Abstract

Due to the complexity and dynamics of underground construction projects, safety risk management has experienced significant challenges restricting the sustainable development of underground space. The research on risk causal chains and risk coupling has yet to reveal the dynamic interactive characteristics of these risk factors and their temporal relationships over time. This study utilized a complex system view for safety risk analysis, using 37 accident investigation reports of underground construction projects. Combined with two novel and emerging analytical methods, temporal qualitative comparative analysis and crisp-set qualitative comparative analysis, this study discusses the temporal relationship of risk factors to the cause of accidents and explores the multi-actor coupling characteristics of management risk. The findings indicate that (1) compared with general construction projects, underground construction should pay more attention to management safety risks because they have an obvious time lag effect expressed in all accident causation paths, namely, preceding management risk, management risk, and machine/material risk cross-concurrently, and management risk initiation and (2) underground construction project management risks have three key main paths, namely, single-actor-dominated management deficiency (supervisors, owners, and subcontractors that cause management risks as a single-core actor) and dual-actor-dominated management deficiency (owner and subcontractor as dual core actors of management risk). Multi-actor-dominated management deficiency (owners, subcontractors, and supervisors are the multiple core actors of management risk). This study thus developed a temporal governance framework of underground construction safety risks based on the synergy of multi-actors and proposed risk governance strategies, such as synergistic multi-actor governance, to consider the temporal relationship of safety risk. This study further reveals the temporal and coupling characteristics of safety risks to enrich the risk casual chain theory and risk coupling theory and establish a systematic risk analysis framework for new guidance for safety and risk management for underground construction projects.

1. Introduction

A construction project is a complex system with multiple interactions between actors, materials, and the environment that are all involved in the construction project. The safety risks caused by such relationships are particularly prone to safety accidents and difficult to control [1,2,3]. In particular, underground construction projects are also more prone to safety risk accidents due to their complex construction technology, large excavation depth, unstable geological conditions, and numerous actors [4,5,6,7]. In 2021, there were 5190 fatal workplace injuries in the U.S., with the second-highest number of deaths being in construction and extractive industries related to underground projects [8]. As the largest emerging economy, underground construction accidents, which are mainly earthwork and foundation pit collapse, accounted for 30.43% of the major accidents in China in 2020 [9]. However, prior research on underground projects mainly focused on rail transit, and most of them focused on an analysis of risk factors related to construction technology [10,11,12]. Also, the interactive characteristics and temporal characteristics of these risk factors have not been examined from a holistic perspective. Therefore, it is of great theoretical and practical significance to effectively identify the safety risk factors and causative path of such construction to achieve sustainable development of underground spaces.

The development and application of accident-causing theory and risk coupling theory in underground construction project safety management both play a significant role in identifying safety risks and preventing safety accidents [13,14]. However, analysis of the causal chain theory and risk coupling theory of existing safety accidents cannot effectively enough adapt to the dynamic characteristics of underground construction safety risks. Applying the causal chain theory, the temporal characteristics of the risk causative chain are static, and the leading factor of accidents is always management risk, while the direct factor is always operator risk [15]. Thus, prior research based on causal chain theory and risk coupling theory does not reflect the dynamic combination relationship and temporal relationship of risk factors from the perspective of the whole system, as well as the multi-centrality and synergy of multi-actors for dynamic risk evolution. It is thus more difficult to explain the complex mechanism of safety risk for underground construction projects.

Applying the complex system view, safety risks in complex systems are non-linear, dynamic, and highly complex [1], while safety risk factors are interdependent and co-evolve over time; that is, there is no unique optimal solution for the generation of safety risks, and different combination paths and time sequence relationships may exist among these risk factors [16,17,18]. Therefore, exploring the causes and cures for safety risks in underground construction projects must be based on data from typical underground project safety accidents that have already occurred. This study thus proposes a novel dynamic risk analysis perspective based on a complex system view, integrated causal chain theory, and risk coupling theory. First, we construct a dynamic temporal qualitative comparative analysis (TQCA) model to investigate the interactions and the temporal relationships among the risk factors over time. Then, we construct a crisp-set qualitative comparative analysis (csQCA) model to investigate the multi-actor coupling characteristics of management risk. Finally, we create a temporal safety risk governance framework using the synergy of multi-actors according to the results of these configurations. This paper thus supplements the study of the temporal relationship and configuration analysis of safety risk and offers both theoretical and managerial implications that shed new light on the ongoing overall analysis of safety risks in underground construction projects.

The remainder of this paper proceeds as follows. First, the relevant literature is briefly discussed, the risk factors are identified using grounded theory, and the application of TQCA and csQCA for the formation mechanism of safety risk is introduced in detail. The research results are then presented, and the safety risk management mechanism is discussed. Finally, both conclusions and research limitations are presented, and related future research opportunities are offered.

2. Literature Review

2.1. Identification of Safety Risk

The most effective way to improve construction safety performance is to identify the potential risks and mitigate or minimize them before an accident occurs [19]. The research on safety risk identification of underground construction can thus be mainly divided into two aspects. On the one hand, it is identifying unsafe risk factors on site from the perspective of what causes accidents. Fung et al. (2010) developed a Risk Assessment Model (RAM) for safety risk identification and assessment for different accident types, such as being trapped in or between objects, injured whilst lifting or carrying, slipping, tripping, or falling on the same level, etc. [20]. However, that study did not clearly distinguish the types of unsafe risk factors that occur on site. Ding et al. (2012), taking a tunnel project as an example, identified 16 construction risk factors from three aspects, namely, technical risk, environmental risk, and geological risk, but did not consider the risk from worker operation [21]. Chen et al. (2022) used the perspectives of technology, the organization and management, the environment, and people that make unreasonable personnel arrangements for safety management, have no regular inspection and supervision mechanism, weak safety awareness of personnel, and unreasonable construction technology to determine the core risk factors for construction [22]. In some cases, unsafe mechanical equipment and materials, as well as human error, may be the key factors that lead to safety incidents [23]. Unsafe behaviors are the most frequent and direct causes of accidents [24], and the main forms of these are storing in an improper location, not wearing a safety helmet, working with illness, engaging in unsafe behaviors during rework, and working after drinking [25,26]. In addition, environmental conditions are another main risk factor involved in construction accidents. For example, a site’s natural environment and weather conditions will affect the occurrence of safety accidents [27]. This kind of research analyzes the safety risk factors based on the direct cause of the accident, a process that is helpful to effectively determine the unsafe factors on site; however, it does not consider the indirect management effects of the interaction between organizations on the cause of the accident. Considering that a project involves many actors (including customers, consultants, designers, contractors, supervisors, etc.), these management risk factors are pretty complex. On the other hand, research has shown that the key management risks that affect safety in subway construction may include safety attitudes, construction site safety, government supervision, market restrictions, task unpredictability, lack of safety inspection, and ineffective safety management systems [28,29]. Indeed, management risks and loss of life can be effectively avoided through enhanced safety training and education, appropriate use of safety devices, and appropriate safety inspections [30].

A review of the above research indicates that a large number of studies have explored the risk factors related to people, materials, machines, management, and the environment, but most of these studies are based on subjective data. Few studies have identified safety risk factors by mining objective data, such as accident investigation reports, and identified management risks based on multi-actor classification.

2.2. Dynamic Evolution of Safety Risk

Risk coupling is a phenomenon in which multiple safety risk factors occur at the same time, interact and change continuously, and finally amplify the probability of construction accidents [31]. The theory of risk coupling points out that risk factors are not isolated, especially for mega underground construction projects, which have long periods, complicated environments, and a multiplicity of mechanical equipment and personnel; the different safety risk factors and actors have coupling effects among them, which can produce new risk and even lead an accident [14,32]. Thus, revealing the formation and mechanisms of the evolution of a project’s core safety risks is a prerequisite for developing effective safety risk control. To explore the interaction characteristics of underground construction safety risk factors from a comprehensive system-level perspective, Heydari et al. (2024) further clarified the variable mechanisms through which owners influence contractors’ safety behavior using a system dynamic approach [33]. For safety regulation during the operation of major infrastructure projects and to prevent potential risky losses and adverse social impacts, Xue et al. (2024) proposed a dynamic risk analysis model that integrates evolutionary games and system dynamics to optimize safety regulation strategies using bounded rationality that involves different stakeholders, such as operating companies, government departments, and the public [34]. From the perspective of risk coupling, the coupling of human–environment–management factors is more likely to cause serious safety risks, and the coupling of these human–management factors has the greatest impact on safety risk [35]. For example, the network connection between supervisors and workers and the centralization of supervisors will lead to unsafe behavior of workers and even to the actual occurrence of safety risks [36]. From the perspective of management risk, inadequate government supervision, ineffective safety management system, inadequate safety inspection, delayed hazard identification and elimination, and operation method error will generate more risk chains [37].

Although the above studies have explored the impacts of the dynamic evolution of risk factors on safety risks, there are still deficiencies. On the one hand, few studies have explored the dynamic temporal characteristics of risk factors using the time dimension. On the other hand, the interactive characteristics of multi-actor management risks have also not been fully discussed.

2.3. Governance Strategy for Safety Risk

As a result of the complexity of underground construction safety risks, safety governance strategies must be constantly optimized to prevent those risks. In a study of safety risk-management strategies related to the levels of construction and organizational management, Yiu et al. (2019) concluded that safety management systems have a positive impact on controlling hazards and reducing accidents, thereby ensuring safer working conditions, and reducing injury to operators in underground construction projects [38]. From the perspective of specific organizational governance strategies, the risk attitudes of project managers also affect the project risk assessment level [39], so managers should prioritize the development of their management skills for the most effective management of safety risks and ensure a safe environment for construction projects [40]. Further, it should be taken into account that the traditional mode of risk control as the independent bearing of risks can no longer meet the requirements for dealing with the complexity of safety risks. When considering the multi-actors of a construction project, the multi-actor risk co-management mechanism becomes an important governance strategy. A network governance structure should be established to achieve mutual benefit and support rather than just administrative assignment and resource dependence. It must be the focus of the security risk governance structure to form a governance network by sharing information with all the independent organizations, thereby forming both coordination and consistency of their actions [41].

Prior research on construction risk governance strategies shows a trend in the diversification of perspectives and methods. However, there is a relative lack of research on any joint temporal governance mechanisms for multiple actors. Risk governance strategies that are based solely on the perspective of one subject or one technology can no longer meet the needs for successful risk management of complex construction systems.

Above all, the previous research on safety risk identification, safety risk coupling, and its evolution and safety risk governance has provided an important basis for underground construction risk management. However, several gaps still remain. These include the following:

- (1)

- There is a lack of in-depth research on the causal relationship between risk factors and risks that are considering time variables. The generation of underground construction safety risks depends on the role of the risk factors in the project implementation process, that is, whether the risk-causing factors will induce further generation and greater transfer of risks with the change of time. Therefore, the research on the generation mechanism of safety risks in underground construction that considers the time sequence will analyze both the safety risk factors and the internal mechanism of safety risks more comprehensively and objectively, thereby laying a better foundation for the management strategy of those unique safety risks;

- (2)

- In the past, risk management research focused on the identification, evaluation, and analysis of risk factors. In recent years, although some scholars have paid attention to the evolution of risk in time and space, they often have also focused on the time evolution of a single variable or the horizontal interaction between multiple factors, but ignoring the coupling relationship between people, organizations, behaviors, technology, and environment in the risk system over time. However, the risk state of the construction system at any time depends not only on the state of the current factors but also on the influence of the time before each factor. Therefore, the analysis of underground engineering construction safety risk using a time series coupling system will help depict the time series evolution law of risk more accurately and truly;

- (3)

- According to their different roles and functions, the participants of underground construction projects are often in different central positions, and thus, the risk control strategy based on a certain subject or technology cannot meet the needs of that complex risk management. In view of the generation mechanism and dynamic evolution law of safety risks in underground construction projects, it is a realistic and urgent problem for how to better play the cross-linkage role of multi-agents in different construction processes or stages and thereby tap their joint governance potential fully.

3. Research Methodology

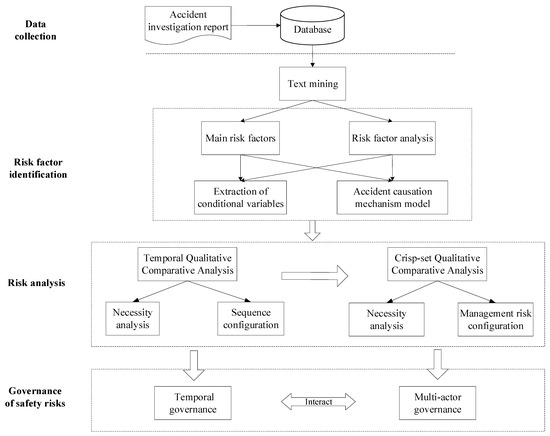

We first identify here the safety risk factors based on textual analysis, and then we combine TQCA and csQCA to explore the temporal relationship of underground construction risk factors and the coupling characteristics of management risk. Finally, together with the results of the QCA, a safety risk governance framework is constructed, and risk governance strategies are proposed for each actor. Figure 1 shows the framework for the methods.

Figure 1.

The framework for the methods.

3.1. Cases and Data

Relative to the work in other industries, construction projects are prone to more serious safety accidents due to their more complex construction environment, strong operational mobility, and numerous actors [19,42]. The proportion of safety accidents that are closely related to underground construction project activities, such as earthwork failure and foundation pit collapse, has also been at a high level for years, which is a key difficulty for risk prevention and the control of construction projects. This study, therefore, uses underground construction projects to gather its data sample. We collected 50 safety accident investigation reports on underground construction projects that were publicly released by the emergency administration of the Bureau of Chinese Provinces and Cities, the Ministry of Housing and Urban-Rural Development, the government websites of Chinese provinces and cities, and news media reports from 2011 to 2021 that had aroused wide public concern.

By text mining each report for these 50 accident investigations, selecting those reports that met the purpose of this study for further research and analysis, and removing rail and pipeline engineering projects like subways and tunnels as well as some incomplete cases where the reporting was defective, 37 accident investigation reports were ultimately selected. To ensure the reliability and validity of the encoding results, this paper uses a range of resources to triangulate the research questions, including primary data, such as interviews and observations, as well as secondary data, such as other official data, media reports, professional books, and literature. The basic data used are shown in Table 1 below.

Table 1.

Descriptive statistics of underground construction project safety accident cases.

3.2. Safety Risk Factor Identification Using Text Mining

In this study, in terms of the programmed coding of grounded theory, Nvivo11 qualitative analysis software was used to analyze and refine the causes of the underground construction project safety accident investigation reports. First, all the factors noted in the accident investigation report were extracted as the initial category, and then the initial category was merged into sub-categories according to the risk sources of the factors. Finally, the sub-categories are abstractly re-named into four categories according to the classification methods recognized by the current theoretical circles. For example, the original text “the owner contracts out construction project to a contractor that does not possess the corresponding construction qualifications” will be extracted as the initial category “illegal contracting by owners”. Then, the initial category was merged into “ineffective project management of the owner”. Finally, “ineffective project management of the owner” is categorized as poor actor management (management risk). To ensure the objectivity of this coding, we discussed instances of inconsistent coding and also consulted an expert group on any controversial coding. Through discussion with this expert group, this study was able to combine construction material risk and construction machine risk with similar properties into machine/material risk, finally clustering them into 37 underground construction project safety accident investigation reports (5 cases were reserved for a theoretical saturation test to obtain the 12 sub-categories and the 4 main categories). These 4 main categories were unsafe construction behavior of operators, poor actor management, unsafe materials/machines, and complex environments. The specific main categories and sub-categories are shown in Table 2. The four main categories mentioned are basically consistent with the classification of the causes of safety accidents in other documents, i.e., people, things, management, and environment [43]. We then calculated the proportion of occurrences of each main category as operator risk (12.13%), material/machine risk (2.54%), environmental risk (2.03%), and management risk (83.25%). Specifically, these were ineffective safety management by the general contractor (27.92%), ineffective construction management of the subcontractors (25.63%), ineffective project management of the owner (11.68%), supervision failure (10.66%), and ineffective government supervision (7.36%). It thus can be seen that the most important risk factors for underground construction accidents are management risk and ineffective safety management of the general contractor and subcontractors are the main management risks. This knowledge indicates that, unlike other projects, the risk factors of underground construction accidents mainly relate to the unsafe management behavior of the construction organizations, especially the management deficiencies of the general contractors and subcontractors.

Table 2.

Coding results for the influencing factors.

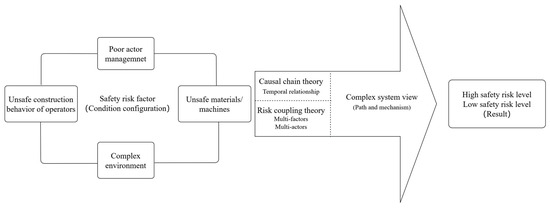

From the results of this grounded analysis, we chose “underground construction project safety risk level” as the core category, around which the following logical line was formed: In the process of underground construction project construction, the unsafe construction behavior of operators, poor actor management, unsafe materials/machines, and complex environments lead to safety risks in an underground construction project by forming a configuration of risk conditions. That specific formation mechanism is shown in Figure 2.

Figure 2.

Safety risk formation mechanism diagram for an underground construction project.

4. Case Study 1: Causes of Safety Risks Based on a Dynamic Configuration

4.1. Variable Setting and Assignment

This study takes the four main categories extracted from the grounded theory as the influencing factors for safety risk and as the conditional variables. The safety risk level is the result variable in the TQCA model. The specific variables are shown in Table 3. According to the study by Qi et al. (2023), all underground construction accidents are categorized as fatal accidents and non-fatal accidents [44]. The assignment principle of the result variable is the following: 0 is assigned to non-fatal accidents, and 1 is assigned to fatal accidents. The assignment of the conditional variables is as follows: if the conditional variable does not exist in the accident case, then the value is 0, and if the conditional variable exists, then the value is 1.

Table 3.

Variables selection and their description.

4.2. Construct a Truth Table

To use the existing QCA software and algorithm for sequence analysis in the TQCA method, we encoded any two conditional variables as sequential variables to generate 12 sequential conditions [45]. Specifically, in a given accident, if risk factor A occurs before risk factor B, then condition AB is coded as 1, and BA is coded as 0, and vice versa. If neither risk factor A or B is present for the accident, such that there is no sequence between A and B, then both sequence variables AB and BA are coded as 0. If the sequence variables AB and BA are both encoded as 1, they can be simplified to A*B [46]. Thus, the accident-causation chains for all accidents are uniquely determined, and there is no duplication or omission. The truth table used in this study was constructed using the above principles.

4.3. Necessity Analysis

Before the conditional configuration analysis, fsQCA3.0 software was used to conduct a necessity analysis. The consistency and coverage for each conditional variable are obtained from a necessity analysis, where consistency reflects the extent to which each conditional variable forms a subset of the result variable. In general, consistency scores that are higher than 0.9 indicate that the conditional variable forms a necessary condition for the result variable [47]. The necessity analysis results gathered from TQCA show that the consistency score of each sequence condition was lower than 0.9, indicating that all sequence conditions are not necessary conditions [48] and that there are more complex risk causative chains, and further analysis and discussion of the risk path between the sequential conditions are still needed to determine the real project safety risk causative chain.

4.4. Configuration Results

We entered a truth table in the fsQCA3.0 software, automatically removed the residual logical terms, and screened out the antecedent conditional configurations sufficient for the interpreted results according to the threshold value for set consistency 0.8 and the threshold value for case frequency 1 [49]. Then, we selected the corresponding prime implication terms according to the theoretical knowledge and set the conditional variable to indicate either presence or absence [50]. Three configuration schemes for the reduced solutions, intermediate solutions, and complex solutions were obtained. For this study, we chose the intermediate solutions to analyze the sequence configurations.

The detailed results are shown below in Table 4. Table 4 lists eight sequence configurations. Each sequence configuration represents the risk factors that caused the safety accident and the occurrence order of every risk factor. For example, AP means that management risk (A) occurs first, and operator risk (P) occurs later. A*M means that the occurrence of managing risks (A) and machine/material risks (M) does not have any specific order.

Table 4.

Sequence configuration results.

These results indicate that there are typical time lag characteristics for all safety risk factors, and a total of eight sequence configurations constitute the best path for the formation of underground construction project safety risks. Among these, the solution consistency is 1, greater than the critical value of 0.85, indicating that eight sequence configurations had sufficient conditions for the formation of project safety risks [50]. The solution coverage is 1, indicating that these eight condition configurations can explain all cases of underground accidents in use with a high degree of interpretation.

We categorized all the configurations into three types based on the characteristics of each risk factor in each configuration. Table 4 presents the dynamic configuration results for Study 1: Management risk preceding (including configurations 1 and 2); management risk and machine/material risk cross-concurrent (including configurations 3, 4, and 5); and management risk initiating and concluding (including configurations 6, 7, and 8). These types are sufficient for explaining the formation mechanism of safety risks in underground construction projects. Configurations 4 and 5 can be combined into A*MP based on the TQCA algorithm, and configurations 7 and 8 can be combined into AP*EA for the TQCA algorithm. To prevent construction safety risks effectively, it is also necessary to explain each configuration path based on the actual situation case.

- Type 1: Management risk preceding type

This type of risk includes configurations 1 and 2. The core of this risk type is that the management risk factor appears for the first time in the entire accident and is the primary factor causing it. Thus, in the sequence in configuration 1, management risk occurs, followed by operator risk, which eventually leads to accidents. In particular, the actors’ management during the initial stages of the project is insufficient and includes a lack of pre-construction risk and the inspection and rectification of hidden dangers and other aspects. These cause or aggravate construction operator risks, such as not wearing safety gear and violating operating regulations, ultimately leading to safety risks. An example is the poisoning and asphyxiation accident that occurred in Baiyun, Guangdong Province. In the pre-construction period, the owner was illegally subcontracted, the contractor’s emergency plan was imperfect, and safety education was not provided. During the construction, the owner neglected to supervise or manage the contractor, and the contractor did not have proper supervision of the operators. This circumstance led to the operators’ being lax in their safety awareness during construction, and the operator entered into a space containing toxic gas without safety protective gear, which was a safety risk. Sequence configuration 2 shows that the appearance of management risk is followed by environmental risk, which can lead to accidents. In particular, the actors’ management was insufficient in the initial stages of the project, including imperfect or undeveloped contingency plans, an inadequate setting of construction safety measures, a failure to require stopping the construction in time, and an inadequate identification of risk factors. The project was also affected by the complex environment, which included poor geological conditions and construction disturbances, eventually leading to the occurrence of safety risks.

- Type 2: Management risk and machine/material risk of a cross-concurrent type

This type of risk includes configurations 3, 4, and 5. At its core, this type of risk entails that both management risk and machine/material risk appear first in an accident, but there is no necessary sequence between the two. In sequence configuration 3, the intersection of management risk and machine/material risk causes safety accidents. The sequence of configurations 4 and 5, when combined, showed that management risk and machine/material risk were cross-concurrent, and then operator risk occurred, which led to the accident. In particular, the management risk and machine/material risk were cross-concurrent, such as the insufficient inspection of machines and equipment before construction, the insufficient management of machines and equipment, insufficient equipment maintenance, and inherent safety risks in the chosen construction materials. Further, it is followed by construction without regard to risk, equipment operation that is not standardized, and other operator risks, which eventually lead to accidents. For example, in an electric shock accident in Yunfu, Guangdong Province, and the mechanical injury accident in Bijiang, Guizhou Province, the former contractor violated the rules of outsourcing at an early stage, together with having a lack of effective safety management during the construction period and a failure to detect and eliminate the safety risks of construction equipment in a timely fashion, resulting in the use of equipment with safety risks without wearing protective gear that led to safety risks. The latter indicates that in the early stage of construction, if the leasing department provides equipment with safety risks, and the workers lack effective management and fail to eliminate potential risks in time, safety accidents can be caused due to the violation of operational regulations by the operators.

- Type 3: Management risk initiating and concluding risk type

This type of risk includes configurations 6–8. The core of this type of risk is that management risk forms both the first and last factors in safety accidents. The combination of configurations 7 and 8 shows that environmental risk and operator risk are cross-concurrent after the appearance of management risk and a safety accident was ultimately caused by the appearance of management risk. Configuration 6 shows that following the appearance of management risk, there is a machine/materials risk, followed by operator risk, and ultimately, a safety accident because of the appearance of management risk. Specifically, there was insufficient management of the actors in the pre-construction period, such as the inadequate inspection of machine/material management, inadequate identification of potential risks, and inadequate safety education and disclosure. Safety risks then appear in the machines and materials during the construction phase, such as inadequate maintenance and insufficient inspection before using the equipment. Operator risk can follow, such as when the operation is not performed according to standards and guidelines and risky construction.

Finally, safety risks also occurred due to the inappropriate management of the main actors, who could not find and stop construction violations in time and were unable to impose corrective measures in time. For example, in the collapse accident in Yangzhou, Jiangsu Province, before the construction began, the construction organization featured management risks, such as the inadequate implementation of safety education, illegal changes in the sequence of construction, and lack of safety administrators. Then, after the foundation pit was seriously affected by rain, the operators violated the regulations for construction, and the project actors did not stop to rectify the violations in time, eventually leading to major safety accidents. The main configuration characteristics are shown below in Table 5.

Table 5.

Temporal configuration characteristics of multi-factor risks.

5. Case Study 2: Coupling Characteristics Analysis of Multi-Actors on Management Risk

There are many actors in projects, so potential risks that fall on actors must be the focus here. According to the results of the above analysis of the safety risk path, management risk is an important factor in the formation of safety risk. With the exception of configuration 4, management risk forms the primary factor for all configurations. The formation of management risk is thus often the result of the coupling of multiple actors. Due to mutual operation among actors, a coupling is likely to occur, which will affect the completion of the construction [3]. Therefore, it is necessary to study the coupling characteristics of multiple actors on management risks further by combining csQCA.

5.1. Variable Setting and Assignment

In csQCA, the five sub-categories of management risk for the four main categories extracted by the grounded analysis were taken as the management factors for safety risk and also as conditional variables. In addition, the level of project safety accident risk was taken as the result variable for the csQCA coding operations and connotation analysis. The specific variables are shown in Table 6. That assignment principle is consistent with the TQCA.

Table 6.

csQCA variable selection and description.

5.2. Necessity Analysis

Necessity analysis is required before csQCA, and that result shows that the consistency of the conditional variables is lower than 0.9, indicating that none of the conditional variables are necessary for project safety risk. Therefore, the formation of project safety risk accidents is not caused by a single actor but rather by the interaction between multiple actors, which makes them both diversified and suitable for further configuration analysis.

5.3. Configuration Results

csQCA also uses fsQCA3.0 software and is based on intermediate solutions. In csQCA, conditions that appear simultaneously in reduced and intermediate solutions are regarded as core conditions that are vital to the outcome variable, while those conditions that only appear in intermediate solutions are regarded as edge conditions (secondary conditions) that theoretically impact the outcome variable, but lack practical cases [51]. Specific calculation results can be seen in Table 7.

Table 7.

csQCA configuration results.

In Table 7, it can be seen that five conditional configurations reveal the coupling characteristics of multiple actors on management risk and refer to five management risk types. The solution consistency is 0.9697, which is greater than the critical value of 0.85, indicating that the five conditional configurations are sufficient for forming project safety risks. To avoid management risks effectively and put forward joint governance strategies, it is necessary to explain each configuration path based on actual cases.

Table 7 shows the management configuration results for multi-actor coupling in relation to management risks. According to the characteristics of the core conditions and edge conditions and when combined with the actual situation of the case, the five configurations are explained in the following discussion.

- C1: Single-actor-dominated management deficiency

This type of configuration contains three paths, namely, supervisor deficiency, owner management deficiency, and subcontractor management deficiency. In the configuration of supervisor deficiency, a configuration with supervisory failure as the core condition followed by the general contractor’s ineffective safety management as the secondary condition can cause safety risks. Due to the absence of supervision, the construction site could not be effectively supervised and managed, and construction problems could also not be supervised and rectified in a timely fashion, so the general contractor was lax and lacked full management of the construction site and also could not rectify the problems according to the regulations in a timely fashion, resulting in safety risks in the construction that cannot be eliminated in a timely fashion and eventually serious safety risks.

The owner management deficiency type shows that a configuration with ineffective project management by the owner and effective construction management by the subcontractor as the core conditions and ineffective safety management by the general contractor as the second condition can cause safety risks. If the owner’s overall management of the project is insufficient, there is no good responsibility mechanism for construction safety, and that owner even acquiesces to the construction organization’s illegal construction behaviors, making its binding force on the construction organization insufficient, leading to the general contractor’s lax management, ignoring of the government’s supervision requirements, and failure to organize and manage construction in strict accordance with regulations. This situation leads to safety risks.

Subcontractor management deficiency shows a configuration with effective safety management by the general contractor and adequate government supervision as secondary conditions but with ineffective construction management by the subcontractor and effective supervision by supervisory departments as core conditions that are causing safety risks. The ineffective construction management of subcontractors leads to chaotic construction site management, which further increases safety risks at the construction site and makes it easier to conduct and accept unsafe construction behavior, leading to safety risks.

- C2: Dual-actor-dominated management deficiency

In this type of configuration, two management actors cause the safety risks. This configuration shows that ineffective project management by the owner and ineffective construction management by the subcontractor as the core conditions, and effective government regulation and effective safety management by the general contractor as secondary conditions can cause safety risks. In particular, the owner’s management is lax, including insufficient management of the project and insufficient inspection and supervision of the construction site, preventing any strict examination of the contractor’s qualification in the early stages of the project and even enabling illegal subcontracting. This situation leads to lax management of subcontractors, insufficient or even absence of safety education and technical disclosures for operators, a lack of organization and effective management of the construction site, failures to detect and correct non-standard construction behaviors in a timely fashion, and even a blind organization of the ongoing construction to meet the deadline, again leading to safety risks.

- C3: Multi-actor-dominated management deficiency

In this configuration, inadequate multi-actor management is the cause of safety risks. Ineffective project management by the owner, ineffective construction management by subcontractors, and failure of supervision as core conditions and effective government supervision as a secondary condition lead to safety risks. In the case of effective supervision by the government, regardless of whether the general contractor is effectively managed, only the tripartite synergistic lack of management by the owner, subcontractors, and supervisors can lead to safety risk accidents. In particular, the poor management of multiple actors across the entire construction process entails buried risks and hidden dangers. In the end, the lack of comprehensive multi-actor management leads to safety risks.

6. Discussion

6.1. Characteristics of Safety Risk Factors in Underground Construction Projects

The safety risk factors of underground construction projects are different from those of general construction projects and underground rail projects. A portion of the previous research has identified risk factors associated with high energy levels (mechanical, hazardous substances) and human error (improperly secured tools) as the most important risk shapers for accidents at construction projects [23]. In particular, three violations by staff (violation of command, violation of operating procedures, and violation of labor discipline), unsafe materials, and poor working environment conditions may lead to a higher probability of accidents [52]. Zhou et al. (2022) suggested that environmental conditions and material/machine conditions have the greatest influence on the risk of collapse in subway construction [53]. However, by calculating the proportion of each risk factor that appears in accidents, we found that management problems of general contractors and subcontractors were the most important risk factors for underground construction accidents, followed by unsafe behaviors of operators. On the one hand, this knowledge reflects that compared to metro construction accidents, underground construction accidents are relatively less affected by hydrogeological and other environmental risks. On the other hand, this knowledge shows that underground construction projects are more difficult and more complex to manage than general construction projects.

6.2. Multi-Temporal Pathways for Safety Risk Formation in Underground Construction Projects

The temporal relationship between the safety risk factors in underground construction projects is different than that for general construction and railroad projects. Prior research has shown that safety risk accidents in general construction projects are often related to unsafe operator behavior and in urban railroad projects to the work environment and supervisors [54]. In the risk causation chain, management risk is often considered as the source risk of safety accidents, while operator risk is the direct causative factor of accidents [15]. Combining the three types of risk timing and accident investigation reports, we found that the temporal relationship of safety risks in underground construction projects possesses characteristics that are different from general construction projects: First, management risk occupies a core position in this risk timing series chain and is often the first factor in the time series chain. In addition, when management risks recur in the time series chain, that often leads to more serious construction safety accidents.

Second, the occurrence of machine/material risks is often accompanied by the emergence of management risks. On the one hand, the occurrence of machine material risks may be caused by the negligence of management, and on the other hand, if the management department cannot solve the machine material risks in time, that scenario will directly lead to construction safety accidents. Third, operator risk cannot be ignored except in configurations 2 and 3; other configurations have operator risk.

The emergence of operator risks often has the following characteristics: First, it appears as the direct cause of the accident; that is, it appears at the end of the timing chain. This situation is often a mechanical injury accident with small casualties. Second, before any occurrence of management risks, this situation is often caused by the management department’s own management lack or wrong management decisions, leading to operators’ following dangerous construction behaviors that lead to construction safety accidents.

Third, before and after the occurrence of management risks, this situation is often accompanied by the recurrence of management risks and generally manifested as a lack of management in the early stage of construction, unsafe construction behaviors of operators during the construction process, and unfavorable supervision by the management side, which cannot stop violations in time, and management risk recurrence. This scenario often leads to more serious safety accidents, such as collapses.

6.3. Multi-Actor Coupling Characteristics of Underground Construction Project Management Risk

The results of TQCA indicate that, unlike general construction projects, management risk is the core causal factor of safety risk in underground construction projects. Further, these csQCA results show that the management risk of safety accidents in underground construction projects is not caused by a single actor but instead by the interaction of multiple actors. Based on the known underground construction project accident cases and configuration analysis results, the coupling characteristics of management risk are related to the risk time-series relationships. Specifically, single-actor-dominated management deficiencies are common in all safety risk time-series chains. This management risk type tends to result in mechanical injuries, poisoning, and electrocution with lesser losses.

Dual-actor-dominated management deficiency generally accompanies machine/material risk and ultimately leads to operator risk. This type of management risk tends to result in less costly machinery injuries. Multi-actor-dominated management deficiency often leads directly to operator risk, which then causes large and costly collapses or less costly mechanical injuries. The position of management risk, coupled with different actors in the risk timing chain, is also different, and these specific results are shown in Table 8.

Table 8.

Management risk configuration characteristics of multi-actor risks.

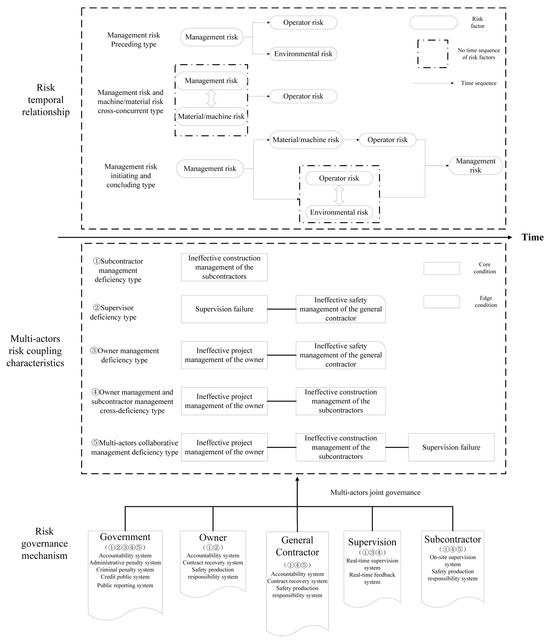

7. Theoretical Implications

The causes and risk factors of organizational accidents are multi-dimensional and cumulative across time [55]. Only by preventing risks at their sources, intervening in their spread along the project paths, and cooperating with multiple actors in real-time can we effectively identify and control potential safety risks at different stages, thereby preventing the risk management gap and truly realizing a nip in the bud to lower risk. Using the analysis results for TQCA and csQCA, we can develop a temporal safety risk governance framework that is based on the synergy of multiple actors, as shown in Figure 2.

7.1. The Dynamic Temporal Characteristics of Safety Risk Factors

This study enriches the discussion of risk temporal relationships between risk causal chain theory and risk coupling theory. The first segment showed the timing chain of risk factors, revealing the temporal characteristics of underground construction project safety risks and the dynamic interaction characteristics of risk factors. This segment reveals the time lag characteristic of risk factors in underground construction safety incidents. When compared to general construction projects, underground construction safety should pay more attention to management-induced safety risks, including both the antecedent risks that lead to the occurrence of management risks and the other subsequent risks that may be triggered by management risks, as management risks and other safety risk factors have obvious time lag effects and are then manifested in the typical accident causation paths of various types of accidents.

According to this part, the causes of accidents can usually be traced back to the decision-making that took place before the start of the project [56], that is, the governance gaps between the generation of risk factors at the beginning and the occurrence of risks or accidents at the end. The evolution of risk factors over time is an inherent feature of risk, and risk is in a state of constant transfer and reorganization as time passes and the environment changes. Taking into account the fact that all risks in a system feature a large latency and influence and that all elements of a system interact with each other as the system changes over time, the most effective way of improving construction safety is to identify potential risks before an accident occurs and then reduce or minimize all relevant risks [19,20]. Most of the current theories focus on the evolution of individual risk factors or interactions between different factors, and thus, little attention is paid to the impact of the temporal relationship of risk factors on safety accidents.

There has also been insufficient research on the formation mechanism of formation for multiple risk factors, even when taking the time lag effect into account. Here, TQCA was used to explore the source risk for different safety accidents and the diffusion path of risk factors with change over time, analyzing the influence mechanism of the time sequence relationship of risk factors on construction safety accidents, exploring the characteristics of time sequence relationship of risk factors in different accidents, supplementing the interaction mechanisms and the temporal relationships among multiple risk factors across different accidents, considering the effects of time lag, revealing the latency length of various risks in different accidents, enriching the application of accident causation theory in underground construction safety accidents, and providing theoretical guidance for the better management of the time sequence for risk.

7.2. The Interaction Effects of Multi-Actor Risk

This study enriches the discussion of multi-actor risk coupling characteristics in risk coupling theory. The second examined the management risk coupling characteristics through the multi-actor and explained the core risk actor for different combination paths. Based on the temporal relationship of safety risks presented in Part I, we find that management risk is an important factor in the risk chain, as it occurs at all stages of the risk chain and reveals the formation of management risk in the safety accident causation chain. The complexity of safety risk increased as the number of actors in the project grew [57]. The second part shows that any actor may take the form of a potential risk factor because interactions among actors may produce a “butterfly effect” that can seriously affect construction safety overall [3]. In other words, underground construction project management risks have a variety of formations. The formations of management risk are summarized in Part II of Figure 2.

The results of csQCA showed that the formation of management risks is affected by the coupling between these multiple actors. Previous efforts have focused on the effect of a single actor on safety risk. Such actors often appear in different central positions, and it is difficult to effectively manage safety risks and avoid safety accidents when relying on a single actor alone. Therefore, we used csQCA to analyze the coupling characteristics of multi-actors on management risks, revealing the manifestations of the core actors and the roles that each actor plays in different safety accidents, thereby expanding the risk coupling research on that multi-actor when addressing risk.

7.3. A Multi-Actor Collaborative Temporal Governance Strategy

This study not only revealed the temporal relationship of safety risks but also the coupling characteristics of multi-actors through a complex system review. This study developed a temporal governance framework of construction safety risks based on the synergy of multiple actors and reconciled the risk causal chain theory and risk coupling theory, thereby providing a new analytical perspective for risk management theory. The third key aspect is the safety risk management mechanisms of multi-actor synergy. Combined with the risk temporal relationship and the coupling characteristics of multiple actor management risk, actual synergy management mechanisms among these actors should differ for different safety risks. In previous studies, risk management and actor management were often carried out independently, which hindered the development of risk–actor management integration [58]. This paper integrates actor management and safety risk management for the different safety risk paths within the synergy of multiple actors. For core and auxiliary actors, the governance mechanism whereby each actor should build a joint multi-actor governance strategy is thus proposed to complement the governance mechanisms of risk–actor management integration. Specifically, a single actor cannot solve the management risk configuration presented in Part II. Therefore, it is necessary to realize joint governance between all the different actors to address complex management risks successfully. In other words, a management actor needs to be involved in the governance of several management risks, not just a single risk (See Figure 3).

Figure 3.

Temporal safety risk governance framework based on the synergy of multiple actors.

In response to the call for a complex system view to achieve a “combination” methodology, this study introduces the configuration perspective and QCA method into construction safety risk analysis. Different from the traditional causal chain theory and risk coupling theory, this complex system view is a more comprehensive and reasonable theoretical perspective and synthesizes the viewpoints of the two theories. Based on this focus, the results of this paper simultaneously reveal the dynamic coupling characteristics and time sequence characteristics of risk factors and analyze the relationship between the different time sequences of risk factors and safety risk accidents in the whole system to reveal the impact of the synergistic effect of multiple actors on safety risks. The research ideas and theoretical perspective offered in this paper are not only applicable to underground construction projects but also to other types of complex projects, which makes it a novel and universal safety risk analysis method.

8. Practical Implications of This Study

To ensure underground construction project occupational health and safety and achieve sustainable production, a reasonable and effective management system should be created [59], and all actors, including the owner, the design department, and government agencies, should work collaboratively to assume the several risk management responsibilities [60]. In addition to the results of sequence configuration, all of the sequence configurations, except for sequence configurations 3 and 4, show that management risk is the source risk for a construction safety risk. Thus, in actual risk management, management risk should be the primary control factor, and all actors should cooperate to control and achieve the early blocking, middle control, and later disposal of management risk. From the governance framework above, the following governance strategies are proposed for construction safety risk governance to improve the safety risks of construction.

The government’s supervision of each actor is important to control the safety risk of the construction [28], and if the government cannot introduce perfect management methods, then it cannot effectively restrain construction departments’ behavior, which is not conducive to construction safety [61]. For each type of management risk manifestation, the government should be involved in collaborative management and perform effective supervision and management of the other actors and bear the risk of low quality [26], including improving the accountability system, constructing administrative and criminal penalty systems, and creating public credit systems and public reporting systems.

For the three paths in the single-actor-dominated management deficiency, targeted governance policies should be adopted. The supervisor deficiency requires joint management by the government and the owner to effectively avoid the occurrence of the supervisory department and general contractor management risks. In construction, the first and foremost factor in improving project safety is generating new and effective safety management measures with leadership by the owner [62]. The owner should create a responsibility and accountability system and improve the contract recovery system to prevent the problem of mutual shifting of responsibilities and compensation disputes. At the same time, the owners should implement daily inspections and supervision, cooperating fully with the government to achieve effective supervision and management of the contracting departments and their supervision.

For the owner management deficiency type, the government and supervision need to cooperate and manage issues jointly. While the government restrains the owner, the supervision department constructs and improves real-time supervision and feedback systems, strengthens the supervision and management of the construction department, implements daily construction inspection and supervision, communicates with the government promptly, reports irregularities, and urges the rectification construction department to implement corrective measures that effectively restrain the general constructor and prevent the owner management risks The management and monitoring of key parts and all weak links in construction departments during the construction process should be strengthened.

The core of the subcontractor management deficiency is controlling the management risk of subcontractors. The government, the owner, the general contractor, the subcontractors, and the supervision department should jointly manage, establish, and improve the overall governance system, and all departments should carry out joint inspections to achieve effective supervision and management of the subcontractor, thereby ensuring the construction site and operator construction safety, avoiding the management risk of the subcontractor, and controlling the influence path of this type of risk.

For the dual-actor-dominated management deficiency, the government, general contractors, supervisory departments, and subcontractors should collaborate and jointly govern to effectively control the management deficiencies of the owner and the subcontractor. First, contractors should pay close attention and implement risk management [63]. The general contractor should build an accountability system, improve the contract recovery system and the construction safety responsibility system, strengthen communication with other actors to regulate construction safety behavior [64], and adequately perform risk prevention and control of the construction site [65]. Secondly, the subcontractor should improve the site-supervision system and the construction-safety responsibility system by strengthening the management and supervision of the construction site and effectively restraining the construction behavior of subordinate subcontractors (labor team).

The core of the multi-actor collaborative management deficiency type rests in the ineffective management of the owners, subcontractors, and supervisors. This type of risk should be jointly and cooperatively managed by the government, the general contractor, and subcontractors, using the government to coordinate and supervise the owner, subcontractors, and supervisors, while the general contractor and subcontractors jointly manage and control the construction behavior of their subcontractors. In that way, the construction behaviors of the owner, subcontractors, and supervisors are restrained to avoid the occurrence of management risks and control these types of risks if and when they do occur.

9. Conclusions and Limitations

9.1. Conclusions

This study combined causal chain theory and risk coupling theory by applying a complex system view for underground construction project safety risk analysis. It also explored the dynamic interactive characteristics of risk factors and their temporal relationships and discussed the multi-actor coupling characteristics of management risk. The results also provide a new risk analysis perspective for other fields to achieve sustainable development. The main conclusions of this particular paper are the following:

First, underground construction project safety risk factors exhibit typical time-lag characteristics. According to the results of the TQCA analysis, it was found that the risk factors are not static chain relationships but dynamic temporal relationships with various forms. On the one hand, management risk is the leading factor that leads to the occurrence of other risks. On the other hand, the management risk and machine/material risk taken together are leading factors in the occurrence of other risks. Management risk is not only the leading factor in accident occurrence but also a direct factor that destroys the last barrier and leads to the accident. This finding indicates that the time sequence position of risk factors in the accident causative chain is not fixed, and thus, the traditional static causative theory cannot meet complex risk management needs.

Second, the formation of underground construction project management risks is the result of the coupling of multiple actors. According to the results from the TQCA, management risk is the core factor in the formation of safety risk. Therefore, this study discusses the multi-actor coupling characteristics of management risk based on csQCA. These results showed that there are various coupling ways that occur between management actors, the core actors of different accidents are different, and those core actors are often not unique. This finding shows that the governance of safety risks should not only consider the role of a single actor but also consider the synergy that occurs between all the various actors.

Third, we propose a temporal governance mechanism to control underground construction project safety risks via the synergy of multiple actors based on the temporal characteristics of safety risk and the coupling characteristics of multiple actors for management risk. This study thus developed a temporal safety risk governance framework based on the synergy of multiple actors. In the process of undertaking risk management, attention should be paid to the synergies that occur among multi-actors through joint management among these multi-actors, according to the time sequence characteristics of the risk factors. It is then easier to accurately identify the leading risk factors, control the transmission of risk factors, and dispose of the last risk factors in a timely manner. However, the full occurrence of safety risks can be controlled effectively only by realizing the ongoing and positive temporal management mechanism of multi-actor coordination.

There is an obvious time sequence phenomenon in the occurrence of various risks and safety accidents in underground engineering. That is, there are different degrees of latency from the occurrence of the risk factors to the final accident. Although some projects have begun to implement real-time monitoring technology for potential safety hazards, the “inertia” that has formed in risk response for a long time is often “slow” in dealing with complex risk environments with a time delay. The time sequence combination path of risk factors put forward in this paper is an analysis of the time sequence relationship of safety risk factors to accident prevention and a multi-agent joint time sequence governance framework of accident prevention that is achieved through an analysis of the combination path between different risk management subjects. The research findings of this paper thus strengthen the understanding of the accident-causing process and can expand the application of risk management theory going forward.

9.2. Limitations and Future Research

The limitations of this study were the following: First, the cases were drawn from secondary textual information that is publicly available, and the number of cases and their degree of case detail were somewhat limited. In addition, there was strong subjectivity involved in the case selection and the grounded theory coding process, which can be further examined in the future to obtain first-hand information through expert interviews and questionnaires to carry out actual empirical research. Second, the life cycle of a project is long, and the risk factors are both diverse and complex in their composition. Future research should consider the introduction of time-lag QCA to explore the characteristics of safety risk configurations under several inter-temporal changes.

Author Contributions

X.W. is primarily responsible for conceptualizing the research questions, financial support, manuscript revisions, and project management; P.S. is mainly responsible for data collection and analysis and the initial writing of the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Research Foundation of Humanities and Social Sciences of the Ministry of Education of China, Grant Number 22YJC630158.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Huang, L.; Wu, C.; Wang, B. Challenges, Opportunities and Paradigm of Applying Big Data to Production Safety Management: From a Theoretical Perspective. J. Clean. Prod. 2019, 231, 592–599. [Google Scholar] [CrossRef]

- Milch, V.; Laumann, K. Interorganizational complexity and organizational accident risk: A literature review. Saf. Sci. 2016, 82, 9–17. [Google Scholar] [CrossRef]

- Li, W.; Zhang, L.; Liang, W. An Accident Causation Analysis and Taxonomy (ACAT) model of complex industrial system from both system safety and control theory perspectives. Saf. Sci. 2017, 92, 94–103. [Google Scholar] [CrossRef]

- Bobylev, N. Mainstreaming Sustainable Development into a City’s Master Plan: A Case of Urban Underground Space Use. Land Use Policy 2009, 26, 1128–1137. [Google Scholar] [CrossRef]

- Lin, S.-S.; Shen, S.-L.; Zhou, A.; Xu, Y.-S. Risk Assessment and Management of Excavation System Based on Fuzzy Set Theory and Machine Learning Methods. Autom. Constr. 2021, 122, 103490. [Google Scholar] [CrossRef]

- Peng, F.-L.; Qiao, Y.-K.; Sabri, S.; Atazadeh, B.; Rajabifard, A. A Collaborative Approach for Urban Underground Space Development toward Sustainable Development Goals: Critical Dimensions and Future Directions. Front. Struct. Civ. Eng. 2021, 15, 20–45. [Google Scholar] [CrossRef]

- Xie, Z.; Jiang, F.; Xu, J.; Zhai, Z.; He, J.; Zheng, D.; Lian, J.; Hou, Z.; Zhao, L.; Wang, Y.; et al. A Narrative of Urban Underground Pipeline System Disasters in China in 2021: Spatial and Temporal Distribution, Causal Analysis, and Response Strategies. Sustainability 2023, 15, 10067. [Google Scholar] [CrossRef]

- Chao, P.; Biao, M.A.; Zhang, C. Poverty Alleviation through E-Commerce: Village Involvement and Demonstration Policies in Rural China. J. Integr. Agric. 2021, 20, 998–1011. [Google Scholar]

- Chen, G.; Tan, W.; Zhang, S.; Yan, B. Influence of Interpersonal and Institutional Trust on the Participation Willingness of Farmers in E-Commerce Poverty Alleviation. Front. Psychol. 2021, 12, 727644. [Google Scholar] [CrossRef]

- Yan, H.; Gao, C.; Elzarka, H.; Mostafa, K.; Tang, W. Risk Assessment for Construction of Urban Rail Transit Projects. Saf. Sci. 2019, 118, 583–594. [Google Scholar] [CrossRef]

- Zhang, S.; Shang, C.; Wang, C.; Song, R.; Wang, X. Real-Time Safety Risk Identification Model during Metro Construction Adjacent to Buildings. J. Constr. Eng. Manag. 2019, 145, 04019034. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, S.; Zhang, X.; Zhao, T. Identification of Critical Causes of Construction Accidents in China Using a Model Based on System Thinking and Case Analysis. Saf. Sci. 2020, 121, 606–618. [Google Scholar] [CrossRef]

- Chi, S.; Han, S. Analyses of Systems Theory for Construction Accident Prevention with Specific Reference to OSHA Accident Reports. Int. J. Proj. Manag. 2013, 31, 1027–1041. [Google Scholar] [CrossRef]

- Guo, D.; Song, Z.; Xu, T.; Zhang, Y.; Ding, L. Coupling Analysis of Tunnel Construction Risk in Complex Geology and Construction Factors. J. Constr. Eng. Manag. 2022, 148, 04022097. [Google Scholar] [CrossRef]

- Li, S.; Wu, X.; Wang, X.; Hu, S. Relationship between Social Capital, Safety Competency, and Safety Behaviors of Construction Workers. J. Constr. Eng. Manag. 2020, 146, 04020059. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, B.; Wang, D.; Lei, D.; Tong, R. Risk coupling analysis under accident scenario evolution: A methodological construct and application. Risk Anal. 2024, 44, 1482–1497. [Google Scholar] [CrossRef]

- Xiong, M.; Wang, H.; Che, C.; Sun, M. Application of text mining and coupling theory to depth cognition of aviation safety risk. Reliab. Eng. Syst. Saf. 2024, 245, 110032. [Google Scholar] [CrossRef]

- Wood, L.C.; Duong, L.N.K.; Wang, J.X. Business Process Improvement for Sustainable Technologies Investments in Construction: A Configurational Approach. Sustainability 2022, 14, 5697. [Google Scholar] [CrossRef]

- Choe, S.; Leite, F. Assessing Safety Risk among Different Construction Trades: Quantitative Approach. J. Constr. Eng. Manag. 2017, 143, 04016133. [Google Scholar] [CrossRef]

- Fung, I.W.; Tam, V.W.; Lo, T.Y.; Lu, L.L. Developing a Risk Assessment Model for Construction Safety. Int. J. Proj. Manag. 2010, 28, 593–600. [Google Scholar] [CrossRef]

- Ding, L.Y.; Yu, H.L.; Li, H.; Zhou, C.; Wu, X.G.; Yu, M.H. Safety risk identification system for metro construction on the basis of construction drawings. Autom. Constr. 2012, 27, 120–137. [Google Scholar] [CrossRef]

- Chen, W.; Deng, J.; Niu, L. Identification of Core Risk Factors and Risk Diffusion Effect of Urban Underground Engineering in China: A Social Network Analysis. Saf. Sci. 2022, 147, 105591. [Google Scholar] [CrossRef]

- Tixier, A.J.-P.; Hallowell, M.R.; Rajagopalan, B. Construction Safety Risk Modeling and Simulation. Risk Anal. 2017, 37, 1917–1935. [Google Scholar] [CrossRef] [PubMed]

- Fang, D.; Zhao, C.; Zhang, M. A Cognitive Model of Construction Workers’ Unsafe Behaviors. J. Constr. Eng. Manag. 2016, 142, 04016039. [Google Scholar] [CrossRef]

- Duan, P.; Zhou, J. Cascading Vulnerability Analysis of Unsafe Behaviors of Construction Workers from the Perspective of Network Modeling. Eng. Constr. Archit. Manag. 2023, 30, 1037–1060. [Google Scholar] [CrossRef]

- Love, P.E.; Ika, L.; Luo, H.; Zhou, Y.; Zhong, B.; Fang, W. Rework, Failures, and Unsafe Behavior: Moving toward an Error Management Mindset in Construction. IEEE Trans. Eng. Manag. 2020, 69, 1489–1501. [Google Scholar] [CrossRef]

- Zhang, S.; Loosemore, M.; Sunindijo, R.Y.; Galvin, S.; Wu, J.; Zhang, S. Assessing Safety Risk Management Performance in Chinese Subway Construction Projects: A Multistakeholder Perspective. J. Manag. Eng. 2022, 38, 05022009. [Google Scholar] [CrossRef]

- Yu, Q.Z.; Ding, L.Y.; Zhou, C.; Luo, H.B. Analysis of Factors Influencing Safety Management for Metro Construction in China. Accid. Anal. Prev. 2014, 68, 131–138. [Google Scholar] [CrossRef]

- Na, X.U.; Ling, M.A.; Liu, Q.; Li, W.; Deng, Y. An Improved Text Mining Approach to Extract Safety Risk Factors from Construction Accident Reports. Saf. Sci. 2021, 138, 105216. [Google Scholar]

- Chi, S.; Han, S.; Kim, D.Y.; Shin, Y. Accident Risk Identification and Its Impact Analyses for Strategic Construction Safety Management. J. Civ. Eng. Manag. 2015, 21, 524–538. [Google Scholar] [CrossRef]

- Li, X.; Yang, X.; Feng, K.; Liu, C. Automatic monitoring the risk coupling of foundation pits: Integrated point cloud, computer vision and Bayesian networks approach. Eng. Constr. Archit. Manag. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Xiang, P.; Yang, Y.; Yan, K.; Jin, L. Identification of Key Safety Risk Factors and Coupling Paths in Mega Construction Project. J. Manag. Eng. 2024, 40, 04024023. [Google Scholar] [CrossRef]

- Heydari, M.; Heravi, G.; Raeisinafchi, R.; Karimi, H. A Dynamic Model to Assess the Role of Site Supervision Systems in the Safety Performance of Construction Projects. J. Constr. Eng. Manag. 2024, 150, 04024001. [Google Scholar] [CrossRef]

- Xue, X.; Ji, A.; Luo, X.; Dou, Y.; Fan, H. Integrating Evolutionary Game and System Dynamics for Multi-Player Safety Regulation of Major Infrastructure Projects in China. J. Civ. Eng. Manag. 2024, 30, 307–325. [Google Scholar] [CrossRef]

- Qiao, W. Analysis and Measurement of Multifactor Risk in Underground Coal Mine Accidents Based on Coupling Theory. Reliab. Eng. Syst. Saf. 2021, 208, 107433. [Google Scholar] [CrossRef]

- Li, S.; Fan, M.; Wu, X. Effect of Social Capital between Construction Supervisors and Workers on Workers’ Safety Behavior. J. Constr. Eng. Manag. 2018, 144, 04018014. [Google Scholar] [CrossRef]

- Cheng, L.; Cao, D. Evolution Model and Quantitative Assessment of Risk Network in Housing Construction Accidents. Eng. Constr. Archit. Manag. 2024, 31, 227–246. [Google Scholar] [CrossRef]

- Yiu, N.S.; Chan, D.W.; Shan, M.; Sze, N.N. Implementation of Safety Management System in Managing Construction Projects: Benefits and Obstacles. Saf. Sci. 2019, 117, 23–32. [Google Scholar] [CrossRef]

- Qazi, A.; Daghfous, A.; Khan, M.S. Impact of Risk Attitude on Risk, Opportunity, and Performance Assessment of Construction Projects. Proj. Manag. J. 2021, 52, 192–209. [Google Scholar] [CrossRef]

- Zou, P.X.; Sunindijo, R.Y. Skills for Managing Safety Risk, Implementing Safety Task, and Developing Positive Safety Climate in Construction Project. Autom. Constr. 2013, 34, 92–100. [Google Scholar] [CrossRef]

- Powell, W. Neither market nor hierarchy. In The Sociology of Organizations: Classic, Contemporary, and Critical Readings; SAGE Publications, Inc.: New York, NY, USA, 2003; Volume 315, pp. 104–117. [Google Scholar]

- Iqbal, S.; Choudhry, R.M.; Holschemacher, K.; Ali, A.; Tamošaitienė, J. Risk Management in Construction Projects. Technol. Econ. Dev. Econ. 2015, 21, 65–78. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, Z.; Chen, B.; Xing, Z.; Liu, J.; Li, J. Research on the Prediction Model for the Security Situation of Metro Station Based on PSO/SVM. J. Intell. Learn. Syst. Appl. 2013, 5, 237–244. [Google Scholar] [CrossRef][Green Version]

- Qi, H.; Zhou, Z.; Yuan, J.; Li, N.; Zhou, J. Accident Pattern Recognition in Subway Construction for the Provision of Customized Safety Measures. Tunn. Undergr. Space Technol. 2023, 137, 105157. [Google Scholar] [CrossRef]

- Cheng, R.; Wang, J.; Liao, P.-C. Temporal Visual Patterns of Construction Hazard Recognition Strategies. Int. J. Environ. Res. Public Health 2021, 18, 8779. [Google Scholar] [CrossRef] [PubMed]

- Caren, N.; Panofsky, A. TQCA: A Technique for Adding Temporality to Qualitative Comparative Analysis. Sociol. Methods Res. 2005, 34, 147–172. [Google Scholar] [CrossRef]

- Dul, J. Identifying Single Necessary Conditions with NCA and fsQCA. J. Bus. Res. 2016, 69, 1516–1523. [Google Scholar] [CrossRef]

- Xiong, F.; Shao, Y.; Fan, H.; Xie, Y. Analysis of the Motivation behind Corporate Social Responsibility Based on the csQCA Approach. Sustainability 2023, 15, 10622. [Google Scholar] [CrossRef]

- Cheng, C. A Research on the Decision-Making of Resource-Based Company’s Cross-Border M&A from the Perspective of State Institutions and Organizational Routines. Sci. Res. Manag. 2019, 40, 111–120. [Google Scholar]

- Pappas, I.O.; Woodside, A.G. Fuzzy-Set Qualitative Comparative Analysis (fsQCA): Guidelines for Research Practice in Information Systems and Marketing. Int. J. Inf. Manag. 2021, 58, 102310. [Google Scholar] [CrossRef]

- Fiss, P.C. Building Better Causal Theories: A Fuzzy Set Approach to Typologies in Organization Research. Acad. Manag. J. 2011, 54, 393–420. [Google Scholar] [CrossRef]

- Tian, Z.; Chen, Q.; Zhang, T. A Method for Assessing the Crossed Risk of Construction Safety. Saf. Sci. 2022, 146, 105531. [Google Scholar] [CrossRef]

- Zhou, Z.; Goh, Y.M.; Shi, Q.; Qi, H.; Liu, S. Data-Driven Determination of Collapse Accident Patterns for the Mitigation of Safety Risks at Metro Construction Sites. Tunn. Undergr. Space Technol. 2022, 127, 104616. [Google Scholar] [CrossRef]

- Guo, S.; Tang, B.; Liang, K.; Zhou, X.; Li, J. Comparative Analysis of the Patterns of Unsafe Behaviors in Accidents between Building Construction and Urban Railway Construction. J. Constr. Eng. Manag. 2021, 147, 04021027. [Google Scholar] [CrossRef]