Investigating Polylactic Acid Foam–Plant Fiber Composites for Sound Absorption and Insulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Theoretical Background

2.2. Considered Samples and Manufacturing Process

- Form: Expanded beads

- Color: White

- Odor: Sweetish

- Density (g/mL): 10–200 kg/m3 at 20 °C

- Melting point/range: (150–160 °C)

- Decomposition temperature: 250 °C

- Autoignition temperature: 388 °C

- Solubility (Water): Insoluble

- Thermal degradation: starts from 230 °C

- molding,

- heating under load,

- cooling.

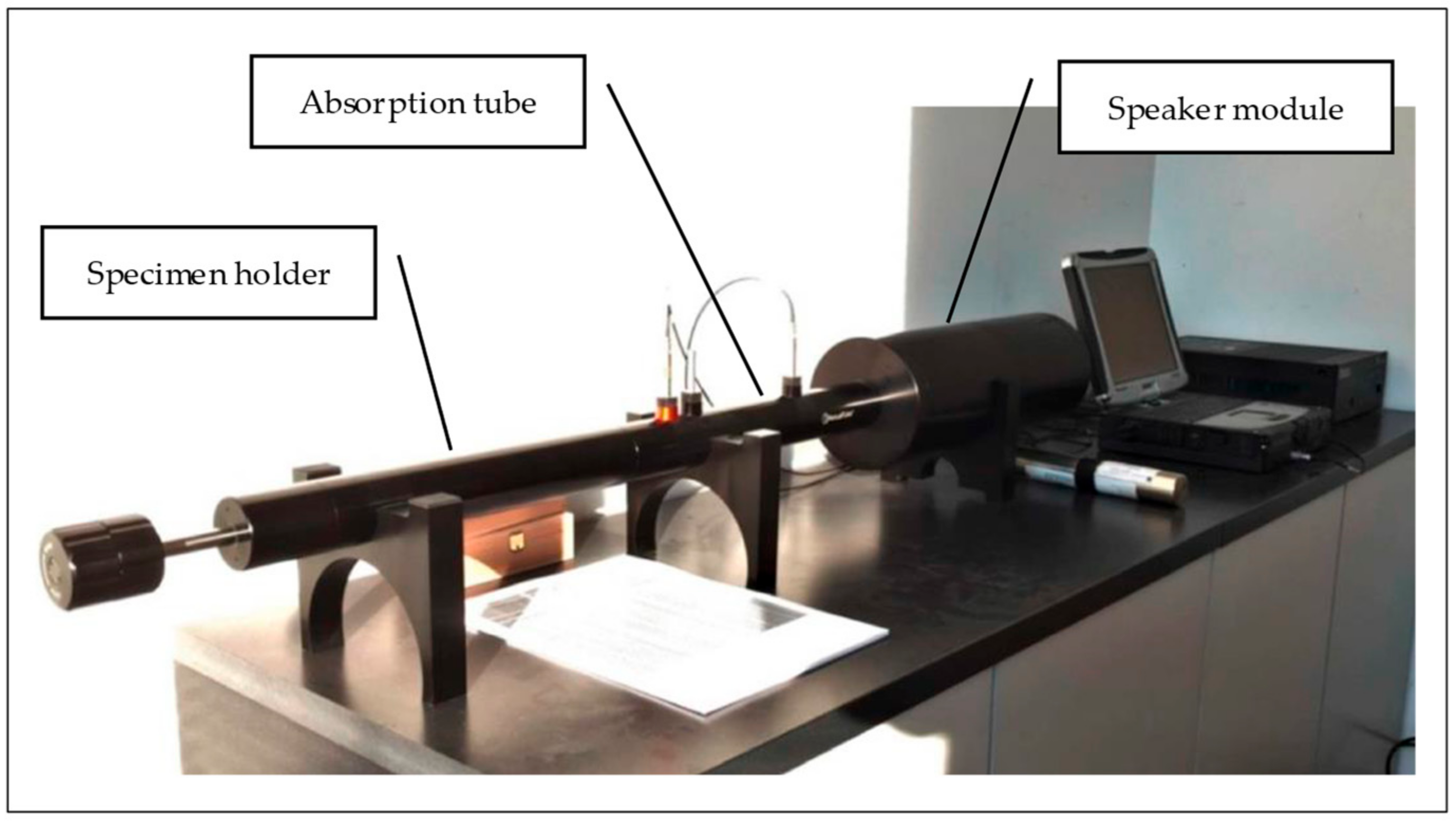

2.3. Testing Equipment

2.4. Testing Procedure and Environment Conditions

- For Specimens A and B (Table 1), the atmospheric pressure was 102,000 (±50) Pa, the average temperature was 21 (±1) °C, and the average relative humidity was 58 (±5)%.

- For Specimens C and D (Table 1), the atmospheric pressure was 100,900 (±50) Pa, the average temperature was 19 (±1) °C, and the average relative humidity was 45 (±5)%.

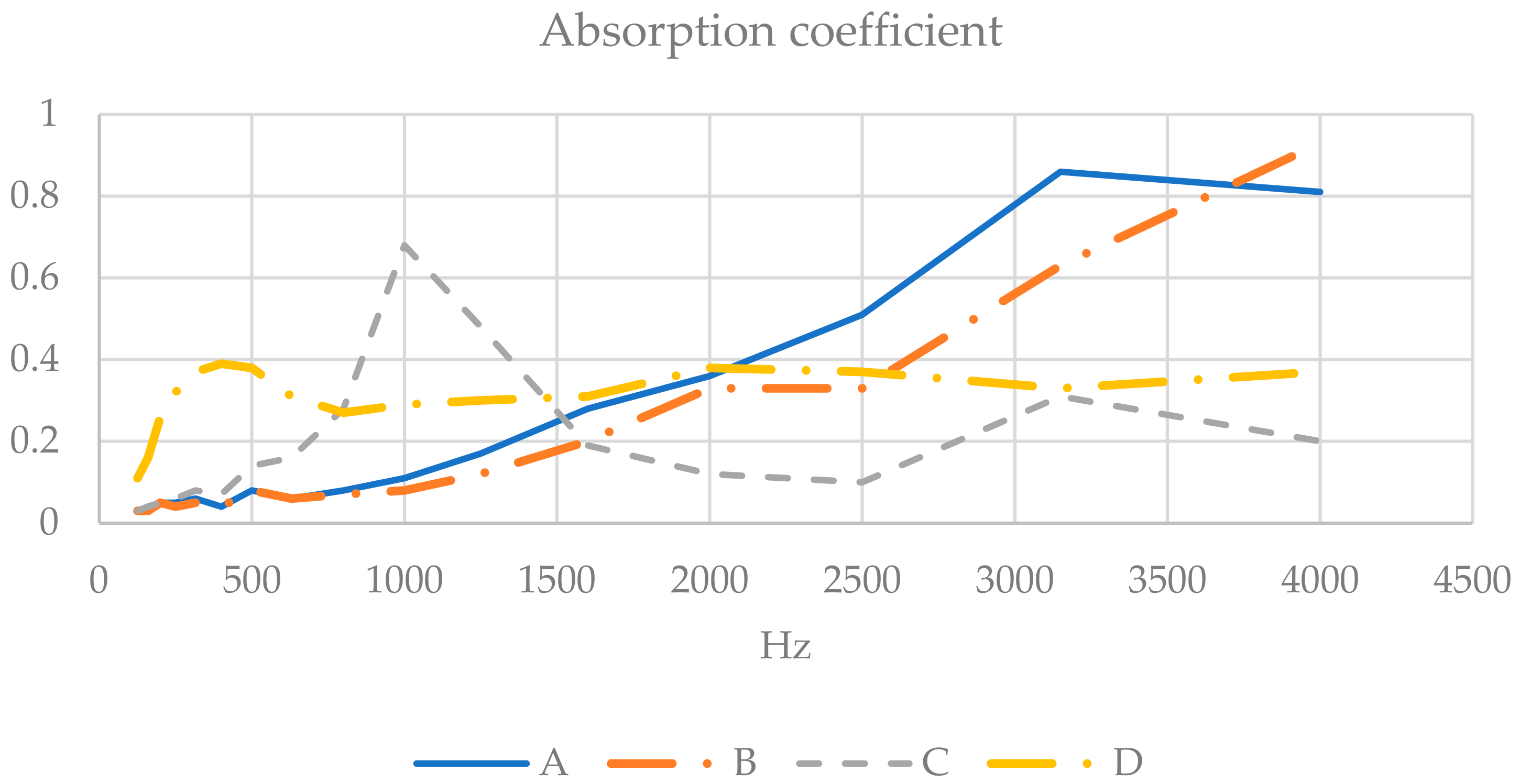

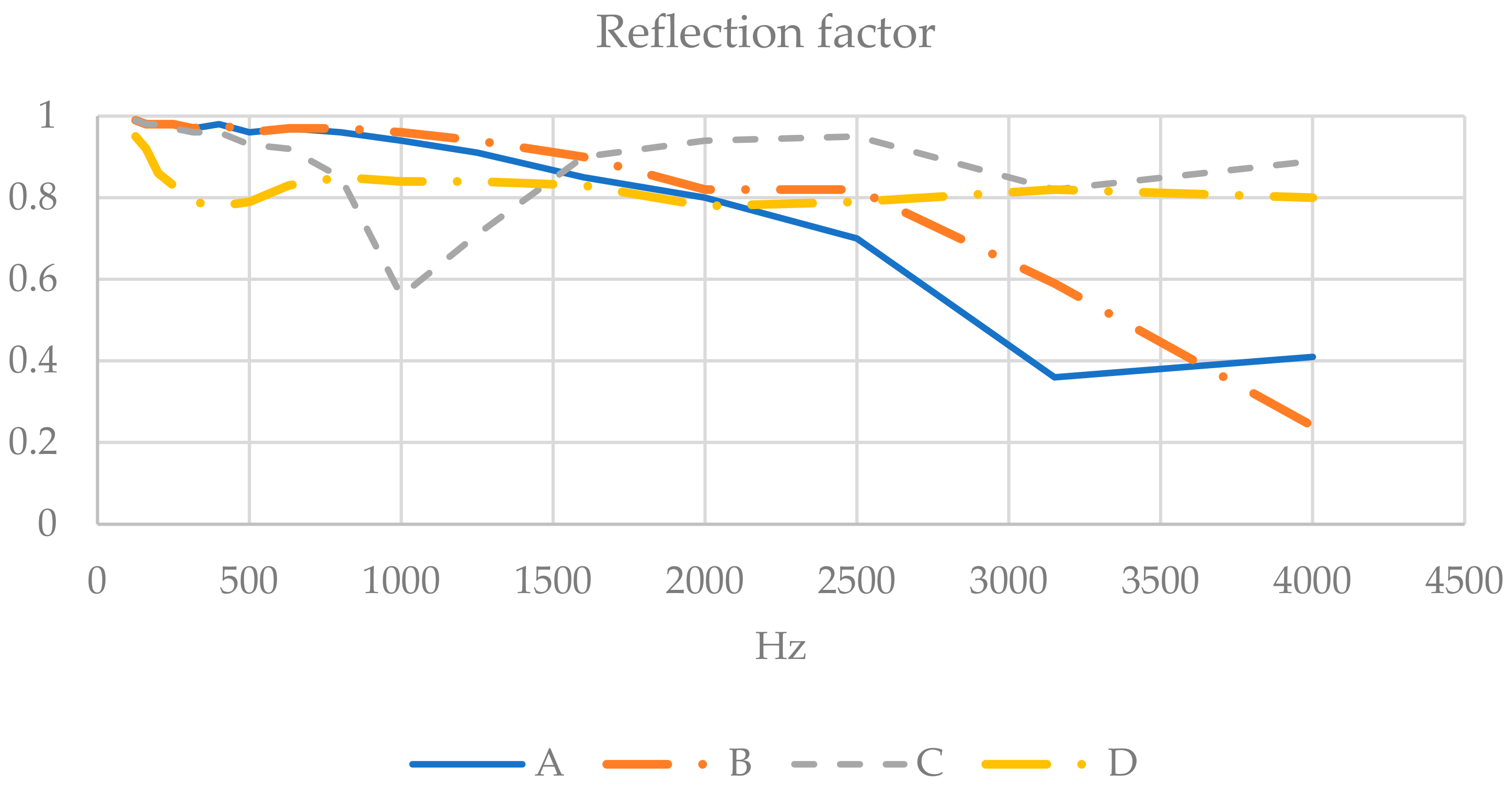

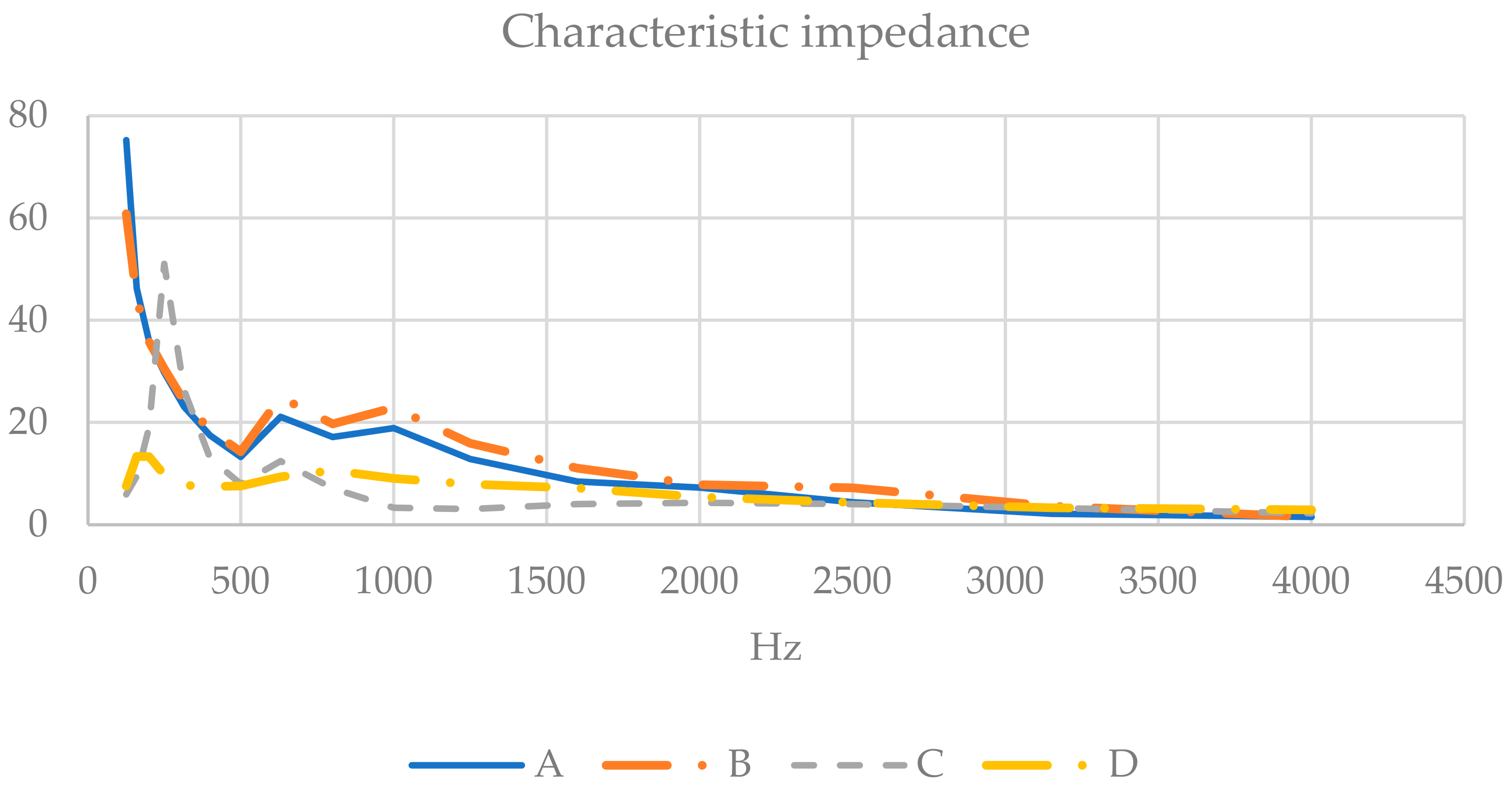

3. Results

4. Discussion

4.1. About the Obtained Results

- The sound absorption and reflection properties of PLA, in the form of foam or pre-expanded spheres, can benefit from the addition of plant fiber waste.

- The insulation and acoustic absorption performance of the composite biomaterial exhibit similar behavior depending on the type of plant fiber used together with PLA.

- PLA can be used as a binding agent within composite biomaterials, overcoming the need for costly and often non-biodegradable additives. This also reduces the environmental impact of the PLA.

- The possibility of reducing the amount of PLA used within the composite biomaterial brings cost benefits, allowing to improve the competition with traditionally used petroleum-derived materials for insulation and acoustic absorption. Additionally, this helps reduce the environmental impact of PLA.

- The dependency of the insulation and acoustic absorption performance of the composite biomaterial on parameters such as material thickness and density appears to be consistent with the existing literature, suggesting that optimization of these performances in relation to these parameters could be carried out following already established rules.

4.2. Limits of the Work and Suggestions for Future Developments

4.3. Expected Impact

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural Fiber Reinforced Polylactic Acid Composites: A Review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Islam, M.Z.; Sarker, M.E.; Rahman, M.M.; Islam, M.R.; Ahmed, A.T.M.F.; Mahmud, M.S.; Syduzzaman, M. Green Composites from Natural Fibers and Biopolymers: A Review on Processing, Properties, and Applications. J. Reinf. Plast. Compos. 2022, 41, 526–557. [Google Scholar] [CrossRef]

- Bhuvaneswari, V.; Devarajan, B.; Arulmurugan, B.; Mahendran, R.; Rajkumar, S.; Sharma, S.; Mausam, K.; Li, C.; Eldin, E.T. A Critical Review on Hygrothermal and Sound Absorption Behavior of Natural-Fiber-Reinforced Polymer Composites. Polymers 2022, 14, 4727. [Google Scholar] [CrossRef]

- Ouakarrouch, M.; Bousshine, S.; Bybi, A.; Laaroussi, N.; Garoum, M. Acoustic and Thermal Performances Assessment of Sustainable Insulation Panels Made from Cardboard Waste and Natural Fibers. Appl. Acoust. 2022, 199, 109007. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Aly, N.M.; Seddeq, H.S.; Elnagar, K.; Hamouda, T. Acoustic and Thermal Performance of Sustainable Fiber Reinforced Thermoplastic Composite Panels for Insulation in Buildings. J. Build. Eng. 2021, 40, 102747. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Lascaro, E.; Lopez, G.A.; Ricciardi, P. Sustainable Panels with Recycled Materials for Building Applications: Environmental and Acoustic Characterization. Energy Procedia 2016, 101, 972–979. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D. Rice Plant Waste Reinforced Polyurethane Composites for Use as the Acoustic Absorption Material. Appl. Acoust. 2021, 173, 107733. [Google Scholar] [CrossRef]

- Azlin, M.N.M.; Sapuan, S.M.; Ilyas, R.A.; Zainudin, E.S.; Zuhri, M.Y.M. Natural Polylactic Acid-Based Fiber Composites: A Review. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 21–34. [Google Scholar] [CrossRef]

- Rezaieyan, E.; Taban, E.; Berardi, U.; Mortazavi, S.B.; Faridan, M.; Mahmoudi, E. Acoustic Properties of Natural Fiber Reinforced Composite Micro-Perforated Panel (NFRC-MPP) Made from Cork Fiber and Polylactic Acid (PLA) Using 3D Printing. J. Build. Eng. 2024, 84, 108491. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Conti, L.; Rossi, G.; Rotini, F. Conceptual Design of a Small Production Plant for Eco-Friendly Packaging. J. Eng. Des. Technol. 2024, 22, 1257–1281. [Google Scholar] [CrossRef]

- Rossi, G.; Conti, L.; Fiorineschi, L.; Marvasi, M.; Monti, M.; Rotini, F.; Togni, M.; Barbari, M. A New Eco-Friendly Packaging Material Made of Straw and Bioplastic. J. Agric. Eng. 2020, 51, 185–191. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative Analysis of Building Insulation Material Properties and Performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Mohammadi, M.; Taban, E.; Tan, W.H.; Che Din, N.B.; Putra, A.; Berardi, U. Recent Progress in Natural Fiber Reinforced Composite as Sound Absorber Material. J. Build. Eng. 2024, 84, 108514. [Google Scholar] [CrossRef]

- Ahmad, H.; Chhipi-Shrestha, G.; Hewage, K.; Sadiq, R. A Comprehensive Review on Construction Applications and Life Cycle Sustainability of Natural Fiber Biocomposites. Sustainability 2022, 14, 15905. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly(Lactic Acid) (PLA) and Polyhydroxyalkanoates (PHAs), Green Alternatives to Petroleum-Based Plastics: A Review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef]

- Sinha, A.K.; Rao, K.R.; Soni, V.K.; Chandrakar, R.; Sharma, H.K.; Kumar, A. A Review on Mechanical Properties of Natural Fibre Reinforced PLA Composites. Curr. Mater. Sci. 2021, 16, 365–375. [Google Scholar] [CrossRef]

- Cheng, P.; Wang, K.; Peng, Y.; Ahzi, S. Effects of Cellular Crossing Paths on Mechanical Properties of 3D Printed Continuous Fiber Reinforced Biocomposite Honeycomb Structures. Compos. Part. A Appl. Sci. Manuf. 2024, 178, 107972. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Li, S.; Rao, Y.; Le Duigou, A.; Wang, K.; Ahzi, S. 3D Printed Continuous Fiber Reinforced Composite Lightweight Structures: A Review and Outlook. Compos. B Eng. 2023, 250, 110450. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Petrů, M.; Noman, M.T.; Mishra, R.; Militký, J. Sound Absorption Properties of Natural Fibers: A Review. Sustainability 2020, 12, 8477. [Google Scholar] [CrossRef]

- Samsudin, E.M.; Ismail, L.H.; Kadir, A.A. A Review on Physical Factors Influencing Absorption Performance of Fibrous Sound Absorption Material from Natural Fibers. ARPN J. Eng. Appl. Sci. 2016, 11, 3703–3711. [Google Scholar]

- Chin Vui Sheng, D.D.; Yahya, M.N.B.; Che Din, N.B. Sound Absorption of Microperforated Panel Made from Coconut Fiber and Polylactic Acid Composite. J. Nat. Fibers 2022, 19, 2719–2729. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S.; Bakri, M.K.B.; Kok Heng, S.; Rahman, M.R.; Kakar, A. Analysis of Natural Fiber Polymer Composites: Effects of Alkaline Treatment on Sound Absorption. J. Reinf. Plast. Compos. 2016, 35, 703–711. [Google Scholar] [CrossRef]

- Chin, D.D.V.S.; Yahya, M.N.B.; Che Din, N.B.; Ong, P. Acoustic Properties of Biodegradable Composite Micro-Perforated Panel (BC-MPP) Made from Kenaf Fibre and Polylactic Acid (PLA). Appl. Acoust. 2018, 138, 179–187. [Google Scholar] [CrossRef]

- Sekar, V.; Yong Eh Noum, S.; Putra, A.; Sivanesan, S.; Chun Chin, K.; San Wong, Y.; Hafizah Kassim, D. Acoustic Properties of Micro-Perforated Panels Made from Oil Palm Empty Fruit Bunch Fiber Reinforced Polylactic Acid. Sound. Vib. 2021, 55. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Singh, J.; Singh, S.; Singh, G. Emerging Progressive Developments in the Fibrous Composites for Acoustic Applications. J. Manuf. Process 2023, 102, 443–477. [Google Scholar] [CrossRef]

- Sheng, D.D.C.V.; Wong, K.Y.; Asyraf, M.R.M.; Yahya, M.N.B.; Din, N.B.C.; Reddy, N.; Sekar, V. Sound Absorption Performance of Coir Fiber/Polylactic Acid Composite Microperforated Panel. INTER-NOISE NOISE-CON Congr. Conf. Proc. 2023, 268, 1454–1461. [Google Scholar] [CrossRef]

- Nofar, M.; Park, C.B. Poly (Lactic Acid) Foaming. Prog. Polym. Sci. 2014, 39, 1721–1741. [Google Scholar] [CrossRef]

- Parker, K.; Garancher, J.P.; Shah, S.; Fernyhough, A. Expanded Polylactic Acid—An Eco-Friendly Alternative to Polystyrene Foam. J. Cell. Plast. 2011, 47, 233–243. [Google Scholar] [CrossRef]

- Suwanmanee, U.; Varabuntoonvit, V.; Chaiwutthinan, P.; Tajan, M.; Mungcharoen, T.; Leejarkpai, T. Life Cycle Assessment of Single Use Thermoform Boxes Made from Polystyrene (PS), Polylactic Acid, (PLA), and PLA/Starch: Cradle to Consumer Gate. Int. J. Life Cycle Assess. 2013, 18, 401–417. [Google Scholar] [CrossRef]

- Fonseca, A.; Ramalho, E.; Gouveia, A.; Figueiredo, F.; Nunes, J. Life Cycle Assessment of PLA Products: A Systematic Literature Review. Sustainability 2023, 15, 12470. [Google Scholar] [CrossRef]

- Rezvani Ghomi, E.; Khosravi, F.; Saedi Ardahaei, A.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef] [PubMed]

- Morão, A.; de Bie, F. Life Cycle Impact Assessment of Polylactic Acid (PLA) Produced from Sugarcane in Thailand. J. Polym. Environ. 2019, 27, 2523–2539. [Google Scholar] [CrossRef]

- Gironi, F.; Piemonte, V. Life Cycle Assessment of Polylactic Acid and Polyethylene Terephthalate Bottles for Drinking Water. Env. Prog. Sustain. Energy 2011, 30, 459–468. [Google Scholar] [CrossRef]

- Mahalle, L.; Alemdar, A.; Mihai, M.; Legros, N. A Cradle-to-Gate Life Cycle Assessment of Wood Fibre-Reinforced Polylactic Acid (PLA) and Polylactic Acid/Thermoplastic Starch (PLA/TPS) Biocomposites. Int. J. Life Cycle Assess. 2014, 19, 1305–1315. [Google Scholar] [CrossRef]

- Seile, A.; Spurina, E.; Sinka, M. Reducing Global Warming Potential Impact of Bio-Based Composites Based of LCA. Fibers 2022, 10, 79. [Google Scholar] [CrossRef]

- Findrik, E.; Meixner, O. Drivers and Barriers for Consumers Purchasing Bioplastics—A Systematic Literature Review. J. Clean. Prod. 2023, 410, 137311. [Google Scholar] [CrossRef]

- Mosanenzadeh, S.G.; Naguib, H.E.; Park, C.B.; Atalla, N. Development, Characterization, and Modeling of Environmentally Friendly Open-Cell Acoustic Foams. Polym. Eng. Sci. 2013, 53, 1979–1989. [Google Scholar] [CrossRef]

- Mosanenzadeh, S.G.; Naguib, H.E.; Park, C.B.; Atalla, N. Development of Polylactide Open-Cell Foams with Bimodal Structure for High-Acoustic Absorption. J. Appl. Polym. Sci. 2014, 131, 39518. [Google Scholar] [CrossRef]

- Yao, R.; Yao, Z.; Zhou, J.; Liu, P. Mechanical and Acoustical Properties of Polylactic Acid Based Multilayer-Structured Foam Biocomposites. J. Reinf. Plast. Compos. 2016, 35, 785–795. [Google Scholar] [CrossRef]

- Hu, S.; She, H.; Yang, G.; Zang, C.; Li, C. The Influence of Interface Roughness on the Vibration Reduction Characteristics of an Under-Platform Damper. Appl. Sci. 2023, 13, 2128. [Google Scholar] [CrossRef]

- Oh, J.H.; Kim, J.S.; Nguyen, V.H.; Oh, I.K. Auxetic Graphene Oxide-Porous Foam for Acoustic Wave and Shock Energy Dissipation. Compos. B Eng. 2020, 186, 107817. [Google Scholar] [CrossRef]

- Cox, T.J.; D’Antonio, P. Acoustic Absorbers and Diffusers Theory, Design and Application, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9781498741002. [Google Scholar]

- DEHDASHTI, A.; MALEKMOHAMADI, A.; GHAEINI, G. Determining and Comparison of Sound Absorption Coefficients Using Small Reverberation Chamber and Test Tube Methods. Int. J. Occup. Hyg. 2021. [Google Scholar] [CrossRef]

- BEWI BEWI BioFoam. Available online: https://bewi.com/products/biofoam/ (accessed on 21 February 2024).

- Getme, A.S.; Patel, B. A Review: Bio-Fiber’s as Reinforcement in Composites of Polylactic Acid (PLA). Mater. Today Proc. 2020, 26, 2116–2122. [Google Scholar] [CrossRef]

- ISO 10534-2:2023; Determination of Acoustic Properties in Impedance Tubes—Part 2: Two-Microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. International Standard Organisation: Geneva, Switzerland, 2023.

- AKUSTIK FORSCHUNG AFD 1000-AcoustiTube ® Manual Analysis Software AFD 1001 Measurement of Sound Absorption Coefficient Acc. to. Available online: https://www.mip.fi/images/docs/fi/afd1001.pdf (accessed on 24 February 2024).

- ISO 10534-1:2023; Determination of Acoustic Properties in Impedance Tubes—Part 1: Method Using Standing Wave Ratio. International Standard Organisation: Geneva, Switzerland, 2001.

- Zwikker, C.; Kosten, C. Sound Absorbing Materials, 1st ed.; Elsevier Pub. Co.: New York, NY, USA, 1949. [Google Scholar]

- Prabhune, S.; Munde, Y.; Shinde, A.; Siva, I. Appraising the Acoustic Performance and Related Factors of Natural Fiber: A Review. J. Nat. Fibers 2022, 19, 13475–13494. [Google Scholar] [CrossRef]

- Amares, S.; Sujatmika, E.; Hong, T.W.; Durairaj, R.; Hamid, H.S.H.B. A Review: Characteristics of Noise Absorption Material. J. Phys. Conf. Ser. 2017, 908, 012005. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.; Zhang, C.; Ren, L.; Yu, H.; Galland, M.A.; Ichchou, M. Acoustic Characteristics Parameters of Polyurethane/Rice Husk Composites. Polym. Compos. 2019, 40, 2653–2661. [Google Scholar] [CrossRef]

- Lanoye, R.; Vermeir, G.; Lauriks, W.; Kruse, R.; Mellert, V. Measuring the Free Field Acoustic Impedance and Absorption Coefficient of Sound Absorbing Materials with a Combined Particle Velocity-Pressure Sensor. J. Acoust. Soc. Am. 2006, 119, 2826–2831. [Google Scholar] [CrossRef]

- Hirosawa, K.; Takashima, K.; Nakagawa, H.; Kon, M.; Yamamoto, A.; Lauriks, W. Comparison of Three Measurement Techniques for the Normal Absorption Coefficient of Sound Absorbing Materials in the Free Field. J. Acoust. Soc. Am. 2009, 126, 3020–3027. [Google Scholar] [CrossRef]

- Ingrd, U.; Bolt, R.H. A Free Field Method of Measuring the Absorption Coefficient of Acoustic Materials. J. Acoust. Soc. Am. 1951, 23, 509–516. [Google Scholar] [CrossRef]

- Champoux, Y.; L’Espérance, A. Numerical Evaluation of Errors Associated with the Measurement of Acoustic Impedance in a Free Field Using Two Microphones and a Spectrum Analyzer. J. Acoust. Soc. Am. 1988, 84, 30–38. [Google Scholar] [CrossRef]

| Sample Code | Description |

|---|---|

| A | 3 cylindrical specimens, with nominal diameters of 40 mm, made of grape stalks and bioplastic in a ratio of 50/50 (by weight). Nominal mean weight: 2.33 g (for specimen). Mean thickness: 15.6 mm Density: 119 kg/m3 |

| B | 3 cylindrical specimens, with nominal diameters of 40 mm, made of wood straw and bioplastic in a ratio of 50/50 (by weight). Nominal mean weight: 1.33 g (for specimen). Mean thickness: 9.1 mm Density: 117 kg/m3 |

| C | 4 cylindrical specimens, with nominal diameters of 40 mm, made of 100% bioplastic. Nominal mean weight: 9.65 g (for specimen). Mean thickness: 50 mm Density: 154 kg/m3 |

| D | 4 cylindrical specimens, with nominal diameters of 40 mm, made of wood straw and bioplastic in a ratio of 50/50. Nominal mean weight: 9.87 g (for specimen). Mean thickness: 49 mm Density: 157 kg/m3 |

| Instrument | Description |

| Impedance tube | AcoustiTube “AFD-1000” impedance tube, 40 mm diameter (Sinus, Vienna, Austria). |

| Real-time analyzer | Sinus “Soundbook” two-channel real-time analyzer (Sinus, Vienna, Austria). |

| Software | AFD1001.1 impedance tube software (Sinus, Vienna, Austria) [49]. |

| Power amplifier | Atlas Sound “PA601” power amplifier (AtlasIED, Phoenix, AZ, USA). |

| Scale | Radwag “WLC 20/A2” electronic scale (Radwag, Radom, Poland) |

| Thermo-hygrometer | Delta Ohm “HD206-2” thermo-hygrometer (Delta Ohm, Padua, Italy) |

| Barometer | Brüel & Kjær “UZ001” barometer (Brüel & Kjær, Nærum, Denmark) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rotini, F.; Fiorineschi, L.; Conti, L.; Rossi, G. Investigating Polylactic Acid Foam–Plant Fiber Composites for Sound Absorption and Insulation. Sustainability 2024, 16, 6913. https://doi.org/10.3390/su16166913

Rotini F, Fiorineschi L, Conti L, Rossi G. Investigating Polylactic Acid Foam–Plant Fiber Composites for Sound Absorption and Insulation. Sustainability. 2024; 16(16):6913. https://doi.org/10.3390/su16166913

Chicago/Turabian StyleRotini, Federico, Lorenzo Fiorineschi, Leonardo Conti, and Giuseppe Rossi. 2024. "Investigating Polylactic Acid Foam–Plant Fiber Composites for Sound Absorption and Insulation" Sustainability 16, no. 16: 6913. https://doi.org/10.3390/su16166913

APA StyleRotini, F., Fiorineschi, L., Conti, L., & Rossi, G. (2024). Investigating Polylactic Acid Foam–Plant Fiber Composites for Sound Absorption and Insulation. Sustainability, 16(16), 6913. https://doi.org/10.3390/su16166913