Practical Use of Materials of Natural Origin as Loose-Fill Insulations in Open-Diffusion Constructions—Observation and Numerical Simulation

Abstract

:1. Introduction

2. Possible Application of Natural Origin Materials as Loose-Fill Thermal Insulation

3. Materials and Methods

3.1. Materials

3.1.1. General Information

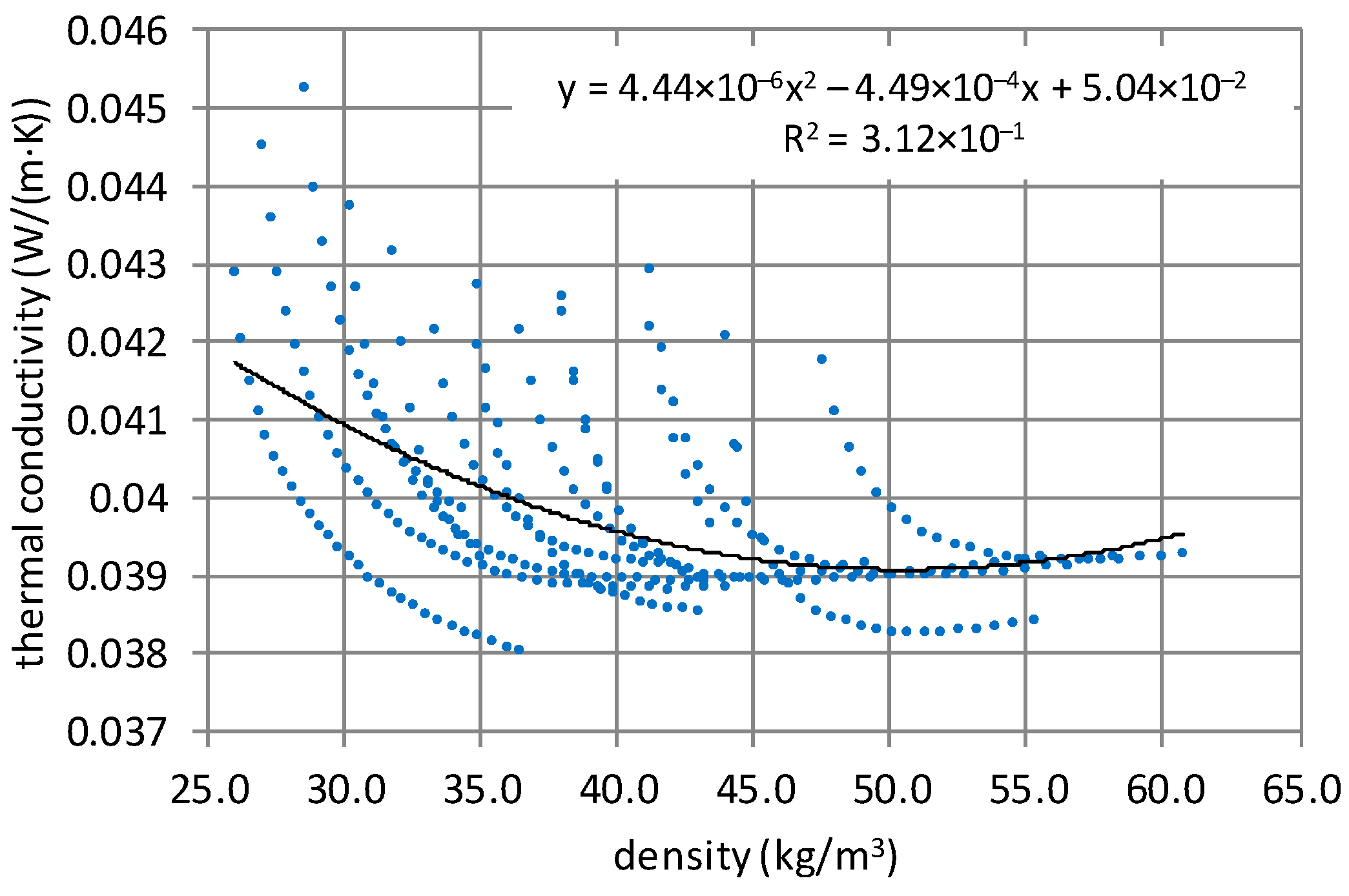

3.1.2. Wood Wool

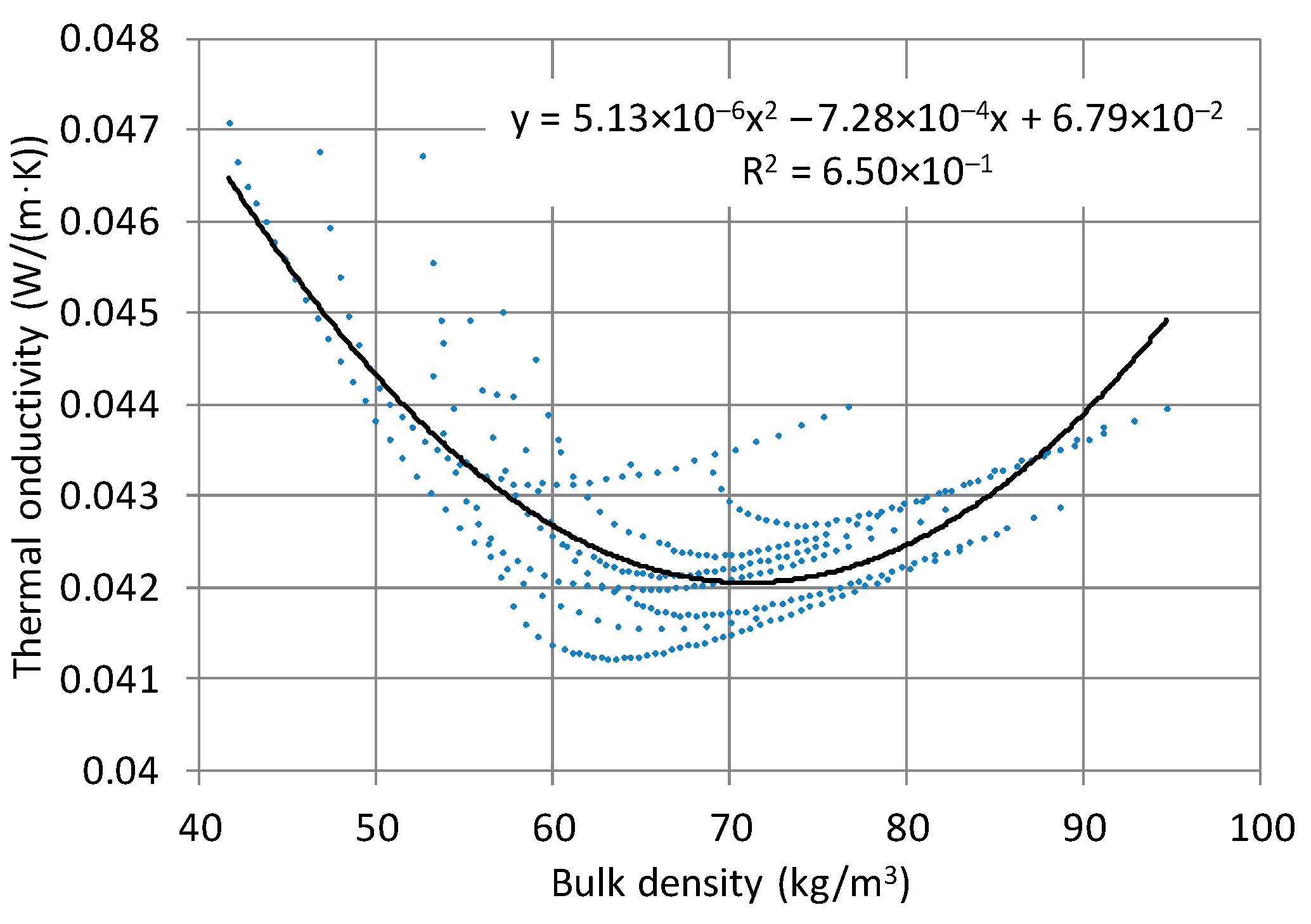

3.1.3. Cellulose Fibers

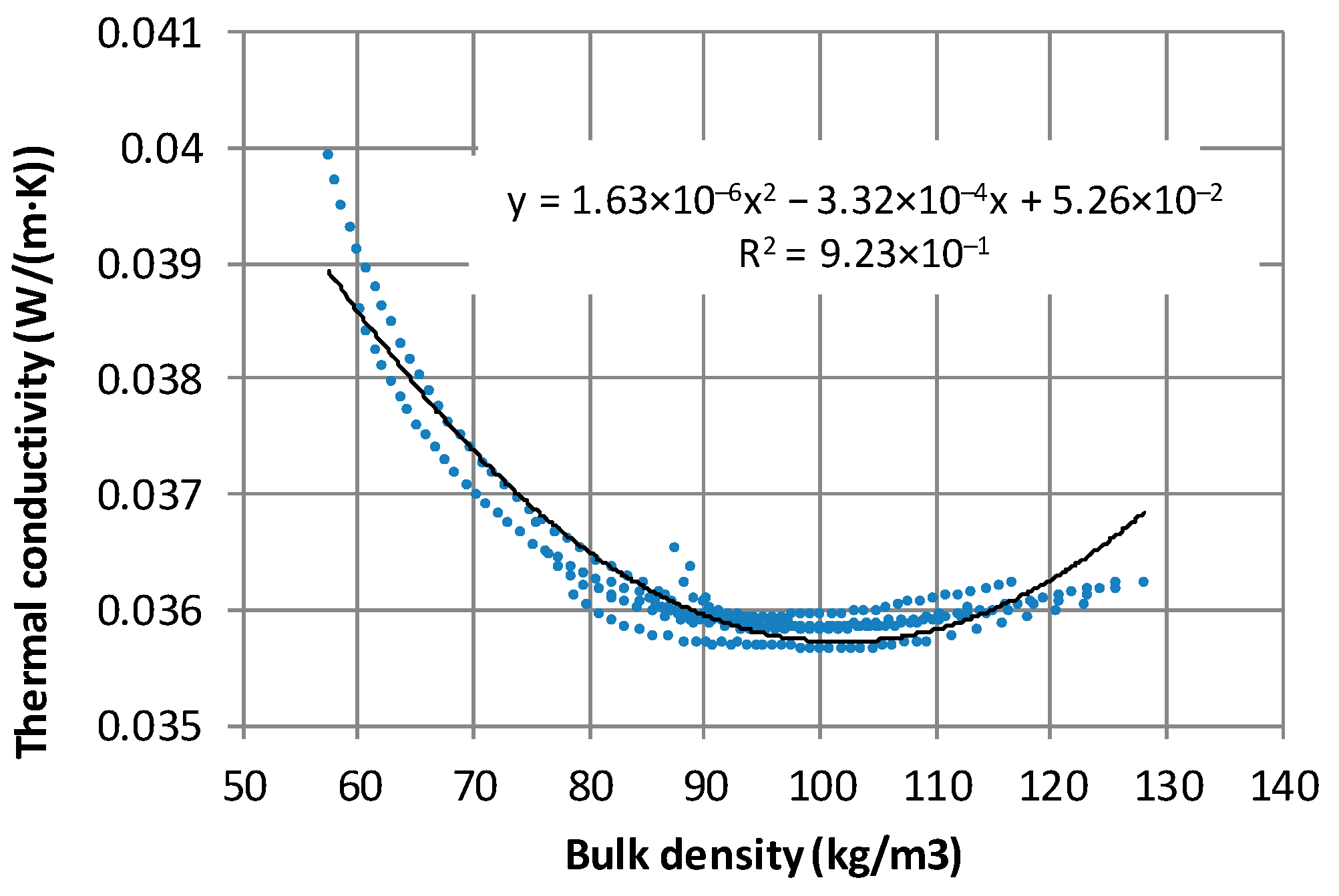

3.1.4. Hemp Shives

3.1.5. Mineral Wool

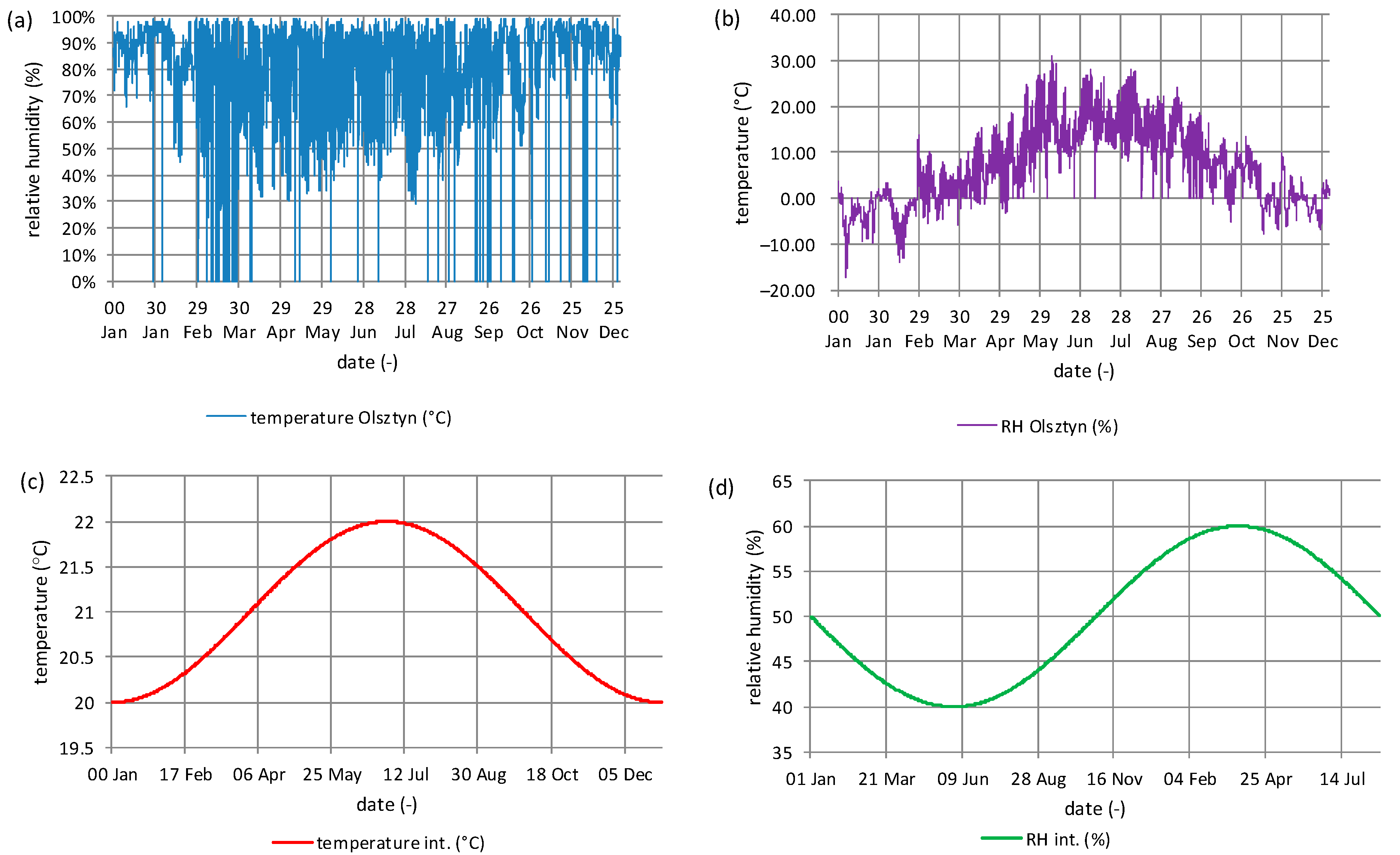

3.2. Method

4. Results and Discussion

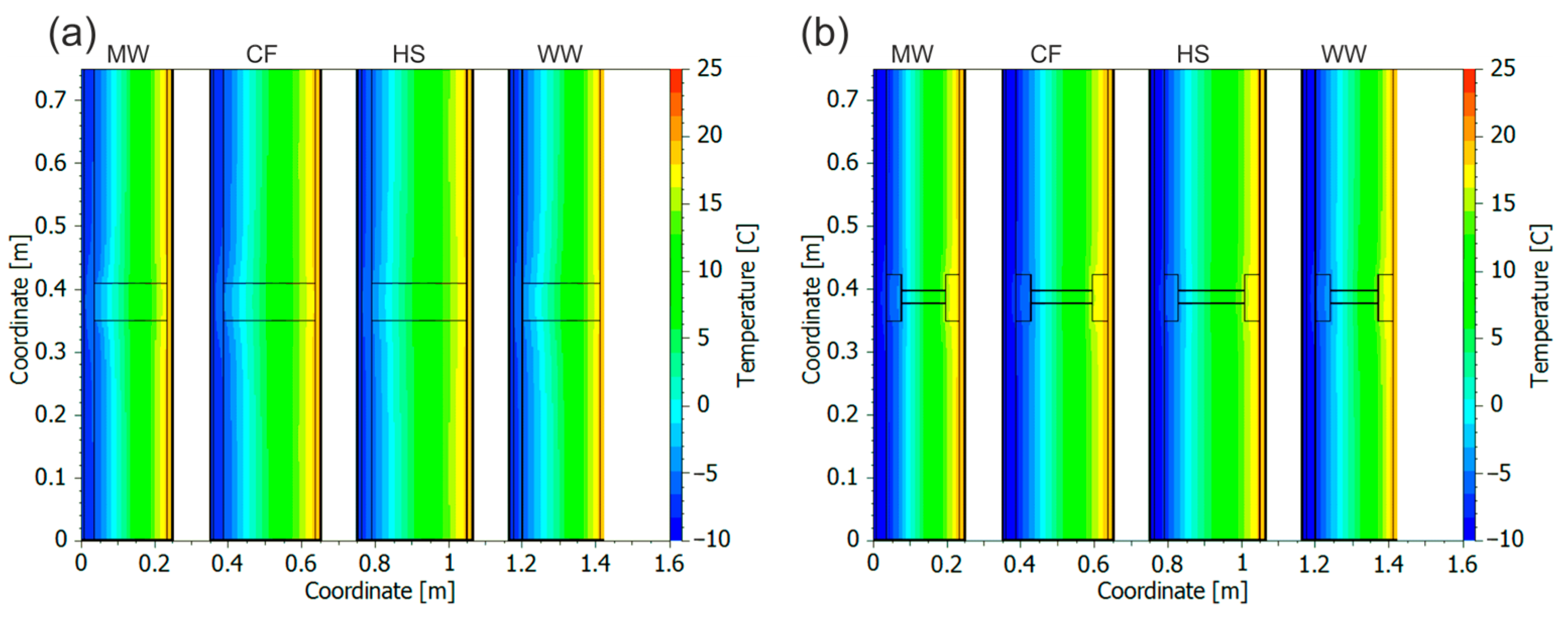

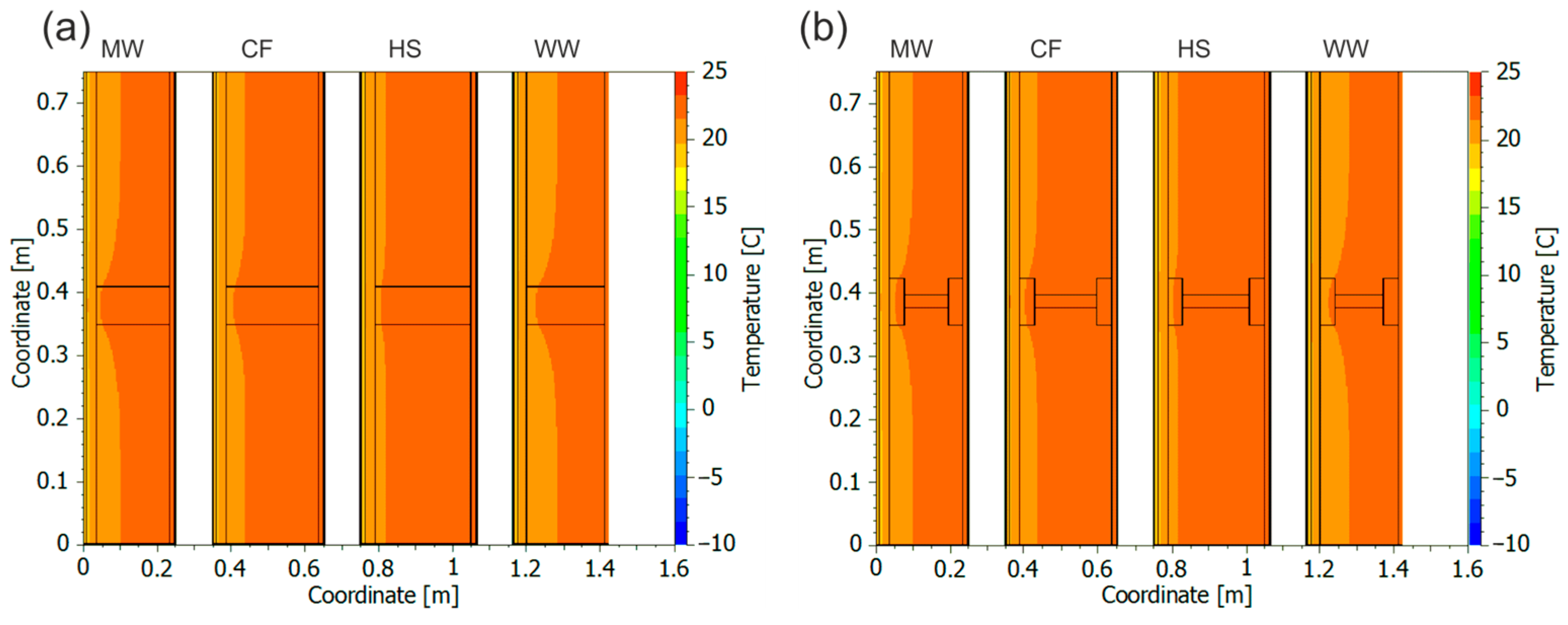

4.1. Temperature Distribution and Heat Flux

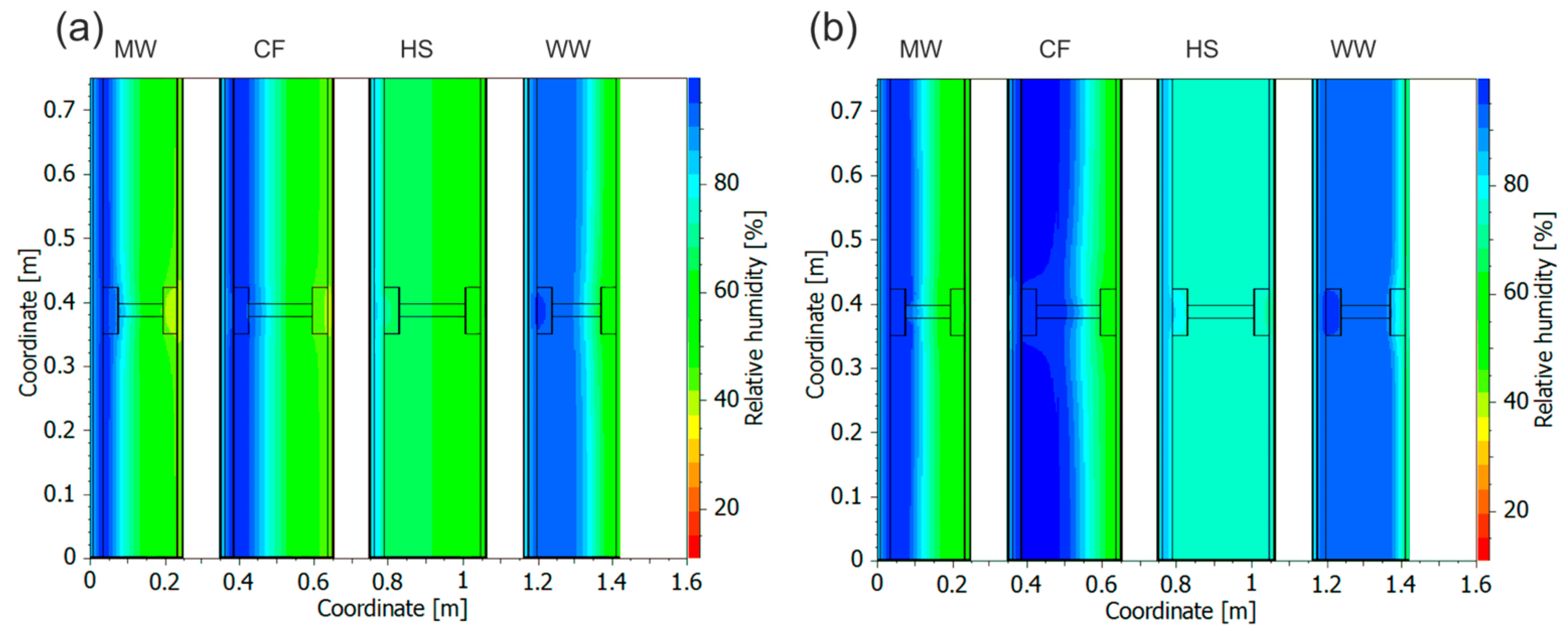

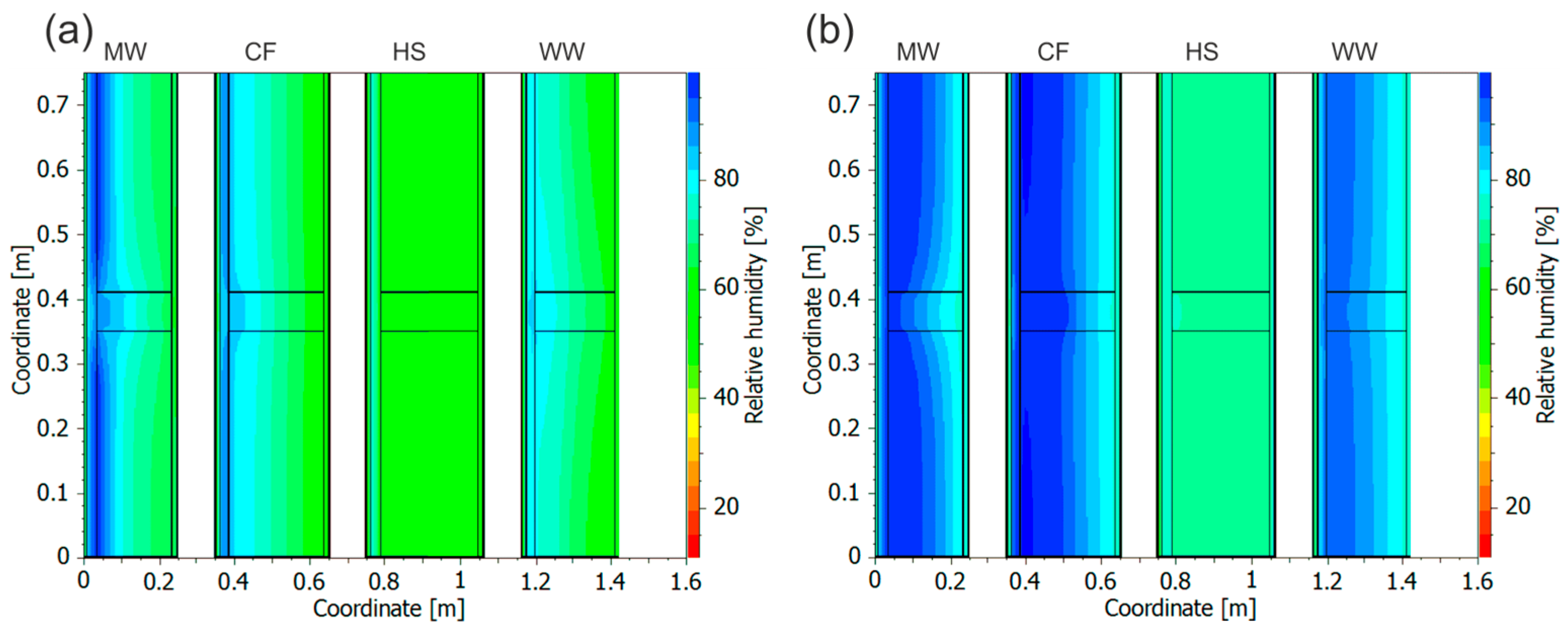

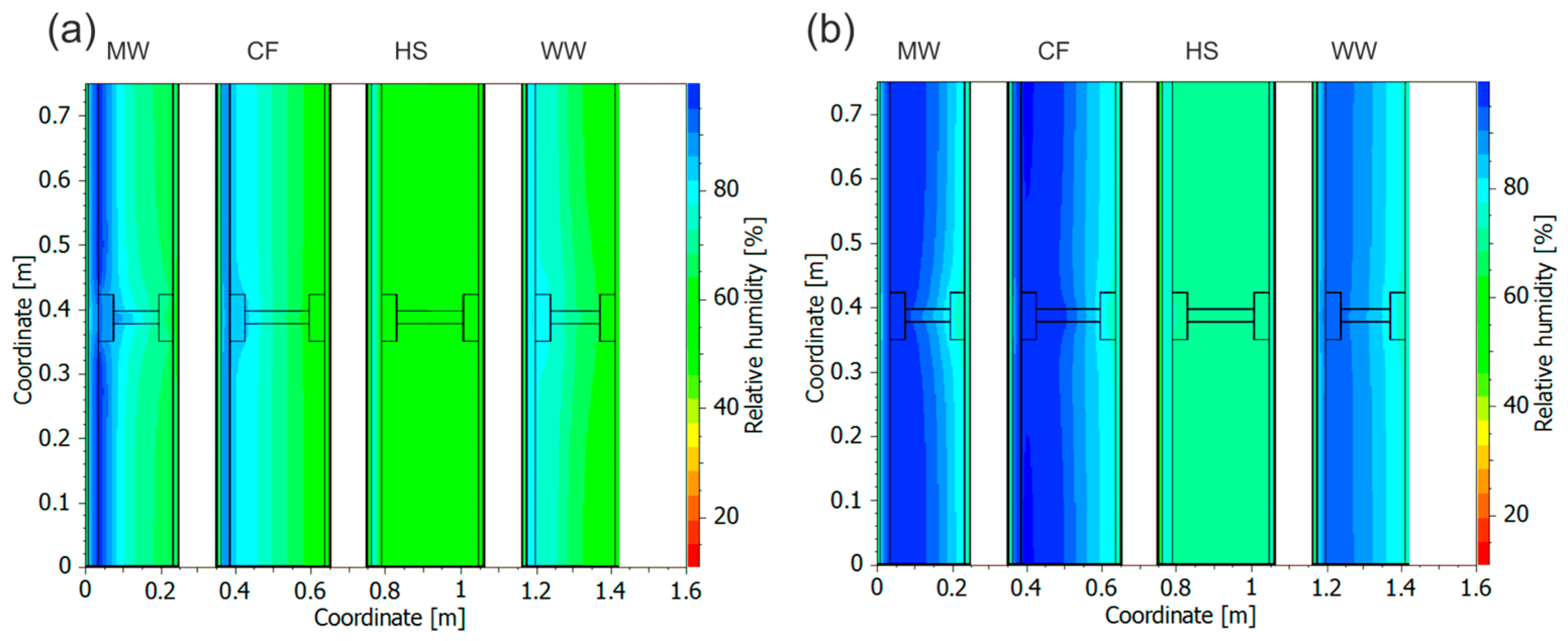

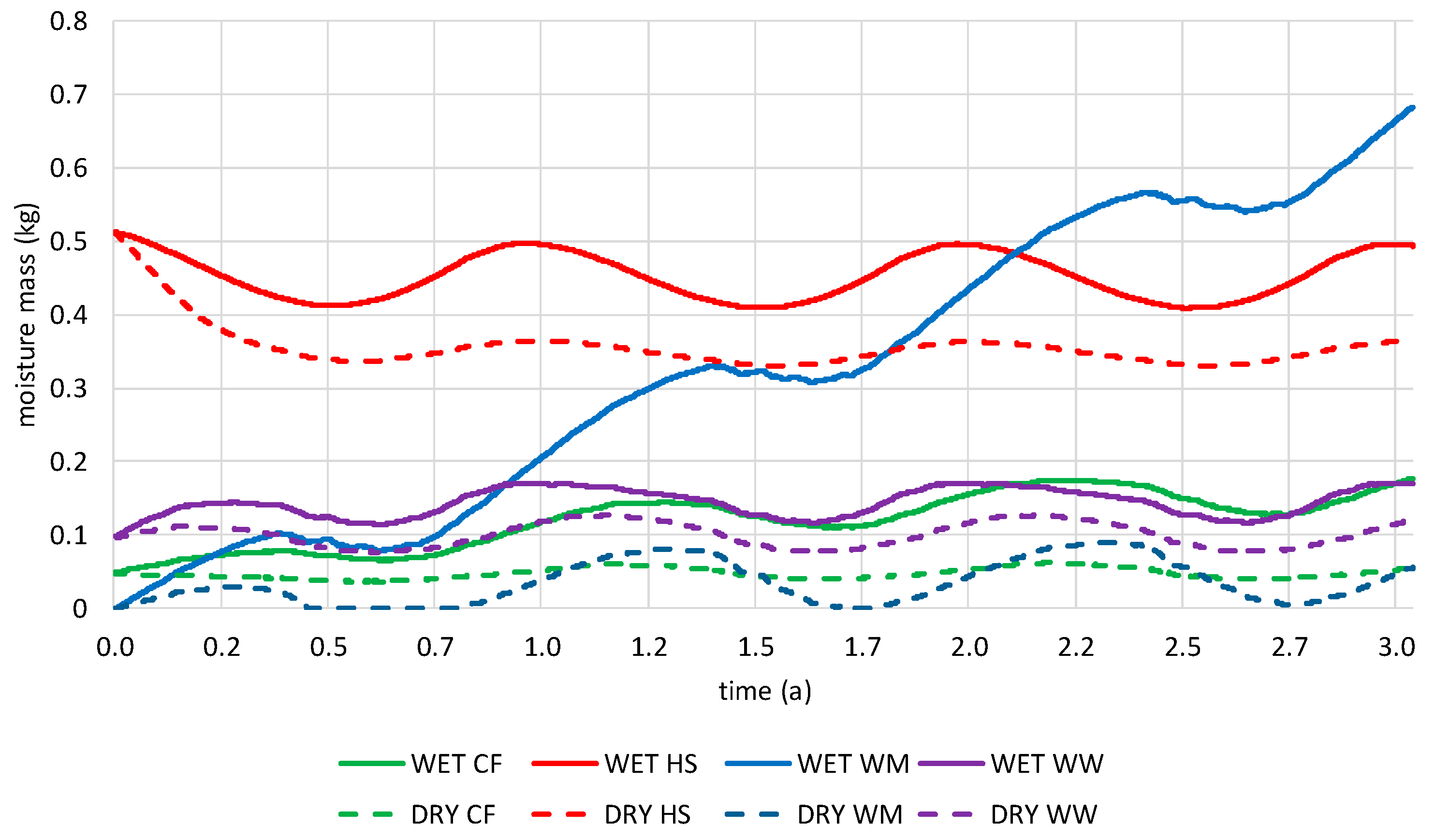

4.2. Relative Humidity Distribution

5. Comparison of the Environmental Impact of Organic Insulation with Traditional Insulation in a Single-Family House

6. Conclusions

- –

- Organic materials, presented in the paper, can be used as loose-fill thermal insulations in wooden frame walls. They are characterized by low thermal conductivity, not higher than 0.052 (W/(m·K)).

- –

- A complex hygrothermal analysis of diffusion-open frame walls indicates the ability of these materials to buffer moisture and release it into the interior. However, diffusion openness in both directions is required.

- –

- In the case of MW, the moisture transport is clearly toward the outside, which has its advantages but also carries the risk of condensation at contact with the external cladding boards. Therefore, walls insulated with mineral wool require a water vapor retarder.

- –

- A comparative analysis of internal humidity conditions, dry and wet, indicates that in the case of increased humidity inside the room, the moisture content in the insulating materials increases significantly. MW tends to increase the moisture accumulation in the material in subsequent years. This will result in condensation in the material. Organic materials, except CF, do not have this feature. HS and WW remain stable and in the summer release the moisture, accumulated in the autumn and winter, into the interior. Thanks to this feature, organic materials have the ability to regulate the humidity level in the room.

- –

- Among the analyzed organic materials, HS is characterized by the highest moisture capacity and, at the same time, next to WW, the highest stability.

- –

- The analysis showed little influence of the shape of the structural elements (rectangular wooden or I-beams) on the moisture condition of the walls. Wooden, rectangular elements, having bigger dimensions and high hygroscopicity, store more moisture than the I-beams. Thus, this will cause disturbances in the adjacent thermal insulation materials.

- –

- The influence of the shape of construction elements is visible on the heat flow; limiting thermal bridges by narrowing the wooden cross-section slightly increases the temperature on the inner surface of the wall.

- –

- In terms of the carbon footprint of building materials, the usage of natural-based materials as thermal insulation accounts for a huge reduction in CO2 emissions when compared to mineral wool.

- –

- Currently, the authors are working on practical aspects of other organic materials as thermal insulations. These mainly include basic research on raw materials, but we are also testing ready-made modules and building elements, checking their behavior in changing climatic conditions. With the examined material properties, it will be possible to perform further numerical calculations. Attention is now focused on the behavior of thermal insulation made of organic materials during periods of elevated temperatures. In parallel, research on the possibilities of using organic materials to isolate log houses from the inside is being conducted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alhavari, A.; Mukhopadhyaya, P. Thermal Bridges in Building Envelopes an Overview of Impacts and Solutions. Int. Rev. Appl. Sci. Eng. 2018, 9, 31–40. [Google Scholar]

- Building Performance Institute Europe (BPIE). Renovation Strategies of Selected EU Countries—A Status Report on Compliance with Article 4 of the Energy Efficiency Directive; BPIE: Brussels, Belgium, 2014; Available online: https://bpie.eu/wp-content/uploads/2015/10/Renovation-Strategies-EU-BPIE-2014.pdf (accessed on 5 April 2024).

- Yuan, X.; Wang, X.; Zuo, J. Renewable energy in buildings in China—A review. Renew. Sustain. Energy Rev. 2013, 24, 1–8. [Google Scholar] [CrossRef]

- Brzyski, P.; Grudzińska, M.; Majerek, D. Analysis of the Occurrence of Thermal Bridges in Several Variants of Connections of the Wall and the Ground Floor in Construction Technology with the Use of a Hemp–Lime Composite. Materials 2019, 12, 2392. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Global Status Report for Buildings and Construction. 2022. Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 5 April 2024).

- The United Nations. Paris Agreement. 2015. Available online: https://unfccc.int/sites/default/files/english_paris_agreement.pdf (accessed on 21 November 2023).

- European Parliament. Directive 2002/91/EC of the European parliament and of the council of 16 December 2002 on the energy performance of buildings. Off. J. Eur. Communities 2003, 46, 65–71. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2003:001:0065:0071:en:PDF (accessed on 5 April 2024).

- European Parliament. Directive 2023/955/EU of the European parliament and the council of 30 May 2018 on the energy perfromance of buildings. Off. J. Eur. Communities 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32023L1791&qid=1700576301961 (accessed on 5 April 2024).

- Trotta, G. Assessing energy efficiency improvements, energy dependence, and CO2 emissions in the European Union using a decomposition method. Energy Effic. 2019, 12, 1873–1890. [Google Scholar] [CrossRef]

- Almeida, M.I.; Dias, A.C.; Demertzi, M.; Arroja, L. Contribution to the development of product category rules for ceramic bricks. J. Clean. Prod. 2015, 92, 206–215. [Google Scholar] [CrossRef]

- Quinteiro, P.; Almeida, M.; Dias, A.C.; Araujo, A.; Arroja, L. The Carbon Footprint of Ceramic Products. In Assessment of Carbon Footprint in Different Industrial Sectors; Springer: Singapore, 2014; Volume 1, pp. 113–150. [Google Scholar] [CrossRef]

- Florentin, Y.; Pearlmutter, D.; Givoni, B.; Gal, E. A life-cycle energy and carbon analysis of hemp-lime bio-composite building materials. Energy Build. 2017, 156, 293–305. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Eng. Sustain. 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Schenk, D.; Amiri, A. Life cycle energy analysis of residential wooden buildings versus concrete and steel buildings: A review. Front. Built Environ. 2022, 8, 975071. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Grudzińska, M.; Brzyski, P. The Occurrence of Thermal Bridges in Hemp-Lime Construction Junctions. Period. Polytech. Civ. Eng. 2019, 63, 377–387. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Kosiński, P.; Brzyski, P.; Skoratko, A.; Motacki, W. Thermal properties of raw hemp fiber as a loose-fill insulation material. J. Nat. Fibers 2018, 15, 717–730. [Google Scholar] [CrossRef]

- Salonen, T.; Fischer, H.; Korjenic, A. Chopped Straw as an Insulation Material: The Influence of Different Blow-In Technologies and Flame Retardants on Hygrothermal Properties. Buildings 2023, 13, 2555. [Google Scholar] [CrossRef]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied energy and carbon of building insulating materials: A critical review. Clean. Environ. Syst. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Miros, A.; Bajorek, A.; Kubacki, J. Examination of the Thermal Conductivity of the Wood Wool Products for Thermal Insulation of Moisture Sorption. In Proceedings of the International Conference on Heat Transfer and Fluid Flow, Prague, Czech Republic, 11–12 August 2014; p. 188. [Google Scholar]

- Zhou, Y.; Trabelsi, A.; El Mankibi, M. A review on the properties of straw insulation for buildings. Constr. Build. Mater. 2022, 330, 127215. [Google Scholar] [CrossRef]

- Troppova, E.; Svehlik, M.; Tippner, J.; Wimmer, R. Influence of temperature and moisture content on the thermal conductivity of wood-based fibreboards. In Materials and Structures, Plizzari Giovanni; Springer: Berlin, Germany, 2015; Volume 48, pp. 4077–4083. [Google Scholar]

- Abdou, A.; Budaiwi, I. The variation of thermal conductivity of fibrous insulation materials under different levels of moisture content. Constr. Build. Mater. 2013, 43, 533–544. [Google Scholar] [CrossRef]

- Volf, M.; Divis, J.; Havlik, F. Thermal, Moisture and Biological Behaviour of Natural Insulating Materials. Energy Procedia 2015, 78, 1599–1604. [Google Scholar] [CrossRef]

- Korjenic, A.; Petranek, V.; Zach, J.; Hroudova, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Rahim, M.; Douzane, O.; Tran Le, A.D.; Langlet, T. Effect of moisture and temperature on thermal properties of three bio-based materials. Constr. Build. Mater. 2016, 111, 119–127. [Google Scholar] [CrossRef]

- Nicolajsen, A. Thermal transmittance of a cellulose loose-fill insulation material. Build. Environ. 2005, 40, 907–914. [Google Scholar] [CrossRef]

- Kosiński, P.; Brzyski, P.; Tunkiewicz, M.; Suchorab, Z.; Wiśniewski, D.; Palczyński, P. Thermal Properties of Hemp Shives Used as Insulation Material in Construction Industry. Energies 2022, 15, 2461. [Google Scholar] [CrossRef]

- Kosiński, P. Moisture Transport in Loose Fibrous Insulations under Steady-State Boundary Conditions. Materials 2023, 16, 7656. [Google Scholar] [CrossRef]

- Steico Naturalny System Budowlany. Available online: https://www.steico.com/pl/ (accessed on 8 April 2024).

- Notice of the Minister of Development and Technology of 15 April 2022 on the Announcement of the Consolidated Text of the Regulation of the Minister of Infrastructure on the Technical Conditions to be Met by Buildings and Their Location (Polish: Obwieszczenie Ministra Rozwoju i Technologii z dnia 15 Kwietnia 2022 r. w Sprawie Ogłoszenia Jednolitego Tekstu Rozporządzenia Ministra Infrastruktury w Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budynki i ich Usytuowanie). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20220001225 (accessed on 17 April 2024).

- ISO 6946; Building Components and Building Elements. Thermal Resistance and Thermal Transmittance. Calculation Methods. European Committee for Standardization: Geneva, Switzerland, 2017.

- Brachelet, F.; Mounir, A.; Antczak, E.; Flore, B.; Didier, D.; Alain, L. Hygrothermal Behaviour of Flax Shives Used as Insulation Material in an Attic of a Traditional House. MATEC Web Conf. 2020, 307, 01017. [Google Scholar] [CrossRef]

- Nováková, P. Use of Technical Hemp in the Construction Industry. MATEC Web Conf. 2018, 146, 03011. [Google Scholar] [CrossRef]

- Typical Meteorological Year in Poland. Available online: https://www.gov.pl/web/archiwum-inwestycje-rozwoj/dane-do-obliczen-energetycznych-budynkow (accessed on 10 December 2023).

| Properties | Lime-Cement Plaster | OSB | Clay Board | Mineral Wool | Cellulose Fibers | Hemp Shives | Wood Wool |

|---|---|---|---|---|---|---|---|

| Thickness (m) | 0.010 | 0.025 | 0.016 | 0.200 | 0.250 | 0.260 | 0.210 |

| Density (kg/m3) | 1023.8 | 595.0 | 1699.9 | 100.0 | 60.0 | 115.0 | 50.0 |

| Porosity (m3/m3) | 0.61 | 0.90 | 0.36 | 0.92 | 0.78 | 0.79 | 0.82 |

| Specific heat (J/(kg⋅K)) | 1090.0 | 1500.0 | 833.8 | 840.0 | 2500 | 1600.0 | 1660 |

| Thermal conductivity (W/(m⋅K)) | 0.220 | 0.130 | 0.91 | 0.040 | 0.0495 | 0.051 | 0.039 |

| Diffusion resistance (-) | 6.1 | 165.0 | 14.2 | 1.00 | 3.5 | 3.5 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosiński, P.; Patyna, K. Practical Use of Materials of Natural Origin as Loose-Fill Insulations in Open-Diffusion Constructions—Observation and Numerical Simulation. Sustainability 2024, 16, 4593. https://doi.org/10.3390/su16114593

Kosiński P, Patyna K. Practical Use of Materials of Natural Origin as Loose-Fill Insulations in Open-Diffusion Constructions—Observation and Numerical Simulation. Sustainability. 2024; 16(11):4593. https://doi.org/10.3390/su16114593

Chicago/Turabian StyleKosiński, Piotr, and Krystian Patyna. 2024. "Practical Use of Materials of Natural Origin as Loose-Fill Insulations in Open-Diffusion Constructions—Observation and Numerical Simulation" Sustainability 16, no. 11: 4593. https://doi.org/10.3390/su16114593

APA StyleKosiński, P., & Patyna, K. (2024). Practical Use of Materials of Natural Origin as Loose-Fill Insulations in Open-Diffusion Constructions—Observation and Numerical Simulation. Sustainability, 16(11), 4593. https://doi.org/10.3390/su16114593