Development and Analysis of Artificial Ornamental Stone with Industrial Wastes and Epoxy Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Materials’ Characterization Methods

2.2.2. Polymeric Composites’ Proportioning and Production

2.2.3. Polymeric Composites’ Characterization Methods

3. Results and Discussion

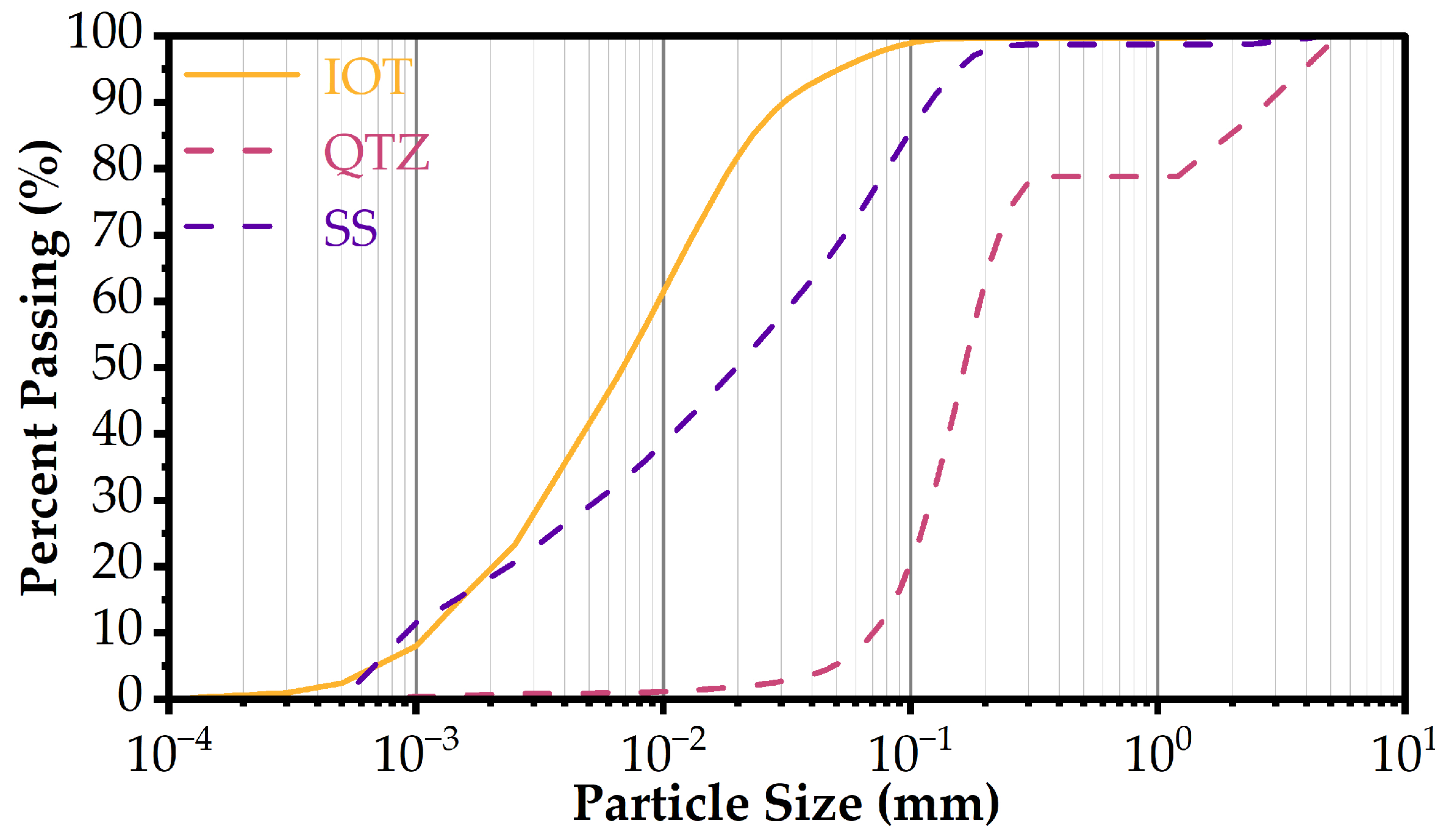

3.1. Materials’ Characterization

3.1.1. Materials’ Chemical and Mineral Composition

3.1.2. Materials’ Physical and Mechanical Properties

3.1.3. Materials’ Morphology

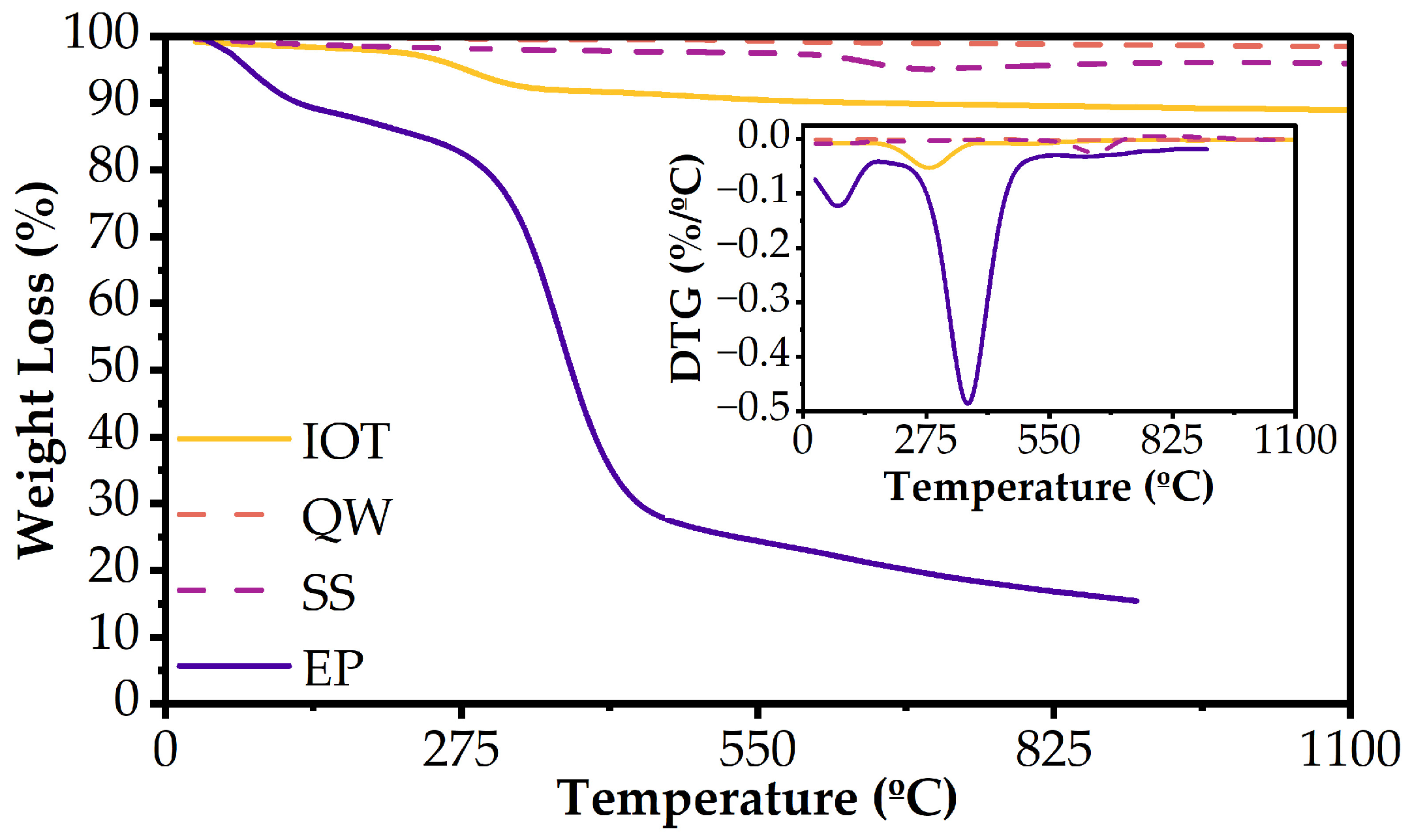

3.1.4. Materials’ Thermal Behavior

3.2. Polymeric Composites’ Characterization

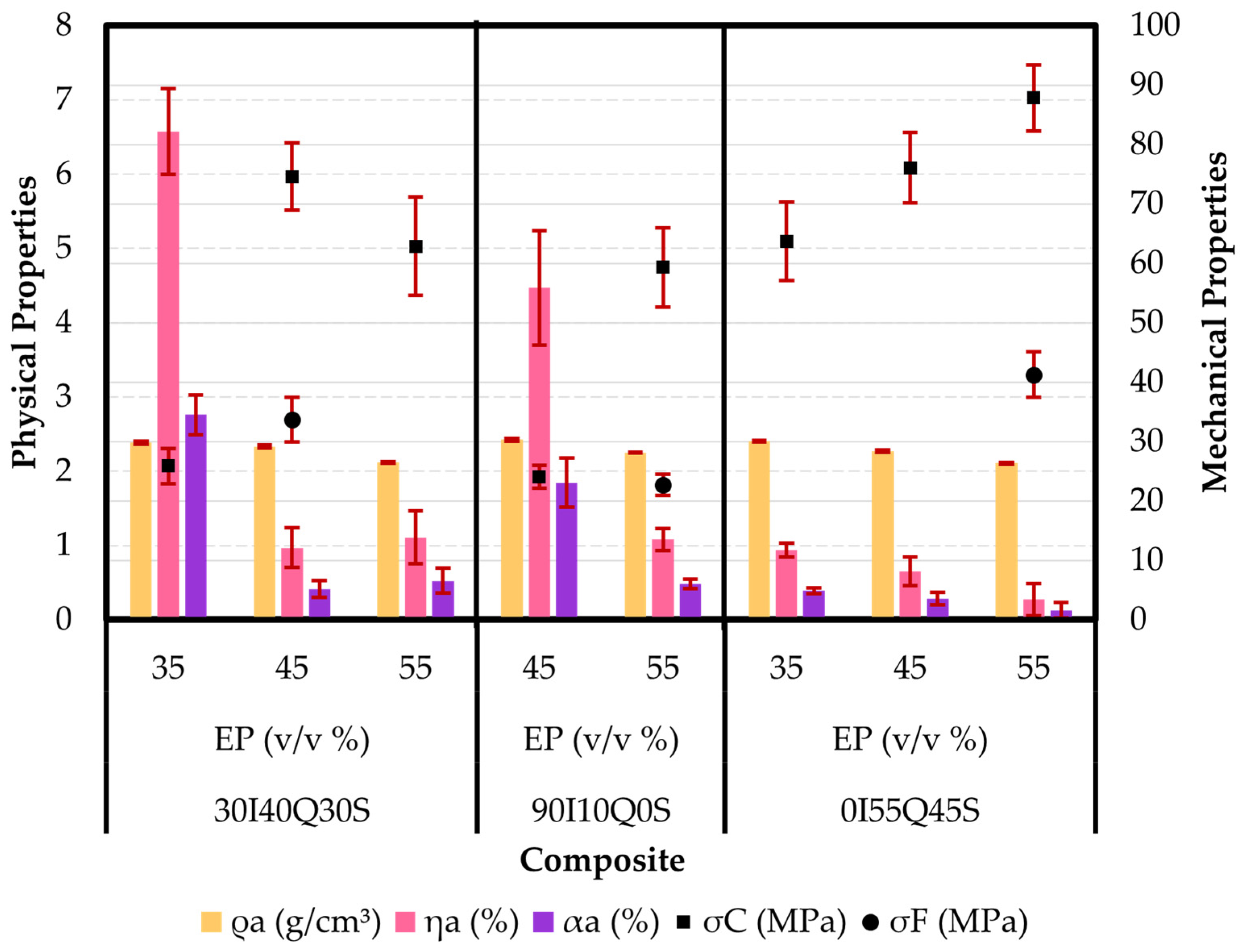

3.2.1. Composites’ Physical and Mechanical Properties

3.2.2. Composites’ Morphology

3.2.3. Composites’ Thermal Behavior

3.3. Applicability of the Polymeric Composites as AOS and Competitiveness

4. Conclusions

- IOTs are rich in Fe2O3, contributing to their high density and reddish color, while QTZ, mainly composed of SiO2, reduces density and enhances mechanical performance due to quartz’s hardness. SS has high CaO and Fe2O3 content, which leads to its high density. The high fine contents in IOTs and SS increase their water absorption.

- The 90I10Q0S composites showed the poorest performance, with high density, water absorption, and porosity and low mechanical strength and thermal stability, largely due to the high fine content of IOTs. In contrast, 0I55Q45S composites demonstrated the best performance, attributed to QTZ and SS’s favorable chemical compositions and low fine contents and a good interface with the EP matrix. The 30I40Q30S composites exhibited intermediate performance due to a balanced composition of all industrial wastes.

- The polymeric composites 30I40Q30S 45 v/v % EP, 90I10Q0S 55 v/v % EP, and 0I55Q45S 55 v/v % EP exhibited strong performance, with 0I55Q45S 55 v/v % EP showing the best overall properties: an apparent density of 2.1 g/cm3, porosity of 0.3%, water absorption of 0.1%, and flexural strength of 41.25 MPa. The 30I40Q30S 45 v/v % EP composite also performed well, with a density of 2.3 g/cm3, porosity of 1.0%, water absorption of 0.4%, and flexural strength of 33.67 MPa. While the 90I10Q0S 55 v/v % EP composite had slightly lower metrics, it still demonstrated competitive properties. All three composites are suitable for use as AOS, with 30I40Q30S 45 v/v % EP and 0I55Q45S 55 v/v % EP applicable without restrictions for internal and external wall cladding. However, the 90I10Q0S 55 v/v % EP composite requires a sealant for wet areas and is limited to areas with occasional water exposure when used in tops or countertops.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. Geological Survey. Mineral Commodity Summaries. Available online: https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-iron-ore.pdf (accessed on 10 July 2024).

- National Mining Agency—ANM. Brazilian Mineral Yearbook. Available online: https://app.powerbi.com/view?r=eyJrIjoiODIyOWJlMTgtZTBlNi00ODFhLWJiOGEtYzlmOWM3MjhmMWQ4IiwidCI6ImEzMDgzZTIxLTc0OWItNDUzNC05YWZhLTU0Y2MzMTg4OTdiOCJ9 (accessed on 10 July 2024). (In Portuguese)

- Worldsteel Association. 2024 World Steel in Figures. Available online: https://worldsteel.org/wp-content/uploads/World-Steel-in-Figures-2024.pdf (accessed on 10 July 2024).

- Mineral Technology Center—CETEM. Environmental Aspects of the Mining and Steelmaking Industries. Available online: http://mineralis.cetem.gov.br/bitstream/cetem/765/1/CCL00390010.pdf (accessed on 10 June 2023). (In Portuguese)

- Collares, E.G.; Francklin, I.; Motta, L.A.D.C. Evaluation of the aggregate produced from wastes of quartzite mining sites to use in concrete. Soils Rocks 2012, 35, 251–266. [Google Scholar] [CrossRef]

- Brazil Steel Institute. Sustainability Indicators: Environmental Data. Available online: https://acobrasil.org.br/site/indicadores-de-sustentabilidade/ (accessed on 25 March 2023). (In Portuguese).

- Matiolo, E.; Couto, H.J.B.; Lima, N.; Silva, K.; de Freitas, A.S. Improving recovery of iron using column flotation of iron ore slimes. Min. Eng. 2020, 158, 106608. [Google Scholar] [CrossRef]

- El Machi, A.; El Berdai, Y.; Mabroum, S.; Safhi, A.e.M.; Taha, Y.; Benzaazoua, M.; Hakkou, R. Recycling of Mine Wastes in the Concrete Industry: A Review. Buildings 2024, 14, 1508. [Google Scholar] [CrossRef]

- Martins, L.M.; Peixoto, R.A.F.; Mendes, J.C. Quartzite tailings in civil construction materials: A systematic review. Clean Technol. Environ. Policy 2023, 25, 1807–1824. [Google Scholar] [CrossRef]

- Colla, V.; Branca, T.A.; Pietruck, R.; Wölfelschneider, S.; Morillon, A.; Algermissen, D.; Rosendahl, S.; Granbom, H.; Martini, U.; Snaet, D. Future Research and Developments on Reuse and Recycling of Steelmaking By-Products. Metals 2023, 13, 676. [Google Scholar] [CrossRef]

- United Nations—UN. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 8 July 2024).

- Sá, T.S.W.; Oda, S.; Balthar, V.K.C.B.L.M.; Toledo Filho, R.D. Use of iron ore tailings and sediments on pavement structure. Constr. Build. Mater. 2022, 342, 128072. [Google Scholar] [CrossRef]

- Liu, K.; Wang, S.; Quan, X.; Jing, W.; Xu, J.; Zhao, N.; Liu, B.; Ying, H. Industrial byproduct Iron ore tailings as ecofriendly materials in the utilization of cementitious composites. Constr. Build. Mater. 2023, 372, 130813. [Google Scholar] [CrossRef]

- Gong, L.; Hua, X.; Yao, B.; Liang, J.; Tian, G. Novel red composite pigment with high thermostability from iron ore tailings: Synthesis and coloring mechanism. Ceram. Int. 2022, 49, 5066–5076. [Google Scholar] [CrossRef]

- Silva, M.C.A.; Leão, V.A.; Reis, E.L. Incorporation of quartzite fines in the production of red ceramics. J. Clean. Prod. 2021, 288, 125098. [Google Scholar] [CrossRef]

- Barros, S.V.A.; Marciano, J.E.A.; Ferreira, H.C.; Menezes, R.R.; Neves, G.A. Addition of quartzite residues on mortars: Analysis of the alkali aggregate reaction and the mechanical behavior. Constr. Build. Mater. 2016, 118, 344–351. [Google Scholar] [CrossRef]

- Gehlot, T.; Sankhla, S.S.; Parihar, S. Compressive, flexural strength test and chloride ion permeability test of concrete incorporating quartzite rock dust. Mater. Today Proc. 2021, 45, 4724–4730. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q.; Luo, T. A quantitative method to assess and predict the exothermic behavior of steel slag blended cement. Cem. Concr. Res. 2024, 175, 107373. [Google Scholar] [CrossRef]

- Carvalho, V.R.; Costa, L.C.B.; Elói, F.P.F.; Bezerra, A.C.S.; Carvalho, J.M.F.; Peixoto, R.A.F. Performance of low-energy steel slag powders as supplementary cementitious materials. Constr. Build. Mater. 2023, 392, 131888. [Google Scholar] [CrossRef]

- Rana, A.; Singh, N. Microstructural characteristics of iron-steel slag concrete: A brief review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Fontes, W.C.; Mendes, J.C.; da Silva, S.N.; Peixoto, R.A.F. Mortars for laying and coating produced with iron ore tailings from tailing dams. Constr. Build. Mater. 2016, 112, 988–995. [Google Scholar] [CrossRef]

- de Carvalho, J.M.F.; Fontes, W.C.; de Azevedo, C.F.; Brigolini, G.J.; Schmidt, W.; Peixoto, R.A.F. Enhancing the eco-efficiency of concrete using engineered recycled mineral admixtures and recycled aggregates. J. Clean. Prod. 2020, 257, 120530. [Google Scholar] [CrossRef]

- Carrieri, M.; Guzzardo, C.; Farcas, D.; Cena, L.G. Characterization of Silica Exposure during Manufacturing of Artificial Stone Countertops. Int. J. Environ. Res. Public Health 2020, 17, 4489. [Google Scholar] [CrossRef] [PubMed]

- Gomes, M.L.P.M.; Carvalho, E.A.S.; Barreto, G.N.S.; Rodriguez, R.J.S.; Monteiro, S.N.; Vieira, C.M.F. Development of Sustainable Artificial Stone Using Granite Waste and Biodegradable Polyurethane from Castor Oil. Sustainability 2022, 14, 6380. [Google Scholar] [CrossRef]

- Ribeiro, C.E.G.; Rodriguez, R.J.S.; Vieira, C.M.F.; Carvalho, E.A.; Candido, V.S.; Monteiro, S.N. Fabrication of Artificial Stone from Marble Residue by Resin Transfer Molding. Mater. Sci. For. 2014, 775–776, 336–340. [Google Scholar] [CrossRef]

- Shelley, M.Y. Epoxy Resins. In Polymer Data Handbook, 1st ed.; Mark, J.E., Ed.; Oxford University Press: Cincinnati, OH, USA, 1998; pp. 90–96. ISBN 0195107896. [Google Scholar]

- Agrizzi, C.P.; Carvalho, E.A.S.; Borlini Gadioli, M.C.; Barreto, G.N.S.; de Azevedo, A.R.G.; Monteiro, S.N.; Vieira, C.M.F. Comparison between Synthetic and Biodegradable Polymer Matrices on the Development of Quartzite Waste-Based Artificial Stone. Sustainability 2022, 14, 6388. [Google Scholar] [CrossRef]

- Barreto, G.N.S.; Carvalho, E.A.S.; Souza, V.d.S.d.; Gomes, M.L.P.M.; de Azevedo, A.R.G.; Monteiro, S.N.; Vieira, C.M.F. Engineered Stone Produced with Glass Packaging Waste, Quartz Powder, and Epoxy Resin. Sustainability 2022, 14, 7227. [Google Scholar] [CrossRef]

- Mostovoi, A.S.; Kurbatova, E.A. Controlling the properties of epoxy composites filled with brick dust. Russ. J. Appl. Chem. 2017, 90, 267–276. [Google Scholar] [CrossRef]

- Upadhyay, P.; Rajput, V.; Rajput, P.S.; Mishra, V.; Khan, I.A.; Jha, A.; Agrawal, A. Physical, mechanical and sliding wear behaviour of epoxy composites filled with micro-sized marble dust composites. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- NBR NM 26; Aggregates–Sampling. Brazilian Association of Technical Norms–ABNT: Rio de Janeiro, Brazil, 2009. (In Portuguese)

- NBR 16916; Fine Aggregates—Determination of Bulk Density and Water Absorption. Brazilian Association of Technical Norms—ABNT: Rio de Janeiro, Brazil, 2021. (In Portuguese)

- NBR 17054; Aggregates—Determination of Particle-Size Distribution—Testing Methods. Brazilian Association of Technical Norms—ABNT: Rio de Janeiro, Brazil, 2022. (In Portuguese)

- D570; Standard Test Method for Water Absorption of Plastics. American Society for Testing and Materials—ASTM: West Conshohocken, PA, USA, 2022.

- D792; Standard Test Method for Density and Specific Gravity (Relative Density) of Plastics by Displacement. American Society for Testing and Materials—ASTM: West Conshohocken, PA, USA, 2020.

- D695; Standard Test Method for Compressive Properties of Rigid Plastics. American Society for Testing and Materials—ASTM: West Conshohocken, PA, USA, 2015.

- D790; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials—ASTM: West Conshohocken, PA, USA, 2017.

- NBR 15845-2; Rocks for Cladding. Part 2: Determination of Bulk Density, Apparent Porosity and Water Absorption. Brazilian Association of Technical Norms—ABNT: Rio de Janeiro, Brazil, 2015. (In Portuguese)

- NBR 15845-5; Rocks for Cladding. Part 5: Determination of Uniaxial Compressive Strength. Brazilian Association of Technical Norms—ABNT: Rio de Janeiro, Brazil, 2015. (In Portuguese)

- NBR 15845-6; Rocks for Cladding. Part 6: Determination of the Modulus of Rupture (Three-point Flexural Strength). Brazilian Association of Technical Norms—ABNT: Rio de Janeiro, Brazil, 2015. (In Portuguese)

- Jabbar, F.J. Study the Thermal Properties of Epoxy Resin Reinforced with Calcium Oxide Fibers. Smart Sci. 2021, 9, 61–69. [Google Scholar] [CrossRef]

- Pour, Z.; Ghaemy, M. Thermo-mechanical behaviors of epoxy resins reinforced with silane-epoxide functionalized α-Fe2O3 nanoparticles. Prog. Org. Coat. 2014, 77, 1316–1324. [Google Scholar] [CrossRef]

- Jin, F.; Park, S. Thermal properties of epoxy resin/filler hybrid composites. Polym. Degrad. Stab. 2012, 97, 2148–2153. [Google Scholar] [CrossRef]

- Xie, Q.; Fu, K.; Liang, S.; Liu, B.; Lu, L.; Yang, X.; Huang, Z.; Lü, F. Micro-Structure and Thermomechanical Properties of Crosslinked Epoxy Composite Modified by Nano-SiO2: A Molecular Dynamics Simulation. Polymers 2018, 10, 801. [Google Scholar] [CrossRef]

- Fontes, W.C.; de Carvalho, J.M.F.; Andrade, L.C.R.; Segadães, A.M.; Peixoto, R.A.F. Assessment of the use potential of iron ore tailings in the manufacture of ceramic tiles: From tailings-dams to “brown porcelain”. Constr. Build. Mater. 2019, 206, 111–121. [Google Scholar] [CrossRef]

- Pinto, D.; Bernardo, L.; Amaro, A.; Lopes, S. Mechanical properties of epoxy nanocomposites using titanium dioxide as reinforcement—A review. Constr. Build. Mater. 2015, 95, 506–524. [Google Scholar] [CrossRef]

- Brazilian Association of Ornamental Stones Industry–ABIROCHAS. Application Guide for Ornamental Stones; ABIROCHAS: Brasilia, Brazil, 2020. (In Portuguese) [Google Scholar]

- Carvalho, E.A.S.; Marques, V.R.; Rodrigues, R.J.S.; Ribeiro, C.E.G.; Monteiro, S.N.; Vieira, C.M.F. Development of Epoxy Matrix Artificial Stone Incorporated with Sintering Residue from Steelmaking Industry. Mater. Res. 2015, 18, 235–239. [Google Scholar] [CrossRef]

- Peixoto, J.; Carvalho, E.A.S.; Gomes, M.L.P.M.; Guimarães, R.d.S.; Monteiro, S.N.; de Azevedo, A.R.G.; Vieira, C.M.F. Incorporation of Industrial Glass Waste into Polymeric Resin to Develop Artificial Stones for Civil Construction. Arab. J. Sci. Eng. 2021, 47, 4313–4322. [Google Scholar] [CrossRef]

- Gomes, M.L.P.M.; Carvalho, E.A.S.; Demartini, T.J.C.; de Carvalho, E.A.; Colorado, H.A.; Vieira, C.M.F. Mechanical and physical investigation of an artificial stone produced with granite residue and epoxy resin. J. Compos. Mater. 2020, 55, 1247–1254. [Google Scholar] [CrossRef]

- Carvalho, E.A.S.; Vilela, N.d.F.; Monteiro, S.N.; Vieira, C.M.F.; da Silva, L.C. Novel Artificial Ornamental Stone Developed with Quarry Waste in Epoxy Composite. Mater. Res. 2018, 21, e20171104. [Google Scholar] [CrossRef]

- Gomes, M.L.P.M.; Carvalho, E.A.S.; Sobrinho, L.N.; Monteiro, S.N.; Rodriguez, R.J.S.; Vieira, C.M.F. Production and characterization of a novel artificial stone using brick residue and quarry dust in epoxy matrix. J. Mater. Res. Technol. 2018, 7, 492–498. [Google Scholar] [CrossRef]

- Carvalho, E.A.S.; Magalhães, J.P.B.; Rodriguez, R.J.S.; Carvalho, E.A.; Monteiro, S.N.; Vieira, C.M.F. Reuse of Quarry Waste in Artificial Stone Production with Using Vacuum, Compression, and Vibration. In Green Materials Engineering: An EPD Symposium in Honor of Sergio Monteiro; Springer International Publishing: New York, NY, USA, 2019; pp. 241–247. [Google Scholar] [CrossRef]

| Composite | EP 2 Content (v/v %) | IOTs 2 (v/v %) | QTZ 2 (v/v %) | SS 2 (v/v %) |

|---|---|---|---|---|

| 30I40Q30S (7.68) 1 | 35 | 19.50 | 26.00 | 19.50 |

| 45 | 16.50 | 22.00 | 16.50 | |

| 55 | 13.50 | 18.00 | 13.50 | |

| 90I10Q0S (9.33) 1 | 45 | 49.50 | 5.50 | - |

| 55 | 40.50 | 4.50 | - | |

| 0I55Q45S (9.47) 1 | 35 | - | 35.75 | 29.25 |

| 45 | - | 30.25 | 24.75 | |

| 55 | - | 24.75 | 20.25 |

| Industrial Waste * | Oxides (Content, %) | Mineral Structures |

|---|---|---|

| IOTs | Fe2O3 (71.4) | Goethite |

| Al2O3 (8.7) | Hematite | |

| SiO2 (8.4) | Kaolinite | |

| Other oxides (1.5) | Gibbsite | |

| LOI (10.0) | Quartz | |

| QTZ | SiO2 (93.6) | Quartz |

| Al2O3 (4.6) | ||

| Other oxides (1.0) | ||

| LOI (0.8) | ||

| SS | CaO (33.8) | Brownmillerite Calcite Larnite Wüstite |

| Fe2O3 (31.1) | ||

| SiO2 (16.1) | ||

| MgO (6.4) | ||

| Al2O3 (4.4) | ||

| Other oxides (6.4) | ||

| LOI (1.8) |

| Material * | Bulk Density (g/cm3) | Water Absorption (%) |

|---|---|---|

| IOTs | 3.68 | 17.44 |

| QTZ | 2.53 | 0.42 |

| SS | 3.71 | 15.16 |

| EP | 1.14 | 0.07 |

| Composite | ρa (g/cm3) | ηa (%) | αa (%) | σC (MPa) | EC (GPa) | σF (MPa) | EF (GPa) | |

|---|---|---|---|---|---|---|---|---|

| 30I40Q30S | 35 v/v % EP | 2.4 ± 0.0 | 6.6 ± 0.6 | 2.8 ± 0.3 | 26 ± 3 | 0.65 ± 0.05 | NT | NT |

| 45 v/v % EP | 2.3 ± 0.0 | 1.0 ± 0.3 | 0.4 ± 0.1 | 75 ± 6 | 1.30 ± 0.04 | 34 ± 4 | 1.51 ± 0.32 | |

| 55 v/v % EP | 2.1 ± 0.0 | 1.1 ± 0.4 | 0.5 ± 0.2 | 63 ± 8 | 1.14 ± 0.09 | NT | NT | |

| 90I10Q0S | 45 v/v % EP | 2.4 ± 0.0 | 4.5 ± 0.8 | 1.8 ± 0.3 | 24 ± 2 | 0.31 ± 0.04 | NT | NT |

| 55 v/v % EP | 2.3 ± 0.0 | 1.1 ± 0.1 | 0.5 ± 0.1 | 59 ± 7 | 0.97 ± 0.11 | 23 ± 2 | 1.12 ± 0.15 | |

| 0I55Q45S | 35 v/v % EP | 2.4 ± 0.0 | 0.9 ± 0.1 | 0.4 ± 0.0 | 64 ± 7 | 1.24 ± 0.08 | NT | NT |

| 45 v/v % EP | 2.3 ± 0.0 | 0.6 ± 0.2 | 0.3 ± 0.1 | 76 ± 6 | 1.27 ± 0.08 | NT | NT | |

| 55 v/v % EP | 2.1 ± 0.0 | 0.3 ± 0.2 | 0.1 ± 0.1 | 88 ± 6 | 1.26 ± 0.05 | 41 ± 4 | 1.72 ± 0.3 | |

| Application Guide for Ornamental Stones—Requirements | ||

| Property | Class | Parameter |

| Water absorption (%) | A1 | ≤0.4% |

| A2 | >0.4% | |

| Three-point flexural strength (MPa) | C1 | ≥8.0 |

| C2 | <8.0 | |

| Produced Polymeric Composites’ Classification | ||

| Composite | Class | Applicability 1 |

| 30I40Q30S 45 v/v % EP | A1C1 |

|

| 90I10Q0S 55 v/v % EP | A2C1 |

|

| 0I55Q45S 55 v/v % EP | A1C1 |

|

| Author | ρA (g/cm3) 2 | ηA (%) 2 | αA (%) 2 | σF (Mpa) 2 | |

|---|---|---|---|---|---|

| Agrizzi et al. [27] | 2.4 ± 0.0 | 0.4 ± 0.2 | 0.2 ± 0.1 | 27.96 ± 1.86 | |

| Carvalho et al. [48] | 2.7 ± 0.0 | 0.5 ± 0.1 | 0.2 ± 0.0 | 57.57 ± 3.21 | |

| 2.7 ± 0.0 | 0.6 ± 0.2 | 0.2 ± 0.1 | 41.70 ± 4.08 | ||

| Barreto et al. [28] | 2.3 ± 0.0 | 0.2 ± 0.0 | 0.1 ± 0.0 | 33.54 ± 4.05 | |

| Peixoto et al. [49] | 1.8 ± 0.0 | 0.8 ± 0.0 | 0.4 ± 0.1 | 25.40 ± 0.90 | |

| Gomes et al. [50] | 2.3 ± 0.0 | 0.2 ± 0.0 | 0.1 ± 0.1 | 32.92 ± 2.92 | |

| Carvalho et al. [51] | 2.4 ± 0.1 | 0.8 ± 0.2 | 0.4 ± 0.1 | 30.00 ± 1.00 | |

| 2.3 ± 0.0 | 0.6 ± 0.0 | 0.3 ± 0.0 | 32.00 ± 3.00 | ||

| Gomes et al. [52] | 2.1 ± 0.0 | 0.2 ± 0.0 | 0.4 ± 0.1 | 30.00 ± 3.00 | |

| Carvalho et al. [53] | 2.3 ± 0.0 | 0.3 ± 0.0 | 0.1 ± 0.0 | 32.00 ± 1.98 | |

| Silva et al. (This study) | 30I40Q30S 45 v/v % EP 1 | 2.3 ± 0.0 | 1.0 ± 0.3 | 0.4 ± 0.1 | 33.67 ± 3.72 |

| 90I10Q0S 55 v/v % EP | 2.3 ± 0.0 | 1.1 ± 0.1 | 0.5 ± 0.1 | 22.64 ± 1.78 | |

| 0I55Q45S 55 v/v % EP | 2.1 ± 0.0 | 0.3 ± 0.2 | 0.1 ± 0.1 | 41.25 ± 3.87 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, R.N.; Santos, A.R.d.; Patrício, P.S.d.O.; Fontes, W.C. Development and Analysis of Artificial Ornamental Stone with Industrial Wastes and Epoxy Resin. Sustainability 2024, 16, 7715. https://doi.org/10.3390/su16177715

Silva RN, Santos ARd, Patrício PSdO, Fontes WC. Development and Analysis of Artificial Ornamental Stone with Industrial Wastes and Epoxy Resin. Sustainability. 2024; 16(17):7715. https://doi.org/10.3390/su16177715

Chicago/Turabian StyleSilva, Rivelino Neri, Anderson Ravik dos Santos, Patrícia Santiago de Oliveira Patrício, and Wanna Carvalho Fontes. 2024. "Development and Analysis of Artificial Ornamental Stone with Industrial Wastes and Epoxy Resin" Sustainability 16, no. 17: 7715. https://doi.org/10.3390/su16177715

APA StyleSilva, R. N., Santos, A. R. d., Patrício, P. S. d. O., & Fontes, W. C. (2024). Development and Analysis of Artificial Ornamental Stone with Industrial Wastes and Epoxy Resin. Sustainability, 16(17), 7715. https://doi.org/10.3390/su16177715