Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review

Abstract

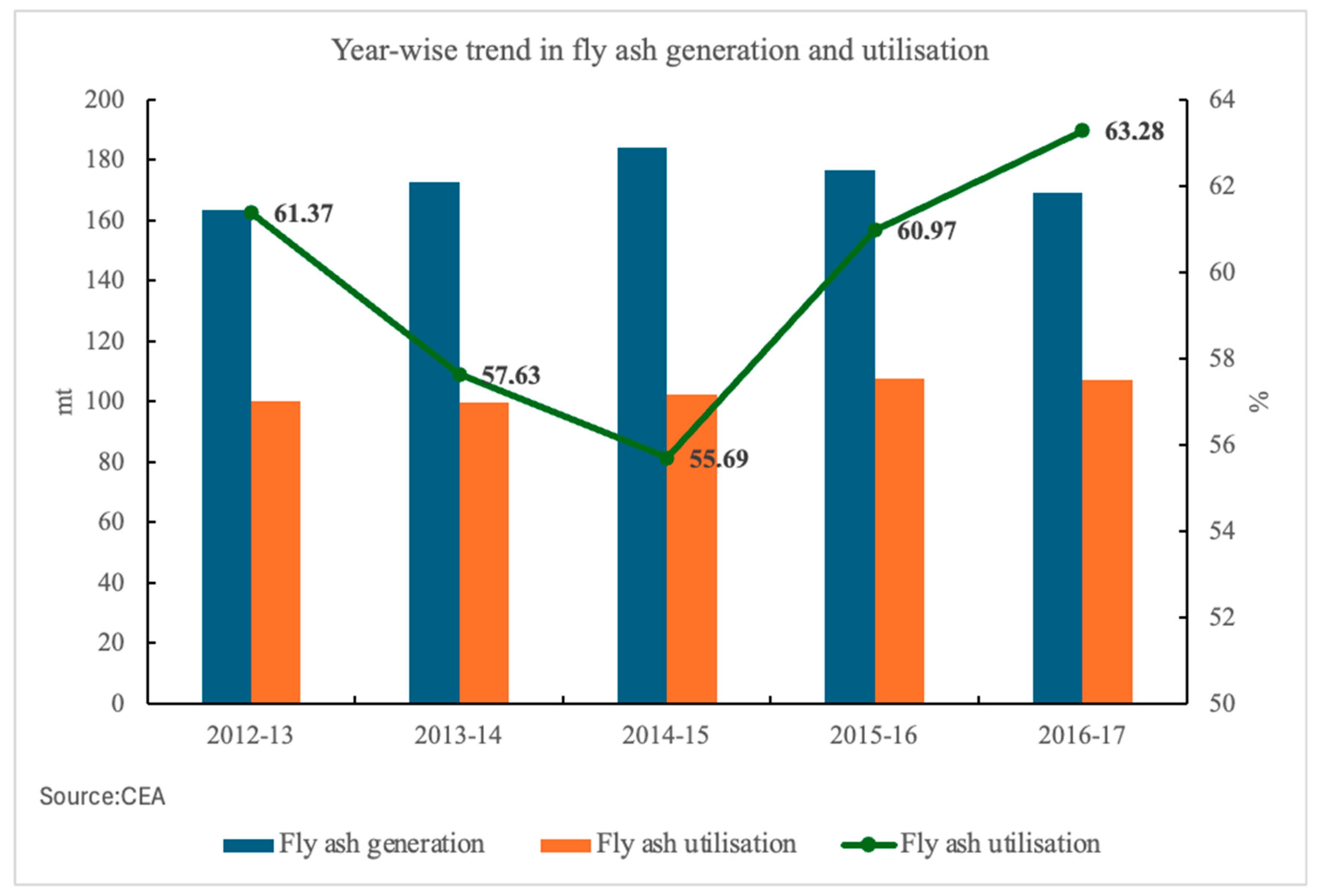

1. Introduction

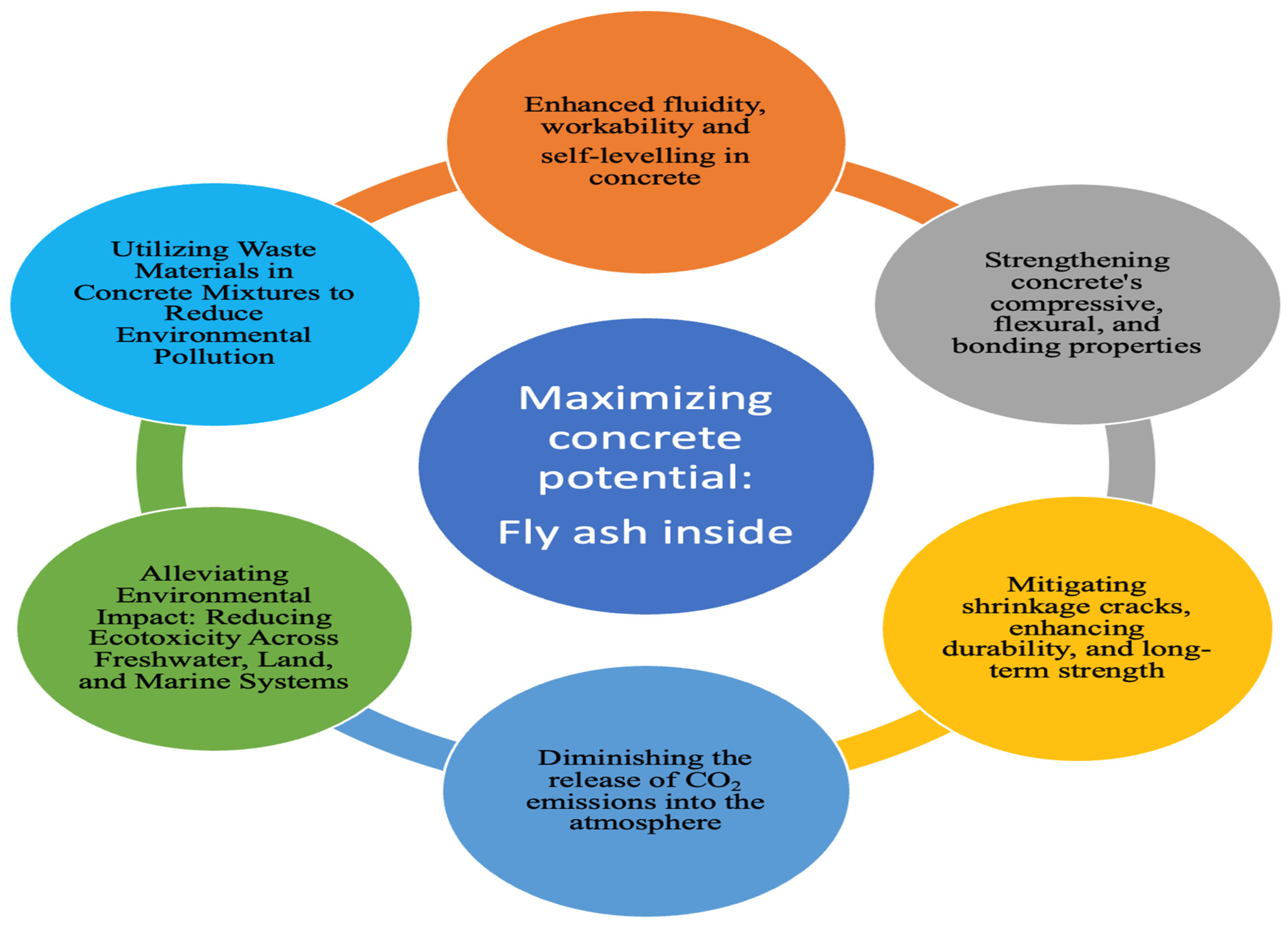

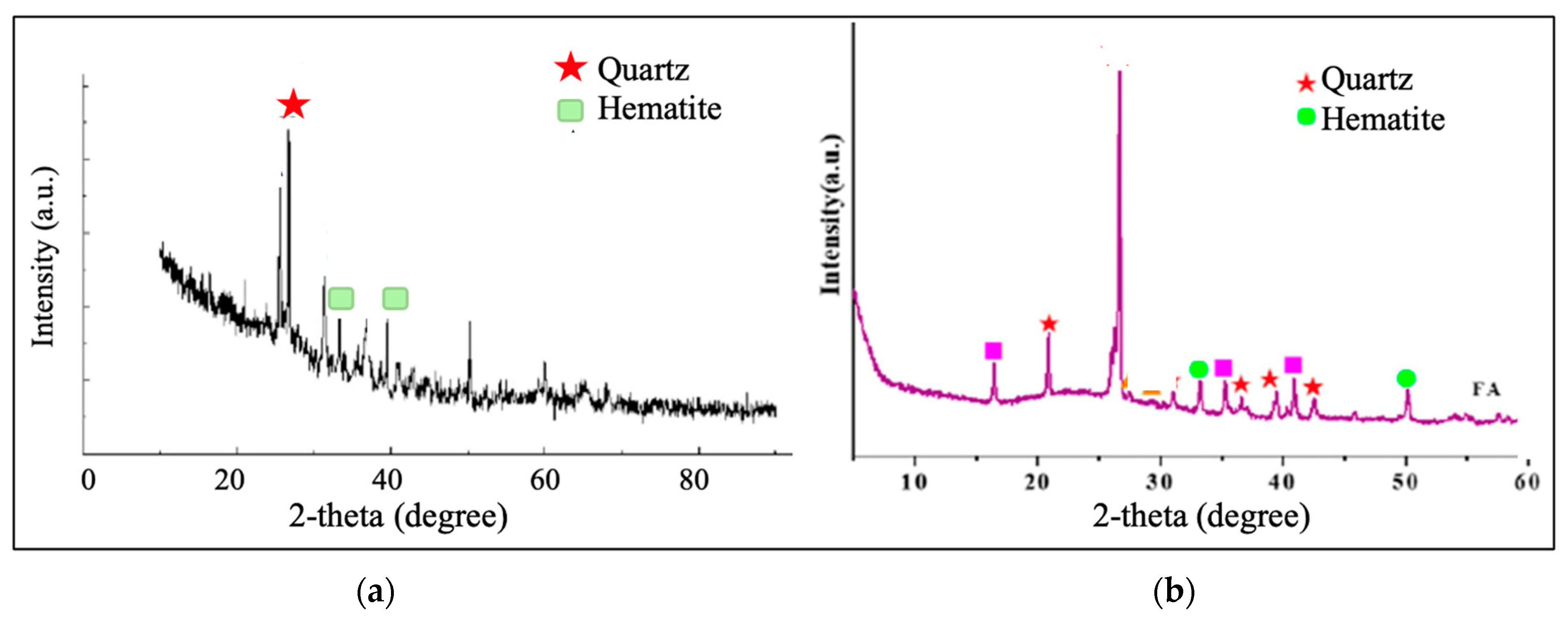

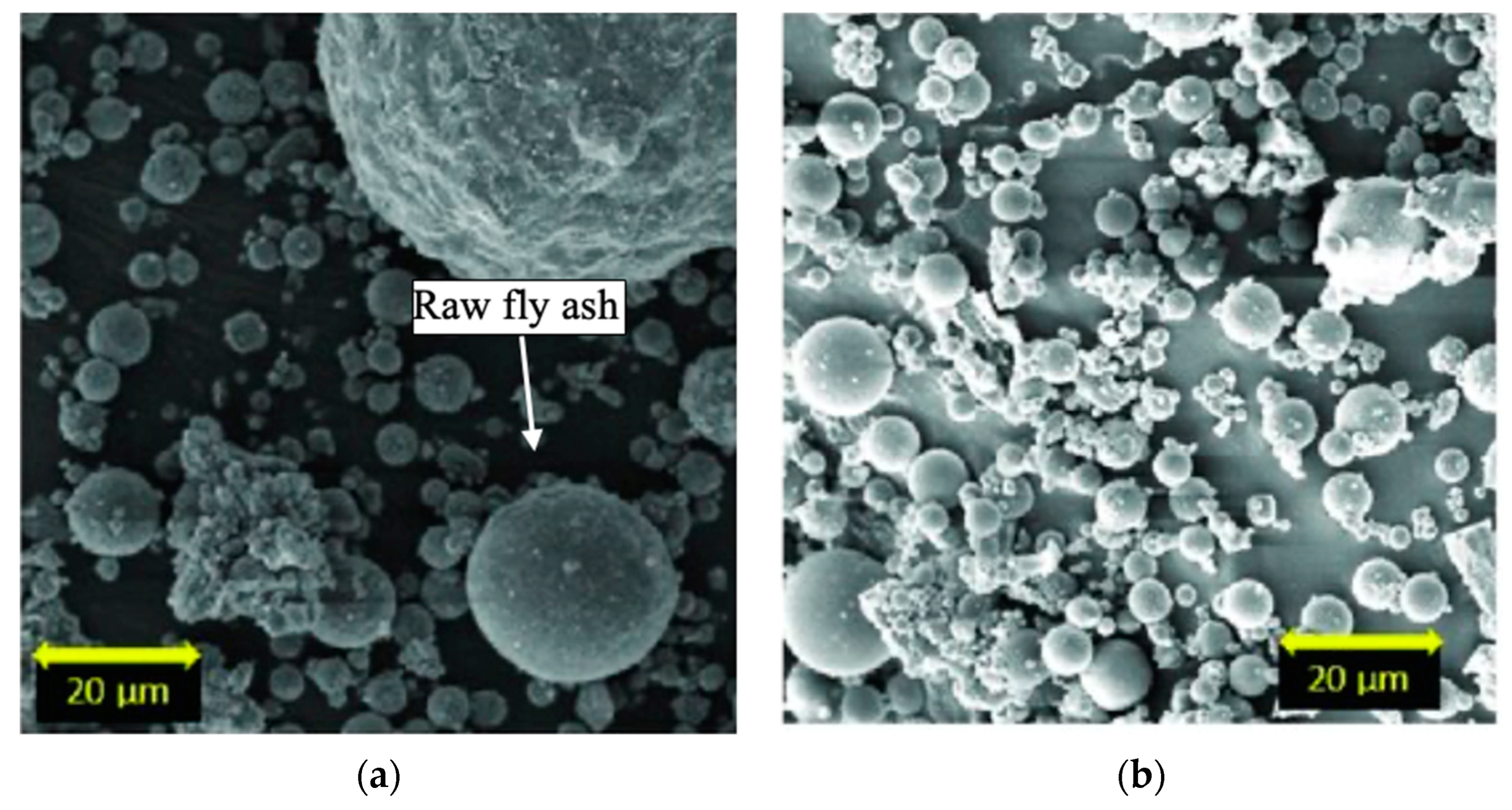

2. Exploring FA: Definition and Uses in Concrete Industry

| References | SiO2 | CaO | Fe2O3 | Al2O3 | MgO | SO3 | K2O | Na2O | LOI | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| Lin et al. [25] | 29.47 | 35.54 | 3.49 | 19.27 | 1.82 | 7.96 | - | - | – | - |

| Subramaniam and Sathiparan [26] | 50.8 | 6.3 | 6.8 | 29.1 | 1.9 | 1.9 | 0.9 | 2.2 | – | 1.2 |

| Hwang and Yeon [27] | 30.8 | 5 | 39.6 | 9.9 | 0.4 | 11.4 | 1.0 | 0.9 | 7.6 | 0.6 |

| Ni et al. [28] | 42.1 | 11.7 | 3.5 | 19.3 | 1.8 | 7.4 | – | – | – | 3.1 |

| Singh et al. [29] | 57.4 | 0.3 | 28.5 | 9.1 | 9.7 | 3.0 | 0.6 | – | 16.0 | 0.9 |

| Wang et al. [30] | 56.2 | 3.8 | 22.4 | 14.1 | 2.6 | 1.0 | 2.1 | 0.2 | 1.5 | – |

| Saboo et al. [31] | 47.5 | 11.3 | 8.2 | 21.7 | 2.5 | 1.7 | – | – | 2.5 | – |

| Opiso et al. [32] | 23.9 | 23.3 | 4.4 | 26.7 | 0.1 | – | – | 1.3 | – | 0.1 |

| Liu et al. [33] | 51.3 | 10.7 | 7.2 | 23.2 | 2.9 | 1.9 | – | – | 2.5 | – |

| Muthaiyan and Thirumalai [34] | 51.6 | 10.8 | 13.2 | 24.2 | 2.2 | 2.8 | 2.6 | 0.7 | 0.4 | 0.7 |

| Swe et al. [35] | 41.7 | 11.1 | 7.0 | 28.0 | 1.2 | 0.4 | 1.9 | 1.5 | – | 1.0 |

| Shafabakhsh and Ahmadi [36] | 50.9 | 1.6 | 4.7 | 27.9 | 2.3 | – | – | – | 3.7 | – |

| Peng et al. [37] | 50.2 | 12.5 | 7.2 | 23.2 | 2.9 | – | – | – | 2.5 | – |

| Soto-P’erez and Hwang [38] | 30.8 | 39.6 | 5.0 | 9.9 | 0.4 | 11.4 | 1.0 | 0.9 | 7.6 | 0.6 |

| Mohammed et al. [39] | 36.4 | 17.5 | 18.2 | 17.8 | 0.95 | 2.59 | 2.16 | 0.59 | 1.49 | – |

| Ong et al. [40] | 46.0 | 8.4 | 2.1 | 30.5 | 0.1 | 0.4 | – | 1.3 | 1.1 | 1.8 |

3. Effects of FA on the Workability and Physical, Mechanical, and Durability Properties of Concrete

3.1. Utilizing FA for Enhanced Concrete Workability

3.2. Influence of FA on Concrete’s Apparent Porosity

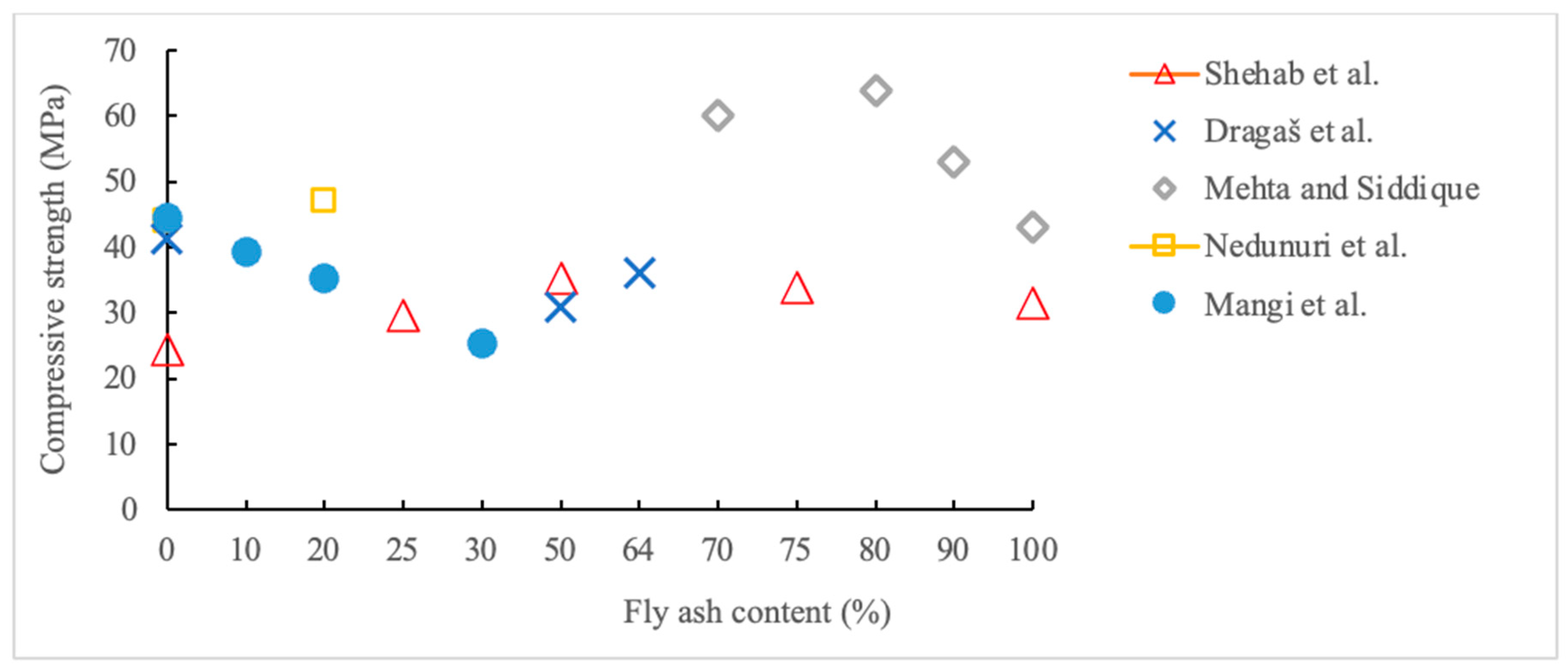

3.3. Compressive Strength Analysis: Concrete Performance with FA Admixtures

3.4. Examining Concrete Flexural Strength with FA Addition

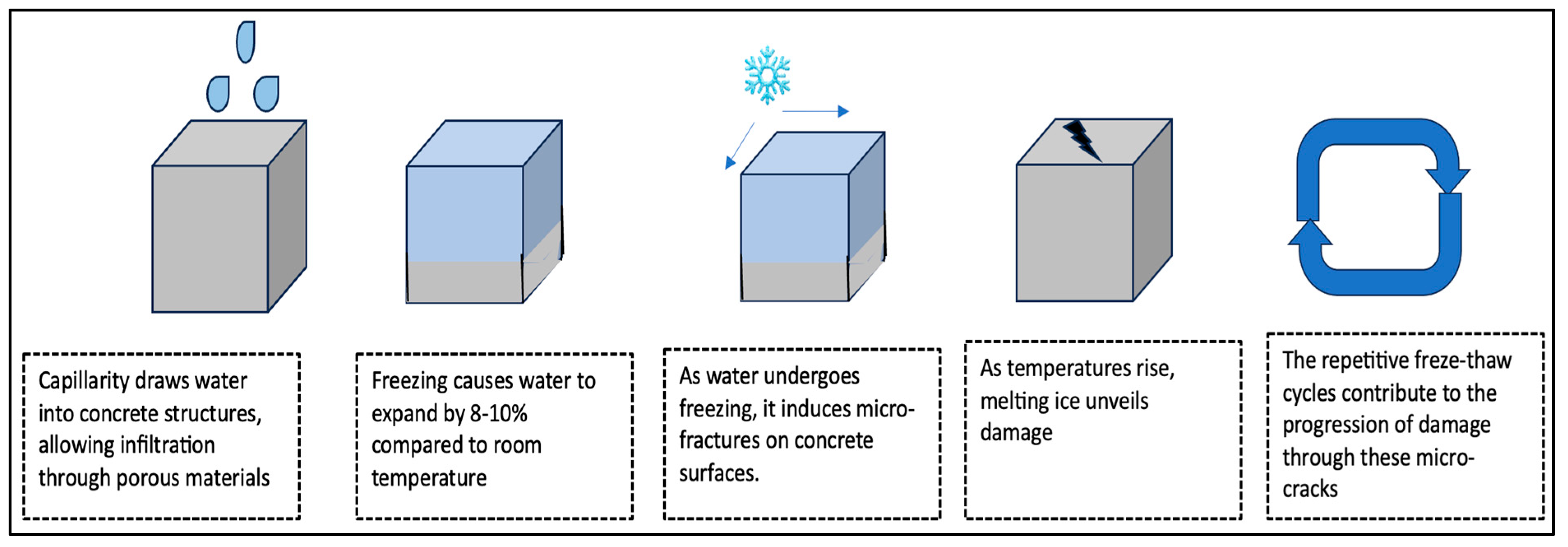

3.5. Assessing Freeze–Thaw Resistance in Concrete Enhanced by FA

3.6. Cycles Impacting the Durability of a Concrete Structure

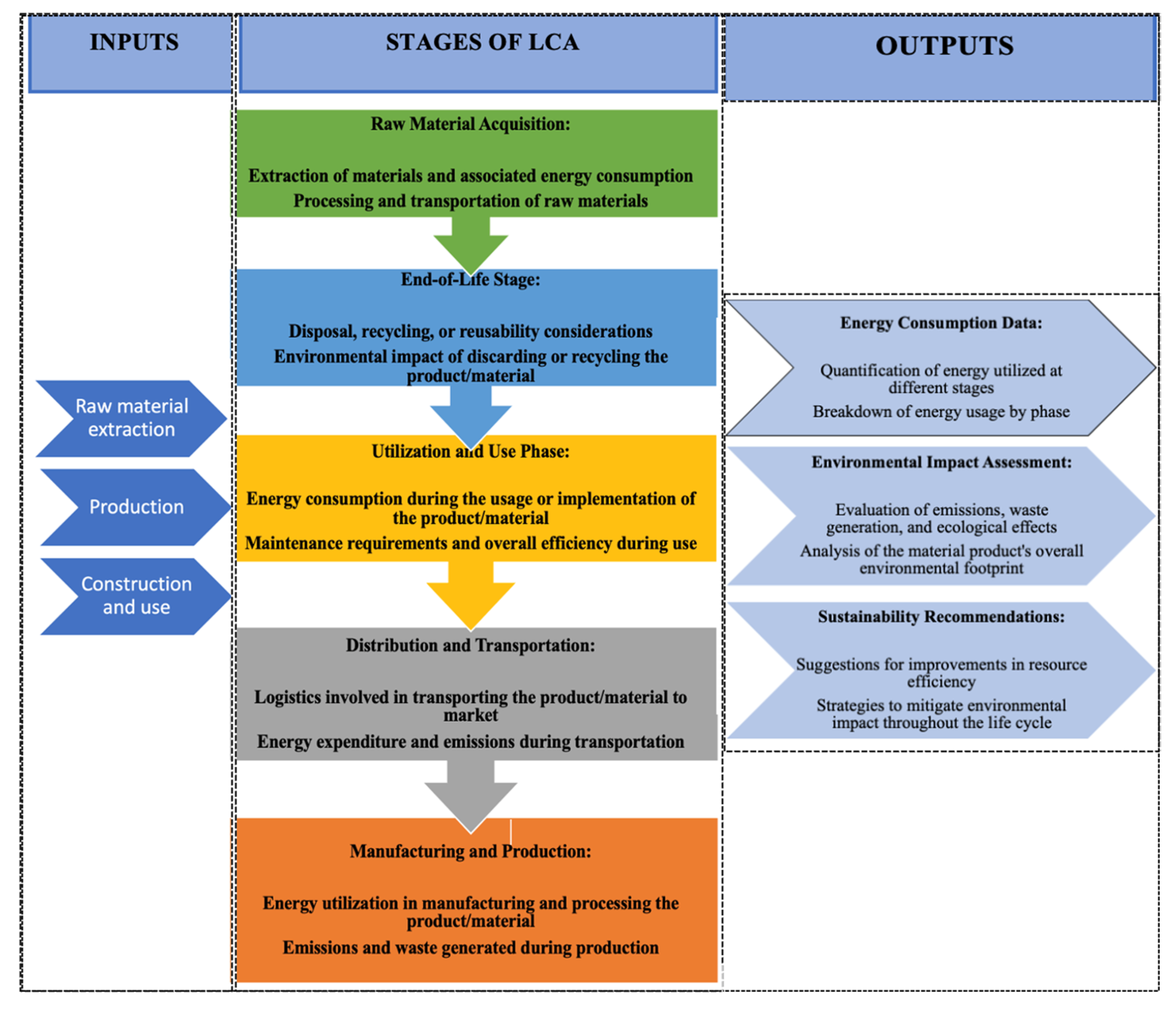

4. Environmental Impact Analysis: Concrete Incorporating FA—A Life Cycle Assessment

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahasenan, N.; Smith, S.; Humphreys, K. The cement industry and global climate change: Current and potential future cement industry CO2 emissions. In Proceedings of the Greenhouse Gas Control Technologies-6th International Conference, Kyoto, Japan, 1–4 October 2002; Elsevier: Amsterdam, The Netherlands, 2003; pp. 995–1000. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lin, E. Emerging energy-efficiency and CO2 emission-reduction technologies for cement and concrete production: A technical review. Renew. Sustain. Energy Rev. 2012, 16, 6220–6238. [Google Scholar] [CrossRef]

- Shen, W.; Cao, L.; Li, Q.; Zhang, W.; Wang, G.; Li, C. Quantifying CO2 emissions from China’s cement industry. Renew. Sustain. Energy Rev. 2015, 50, 1004–1012. [Google Scholar] [CrossRef]

- Sakir, S.; Raman, S.N.; Safiuddin, M.; Kaish, A.A.; Mutalib, A.A. Utilization of by-products and wastes as supplementary cementitious materials in structural mortar for sustainable construction. Sustainability 2020, 12, 3888. [Google Scholar] [CrossRef]

- Tyrer, M.; Cheeseman, C.R.; Greaves, R.; Claisse, P.A.; Ganjian, E.; Kay, M.; Churchman-Davies, J. Potential for carbon dioxide reduction from cement industry through increased use of industrial pozzolans. Adv. Appl. Ceram. 2010, 109, 275–279. [Google Scholar] [CrossRef]

- Costa, F.N.; Ribeiro, D.V. Reduction in CO2 emissions during production of cement, with partial replacement of traditional raw materials by civil construction waste (CCW). J. Clean. Prod. 2020, 276, 123302. [Google Scholar] [CrossRef]

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Bashar, I.I.; Alengaram, U.J.; Jumaat, M.Z. Enunciation of embryonic palm oil clinker based geopolymer concrete and its engineering properties. Constr. Build. Mater. 2022, 318, 125975. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Kontoni, D.P.N.; Ebid, A.M.; Dabbaghi, F.; Soleymani, A.; Jahangir, H.; Nehdi, M.L. Multi-objective optimization of sustainable concrete containing fly ash based on environmental and mechanical considerations. Buildings 2022, 12, 948. [Google Scholar] [CrossRef]

- Cyr, M. Influence of supplementary cementitious materials (SCMs) on concrete durability. In Eco-Efficient Concrete; Woodhead Publishing: Sawston, UK, 2013; pp. 153–197. [Google Scholar] [CrossRef]

- Mohammadi, A.; Ramezanianpour, A.M. Investigating the environmental and economic impacts of using supplementary cementitious materials (SCMs) using the life cycle approach. J. Build. Eng. 2023, 79, 107934. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, J.; Liu, Z. Service life prediction and environmental impact evaluation of recycled aggregate concrete with supplementary cementitious materials. Constr. Build. Mater. 2023, 395, 132270. [Google Scholar] [CrossRef]

- Iacovidou, E.; Hahladakis, J.; Deans, I.; Velis, C.; Purnell, P. Technical properties of biomass and solid recovered fuel (SRF) co-fired with coal: Impact on multi-dimensional resource recovery value. Waste Manag. 2018, 73, 535–545. [Google Scholar] [CrossRef]

- Napp, T.A.; Gambhir, A.; Hills, T.P.; Florin, N.; Fennell, P.S. A review of the technologies, economics and policy instruments for decarbonising energy-intensive manufacturing industries. Renew. Sustain. Energy Rev. 2014, 30, 616–640. [Google Scholar] [CrossRef]

- Vijaya, M.; Reddy, S.; Reddy, R.; Madan, K.; Reddy, M.; Nataraja, M.C.; Murthy, K. Durabılıty Aspects of Hıgh Performance Concrete Contaınıng Supplementary Cementıng Materıals. 2012. Available online: www.ijscer.com (accessed on 12 May 2024).

- Reddy, M.V.S.; Reddy, I.R.; Reddy, K.M.M.; Kumar, C.R. Durability aspects of standard concrete. Int. J. Struct. Civ. Eng. Res. 2013, 2, 40–46. [Google Scholar]

- Zahid, C.Z.B.; Rezwan, M.M.; Mohammed, T.U. Service life optimization and life cycle assessment of concrete using SCMs as partial replacement of cement. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2023; Volume 2521, p. 012008. [Google Scholar] [CrossRef]

- Rebitzer, G. Integrating life cycle costing and life cycle assessment for managing costs and environmental impacts in supply chains. In Cost Management in Supply Chains; Physica-Verlag HD: Heidelberg, Germany, 2002; pp. 127–146. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice husk ash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life cycle assessment of sustainable concrete with recycled aggregate and supplementary cementitious materials. Resour. Conserv. Recycl. 2023, 193, 106947. [Google Scholar] [CrossRef]

- Ribeiro, J.; Silva, T.F.; Mendonça Filho, J.G.; Flores, D. Fly ash from coal combustion–An environmental source of organic compounds. Appl. Geochem. 2014, 44, 103–110. [Google Scholar] [CrossRef]

- Rafieizonooz, M.; Khankhaje, E.; Rezania, S. Assessment of environmental and chemical properties of coal ashes including fly ash and bottom ash, and coal ash concrete. J. Build. Eng. 2022, 49, 104040. [Google Scholar] [CrossRef]

- Lo, F.C.; Lee, M.G.; Lo, S.L. Effect of coal ash and rice husk ash partial replacement in ordinary Portland cement on pervious concrete. Constr. Build. Mater. 2021, 286, 122947. [Google Scholar] [CrossRef]

- Dulkadiroğlu, H. Türkiye’de elektrik üretiminin sera gazi emisyonlari açisindan incelenmesi. Niğde Ömer Halisdemir Üniversitesi Mühendislik Bilim. Derg. 2018, 7, 67–74. [Google Scholar] [CrossRef][Green Version]

- Lin, K.L.; Lin, W.T.; Korniejenko, K.; Hsu, H.M. Application of ternary cementless hybrid binders for pervious concrete. Constr. Build. Mater. 2022, 346, 128497. [Google Scholar] [CrossRef]

- Subramaniam, D.N.; Sathiparan, N. Comparative study of fly ash and rice husk ash as cement replacement in pervious concrete: Mechanical characteristics and sustainability analysis. Int. J. Pavement Eng. 2023, 24, 2075867. [Google Scholar] [CrossRef]

- Hwang, S.; Yeon, J.H. Fly ash-added, seawater-mixed pervious concrete: Compressive strength, permeability, and phosphorus removal. Materials 2022, 15, 1407. [Google Scholar] [CrossRef]

- Ni, T.; Xu, F.; Gao, C.; Yang, Y.; Ma, W.; Kong, D. Chemical activation of pozzolanic activity of sludge incineration ash and application as row bonding materials for pervious ecological brick. Constr. Build. Mater. 2022, 329, 127199. [Google Scholar] [CrossRef]

- Singh, T.; Siddique, R.; Sharma, S. Effectiveness of using Metakaolin and fly ash as supplementary cementitious materials in pervious concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 7359–7382. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Liang, X.; Zhou, H.; Xie, N.; Dai, Z. Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based on the cement-aggregate ratio. Constr. Build. Mater. 2019, 202, 387–395. [Google Scholar] [CrossRef]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of fly ash and metakaolin on pervious concrete properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- Opiso, E.M.; Supremo, R.P.; Perodes, J.R. Effects of coal fly ash and fine sawdust on the performance of pervious concrete. Heliyon 2019, 5, e02783. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, L.; Gong, Y. Strength time–varying and freeze–thaw durability of sustainable pervious concrete pavement material containing waste fly ash. Sustainability 2018, 11, 176. [Google Scholar] [CrossRef]

- Muthaiyan, U.M.; Thirumalai, S. Studies on the properties of pervious fly ash–cement concrete as a pavement material. Cogent Eng. 2017, 4, 1318802. [Google Scholar] [CrossRef]

- Swe, T.M.; Jongvivatsakul, P.; Pansuk, W. Properties of pervious concrete aiming for LEED green building rating system credits. Eng. J. 2016, 20, 61–72. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Ahmadi, S. Evaluation of coal waste ash and rice husk ash on properties of pervious concrete pavement. Int. J. Eng. 2016, 29, 192–201. [Google Scholar]

- Peng, H.; Yin, J.; Song, W. Mechanical and hydraulic behaviors of eco-friendly pervious concrete incorporating fly ash and blast furnace slag. Appl. Sci. 2018, 8, 859. [Google Scholar] [CrossRef]

- Soto-Pérez, L.; Hwang, S. Mix design and pollution control potential of pervious concrete with non-compliant waste fly ash. J. Environ. Manag. 2016, 176, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, B.S.; Liew, M.S.; Alaloul, W.S.; Khed, V.C.; Hoong, C.Y.; Adamu, M. Properties of nano-silica modified pervious concrete. Case Stud. Constr. Mater. 2018, 8, 409–422. [Google Scholar] [CrossRef]

- Oner, A.D.N.A.N.; Akyuz, S.; Yildiz, R. An experimental study on strength development of concrete containing fly ash and optimum usage of fly ash in concrete. Cem. Concr. Res. 2005, 35, 1165–1171. [Google Scholar] [CrossRef]

- ASTM C618-15; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use. Annu. Book ASTM Stand: Philadelphia, PA, USA, 2015; pp. 3–6. [CrossRef]

- Available online: https://kcflyash.com/fly-ash-uses/concrete-products/ (accessed on 12 May 2024).

- Venkata Suresh, G.; Karthikeyan, J. Influence of chemical curing technique on the properties of fly ash aggregates prepared without conventional binders. J. Struct. Eng. 2016, 43, 381–389. [Google Scholar]

- Ali, A.; Chiang, Y.W.; Santos, R.M. X-ray diffraction techniques for mineral characterization: A review for engineers of the fundamentals, applications, and research directions. Minerals 2022, 12, 205. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R. Effects of class C and class F fly ash on mechanical and microstructural behavior of clay soil—A comparative study. Materials 2022, 15, 1845. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics–Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Olarewaju, A.J. Engineering properties of concrete mixed with varying degrees of coal fly ash. Am. J. Eng. Res. 2016, 5, 146–149. [Google Scholar]

- Danish, A.; Mosaberpanah, M.A. Formation mechanism and applications of cenospheres: A review. J. Mater. Sci. 2020, 55, 4539–4557. [Google Scholar] [CrossRef]

- Nordin, A.P.; Da Silva, J.; de Souza, C.T.; Niekraszewicz, L.A.; Dias, J.F.; da Boit, K.; Oliveira, M.L.S.; Grivicich, I.; Garcia, A.L.H.; Oliveira, L.F.S.; et al. In vitro genotoxic effect of secondary minerals crystallized in rocks from coal mine drainage. J. Hazard. Mater. 2018, 346, 263–272. [Google Scholar] [CrossRef]

- Quispe, D.; Pérez-López, R.; Silva, L.F.; Nieto, J.M. Changes in mobility of hazardous elements during coal combustion in Santa Catarina power plant (Brazil). Fuel 2012, 94, 495–503. [Google Scholar] [CrossRef]

- Silva, L.F.O.; Sampaio, C.H.; Guedes, A.; De Vallejuelo, S.F.O.; Madariaga, J.M. Multianalytical approaches to the characterisation of minerals associated with coals and the diagnosis of their potential risk by using combined instrumental microspectroscopic techniques and thermodynamic speciation. Fuel 2012, 94, 52–63. [Google Scholar] [CrossRef]

- Yin, S.; Yan, Z.; Chen, X.; Wang, L. Effect of fly-ash as fine aggregate on the workability and mechanical properties of cemented paste backfill. Case Stud. Constr. Mater. 2022, 16, e01039. [Google Scholar] [CrossRef]

- Uysal, M.; Akyuncu, V. Durability performance of concrete incorporating Class F and Class C fly ashes. Constr. Build. Mater. 2012, 34, 170–178. [Google Scholar] [CrossRef]

- Ashtiani, M.S.; Scott, A.N.; Dhakal, R.P. Mechanical and fresh properties of high-strength self-compacting concrete containing class C fly ash. Constr. Build. Mater. 2013, 47, 1217–1224. [Google Scholar] [CrossRef]

- Available online: https://powerline.net.in/2018/06/30/sustainable-ash-utilisation (accessed on 12 May 2024).

- Yoon, S.; Monteiro, P.J.; Macphee, D.E.; Glasser, F.P.; Imbabi, M.S.E. Statistical evaluation of the mechanical properties of high-volume class F fly ash concretes. Constr. Build. Mater. 2014, 54, 432–442. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Lachemi, M. Self-compacting concrete incorporating high volumes of class F fly ash: Preliminary results. Cem. Concr. Res. 2001, 31, 413–420. [Google Scholar] [CrossRef]

- Naik, T.R.; Ramme, B.W.; Kraus, R.N.; Siddique, R. Long-term performance of high-volume fly ash concrete pavements, ACI. Mater. J. 2003, 100, 150–155. [Google Scholar]

- Bayat, O. Characterisation of Turkish fly ashes. Fuel 1998, 77, 1059–1066. [Google Scholar] [CrossRef]

- Siddique, R. Waste Materials and By-Products in Concrete; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Nematollahi, B.; Sanjayan, J. Effect of different superplasticizers and activator combinations on workability and strength of fly ash based geopolymer. Mater. Des. 2014, 57, 667–672. [Google Scholar] [CrossRef]

- Chandra, L.; Hardjito, D. The impact of using fly ash, silica fume and calcium carbonate on the workability and compressive strength of mortar. Procedia Eng. 2015, 125, 773–779. [Google Scholar] [CrossRef]

- Nguyen, T.B.T.; Saengsoy, W.; Tangtermsirikul, S. Effect of initial moisture of wet fly ash on the workability and compressive strength of mortar and concrete. Constr. Build. Mater. 2018, 183, 408–416. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Altan, I.; Öz, H.Ö. Utilization of cold bonded fly ash lightweight fine aggregates as a partial substitution of natural fine aggregate in self-compacting mortars. Constr. Build. Mater. 2015, 74, 9–16. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Demirel, S.; Öz, H.Ö.; Güneş, M.; Çiner, F.; Adın, S. Life-cycle assessment (LCA) aspects and strength characteristics of self-compacting mortars (SCMs) incorporating fly ash and waste glass PET. Int. J. Life Cycle Assess. 2019, 24, 1139–1153. [Google Scholar] [CrossRef]

- Makrides-Saravanos, E. Engineering Properties of High-Performance Concrete Containing Large Volume of Class C Fly Ash. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 1995. [Google Scholar]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes–A review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Asa, E.; Shrestha, M.; Baffoe-Twum, E.; Awuku, B. Development of sustainable construction material from fly ash class C. J. Eng. Des. Technol. 2020, 18, 1615–1640. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Ahmed, T.; Elchalakani, M.; Karrech, A.; Dong, M.; Mohamed Ali, M.S.; Yang, H. ECO-UHPC with high-volume class-F fly ash: New insight into mechanical and durability properties. J. Mater. Civ. Eng. 2021, 33, 04021174. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud Univ. -Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Bentz, D.P.; Ferraris, C.F.; Galler, M.A.; Hansen, A.S.; Guynn, J.M. Influence of particle size distributions on yield stress and viscosity of cement–fly ash pastes. Cem. Concr. Res. 2012, 42, 404–409. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Tohumcu, İ. Effects of different curing regimes on the compressive strength properties of self compacting concrete incorporating fly ash and silica fume. Mater. Des. 2013, 51, 12–18. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the behaviour of high volume fly ash based self compacting concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- Prasad, B.R.; Eskandari, H.; Reddy, B.V. Prediction of compressive strength of SCC and HPC with high volume fly ash using ANN. Constr. Build. Mater. 2009, 23, 117–128. [Google Scholar] [CrossRef]

- Da Silva, P.R.; De Brito, J. Experimental study of the porosity and microstructure of self-compacting concrete (SCC) with binary and ternary mixes of fly ash and limestone filler. Constr. Build. Mater. 2015, 86, 101–112. [Google Scholar] [CrossRef]

- Liu, M. Self-compacting concrete with different levels of pulverized fuel ash. Constr. Build. Mater. 2010, 24, 1245–1252. [Google Scholar] [CrossRef]

- de Matos, P.R.; de Oliveira, A.L.; Pelisser, F.; Prudêncio, L.R., Jr. Rheological behavior of Portland cement pastes and self-compacting concretes containing porcelain polishing residue. Constr. Build. Mater. 2018, 175, 508–518. [Google Scholar] [CrossRef]

- Alaka, H.A.; Oyedele, L.O.; Toriola-Coker, O.L. Effect of excess dosages of superplasticizer on the properties of highly sustainable high-volume fly ash concrete. Int. J. Sustain. Build. Technol. Urban Dev. 2016, 7, 73–86. [Google Scholar] [CrossRef]

- Mohammed, T.; Aguayo, F.; Nodehi, M.; Ozbakkaloglu, T. Engineering properties of structural lightweight concrete containing expanded shale and clay with high volume class F and class C fly ash. Struct. Concr. 2023, 24, 4029–4046. [Google Scholar] [CrossRef]

- Ge, X.; Hu, X.; Shi, C. Impact of micro characteristics on the formation of high-strength Class F fly ash-based geopolymers cured at ambient conditions. Constr. Build. Mater. 2022, 352, 129074. [Google Scholar] [CrossRef]

- Lammertijn, S.; De Belie, N. Porosity, gas permeability, carbonation and their interaction in high-volume fly ash concrete. Mag. Concr. Res. 2008, 60, 535–545. [Google Scholar] [CrossRef]

- Khan, M.I. Permeation of high performance concrete. J. Mater. Civ. Eng. 2003, 15, 84–92. [Google Scholar] [CrossRef]

- Sinsiri, T.; Chindaprasirt, P.; Jaturapitakkul, C. Influence of fly ash fineness and shape on the porosity and permeability of blended cement pastes. Int. J. Miner. Metall. Mater. 2010, 17, 683–690. [Google Scholar] [CrossRef]

- Yu, Z.; Ye, G. The pore structure of cement paste blended with fly ash. Constr. Build. Mater. 2013, 45, 30–35. [Google Scholar] [CrossRef]

- Poon, C.S.; Wong, Y.L.; Lam, L. The influence of different curing conditions onthe pore structure and related properties of fly-ash cement pastes and mortars. Constr. Build. Mater. 1997, 11, 383–393. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Rukzon, S. Strength, porosity and corrosion resistance of ternary blend Portland cement, rice husk ash and fly ash mortar. Constr. Build. Mater. 2008, 22, 1601–1606. [Google Scholar] [CrossRef]

- Majko, R.M.; Pistilli, M.F. Optimizing the amount of Class C fly ash in concrete mixtures. Cem. Concr. Aggreg. 1984, 6, 105–119. [Google Scholar] [CrossRef]

- Marinković, S.; Dragaš, J. Fly ash. In Waste and Supplementary Cementitious Materials in Concrete; Woodhead Publishing: Sawston, UK, 2018; pp. 325–360. [Google Scholar] [CrossRef]

- Glasser, F.P.; Diamond, S.; Roy, D.M. Hydration reactions in cement pastes incorporating fly ash and other pozzolanic materials. MRS Online Proc. Libr. 1986, 85, 167. [Google Scholar] [CrossRef]

- Misra, A. Stabilization characteristics of clays using class C fly ash. Transp. Res. Rec. 1998, 1611, 46–54. [Google Scholar] [CrossRef]

- Wang, L.; He, Z.; Cai, X. Characterization of pozzolanic reaction and its effect on the CSH gel in fly ash-cement paste. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2011, 26, 319–324. [Google Scholar] [CrossRef]

- Harison, A.; Srivastava, V.; Herbert, A. Effect of fly ash on compressive strength of Portland pozzolona cement concrete. J. Acad. Ind. Res. 2014, 2, 476–479. [Google Scholar]

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Sun, J.; Shen, X.; Tan, G.; Tanner, J.E. Compressive strength and hydration characteristics of high-volume fly ash concrete prepared from fly ash. J. Therm. Anal. Calorim. 2019, 136, 565–580. [Google Scholar] [CrossRef]

- Shehab, H.K.; Eisa, A.S.; Wahba, A.M. Mechanical properties of fly ash based geopolymer concrete with full and partial cement replacement. Constr. Build. Mater. 2016, 126, 560–565. [Google Scholar] [CrossRef]

- Dragaš, J.; Ignjatović, I.; Tošić, N.; Marinković, S. Mechanical and time-dependent properties of high-volume fly ash concrete for structural use. Mag. Concr. Res. 2016, 68, 632–645. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Properties of low-calcium fly ash based geopolymer concrete incorporating OPC as partial replacement of fly ash. Constr. Build. Mater. 2017, 150, 792–807. [Google Scholar] [CrossRef]

- Nedunuri, S.S.S.A.; Sertse, S.G.; Muhammad, S. Microstructural study of Portland cement partially replaced with fly ash, ground granulated blast furnace slag and silica fume as determined by pozzolanic activity. Constr. Build. Mater. 2020, 238, 117561. [Google Scholar] [CrossRef]

- Mangi, S.A.; Wan Ibrahim, M.H.; Jamaluddin, N.; Arshad, M.F.; Mudjanarko, S.W. Recycling of coal ash in concrete as a partial cementitious resource. Resources 2019, 8, 99. [Google Scholar] [CrossRef]

- Mondal, S.K.; Clinton, C.; Ma, H.; Kumar, A.; Okoronkwo, M.U. Effect of Class C and Class F Fly Ash on Early-Age and Mature-Age Properties of Calcium Sulfoaluminate Cement Paste. Sustainability 2023, 15, 2501. [Google Scholar] [CrossRef]

- Savaş, H.; Türköz, M.; Seyrek, E.; Ünver, E. Comparison of the effect of using class C and F fly ash on the stabilization of dispersive soils. Arab. J. Geosci. 2018, 11, 1–13. [Google Scholar] [CrossRef]

- Bachus, R.C.; Terzariol, M.; Pasten, C.; Chong, S.H.; Dai, S.; Cha, M.S.; Santamarina, J.C. Characterization and engineering properties of dry and ponded class-F fly ash. J. Geotech. Geoenviron. Eng. 2019, 145, 04019003. [Google Scholar] [CrossRef]

- Zhang, P.; Wittmann, F.H.; Vogel, M.; Müller, H.S.; Zhao, T. Influence of freeze-thaw cycles on capillary absorption and chloride penetration into concrete. Cem. Concr. Res. 2017, 100, 60–67. [Google Scholar] [CrossRef]

- Sicat, E.; Gong, F.; Zhang, D.; Ueda, T. Change of the coefficient of thermal expansion of mortar due to damage by freeze thaw cycles. J. Adv. Concr. Technol. 2013, 11, 333–346. [Google Scholar] [CrossRef]

- Hang, M.; Cui, L.; Wu, J.; Sun, Z. Freezing-thawing damage characteristics and calculation models of aerated concrete. J. Build. Eng. 2020, 28, 101072. [Google Scholar] [CrossRef]

- Islam, M.M.; Alam, M.T.; Islam, M.S. Effect of fly ash on freeze–thaw durability of concrete in marine environment. Aust. J. Struct. Eng. 2018, 19, 146–161. [Google Scholar] [CrossRef]

- Sideris, K.; Justnes, H.; Soutsos, M.; Sui, T. Fly ash. In Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials: State-of-the-Art Report of the RILEM Technical Committee 238-SCM, Working Group; Springer: Cham, Switzerland, 2018; Volume 4, pp. 55–98. [Google Scholar] [CrossRef]

- Öztürk, H.; Kılınçkale, F.M. The effect of wetting-drying/freezing-thawing cycles on properties of non-air entrained fly ash substituted cement-based composites. Ceram. Int. 2023, 49, 10993–11004. [Google Scholar] [CrossRef]

- Berry, E.E.; Malhotra, V.M. Fly ash for use in concrete-a critical review. J. Proc. 1980, 77, 59–73. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, C.; Liang, Y.; Luo, J.; Wang, X.; Feng, Y.; Abomohra AE, F. Life cycle assessment and impact correlation analysis of fly ash geopolymer concrete. Materials 2021, 14, 7375. [Google Scholar] [CrossRef]

- Orozco, C.R.; Tangtermsirikul, S.; Sugiyama, T.; Babel, S. Comparative environmental assessment of low and high CaO fly ash in mass concrete mixtures for enhanced sustainability: Impact of fly ash type and transportation. Environ. Res. 2023, 234, 116579. [Google Scholar] [CrossRef]

| Process | Environmental Pollution | CO2 Emissions |

|---|---|---|

| Raw Material Acquisition | Land Alteration and Destruction | High |

| Clinker Production | High Calcination Temperature | Primary Emission Source |

| Combustion and Energy Usage | Fuel Combustion | High |

| Transportation | Fuel Usage and Carbon Footprint | Moderate to High |

| Waste Management | Waste Disposal and Recycling | Moderate |

| Type of SCM | CO2 Reduction | Environmental Contributions | Economic Benefits | Technical Advantages |

|---|---|---|---|---|

| Fly Ash | Moderate to High | Resource Recycling | Cost-effective | Enhanced Durability and Strength |

| Silica Fume | High | Reduced Carbon Footprint | Higher Cost | Increased Strength and Density |

| Ground Granulated Blast Furnace Slag | High | Waste Management | Moderate Cost | Chemical Resistance and Thermal Performance |

| Aspect | Impact | Detailed Description |

|---|---|---|

| CO2 Reduction | Reduced Carbon Footprint | Reduction in CO2 emissions through the use of pozzolans instead of cement |

| Conservation of Natural Resources | Efficient Utilization of Raw Materials | Pozzolans contribute to the preservation of natural resources |

| Durability and Service Life | Long-lasting and Durable Structures | Pozzolans enhance concrete durability, leading to longer service life |

| Waste Management and Recycling | Waste Reduction and Recycling Opportunities | Pozzolans contribute to reduced concrete waste and enable recycling |

| Energy Efficiency | Reduced Energy Consumption in Production Processes | Pozzolans lower energy consumption in concrete production |

| Stage | Impact | Detailed Description |

|---|---|---|

| Raw Material Acquisition | Resource Reduction, Waste Management | Extraction and recycling of FA, optimizing resource utilization |

| Production | Energy Efficiency, Carbon Reduction | Energy efficiency and CO2 reduction in FA incorporation in concrete |

| Transportation | Carbon Footprint, Transportation Costs | Impact of FA transportation on carbon footprint and costs |

| Construction | Increased Durability, Reduced Maintenance Needs | Improved durability of concrete and decreased maintenance requirements |

| Recycling | Waste Reduction, Recycling Opportunities | Recycling potential and waste reduction through reused concrete |

| Waste Management | Waste Disposal, Recovery Opportunities | Environmental impact and management of FA and concrete waste |

| Aspect | Impact | Detailed Description | Quantitative Impact (Example) |

|---|---|---|---|

| CO2 Reduction | Reduced Carbon Footprint | Reduction in CO2 emissions through pozzolan use | 25% decrease in CO2 emissions |

| Conservation of Natural Resources | Efficient Utilization of Raw Materials | Lower consumption of natural resources due to pozzolan use | 30% reduction in raw material usage |

| Durability and Service Life | Long-lasting and Durable Structures | Increased lifespan of structures with pozzolan-enhanced concrete | 40% longer service life |

| Waste Management and Recycling | Waste Reduction and Recycling Opportunities | Reduced concrete waste and potential for recycling | 20% decrease in waste production |

| Energy Efficiency | Reduced Energy Consumption in Production Processes | Lower energy requirements in concrete production | 15% decrease in energy consumption |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbulut, Z.F.; Yavuz, D.; Tawfik, T.A.; Smarzewski, P.; Guler, S. Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review. Sustainability 2024, 16, 4905. https://doi.org/10.3390/su16124905

Akbulut ZF, Yavuz D, Tawfik TA, Smarzewski P, Guler S. Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review. Sustainability. 2024; 16(12):4905. https://doi.org/10.3390/su16124905

Chicago/Turabian StyleAkbulut, Zehra Funda, Demet Yavuz, Taher A. Tawfik, Piotr Smarzewski, and Soner Guler. 2024. "Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review" Sustainability 16, no. 12: 4905. https://doi.org/10.3390/su16124905

APA StyleAkbulut, Z. F., Yavuz, D., Tawfik, T. A., Smarzewski, P., & Guler, S. (2024). Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review. Sustainability, 16(12), 4905. https://doi.org/10.3390/su16124905