Research on Intelligent Prefabricated Reinforced Concrete Staircase Lifting Point Setting Method Considering Multidimensional Spatial Constraint Characteristics

Abstract

1. Introduction

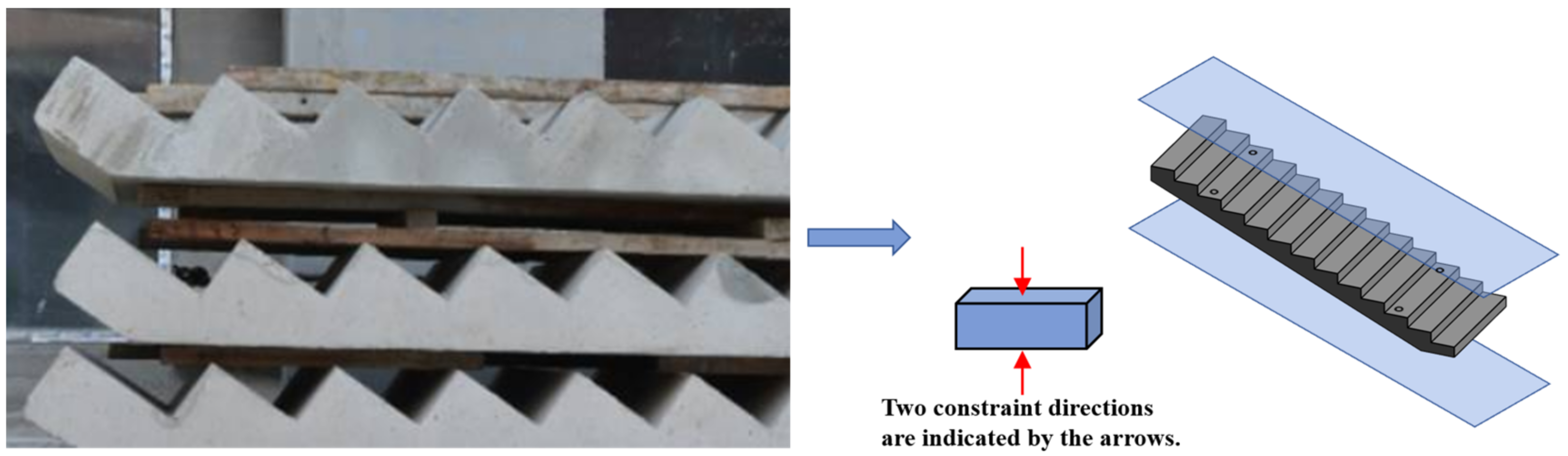

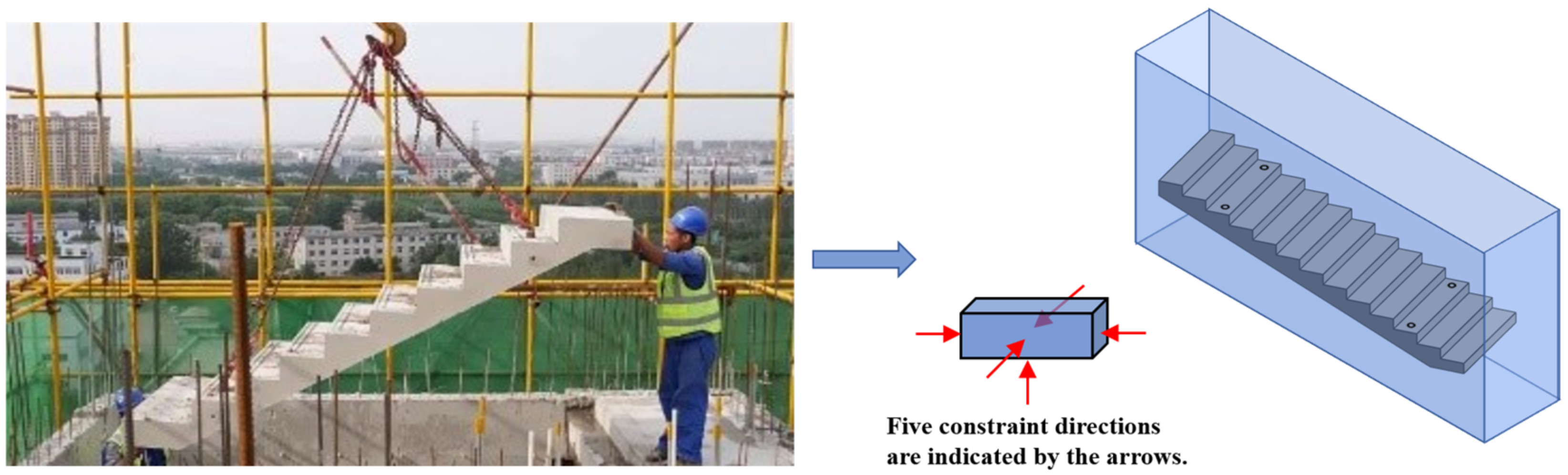

2. Analysis of Prefabricated Staircase Lifting Point Setting under Multidimensional Spatial Constraints

2.1. Lifting Process Analysis

2.2. Analysis of Quality Issues

2.3. Analysis of Lifting Point Considerations

- (1)

- Security factors

- (2)

- Stability factors

- (3)

- Ease of construction factors

- (4)

- Economic factors

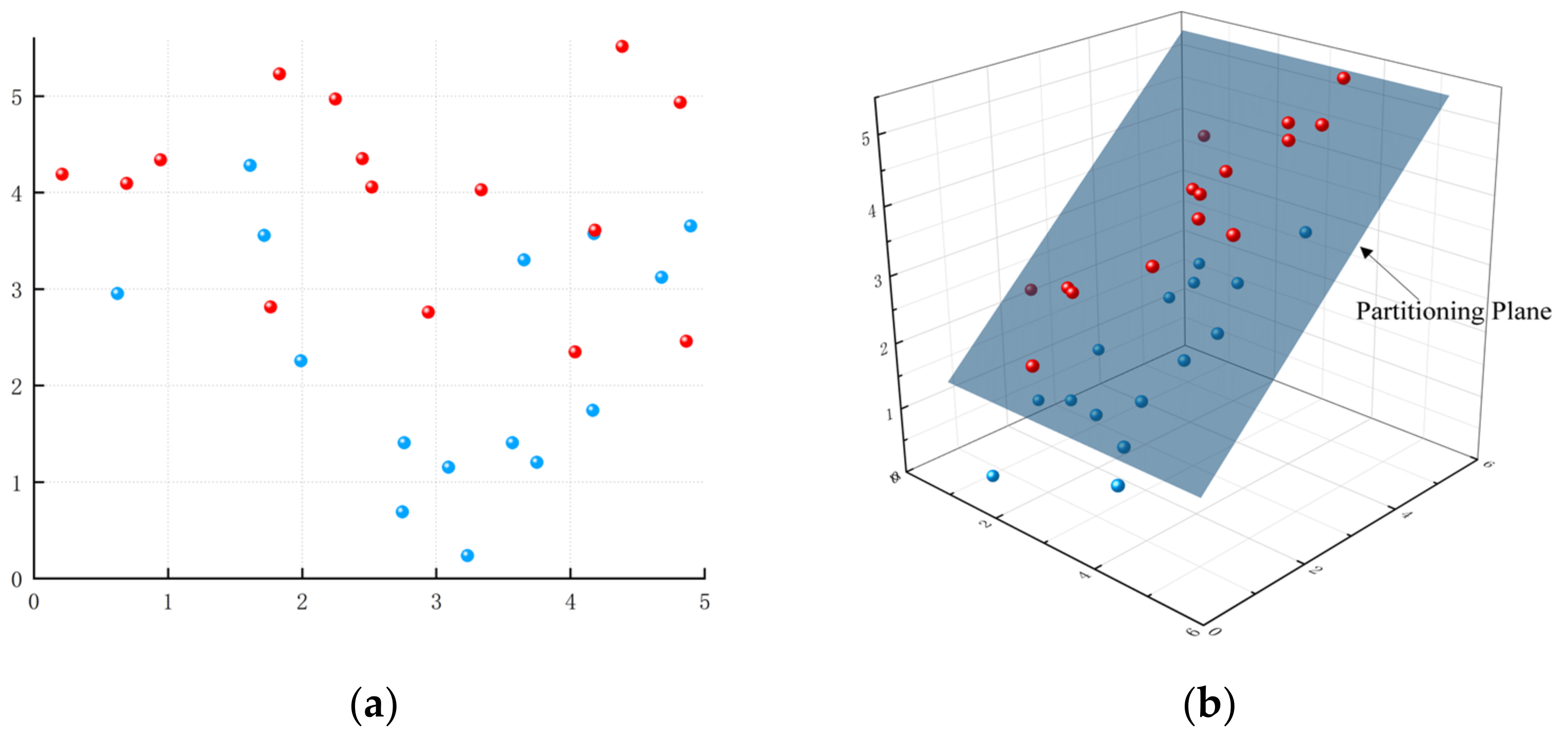

3. Intelligent Algorithm for Lifting Point Setting of PC Staircase Based on Small-Sample Database

3.1. Small-Sample Database Creation

3.2. Classification Prediction Algorithm for Support Vector Machines

3.3. Hyperparametric Process Optimization

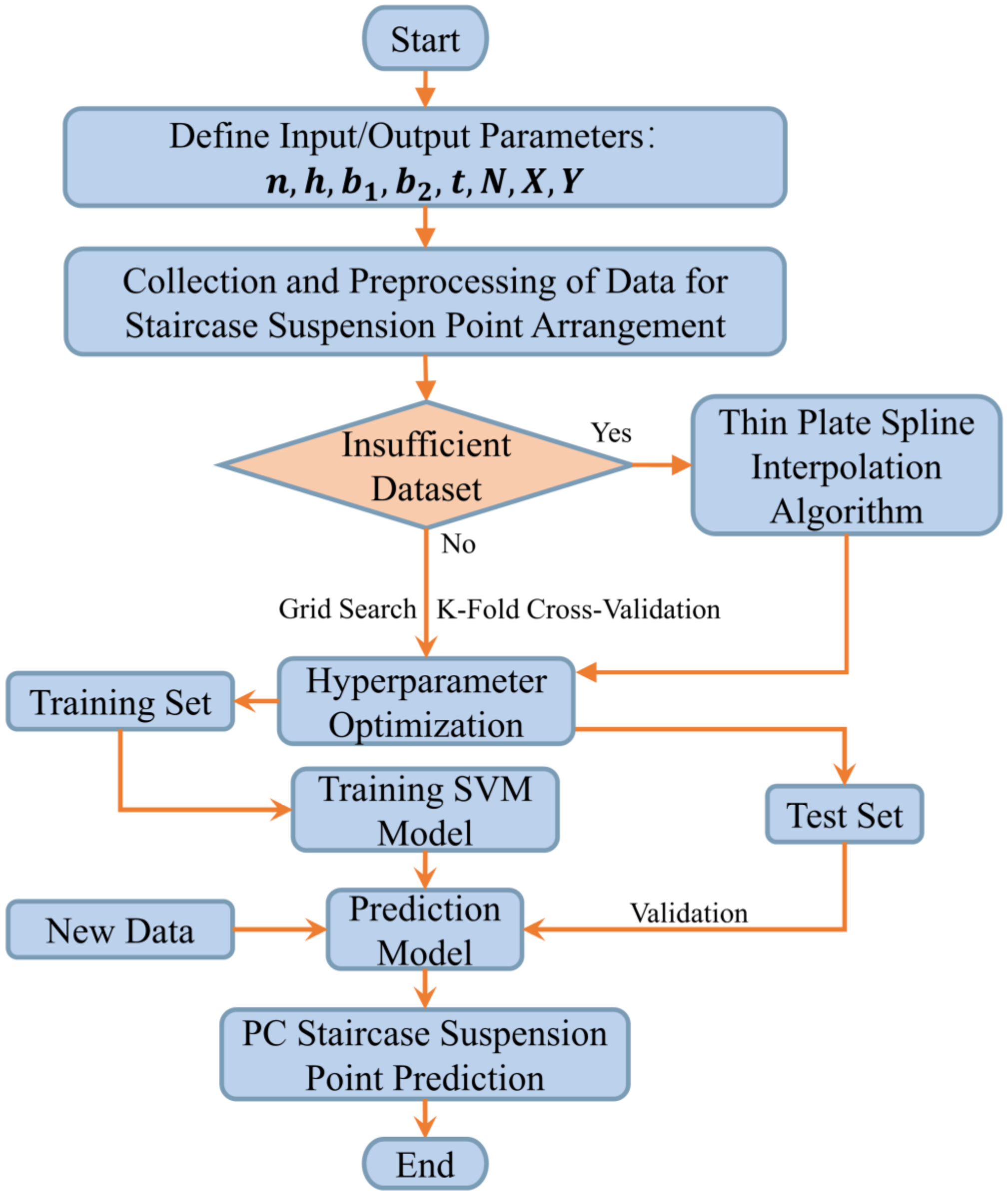

3.4. Algorithmic Technology Flow Diagram

4. A Case Study of Machine Learning-Based Stair Lifting Point Setting

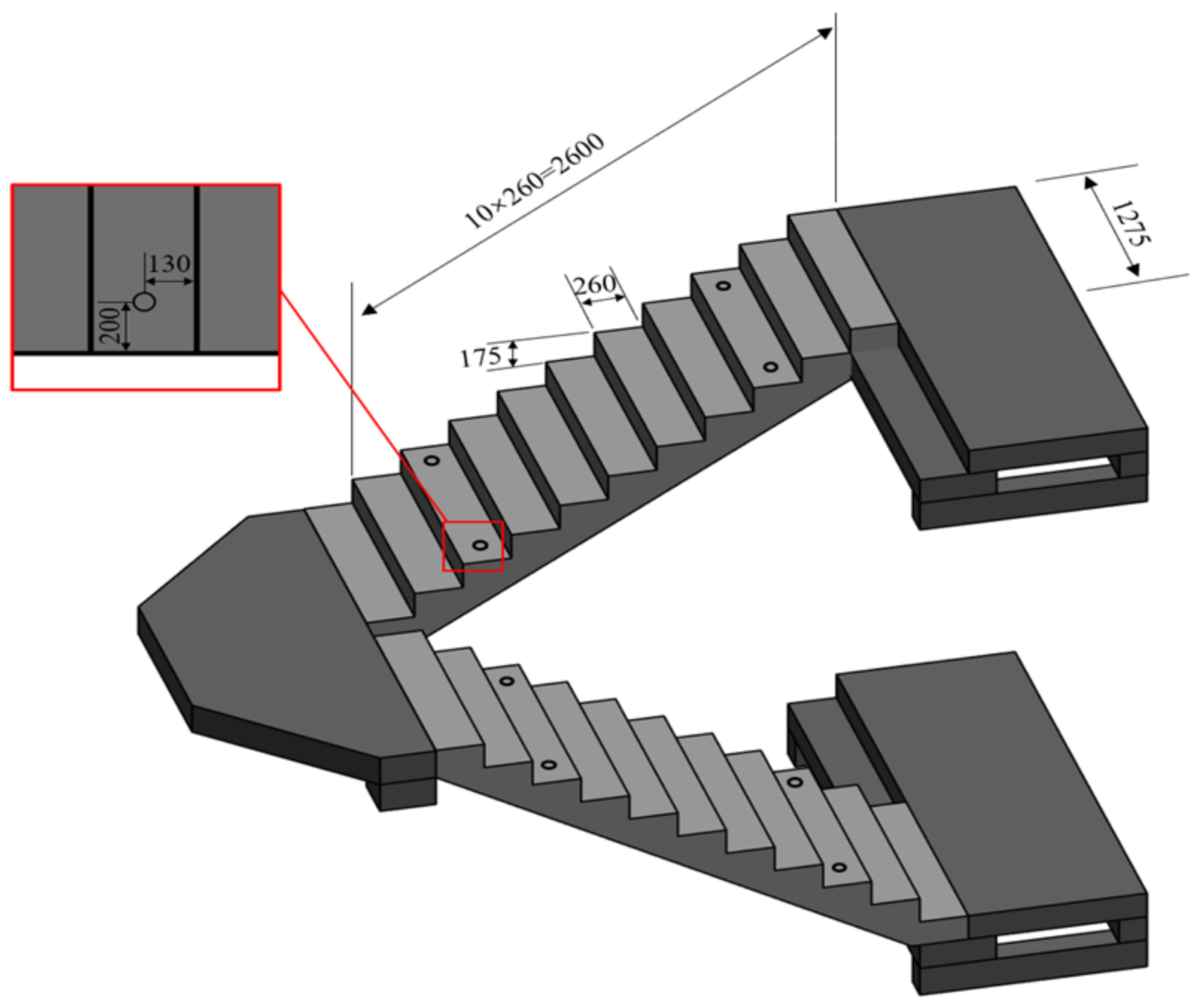

4.1. PC Staircase Lifting Point Setting Method

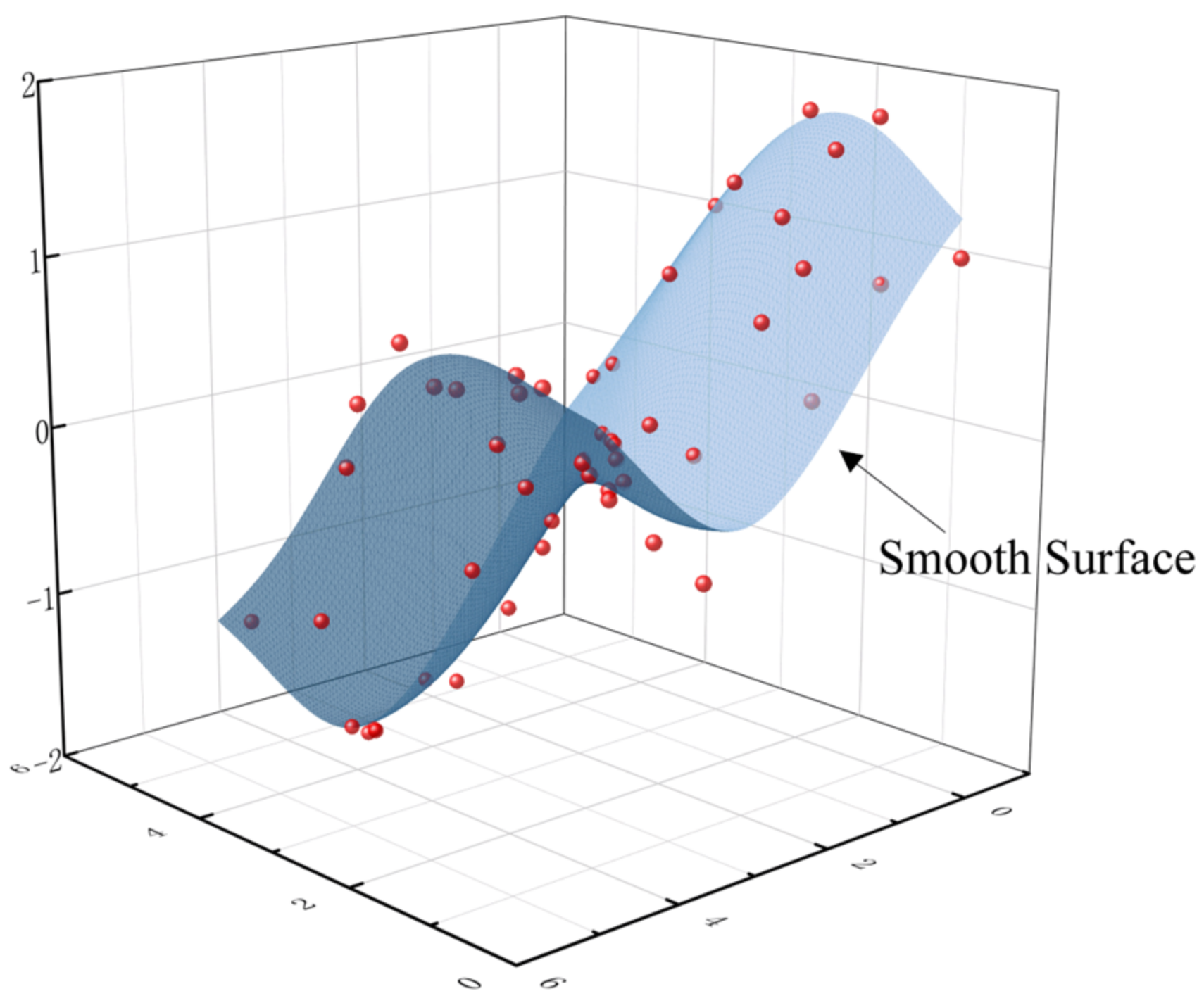

4.2. Thin-Plate Spline Interpolation Algorithm

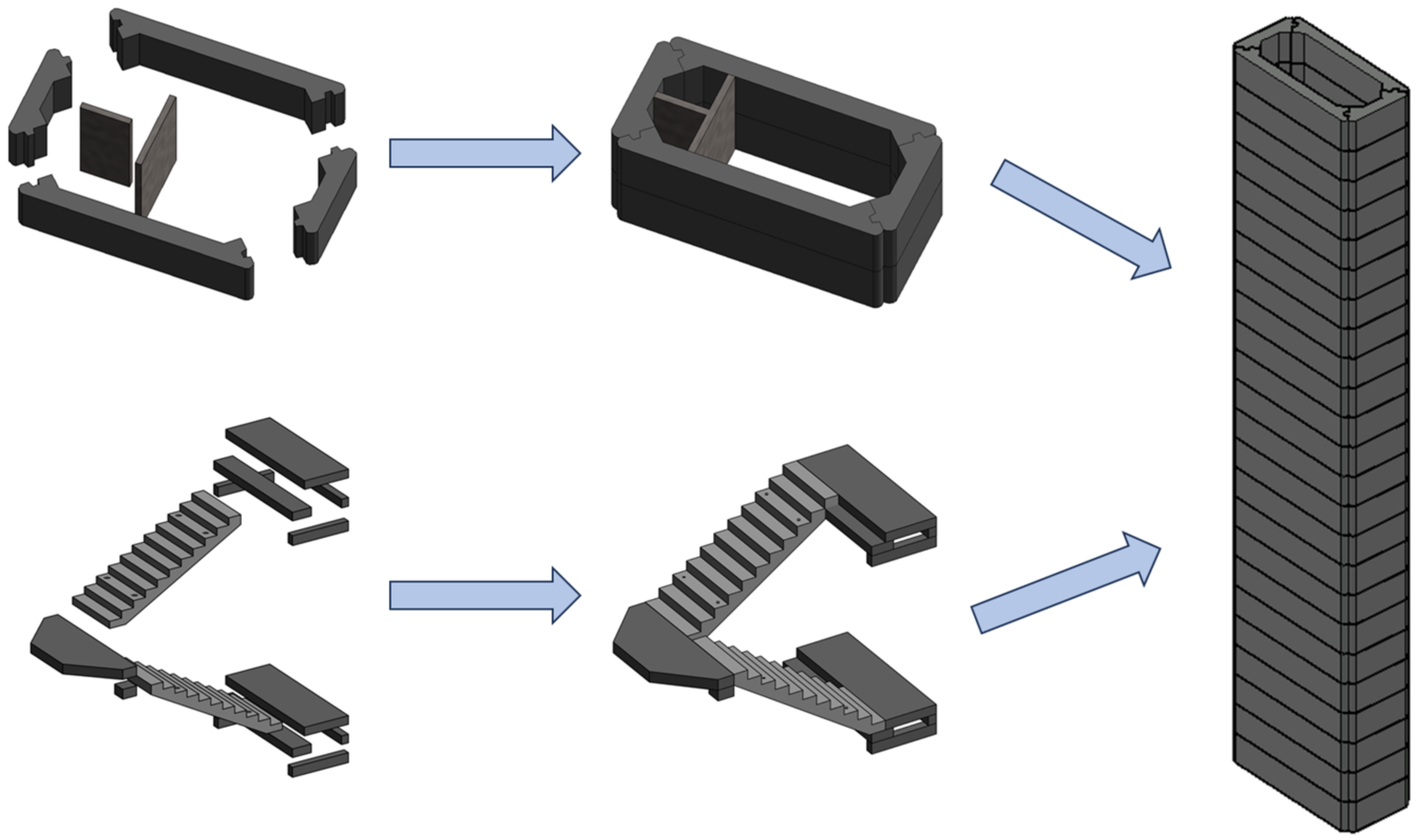

4.3. PC Staircase Production Process

- (1)

- The reinforcing cage of a PC staircase should be fully inspected before closing the mold to ensure quality. The reinforcement cage should be tied to determine the size of the protective layer, the degree of curvature, and the spacing of the number of specifications and no more than one tie should be omitted. At the same time, the reinforcement should be smooth, free of oil and rust, and should not be bent. When tying, we need to make sure that the upper and lower longitudinal bars, edge longitudinal bars, edge reinforcement intersections are firmly tied, and the intersections of the middle upper and lower distribution bars can be staggered and tied at intervals. When the stepping reinforcement cage is tied, the bracing iron or tying frame should be set to fix the thickness spacing of the reinforcement, which not only ensures the thickness size requirement but also improves the degree of regularity. Attention should be paid to avoid pin key holes, hanging nails, and other embedded parts. It is recommended to break down the reinforcement material into three parts according to the drawings: staircase upper platform, staircase lower platform and staircase tread for tying. The tied rebar cage is stored in a special rack to avoid deformation. The mold can be closed only after passing the inspection and attention should be paid to the strength when closing the mold to avoid knocking off the protective layer’s pads.

- (2)

- Before the construction of a PC staircase template, it is necessary to comprehensively check the mold to ensure that there is no gap, and the ends, anti-slip strips, drip strips and the bottom and side mold splices need to be reinforced by electric welding. When applying a release agent, it should be in place, measured and positioned accurately before installation, and channel steel and shaped steel template should be used for reinforcement to ensure that there are no phenomena such as mold rise and displacement. After the reinforcement is completed, each cycle of construction must be completed to check the template’s structural dimensions, plane position, and verticality. Before closing the mold, the sealing tape should be checked to prevent the double-sided adhesive from breaking, shifting, or integrating into the concrete. After closing the mold, the tightness of the bolts should be checked to prevent loosening and slurry leakage during vibration. Before demolding, it is necessary to carry out strength testing of the components to reach 75% of the design strength level and not less than 15 MPa before demolding. In the process of lifting and transferring, impacts, lifting chains, hooks, and stairs not in the same straight line when lifting should be avoided to prevent swinging impact molds or in the process of transferring, impact objects leading to chipping corners.

- (3)

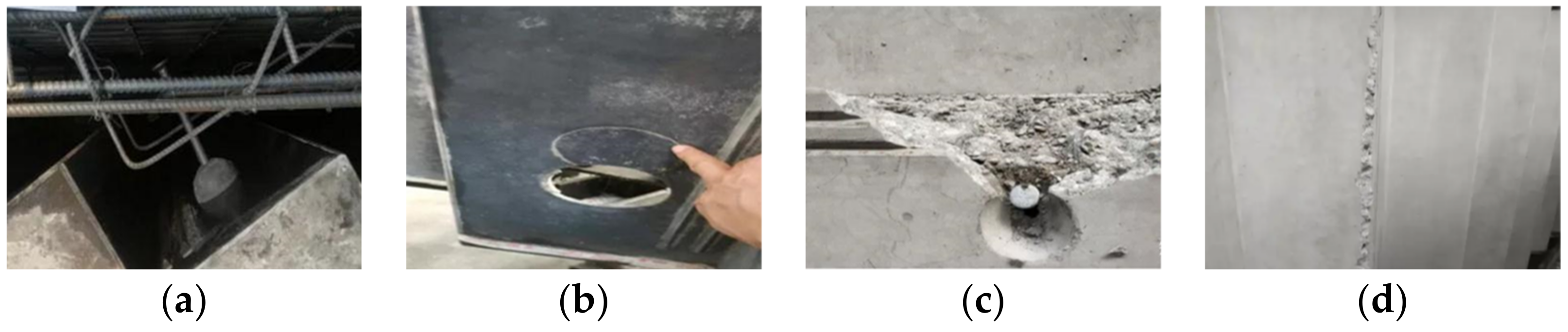

- Hanging nails need to be checked before installation, to ensure the glue wave is clean; during the installation, not only should the hanging nails required for the workpiece and the surrounding concrete be clean, but one should also ensure that the hanging nails do not exhibit a leakage of slurry phenomenon, and fasten the good hanging nails and molds so that they are in a perpendicular state to ensure that the finished product of the components of the hanging nails are not skewed and the installation is safe for transferring.

- (4)

- When pouring concrete for a PC staircase, it is necessary to control the quality of cement, concrete ratio, and slump. When the concrete is vibrated, it should be poured in layers, vibrated in layers, and one should master the vibration time and the depth of each vibrator insertion.

4.4. PC Staircase Lifting Process Analysis

- (1)

- Review the size and elevation of the construction PC staircase components before proceeding with construction. Review the size and elevation of the construction PC staircase components. Simulate the construction process in Revit to check the possible collision; the checking process is shown in Figure 15. Prepare a special construction program for the assembled staircase installation, carry out a second-level technical briefing and a safety briefing to construction technicians, and carry out a detailed third-level technical, safety, and operation briefing to the team.

- (2)

- When binding side-wall reinforcement in a restricted space, simultaneously bind the corbel reinforcement, and reserve the straight thread for the corbel reinforcement; after the side wall is poured, chisel away the concrete at the location of the pre-embedded reinforcing bars, bind the corbel reinforcement, and close the mold for pouring the corbel. The poured corbel is shown as (a) in Figure 16. According to the construction drawings, calculate the coordinates and elevation of each staircase, and carry out construction sampling on site after checking.

- (3)

- If a PC staircase adopts a horizontal lifting method, use bolts to connect the universal lugs with the nuts in the pre-embedded lifting ring of the staircase board, check the unloading buckle ring before lifting, and confirm that it is firm before lifting slowly. When lifting to the surface of the stair board, pause at 0.5 m, according to the direction of the stair board, to adjust the position and ensure the requirements of a slow operation in place, prohibiting a fast and fierce release, so as not to cause damage to the stair board vibration folding. After the staircase board is basically in place, according to the control line, use a crowbar to fine-tune the correction. After the correction of the stair section is completed, fix the pre-embedded parts of the stair section with the pre-embedded bolts of the structure. The staircase board is lifted as shown in (b) in Figure 16.

- (4)

- The connection between prefabricated staircase board and cast-in-place part is treated with cement mortar filling. After the staircase plate is fixed with bolts, cement mortar is filled in the connecting part of the prefabricated staircase plate and resting platform, which is required to be filled from one side of the staircase board to the other side, and the cement mortar can be regarded as having been filled when it is overflowing.

5. Conclusions

- (1)

- By analyzing the demand for four lifting operations during the production, transportation, and installation of PC staircases, the multidimensional spatial limitations of PC staircases at different stages were clarified, and it was proposed that the setting of lifting points for PC staircases should consider the factors of safety, stability, construction convenience, and economy.

- (2)

- A database of prefabricated staircase lifting point settings was established, and a thin-plate spline interpolation algorithm was introduced to expand it, which solved the technical difficulty of not being able to make predictions due to insufficient sample data. In order to enhance the reliability of the model performance evaluation, the k-fold cross-validation method was used to determine the ratio of the training set and test set, and the final optimal solution in the number of cross-folds was derived as 10.

- (3)

- Based on the support vector machine classification prediction algorithm, the kernel function scale parameter and penalty factor were optimized based on the grid search method, which resulted in the optimal kernel function scale parameter of 7.0 and the optimal penalty factor of 10.0. Then, an algorithm for the setting of lifting points of prefabricated assembled reinforced concrete staircase based on the small-sample database was established with these optimal parameters. After inputting the design parameters of the number of treads, the height of the treads, the width of the treads, the width of the staircase, and the weight of the staircase, the algorithm of this paper was run to obtain the number of lifting points and lifting point locations of the PC staircase that satisfied the construction safety, efficiency, and quality.

- (4)

- The reliability of the precast reinforced concrete staircase lifting point setting method proposed in this paper considering multidimensional spatial constraint features was verified through the construction of prefabricated staircases in deep shafts for assembly construction at the Chongqing metro station, which avoided the problems of cracking and collision of PC staircases. Calculated by the PC staircase lifting point prediction algorithm based on support vector machine classification, the number of lifting points of the PC staircase in that case was 4, and the lifting point location was at the center of the third step, 200 mm from the edge of the ladder section.

- (5)

- Our intelligent PC staircase lifting point setting method considering multidimensional spatial constraint features is not only applicable to PC staircases but can also be applied to other similar components. The method can be further optimized in future research to make it more compatible with different component types and construction scenarios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y. Features and Construction of Prefabricated Buildings. Adv. Civ. Ind. Eng. IV 2014, 580–583, 2262–2265. [Google Scholar] [CrossRef]

- Wang, M.; Yao, G.; Yang, Y.; Sun, Y.; Yan, M.; Deng, R. Deep learning-based object detection for visible dust and prevention measures on construction sites. Dev. Built Env. 2023, 16, 100245. [Google Scholar] [CrossRef]

- Yao, G.; Chen, Y.; Yang, Y.; Ma, X.; Men, W. Investigation on Buckling Performance of Prefabricated Light Steel Frame Materials under the Action of Random Defects during Construction. Materials 2023, 16, 5666. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Ye, X.; Guo, Y.; Zhang, R.; Ma, Z. Probabilistic method for wind speed prediction and statistics distribution inference based on SHM data-driven. Probabilist. Eng. Mech. 2023, 73, 103475. [Google Scholar] [CrossRef]

- Ding, Y.; Wei, Y.J.; Xi, P.; Ang, P.P.; Han, Z. A long-term tunnel settlement prediction model based on BO-GPBE with SHM data. Smart Struct. Syst. 2024, 33, 17–26. [Google Scholar]

- Yao, H.; She, J.; Zhou, Y. Risk assessment of construction safety accidents based on association rule mining and Bayesian network. J. Intell. Constr. 2024. [Google Scholar] [CrossRef]

- Jiang, P.; Wang, Z.; Li, N.; Song, X.; Chen, Y.; Wang, W. Cumulative deformation and non-coaxial characteristics of fiber and cement-modified iron tailings under the rotation of principal stress. Transp. Geotech. 2023, 43, 101114. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, J.; Wang, J.; Tian, M.; Liu, S. Safety Risk Analysis for Prefabricated Building Hoisting Construction Based on STPA-BN. In Proceedings of the Iccrem 2021: Challenges of the Construction Industry Under the Pandemic, Beijing, China, 16–17 October 2021; pp. 171–180. [Google Scholar]

- Sun, Y.; Yang, Y.; Yao, G.; Wei, F.; Wong, M. Autonomous Crack and Bughole Detection for Concrete Surface Image Based on Deep Learning. IEEE Access 2021, 9, 85709–85720. [Google Scholar] [CrossRef]

- Goh, J.; Hu, S.; Fang, Y. Human-in-the-Loop Simulation for Crane Lift Planning in Modular Construction On-Site Assembly. In Proceedings of the Computing in Civil. Engineering 2019: Visualization, Information Modeling, and Simulation, Atlanta, GA, USA, 17–19 June 2019; pp. 71–78. [Google Scholar]

- Duan, Y.; Li, G. Analysis on the Quality Problems and Preventive Measures of Prefabricated Building Construction. In Proceedings of the 2018 7th International Conference On Advanced Materials and Computer Science (Icamcs 2018), Dalian, China, 21–22 November 2018; pp. 411–414. [Google Scholar]

- Kong, X.; Wang, S.; Zhang, W.; Ling, X.; Zhao, J. Feasibility of winter construction for prefabricated subway station: Waterproof performance analysis of composite cross-section gasket treated by low temperature. Cold Reg. Sci. Technol. 2024, 219, 104109. [Google Scholar] [CrossRef]

- Chen, K.; Chen, X.; Wang, L.; Yang, W.; Qiu, T.; Su, D.; Wu, H. Low-carbon effects of constructing a prefabricated subway station with temporary internal supports: An innovative case of Shenzhen, China. J. Clean. Prod. 2023, 426, 139023. [Google Scholar] [CrossRef]

- Chigan, X.; Guo, K.; Li, Q.; Luo, F.; Zhang, Y.; Xu, G.; Xu, Z.; Zhao, J. Design and Optimization Method of Internal Support System for Prefabricated Shaft of Underground Subway Station. In Proceedings of the 2022 8th International Conference on Hydraulic and Civil Engineering: Deep Space Intelligent Development and Utilization Forum (ICHCE), Xi’an, China, 25–27 November 2022; pp. 397–400. [Google Scholar]

- Shen, J.; Wu, Q.; Peng, C.; Zhao, S. BIM-based ventilation shaft construction schedule simulation and plan optimization. In Proceedings of the 2020 2nd International Conference on Civil Engineering, Environment Resources and Energy Materials, Changsha, China, 18–20 September 2020; p. 634. [Google Scholar]

- Li, L.; Qiu, Z.; Dong, Y.; Du, X. Risk caused by construction of the metro shaft adjacent to building and its control measure. Procedia Eng. 2016, 165, 40–48. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Xian, B.; Chai, H.K.; Yu, Z.; Zhang, Y.; Zhu, T.; Yuen, K. Baseline-Free Detection Method for Change of Lateral Stiffness of High-Rise Building Based on Statistical Moment Curvature. Struct. Control Health Monit. 2023, 2023, 4373174. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, W.; Gao, Z.; Yu, Z.; Zhang, Y. Research Progress of SHM System for Super High-Rise Buildings Based on Wireless Sensor Network and Cloud Platform. Remote. Sens. 2023, 15, 1473. [Google Scholar] [CrossRef]

- Yin, J.; Huang, R.; Sun, H.; Cai, S. Multi-objective optimization for coordinated production and transportation in prefabricated construction with on-site lifting requirements. Comput. Ind. Eng. 2024, 189, 110017. [Google Scholar] [CrossRef]

- Li, P.; Wang, H. A novel strategy for the crossarm length optimization of PSSCs based on multi-dimensional global optimization algorithms. Eng. Struct. 2021, 238, 112238. [Google Scholar] [CrossRef]

- Li, P.; Chen, G.; Qiu, J.; Qian, J.; Ding, D.; Jian, B.; Zhang, X.; Xiong, G. Experimental and numerical investigation into the load-carrying capacity of aluminium alloy H-sectional stocky columns under axial compression. J. Build. Eng. 2024, 87, 108777. [Google Scholar] [CrossRef]

- Yang, Y.; Du, H.; Yao, G.; Ma, X.; Men, W. Time-Varying Mechanical Analysis of Long-Span Spatial Steel Structures Integral Lifting in Construction Basing Building Information Model. Sustainability 2023, 15, 11256. [Google Scholar] [CrossRef]

- Guo, Z.L.; Gao, S.; Liu, J.E. Application of BIM Technology in Prefabricated Buildings. In Proceedings of the 2nd International Conference On Materials Science, Energy Technology and Environmental Engineering (Msetee 2017), Zhuhai, China, 28–30 April 2017; p. 81. [Google Scholar]

- Huang, W.; Lei, Y.; Zhang, S. Research on Existing Problems of Fabricated Building in China. In Proceedings of the Iccrem 2017: Prefabricated Buildings, Industrialized Construction, and Public-Private Partnerships, Guangzhou, China, 10–12 November 2017; pp. 180–188. [Google Scholar]

- Alharbi, J.; Bhattacharyya, S. Machine Learning with System/Software Engineering in Selection and Integration of Intelligent Algorithms. In Proceedings of the 2021 15Th Annual Ieee International Systems Conference (Syscon 2021), Vancouver, BC, Canada, 15 April–15 May 2021. [Google Scholar]

- Xu, P. Review on Studies of Machine Learning Algorithms. J. Phys. Conf. Ser. 2019, 1187, 052103. [Google Scholar] [CrossRef]

- Wang, R.; Chen, G.; Liu, Y. A Dynamic Model of Machine Learning and Deep Learning in Shield Tunneling Parameters Prediction. In Proceedings of the 17th East Asian-Pacific Conference On Structural Engineering and Construction, Easec—17 2022, Singapore, 27–30 June 2022; Volume 302, pp. 1241–1254. [Google Scholar]

- Zhang, X.; Lin, X.; Zhang, W.; Feng, Y.; Lan, W.; Da, Y.; Hu, K. Intelligent recognition of voids behind tunnel linings using deep learning and percussion sound. J. Intell. Constr. 2023, 1, 9180029. [Google Scholar] [CrossRef]

- Li, P.; Wang, H.; Nie, D.; Wang, D.; Wang, C. A method to analyze the long-term durability performance of underground reinforced concrete culvert structures under coupled mechanical and environmental loads. J. Intell. Constr. 2023, 1, 9180011. [Google Scholar] [CrossRef]

- Drucker, H.; Wu, D.H.; Vapnik, V.N. Support vector machines for spam categorization. IEEE Trans. Neural Netw. 1999, 10, 1048–1054. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Ye, X.; Zhang, H.; Zhang, X. Fatigue life evolution of steel wire considering corrosion-fatigue coupling effect: Analytical model and application. Steel Compos. Struct. 2024, 50, 363–374. [Google Scholar]

- Yao, G.; Sun, W.T.; Yang, Y. Analysis and Identification of Building Construction Accident Risk in China basing Exclusively Database. IOP Conf. Ser. Earth Environ. Sci. 2022, 1101, 072009. [Google Scholar] [CrossRef]

- Thai, H.T. Machine learning for structural engineering: A state-of-the-art review. Structures 2022, 38, 448–491. [Google Scholar] [CrossRef]

- Jiang, P.; Chen, Y.; Wang, W.; Yang, J.; Wang, H.; Li, N.; Wang, W. Flexural behavior evaluation and energy dissipation mechanisms of modified iron tailings powder incorporating cement and fibers subjected to freeze-thaw cycles. J. Clean. Prod. 2022, 351, 131527. [Google Scholar] [CrossRef]

- Ling, H.; Qian, C.; Mang, W.; Liang, C.; Chen, H. Combination of Support Vector Machine and K-Fold cross validation to predict compressive strength of concrete in marine environment. Constr. Build. Mater. 2019, 206, 355–363. [Google Scholar] [CrossRef]

- Sibson, R.; Stone, G. Computation of Thin-plate Splines. Siam. J. Sci. Stat. Comput. 1991, 12, 1304–1313. [Google Scholar] [CrossRef]

- Dyn, N.; Levin, D. Construction of Surface Spline Interpolants of Scattered Data Over Finite Domains. Rairo-Anal. Numer.-Numer. Anal. 1982, 16, 201–209. [Google Scholar] [CrossRef][Green Version]

| Tread Number | Staircase Width (mm) | Tread Height (mm) | Tread Width (mm) | Staircase Weight (t) | Lifting Points Number |

|---|---|---|---|---|---|

| 8 | 1125 | 175.0 | 260 | 1.61 | 4 |

| 8 | 1195 | 175.0 | 260 | 1.72 | 4 |

| 9 | 1125 | 161.1 | 260 | 1.81 | 4 |

| 9 | 1195 | 161.1 | 260 | 1.92 | 4 |

| 9 | 1125 | 166.6 | 260 | 1.84 | 4 |

| 9 | 1195 | 166.6 | 260 | 1.95 | 4 |

| 16 | 1160 | 175.0 | 260 | 4.34 | 8 |

| 16 | 1210 | 175.0 | 260 | 4.50 | 8 |

| 17 | 1160 | 170.6 | 260 | 4.64 | 8 |

| 17 | 1210 | 170.6 | 260 | 4.83 | 8 |

| 18 | 1160 | 166.7 | 260 | 4.98 | 8 |

| 18 | 1210 | 156.7 | 260 | 5.20 | 8 |

| Cross-Validation Folds | Minimum RMSE | Penalty Factor | Kernel Function Scale Parameters | Optimization Search Time (s) |

|---|---|---|---|---|

| 4 | 0.360 | 10.0 | 6.5 | 270.03 |

| 6 | 0.326 | 10.0 | 6.9 | 377.11 |

| 8 | 0.265 | 10.0 | 7.4 | 610.05 |

| 10 | 0.254 | 10.0 | 7.0 | 776.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Cai, X.; Yao, G.; Wang, M.; Zhou, C.; Lei, T.; Zhang, Y. Research on Intelligent Prefabricated Reinforced Concrete Staircase Lifting Point Setting Method Considering Multidimensional Spatial Constraint Characteristics. Sustainability 2024, 16, 5843. https://doi.org/10.3390/su16145843

Yang Y, Cai X, Yao G, Wang M, Zhou C, Lei T, Zhang Y. Research on Intelligent Prefabricated Reinforced Concrete Staircase Lifting Point Setting Method Considering Multidimensional Spatial Constraint Characteristics. Sustainability. 2024; 16(14):5843. https://doi.org/10.3390/su16145843

Chicago/Turabian StyleYang, Yang, Xiaodong Cai, Gang Yao, Meng Wang, Canwei Zhou, Ting Lei, and Yating Zhang. 2024. "Research on Intelligent Prefabricated Reinforced Concrete Staircase Lifting Point Setting Method Considering Multidimensional Spatial Constraint Characteristics" Sustainability 16, no. 14: 5843. https://doi.org/10.3390/su16145843

APA StyleYang, Y., Cai, X., Yao, G., Wang, M., Zhou, C., Lei, T., & Zhang, Y. (2024). Research on Intelligent Prefabricated Reinforced Concrete Staircase Lifting Point Setting Method Considering Multidimensional Spatial Constraint Characteristics. Sustainability, 16(14), 5843. https://doi.org/10.3390/su16145843