Study on the Performance Optimization of Plant-Growing Ecological Concrete

Abstract

1. Introduction

2. Materials

- (1)

- (2)

- Coarse aggregate: Natural pebbles with a single gradation ranging from 20.00 to 26.50 mm were selected, and their characteristics are elucidated in Table 3.

- (3)

- Admixture: A reinforcing agent for pervious concrete was adopted. The dosage of the enhancer is 3.3% of the mass of the binder material, and its specific components are shown in Table 4.

- (4)

- Acetic acid: The composition of acetic acid is presented in Table 5.

- (5)

- Water: Sourced from the local tap water in Xinjiang.

3. Methods

3.1. Response Surface Methodology

3.2. Experimental Research

3.3. Testing Methods

- (1)

- Method of specimen formation: The aggregate particle size of plant-growing ecological concrete is relatively large, and the specimen size should not be too small. This test prepares it into a cubic specimen of 150 mm × 150 mm × 150 mm (Figure 2). The molded specimen is covered with plastic film and cured in the curing room for 3 days before demolding. The demolded specimen is lightly watered during daily maintenance to replenish moisture loss and cured until 28 days for testing.

- (2)

- Compressive Strength: The side of the specimen was selected as the compression surface to ensure that the compressed surface was relatively flat and free of protrusions. The compressive strength test was conducted using the DYE-2000 digital pressure testing machine (Cangzhou Huaheng Testing Instrument Co., Ltd., Cangzhou, China), and the specific testing operations were carried out in accordance with the relevant provisions of the (GB/T50081-2019) “Standard Test Methods for Mechanical Properties of Ordinary Concrete” [25]. Considering the low strength of the specimen, continuous and uniform loading was applied during the test, with the loading rate controlled at 0.3 MPa/s to 0.5 MPa/s.

- (3)

- Continuous Porosity: The porosity of plant-growing ecological concrete includes effective and ineffective pores. Effective pores refer to the pores within the concrete specimens that are connected to the external air, while ineffective pores refer to the enclosed pores that are not connected to the external air. It is evident that the effective porosity rate discussed in this paper pertains to the pores that substantially affect permeability, air permeability, and the growth of plant roots, which is different from the effective porosity rate defined for other materials. To distinguish, this paper refers to the experimental method in “Ecological Concrete Slope Protection Technology and Application” [26] and names the effective porosity rate as continuous porosity. The drainage method is utilized to measure the continuous porosity of plant-growing ecological concrete, as shown in the following formula:

- (4)

- Concrete alkalinity test: To determine the dilution pH of soluble solids in cement paste, the in-situ leaching method was adopted. We scraped off the cement paste from the broken concrete pieces and ground it into a powder that passed through a standard sieve with a 0.074 mm aperture. The powdered cementitious material was mixed with distilled water at a mass ratio of 1:10, stirred evenly, and left to stand for 1 h. After standing, the supernatant was taken, the powder residue in the filtrate was filtered out, and then the determination was carried out. The determination method followed the standard (HJ 1147-2020) “Water Quality-Determination of pH Value-Electrometric Method” [27].

- (5)

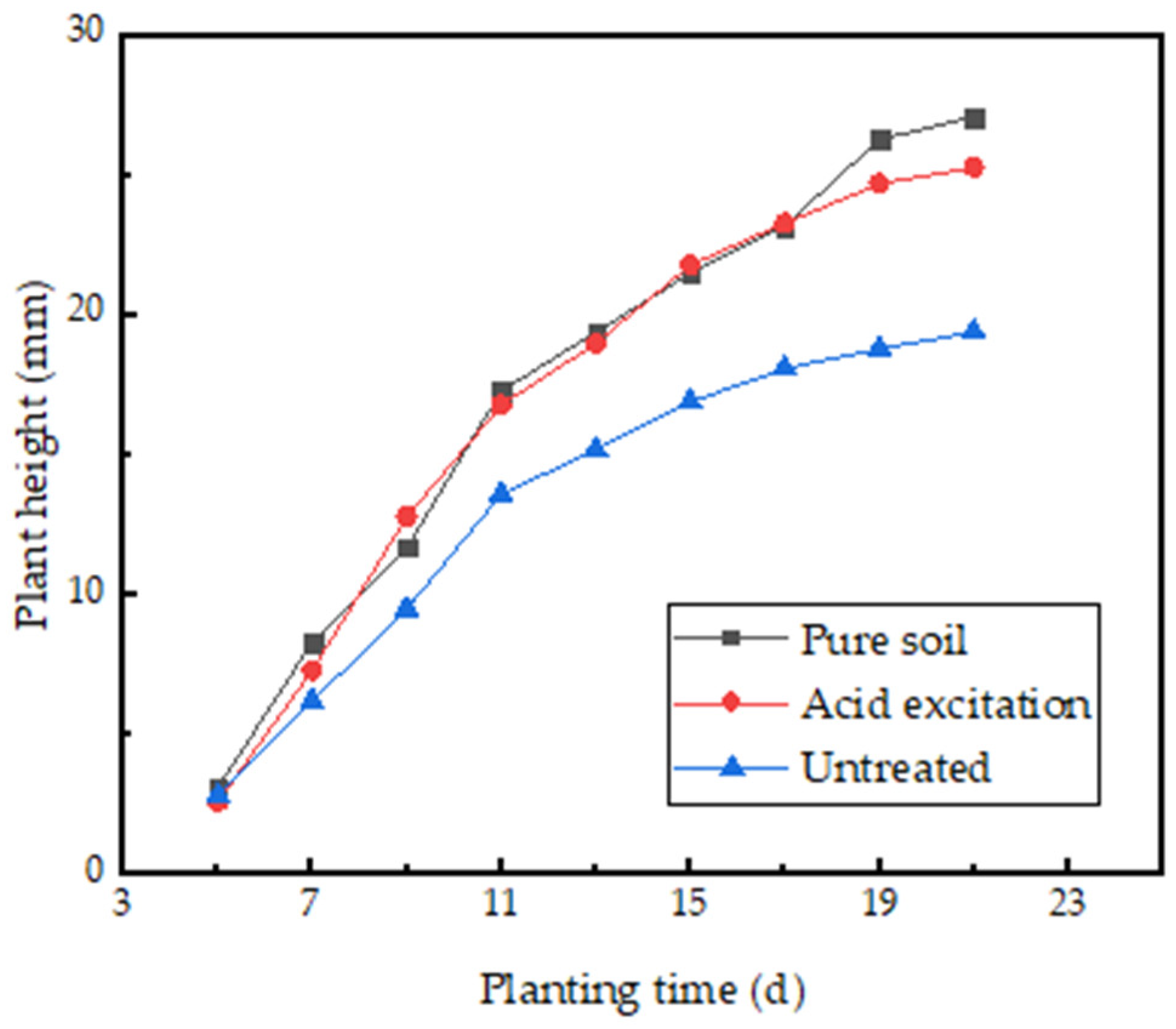

- Planting test: The experiment utilized three methods: pure soil natural planting, planting of test pieces after alkali reduction treatment, and planting of test pieces without alkali reduction treatment. Each method was set with 10 samples. Each sample had a planting area of 150 mm × 150 mm and 100 seeds of tall festuca were sown. The ultimate criterion was whether the roots of the tall fescue could penetrate the soil layer and reach into the concrete, to analyze the vegetative effectiveness of the plant-growing ecological concrete. As shown in Figure 3, the planting soil was a mix of inorganic soil, organic fertilizer, coconut coir, and vermiculite in a 7:2:2:1 ratio. As illustrated in Figure 4, soaking the specimens in nutrient soil diluted with water before the planting experiment can effectively fill the pores of the specimens, which is beneficial for the subsequent growth of the plants.

4. Results

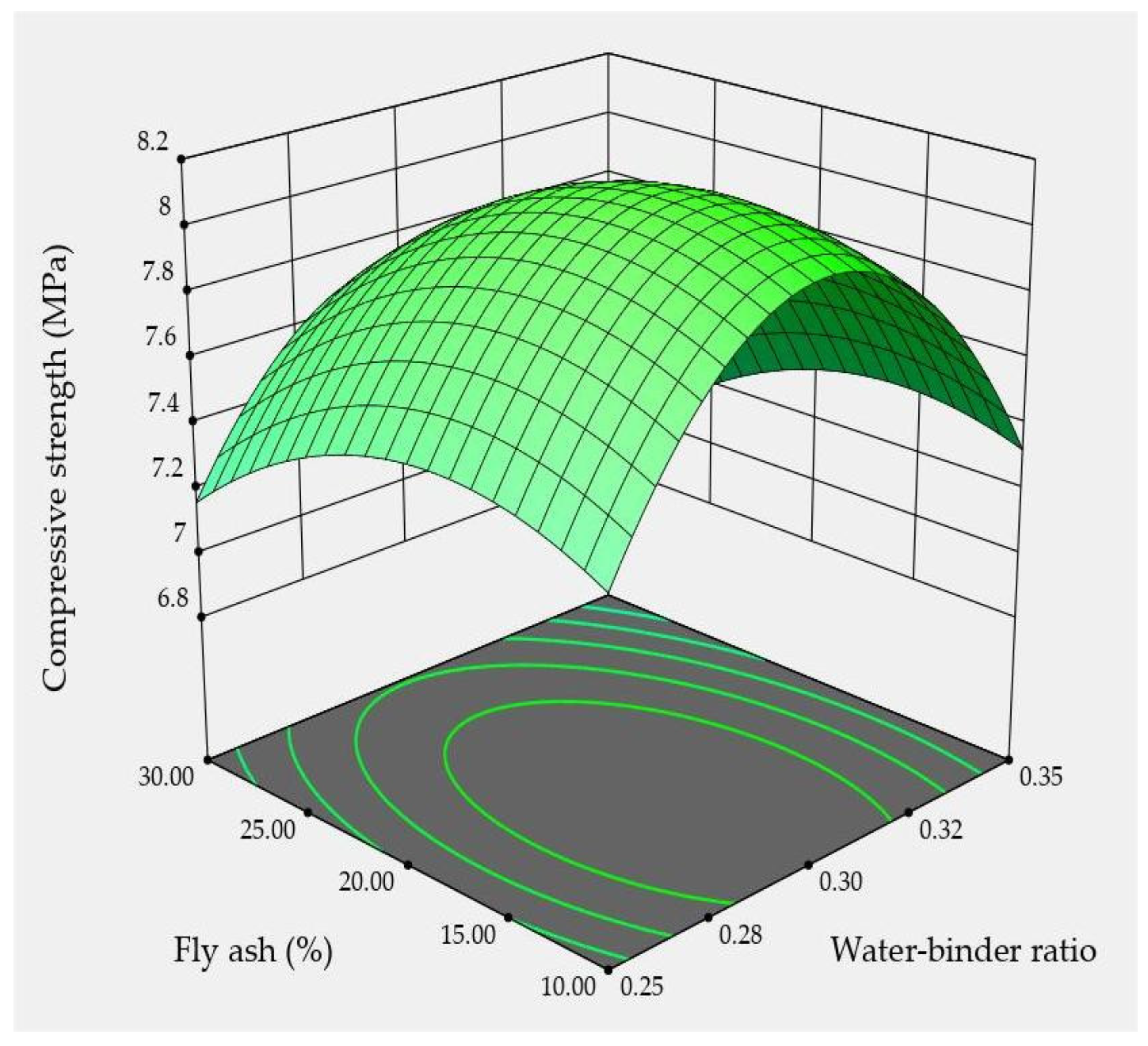

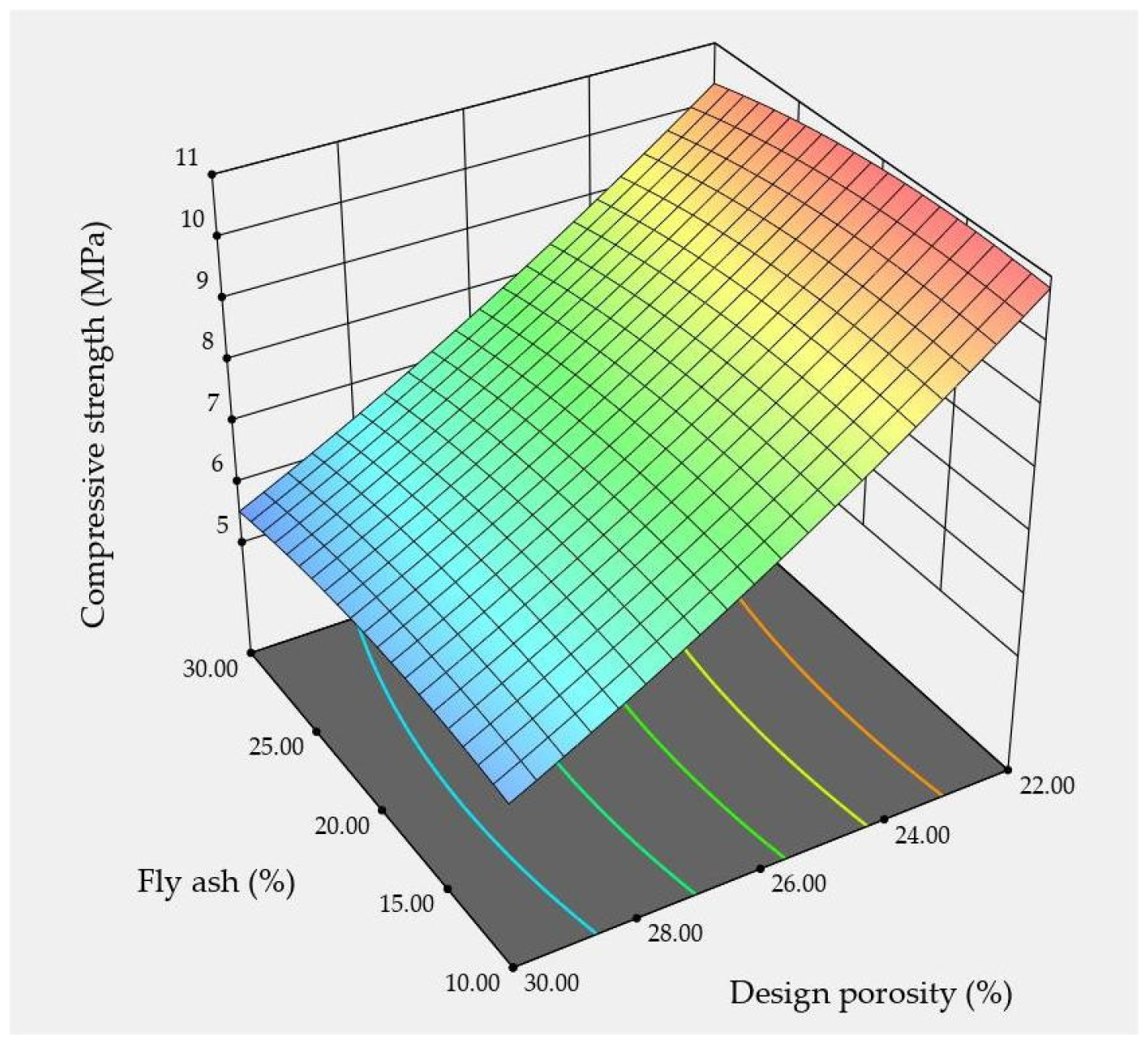

4.1. Regression Model

4.2. Alkali Reduction Treatment

4.2.1. Mix Proportion Optimization Results

4.2.2. Acid Excitation

4.3. Vegetative Experiment

5. Discussion

5.1. The Effect of Different Factors

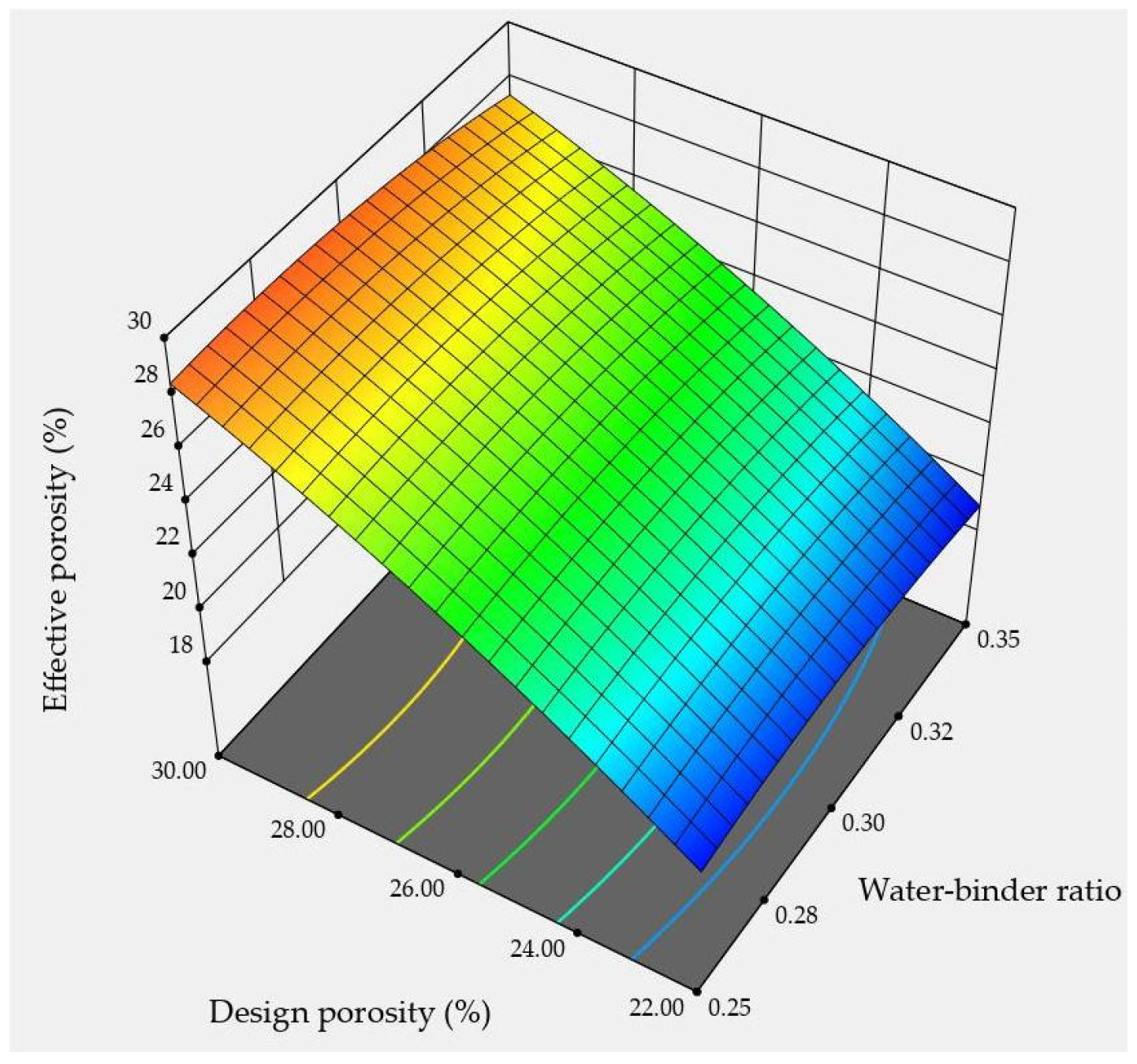

5.1.1. Analysis of Compressive Strength

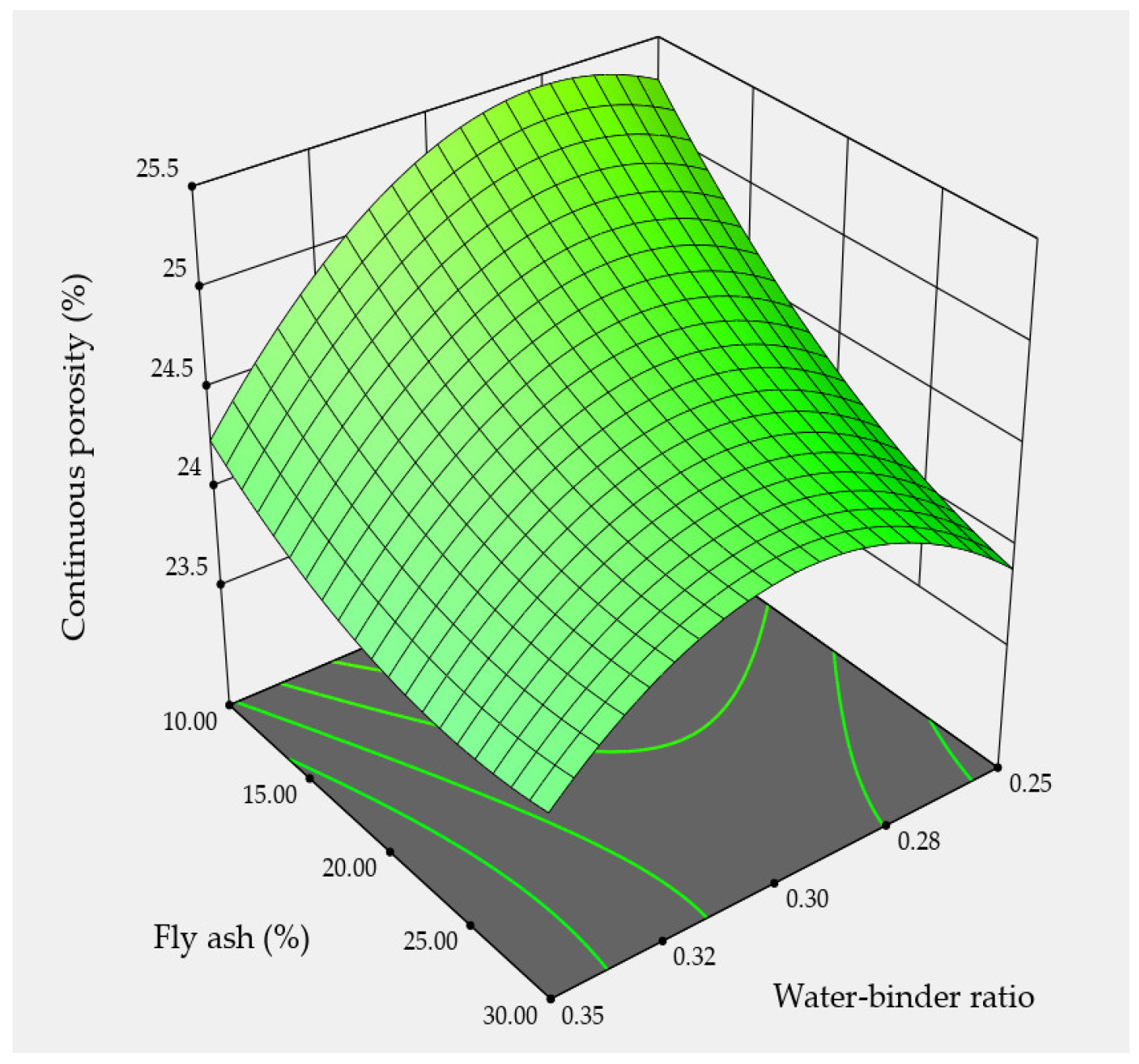

5.1.2. Analysis of Continuous Porosity

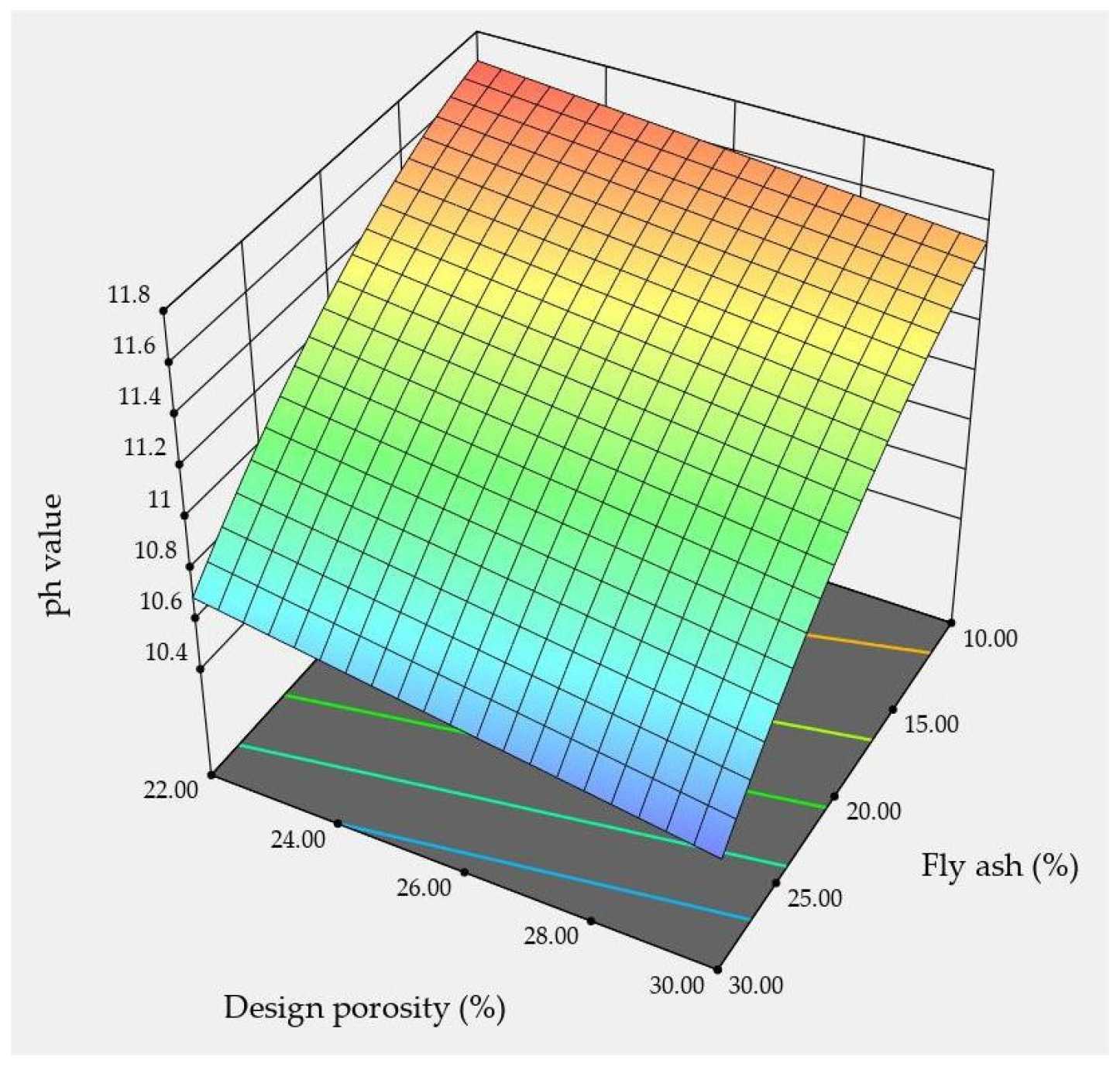

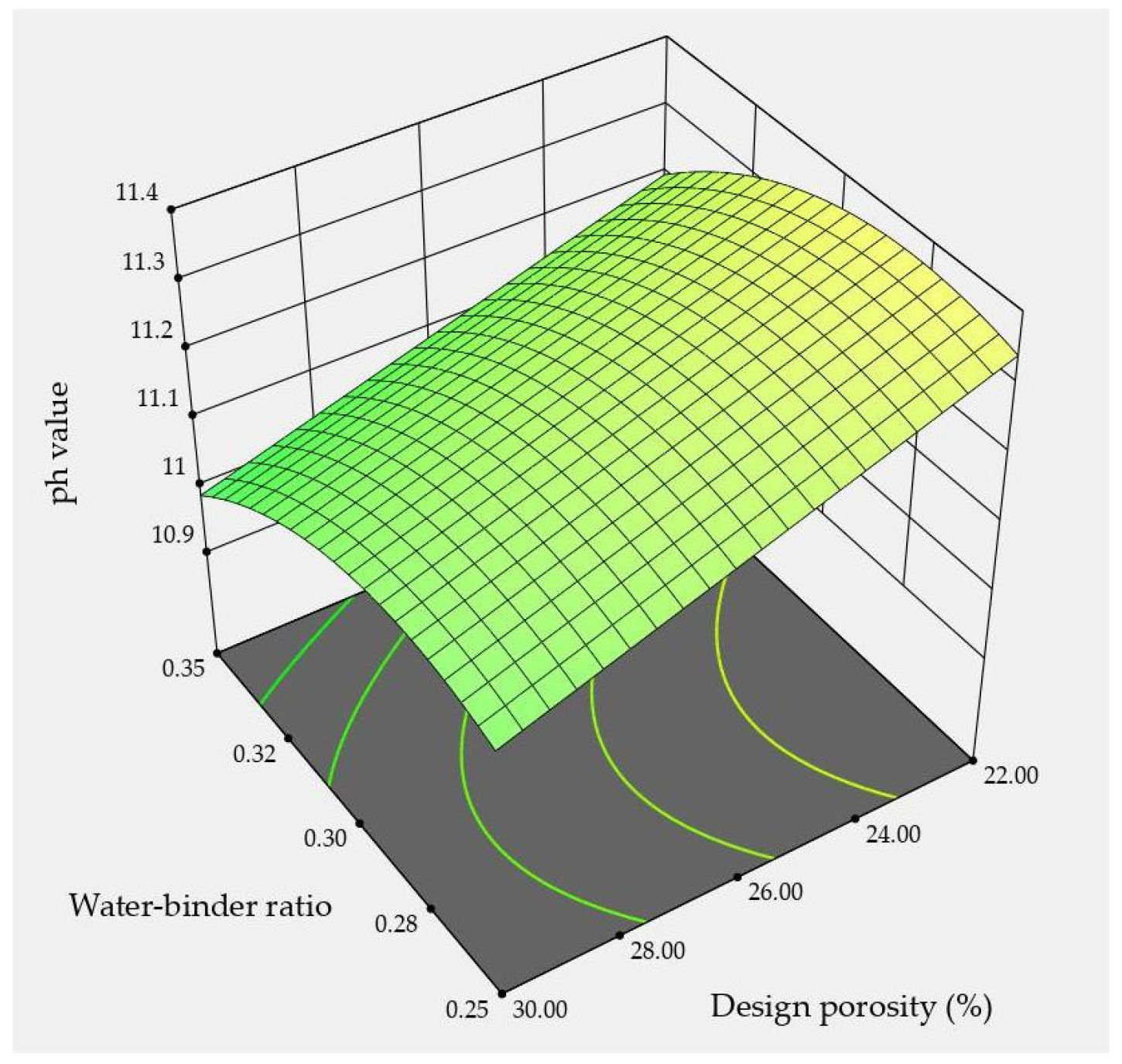

5.1.3. Analysis of pH Value

5.2. Acid Activation

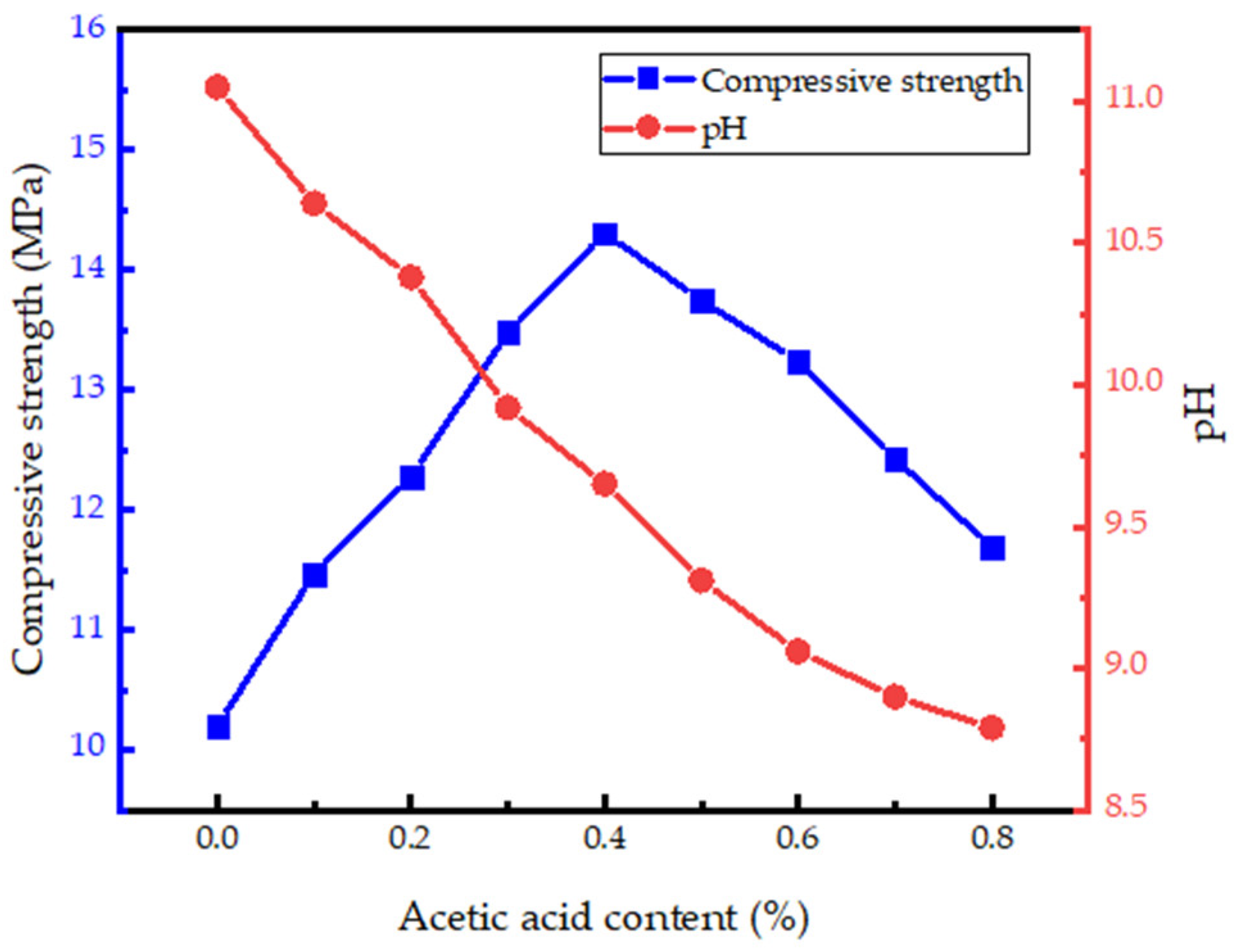

5.2.1. Influence of Acetic Acid Content on Concrete

5.2.2. Discussion on Planting Performance

6. Conclusions

- (1)

- The optimized mix proportion obtained by the regression model established through the response surface method is as follows: water-to-binder ratio of 0.30, fly ash content of 26%, and designed porosity rate of 22%. The predicted performance is a compressive strength of 10.32 MPa, continuous porosity rate of 20.00%, and pH value of 11. Further experimental validation showed that this mix proportion had a compressive strength of 10.11 MPa, a continuous porosity rate of 20.71%, and a pH value of 10.79. The errors were 2.03%, 3.55%, and 1.91%, respectively, all less than the 5% error range, indicating that the regression model about the basic properties of plant-growing ecological concrete established by the response surface method experiment is accurate and effective;

- (2)

- Acetic acid, as an activator, can significantly enhance the compressive strength of plant-growing ecological concrete and reduce its alkalinity. An acetic acid content of 0.4% of the weight of the cementitious materials is optimal for improving the performance of plant-growing ecological concrete with the optimized mix. The test results show that the compressive strength increased by 40.29%, and the pH value decreased by 6.33%;

- (3)

- Acetic acid can improve the plant-growing performance of plant-growing ecological concrete. The plant-growing ecological concrete specimens treated with the abovementioned alkali reduction showed similar vegetative performance when tested with tall fescue compared to pure soil planting and were significantly better than the concrete specimens without alkali reduction treatment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ido, S.; Shimrit, P.F. Blue is the new green–ecological enhancement of concrete based coastal and marine infrastructure. Ecol. Eng. 2015, 84, 260–272. [Google Scholar] [CrossRef]

- Xie, N.; Akin, M.; Shi, X. Permeable concrete pavements: A review of environmental benefits and durability. J. Clean. Prod. 2019, 210, 1605–1621. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material—Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Liu, H.; Jia, Y.; Niu, C. “Sponge city” concept helps solve China’s urban water problems. Environ. Earth Sci. 2017, 76, 473. [Google Scholar] [CrossRef]

- Mosaberpanah, M.A.; Olabimtan, S.B.; Balkis, A.P.; Rabiu, B.O.; Oluwole, B.O.; Ajuonuma, C.S. Effect of Biochar and Sewage Sludge Ash as Partial Replacement for Cement in Cementitious Composites: Mechanical, and Durability Properties. Sustainability 2024, 16, 1522. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N. Mechanical characterisation and flexural performance of eco-friendly concrete produced with fly ash as cement replacement and coconut shell coarse aggregate. Int. J. Environ. Sustain. Dev. 2019, 18, 131–148. [Google Scholar] [CrossRef]

- Xu, W. Theory and Practice of Vegetated Concrete Ecological Protection Technology, 1st ed.; China Water Power Press: Beijing, China, 2012. [Google Scholar]

- Yang, S. Study of the Shrinkage, Fissure and Permeability Characteristics of the Vegetation Growing Conerete Using Typical Organic Materials. Master’s Thesis, China Three Gorges University, Yichang, China, 2018. [Google Scholar]

- Ćosić, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of aggregate type and size on properties of pervious concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Huang, J.; Luo, Z.; Khan, M.B.E. Impact of aggregate type and size and mineral admixtures on the properties of pervious concrete: An experimental investigation. Constr. Build. Mater. 2020, 265, 120759. [Google Scholar] [CrossRef]

- Moretti, L.; Mascio, P.D.; Fusco, C. Porous concrete for pedestrian pavements. Water 2019, 11, 2105. [Google Scholar] [CrossRef]

- Oviedo, I.; Pradena, M.; Link, Ó.; Balbo, J.T. Using Natural Pozzolans to Partially Replace Cement in Pervious Concretes: A Sustainable Alternative? Sustainability 2022, 14, 14122. [Google Scholar] [CrossRef]

- Sumanasooriya, M.S.; Neithalath, N. Pore structure features of pervious concretes proportioned for desired porosities and their performance prediction. Cem. Concr. Compos. 2011, 33, 778–787. [Google Scholar] [CrossRef]

- Starke, P.; Göbel, P.; Coldewey, W.G. Urban evaporation rates for water-permeable pavements. Water Sci. Technol. 2010, 62, 1161–1169. [Google Scholar] [CrossRef] [PubMed]

- Hung, V.V.; Seo, S.Y.; Kim, H.W.; Lee, G.C. Permeability and strength of pervious concrete according to aggregate size and blocking material. Sustainability 2021, 13, 426. [Google Scholar] [CrossRef]

- JC/T 2558-2020; Pervious Concrete. Ministry of Industry and Information Technology of China: Beijing, China, 2020.

- Reji, M.; Kumar, R. Response surface methodology (RSM): An overview to analyze multivariate date. Indian J. Microbiol. Res. 2022, 9, 241–248. [Google Scholar]

- Khuri, A.I. A general overview of response surface methodology. Biom. Biostat. Int. J. 2017, 5, 87–93. [Google Scholar] [CrossRef]

- Box, G.E.P.; Behnken, D.W. Some new three level designs for the study of quantitative variables. Technometrics 1960, 2, 455–475. [Google Scholar] [CrossRef]

- Kováč, M.; Sičáková, A. Pervious Concrete as an Environmental Solution for Pavements: Focus on Key Properties. Environments 2018, 5, 11. [Google Scholar] [CrossRef]

- Zhu, H.T.; Wen, C.C.; Wang, Z.Q.; Li, L. Study on the permeability of recycled aggregate pervious concrete with fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef]

- Chen, X.D.; Wang, H.; Najm, H.; Venkiteela, G. Evaluating engineering properties and environmental impact of pervious concrete with fly ash and slag. J. Clean. Prod. 2019, 237, 117714. [Google Scholar] [CrossRef]

- Saboo, N.; Shivhare, S.; Kori, K.K.; Chandrappa, A.K. Effect of fly ash and metakaolin on pervious concrete properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- CJJ/T 135-2009; Technical Specification for Pervious Cement Concrete Pavement. Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Ural Construction of the People’s Republic of China and State Market Regulatory Administration: Beijing, China, 2019.

- Zhao, Y.Q.; Xing, Z.X. Ecological Concrete Slope Protection Technology and Application, 1st ed.; China Water & Power Press: Beijing, China, 2016; pp. 31–32. [Google Scholar]

- HJ 1147-2020; Water Quality—Determination of pH—Electrode Method. Ministry of Ecological Environment of the People′s Republic of China: Beijing, China, 2020.

- Dou, Y.F.; Liu, F.; Zhang, W.H. Research on comparative analysis of response surface methods. Chin. J. Eng. Des. 2007, 14, 359–363. [Google Scholar]

- Chindaprasirt, P.; Hatanaka, S.; Mishima, N.; Yuasa, Y.; Chareerat, T. Effects of binder strength and aggregate size on the compressive strength and void ratio of porous concrete. Int. J. Miner. Metall. Mater. 2009, 16, 714–719. [Google Scholar]

- Luo, J. Study on the influencing factors of water permeability and strength of pervious cement concrete. Sichuan Cem. 2019, 26, 8–10. [Google Scholar]

- Wang, H.B.; Li, H.; Liang, X.; Zhou, H.N.; Xie, N.; Dai, Z. Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based on the cement-aggregate ratio. Constr. Build. Mater. 2019, 202, 387–395. [Google Scholar] [CrossRef]

- Maguesvari, U.; Sundararajan, A. Influence of fly ash and fine aggregates on the characteristics of pervious concrete. Int. J. Appl. Eng. Res. 2017, 12, 1598–1609. [Google Scholar]

- Sata, V.; Ngopok, C.; Chindaprasirt, P. Properties of pervious concrete containing high-calcium fly ash. Comput. Concr. 2016, 17, 337–351. [Google Scholar] [CrossRef]

- Haji, A.A.; Parikh, K.B.; Shaikh, M.A.; Jamnu, M.A. Experimental investigation of pervious concrete with use of fly ash and silica fume as admixture. Int. J. Innov. Res. Sci. Eng 2016, 2, 154–161. [Google Scholar]

- He, J.; Xu, S.H.S.; Sang, G.C.; Wu, Y.H.; Liu, S. Enhancing the Mechanical Properties and Water Permeability of Pervious Planting Concrete: A Study on Additives and Plant Growth. Materials 2024, 17, 2301. [Google Scholar] [CrossRef]

- Ling, T.Q.; Chen, Q.Q.; Qin, X.; Zhang, J. Mix Proportions Design of Pervious Concrete Pavement and Its Performance lnfluence Factors. J. Chongqing Jiaotong 2019, 38, 38–43+59. [Google Scholar]

- Ganapathy, G.P.; Alagu, A.; Ramachandran, S.; Panneerselvam, A.S.; Arokiaraj, G.G.V.; Panneerselvam, M.; Panneerselvam, B.; Sivakumar, V.; Bidorn, B. Effects of fly ash and silica fume on alkalinity, strength and planting characteristics of vegetation porous concrete. J. Mater. Res. Technol. 2022, 24, 5347–5360. [Google Scholar] [CrossRef]

- Tian, L.; Pang, Z.M.; Quan, H.Z.; Song, H. Physical Properties and Vegetative Adaptation of Eco-porous Concrete. Bull. Chin. Ceram. Soc. 2016, 35, 3381–3386. [Google Scholar]

- Yan, G. Mechanical and Shrinkage Properties of Acid Activated Cement-Based Materials. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2018. [Google Scholar]

- Gil, B.J. Concrete Neutralization Method of the Grass Block and the the Grass Block Which It Manufactures. R.O.K. Patent KR20090078017, 17 July 2009. [Google Scholar]

- Wang, Z.Y.; Chen, L.; Zhang, W.L.; Zhang, K. Environmental compatibility of pervious concrete with recycled coarse aggregate applying in riparian buffer area. Constr. Build. Mater. 2024, 411, 134590. [Google Scholar] [CrossRef]

- Niyomukiza, J.B.; Eisazadeh, A.; Tangtermsirikul, S. Recent advances in slope stabilization using porous vegetation concrete in landslide-prone regions: A review. J. Build. Eng. 2023, 76, 107129. [Google Scholar] [CrossRef]

- Xiong, D.; Chen, F.; Lv, K.; Tan, X.; Huang, Y. The performance and temporal dynamics of vegetation concretes comprising three herbaceous species in soil stabilization and slope protection. Ecol. Eng. 2023, 188, 106873. [Google Scholar] [CrossRef]

| Density /(kg·m−3) | Standard Consistency /% | Specific Surface Area /(m2·kg−1) | Initial Setting Time /min | Final Setting Time /min | 3-Day Compressive Strength /MPa | 28-Day Compressive Strength /MPa |

|---|---|---|---|---|---|---|

| 3040 | 27 | 384 | 172 | 230 | 27.3 | 52.6 |

| Fineness /μm | Water Requirements Ratio /% | SO2 Content /% | Free CaO Content /% | Cl− Content /% | CaO Content /% |

|---|---|---|---|---|---|

| ≤45 | 93.02 | 2 | 0.65 | 0.01 | 6.7 |

| Pebble Size /mm | Packing Density /(kg·m−3) | Compact Packing Density /(kg·m−3) | Apparent Density /(kg·m−3) | Bulk Density in the Loose State /% | Bulk Density in the Compacted State /% |

|---|---|---|---|---|---|

| 20.00~26.50 | 1490 | 1660 | 2593 | 42.53 | 35.97 |

| Nano Silicon Powder | Water Reducer | Cellulose | Calcium Sulfate Crystal Whiskers | Trisodium Phosphate | Calcium Carboxylate | Alkaline Metal Carbonates | Formamide |

|---|---|---|---|---|---|---|---|

| 50~80 | 10~15 | 2~4 | 8~10 | 5~8 | 1.5~5 | 2~6 | 0.5~2 |

| CH3COOH | Cl− | SO42− | Fe | Cu | Pb | (CH3CO)2O |

|---|---|---|---|---|---|---|

| ≥99.5 | ≤0.0001 | ≤0.0002 | ≤0.0001 | ≤0.00005 | ≤0.00005 | ≤0.02 |

| Test | W/B | F /% | P /% | Cement /(kg·m−3) | Coarse Aggregate /(kg·m−3) | Fly Ash /(kg·m−3) | Water /(kg·m−3) |

|---|---|---|---|---|---|---|---|

| 1 | 0.25 | 10 | 26 | 249 | 1627 | 28 | 69 |

| 2 | 0.35 | 10 | 26 | 231 | 1627 | 26 | 90 |

| 3 | 0.25 | 30 | 26 | 194 | 1627 | 83 | 69 |

| 4 | 0.35 | 30 | 26 | 180 | 1627 | 77 | 90 |

| 5 | 0.25 | 20 | 22 | 301 | 1627 | 75 | 94 |

| 6 | 0.35 | 20 | 22 | 278 | 1627 | 70 | 122 |

| 7 | 0.25 | 20 | 30 | 143 | 1627 | 36 | 45 |

| 8 | 0.35 | 20 | 30 | 132 | 1627 | 33 | 58 |

| 9 | 0.30 | 10 | 22 | 325 | 1627 | 36 | 108 |

| 10 | 0.30 | 30 | 22 | 253 | 1627 | 108 | 108 |

| 11 | 0.30 | 10 | 30 | 155 | 1627 | 17 | 52 |

| 12 | 0.30 | 30 | 30 | 120 | 1627 | 52 | 52 |

| 13 | 0.30 | 20 | 26 | 213 | 1627 | 53 | 80 |

| 14 | 0.30 | 20 | 26 | 213 | 1627 | 53 | 80 |

| 15 | 0.30 | 20 | 26 | 213 | 1627 | 53 | 80 |

| 16 | 0.30 | 20 | 26 | 213 | 1627 | 53 | 80 |

| 17 | 0.30 | 20 | 26 | 213 | 1627 | 53 | 80 |

| Test | Compressive Strength /MPa | Continuous Porosity /% | pH | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Test Value | Standard Deviation | Predicted Value | Test Value | Standard Deviation | Predicted Value | Test Value | Standard Deviation | Predicted Value | |

| 1 | 7.43 | 0.18 | 7.41 | 25.23 | 0.32 | 25.28 | 11.60 | 0.05 | 11.58 |

| 2 | 7.31 | 0.11 | 7.33 | 24.39 | 0.33 | 24.26 | 11.45 | 0.06 | 11.43 |

| 3 | 7.18 | 0.14 | 7.16 | 23.76 | 0.52 | 23.9 | 10.49 | 0.09 | 11.51 |

| 4 | 6.87 | 0.18 | 6.89 | 23.83 | 0.35 | 23.78 | 10.38 | 0.03 | 10.40 |

| 5 | 10.22 | 0.29 | 10.23 | 19.27 | 0.61 | 19.09 | 11.35 | 0.04 | 11.37 |

| 6 | 10.09 | 0.19 | 10.07 | 18.95 | 0.43 | 18.96 | 11.21 | 0.05 | 11.23 |

| 7 | 5.27 | 0.18 | 5.30 | 28.45 | 0.48 | 28.44 | 11.15 | 0.03 | 11.13 |

| 8 | 5.11 | 0.14 | 5.10 | 27.25 | 0.38 | 27.43 | 11.03 | 0.03 | 11.01 |

| 9 | 10.82 | 0.31 | 10.83 | 20.01 | 0.30 | 20.13 | 11.71 | 0.03 | 11.71 |

| 10 | 10.34 | 0.31 | 10.35 | 19.42 | 0.30 | 19.46 | 10.76 | 0.04 | 10.73 |

| 11 | 5.75 | 0.14 | 5.74 | 29.34 | 0.46 | 29.3 | 11.52 | 0.05 | 11.56 |

| 12 | 5.54 | 0.15 | 5.53 | 28.23 | 0.37 | 28.11 | 10.44 | 0.03 | 10.44 |

| 13 | 8.14 | 0.18 | 8.13 | 24.65 | 0.41 | 24.64 | 11.25 | 0.04 | 11.22 |

| 14 | 8.11 | 0.19 | 8.13 | 24.59 | 0.32 | 24.64 | 11.12 | 0.05 | 11.22 |

| 15 | 8.19 | 0.32 | 8.13 | 24.41 | 0.40 | 24.64 | 11.21 | 0.04 | 11.22 |

| 16 | 8.08 | 0.20 | 8.13 | 24.81 | 0.30 | 24.64 | 11.27 | 0.04 | 11.22 |

| 17 | 8.15 | 0.30 | 8.13 | 24.73 | 0.47 | 24.64 | 11.23 | 0.03 | 11.22 |

| Source | Compressive Strength | Continuous Porosity | pH | Significance | |||

|---|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | ||

| Model | 5156.85 | <0.0001 | 551.10 | <0.0001 | 165.44 | <0.0001 | significant |

| W/B | 51.61 | <0.0001 | 17.57 | 0.0030 | 11.28 | 0.0064 | |

| F | 189.59 | <0.0001 | 46.62 | 0.0001 | 739.12 | <0.0001 | |

| P | 39,028.37 | <0.0001 | 4251.17 | <0.0001 | 33.03 | 0.0001 | |

| (W/B)·F | 7.19 | 0.0279 | 5.55 | 0.0463 | - | - | |

| (W/B)·P | - | - | 5.19 | 0.0522 | - | - | |

| F·P | 14.51 | 0.0052 | - | - | - | - | |

| (W/B)2 | 1588.43 | <0.0001 | 34.48 | 0.0004 | 8.29 | 0.0150 | |

| F2 | 206.66 | <0.0001 | 5.33 | 0.0498 | 33.50 | 0.0001 | |

| P2 | 172.41 | <0.0001 | 41.34 | 0.0002 | - | - | |

| Lack of fit | 0.4516 | 0.7699 | 2.23 | 0.2285 | 0.8222 | 0.6159 | not significant |

| Fit Statistics | Compressive Strength | Continuous Porosity | pH |

|---|---|---|---|

| R2 | 0.9998 | 0.9982 | 0.9869 |

| R2adj | 0.9996 | 0.9964 | 0.9809 |

| R2pred | 0.9992 | 0.9865 | 0.9696 |

| R2adj–R2pred | 0.0004 | 0.0099 | 0.0113 |

| CV | 0.45% | 0.80% | 0.49% |

| Signal-to-noise ratio | 221.86 | 72.63 | 40.14 |

| Cultivation Method | Planting Time | Germination Rate |

|---|---|---|

| Pure soil planting | 5 d | 91% |

| Specimens treated with acid | 5 d | 87% |

| Untreated specimens | 5 d | 85% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuang, P.; Yan, X.; Wang, X.; Liu, J. Study on the Performance Optimization of Plant-Growing Ecological Concrete. Sustainability 2024, 16, 4575. https://doi.org/10.3390/su16114575

Zhuang P, Yan X, Wang X, Liu J. Study on the Performance Optimization of Plant-Growing Ecological Concrete. Sustainability. 2024; 16(11):4575. https://doi.org/10.3390/su16114575

Chicago/Turabian StyleZhuang, Peiyuan, Xinjun Yan, Xuehu Wang, and Jiaqi Liu. 2024. "Study on the Performance Optimization of Plant-Growing Ecological Concrete" Sustainability 16, no. 11: 4575. https://doi.org/10.3390/su16114575

APA StyleZhuang, P., Yan, X., Wang, X., & Liu, J. (2024). Study on the Performance Optimization of Plant-Growing Ecological Concrete. Sustainability, 16(11), 4575. https://doi.org/10.3390/su16114575