Abstract

Reactive powder concrete (RPC) is a new generation concrete with high strength, used in special structures, and its use is increasing day by day. In this study, instead of using high-strength aggregates typically used in RPC, wastes released in ferrochrome production were used. In addition, the possibility of using fibers obtained from end-of-life automobile tires (ELT), instead of the micro steel fibers typically used in RPC, was investigated. Thus, sustainable green reactive powder concrete (GRPC), the material which is obtained from waste materials except the binder and chemical additive, has been developed. As ferrochrome wastes, olivine, serpentine, rum, slag, and pure waste were used as powder and aggregate in GRPC. Firstly, in GRPC without fiber, the physical and mechanical properties of ferrochrome wastes were examined by using different ratios. Then, the optimum mixture was selected, and different ratios of industrial steel and ELT fiber were added to this mixture. As a result, the compressive strength of GRPC using olivine and pure waste (ferrochrome slag) is close to the reference RPC. However, it is 28% more economical. The flexural strength of the samples with a 4% addition of industrial or ELT fiber increased by 182% and 213%, respectively, compared to the reference sample without fiber. With the use of 4% ELT fiber (by volume) in GRPC, the flexural strength increased by 11% compared to the use of industrial steel fiber. In terms of cost, with the use of ferrochrome waste and ELT fiber, GRPC was 48% more economical. When examined in terms of the flexural and compressive unit strength cost, GRPC was approximately 41% more economical. As a result of this study, high-performance concrete with high mechanical properties that is economical, sustainable, and environmentally friendly has been produced by evaluating the use of waste materials.

Keywords:

green reactive powder concrete; ferrochrome slag; olivine; ELT; fiber; sustainability; waste; recycling 1. Introduction

With developing technology, existing concretes cannot respond to the needs arising in the construction sector, and there is a need for concretes with high strength and durability [1]. One of these concretes is reactive powder concrete (RPC). The high strength and durability properties of this concrete are largely dependent on the aggregates used in it. Generally, the aggregates used in RPC are micro in size and have high strength and durability properties but are disadvantageous in terms of cost and availability [2,3,4,5,6,7,8,9,10,11].

Using more economical and accessible aggregates is now possible by evaluating wastes. Economies can be achieved by using wastes with superior physical and mechanical properties in high-performance concretes [4,6,12,13].

In their study, Savadkoohi and Reisi focus on the use of stone-cutting wastes in the production of reactive powdered concrete (RPC). As a result, the use of 30% granite waste instead of silica sand increased the compressive and flexural strengths by 78% and 60%, respectively, while the water absorption rate of the concrete decreased by 75% [14]. In their work, Gül and Geçten discuss how the Elazığ ferrochrome plant has shown that granulated slag can be used in the production of lightweight concrete [15]. The study by Bakış investigated the usability of reactive powdered concrete in rigid coating using waste ELT fiber and pumice. Using pumice and waste fiber, they reached a flexural strength of 105.2 MPa and a compressive strength of 12.5 MPa [16]. In the study by Aslan et al., the authors used waste glass as an aggregate in RPC. With the use of 30% waste glass in RPC, the compressive strength increased from 192.9 to 258.9 MPa, and the flexural strength increased from 16.2 to 38.7 MPa [17].

In their study, Chen and Jiao investigated the effect of recycled clay brick sands (RCBS) and clay brick dust (RCBP) construction waste on photocatalytic mortar. First, the RCBP was used as supplementary cementitious material to replace cement by weight percentages of 0, 10, 20, and 30 at a fixed water-to-cement ratio of 0.6. Then, an optimal combination (20% RCBP and 80% cement), considering the yield stress, plastic viscosity, and mechanical performance, was used to bind three types of fine aggregates, viz. 100% silica sands, 80% silica sands plus 20% RCBS, and 80% silica sands plus 20% RCBS-based composite photocatalyst (RCBS/TiO2). As a result, they reported that RCBS or RCBS/TiO2 mortar with a mixing ratio not higher than 20% had little effect on the mechanical performance [18]. The same authors have also conducted experimental research on a green building material containing construction and demolition wastes (C&DWs), nano-titanium dioxides (NT), and nano-tourmaline powder (TP). Experimental results revealed that TP increased the compressive strength when the content was not higher than 15 wt%. Moreover, 15 wt% TP combined with 100 wt% NT@RCBS was optimal in producing 950 ions/(s·cc) of negative ions, equivalent to that defined by the World Health Organization (WHO) in clean air [19].

One of the waste aggregates is ferrochrome slags. There are many studies in the literature on the use of ferrochrome in conventional concrete. In these studies, ferrochrome waste is generally evaluated as aggregate. In the study by Yazıcıoğlu et al., the effect of ferrochrome waste on the compressive strength and impact energy of conventional concrete was examined. As a result, they showed that it could be used in ferrochrome concrete as a 5% cement substitute [20]. Sancak and Çoban, in their work, investigated the effect of the use of chromium and olivine wastes in concrete on compressive strength. They observed an increase in compressive strength values in concretes produced using chromium and olivine waste [21]. In an experimental study on recycled fine aggregates obtained from waste construction and reactive powder concrete, the compressive, splitting tensile, and flexural strength of the concrete increased significantly [22].

In this study, the possibility of using ferrochrome wastes in RPC was investigated. Chromite ore is subjected to heat treatment to produce ferrochrome and the accompanying waste slag. In the production of 1 ton of ferrochrome, approximately 1.5 tons of waste slag is produced [23,24]. In total, 41 million tons of ferrochrome are processed every year in the world, and about 6.9 million tons are produced in Turkey [23,24,25,26]. Accordingly, approximately 9 million/year tons of ferrochrome waste are generated. There is serious environmental pollution arising from the storage of these wastes around the world.

When the studies were examined, no study on the use of ferrochrome wastes in RPC was encountered. In previous studies conducted by us on RPC, quartz aggregates were used as aggregates. Although the strength of quartz aggregate is high, it is a material with a very high cost (USD 260/ton).

In the first phase of the study, in order to obtain a more economical RPC, the possibility of using ferrochrome wastes obtained from Elazığ Ferrochrome (Turkey) instead of quartz aggregate was investigated.

The excess of waste slags when obtaining ferrochrome creates storage problems and, therefore, serious environmental pollution and disposal costs [27]. This study will contribute to the solution of environmental and disposal problems of ferrochrome slags. Due to the superior properties of these wastes, it is thought that the cost will be significantly reduced by making a positive contribution to the mechanical properties of RPC.

To improve the mechanical properties of ordinary concrete such as tensile strength, crack resistance, abrasion resistance, and impact resistance, as well as toughness, steel, glass, and polypropylene fibers are added. Fiber-reinforced concrete is a composite material with significantly different mechanical and physical properties compared to plain concrete. One of the most crucial mechanical properties of fiber-reinforced concrete is its energy-absorbing capacity. In the studies on ultra-high-performance concretes (UHPC), steel fibers have frequently been preferred [28,29,30,31,32,33,34].

The characteristic properties of fibers, i.e., adhesion capacity at the matrix–fiber interface, ductility, volume, dispersion, and orientation of the fiber, shape, and aspect ratio, directly affect the increase in strength and toughness, the degree of ductility, the extent of post-cracking behavior, and simple and multiple cracking [35].

With the inclusion of steel fibers in RPC, disintegration of the structural element is prevented, and failure occurs in a controlled manner. It has been shown that micro steel fibers in RPC reduce crack spacing and width and bridge cracks, thereby increasing resistance to deformation in engineering applications after peak load. In fiber RPC column samples, the higher number of cracks and their uniform distribution demonstrate the benefit of using steel fibers in distributing stresses throughout the column due to the increased ductility provided by these fibers [36].

The fiber reinforcement mechanism was described by Yang et al. and Ni et al. In fibrous RPC, during the pre-cracking stage, the load is transferred to the steel fibers through the RPC matrix and interfacial adhesion. Thus, both the steel fibers and the RPC matrix carry the load together. After cracking, only the steel fibers carry the load through mechanical interlocking and friction at the fiber–matrix interface. As the fibers are pulled out, crack energy is absorbed, and deflection and load increase. Therefore, the interfacial bond adhesion property between steel fibers and RPC matrix plays an important role in the resultant mechanical properties of RPCs [37,38].

The use of steel fibers in UHPC is considerably higher than in conventional concrete. This significantly increases the cost and hinders the widespread use of UHPC. Waste fibers can be used to reduce the cost of fiber. Generally, fibers obtained from tires that have completed their life are used as waste fibers in normal concrete. Tikrite and Hadi used ELT wire in the RPC at the rate of 1%, 2%, 3%, and 4% of total volume. As a result, they stated that the fluidity of RPC was adversely affected by the addition of 4% SCT fiber and that it had a positive effect on mechanical properties [39]. Fares et al. used different ratios of ETL fiber in UHPC (1.3%, 1.5%, 1.9%, and 2.5%). In the study, a flexural strength of 20 MPa was achieved and, at the same time, they could reduce the cost of UHPC by 40% [40].

Every year, 1.6 billion new tires are produced around the world. As a result, around 1 billion waste tires are produced every year. In total, 100 million tires can be recycled from this waste. Recyclable tire corresponds to 6.5% of the tire produced. In addition, non-recyclable tires pose a serious environmental problem for the world [41].

In the second phase of the study, the usability of waste ELT fiber instead of industrial steel fibers, which constitute the largest cost in RPC containing waste ferrochrome aggregate, was investigated. Samples were produced using different combinations of these wastes. Compressive and flexural strength, fracture toughness, and cost were examined on samples produced using waste ferrochrome and ELT fibers. This study will contribute to the literature on the use of ferrochrome and ETL wastes in RPC and will increase interest in sustainable, environmentally friendly, and economical building materials.

2. Material and Method

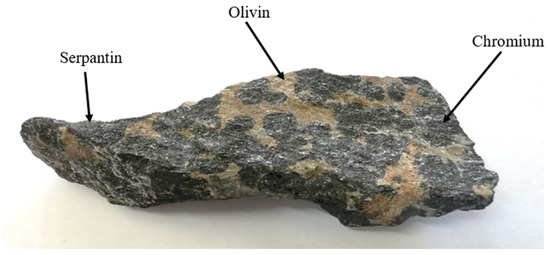

It consists of RPC, cement, silica fume, aggregate, steel fiber, water, and chemical additives. Among the main components of reactive powder concrete, cement is the material with the largest quantity. In experimental studies, high-performance cement of type PC 52.5 CEM I R, which was usually used in previous experimental studies, was preferred [28]. Non-condensed silica fume coded 968-U of Elkem Company in Norway was used as silica fume. The chemical composition and physical properties of high-performance cement and silica fume are given in Table 1. In the study, the water/binder ratio ranged from 0.18 to 0.20. Polycarboxylic ether-based (Master Gluonium ACE 450) chemical additive was used to achieve the desired workability. As an aggregate, quartz, a hard and solid rock, was used. The compressive strength of quartz aggregate reaches up to about 180 MPa. Since it is a very hard aggregate with a hardness degree in the range of 7–8 Mohs, its wear resistance is high [28]. The quartz powder used in the experiments is 0–100 μm, and the quartz sand is grain-sized in the range of 100–600 μm. The ferrochrome waste used as the aggregate is a solid waste of submerged electric arc furnaces obtained during the production of ferrochrome alloy. Ferrochrome slags were used in this study as Chromium Slag, olivine serpentine, and pure waste. The raw material, chromium ore, is given in Figure 1. The gray color in the raw material indicates serpentine, the yellow-green color indicates olivine, and the bright gray color indicates chromite ore.

Table 1.

Properties of cement and silica fume.

Figure 1.

Chromite ore.

Olivine (Figure 2) and serpentine are separated from chromite ore by mechanical means before heat treatment with dimensions of 0–500 μm. In the production of ferrochrome, an electric arc furnace is used, and the metal is melted. Due to its weight, ferrochrome metal is isolated from the slag and collected at the bottom of the furnace. Differences in the specific gravity of the metal and slag aid the separation process. Then, as a result of the heat treatment of the chromite (bright gray color) material, the remaining waste as a result of the removal of pure chromium from it is called Chromium Slag. Ferrochrome slag (FCS) majorly comprises 27–33% SiO2, 15–25% Al2O3, 20–35% MgO, and 10–15% iron–chromium compounds [13]. This waste is amorphous, has different sizes, and contains approximately 10% chromium. The material resulting from the decomposition of chromium contained in chromium as a result of magnetic processes of chromium-containing slag waste is called pure waste (ferrochrome slag). As a result of the separation of chromium, there is about 2% chromium in the pure waste (Figure 3). This waste is in the dimensions of 0–7 mm and can be ground to the desired dimensions. All the ferrochrome waste is irregularly shaped, the surface is rough, and the color is dark gray. The physical properties of these materials are given in Table 2. Material densities were measured as approximately 3 gr/cm3. The high density of the aggregate was considered an indication that it was hard, durable, and gapless. Unless the production process of chrome wastes changes, the content of the wastes is not expected to change significantly. The grinding mill used to grind waste can be adjusted for different grain sizes. After grinding, the materials are sieved and classified into specific grain sizes. Aggregate mixing ratios are made according to this grain size classification. The homogeneity of the mixture and consistency of the experiments are checked with the previous experimental studies.

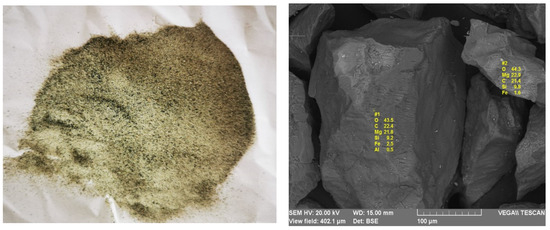

Figure 2.

Olivine formal and SEM image.

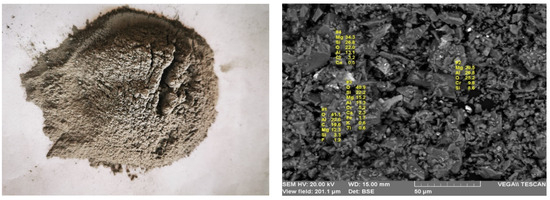

Figure 3.

Ferrochrome slag (pure waste) formal and SEM image.

Table 2.

Features of chromite waste materials.

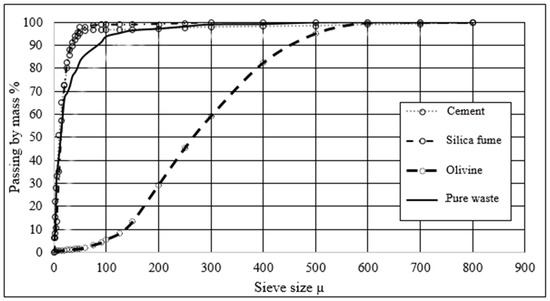

During ferrochrome production, olivine waste reaches a maximum size of 500 μm. For this reason, it was not subjected to any grounding process before being used in experiments. Olivine is predominantly composed of the minerals Mg, C, Si, and Fe (Figure 2). The pure waste was dried in the oven and ground in a laboratory blade mill to a size of 100–500 μm. Pure waste (ferrochrome slag) consists mainly of the minerals Mg, C, Cr, Si, and Al (Figure 3). The granulometry curve of olivine, pure waste, and other granular materials used in the experiment is given in Figure 4.

Figure 4.

Particle size analysis of granule materials.

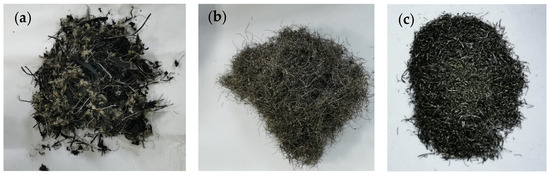

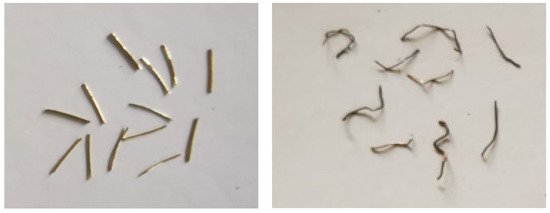

The industrial steel fibers used in this study are coated with brass against corrosion and have a diameter of 0.16 mm and a length of 6 mm. As an alternative to industrial life, microfiber size materials obtained from waste tires (ELT) by mechanical means are used. ELT fibers were screened and fibers with dimensions below 1 cm were selected. The physical and mechanical properties of steel and ELT fibers are given in Table 3, and the distribution ratio and geometry of fibers obtained from waste tires are given in Figure 5 and Figure 6, respectively. The ELT fiber is composed of rubber and thread residues (25%), fine macro fibers (60%), and fine microfibers (15%).

Table 3.

Physical and mechanical properties of Industrial steel and ELT fibers.

Figure 5.

Waste tire components: (a) rubber, thread, and heel wire mix; (b) Fine macro fiber; (c) fine microfiber.

Figure 6.

Industrial steel and ELT fibers.

Method

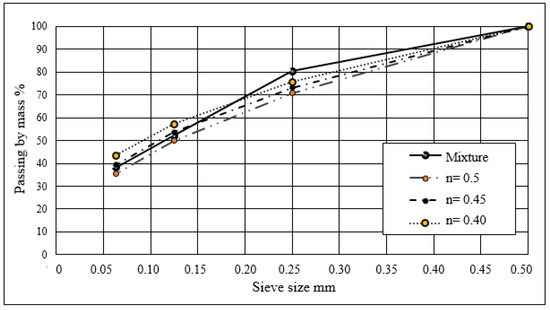

Different mixture theories have been used in the literature in reactive powder concrete production [2,11,42,43,44,45,46,47,48,49]. First, the aggregate mixture ratios were determined. Mixing ratios were determined using the sieve analysis results of ferrochrome wastes and using the different Fuller [48] coefficients (n = 0.4–0.45 and 0.50) (Figure 7, Table 4). RPC samples were produced according to these aggregate mixtures. Components other than aggregate were derived from our previous studies [28].

Figure 7.

Graph of aggregate mixing ratios and particle size analysis.

Table 4.

Mixing ratios and compressive strength results.

A 100 × 100 × 100 mm cube was used for compressive strength tests and rectangular prism specimens with dimensions of 50 × 50 × 300 mm were used for flexural tests. The samples were removed from the mold after 24 h and cured in 20 °C water for 28 days. Compressive and flexural strength tests were performed on the samples at the end of day 28 (Figure 8). Mixing ratios and compressive strength results are given in Table 4.

Figure 8.

Compressive strength test stand and reference broken sample image.

In the three-point flexural test performed on the samples, the loading speed of the test device has been adjusted in a way that it will deflect in 0.5–1 mm/min. on the middle point of the beam [28]. Samples have been loaded at this speed until they are completely fractured, and load–deflection graphics have been attained [49,50,51,52,53,54].

The following formula is used to calculate the fracture energy.

Here, Gf = fracture energy (N/m); δ0 = the deformation of the beam during migration expressed as (m). According to the Japanese standard JSCE SF-4, the toughness assessment is calculated by taking into account the part of the beam opening up to the deflection of 1/150. The equivalent flexural strength due to toughness is then calculated [55].

Here, σe = equivalent flexural strength due to toughness (MPa); δ = expressed as the deflection of 1/150 of the beam span. The results of the flexural test were evaluated according to this standard and the results were compared.

3. Results and Discussion

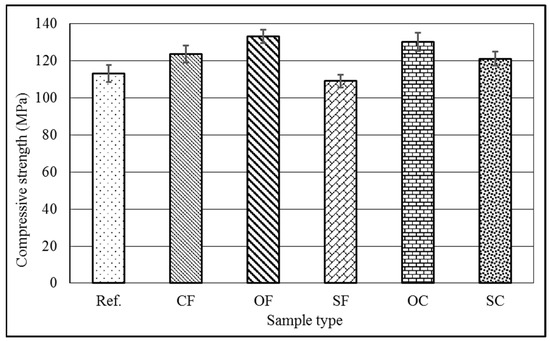

As a result of the experiment, it was observed that the samples produced from waste materials generally increased their compressive strength compared to the reference sample. According to the compressive strength values, the highest strength and the most economical mixing ratio were provided at the mixture rate of 70% pure waste and 30% olivine. Although the compressive strength of the Chromium Slag + olivine mixture is high, Chromium Slag waste containing 10% chromium is not preferred due to the fact that it is ground, and the associated cost is high.

The compressive strength graph with different aggregate mixture ratios is given in Figure 9. It is thought that as the specific gravity values of ferrochrome waste aggregates are higher than quartz aggregates (Table 2) and the strength of these waste aggregates may also be higher, this situation will have a positive effect on the concrete compressive strength. As the waste aggregates have a sharp and rough surface as a result of crushing and grinding (Figure 2 and Figure 3), the interface adherence with the cement paste is increased. In addition, the fact that waste aggregate mixtures have different-sized grains, which allows a good granulometry mixture, positively affects the compressive strength.

Figure 9.

Compressive strength graph of samples with different aggregate mixing ratios.

When the studies in the literature are taken into consideration, it is known that the optimum fiber ratio in RPC is 4% and when more fiber is added than this rate, workability and placement problems arise [6,8,11]. Therefore, to investigate the effect of industrial and waste fibers, fibers in the proportions of 1%, 2%, 3%, and 4% by volume were added to the mixture. The mixing ratios and compressive strength results are given in Table 5. The sample with waste aggregate and waste ELT fiber content was named Green reactive powder concrete (GRPC). In Table 5, the number after GRPC refers to the percentage of fiber by volume, and the letter refers to either industrial (E) or ELT (W) fiber.

Table 5.

Mixing ratios (kg/m3) and compressive strength of industrial and ELT fiber-added RPC and GRPC.

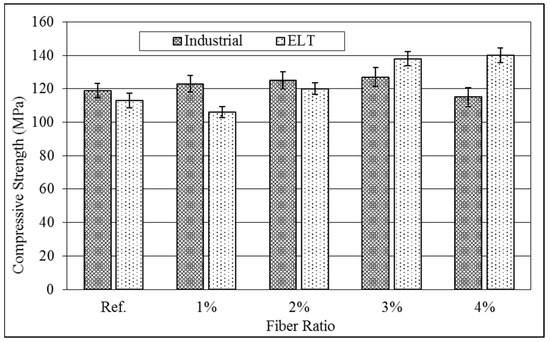

When the compressive strength graph of the fiber-reinforced samples (Figure 10) was examined, the compressive strength of the sample with 1% industrial fiber content was obtained as 119 MPa, while the compressive strength of the sample containing 4% fiber increased by 6.7% and reached 127 MPa. In ELT fiber, it increased by 32% and reached 140 MPa. In general, compressive strength increased with the increasing fiber amount. The fibers resist the internal tensile stresses that occur during the compressive strength test due to the adherence they form with the paste. In addition, microfibers are thought to contribute to strength by acting as a solid aggregate in concrete.

Figure 10.

Fiber ratio compressive strength change graph.

In the flexural test, the fracture is sudden with the formation of cracks in the non-fibrous samples as in conventional concretes. The way the fiber-containing samples broke, the beginning of the crack and the fracture were close to the middle zone of the beam, where the maximum moment was formed.

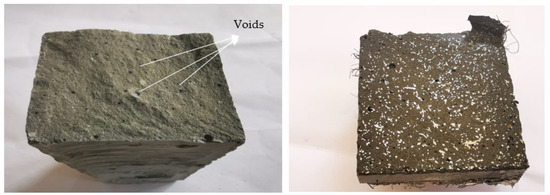

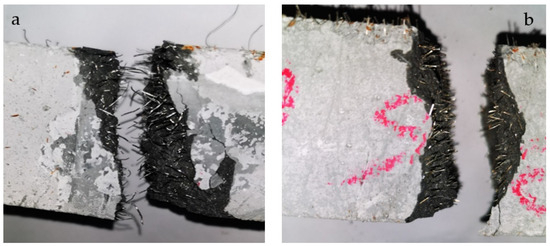

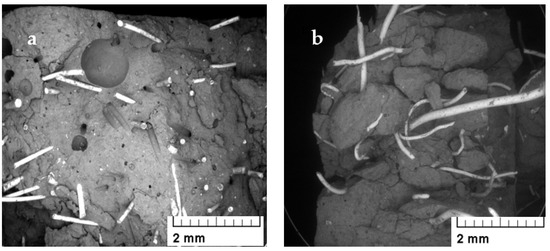

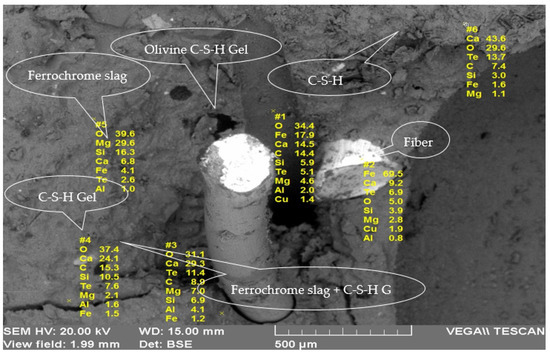

When the fibrous sample sections are examined, it is seen that the fibers are homogeneously distributed and there are micro-independent air gaps (Figure 11). As a result of the flexural test, it was seen that the fibers were stripped out of the concrete (Figure 12 and Figure 13). Due to the short fiber lengths, the crack broke before it spread to the entire beam. This situation adversely affects all the mechanical properties of the flexural specimens. Due to the fact that the tensile strength (~2000 MPa) of industrial and ELT fibers is very high, rupture was not possible during the test. Due to the complex geometric structure of the ELT fiber in the longitudinal direction, it was more difficult to stand out from the cake than industrial fiber. When the internal structure of the samples is examined, it is seen that the expected C-S-H gels are formed, and the micro-sized olivine and pure waste are homogeneously distributed in the cement paste and fill the gaps (Figure 14). The high amount of Ca in the region where the C-S-H gel exists indicates that free lime (CaO and Ca(OH)2) has formed. It is understood that olivine and pure waste are inert materials in micro sizes and do not create a pozzolanic activity with cement components. Although the ELT fiber geometry strengthens the stripping, it is seen that the fiber surface is smooth and, therefore, there are few paste residues on the fiber surface (Figure 13 and Figure 14). It is thought that low fiber surface roughness may cause the fibers to be stripped from the paste more easily, and this situation negatively affects the bending strength. The difficulty in stripping ELT fibers in the paste directly improves the mechanical properties of RPC. Therefore, increasing the surface roughness of ELT fibers by mechanical or chemical methods can contribute positively to the mechanical properties of RPC.

Figure 11.

After the flexural strength test: non-fiber and fiber sample cross-sections.

Figure 12.

After the flexural strength test, the fracture surface of the ELT (a) and industrial (b) fibrous specimen.

Figure 13.

SEM image of fiber samples: (a) industrial fiber; (b) ELT fiber.

Figure 14.

SEM image of GRPC with fiber content.

In the pre-cracking stage, the load is transferred to the steel fibers through the RPC matrix and through the interstitial continuation. After cracking, the load is carried through the steel fibers via mechanical interlocking at the fiber–matrix interface. As the fiber is stripped and the crack mouth opens, the deflection increases, and the energy is absorbed.

Previous studies have also addressed the effect of fiber geometry and ratio on mechanical properties. It has been mentioned that appropriate fiber geometry, which will strengthen the peeling, has a positive effect on the mechanical properties and increases the ductility [37,38,56,57].

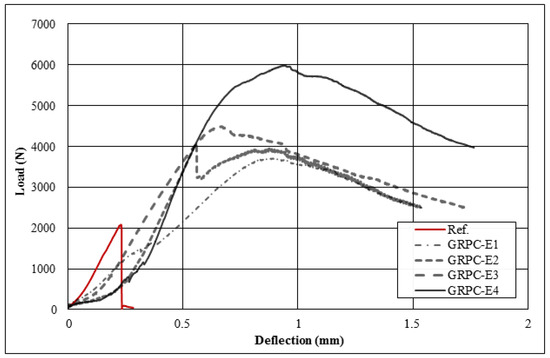

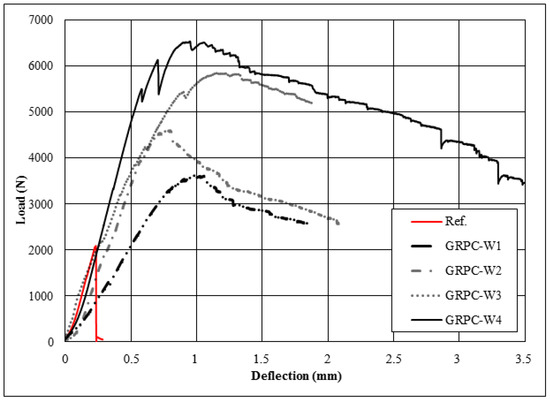

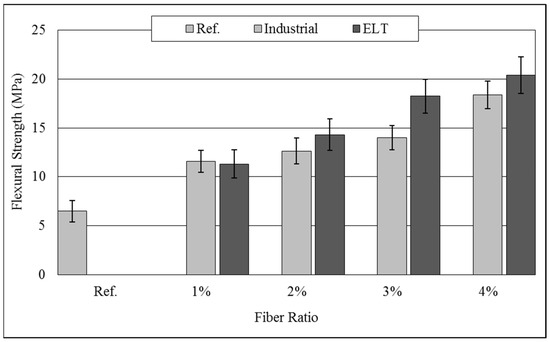

The test results of the flexural samples are given in Figure 15, Figure 16 and Figure 17 and Table 6. The initial crack strength and flexural strength of the reference sample produced without fiber is 6.50 MPa, the equivalent flexural strength is 0.56 MPa, and the maximum deformation is 0.24 mm. The fracture toughness was calculated as 0.47 Nm and the fracture energy was 189.00 joule/m2. Due to the fact that crack formation and fracture occur at the same time, the values of initial crack strength and flexural strength are equal to each other.

Figure 15.

Load–deflection curve graph of industrial fiber samples.

Figure 16.

Load–deflection curve graph of ELT fiber samples.

Figure 17.

Fiber ratio–flexural strength change graph.

Table 6.

Flexural test results of ELT and industrial fiber-added GRPC.

In this case, it was observed that the flexural strength of industrial and ELT fiber samples with 1% fiber additive increased by 78% and 74%, respectively, compared to the reference sample without fiber. When evaluated in terms of fracture toughness, an approximately eight times increase was observed in both fiber types. In the fibrous sample, the load continues to carry the load even after the deflection curve exceeds the peak load, and the crack opening and fracture occur. As the fiber ratio increases, the flexural mechanical properties increase. In the fiber content of 4%, which is the highest rate, when ELT is compared with industrial fiber, it is seen that only the fracture toughness is approximately close to the initial crack, the flexural strength increases by 11%, the fracture energy is twice as high, and the equivalent flexural strength is approximately 22%. It was observed that the flexural strength of industrial and ELT fiber samples with 4% fiber additives increased by 182% and 213%, respectively, compared to the reference sample without fibers. ELT fibers have shown a better performance than industrial fibers. The reason for this difference is that the waste fibers added to the matrix act as ribbed reinforcement due to their mechanical obtainment and that they have folds in shape, making it more difficult to stand out from the matrix (Figure 12 and Figure 13). This ensured that the sample had a high energy absorption capacity.

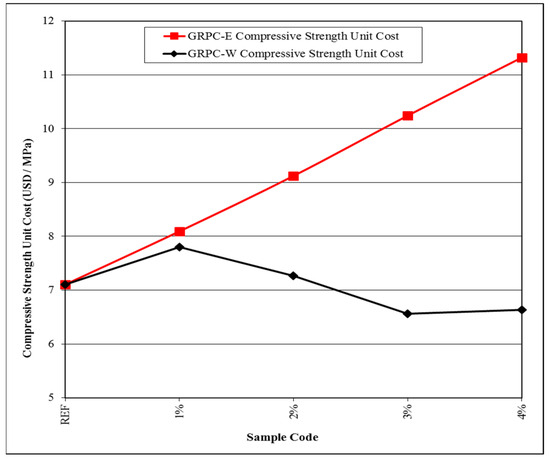

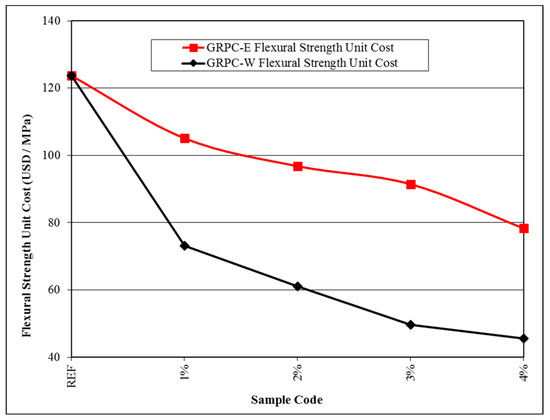

In the second phase of the study, the effect of ferrochrome and ELT fiber wastes on unit cost was investigated. Cost calculations are given in Table 7. The cost of 1 m3 without fiber GRPC is 28% more economical compared to RPC. Fiber is the material with the highest cost in RPC. As the proportion of fiber in the mixture increases, this ratio increases significantly. For example, at 4% fiber content, GRPC-W4 is 35% more economical than GRPC-4E. As a result, with the use of waste aggregates and fibers (GRPC-W4), approximately 48% reduction in cost is achieved. The unit strength cost was obtained by dividing the cost of 1 m3 GRPC by compressive and flexural strengths (Table 8). Using these values, the graphs in Figure 18 and Figure 19 are plotted to better understand the effect of fiber quantity on unit cost. As the amount of industrial fibers increases, the unit cost of compressive strength increases. As the amount of ETL fiber increases, the unit cost of compressive strength increases slightly and then decreases. As the amount of industrial and ELT fibers increases, the unit cost of flexural strength decreases. The unit cost of flexural strength is 37% and 64% more economical in industrial and ELT fibers at 4% fiber content, respectively. At a fiber content of 4%, for the unit cost of compressive and flexural strength, ELT fiber is 41% and 42% more economical than industrial fibers, respectively.

Table 7.

Cost of 1 m3 RPC and GRPC.

Table 8.

Unit strength cost of GRPC.

Figure 18.

Fiber ratio compressive strength unit cost change graph.

Figure 19.

Fiber ratio–flexural strength unit cost change graph.

4. Conclusions

In this study, the usability of ELT fiber with chromium waste, which is ferrochrome slag, as an alternative to aggregates and fibers used in traditional reactive powder concrete was investigated.

Firstly, the granulometry of chromium wastes was determined and ground to the desired dimensions for use in RPC. Then, these wastes were used without fiber RPC at different rates and their compressive strength properties were examined. There was no significant change in the compressive strength with the use of ferrochrome waste instead of quartz aggregates. When the internal structure of the samples is examined, it is seen that the expected C-S-H gels are formed, and the micro-sized olivine and pure waste are homogeneously distributed in the cement paste and fill the gaps.

Secondly, the optimum mixing ratio was determined according to the compressive strength results. The compressive and flexural strength properties of industrial and ELT fibers were examined by using 1%, 2%, 3%, and 4% (by volume) ratios. Due to the complex geometric structure of ELT fiber (Figure 12 and Figure 13), it provided a serious advantage in terms of adherence, and there were significant increases in flexural strength compared to industrial fiber (Figure 17). However, compressive strength increased by 3% and 4% with high fiber ratio (Figure 10). This increase is due to the fact that the waste fibers added to the matrix behave like a ribbed reinforcement due to their mechanical obtainment, making it more difficult to strip them from the matrix. This situation resulted in a sample with high energy absorption capacity. The largest significant change in toughness in ELT fiber-doped GRPC compared to industrial fiber-doped RPC was the increase of 23% in 3% fiber content. It was observed that the flexural strength of industrial and ELT fiber samples with 4% fiber additives increased by 182% and 213%, respectively, compared to the reference sample without fibers.

Due to the fact that aggregate and fiber are waste, RPC is named GRPC (Green Reactivate Powder Concrete), as it is environmentally friendly. The cost of GRPC without fiber is 28% more economical compared to RPCs. With the use of waste aggregates and fibers, approximately 48% economy is achieved. Fiber is the material with the highest cost in RPC. In particular, with the fiber content of 4%, the cost of compressive and flexural unit strength decreased by 41% and 42%, respectively.

As a result of this study, an environmentally sustainable GRPC has been developed to improve the mechanical properties of RPC and to increase its use in the construction sector, while also aiding in the disposal of environmental wastes.

Author Contributions

Conceptualization: I.A. and M.I.; methodology: M.I.; software: I.A. and M.I.; validation: I.A. and M.I.; formal analysis: I.A. and M.I.; investigation: I.A. and M.I.; resources: I.A. and M.I.; data curation: I.A. and M.I.; writing—original draft preparation: I.A.; writing—review and editing: I.A. and M.I.; visualization: I.A. and M.I.; supervision: M.I.; project administration: M.I.; funding acquisition: I.A. and M.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Sakarya University of Applied Sciences, Scientific Research Foundation (Project numbers: 072-2022, 089-2022, 114-2022, 112-2022).

Institutional Review Board Statement

The study did not require ethical approval.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank Sakarya University of Applied Sciences.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Su, X.; Ren, Z.; Li, P. Review on physical and chemical activation strategies for ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2024, 149, 105519. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Composition of reactive powder concrete. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Aitcin, P.C. Cement of yesterday and today concrete of tomorrow. Cem. Concr. Res. 2000, 30, 1349–1359. [Google Scholar] [CrossRef]

- Yazıcı, H. The effect of curing conditions on compressive strength of ultra high strength concrete with high volume mineral admixtures. Build. Environ. 2007, 42, 2083–2089. [Google Scholar] [CrossRef]

- Dugat, J.; Roux, N.; Bernier, G. Mechanical properties of reactive powder concretes. Mater. Struct. 1996, 29, 233–240. [Google Scholar] [CrossRef]

- Matte, V.; Moranville, M. Durability of reactive powder composites: Influence of silica fume on the leaching properties of very low water/binder pastes. Cem. Concr. Compos. 1999, 21, 1–9. [Google Scholar] [CrossRef]

- Chan, Y.; Chu, S. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Aitcin, P.C. Concrete the most widely used construction materials. ACI SP 1995, 154, 257–266. [Google Scholar]

- Yazıcı, H.; Yardımcı, M.Y.; Aydın, S.; Karabulut, A.S. Mechanical properties of reactive powder concrete containing mineral admixtures under different curing regimes. Constr. Build. Mater. 2009, 23, 1223–1231. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M.H. Reactive powder concretes with high ductility and 200–800 MPa compressive strength. In Concrete Technology: Past, Present, and Future: Proceedings of the V. Mohan Malhotra Symposium; American Concrete Institute: Farmington Hills, MI, USA, 1994; Volume 144, pp. 507–518. [Google Scholar]

- Teichman, T.; Schmidt, M. Influence of the packing density of fine particles on structure, strength and durability of UHPC. In Ultra High Performance Concrete (UHPC): Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; Kassel University Press: Kassel, Germany, 2004; pp. 312–323. [Google Scholar]

- Zhang, Y.S.; Sun, W.; Liu, S.F.; Jiao, C.J.; Lai, J.Z. Preparation of C200 green reactive powder concrete and its static–dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar]

- Das, S.K.; Tripathia, A.K.; Kandia, S.K.; Mustakimb, S.M.; Bhoia, B.; Rajputa, P. Ferrochrome slag: A critical review of its properties, environmental issues and sustainable utilization. J. Environ. Manag. 2023, 326, 116674. [Google Scholar] [CrossRef] [PubMed]

- Savadkoohi, M.S.; Reisi, M. Granit atıkların Reaktif Pudra Betonda kullanılması ile çevre koruma temelli sürdürülebilir kalkınma. J. Clean. Prod. 2020, 266, 121973. [Google Scholar] [CrossRef]

- Gül, R.; Geçten, O. Elazığ ferrokrom işletmesi granüle cürufunun hafif beton üretiminde kullanılabilirliğini araştırılması. In Endüstriyel Atıkların İnşaat Sektöründe Kullanılması Sempozyumu Bildiriler Kitabı; TMMOB İnşaat Mühendisleri Odası: Ankara, Turkey, 1993; pp. 291–301. [Google Scholar]

- Bakış, A. Atık çelik lif takviyeli pomza içeren reaktif pudra betonun rijit kaplama imalatında kullanımı çalışması. BEU J. Sci. 2018, 7, 63–71. [Google Scholar]

- Aslan, S.; Öksüzer, N.; Gökçe, H.S. Improvement of mechanical and transport properties of reactive powder concrete using graphene nanoplatelet and waste glass aggregate. Constr. Build. Mater. 2022, 318, 126199. [Google Scholar] [CrossRef]

- Chen, X.F.; Jiao, C.J. Effect of construction wastes on the rheo-physical behavior of photocatalytic mortar. Case Stud. Constr. Mater. 2022, 16, e01049. [Google Scholar] [CrossRef]

- Chen, X.F.; Jiao, C.J. A photocatalytic mortar prepared by tourmaline and TiO2 treated recycled aggregates and its air-purifying performance. Case Stud. Constr. Mater. 2022, 16, e01073. [Google Scholar] [CrossRef]

- Yazıcıoğlu, S.; Gönen, T.; Çobanoğlu, Ö.C. Elazığ ferrokrom cürufunun betonun basınç dayanımı ve çarpma enerjisi üzerine etkisi. Fırat Üniversitesi Fen Ve Mühendislik Bilim. Derg. 2005, 17, 681–686. [Google Scholar]

- Sancak, E.; Çoban, Ö. The effect on reinforcing bar corrosion properties of usage of olivine wastes on concrete. Selcuk Univ. J. Eng. Sci. Tech. 2014, 2, 26–41. [Google Scholar]

- Wu, H.; Liu, X.; Ma, X.; Liu, G. Effects of Multi-Walled Carbon Nanotubes and Recycled Fine Aggregates on the Multi-Generational Cycle Properties of Reactive Powder Concrete. Sustainability 2024, 16, 2084. [Google Scholar] [CrossRef]

- Taşdemir, A. Enjeksiyon Yöntemiyle Üretilen Kristal Yapılı Ferrokrom Cürufu Katkılı Betonların Fiziksel Özelliklerinin Araştırılması. Master’s Thesis, Fırat Üniversitesi Fen Bilimleri Enstitüsü Yapı Eğitimi Anabilim Dalı, Elazığ, Turkey, 2006; pp. 13–124. [Google Scholar]

- Panda, C.R.; Mishra, K.K.; Nayak, B.D.; Rao, D.S.; Nayak, B.B. Release behaviour of chromium from ferrochrome slag. Int. J. Environ. Technol. Manag. 2012, 26, 261–274. [Google Scholar] [CrossRef]

- United States Geological Survey. Chromium Data Sheet. Mineral Commodity Summaries 2022. Available online: https://www.usgs.gov/ (accessed on 10 December 2023).

- Erdoğan, S.T. Öğütülmüş ferrokrom cürufu kullanılarak jeopolimer üretimi. In Proceedings of the 9th National Congress on Concrete, İzmir, Turkey, October 2011; pp. 12–35. Available online: https://users.metu.edu.tr/sinante/8UBK.pdf (accessed on 1 December 2023).

- Jiao, M.; Rong, Z.; Zhang, L. A critical review of the material characteristics, utilizations, limitations and advanced applications of ferrochrome slag. Constr. Build. Mater. 2024, 426, 136180. [Google Scholar] [CrossRef]

- Ipek, M.; Yılmaz, K.; Uysal, M. The effect of pre-setting pressure applied flexural strength and fracture toughness of reactive powder concrete during the setting phase. Constr. Build. Mater. 2012, 26, 459–465. [Google Scholar] [CrossRef]

- Wang, M.L. Constitutive properties of SIFCON. In Proceedings of the Workshop on Fibre Reinforced Cement and Concrete, Sheffield, UK, 28–30 July 1994; pp. 237–255. [Google Scholar]

- Lankard, D.R. Properties, applications: Slurry infiltrated fiber concrete (SIFCON). MRS Online Proc. Libr. 1984, 42, 287–306. [Google Scholar] [CrossRef]

- Lankard, D.R.; Newell, J.K. Preparation of highly reinforced steel fiber reinforced concrete composites. In Fiber Reinforced Concrete–International Symposium; ACI SP-81; American Concrete Institute: Detroit, MI, USA, 1984; pp. 287–306. [Google Scholar]

- Lankard, D.R. Preparation, properties and application of cement-based composites containing 5 to 20 percent steel fibre. In Steel Fibre Concrete, Proceedings US-Sweden Joint Seminar; Shah, S.P., Skarendahl, A., Eds.; Elsevier Applied Science Publishers: Barking, UK, 1985; pp. 199–217. [Google Scholar]

- Tuyan, M.; Yazıcı, H. Pull-out behavior of single steel fiber from SIFCON matrix. Constr. Build. Mater. 2012, 1, 571–577. [Google Scholar] [CrossRef]

- Goldman, A.; Bentur, A. The influence of microfillers on enhancement of concrete strength. Cem. Concr. Res. 1993, 23, 962–972. [Google Scholar] [CrossRef]

- Mahesh, K.; Chetan, D. Comparative Study of Reactive Powder Concrete Containing Steel Fibers and Recron 3S Fibers. J. Eng. Res. Stud. 2010, 1, 83–89. [Google Scholar]

- Kadhum, M.M.; Mankhi, B.S. Behavior of Reactive Powder Concrete Columns with or without Steel Ties. Civ. Environ. Res. 2016, 8, 19–26. [Google Scholar]

- Yang, G.; Wei, J.; Yu, Q.; Huang, H.; Li, F. Investigation of the Match Relation between Steel Fiber and High-Strength Concrete Matrix in Reactive Powder Concrete. Materials 2019, 12, 1751. [Google Scholar] [CrossRef]

- Ni, W.; Cui, X.; Yuan, J.; Sun, W.; Cui, C.; Wu, Y.; Feng, J. The influence of fiber, aggregate and cementitious materials on the mechanical properties of ultra-high content steel fiber reinforced reactive powder concrete. Constr. Build. Mater. 2024, 431, 136530. [Google Scholar] [CrossRef]

- Al-Tikrite, A.; Hadi, M.N.S. Mechanical properties of reactive powder concrete containing ındustrial and waste steel fibres at different ratios under compression. Constr. Build. Mater. 2017, 154, 1024–1034. [Google Scholar] [CrossRef]

- Fares, G.; Alsaif, A.; Alhozaimy, A. Hybridization and cost-performance analysis of waste tire steel fibers ınto high-volume powdered scoria rocks-based ultra-high performance concrete. J. Build. Eng. 2023, 72, 2–18. [Google Scholar] [CrossRef]

- Last Visited on 18–23. 2023. Available online: https://www.goldsteinresearch.com/report/global-tire-recycling-industry-market-trends-analysis (accessed on 5 December 2023).

- Bonneau, O.; Lachemi, M.; Dallaire, E.; Dugat, J.; Aitcin, P.C. Mechanical properties and durability of two industrial reactive powder concretes. ACI Mater. J. 1997, 94, 286–290. [Google Scholar]

- Talebinejad, I.; Bassam, S.A.; Iranmanesh, A.; Shekarchizadeh, M. Optimizing mix proportions of normal weight reactive powder concrete with strengths of 200–350 Mpa. In Ultra High Performance Concrete (UHPC): Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; Kassel University Press: Kassel, Germany, 2004; pp. 133–141. [Google Scholar]

- Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Mooney, M. The viscosity of concentrated suspension of spherical particles. J. Colloid Sci. 1951, 6, 162–170. [Google Scholar] [CrossRef]

- Furnas, C.C. Grading aggregates—I. Mathematical relations for beds of broken solids of maximum density. Ind. Eng. Chem. ACE 1931, 23, 1052–1058. [Google Scholar] [CrossRef]

- Glavind, M.; Olsen, G.S.; Petersen, C. Packing Calculations and Concrete Mix Design; The Nordic Concrete Federation Teknologisk Institut Beton: Denmark, Finland, 1993; Volume 13, pp. 21–34. [Google Scholar]

- Fuller, W.; Thompson, S.E. The laws of proportioning concrete. Trans. Am. Soc. Civ. Eng. 1907, 1053, 67–143. [Google Scholar] [CrossRef]

- Abdel-Jawad, Y.A.; Abdullah, W.S. Design of maximum density grading. Constr. Build. Mater. 2002, 16, 495–508. [Google Scholar] [CrossRef]

- Ipek, M. The flexural strength and fracture toughness of reactive powder concrete in response to changing fibre size and pre-setting pressure. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 412–424. [Google Scholar] [CrossRef]

- TS 10513; Çelik Teller-Beton Takviyesinde Kullanılan. Turkish Standards Institute: Ankara, Turkey, 1992.

- TS 10514; Beton-Çelik Tel Takviyeli-Çelik Telleri Betona Karıştırma Ve Kontrol Kuralları. Turkish Standards Institute: Ankara, Turkey, 1992.

- TS 10515; Çelik Tel Takviyeli Betonun Eğilme Mukavemeti Deney Metodu. Turkish Standards Institute: Ankara, Turkey, 1992.

- ASTM C 1018; Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading), Annual Book of ASTM Standards. V 4.02. American Society for Testing and Materials: Philadelphia, PA, USA, 1989; pp. 637–644.

- JSCE Standard SF-4; Method of Test for Flexural Strength and Flexural Toughness of Fiber Reinforced Concrete. Japan Society of Civil Engineers (JSCE) Standard: Tokyo, Japan, 1984; pp. 58–66.

- Fayed, S.; Walid, M. Flexural rigidity and ductility of RC beams reinforced with steel and recycled plastic fibers. Steel Compos. Struct. Int. J. 2021, 41, 317–334. [Google Scholar]

- Fayed, S.; Walid, M. Evaluate the effect of steel, polypropylene and recycled plastic fibers on concrete properties. Adv. Concr. Constr. 2020, 10, 319–332. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).