Abstract

The lack of adequate sanitation in Brazil overloads the health system and causes deaths. The utilization of sewage sludge hinders advancements in water treatment. This study aimed to assess the feasibility of producing briquettes by blending sewage sludge with Pinus sp. sawdust. The sewage sludge was sourced from a water treatment facility, while the Pinus sp. sawdust was obtained from a sawmill. Elemental analysis, proximate analysis, and calorific value were evaluated for both biomasses. Briquettes were manufactured using a hydraulic press, varying the proportion of sewage sludge from 0% to 95%, followed by thermogravimetric analysis. Pinus sp. sawdust exhibited higher carbon, oxygen, and hydrogen content, whereas sewage sludge contained more nitrogen and sulfur. The sawdust had greater fixed carbon content, volatile matter, and calorific value, while the sewage sludge had higher ash content. Samples with higher sewage sludge content showed better thermal resistance, with 100% sewage sludge retaining 63.3% mass after exposure to 950 °C. Briquettes with higher sewage sludge content had increased energy density. Considering the elevated nitrogen, sulfur, and ash content, sewage sludge should be limited to 5% in briquette production with Pinus sp. sawdust. This research underscores a significant avenue for sewage sludge utilization and sustainable bioenergy production.

1. Introduction

Water treatment in Brazil continues to fall short of the necessary standards required to serve the nation’s needs [1,2]. The improper disposal of untreated sewage into the environment poses a risk of disease transmission and water contamination [3]. The sewage treatment process involves several stages to eliminate undesirable substances and improve water quality for safe disposal. Initially, preliminary treatment employs physical methods to remove large solids. Following this, primary treatment further addresses physical impurities like oils, greases, and organic matter. Secondary treatment, primarily biological, targets the removal of nitrogen, phosphorus, and additional organic materials. Tertiary treatment then complements these stages by focusing on specific substance removal. Throughout this process, sewage sludge is produced in significant quantities, prompting the need for research into its effective utilization. Proper management of sewage sludge is essential not only for environmental protection but also for exploring potential beneficial applications such as agricultural use or energy production. Therefore, ongoing studies on sewage sludge utilization are crucial for optimizing the overall efficiency and sustainability of sewage treatment processes.

One of the factors limiting the expansion of water treatment is the disposal of sewage sludge generated in the process [4]. This material is complex, rich in organic matter and nutrients containing a variety of chemical compounds and pathogens [5], and is found in solid, semi-solid, or liquid form depending on the moisture content [6,7].

Utilizing sludge from Water Treatment Plants (WTPs) for energy generation presents a promising option. One potential avenue involves producing briquettes using sludge as a primary raw material. This approach not only offers an alternative to conventional solid fuels but also presents additional benefits. By utilizing sludge for briquette production, it becomes possible to mitigate greenhouse gas emissions (GHGs) and reduce reliance on traditional solid fuels, thereby curbing deforestation. Moreover, this process contributes to the circular economy by valorizing wastewater byproducts, transforming what would otherwise be considered waste into a valuable resource. By adopting such innovative methods for sludge utilization, WTPs can not only manage their waste more sustainably but also contribute positively to environmental conservation efforts. This underscores the importance of exploring diverse avenues for sludge utilization within the context of wastewater treatment [8].

A feasible and common alternative is to incorporate sawdust into briquette production, owing to the chemical composition and quality of the sludge. Pinus sp. wood serves as one of the sources of sawdust. This wood typically contains ash content, volatile matter, and fixed carbon ranging from 0.83% to 0.92%, 65.8% to 82%, and 17.17% to 33.3%, respectively, with a higher heating value between 14.64 and 20.1 MJ/g [9,10]. The ash does not combust, making it undesirable for energy generation, volatile materials lead to rapid combustion, playing a crucial role in the ignition process [11], and, finally, fixed carbon ensures a slower and more prolonged burn and is directly related to the heating value [12].

Briquetting is a method that involves compressing lignocellulosic biomass to create compact and solid forms from irregular particles [13]. The briquettes’ quality is affected by factors inherent to the process, such as the pressure and temperature applied during processing, and factors related to biomass quality, such as moisture, particle size, density, and chemical composition [14,15,16]. The process begins with the crushing and grinding of biomass into particles ranging from 5 to 10 mm in size. These particles are then compacted under a high pressure and temperatures between 100 and 120 °C [17,18]. Briquettes produced from textile sludge exhibit a higher calorific value of 12 MJ·kg−1, a value lower than that found for eucalyptus and pine wood: 19.42 and 19.48 MJ·kg−1, respectively [19,20].

The utilization of sludge from Water Treatment Plants (WTPs) for energy generation presents promising prospects; this idea fits into the context of the circular economy and sustainable development by proposing a model that utilizes recycled materials as raw materials. In doing so, this reduces the demand for virgin natural resources and minimizes the amount of waste sent to landfills, thus promoting environmental sustainability. Nonetheless, the quality of sludge necessitates its incorporation into a blend with another raw material for the production of briquettes. Hence, the aim of this research endeavor was to contribute towards offering a sustainable and economically viable solution for the disposal of sewage sludge by crafting briquettes tailored for energy generation purposes. The overarching expectation is that the outcomes of this study will bolster the feasibility of water treatment operations by harnessing the principal byproduct of the process and fostering an alternative avenue for the fabrication of environmentally friendly solid biofuel.

2. Materials and Methods

2.1. Biological Material

The sludge utilized in this study originated from the Capim Branco Treatment Plant, situated in the city of Uberlândia, in the state of Minas Gerais, Brazil. The geographical coordinates of the treatment plant are approximately 8°30′ to 19°30′ S latitude and 47°50′ to 48°50′ W longitude. Concurrently, the sawdust utilized was sourced from residues of Pinus sp. obtained from local sawmills within the same city. This collaboration between the treatment plant and local sawmills underscores the potential for synergistic partnerships within the region to address waste management challenges and explore sustainable solutions. By leveraging locally available resources, such as wastewater sludge and sawmill residues, there is an opportunity to not only manage waste effectively but also to create value-added products, thereby contributing to the region’s economic and environmental sustainability goals.

2.2. Biomass Characterization

The material was stored in a climatic chamber, then crushed in a Wiley mill and sieved. The fraction retained between 40 and 60 mesh sieves was used for proximate analysis and higher calorific value determination, while the fraction that passed through the 200-mesh sieve was used for elemental and thermogravimetric analysis.

The proximate analysis (ash content, volatile matter, and fixed carbon) was conducted following the methodology described in the NBR 8112 standard by ABNT (Brazilian Association of Technical Standards) in 1986 [21]. The higher heating value was determined using the same methodology adapted from the NBR 8633 standard by ABNT in 1984 [22].

Elemental analysis (CHNS-O) was conducted employing the CHNS-O Flash EA 1112 Series apparatus, utilizing approximately 2.5 mg (±0.5) of sample, either sawdust or sewage sludge. This analytical instrumentation facilitated the determination of the carbon, hydrogen, nitrogen, oxygen, and sulfur levels present within the samples. Furthermore, calculations were performed to ascertain the ratios between the carbon and hydrogen (C/H) as well as the carbon and nitrogen (C/N) levels within both the sewage sludge and sawdust.

The thermogravimetric analysis was conducted using the following sewage sludge proportions: 0, 5, 15, 25, 35, 65, 75, 85, 95%, and 100%; Pinus sp. sawdust was used to complement each treatment. The test was carried out using a Thermogravimetric Analyzer, Discovery TGA55, from the brand TA Instruments, with a heating rate of 10 °C min⁻¹, under a nitrogen atmosphere, in the temperature range of 25 to 950 °C.

2.3. Briquette Production

The manufactured briquettes were segregated into ten distinct treatments according to the varying proportions of sewage sludge and Pinus sp. sawdust utilized, as detailed in Table 1. Each treatment involved the production of 10 briquettes, resulting in a total of 100 briquettes across all treatments.

Table 1.

Proportion of sewage sludge and sawdust for briquette production and the amount of mass for each raw material for conducting the experiment.

The raw material for briquette production was conditioned in a climate chamber at 25 °C and 50% relative humidity until the mass stabilized. The process of briquetting was executed utilizing a hydraulic press (model Marconi MA-098/CP0), produced by the company Marconi, located in the city of Piracicaba, Brazil, wherein a force of five tons was exerted onto a cylinder with an area of 5 cm2, yielding a pressure of 1020 kgf cm⁻2. This pressure was sustained for a duration of 30 s. Subsequently, the briquettes underwent conditioning within a climatic chamber (model MA835/988ABCP) set to 50% relative humidity and were maintained at a temperature of 25 °C for a period spanning ten days.

The briquettes’ moisture on a dry basis was determined using the following equation: Mc = (Wm − Dm)/Dm, where Mc = moisture content of the briquette on a dry basis; Wm = wet mass of the briquette; and Dm = dry mass of the briquette after drying in an oven.

The bulk density of the briquettes was evaluated as the quotient of the briquettes’ mass post-conditioning and their volume. Mass measurements were executed employing a precision balance with a sensitivity of 0.01 g, while dimensions were assessed utilizing a caliper with a sensitivity of 0.01 mm under the assumption of a cylindrical shape for all samples. Energy density was determined by multiplying the higher heating value (HHV) by the bulk density of the briquette (BD). This meticulous procedure ensured accurate characterization of the briquettes’ physical properties, providing essential insights into their compactness and potential energy output. Such comprehensive analysis aids in optimizing the formulation and production process, thereby facilitating the development of efficient and sustainable solid biofuels for energy generation purposes.

2.4. Statistical Analysis

The analyses of sawdust and sewage sludge were compared using a completely randomized design (CRD). The means were subjected to a homogeneity of variance analysis using the Cochran test and then the treatments were subjected to the t-Student test with a confidence level of 95%.

3. Results

3.1. Characterization of Sewage Sludge and Pinus sp. Sawdust

The elemental chemical composition of sewage sludge and pine sawdust differed; elements targeted for energy generation, such as carbon and hydrogen, are present in higher proportions in wood, while undesirable components for energy generation, such as sulfur and nitrogen, were found in higher proportions in sewage sludge (Table 2).

Table 2.

Elemental composition of sewage sludge and Pinus sp. sawdust in relation to dry mass.

Pinus sp. sawdust exhibited higher fixed carbon content and volatile matter and superior calorific value, while sewage sludge showed higher ash content (Table 3).

Table 3.

Proximate analysis (fixed carbon, volatile matter, and ash) and higher calorific value (HCV) of sewage sludge and pine sawdust.

3.2. Thermogravimetric Analysis

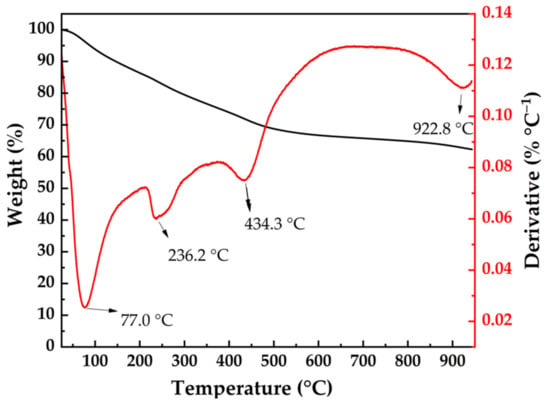

The thermal decomposition of sewage sludge is marked by low mass loss with increasing temperature and a high amount of residue at the end of the test (Figure 1).

Figure 1.

TGA/DTG curves for the sample with 100% sewage sludge.

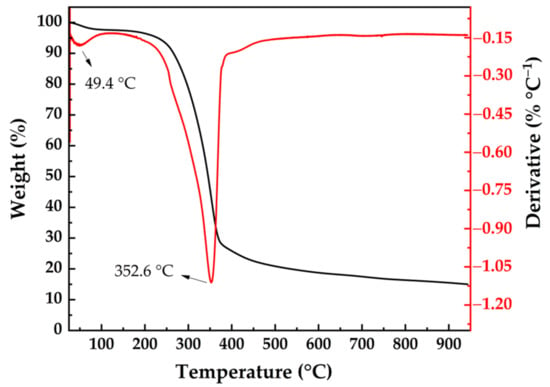

The thermogravimetric curve of the sample with 100% Pinus sp. sawdust showed the maximum degradation rate at 352.6 °C, with a residue of less than 20% (Figure 2).

Figure 2.

TGA/DTG curves for the sample with 100% Pinus sp. sawdust.

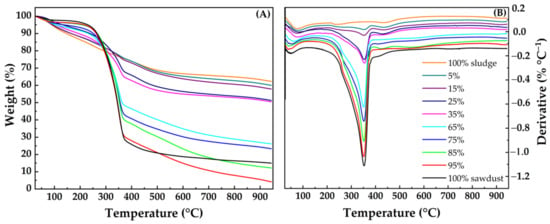

The thermogravimetric analyses of the briquettes produced from the mixture of the two components in different compositions, namely 5, 15, 25, 35, 65, 75, 85, and 95% w/w sludge/sawdust, showed differences in the behavior of sewage sludge and sawdust at high temperatures and a synergistic effect when both samples were analyzed together (Figure 3).

Figure 3.

Curves of (A) TGA and (B) DTG for the briquette samples produced in the proportions of 5, 15, 25, 35, 65, 75, 85, and 95% w/w sludge/sawdust.

The main thermal degradation information of the sludge, sawdust, and samples with different proportions of these materials can be summarized based on the data in Table 4.

Table 4.

Thermogravimetric data obtained from TGA/DTG curves for sludge/sawdust samples in different tested compositions.

3.3. Briquette Evaluation

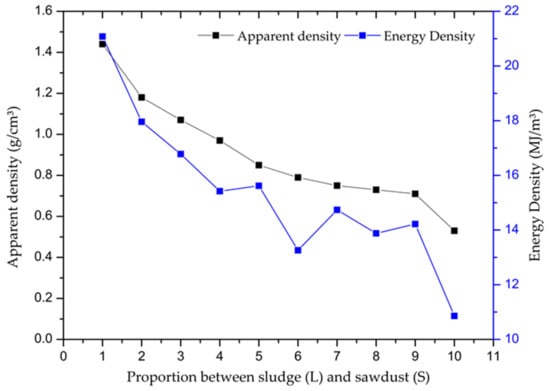

The addition of sewage sludge increased the apparent density and energy density of the briquettes and no synergistic effect was observed when the two were mixed (Figure 4).

Figure 4.

Bulk density and energy density of briquettes produced with sewage sludge and Pinus sp. sawdust.

4. Discussion

4.1. Characterization of Sewage Sludge and Pinus sp. Sawdust

The carbon and hydrogen content is directly related to the calorific value of biomass [23,24] (Table 2). Pine sawdust demonstrates superior quality in this regard, likely due to its favorable composition in these elements. While both carbon and hydrogen contribute positively to energy generation, hydrogen exhibits greater energy potential. Therefore, maintaining a lower C/H ratio is advantageous for maximizing the calorific value of biofuels [25]. Conversely, the higher oxygen content found in pine sawdust poses a drawback for energy generation purposes, as it diminishes the material’s calorific value [26].

Table 2 reveals that the sulfur content exhibited a higher concentration in sewage sludge compared to other materials. During combustion, sulfur undergoes a reaction with atmospheric oxygen, resulting in the production of sulfur oxides (SOx). These oxides pose significant environmental hazards due to their toxic nature. Additionally, they possess a relatively low condensation point, approximately 150 °C, facilitating the formation of acidic compounds upon cooling. Consequently, these acids can instigate corrosion of the equipment utilized for combustion processes. Recognizing the elevated sulfur levels in sewage sludge underscores the importances of implementing appropriate mitigation strategies to minimize the release of SOx into the environment and mitigate potential adverse effects on both human health and infrastructure integrity. Therefore, comprehensive measures, such as the production of briquettes by mixing sewage sludge with wood, a material with a low content of this element, should be adopted to reduce sulfur emissions, ensuring sustainable and environmentally responsible practices in energy generation processes [27].

Pine sawdust exhibited nitrogen content that was six times lower and a C/N ratio that was thirty times higher (Table 2). Nitrogen is undesirable for energy generation as it has no correlation with calorific value and releases nitrogen oxides during combustion, which cause wear on burning equipment and are highly toxic to the environment. A low C/N ratio reduces the amount of nitrogen released into the atmosphere during combustion. Additionally, low values for this ratio result in the rapid release of CO2 into the atmosphere during combustion, exacerbating the negative effects of the greenhouse effect [28]. In this context, the nitrogen content of sewage sludge may be a limiting factor for its use in energy generation, suggesting its use in smaller proportions when mixed with pine sawdust.

Table 3 illustrates that the fixed carbon content in Pinus sp. wood is twofold higher than that found in sewage sludge. This metric signifies the proportion of material that combusts in a solid state, rendering it well suited for energy production by facilitating sustained and consistent combustion [29]. Furthermore, Pinus sp. sawdust exhibits a superior volatile matter content compared to sewage sludge. Volatile matter combusts in a gaseous state, playing a crucial role in ignition during combustion processes. These findings underscore the advantageous properties of Pinus sp. wood, particularly in terms of its composition which is conducive to efficient energy generation. The elevated fixed carbon content ensures prolonged combustion, while the heightened volatile matter content enhances ignition efficiency, collectively contributing to the suitability of Pinus sp. wood as a viable feedstock for sustainable energy production endeavors [11].

The high ash content of sewage sludge compromises its use in briquette production (Table 3); this material is composed of minerals and does not combust, requiring removal after burning. This diminishes the boiler operation time and causes equipment wear. Therefore, to make its use feasible, lower proportions of sewage sludge need to be used in briquettes [30]. Standards require that the ash content in briquettes does not exceed 5%. Thus, the low ash content in pine sawdust allows briquettes to have approximately 8% sewage sludge in their composition. A high ash content was also reported for sewage sludge in China, between 33 and 62% [12].

The higher heating values were recorded at 20.35 and 14.64 MJ/kg for Pinus sp. sawdust and sewage sludge, respectively (Table 3). This metric reflects a direct correlation with elemental carbon and fixed carbon content, while exhibiting an inverse relationship with ash content. Consequently, Pinus sp. sawdust demonstrates a higher value in this regard, attributed to its favorable elemental carbon and fixed carbon compositions. Notably, the higher heating value observed in sewage sludge aligns with the previously reported literature, falling within the range of 8 to 21 MJ/kg [31]. This consistency underscores the reliability and relevance of the obtained results, consolidating the understanding of energy potential inherent in both Pinus sp. sawdust and sewage sludge. Such insights are pivotal for informed decision-making in energy generation strategies, emphasizing the importance of leveraging diverse biomass sources for sustainable and efficient fuel production [31].

4.2. Thermogravimetric Analysis

The TGA curve of the sample with 100% sewage sludge did not show pronounced thermal mass loss events and exhibited high thermal stability, losing only 36.7% of its mass at 950 °C (Figure 1). However, the DTG curve indicates the presence of complex reactive processes evidenced by multiple peaks with different T_max values (temperature at which the maximum decomposition rate occurs). The first peak, at a temperature of 77 °C with a mass loss of about 3.7%, can be attributed to the desorption of water and other volatile components present in the sludge [32]. The peaks at 236.2 and 434.3 °C are primarily associated with the decomposition of organic components and the decomposition of formed organic residues, respectively [32,33].

Finally, the large amount of remaining mass at the end of the test is attributed to the substantial ash content in the material (Figure 1). Due to being composed of minerals, these ashes do not undergo decomposition at the temperatures used in the tests [34]. Hameed et al. [35] also attribute the 130 to 430 °C range of the TGA curve to the reactions involving the decomposition of organic matter.

The TGA/DTG curve of the sample with 100% Pinus sp. sawdust showed a mass loss of about 2.4% with a peak at 49.4 °C (according to DTG), attributed to the removal of water adsorbed by the biomass (Figure 2). Subsequently, there is a pronounced thermal event with a mass loss of about 71.1% and Tonset (onset temperature extrapolated) and Tendset (end temperature extrapolated) equal to 275.9 and 367.9 °C, respectively. This is related to the thermal decomposition of the organic matter that the sawdust is composed of (decomposition of cellulose, hemicellulose, and lignins) [36]. This range corresponds to the decomposition of hemicellulose and cellulose, which are major components of wood. At 950 °C, 15.0% residue remained, mainly consisting of ashes [37].

The thermal profile of pure sludge (100% w/w) changed with the addition of sawdust, with its presence becoming more evident from the addition of 25% sawdust onwards (Figure 3). The addition of 5% and 15% sawdust did not result in significant differences in the thermal stability of the materials, resulting in a profile similar to that of the sludge. Briquettes with 25% and 35% sawdust exhibit intermediate characteristics between profiles with 100% sludge and 100% sawdust. From 65% sawdust onwards, the samples show a thermal behavior that is more similar to pure sawdust, with emphasis on the samples with 85% and 95% sawdust, presenting a residue percentage at the end of the tests that is lower than that of pure sawdust. This indicates a more efficient decomposition of sawdust in the presence of smaller amounts of sludge (15% and 5%, respectively).

The data described in Table 4 allow us to add to the discussion that the % H2O (and other more volatile components) increases as the sludge is added. This is expected since the sludge itself also contains these substances. Furthermore, it is observed that TmáxH2O, corresponding to the temperature at which the release of these components occurs, shifts towards values closer to those of pure sludge as the latter is added.

As for the Tonset of the main thermal decomposition event of the sawdust, although it varies slightly, its values are close to those obtained for pure sawdust. This fact is supported by the close values of Tmax for this event. However, the mass loss percentage of this event progressively decreases, following the reduction in the addition of the organic component of sawdust. It is also noteworthy that Tmax2 (corresponding to the decomposition of the organic component of the sludge and the release of water from its clayey components) emerges for almost all briquettes with less than 95% sawdust, confirming the mixture with sludge.

4.3. Briquette Evaluation

The addition of sewage sludge increased the energy density of the briquettes, with the treatment using 100% sewage sludge showing an energy density exceeding 20 MJ/m3, while the use of 100% pine sawdust generated an energy density close to 10 MJ/m3 (Figure 4). Energy density is given by the product of the material density and its higher heating value [38]. Although the higher heating value of wood is 20.3 MJ/m3 and that of sewage sludge is 14.6 MJ/m3, sewage sludge has a higher density, allowing for a greater mass in briquette formation and, consequently, a higher energy density of the material. Increasing briquette density is desired in the production process due to the associated rise in energy density and mechanical strength, reduced transportation costs, and minimized generation of fines [39,40,41].

5. Conclusions

The sewage sludge showed higher nitrogen and sulfur content, while pine sawdust presented higher carbon, hydrogen, oxygen, and C/H and C/N ratios. In the proximate analysis, the sludge exhibited a lower volatile matter content (35.51%) and fixed carbon content (3.75%) and higher ash content (60.74%), resulting in a calorific value of 14.8 MJ/g, which is lower than for Pinus wood 20.3 MJ/g. Sewage sludge demonstrated high resistance to thermal degradation, with no pronounced mass loss events. Meanwhile, pine sawdust exhibited a greater mass loss between 275.9 and 367.9 °C. The addition of sawdust between 5 and 15% altered the thermal stability of the material, and the addition of 25 to 35% sawdust resulted in behavior that was intermediate between samples with 100% sludge and 100% sawdust. From 65% sawdust onwards, the samples showed thermal behavior closer to the 100% sawdust sample. Finally, the addition of 85 to 95% sawdust, with a residue percentage at the end of the tests that was lower than that of pure sawdust, indicated a more efficient decomposition of sawdust in the presence of smaller amounts of sludge. Regarding the energy density of the briquettes, it was observed that with the gradual addition of sawdust, there was a proportional decrease in the energy density of the briquettes. The use of sewage sludge for briquette production is feasible; however, due to its high nitrogen, sulfur, and ash content, its use should be limited to 5% of the briquette composition.

Author Contributions

Writing—original draft preparation, A.B.P., A.J.V.Z., A.G.C. and S.d.O.A.; writing—review and editing, A.J.V.Z., V.R.d.C., A.d.C.O.C. and S.d.O.A.; investigation, A.B.P., M.V.F., M.B.-V. and S.d.O.A.; methodology, A.B.P., A.J.V.Z., A.M.M.L.C., R.M.N.d.A. and S.d.O.A.; formal analysis, A.J.V.Z., O.P.L., M.B.-V. and M.V.F.; supervision, A.J.V.Z., O.P.L. and S.d.O.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful to the Brazilian agencies “Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)” and “Fundação de Amparo à Pesquisa do Estado de Minas Gerais—FAPEMIG (APQ-03512-18)” and Portuguese agencie Fundação para a Ciência e a Tecnologia (FCT) through a research contract (DL57/2016/CPI382/CT0018) for scholarships and financial support.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated and analyzed during the current study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tabelini, D.B.; Lima, J.P.P.; Borges, A.C.; Aguiar, A. A Review on the Characteristics and Methods of Dairy Industry Wastewater Treatment in the State of Minas Gerais, Brazil. J. Water Process Eng. 2023, 53, 103779. [Google Scholar] [CrossRef]

- Urban, R.C.; Nakada, L.Y.K.; de Lima Isaac, R. A System Dynamics Approach for Large-Scale Water Treatment Plant Sludge Management: A Case Study in Brazil. J. Clean. Prod. 2023, 419, 138105. [Google Scholar] [CrossRef]

- Wu, X.; Nawaz, S.; Li, Y.; Zhang, H. Environmental Health Hazards of Untreated Livestock Wastewater: Potential Risks and Future Perspectives. Environ. Sci. Pollut. Res. 2024, 31, 24745–24767. [Google Scholar] [CrossRef] [PubMed]

- Ding, A.; Zhang, R.; Ngo, H.H.; He, X.; Ma, J.; Nan, J.; Li, G. Life Cycle Assessment of Sewage Sludge Treatment and Disposal Based on Nutrient and Energy Recovery: A Review. Sci. Total Environ. 2021, 769, 144451. [Google Scholar] [CrossRef]

- Hušek, M.; Moško, J.; Pohořelý, M. Sewage Sludge Treatment Methods and P-Recovery Possibilities: Current State-of-the-Art. J. Environ. Manag. 2022, 315, 115090. [Google Scholar] [CrossRef]

- Alejandra Ramírez-Ramírez, M.; Carrillo-Parra, A.; Ruíz-Aquino, F.; Fernando Pintor-Ibarra, L.; González-Ortega, N.; Orihuela-Equihua, R.; Carrillo-Ávila, N.; Luján-Álvarez, C.; Rutiaga-Quiñones, J.G. Evaluation of Selected Physical and Thermal Properties of Briquette Hardwood Biomass Biofuel. BioEnergy Res. 2022, 15, 1407–1414. [Google Scholar] [CrossRef]

- Solayman, H.M.; Hossen, M.A.; Abd Aziz, A.; Yahya, N.Y.; Leong, K.H.; Sim, L.C.; Monir, M.U.; Zoh, K.D. Performance Evaluation of Dye Wastewater Treatment Technologies: A Review. J. Environ. Chem. Eng. 2023, 11, 109610. [Google Scholar] [CrossRef]

- Sanka, P.M.; Snv, L.K.; Komakech, H.; Mandela, N.; Magambo, H. Production of Low Emission Briquettes from Faecal Sludge as an Alternative Source of Cooking Energy. Energy Sustain. Soc. 2023. [Google Scholar] [CrossRef]

- De Oliveira Brotto, J.; Cruz, T.A.; de Oliveira Pereira, I.; Ienczak, J.L.; Peralta, R.A.; Lázaro-Martínez, J.M.; José, H.J.; Rodríguez-Castellón, E.; Moreira, R.d.F.P.M. Mechanistic Insights and Kinetics of Torrefaction of Pine Wood Biomasses Using Solid-State NMR. J. Anal. Appl. Pyrolysis 2023, 172, 106019. [Google Scholar] [CrossRef]

- Gupta, A.; Dutt, B.; Sharma, S. Analysis of Chemical Properties of Thermally Treated Pinus Roxburghii Sargent Wood. Bioresources 2023, 18, 4598–4609. [Google Scholar] [CrossRef]

- Vieira, T.A.S.; Trugilho, P.F.; Carabineiro, S.A.C.; Zanuncio, A.J.V.; Carvalho, A.G.; Branco-Vieira, M. Impact of Chemical Composition on Eucalyptus Wood Clones for Sustainable Energy Production. Forests 2023, 14, 2240. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Wang, Y.; Qu, L. Predicting Higher Heating Value of Sewage Sludges via Artificial Neural Network Based on Proximate and Ultimate Analyses. Water 2023, 15, 674. [Google Scholar] [CrossRef]

- Marreiro, H.M.P.; Peruchi, R.S.; Lopes, R.M.B.P.; Andersen, S.L.F.; Eliziário, S.A.; Junior, P.R. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Montiano, M.G.; Díaz-Faes, E.; Barriocanal, C. Effect of Briquette Composition and Size on the Quality of the Resulting Coke. Fuel Process. Technol. 2016, 148, 155–162. [Google Scholar] [CrossRef]

- Cabrales, H.; Arzola, N.; Araque, O. The Effects of Moisture Content, Fiber Length and Compaction Time on African Oil Palm Empty Fruit Bunches Briquette Quality Parameters. Heliyon 2020, 6, e05607. [Google Scholar] [CrossRef] [PubMed]

- Obi, O.F.; Pecenka, R.; Clifford, M.J. A Review of Biomass Briquette Binders and Quality Parameters. Energies 2022, 15, 2426. [Google Scholar] [CrossRef]

- Ferronato, N.; Calle Mendoza, I.J.; Gorritty Portillo, M.A.; Conti, F.; Torretta, V. Are Waste-Based Briquettes Alternative Fuels in Developing Countries? A Critical Review. Energy Sustain. Dev. 2022, 68, 220–241. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Filleti, R.A.P.; Musule, R.; Matheus, T.T.; Freire, F. A Systematic Review and Life Cycle Assessment of Biomass Pellets and Briquettes Production in Latin America. Renew. Sustain. Energy Rev. 2022, 157, 112042. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating Values of Wood Pellets from Different Species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Rocha, S.; Soares, P.; Maia, L. Briquettes from Sludge in Sewage Treatment Plant: Calorific Power. Environ. Sci. Pollut. Res. 2022, 29, 91096–91104. [Google Scholar] [CrossRef]

- NBR8112; Carvão Vegetal Análise Imediata. ABNT: Rio do Janeiro, Brazil, 1986.

- NBR8633; Carvão Vegetal Determinação Do Poder Calorífico. ABNT: Rio do Janeiro, Brazil, 1984.

- Barzegar, R.; Yozgatligil, A.; Olgun, H.; Atimtay, A.T. TGA and Kinetic Study of Different Torrefaction Conditions of Wood Biomass under Air and Oxy-Fuel Combustion Atmospheres. J. Energy Inst. 2020, 93, 889–898. [Google Scholar] [CrossRef]

- Huang, Y.F.; Lo, S.L. Predicting Heating Value of Lignocellulosic Biomass Based on Elemental Analysis. Energy 2020, 191, 116501. [Google Scholar] [CrossRef]

- Güleç, F.; Pekaslan, D.; Williams, O.; Lester, E. Predictability of Higher Heating Value of Biomass Feedstocks via Proximate and Ultimate Analyses—A Comprehensive Study of Artificial Neural Network Applications. Fuel 2022, 320, 123944. [Google Scholar] [CrossRef]

- Arous, S.; Koubaa, A.; Bouafif, H.; Bouslimi, B.; Braghiroli, F.L.; Bradai, C. Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies 2021, 14, 6529. [Google Scholar] [CrossRef]

- Wang, T.; Rong, H.; Chen, S.; Zhou, Y.; Li, J.; Xiao, Y.; Xue, Y. TG- MS Study on in-Situ Sulfur Retention during the Co-Combustion of Reclaimed Asphalt Binder and Wood Sawdust. J. Hazard. Mater. 2021, 403, 123911. [Google Scholar] [CrossRef] [PubMed]

- Greco, G.; Videgain, M.; Di Stasi, C.; Pires, E.; Manyà, J.J. Importance of Pyrolysis Temperature and Pressure in the Concentration of Polycyclic Aromatic Hydrocarbons in Wood Waste-Derived Biochars. J. Anal. Appl. Pyrolysis 2021, 159, 105337. [Google Scholar] [CrossRef]

- Riaz, S.; Al-Abdeli, Y.M.; Oluwoye, I. Partially Oxidative Torrefaction of Woody Biomass Pellets: Burning Behaviour and Emission Analysis. Bioenergy Res. 2023, 16, 2331–2341. [Google Scholar] [CrossRef]

- De Souza, E.C.; Gomes, J.P.S.; Pimenta, A.S.; de Azevedo, T.K.B.; Pereira, A.K.S.; Gomes, R.M.; Brito, J.O.; Dias Júnior, A.F. Briquette Production as a Sustainable Alternative for Waste Management in the Tannin Extraction Industry. Environ. Sci. Pollut. Res. 2023, 30, 18078–18090. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Phuleria, H.C.; Chandel, M.K. Estimation of Energy Recovery Potential of Sewage Sludge in India: Waste to Watt Approach. J. Clean. Prod. 2020, 276, 122538. [Google Scholar] [CrossRef]

- Dahhou, M.; El Moussaouiti, M.; Benlalla, A.; El Hamidi, A.; Taibi, M.; Arshad, M.A. Structural Aspects and Thermal Degradation Kinetics of Water Treatment Plant Sludge of Moroccan Capital. Waste Biomass Valorization 2016, 7, 1177–1187. [Google Scholar] [CrossRef]

- Yaras, A.; Demirel, B.; Akkurt, F.; Arslanoglu, H. Thermal Conversion Behavior of Paper Mill Sludge: Characterization, Kinetic, and Thermodynamic Analyses. Biomass Convers. Bioref. 2023, 13, 2007–2016. [Google Scholar] [CrossRef]

- Xu, X.; Pan, R.; Chen, R. Combustion Characteristics, Kinetics, and Thermodynamics of Pine Wood Through Thermogravimetric Analysis. Appl. Biochem. Biotechnol. 2021, 193, 1427–1446. [Google Scholar] [CrossRef] [PubMed]

- Hameed, Z.; Naqvi, S.R.; Naqvi, M.; Ali, I.; Taqvi, S.A.A.; Gao, N.; Hussain, S.A.; Hussain, S. A Comprehensive Review on Thermal Coconversion of Biomass, Sludge, Coal, and Their Blends Using Thermogravimetric Analysis. J. Chem. 2020, 2020, 5024369. [Google Scholar] [CrossRef]

- Apaydın Varol, E.; Mutlu, Ü. TGA-FTIR Analysis of Biomass Samples Based on the Thermal Decomposition Behavior of Hemicellulose, Cellulose, and Lignin. Energies 2023, 16, 3674. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M. Thermogravimetric Study of Biomass, Sewage Sludge and Coal Combustion. Energy Convers. Manag. 2013, 75, 425–430. [Google Scholar] [CrossRef]

- De Sousa Oliveira, R.; Santos, L.T.V.; Melo, S.C.; Chagas, M.P.; Ribeiro, D.; Reis, C.A.F.; Novaes, E.; Sette, C.R. Wood Energy Yield for Eucalyptus Clones Growing under Seasonal Drought-Stress in Brazil. Biomass Bioenergy 2021, 154, 106264. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Effect of Species, Particle Size and Compacting Pressure on Relaxed Density and Compressive Strength of Fuel Briquettes. Int. J. Energy Environ. Eng. 2013, 4, 30. [Google Scholar] [CrossRef]

- Antwi-Boasiako, C.; Acheampong, B.B. Strength Properties and Calorific Values of Sawdust-Briquettes as Wood-Residue Energy Generation Source from Tropical Hardwoods of Different Densities. Biomass Bioenergy 2016, 85, 144–152. [Google Scholar] [CrossRef]

- Granado, M.P.P.; Suhogusoff, Y.V.M.; Santos, L.R.O.; Yamaji, F.M.; De Conti, A.C. Effects of Pressure Densification on Strength and Properties of Cassava Waste Briquettes. Renew. Energy 2021, 167, 306–312. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).