Research on Nondestructive Testing Technology for Drilling Risers Based on Magnetic Memory and Deep Learning

Abstract

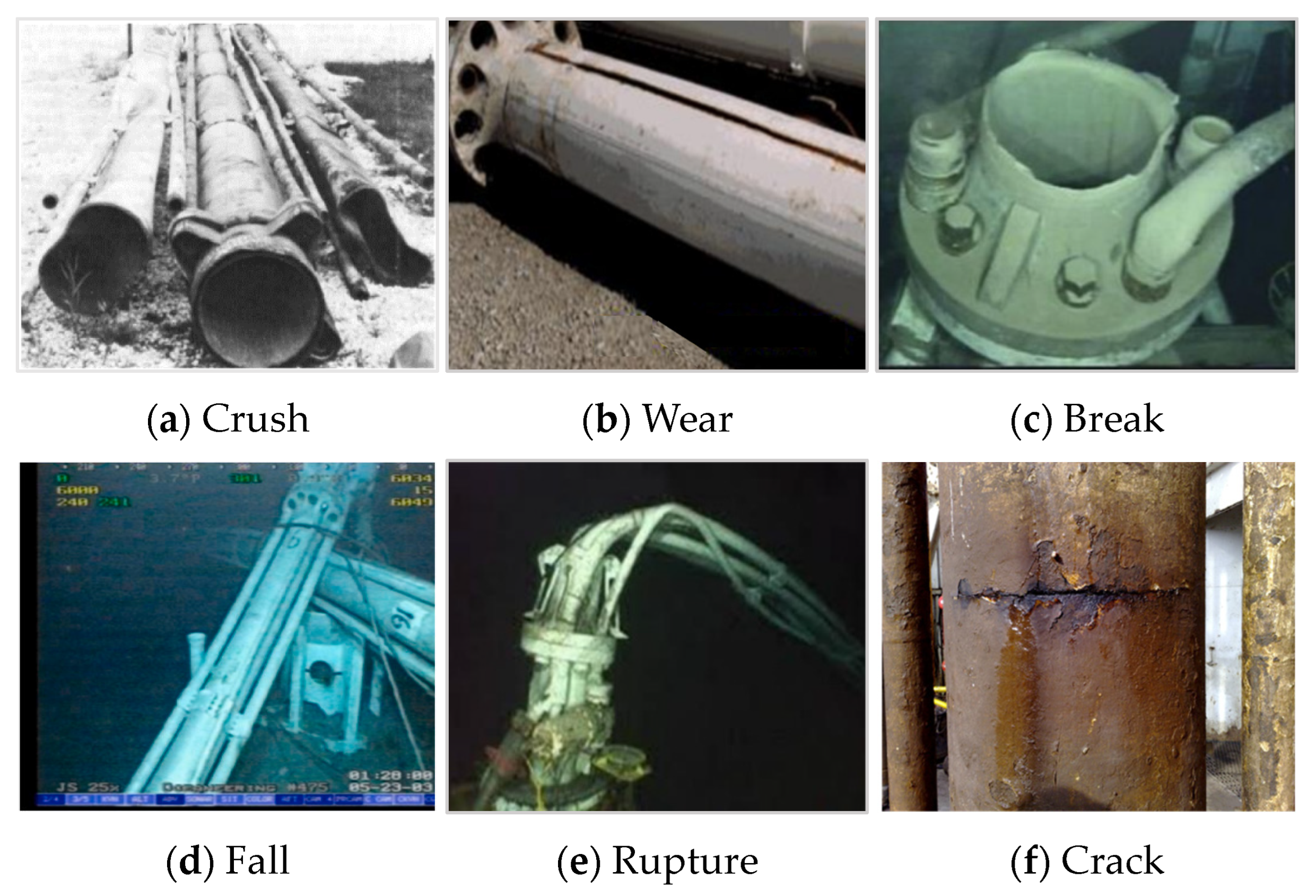

1. Introduction

2. Related Work

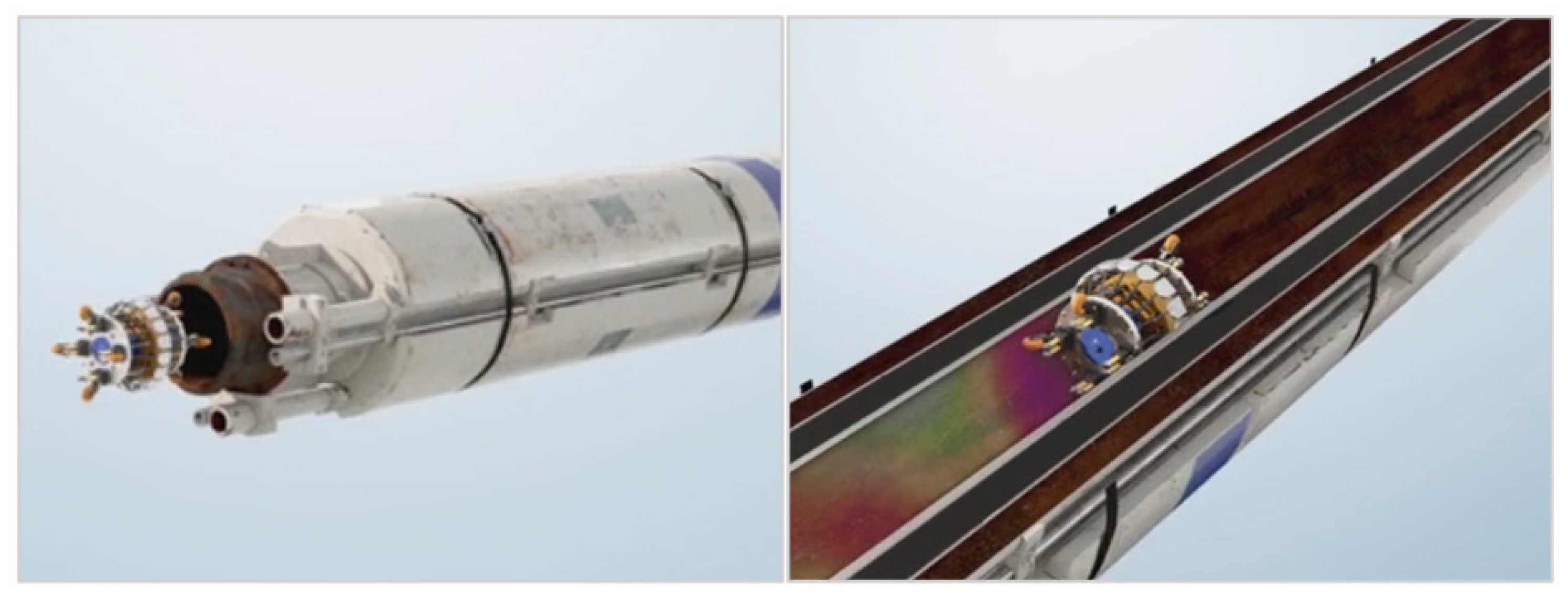

2.1. Existing Nondestructive Testing Devices for Risers

2.2. Research on Intelligent Identification of Pipeline Defects

3. Materials and Methods

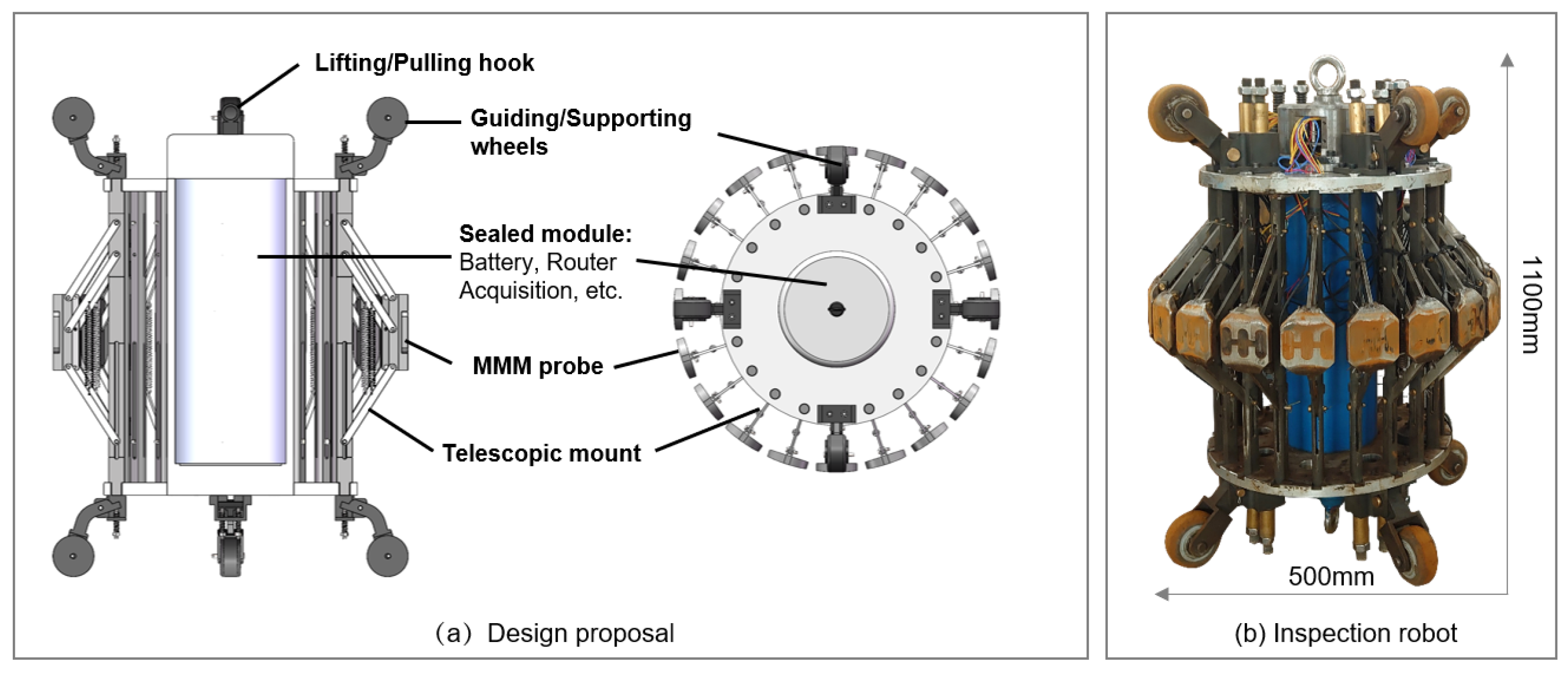

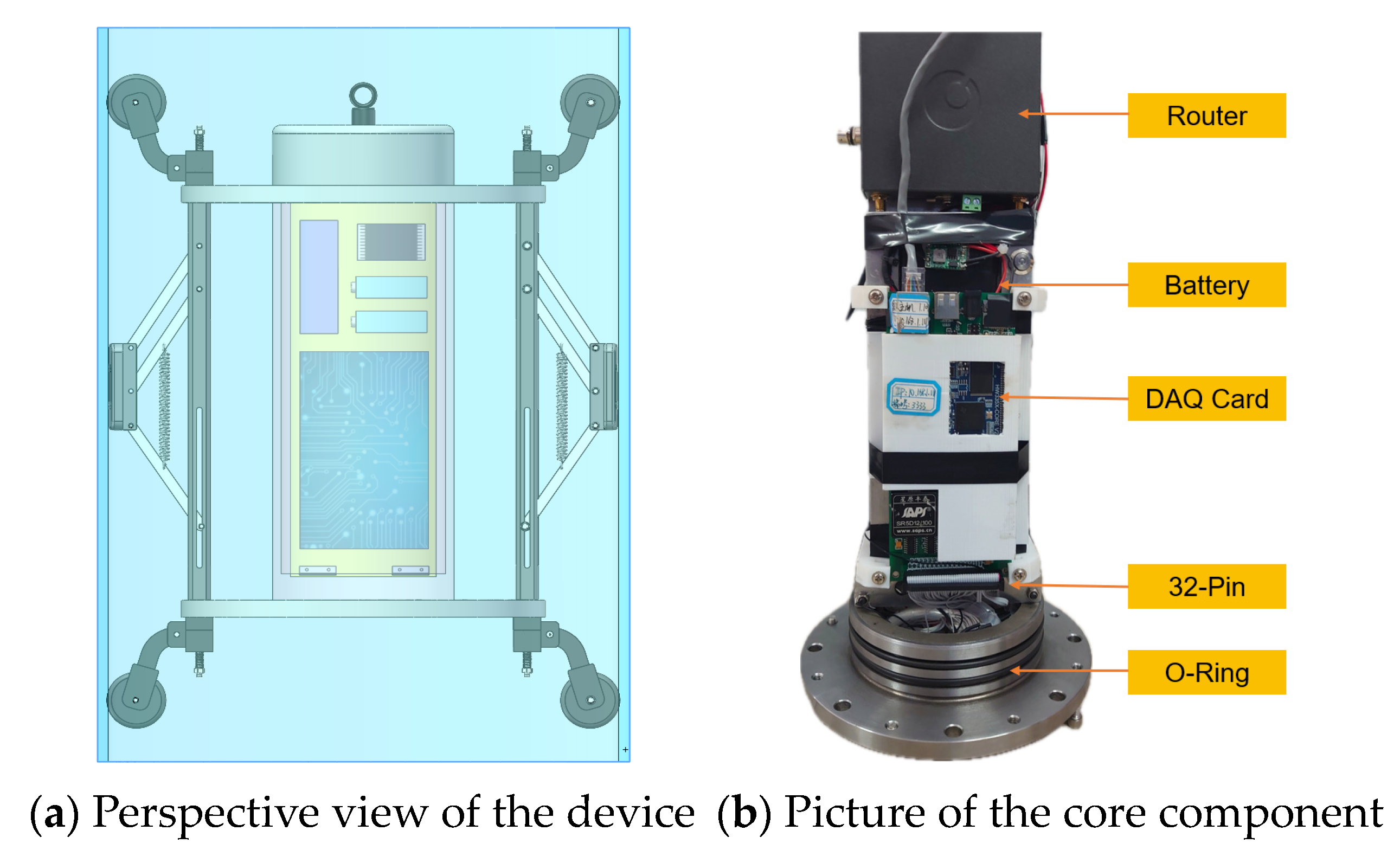

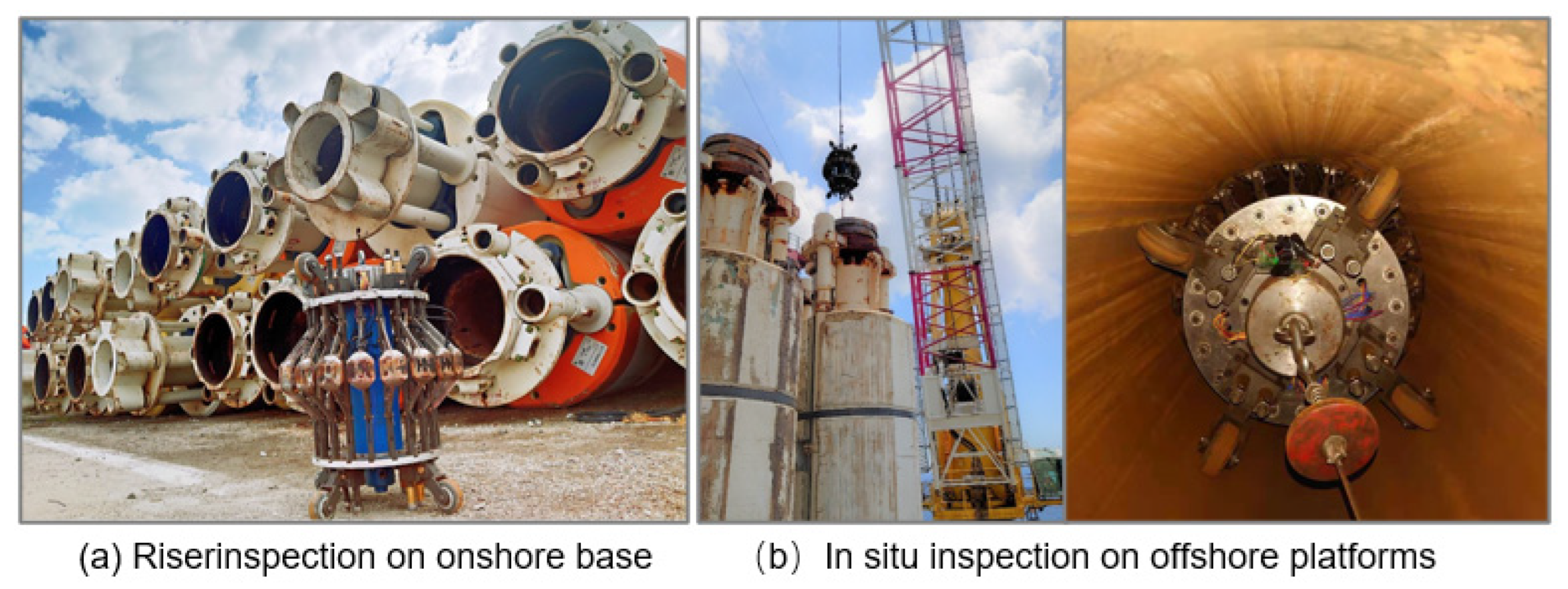

3.1. Development and Application of Magnetic Memory-Based Riser Inspection Robots

3.1.1. Design Requirements

3.1.2. Design Proposal

3.1.3. Industrial Application

3.1.4. Data Visualization Analysis

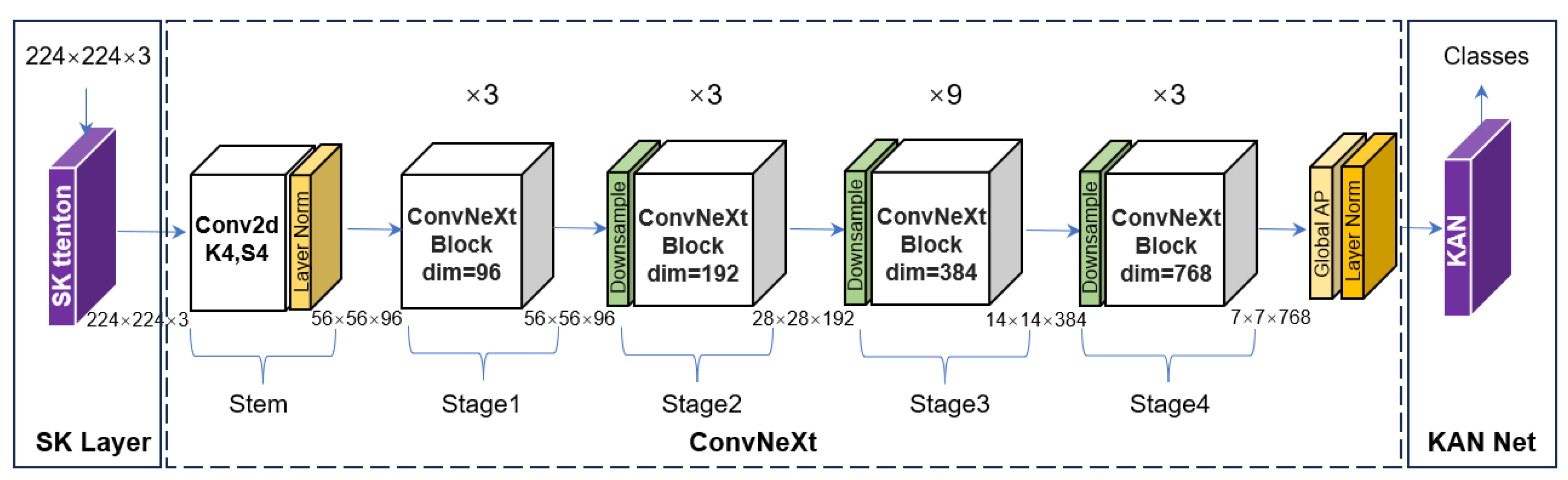

3.2. Intelligent Classification of Defect Images Based on SK-ConvNeXt-KAN

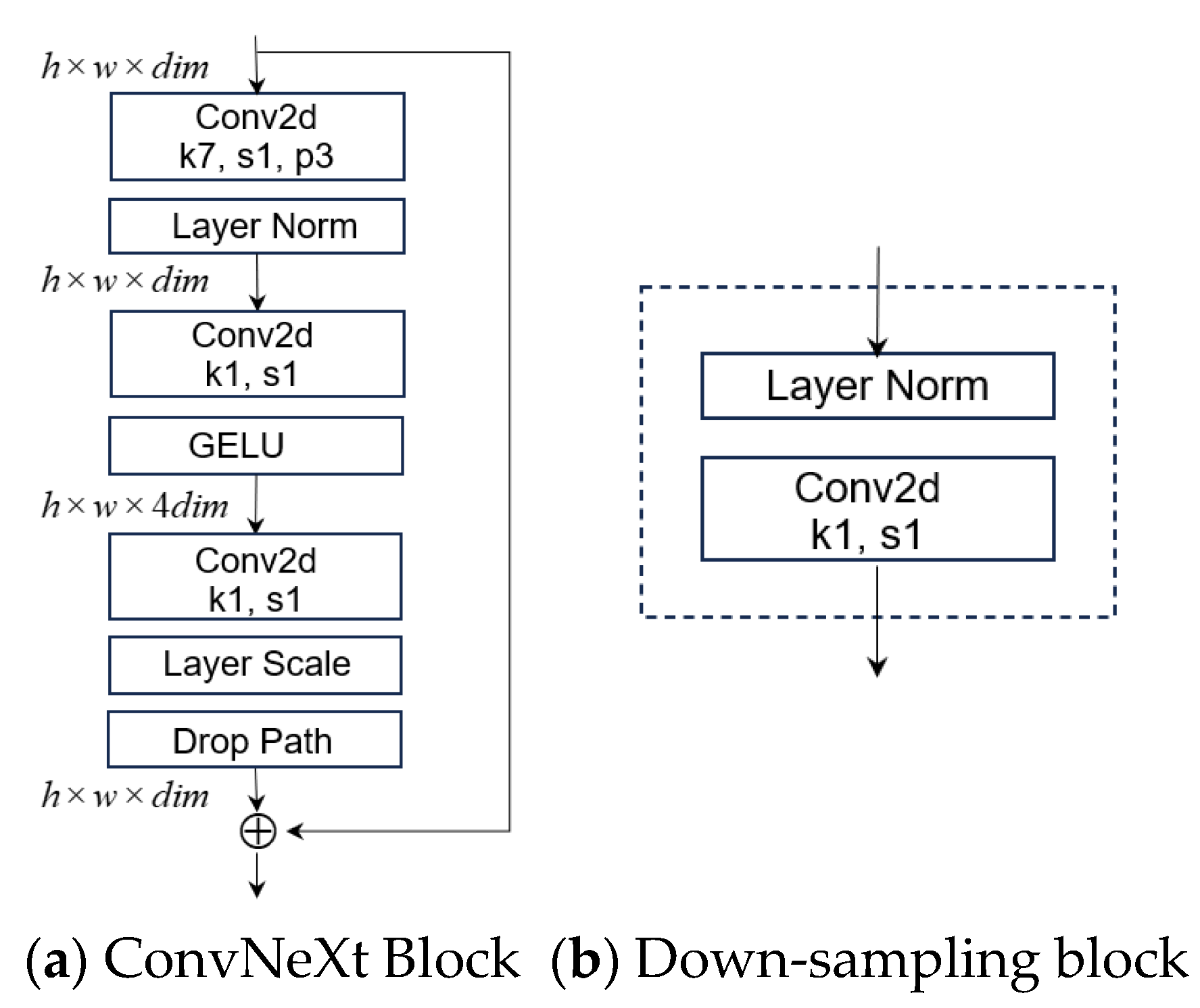

3.2.1. ConvNeXt Network

- Macro design

- Micro design

3.2.2. Selective Kernel Attention

- Split

- Fuse

- Select

3.2.3. Kolmogorov–Arnold Network

3.2.4. SK-ConvNeXt-KAN Network

4. Experiment Results and Discussion

4.1. Experimental Environment

4.2. Dataset and Evaluation Metrics

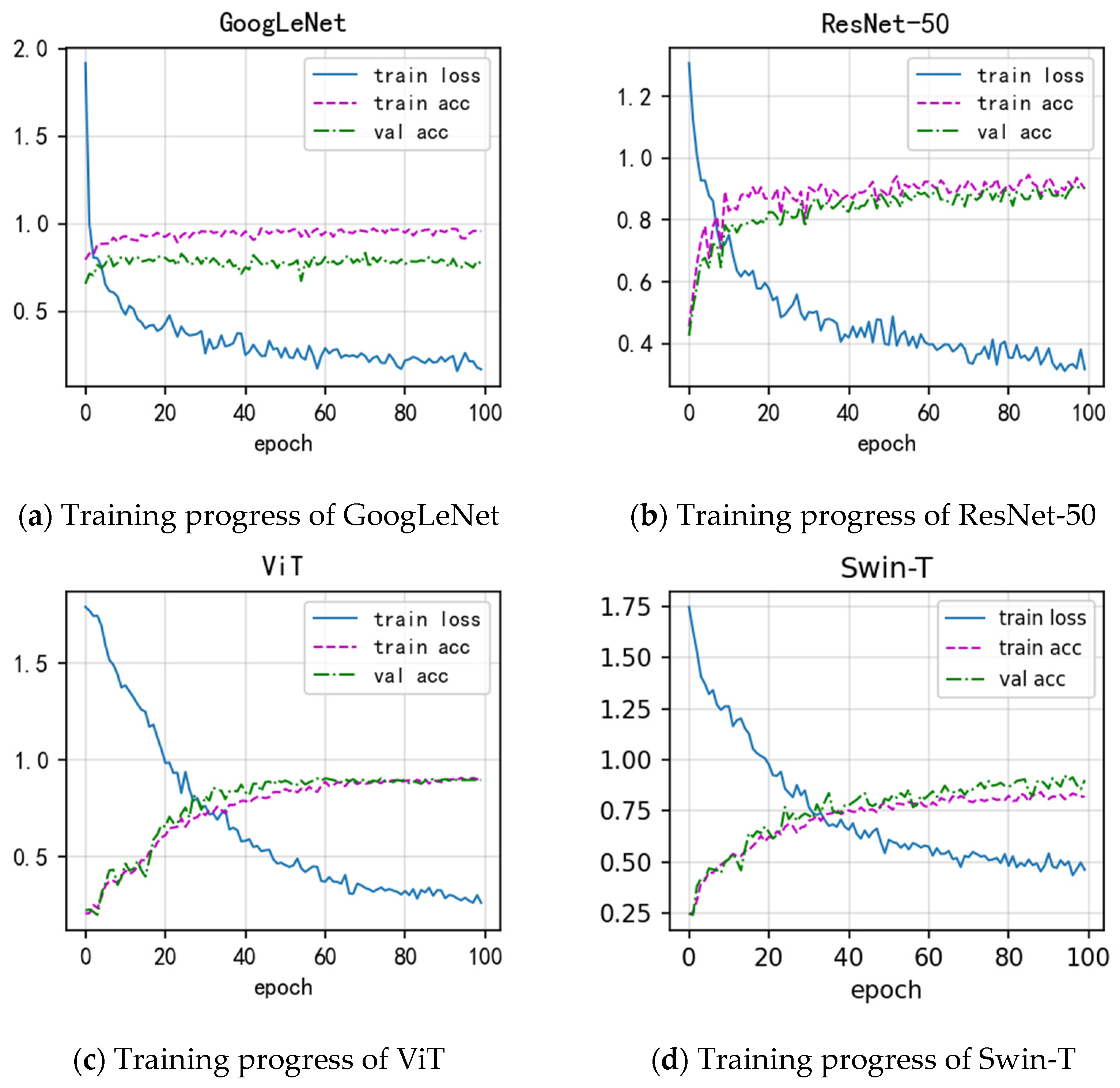

4.3. Comparative Experiment

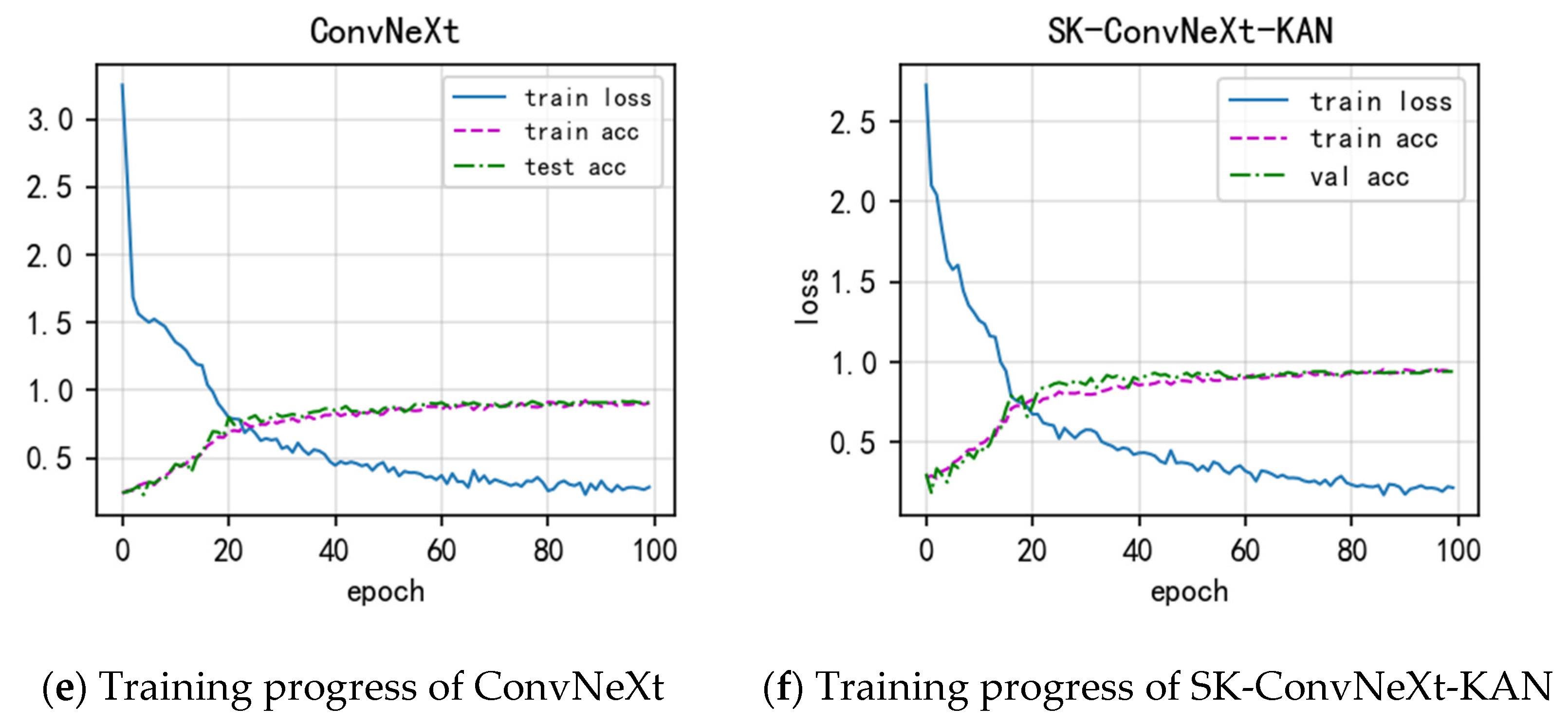

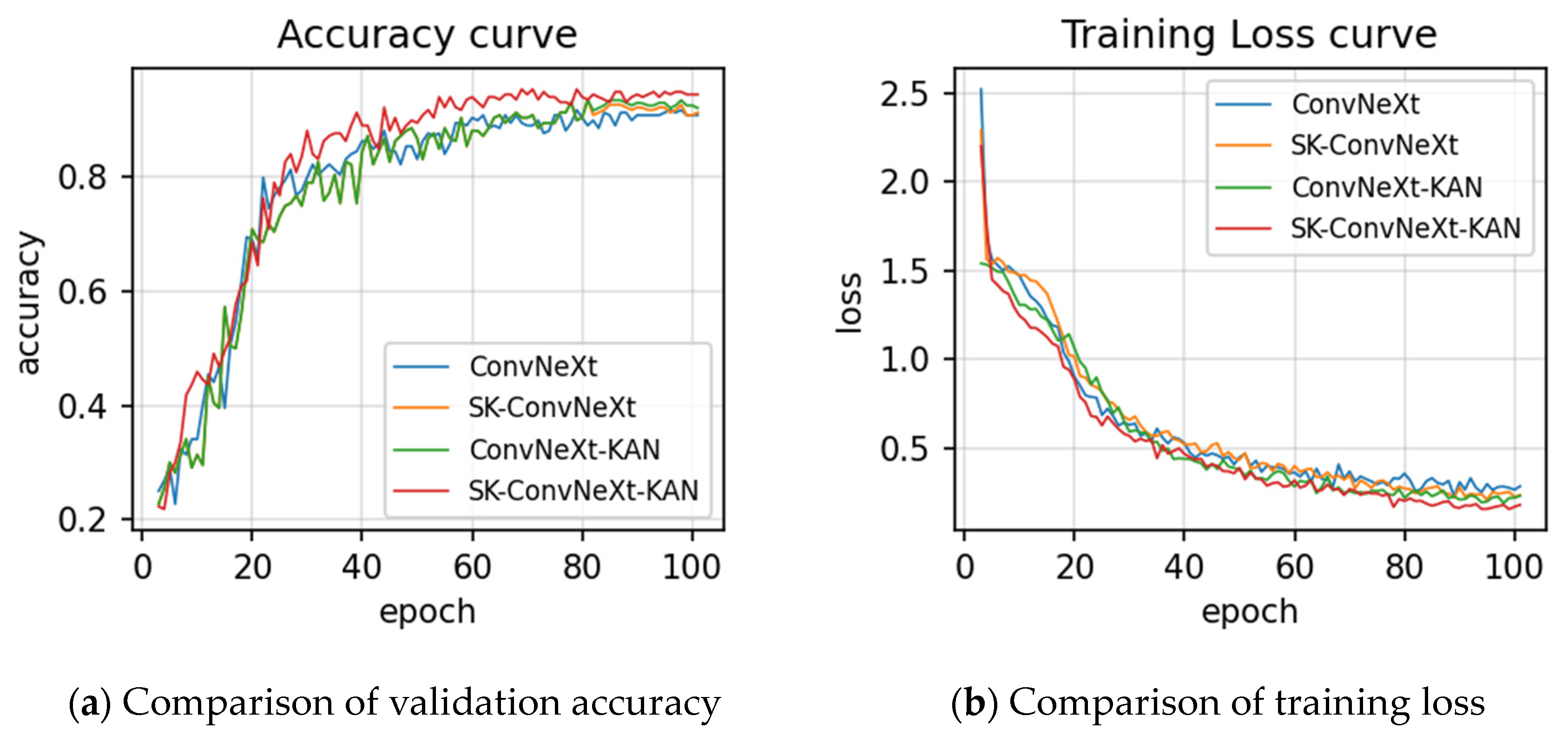

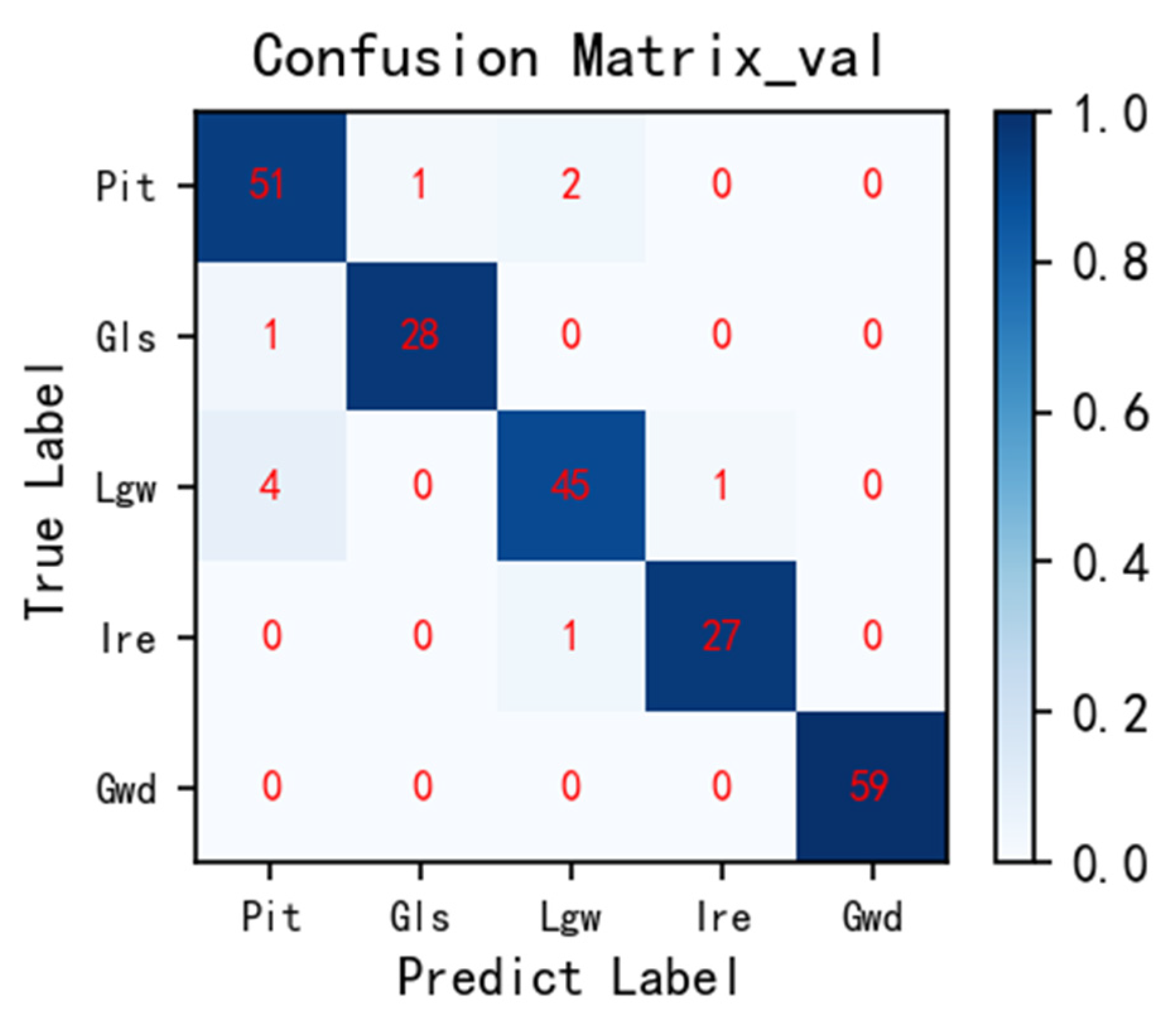

4.4. Ablation Study

- SK-ConvNeXt

- ConvNeXt-KAN

- SK-ConvNeXt-KAN

4.5. Generalization Ability Test

4.5.1. Fivefold Cross-Validation

4.5.2. Cross-Dataset Validation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, X.Q.; Sun, H.X.; Yu, M.R.; Qiu, N.; Li, Y.W.; Liu, F.L.; Chen, G.M. Mechanical analysis of deepwater drilling riser system based on multibody system dynamics. Pet. Sci. 2021, 18, 603–617. [Google Scholar] [CrossRef]

- Wang, Y.; Luan, T.; Gao, D.; Wang, J. Research progress on recoil analysis and control technology of deepwater drilling risers. Energies 2022, 15, 6897. [Google Scholar] [CrossRef]

- Chen, L.; Di, Q.; Lou, E.; Zhou, B.; Zhang, H.; Wang, W.; Hu, F. The visualization of rub-impact characteristics of drill string on casing. J. Pet. Sci. Eng. 2019, 174, 1321–1331. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, D.; Wang, J. Influence of the Heave Motion of a Floating Drilling Platform on the Crossflow Vortex-Induced Vibration of the Deepwater Drilling Riser. SPE J. 2022, 27, 2073–2092. [Google Scholar] [CrossRef]

- Liu, X.; Chen, G.; Chang, Y.; Zhang, L.; Liu, K. Study on Deepwater Drilling Riser Wear. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 25–28 March 2014; p. OTC-24993. OTC. [Google Scholar]

- Erb, P.R.; Ma, T.C.; Stockinger, M.P. Riser Collapse—A Unique Problem in Deep-Water Drilling. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, New Orleans, LA, USA, 20–23 February 1983; p. SPE-11394. SPE. [Google Scholar]

- Prosser, T. Riser system wear: An unrecognized drilling risk. In Proceedings of the AADE National Drilling Conference, Houston, TX, USA, 27–29 March 2001. [Google Scholar]

- Chang, Y.; Zhang, C.; Wu, X.; Shi, J.; Chen, G.; Ye, J.; Xu, L.; Xue, A. A Bayesian Network model for risk analysis of deepwater drilling riser fracture failure. Ocean Eng. 2019, 181, 112. [Google Scholar] [CrossRef]

- Kilner, A.; Yoshioka, R.; Marcollo, H.; Rogers, R.; Taha, M. Failure in Drilling Riser Auxiliary Line Attributed to VIV. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; p. V002T08A090. [Google Scholar]

- Poss, G.; Hall, R., Jr. Subsea drilling riser wear: A case history. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, SPE, Dallas, TX, USA, 22–25 October 1995; p. SPE29392-MS. [Google Scholar]

- Bohan, P.; Lang, D.; Williams, D. Utilizing Advanced Digital Technologies to Provide Automated Drilling Riser Fatigue Tracking to Support Condition-Based Maintenance. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, American Society of Mechanical Engineers, Online. 3–7 August 2020; p. V001T01A031. [Google Scholar]

- Huang, C.; Nagarajaiah, S. Robotic MFL sensor and vibration-based deepwater riser monitoring system. In Proceedings of the Offshore Technology Conference, OTC, Houston, TX, USA, 30 April–3 May 2012; p. OTC23487-MS. [Google Scholar]

- Scottini, R.; Quakkelsteijn, H. Inspection of Coated Subsea Piping and Risers. In Proceedings of the 4th Middle East NDT Conference and Exhibition, Manama, Bahrain, 2–5 December 2007; NDT.net. 2008. [Google Scholar]

- Santos, M.F.; Brito, M.O.; Neves, C.; Menegaldo, L.L. Development of an underwater riser inspection robot. Ind. Robot Int. J. 2013, 40, 402–411. [Google Scholar] [CrossRef]

- Nicolas, Y. In-service Riser Inspection System IRIS. In Proceedings of the Offshore Technology Conference Asia, OTC, Kuala Lumpur, Malaysia, 20–23 March 2018; p. D031S017R002. [Google Scholar]

- Neidhardt, D.; Ziegler, R.; Lancaster, J. Drilling Riser Integrity Assurance for Deepwater Floating Drilling. In Proceedings of the Offshore Technology Conference, OTC, Houston, TX, USA, 1–4 May 2017; p. D011S002R004. [Google Scholar]

- Zhou, W.; Fan, J.; Liu, X.; Liu, S. Quantitative research of defects for pipelines based on metal magnetic memory testing. Insight-Non-Destr. Test. Cond. Monit. 2020, 62, 292–299. [Google Scholar] [CrossRef]

- Zhou, W.; Fan, J.; Ni, J.; Liu, S. Variation of magnetic memory signals in fatigue crack initiation and propagation behavior. Metals 2019, 9, 89. [Google Scholar] [CrossRef]

- Li, W.; Chen, G.; Yin, X.; Li, X.; Liu, J.; Zhao, J.; Zhao, J. Visual and intelligent identification methods for defects in underwater structure using alternating current field measurement technique. IEEE Trans. Ind. Inform. 2021, 18, 3853–3862. [Google Scholar]

- Geng, L.; Dong, S.; Qian, W.; Peng, D. Image Classification Method Based on Improved Deep Convolutional Neural Networks for the Magnetic Flux Leakage (MFL) Signal of Girth Welds in Long-Distance Pipelines. Sustainability 2022, 14, 12102. [Google Scholar] [CrossRef]

- Hou, W.; Wei, Y.; Jin, Y.; Zhu, C. Deep Features Based on a DCNN Model for Classifying Imbalanced Weld Flaw Types. Measurement 2019, 131, 482–489. [Google Scholar] [CrossRef]

- Mao, W.; Ding, L.; Tian, S.; Liang, X. Online Detection for Bearing Incipient Fault Based on Deep Transfer Learning. Measurement 2020, 152, 107278. [Google Scholar] [CrossRef]

- Abu, M.; Amir, A.; Lean, Y.; Zahri, N.; Azemi, S. The Performance Analysis of Transfer Learning for Steel Defect Detection by Using Deep Learning. J. Phys. Conf. Ser. 2021, 1755, 012041. [Google Scholar] [CrossRef]

- Ma, J.; Liu, M.; Hu, S.; Fu, J.; Chen, G.; Yang, A. A Novel CNN Ensemble Framework for Bearing Surface Defects Classification Based on Transfer Learning. Meas. Sci. Technol. 2022, 34, 025902. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Li, D.; Zhang, J. Two-Step Detection of Concrete Internal Condition Using Array Ultrasound and Deep Learning. NDT E Int. 2023, 139, 102945. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, J.; Gao, C.; Xu, J. Internal Defect Detection, Quantification, and Three-Dimensional Localization Based on Impact Echo and Classification Learning Model. Measurement 2023, 218, 113153. [Google Scholar] [CrossRef]

- Ding, J.; Cai, B.; Li, W.; Yin, X.; Li, X.; Chen, Q.; Wang, G. 3D Visual Reconstruction of Corrosion in Underwater Structures Using Alternating Current Field Measurement Technique. Ocean Eng. 2024, 308, 118294. [Google Scholar]

- Wei, M.; Tu, F.; Zhang, P.; Jiang, L.; Jiang, P.; Jing, Y. Composite Excitation Multi-Extension Direction Defect Magnetic Flux Leakage Detection Technology. J. Meas. Sci. Instrum. 2022, 13, 156–165. [Google Scholar] [CrossRef]

- Geng, H.; Xia, H.; Wang, G. Study on Defect Location Method of Inner and Outer Wall of Pipeline during High-Speed Magnetic Flux Leakage Testing. Chin. J. Sci. Instrum. 2022, 43, 70–78. [Google Scholar]

- Chen, H.; Wang, C.; Zuo, X. Research on Methods of Defect Classification Based on Metal Magnetic Memory. NDT E Int. 2017, 92, 82–87. [Google Scholar] [CrossRef]

- Liu, Z.; Mao, H.; Wu, C.Y.; Feichtenhofer, C.; Darrell, T.; Xie, S. A ConvNet for the 2020s. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, New Orleans, LA, USA, 19–24 June 2022; pp. 11976–11986. [Google Scholar]

- Li, X.; Wang, W.; Hu, X.; Yang, J. Selective Kernel Networks. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Long Beach, CA, USA, 16–20 June 2019; pp. 510–519. [Google Scholar]

- Liu, Z.; Wang, Y.; Vaidya, S.; Ruehle, F.; Halverson, J.; Soljačić, M.; Hou, T.Y.; Tegmark, M. KAN: Kolmogorov-Arnold Networks. arXiv 2024, arXiv:2404.19756. [Google Scholar]

- Naidu, G.; Zuva, T.; Sibanda, E.M. A Review of Evaluation Metrics in Machine Learning Algorithms. In Proceedings of the Computer Science On-Line Conference, Cham, Switzerland, 26–28 April 2023; Springer International Publishing: Cham, Switzerland, 2023; pp. 15–25. [Google Scholar]

- Kee, E.; Chong, J.J.; Choong, Z.J.; Lau, M. A Comparative Analysis of Cross-Validation Techniques for a Smart and Lean Pick and Place Solution with Deep Learning. Electronics 2023, 12, 2371. [Google Scholar] [CrossRef]

- Li, Z.; Wei, X.; Hassaballah, M.; Li, Y.; Jiang, X. A Deep Learning Model for Steel Surface Defect Detection. Complex Intell. Syst. 2024, 10, 885–897. [Google Scholar] [CrossRef]

- Zhou, M.; Lu, W.; Jia, J.; Wang, Y. Defect Detection in Steel Using a Hybrid Attention Network. Sensors 2023, 23, 6982. [Google Scholar] [CrossRef]

| Institution | Detector | Method | Type | Features |

|---|---|---|---|---|

| Dutch scholar | RTD | Pulsed Eddy Current | External inspection | Water depth of 150 m |

| Brazil | SIRIS | Visual, Ultrasonic, Radiographic | External inspection | Water depth of 250 m |

| TechnipFMC | IRIS | Electromagnetic, Ultrasonic, and X-ray Inspection | External inspection | Production platforms |

| Weatherford | ORIS | Ultrasonic Testing | Internal inspection | In situ inspection |

| UPC | ACFM | Alternating Current Field Measurement | External inspection | In situ inspection |

| CUP | MMM | Metal Magnetic Memory | Internal inspection | Offline inspection |

| Output Size | ResNet-50 | ConvNeXt-T | |

|---|---|---|---|

| stem | 56 × 56 | 7 × 7, 64, stride 2 3 × 3 max pool, stride 2 | 4 × 4, 96, stride 4 |

| Stage1 | 28 × 28 | ||

| Stage2 | 14 × 14 | ||

| Stage3 | 56 × 56 | ||

| Stage4 | 7 × 7 | ||

| FLOPS |

| Experimental | Configuration | Training Options | Value |

|---|---|---|---|

| Deep Learning Frameworks | PyTorch 1.10.0 | Optimizer | AdamW |

| Programming Language | Python 3.8 | Loss Function | Cross-Entropy |

| CPU | Intel® Core (TM) I5-13500H | Epoch | 100 |

| GPU | NVIDIA GeForce RTX 3060 (6 GB) | Batch size | 16 |

| RAM | 32 GB | Initial Learning Rate | 0.0005 |

| No. | Label | Defect Types | Number | Proportion |

|---|---|---|---|---|

| 1 | Pit | Pitting | 270 | 24.3% |

| 2 | Gls | Groove Loss | 148 | 13.3% |

| 3 | Lgw | Longitudinal Wear | 252 | 22.7% |

| 4 | Ire | Irregular Flaw | 141 | 12.7% |

| 5 | Gwd | Girth Weld | 299 | 26.9% |

| Total | 1110 | 100% | ||

| Model | Training Accuracy (%) | Validation Accuracy (%) |

|---|---|---|

| GoogLeNet | 97.6 | 83.4 |

| ResNet-50 | 94.6 | 90.7 |

| ViT | 90.4 | 90.4 |

| Swin-T | 84.1 | 92.3 |

| ConvNeXt | 91.2 | 91.8 |

| SK-ConvNeXt-KAN | 94.5 | 95.4 |

| Model | Accuracy (%) | Precision (%) | Recall (%) | F1 Score |

|---|---|---|---|---|

| Baseline | 91.8 | 88.43 | 88.55 | 0.884 |

| SK-ConvNeXt | 93.6 | 90.86 | 90.57 | 0.907 |

| ConvNeXt-KAN | 92.7 | 90.03 | 89.13 | 0.895 |

| SK-ConvNeXt-KAN | 95.4 | 91.68 | 91.88 | 0.917 |

| Experiment | Accuracy (%) | Precision (%) | Recall (%) | F1 Score |

|---|---|---|---|---|

| Fold-1 | 94.55 | 91.55 | 91.53 | 0.915 |

| Fold-2 | 95.45 | 93.66 | 92.50 | 0.930 |

| Fold-3 | 95.00 | 92.70 | 92.54 | 0.926 |

| Fold-4 | 94.09 | 91.01 | 91.13 | 0.910 |

| Fold-5 | 95.91 | 93.93 | 92.61 | 0.932 |

| Average | 95.00 | 92.57 | 92.06 | 0.923 |

| No. | Label | Defect Types | Train_Num | Validate_Num |

|---|---|---|---|---|

| 1 | In | Inclusions | 240 | 60 |

| 2 | Pa | Patches | 240 | 60 |

| 3 | Cr | Cracks | 240 | 60 |

| 4 | PS | Pitted Surfaces | 240 | 60 |

| 5 | RS | Rolled-in Scale | 240 | 60 |

| 6 | Sc | Scratches | 240 | 60 |

| Total | 1800 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Fan, J. Research on Nondestructive Testing Technology for Drilling Risers Based on Magnetic Memory and Deep Learning. Sustainability 2024, 16, 7389. https://doi.org/10.3390/su16177389

Liu X, Fan J. Research on Nondestructive Testing Technology for Drilling Risers Based on Magnetic Memory and Deep Learning. Sustainability. 2024; 16(17):7389. https://doi.org/10.3390/su16177389

Chicago/Turabian StyleLiu, Xiangyuan, and Jianchun Fan. 2024. "Research on Nondestructive Testing Technology for Drilling Risers Based on Magnetic Memory and Deep Learning" Sustainability 16, no. 17: 7389. https://doi.org/10.3390/su16177389

APA StyleLiu, X., & Fan, J. (2024). Research on Nondestructive Testing Technology for Drilling Risers Based on Magnetic Memory and Deep Learning. Sustainability, 16(17), 7389. https://doi.org/10.3390/su16177389