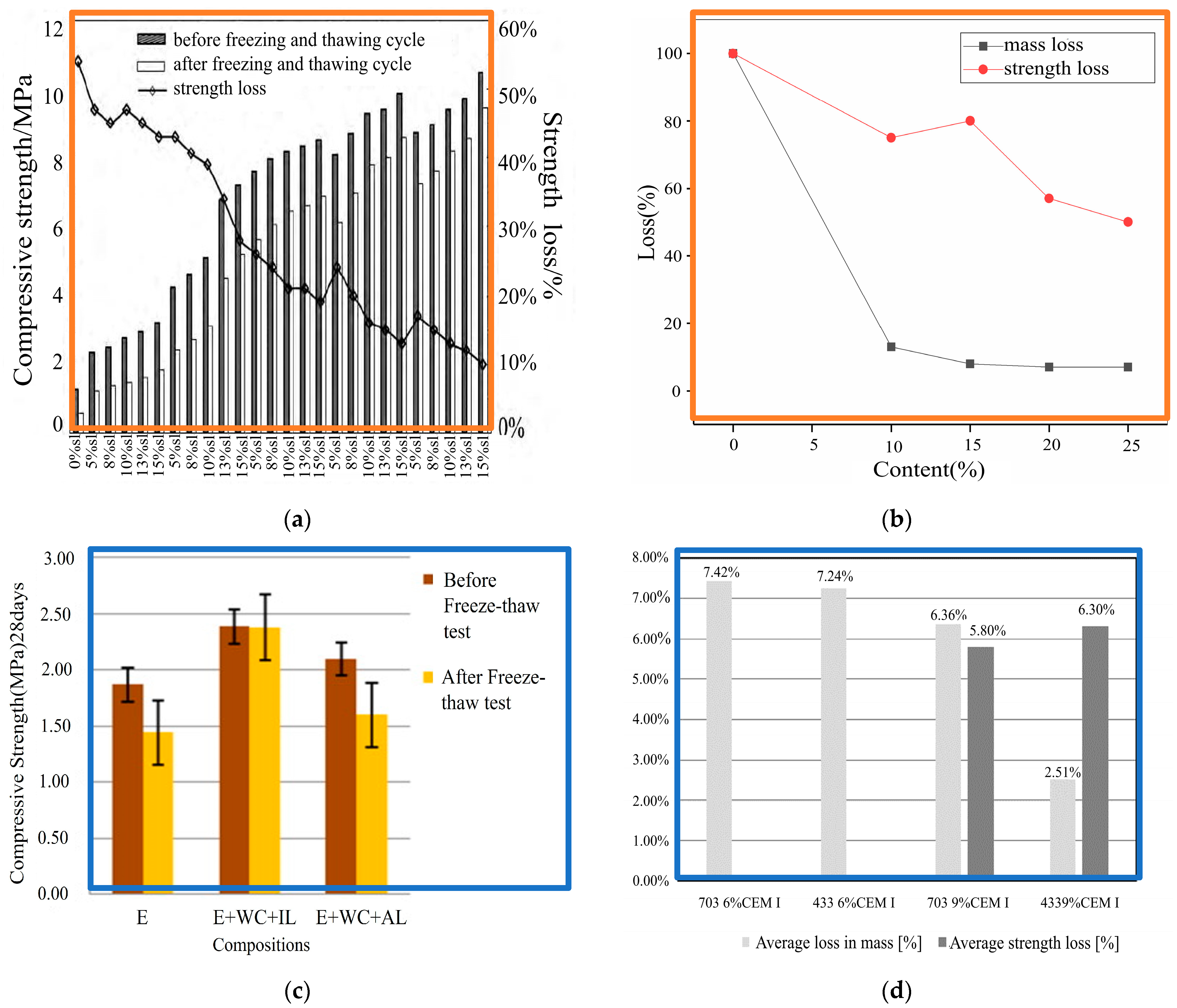

4.1.2. Impact of Chemical Modification on Durability

4.2. Component Optimization

4.2.1. Effect of Component Optimization on Strength

4.2.2. Effect of Component Optimization on Deformability

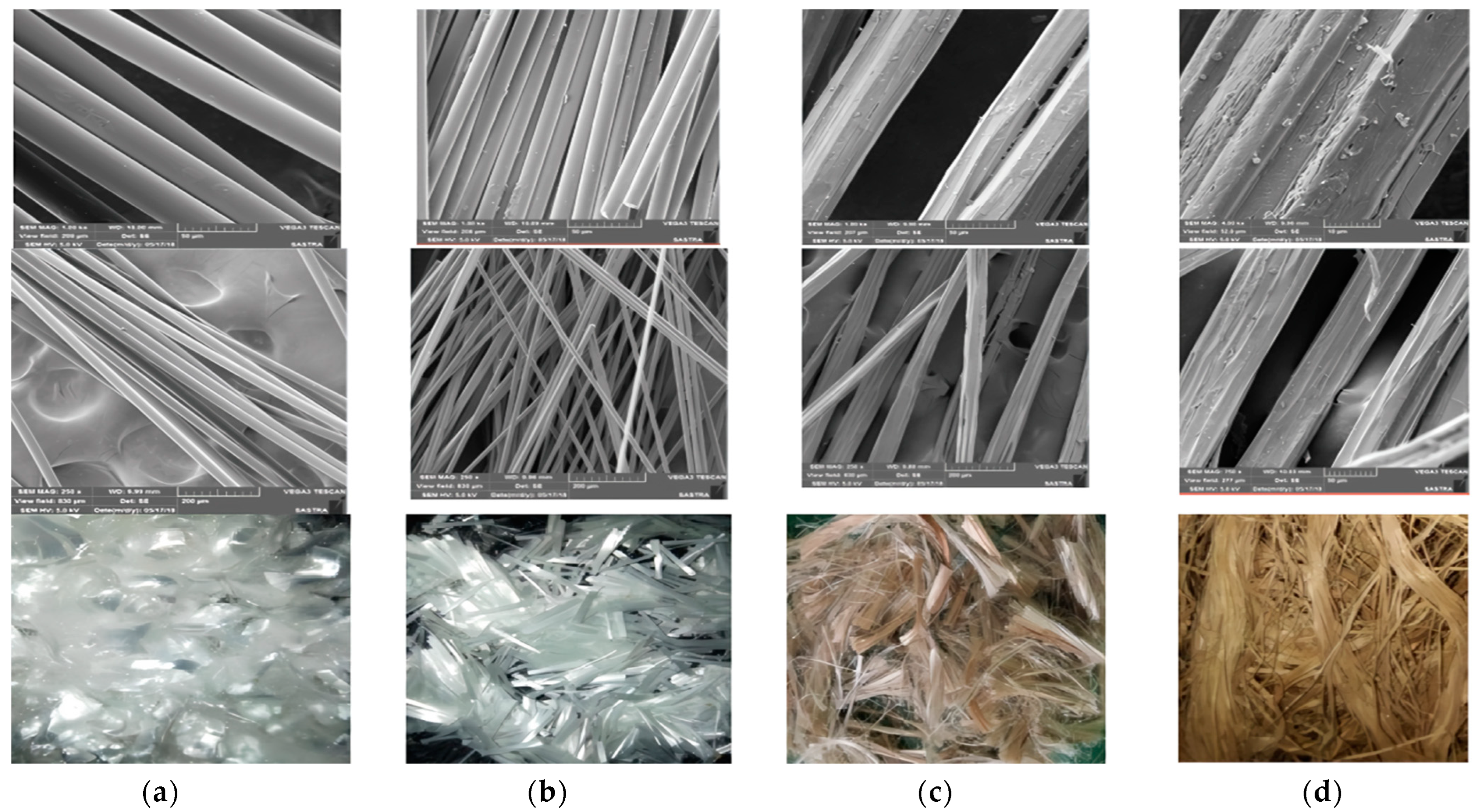

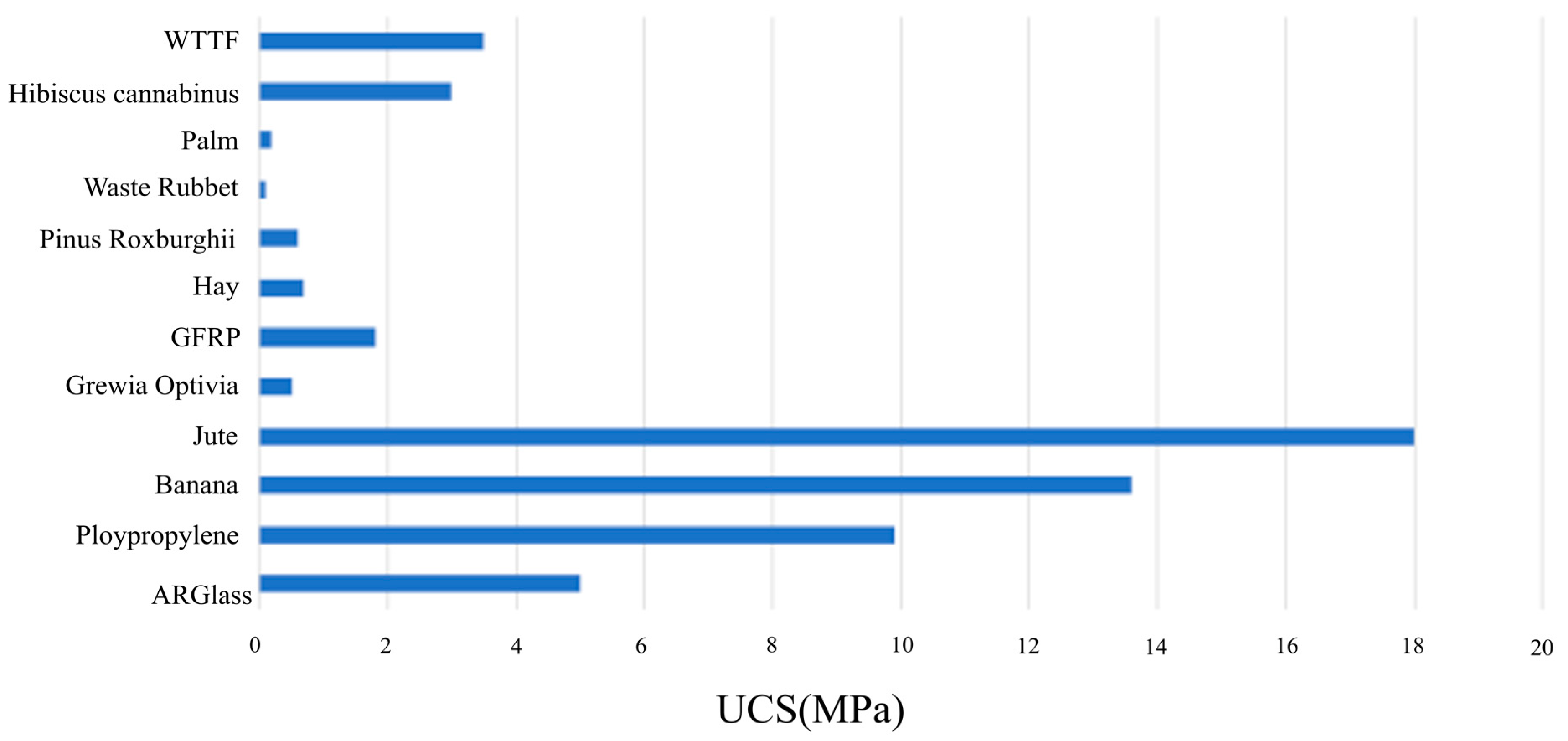

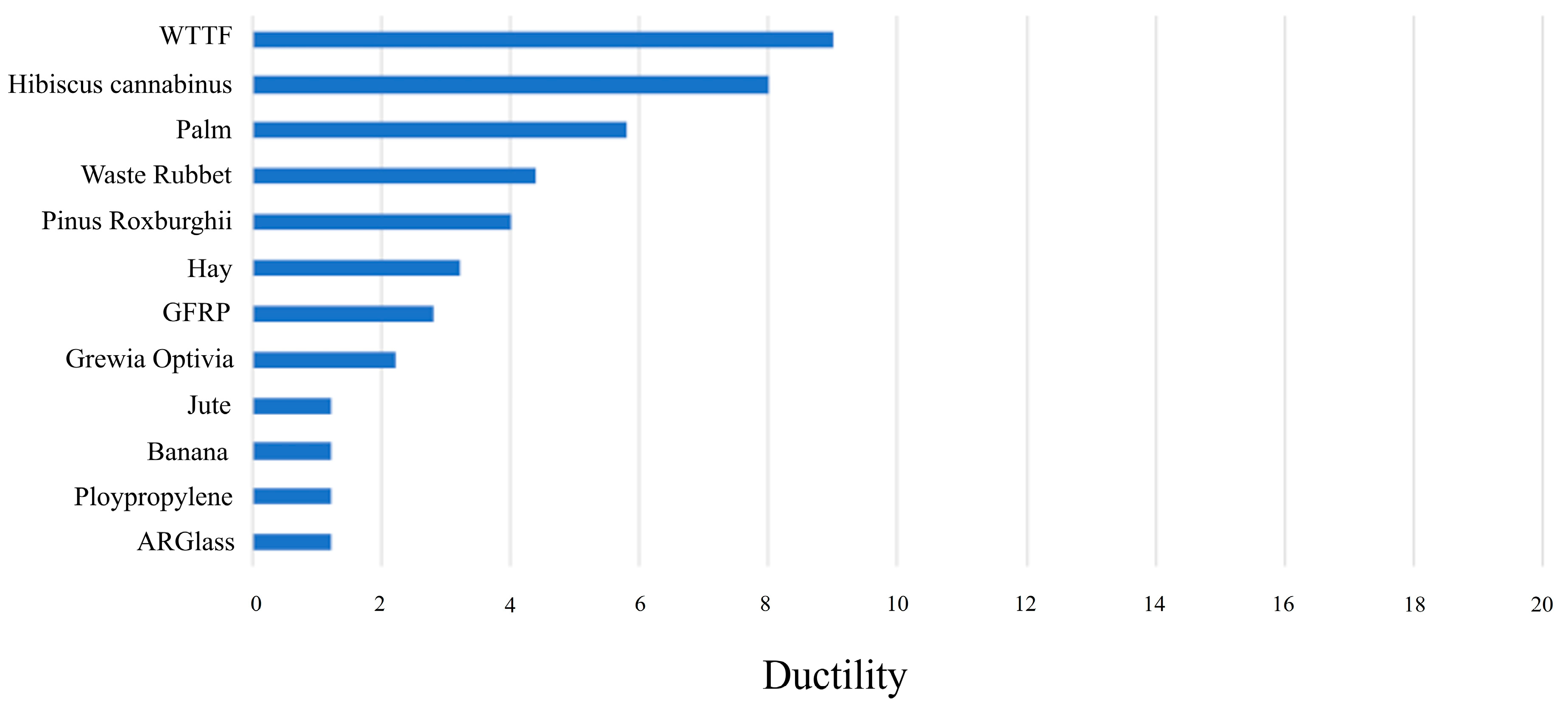

4.3. Composite Modification

5. Research on Thermal and Moisture Performance

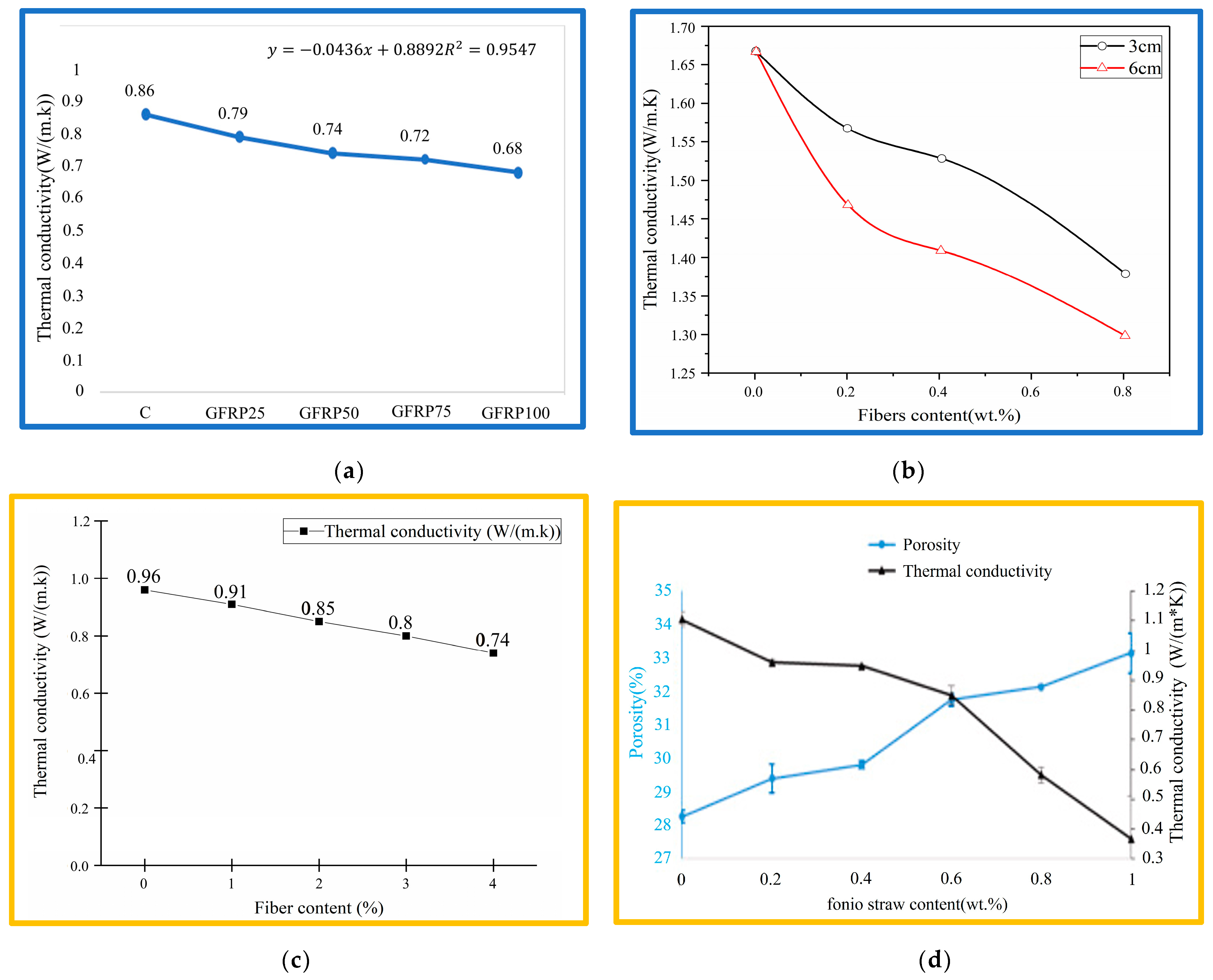

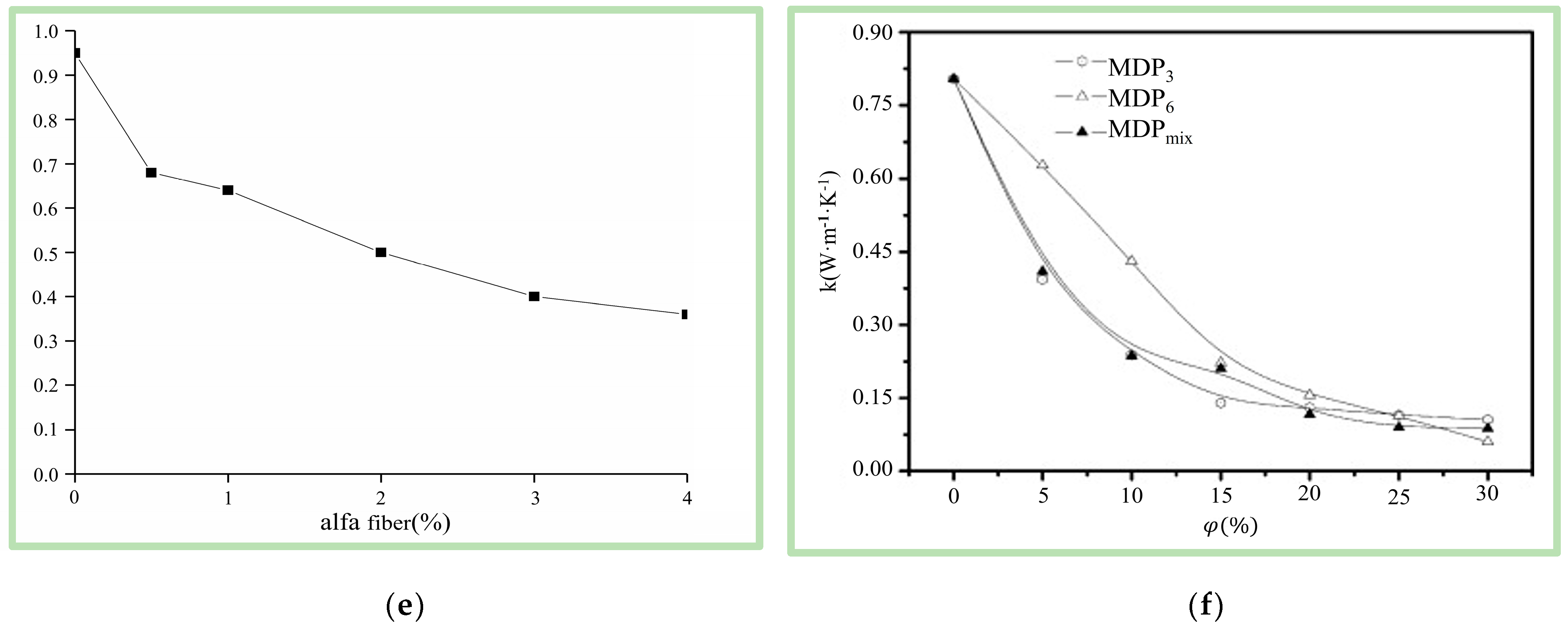

5.1. Thermal Performance Research

5.2. Moisture Performance Research

6. New Perspectives

7. Conclusions

- (1)

- Enhancement of engineering mechanical performance while preserving the thermal and moisture characteristics of earthen materials. Future modifications should target comprehensive performance improvements, not only elevating the mechanical and durability aspects but also holistically considering the effects of modifications, emphasizing the overall enhancement of building performance metrics like resistance to dry–wet cycles, thermal insulation, and heat retention. This contributes to heightened energy efficiency and indoor comfort in constructions.

- (2)

- Application in non-load-bearing structural components of buildings. Deploying earthen materials in load-bearing wall materials often falls short of meeting contemporary architectural demands. Conversely, employing earthen materials in non-load-bearing walls, insulation, and heat retention material areas allows for a more effective utilization of their inherent features such as insulation, moisture regulation, and thermal properties.

- (3)

- Emphasis on research and construction combining local resources in practical application engineering. Currently, most studies are either in the stage of theoretical exploration or improvement research. To effectively apply earthen materials, targeted research is imperative, focusing on local soil resource characteristics, modification methods, performance, durability of earthen wall materials, as well as environmental and economic indicators.

- (4)

- Varied significance of the economic aspect of earthen materials in different scenarios. When selecting earthen materials, a comprehensive consideration of diverse factors is necessary, balancing economic viability with other elements pertinent to specific application contexts. This facilitates the optimal utilization of earthen material advantages and propels their extensive application across different domains.

Author Contributions

Funding

Conflicts of Interest

References

- Meng, X.; Su, X.; Luo, J. Enlightenment and References of Overseas Earth Construction on China. J. Hum. Settl. West China 2019, 34, 104–110. [Google Scholar] [CrossRef]

- Mu, J. Exploring, Renewing and Inheriting the Tradition of Earthen Construction. Archit. J. 2016, 4, 1–7. [Google Scholar]

- Wang, Y.; Liang, J.; Zhang, X.; Zhang, Y.; Gao, Y. Review of raw-soil structure in China. China Civ. Eng. J. 2015, 48, 98–107. [Google Scholar] [CrossRef]

- Jing, Q. Earth construction. Archit. J. 1994, 43–47. [Google Scholar]

- Wang, Y.; Zhong, J.; Shi, Y.; Dengju, K.; Dynasty, Y. Review of overseas research on raw-soil structure. China Civ. Eng. J. 2015, 48, 81–88. [Google Scholar] [CrossRef]

- Wu, C.; Chen, Y.; Wang, X.; Ge, Y.; Han, J.; Chen, C. Modern application strategies and practices of rammed earth materials. Sichuan Archit. 2018, 38, 219–221+223. (In Chinese) [Google Scholar]

- Adegun, O.B.; Adedeji, Y.M.D. Review of economic and environmental benefits of earthen materials for housing in Africa. Front. Archit. Res. 2017, 6, 519–528. [Google Scholar] [CrossRef]

- Reyes, J.C.; Rincon, R.; Yamin, L.E.; Correal, J.F.; Martinez, J.G.; Sandoval, J.D.; Gonzalez, C.D.; Angel, C.C. Seismic retrofitting of existing earthen structures using steel plates. Constr. Build. Mater. 2020, 230, 117039. [Google Scholar] [CrossRef]

- Reyes, J.C.; Smith-Pardo, J.P.; Yamin, L.E.; Galvis, F.A.; Sandoval, J.D.; Gonzalez, C.D.; Correal, J.F. In-plane seismic behavior of full-scale earthen walls with openings retrofitted with timber elements and vertical tensors. Bull. Earthq. Eng. 2019, 17, 4193–4215. [Google Scholar] [CrossRef]

- Reyes, J.C.; Yamin, L.E.; Hassan, W.M.; Sandoval, J.D.; Gonzalez, C.D.; Galvis, F.A. Shear behavior of adobe and rammed earth walls of heritage structures. Eng. Struct. 2018, 174, 526–537. [Google Scholar] [CrossRef]

- Eloundou, L.; Joffroy, T. Earthen Architecture in Today’s World. In Proceedings of the UNESCO International Colloquium on the Conservation of World Heritage Earthen Architecture; UNESCO Publishing: Paris, France, 2013; Available online: www.whc.unesco.org/en/series/36 (accessed on 22 April 2023).

- Van Damme, H.; Houben, H. Earth concrete. Stabilization revisited. Cem. Concr. Res. 2018, 114, 90–102. [Google Scholar] [CrossRef]

- Hu, C. Exploration on the Design of Modern Raw Soil Architecture in MinNan. Master’s Thesis, Xiamen University, Xiamen, China, 2019. [Google Scholar]

- Oubu, K.; Xinfan, H. Foreign soil architecture. World Archit. 1983, 68–71. [Google Scholar] [CrossRef]

- Peiqin, W.; Lock, Z.; Chaijun; Lei, Z.; Chunhua, P.; Jie, Z. To Earth Buildings and Their Structures. Ind. Constr. 2008, 101–105. [Google Scholar]

- Zhao, C.; Akenjiang-Tokhuti. Review of research on vernacular architecture. Sichuan Archit. 2010, 30, 31–33. (In Chinese) [Google Scholar]

- Alzamily, Z.N.; Abed, B.S. Experimental and theoretical investigations of seepage reduction through zoned earth dam material with special core. Mater. Today Proc. 2022, 61, 998–1005. [Google Scholar] [CrossRef]

- Okagbue, C.O.; Onyeobi, T.U.S. Potential of marble dust to stabilise red tropical soils for road construction. Eng. Geol. 1999, 53, 371–380. [Google Scholar] [CrossRef]

- Paul, S.; Sarkar, D. Performance evaluation of natural fiber reinforced Laterite soil for road pavement construction. Mater. Today Proc. 2022, 62, 1246–1251. [Google Scholar] [CrossRef]

- Dong, X.Q. Physical and Mechanical Properties of Modified Soil and Its Application in Raw Soil Construction. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2021. [Google Scholar]

- Guo, L. Experimental Study on Improving the Performance of Raw Soil Materials Based on Physical and Chemical Modification. Master’s Thesis, Shihezi University, Shihezi, China, 2021. [Google Scholar]

- Zhang, F.; Shi, L.; Liu, S.; Shi, J.; Zhang, Y.; Zhang, J. Research on the progress of modification of raw soil building material in China. J. Railw. Sci. Eng. 2022, 19, 2919–2929. [Google Scholar] [CrossRef]

- Zhang, L.; Sang, G. Hygrothermal Comprehensive Property of Soil Based Composite Wall Materials Prepared with Orthogonal Experimental Design. J. Build. Mater. 2020, 23, 372–380. [Google Scholar]

- Available online: www.eartharchitecture.org (accessed on 7 June 2023).

- Liu, Y. Research on the Performance of Construction Waste Recycled Aggregate in Raw-Soil Materials. Master’s Thesis, Beijing Architecture University, Beijing, China, 2022. [Google Scholar]

- Liu, X. The Origin—On the Relevance of Raw Earth Architecture. Northwest Fine Arts 2003, 32–33. [Google Scholar] [CrossRef]

- Cui, L. The Development and Future of Earth Construction. Archit. Cult. 2017, 11. [Google Scholar]

- Zhao, S. Research on the improvement and development of biotechnical engineering. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 1983, 93–103. (In Chinese) [Google Scholar]

- Easton, D. The Rammed Earth House; Chelsea Green Publishing: Chelsea, VT, USA, 2007. [Google Scholar]

- Doat, P.; Hays, A.; Houben, H.; Matuk, S.; Vitoux, F. Building with Earth; The Mud Village Society: New Delhi, India, 1991; pp. 4–11. [Google Scholar]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Shah, T. Investigation of fibre reinforced mud brick as a building material. Constr. Build. Mater. 2005, 19, 313–318. [Google Scholar] [CrossRef]

- Bahar, R.; Benazzoug, M.; Kenai, S. Performance of compacted cement-stabilised soil. Cem. Concr. Compos. 2004, 26, 811–820. [Google Scholar] [CrossRef]

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Alhaik, G.; Dubois, V.; Wirquin, E.; Leblanc, A.; Aouad, G. Evaluate the influence of starch on earth/hemp or flax straws mixtures properties in presence of superplasticizer. Constr. Build. Mater. 2018, 186, 762–772. [Google Scholar] [CrossRef]

- Tourtelot, J.; d’Espinose de Lacaillerie, J.-B.; Duc, M.; Mertz, J.-D.; Bourgès, A.; Keita, E. Strengthening mechanisms of clay building materials by starch. Constr. Build. Mater. 2023, 405, 133215. [Google Scholar] [CrossRef]

- Li, K. The Symbiotic of Construction and Natural—Mechanism of Earth Building; Beijing Institute of Technology: Beijing, China, 2015. [Google Scholar]

- Ge, D. Buildings of “Neo-classicism” in China and Western. Huazhong Archit. 2005, 23, 3. [Google Scholar] [CrossRef]

- Middletown. Neoclassicism and 19th Century Architecture; China Architecture & Building Press: Beijing, China, 2000. [Google Scholar]

- Hou, W. Economic Growth and Environmental Quality in China; Science Press: Beijing, China, 2005. [Google Scholar]

- Wang, J.; Lv, D. To the future of the immature soil buildings. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2001, 2, 147–149. [Google Scholar]

- Maskell, D.; Heath, A.; Walker, P. Laboratory scale testing of extruded earth masonry units. Mater. Des. 2013, 45, 359–364. [Google Scholar] [CrossRef]

- Obonyo, E.; Donkor, P.; Matta, F.; Erdogmus, E. Challenges, opportunities, and solutions in low-cost building envelopes: A case study of low-strength masonry systems. In Proceedings of the Construction Research Congress 2014: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; pp. 564–573. [Google Scholar]

- Wu, E.; Mu, J. Maosi Ecological Demonstration Primary School, Maosi Village, Qingyang, Gansu Province, China, 2007. World Archit. 2008, 34–43. [Google Scholar] [CrossRef]

- Wu, E.; Mu, J. Building from the Land—Maoji Eco-Experimental Primary School. Cities Towns Constr. Guangxi 2013, 56–61. (In Chinese) [Google Scholar]

- Wang, Y.; Gao, X.; Wang, X.; Hui, Y. Cost Analysis of Reinforcement and Reconstruction for the Residence of Raw-Soil Structures. Build. Sci. 2011, 27, 6–9. [Google Scholar] [CrossRef]

- Wu, E.; Mu, J. Practical Study of Ecological Architecture Based on Traditional Construction Technology Maosi Ecological Demonstration Primary School and Bridge Too Far. Time Archit. 2007, 4, 50–57. [Google Scholar]

- Chen, J.; Shan, D. Advance Guard of Aborigines—Vernacular Settlements in the View of Land-Art. Architect 2005, 41–47. [Google Scholar]

- Mao, D. County as an Example Wisdom—Take Baishe Village in Sanyuan from the Perspective of Ecological of Pit Courtyard Village Soil Resources Research on Disaster Prevention Strategies. Master’s Thesis, Ji Lin Jian Zhu University, Changchun, China, 2022. [Google Scholar]

- Morton, T.; Stevenson, F.; Taylor, B.; Smith, N.C. Low Cost Earth Brick Construction; Arc Chartered Architects, Fife: Dalguise, Scotland, 2005. [Google Scholar]

- Dachverband Lehm eV. Lehmbau Verbraucherinformation; Dachverband Lehm eV: Weimar, Germany, 2004. [Google Scholar]

- Schroeder, H. Konstruktion und Ausführung von Mauerwerk aus Lehmsteinen. Mauerwerkkalender 2009, 2009, 271–290. [Google Scholar]

- Adam, E.; Jones, P. Thermophysical properties of stabilised soil building blocks. Build. Environ. 1995, 30, 245–253. [Google Scholar] [CrossRef]

- El Fgaier, F.; Lafhaj, Z.; Antczak, E.; Chapiseau, C. Dynamic thermal performance of three types of unfired earth bricks. Appl. Therm. Eng. 2016, 93, 377–383. [Google Scholar] [CrossRef]

- Oyeyemi, K.D.; Sanuade, O.; Oladunjoye, M.; Aizebeokhai, A.; Olaojo, A.; Fatoba, J.; Olofinnade, O.; Ayara, W.A.; Oladapo, O. Data on the thermal properties of soil and its moisture content. Data Brief 2018, 17, 900–906. [Google Scholar] [CrossRef]

- Randazzo, L.; Montana, G.; Hein, A.; Castiglia, A.; Rodonò, G.; Donato, D. Moisture absorption, thermal conductivity and noise mitigation of clay based plasters: The influence of mineralogical and textural characteristics. Appl. Clay Sci. 2016, 132, 498–507. [Google Scholar] [CrossRef]

- Minke, G. Building with Earth: Design and Technology of a Sustainable Architecture; Fourth and revised edition; Birkhäuser: Basel, Switzerland, 2021. [Google Scholar]

- Saeidpour, M.; Wadsö, L. Comparison of moisture equilibrium of cement-based materials in presence of slag and silica fume in different wetting and drying cycles. In Proceedings of the 1st International Conference on Construction Materials and Structures, Johannesburg, South Africa, 24–26 November 2014. [Google Scholar]

- Minke, G. Earth Construction Handbook: The Building Material Earth in Modern Architecture; WIT Press: Billerica, MA, USA, 2000. [Google Scholar]

- Allinson, D.; Hall, M. Hygrothermal analysis of a stabilised rammed earth test building in the UK. Energy Build. 2010, 42, 845–852. [Google Scholar] [CrossRef]

- Berge, B. The Ecology of Building Materials; Routledge: Oxford, UK, 2009. [Google Scholar]

- Brambilla, A.; Jusselme, T. Preventing overheating in offices through thermal inertial properties of compressed earth bricks: A study on a real scale prototype. Energy Build. 2017, 156, 281–292. [Google Scholar] [CrossRef]

- Fabbri, A.; Morel, J.C. Earthen materials and constructions. In Nonconventional and Vernacular Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 273–299. [Google Scholar]

- Rashidi, S.; Esfahani, J.A.; Karimi, N. Porous materials in building energy technologies—A review of the applications, modelling and experiments. Renew. Sustain. Energy Rev. 2018, 91, 229–247. [Google Scholar] [CrossRef]

- Li, G. Development and Application of Chinese Traditional Rammed Earth Technology. Study Nat. Cult. Herit. 2019, 4, 94–99. [Google Scholar] [CrossRef]

- Jaquin, P.; Augarde, C.; Gallipoli, D.; Toll, D. The strength of unstabilised rammed earth materials. Géotechnique 2009, 59, 487–490. [Google Scholar] [CrossRef]

- Jayasinghe, C.; Kamaladasa, N. Compressive strength characteristics of cement stabilized rammed earth walls. Constr. Build. Mater. 2007, 21, 1971–1976. [Google Scholar] [CrossRef]

- Maniatidis, V.; Walker, P. Structural capacity of rammed earth in compression. J. Mater. Civ. Eng. 2008, 20, 230–238. [Google Scholar] [CrossRef]

- Peng, D. Research on Rammed Earth House Wall Test and Structural Performance Improvement Technology. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2012. [Google Scholar]

- Zhang, B.; Wang, Y.; Xue, L. Modification experimental research on rammed earth material for Hanzhong rural traditional houses. New Build. Mater. 2017, 44, 64–66. [Google Scholar]

- Zhao, C. Compressive Strength Test Study of Modified Adobe Masonry. Master’s Thesis, Xinjiang University, Ürümqi, China, 2010. [Google Scholar]

- Khadka, B.; Shakya, M. Comparative compressive strength of stabilized and un-stabilized rammed earth. Mater. Struct. 2016, 49, 3945–3955. [Google Scholar] [CrossRef]

- Morel, J.-C.; Pkla, A.; Walker, P. Compressive strength testing of compressed earth blocks. Constr. Build. Mater. 2007, 21, 303–309. [Google Scholar] [CrossRef]

- Silveira, D.; Varum, H.; Costa, A.; Martins, T.; Pereira, H.; Almeida, J. Mechanical properties of adobe bricks in ancient constructions. Constr. Build. Mater. 2012, 28, 36–44. [Google Scholar] [CrossRef]

- Wu, F.; Li, G.; Li, H.-N.; Jia, J.-Q. Strength and stress–strain characteristics of traditional adobe block and masonry. Mater. Struct. 2013, 46, 1449–1457. [Google Scholar] [CrossRef]

- Kumar, P.P. Stabilised Rammed Earth for Walls: Materials, Compressive Strength and Elastic Properties. Ph.D. Thesis, Indian Institute of Science, Bengaluru, India, 2011. [Google Scholar]

- Bui, Q.-B.; Morel, J.-C.; Reddy, B.V.; Ghayad, W. Durability of rammed earth walls exposed for 20 years to natural weathering. Build. Environ. 2009, 44, 912–919. [Google Scholar] [CrossRef]

- Heathcote, K. Durability of earthwall buildings. Constr. Build. Mater. 1995, 9, 185–189. [Google Scholar] [CrossRef]

- Narloch, P.; Woyciechowski, P.; Dmowska, E.; Halemba, K. Durability assessment of monolithic rammed earth walls. Arch. Civ. Eng. 2015, 61, 73–88. [Google Scholar] [CrossRef]

- Liu, X. Effect of Construction Waste Recycled Fine Powder on Properties of Raw Soil Materials. Sci. Technol. Innov. 2022, 81–84. [Google Scholar]

- Yang, J. Building Materials and Human Settlements; Tsinghua University Press Ltd.: Beijing, China, 2001; Volume 2. [Google Scholar]

- Ciancio, D.; Jaquin, P.; Walker, P. Advances on the assessment of soil suitability for rammed earth. Constr. Build. Mater. 2013, 42, 40–47. [Google Scholar] [CrossRef]

- Hall, M.; Najim, K.; Dehdezi, P.K. Soil stabilisation and earth construction: Materials, properties and techniques. In Modern Earth Buildings; Elsevier: Amsterdam, The Netherlands, 2012; pp. 222–255. [Google Scholar]

- Tan, W.; Wang, Y.; Chen, Y. Current status of research on soil-curing materials. J. China Foreign Highw. 2004, 24, 4. (In Chinese) [Google Scholar]

- Ding, S.; Wang, W.; Yang, D.; Wu, C. Research progress and application of modification of raw soil building materials. Build. Block Block Constr. 2014, 45–48+51. [Google Scholar] [CrossRef]

- Hossain, K.; Lachemi, M.; Easa, S. Stabilized soils for construction applications incorporating natural resources of Papua New Guinea. Resour. Conserv. Recycl. 2007, 51, 711–731. [Google Scholar] [CrossRef]

- Al-Amoudi, O.S.B.; Khan, K.; Al-Kahtani, N.S. Stabilization of a Saudi calcareous marl soil. Constr. Build. Mater. 2010, 24, 1848–1854. [Google Scholar] [CrossRef]

- Parracha, J.L.; Silva, A.S.; Cotrim, M.; Faria, P. Mineralogical and microstructural characterisation of rammed earth and earthen mortars from 12th century Paderne Castle. J. Cult. Herit. 2020, 42, 226–239. [Google Scholar] [CrossRef]

- Espinosa, I.V.; Ortega, E.O.; Pardo, E.S. El tapial de las murallas de Granada. Re. Rev. Edif. 2019, 26, 58–63. [Google Scholar]

- de la Torre López, M.J.; Sebastián, P.E.; Rodríguez, G.J. A study of the wall material in the alhambra (Granada, Spain). Cem. Concr. Res. 1996, 26, 825–839. [Google Scholar] [CrossRef]

- Naoual, G.; Khalid, R.k.C.; Mouncif, I.; Fabio, F.; Luisa, R.; Ugo, T.; Mohammed, M.; Lehcen, D.; Claude, F.; Nasrrddine, Y. The particular “rammed earth” of the Saadian sugar refinery of Chichaoua (XVIth century, Morocco): Mineralogical, chemical and mechanical characteristics. Environ. Earth Sci. 2012, 66, 129–140. [Google Scholar]

- Cuisinier, O.; Deneele, D.; Masrouri, F. Shear strength behaviour of compacted clayey soils percolated with an alkaline solution. Eng. Geol. 2009, 108, 177–188. [Google Scholar] [CrossRef]

- Jha, A.K.; Sivapullaiah, P.V. Lime Stabilization of Soil: A Physico-Chemical and Micro-Mechanistic Perspective. Indian Geotech. J. 2019, 50, 339–347. [Google Scholar] [CrossRef]

- Croft, J. The structures of soils stabilized with cementitious agents. Eng. Geol. 1967, 2, 63–80. [Google Scholar] [CrossRef]

- Croft, J. The problem in predicting the suitability of soils for cementitious stabilization. Eng. Geol. 1968, 2, 397–424. [Google Scholar] [CrossRef]

- Rogers, C.; Glendinning, S. The role of lime migration in lime pile stabilization of slopes. Q. J. Eng. Geol. Hydrogeol. 1996, 29, 273–284. [Google Scholar] [CrossRef]

- Hao, C. Study on Effects of the Modification Method for the Durability of Adobe Wall Materials. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2011. [Google Scholar]

- Wang, B. Experimental Study on Durability of Rammed Earth Construction Materials. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2006. [Google Scholar]

- Yang, Y.; Zhang, S.; Rong, H.; Zhang, L.; Zhang, Y.; Xu, R.; Wang, X.; Yang, J. Study on modification effect and mechanism of lime-based materials on raw soil. J. Funct. Mater. 2019, 50, 4067–4073. [Google Scholar]

- Ke, S.; Hu, M.; Li, Y.; Liu, Z.; Ye, X. Humidity-controlling Performance and Thermal Conductivity of New Raw Soil Materials. Sci. Technol. Eng. 2019, 19, 134–138. [Google Scholar]

- Ávila, F.; Puertas, E.; Gallego, R. Mechanical characterization of lime-stabilized rammed earth: Lime content and strength development. Constr. Build. Mater. 2022, 350, 128871. [Google Scholar] [CrossRef]

- Yin, D. Study on Gypsum-Based Modified Raw Soil Building Materials. Master’s Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Isik, B.; Tulbentci, T. Sustainable housing in island conditions using Alker-gypsum-stabilized earth: A case study from northern Cyprus. Build. Environ. 2008, 43, 1426–1432. [Google Scholar] [CrossRef]

- Chen, T. The Study on Construction Technology and Optimization Application of Rammed Earth Wall in Traditional I Village Dwellings. Master’s Thesis, Chongqing University, Chongqing, China, 2018. [Google Scholar]

- Mansour, M.B.; Ogam, E.; Jelidi, A.; Cherif, A.S.; Jabrallah, S.B. Influence of compaction pressure on the mechanical and acoustic properties of compacted earth blocks: An inverse multi-parameter acoustic problem. Appl. Acoust. 2017, 125, 128–135. [Google Scholar] [CrossRef]

- Nagaraj, H.; Sravan, M.; Arun, T.; Jagadish, K. Role of lime with cement in long-term strength of Compressed Stabilized Earth Blocks. Int. J. Sustain. Built Environ. 2014, 3, 54–61. [Google Scholar] [CrossRef]

- Ruiz, G.; Zhang, X.; Edris, W.F.; Cañas, I.; Garijo, L. A comprehensive study of mechanical properties of compressed earth blocks. Constr. Build. Mater. 2018, 176, 566–572. [Google Scholar] [CrossRef]

- Sore, S.O.; Messan, A.; Prud’Homme, E.; Escadeillas, G.; Tsobnang, F. Stabilization of compressed earth blocks (CEBs) by geopolymer binder based on local materials from Burkina Faso. Constr. Build. Mater. 2018, 165, 333–345. [Google Scholar] [CrossRef]

- Zak, P.; Ashour, T.; Korjenic, A.; Korjenic, S.; Wu, W. The influence of natural reinforcement fibers, gypsum and cement on compressive strength of earth bricks materials. Constr. Build. Mater. 2016, 106, 179–188. [Google Scholar] [CrossRef]

- Reddy, B.V.; Kumar, P.P. Cement stabilised rammed earth. Part B: Compressive strength and stress-strain characteristics. Mater. Struct. 2011, 44, 695. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Yang, J.; Chen, B. Experimental Research on Properties of Raw Soil Modified by Geopolymeric Cement. Bull. Chin. Ceram. Soc. 2016, 35, 73–77. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B. Loess stabilization using cement, waste phosphogypsum, fly ash and quicklime for self-compacting rammed earth construction. Constr. Build. Mater. 2020, 231, 117195. [Google Scholar] [CrossRef]

- Ding, S.; Wang, W.; Yang, D. Modified testing study of bonding materials used on earth blocks. New Build. Mater. 2016, 43, 75–79. [Google Scholar]

- Yang, Y.; Zhang, S.; Hui, R.; Zhang, L.; Zhang, Y.; Xu, R.; Wang, X.; Yang, J. Modification Effect and Mechanism of Cement-Based Materials on Raw Soil. Bull. Chin. Ceram. Soc. 2019, 38, 929–936. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Chen, B. Experimental Study on Properties of Modified Raw Soil Material adding Phosphogypsum and Fly Ash. Fly Ash Compr. Util. 2016, 1, 3–6+11. [Google Scholar]

- Chen, Q. Experimental Study on Properties of Modified Raw Soil Material. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2017. [Google Scholar]

- Islam, M.S.; Elahi, T.E.; Shahriar, A.R.; Mumtaz, N. Effectiveness of fly ash and cement for compressed stabilized earth block construction. Constr. Build. Mater. 2020, 255, 119392. [Google Scholar] [CrossRef]

- Saranya, R.S.; Sharma, A.K.; Anand, K.B. Performance appraisal of coal ash stabilized rammed earth. J. Build. Eng. 2018, 18, 51–57. [Google Scholar]

- Du, Y.J.; Yu, B.W.; Liu, K.; Jiang, N.J.; Liu, M.D. Physical, Hydraulic, and Mechanical Properties of Clayey Soil Stabilized by Lightweight Alkali-Activated Slag Geopolymer. J. Mater. Civ. Eng. 2017, 19, 04016217. [Google Scholar] [CrossRef]

- Singhi, B.; Laskar, A.I.; Ahmed, M.A. Mechanical Behavior and Sulfate Resistance of Alkali Activated Stabilized Clayey Soil. Geotech. Geol. Eng. 2017, 35, 1907–1920. [Google Scholar] [CrossRef]

- Kariyawasam, K.K.G.K.D.; Jayasinghe, C. Cement stabilized rammed earth as a sustainable construction material. Constr. Build. Mater. 2016, 105, 519–527. [Google Scholar] [CrossRef]

- Shang, J. Optimization Study of Ecological Building Material System of Traditional Rammed Earth Dwelling. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2005. [Google Scholar]

- Wang, Q. Research on the Modification of Raw Soil Materials. Master’s Thesis, Chongqing University, Chongqing, China, 2009. [Google Scholar]

- Degirmenci, N.; Baradan, B. Chemical resistance of pozzolanic plaster for earthen walls. Constr. Build. Mater. 2005, 19, 536–542. [Google Scholar] [CrossRef]

- Basu, I.; Al-Samman, T. Triggering rare earth texture modification in magnesium alloys by addition of zinc and zirconium. Acta Mater. 2014, 67, 116–133. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, L.; Ma, X.; He, J.; Zhu, S. Strength Characteristic of Stabilized Earth Material under Freezing and Thawing Cycle. Bull. Chin. Ceram. Soc. 2016, 35, 2094–2100. [Google Scholar] [CrossRef]

- Assia, Z.; Fazia, F.; Abdelmadjid, H. Sustainability of the stabilized earth blocs under chemicals attack’s effects and environmental conditions. Constr. Build. Mater. 2019, 212, 787–798. [Google Scholar] [CrossRef]

- Ke, S. Study on the New Raw Soil Materials. Master’s Thesis, Nanchang University, Nanchang, China, 2015. [Google Scholar]

- Narloch, P.; Woyciechowski, P. Assessing Cement Stabilized Rammed Earth Durability in A Humid Continental Climate. Buildings 2020, 10, 26. [Google Scholar] [CrossRef]

- Mesbah, A.; Morel, J.; Walker, P.; Ghavami, K. Development of a direct tensile test for compacted earth blocks reinforced with natural fibers. J. Mater. Civ. Eng. 2004, 16, 95–98. [Google Scholar] [CrossRef]

- RG, E.; Mabiala, B.; Ahouet, L.; Goma-Maniongui, J.; GF, D. Characterization of clayey soils from congo and physical properties of their compressed earth blocks reinforced with post-consumer plastic wastes. Geomaterials 2011, 1, 88–94. [Google Scholar]

- Rigassi, V. Compressed Earth Blocks: Manual of Production; CRATerre-EAG: Vilefontaine, France, 1995; Volume I. [Google Scholar]

- Wang, Y.; Wu, Q.; Wang, T.; Liu, F.; Zhang, K. Analysis for effects of gravel contents on compression behavior of raw-soil specimens. Build. Struct. 2017, 47, 76–79. [Google Scholar] [CrossRef]

- Liu, F. Experimental Study on Compressive Strength of Raw Soil Material Modified by Stones, Sand and Cement. Master’s Thesis, Chang’an University, Xi’an, China, 2017. [Google Scholar]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant aggregates and fibers in earth construction materials: A review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Bouhicha, M.; Aouissi, F.; Kenai, S. Performance of composite soil reinforced with barley straw. Cem. Concr. Compos. 2004, 27, 617–621. [Google Scholar] [CrossRef]

- Zare, P.; Narani, S.S.; Abbaspour, M.; Fahimifar, A.; Hosseini, S.M.M.M.; Zare, P. Experimental investigation of non-stabilized and cement-stabilized rammed earth reinforcement by Waste Tire Textile Fibers (WTTFs). Constr. Build. Mater. 2020, 260, 120432. [Google Scholar] [CrossRef]

- Tang, C.S.; Pei, X.J.; Wang, D.Y.; Shi, B.; Jian, L. Tensile Strength of Compacted Clayey Soil. J. Geotech. Geoenviron. Eng. 2014, 141, 04014122. [Google Scholar] [CrossRef]

- Kolathayar, S.; Prasannan, S.; Sharma, A.K. Strength Tests and Model Experiments on Soil Reinforced with Areca and PVA Fibers. In Geotechnical Characterization and Modelling: Proceedings of IGC 2018; Springer: Singapore, 2020. [Google Scholar]

- Kim, Y.; Kim, H.; Lee, G. Mechanical behavior of lightweight soil reinforced with waste fishing net. Geotext. Geomembr. 2008, 26, 512–518. [Google Scholar] [CrossRef]

- Illampas, R.; Silva, R.A.; Charmpis, D.C.; Lourenço, P.B.; Ioannou, I. Validation of the repair effectiveness of clay-based grout injections by lateral load testing of an adobe model building. Constr. Build. Mater. 2017, 153, 174–184. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Devi, S.S. Reinforced soil blocks: Viable option for low cost building units. Constr. Build. Mater. 2018, 189, 1124–1133. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing sustainability of rural adobe houses of hills by addition of vernacular fiber reinforcement. Int. J. Sustain. Built Environ. 2015, 4, 348–358. [Google Scholar] [CrossRef]

- Mohamed, A.E.M.K. Improvement of swelling clay properties using hay fibers. Constr. Build. Mater. 2013, 38, 242–247. [Google Scholar] [CrossRef]

- Gandia, R.M.; Gomes, F.C.; Corrêa, A.A.R.; Rodrigues, M.C.; Mendes, R.F. Physical, mechanical and thermal behavior of adobe stabilized with glass fiber reinforced polymer waste. Constr. Build. Mater. 2019, 222, 168–182. [Google Scholar] [CrossRef]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- Jiesheng, L.; Juan, Z.; Lin, X. Deformation and strength characteristics of sisal fibrous soil. Electron. J. Geotech. Eng. 2014, 19, 1585–1594. [Google Scholar]

- Malekzadeh, M.; Bilsel, H. Swell and Compressibility of fiber reinforced expansive soils. Int. J. Adv. Technol. Civ. Eng. 2012, 1, 42–45. [Google Scholar] [CrossRef]

- Otoko, G.R.; Pedro, P.P. Cement Stabilization of Laterite and Chikoko Soils Using Waste Rubber Fibre. Int. J. Eng. Sci. Res. Technol. 2014, 3, 130–136. [Google Scholar]

- Segetin, M.; Jayaraman, K.; Xu, X. Harakeke reinforcement of soil–cement building materials: Manufacturability and properties. Build. Environ. 2007, 42, 3066–3079. [Google Scholar] [CrossRef]

- Islam, M.S.; Iwashita, K. Earthquake Resistance of Adobe Reinforced by Low Cost Traditional Materials. J. Nat. Disaster Sci. 2010, 32, 1–21. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Pullen, Q.M. Strength and Composition of Willamette Valley Cob: An Earthen Building Material. Bachelor Thesis, Oregon State University, Corvallis, OR, USA, 2009. [Google Scholar]

- Velasco-Aquino, A.A.; Espuna-Mujica, J.A.; Perez-Sanchez, J.F.; Zuñiga-Leal, C.; Palacio-Perez, A.; Suarez-Dominguez, E.J. Compressed earth block reinforced with coconut fibers and stabilized with aloe vera and lime. J. Eng. Des. Technol. 2021, 19, 795–807. [Google Scholar] [CrossRef]

- Yang, J.; Gu, X. Local Compression Property of Rammed Earth Wall with Bamboo Cane Based on ANSYS. J. Guizhou Univ. (Nat. Sci.) 2015, 32, 70–74+78. [Google Scholar] [CrossRef]

- Jamsawang, P.; Suansomjeen, T.; Sukontasukkul, P.; Jongpradist, P.; Bergado, D.T. Comparative flexural performance of compacted cement-fiber-sand. Geotext. Geomembr. 2018, 46, 414–425. [Google Scholar] [CrossRef]

- Jové-Sandoval, F.; Barbero-Barrera, M.M.; Medina, N.F. Assessment of the mechanical performance of three varieties of pine needles as natural reinforcement of adobe. Constr. Build. Mater. 2018, 187, 205–213. [Google Scholar] [CrossRef]

- Youchao, Z.; Yihong, W.; Nana, Z.; Tianya, W. Experimental and Stress-Strain Equation Investigation on Compressive Strength of Raw and Modified Soil in Loess Plateau. Adv. Mater. Sci. Eng. 2016, 2016, 2681038. [Google Scholar]

- Kong, L.; Bao, A.; Luo, S.; Wang, C. Experimental study on modification of Chongqing rural area earth construction wall materials. New Build. Mater. 2017, 44, 45–48+67. [Google Scholar]

- Li, Z.; Yuan, K.; Wang, Y.; Bai, H. Experimental Study on Mixture Ratio of Modified Raw-soil Blocks. Non-Met. Mines 2017, 40, 47–49. [Google Scholar]

- Gomes, M.I.; Faria, P.; Gonçalves, T.D. Earth-based mortars for repair and protection of rammed earth walls. Stabilization with mineral binders and fibers. J. Clean. Prod. 2018, 172, 2401–2414. [Google Scholar] [CrossRef]

- Shen, W. Research on Optimum Mix Proportion and Modification Mechanism of Raw Soil Materials Based on Orthogonal Tests. Bull. Chin. Ceram. Soc. 2018, 37, 3712–3716. [Google Scholar] [CrossRef]

- Zhang, X.; Fang, C.; Lian, Y. Study on comprehensive force-thermal-humidity performance of raw soil-based modified building materials. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2017, 49, 87–91. [Google Scholar] [CrossRef]

- Millogo, Y.; Morel, J.C.; Aubert, J.E.; Ghavami, K. Experimental analysis of Pressed Adobe Blocks reinforced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Babé, C.; Kidmo, D.K.; Tom, A.; Mvondo, R.R.N.; Boum, R.B.E.; Djongyang, N. Thermomechanical characterization and durability of adobes reinforced with millet waste fibers (sorghum bicolor). Case Stud. Constr. Mater. 2020, 13, e00422. [Google Scholar] [CrossRef]

- Ouedraogo, M.; Dao, K.; Millogo, Y.; Aubert, J.E.; Messan, A.; Seynou, M.; Zerbo, L.; Gomina, M. Physical, thermal and mechanical properties of adobes stabilized with fonio (Digitaria exilis) straw. J. Build. Eng. 2019, 23, 250–258. [Google Scholar] [CrossRef]

- Elhamdouni, Y.; Khabbazi, A.; Benayad, C.; Dadi, A.; Ahmid, O.I. Effect of Fiber Alfa on Thermophysical Characteristics of a Material based on Clay. Energy Procedia 2015, 74, 718–727. [Google Scholar] [CrossRef]

- Saidi, M.; Cherif, A.S.; Zeghmati, B.; Sediki, E. Stabilization effects on the thermal conductivity and sorption behavior of earth bricks. Constr. Build. Mater. 2018, 167, 566–577. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, N.; Zhang, L.; Rong, H.; Wei, C. Influence of Modified Materials on Hygrothermal Properties of Raw Soil Block. J. Build. Mater. 2021, 24, 313–317+361. [Google Scholar] [CrossRef]

- Zhang, L.; Sang, G.; Cui, X.; Han, W.; Guo, X. Hygrothermal properties of cement stabilized earth material and both temperature and relative humidity distribution of wall underperiodic boundary conditions. J. Xi’an Univ. Technol. 2022, 38, 96–104. [Google Scholar] [CrossRef]

- Mansour, M.B.; Jelidi, A.; Cherif, A.S.; Jabrallah, S.B. Optimizing thermal and mechanical performance of compressed earth blocks (CEB). Constr. Build. Mater. 2016, 104, 44–51. [Google Scholar] [CrossRef]

- Liu, C. Effect of dry density on the thermal conductivity of raw earth materials and analysis of the applicability of the test method. Qinghai Sci. Technol. 2019, 26, 5. (In Chinese) [Google Scholar]

- Hall, M.; Allinson, D. Assessing the effects of soil grading on the moisture content-dependent thermal conductivity of stabilised rammed earth materials. Appl. Therm. Eng. 2008, 29, 740–747. [Google Scholar] [CrossRef]

- Tang, A.-M.; Cui, Y.-J.; Le, T.-T. A study on the thermal conductivity of compacted bentonites. Appl. Clay Sci. 2007, 41, 181–189. [Google Scholar] [CrossRef]

- Liuzzi, S.; Stefanizzi, P. Fundamental Parameters of Heat and Moisture Transfer for Energy Efficiency in Buildings. Key Eng. Mater. 2014, 632, 79–93. [Google Scholar] [CrossRef]

- Cagnon, H.; Aubert, J.-E.; Coutand, M.; Magniont, C. Hygrothermal properties of earth bricks. Energy Build. 2014, 80, 208–217. [Google Scholar] [CrossRef]

- Ashour, T.; Korjenic, A.; Korjenic, S. Equilibrium moisture content of earth bricks biocomposites stabilized with cement and gypsum. Cem. Concr. Compos. 2015, 59, 18–25. [Google Scholar] [CrossRef]

- Taallah, B.; Guettala, A.; Guettala, S.; Kriker, A. Mechanical properties and hygroscopicity behavior of compressed earth block filled by date palm fibers. Constr. Build. Mater. 2014, 59, 161–168. [Google Scholar] [CrossRef]

- Shang, J.; Ma, X.; Zhang, L. Performance of Humidity Controlling of Modified Soil Materials and Structure Analysis. Bull. Chin. Ceram. Soc. 2015, 34, 3413–3417. [Google Scholar] [CrossRef]

- Xia, W. Optimization of Proportion Earth Modified Wall Material and Analysis on the Thermal and Humidity Properties. Master’s Thesis, Southwest University of Science and Technology, Mianyang, China, 2021. [Google Scholar]

- Hu, M.; Fu, C.; Wei, L.; Guo, X. Investigation of the humidity-controlling performance and mechanism of raw soil materials. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2017, 49, 790–795. [Google Scholar] [CrossRef]

- Mcgregor, F.; Heath, A.; Shea, A.; Lawrence, M. The moisture buffering capacity of unfired clay masonry. Build. Environ. 2014, 82, 599–607. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, L.; Jelle, B.P.; Wang, Y.; Gustavsen, A. Hygrothermal properties of compressed earthen bricks. Constr. Build. Mater. 2018, 162, 576–583. [Google Scholar] [CrossRef]

- Jiang, B.; Wu, T.; Xia, W.; Liang, J. Hygrothermal performance of rammed earth wall in Tibetan Autonomous Prefecture in Sichuan Province of China. Build. Environ. 2020, 181, 107128. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Jiang, S.; Quan, D.; Fang, K.; Wang, B.; Ma, Z. Properties of Sustainable Earth Construction Materials: A State-of-the-Art Review. Sustainability 2024, 16, 670. https://doi.org/10.3390/su16020670

Zhang Y, Jiang S, Quan D, Fang K, Wang B, Ma Z. Properties of Sustainable Earth Construction Materials: A State-of-the-Art Review. Sustainability. 2024; 16(2):670. https://doi.org/10.3390/su16020670

Chicago/Turabian StyleZhang, Youchao, Shuangli Jiang, Dengzhou Quan, Kun Fang, Bo Wang, and Zhiming Ma. 2024. "Properties of Sustainable Earth Construction Materials: A State-of-the-Art Review" Sustainability 16, no. 2: 670. https://doi.org/10.3390/su16020670

APA StyleZhang, Y., Jiang, S., Quan, D., Fang, K., Wang, B., & Ma, Z. (2024). Properties of Sustainable Earth Construction Materials: A State-of-the-Art Review. Sustainability, 16(2), 670. https://doi.org/10.3390/su16020670