Abstract

The goal of this study was to determine the impact of business process automation on the performance of manufacturing companies in Saudi Arabia through the use of a specially designed questionnaire that covered 301 senior employees of the operations, production, and information technology departments in these companies. This research focused on the use of automation in manufacturing companies and its impact on sustainability, operational performance, and institutional performance, including the impact of automation on profitability. The results reflect the status of automation in the Saudi manufacturing market. We observed a strong trend towards automation and this contributes to enhancing profitability, increasing the market share of companies, raising efficiency and productivity, and achieving sustainability. These results were obtained through regression and correlation analysis. The agreement of the survey participants with the data related to automation reflects the relative importance of automation in the Saudi market, shows the positive relationship between automation and performance development, and opens the door to further studies in other sectors or countries.

1. Introduction

Companies today are concerned with their competitive position relative to other competing companies, especially when designing their internal operations [1]. It is no longer possible for companies to be satisfied with local markets. As a result of globalization in the economy and business, it has become necessary for companies to keep pace with this development to succeed in their field of work and to ensure the sustainability of their activities. Therefore, companies that do not respond to market requirements will quickly exit the competition, and one of the most critical current requirements for them is to restructure operations to achieve a distinct competitive position [2]. Because companies want to develop their competitive capabilities, they have applied various techniques such as quality management, the balanced scorecard, re-engineering procedures and other operational tactics which aim to enhance their performance and maintain their competitive position and sustainable work [3].

Many companies today are trying to find new methods to manage change better, which has led to the emergence of the business process engineering BPR concept and its widespread adoption among companies. This concept includes many significant changes such as entirely new processes and changes in performance indicators KPIs [4]. All of this is considered essential for the success of companies in a competitive business environment, mainly since companies contribute to building strategic and competitive relationships, which improves the quality of activities and operations [5].

Today, many companies in various countries rely on systems based on information technology and computer software to a large extent. In the Kingdom of Saudi Arabia, a unique vision has been developed for the country. Vision 2030 motivates companies to adopt automation and information technologies more widely to improve their performance and achieve sustainability in their business. According to [6], companies can build and maintain a competitive advantage by examining the relationship-shifting patterns of competitive rivalry and the emerging structure of the volatile but growing information technology industry. This concept was driven by factors such as the existence of competitive sets of companies from three perspectives: research analysts, competitive suppliers, and service customers. The first perspective builds on and applies previous work in strategic groups, mobility barriers, and firm competencies. The second perspective is practical and depends on practising managers’ perceptions of the competitive environment. The final perspective is based on field research in customer organizations and is rooted in the idea that supplier differentiation will only emerge as a competitive advantage when it aligns with customer needs.

Researchers have categorized processes by different levels of technology into automated, mechanical, and manual processes [4]. In manual and mechanical processes, there is usually a form of human control in the operations; however, they have the disadvantage of high unit costs and low output. Their requirement for human involvement leads to these processes needing to be faster. They also have variability in quality, which is why many companies embrace automation to overcome the problems of mechanized and manual processes. Many organizations have noted that automating their processes mainly aims to enhance operational performance.

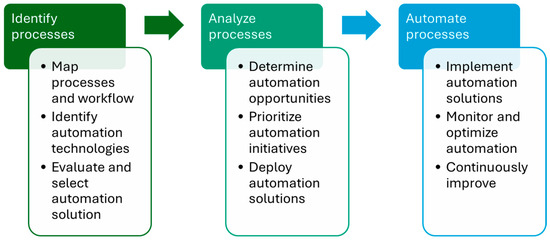

We can define business process automation as the use of technology to automate business processes, increasing simplicity, digital transformation, service quality, and cost containment. Some of the critical components include integrating applications, restructuring labor resources, and utilizing software applications organization-wide. Please see the following graph (Figure 1):

Figure 1.

Business process automation.

According to [7], operational performance is the firm’s performance that is usually measured based on the prescribed indicators or standards of efficiency, effectiveness, and environmental responsibility. Operation performance is mainly determined by five main performance objectives: flexibility, cost, dependability, speed, and quality. These have been arrived at from the perspectives of different stakeholders, including shareholders, customers, society employees, and society. Automation is one of the approaches recommended for many manufacturing companies to improve operational performance. Hence, this study will seek to help understand the effect of business process automation on the operational performance of manufacturing firms in Saudi Arabia.

In the last decade, the manufacturing sector has become a critical area for Saudi Arabia, which has been investing in economic diversification in line with the vision of 2030. The manufacturing sector is expected to help create more employment and revenue for the nation [8]. However, as a developing sector and developing nation, the sector has been facing rising market uncertainty and price fluctuation. This has led to calls for the implementation of intelligent measures for manufacturing processes. Faced with unpredictability in the market and the need to improve productivity and profits, management has been investing in automating their processes as a strategic move.

The initiation of Industry 4.0 in Saudi Arabia (KSA) is marked by a multifaceted approach aimed at bolstering the country’s industrial sector and driving economic growth in alignment with Vision 2030 objectives. The key aspects include substantial investments in infrastructure development tailored to industrial cities, coupled with the provision of industrial development funds and incentives. Additionally, Saudi Arabia has forged a strategic partnership with the World Economic Forum (WEF) to pioneer Industry 4.0 applications and mechanisms. Notably, the commitment is evidenced by plans to significantly increase the number of facilities benefiting from Industry 4.0 stimuli. Moreover, the nation is focused on enhancing technical infrastructure readiness by 50% through digitally enabled projects spanning mining, industry, logistics and energy, supported by a substantial USD 453 billion fund allocation. This comprehensive strategy underscores Saudi Arabia’s dedication to embracing cutting-edge technologies and fostering a dynamic industrial landscape conducive to sustainable economic advancement [9,10,11].

As mentioned, Saudi Arabia continuously invests in the manufacturing sector in line with Vision 2030. However, having depended on the oil economy for many years, many companies are still in their growth stage and, hence, in the automation process, although many have yet to achieve full automation [10]. As aforementioned, automation is one of the approaches used to enhance operation performance objectives. The study by [5] concludes that technological improvements are also known to give businesses a competitive edge by improving quality, cutting costs, boosting efficiency, and giving them more ways to process information. Therefore, a study of the operating performance of manufacturing companies in the KSA regarding their quality, speed, and cost performance goals would show whether or not business process automation has helped them. However, despite the growing significance of the manufacturing companies in the KSA, there are limited empirical studies on the effectiveness of the automation processes and how they affect a company’s operational performance. The manufacturing sector presents an excellent opportunity for the KSA to meet its vision 2030 of economic diversification [12]. Given this, the sector is an essential choice for this study of automation outcomes. A study of the companies’ operational performance will also help to determine whether automation has growth benefits for manufacturing companies. Also, even as many manufacturing companies adopt automation, many face challenges in becoming highly competitive in offering quality products and meeting demand; hence, this study will seek to establish the effect of business process automation on the operational performance of manufacturing companies.

2. Literature Review

2.1. Business Process Automation

Automation is generally described as using information technologies and control systems so that production becomes less dependent on human labor. According to the study by [13] on “Understanding the implications of digitization and automation”, automation is the next step up from machinery in industrialization. Researchers have agreed that mechanization gives people machines that help them with the physical parts of their jobs. Automation reduces the need for people’s labor, such as physical work.

Over the last two decades, Automation has become more critical to the world economy and modern organizations. Ref. [14] describes automation as a broad process that includes all machines and devices used in the manufacturing process that are supposed to replace humans or replace machines directly operated by humans. According to Refs. [15,16], automation consists of machines controling business processes within companies, so the basic concept of automation is a technological change that allows these machines to operate themselves with minimal human intervention. Thus, most of the literature believes that automation is the most advanced technical method and that it improves production outcomes while reducing costs. In reviewing the literature, it was found that there are different types of automation, including:

Industrial Automation (IA) is a modern type of automation for industries that use robots in their operations [15]. Today, robots are being used extensively in industrial companies, especially to carry out dangerous work that requires great effort, which facilitates the work of the human element in these industrial companies.

Robotic process automation (RPA): Programs and software are used to improve the performance of organizational processes and perform tasks and activities of a high degree of complexity. According to [16], a study on “The Fourth Industrial Revolution”, these programs and software can play essential roles in sensitive and critical tasks such as processing customer orders quickly, effectively, and efficiently.

Intelligent process automation (IPA): This type of automation depends on using artificial intelligence to learn and understand how to simulate the interaction between a human on the one hand and a computer on the other hand, aiming to provide intelligent results. In his study, Ref. [17] noted that this type of automation is used in companies where computers carry out adaptation, change, and even experimentation and correction processes intended to simulate human behaviour. The goal is always to bring artificial intelligence to the level of producing products with a highly competitive advantage and the least possible amounts of inputs [17]. These changes in the production sector have significantly improved productivity. However, at the same time, they have led to reductions in traditional jobs as companies have begun to dispense with traditional employees and replace them with machines or artificial intelligence.

Business process automation (BPA): This is described by [16] as an organized process of using automation to improve the efficiency and effectiveness of business operations by designing a working system that includes all the functions and tasks that ensure the company performs its work better, in various fields such as accounting, control, human resources, logistics services, etc. This type of automation helps replace many administrative employees in companies, simultaneously helps raising the level of operations and making them more efficient. At the same time, it allows companies to perform various tasks from anywhere in the world and accelerates delivery to customers.

2.2. Operational Performances

Major changes are taking place in the Kingdom of Saudi Arabia as the new government has been interested in introducing change and development to the local economy [10]. In general, automation in the Kingdom contributes significantly to increasing workers’ well-being and improving work efficiency. Researchers have noted that it is positively associated with dimensions of organizational performance [18]. For a manufacturing company to reach its goals, Ref. [10] states that its processes should be efficient and effective for continuous improvement and development.

According to [19], effectiveness is the ability to meet customer needs, while efficiency is the company’s ability to use its resources efficiently. Researchers have noted that developing correct methods for measuring performance is very important for developing and improving operational performance.

Ref. [20] defined operational performance as including the measurable parts of a company’s activities and operations. Their study covered many aspects, such as defect rates in production, delivery time, cost of quality, and inventory management. Ref. [21] also supports this; these authors defined operational performance within the supply chain as the degree to which operations function well. Their study used supplier performance, customer satisfaction, costs, and delivery time to measure operational performance and efficiency.

From the previous definitions, we note that it is important for companies to be able to develop ways and means to measure their performance. According to [22], measuring performance is about giving a numerical value to the extent of efficiency and effectiveness of the company in a specific process or function, and therefore, measuring efficiency and effectiveness is an essential part of the core management of any company.

In a study by [23], several researchers identified the uses of Total Quality Management (TQM) practices and their impact on the operational performance of quality management and warehouse management in 364 Australian companies. The results indicated that teamwork and respect for people are the most important factors among the total quality factors. The researchers also noted a positive relationship between comprehensive quality and developing operational performance.

In general, when any business process is automated, the main goal is to improve it and increase its success rate, which is called efficiency [19]. Porter’s production maintenance method has been proposed to eliminate six basic types of losses: low yield during the entry period, process defects, slow speed of work, minor stops, adjustment operations, and malfunctions of machinery and equipment [24]. The more efficient something is, the fewer inputs are required to achieve a certain outcome. Many researchers believe re-engineering and automating processes will increase a company’s production efficiency and profitability. Automation can be considered one of the important engines for raising the performance level of industrial companies in the Kingdom of Saudi Arabia [2,8]. Re-engineering is essential to developing a company’s work to become more effective and efficient. This aims to achieve business processes that work in harmony with each other to add real value [3]. Although one of the most important goals of re-engineering is to reduce waste, increase efficiency, and reduce prices, as a study by [2] shows, re-engineering and automating business processes will, at the same time, help companies eliminate old ways of working in order to reach high levels of success.

2.3. Automation, Information Technology and Operational Performance

The literature usually shows a high correlation between automation and information technology as automation mainly relies on information technology, and some studies even use the terms automation and information technology interchangeably. According to [14], it is necessary to use different tools to benefit from automation, such as computers and business software, as well as networking and storage systems, to facilitate communication and the flow of information between all units of the organization and ensure that automation achieves its goal by reducing costs and improving quality. Increased outputs and, indeed, increased customer satisfaction, lead to higher business profitability in the long term.

Ref. [25] addressed the role of automation in the hospitality industry and identified its benefits in the hotel and services sector. The most important of these benefits were raising the efficiency of the sector in general and reducing costs, which led to the flow of investments to this sector. The researchers also focused on the importance of automation in raising customer satisfaction and building a positive personal relationship with them.

Many companies worldwide, even in developing countries, depend on automation and information technology due to their many benefits. For example, the study conducted by [26] notes that, on average, 5% of Africa’s GDP was due to the automation of industrial processes, and the percentage varies in different African countries, reaching 8% in Tanzania. Many economies have been growing because the manufacturing sector has changed owing to IT and business process automation. The research by [26] has shown that many manufacturing industries in Africa and other developing nations are trying to use new technology to turn the country’s manufacturing industry economy into a competitive and dynamic semi-industrial economy by 2025. The study showed that automating manufacturing processes improves production capacity, which is the most important factor in the manufacturing industry’s performance.

The study by [27], “A survey on lean manufacturing implementation in a selected manufacturing industry in Iran”, reported that at the time of the survey, the nation had low levels of automation technology in its manufacturing industries, which made it hard for those industries to perform well. Compared to many industrialized nations, such as the US, which have highly adapted business process automation in their manufacturing companies, the developed nations perform well in these sectors. The research also noted that nations highly invested in business process automation have less pressure to achieve economies of scale.

Studies indicate that business process automation enhances operational performance, yet research in the context of Saudi Arabia is lacking. However, scholars demonstrate that automation fosters manufacturing performance and national development worldwide by reducing costs and increasing productivity.

2.4. Sector Awareness of Benefits and Costs of Business Process Automation

As shown in the studies reviewed above, business process automation in the manufacturing sector has been growing over the years. Hence, in the study titled “Understanding the implications of digitization and automation in the context of Industry”, Ref. [13] noted that it is expected that the owners and employees working in the sectors should be aware of the business process automation, its impact and how it helps in performance and cost reduction. The study showed that AI or the use of machines in the manufacturing industry has been seen as positive in both financial and non-financial terms, so staff or industry owners should know the benefits and costs of using them.

According to [26], when buying new machines and investing in business process automation, business owners should consider the costs, including the financial costs, installation costs, software update costs, and the cost of teaching their workers. According to [8], industrial growth in Saudi Arabia has been one of the main ways the country has tried to catch up to other developed countries in terms of GDP and output in its efforts to diversify the economy. The KSA manufacturing sector and oil and gas production use automation machines in the workplace to improve industrial performance and help the country’s GDP growth. The vision for 2030 is designed to help the KSA develop an effective plan for industrializing so that the country can grow. This means the government is trying to boost the country’s gross domestic product (GDP). Awareness of this is important because it will help people understand the benefits of automation for the country and the manufacturing sector, which is crucial for the economy. The findings of the reviewed studies show that knowing the benefits and costs of business process automation in the manufacturing industry is very important. As [28] noted, staff awareness will help lay the groundwork for future innovation by building a solid foundation of operations-based skills and abilities within businesses.

2.5. Summary

As [16] described, automation involves using machines to replace human labor and control various tasks, impacting sectors like manufacturing. Different types, such as industrial automation and robotic process automation, have been identified by researchers [2]. While some scholars like [29] argue that automation leads to unemployment, others such as [30] highlight its role in enhancing production quality and global competitiveness. Despite concerns about job losses, automation remains vital for growth in the manufacturing sector.

3. Methodology

3.1. Research Approach

A quantitative approach was chosen for this study. Digital data are collected and analyzed statistically to obtain results, and then the results are generalized. This approach, as described in the book by [31], “Introduction to Quantitative Research Methods”, is considered the best for achieving our research objectives as it allows for the collection of digital data related to automation and its impact on the performance of companies in the Kingdom of Saudi Arabia, and thus allows for statistical analysis through which we can identify relationships and patterns within the data.

3.2. Research Design

This study used a descriptive approach. It is assumed that this approach, as ref. [32] indicates, describes and summarizes phenomena and characteristics without influencing or manipulating them. Ref. [33] suggests that descriptive research be used to study phenomena and ensure the accurate representation of society. Therefore, a descriptive approach was used in this study to determine the extent of automation used by manufacturing companies in the Kingdom of Saudi Arabia.

3.3. Target Population

The target population of this study is employees in operations departments, production departments, or information technology departments in industrial companies in the Kingdom of Saudi Arabia as these employees are the most knowledgeable about automation activities and their role in operational activity in companies. The research focused on a sample of 301 employees, an appropriate and sufficient number to determine the prevailing general opinions in the automation field and make a high-confidence generalization.

3.4. Sampling Technique and Sample Size

As we explained above, the sample in this study included participants who work in production, operations, or information technology departments in Saudi industrial companies. As mentioned in the study by [34], such targeted samples can provide an adequate point of view. Regarding the research topic, the larger the sample size, the more representative it is of society. Setting the sample size for this research at 301 was considered sufficient and is a similar sample size to those used in other similar studies.

3.5. Data Collection Process

Data were collected online by distributing the questionnaire to participants via email or social media. Participants were provided with clear instructions on how to fill out the questionnaire. In addition, the reminders sent and the follow-up with the participants ensured a high response rate. A five-point Likert scale was adopted. The questionnaire consisted of a section collecting the demographic data of the participants, a section on automation in industrial companies, and a final section including statements about the performance of these industrial companies. The survey design ensured consistency in the data collection by providing standardized questions and consistent answer options.

Reliability is the stability and consistency of the research instrument, while validity refers to the accuracy and suitability of the research instrument in measuring the required variables [35]. The questionnaire’s reliability and validity were confirmed by testing and validation on a relatively small sample of 10 persons to identify any ambiguities or problems related to the wording, formatting, or answer options. A test-retest reliability analysis was conducted to ensure that the questionnaire was performed. The questionnaire was also submitted to an academic supervisor for review and correction based on his comments and feedback to achieve consistent results.

3.6. Data Analysis

After completing the data collection process, the data were first cleaned to ensure accuracy and to delete incorrect answers or incomplete questionnaires. The data were then coded. Descriptive and inferential analyses were conducted. Descriptive statistics were used to summarize the quantitative data collected and presented in the form of frequencies, cumulative frequencies, percentages, and graphs, while descriptive analysis provided a quick overview of the data, facilitating the identification of patterns and trends. After completing the descriptive analysis, regression and correlation analyses were conducted to examine the relationship between automation and the companies’ performance, where the correlation analysis shows the strength and direction of the relationship between the various variables. In contrast, the regression analysis helps examine the impact of automation on companies, and both analyses allow us to obtain meaningful results from the data collected.

3.7. Ethical Considerations

According to the recommendations of [36], it is necessary to give high priority to ethical considerations in preparing research. Ethical practices were followed during the questionnaire stage in particular and in all steps of preparing this research in general. The participants were informed about the questionnaire and the research, and their consent was obtained prior to their participation. No private or confidential information was requested, and the particpants were assured that their privacy would be preserved, thus ensuring respect for the freedom of the participants and the protection of their information and privacy.

Furthermore, the contributions of the authors and other researchers to the study were acknowledged, ensuring that this ethical aspect of this study was taken into account. In addition to the above, it was confirmed that the involvement of the participants was voluntary, and they were assured that the data would be collected for academic purposes only.

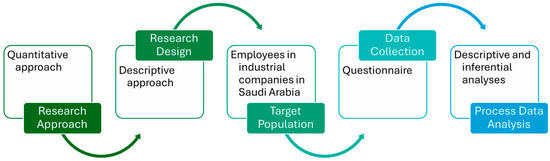

The following graph (Figure 2) illustrates the methodology steps:

Figure 2.

Research Methodology.

4. Results and Findings

4.1. Demographic Background

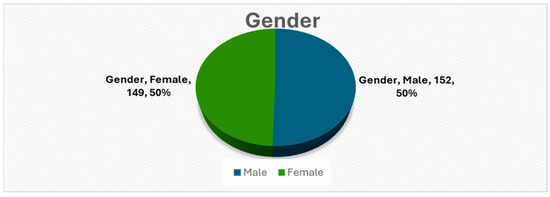

Figure 3 below shows that 50.5% of the respondents in the study were male, while 49.5% were female. The results show no significant gender differences and are unlikely to be gender biased.

Figure 3.

Gender.

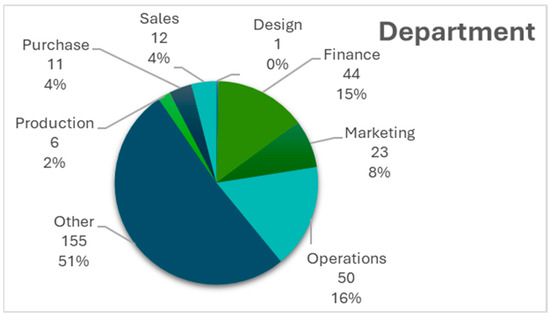

Figure 4 below shows the respondents’ departments: 50.8% in other departments, 16.9% in design, 14.3% in finance, and 7.6% in marketing. Additionally, respondents from operations, sales, HR, and purchase were included, ensuring representation across various departments. The department classifications were chosen based on the target sample of companies.

Figure 4.

Department classifications of respondents.

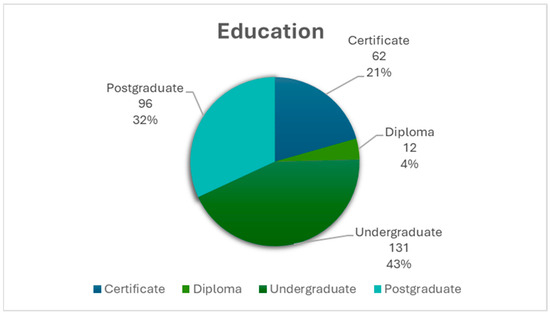

Figure 5 below illustrates the respondents’ education levels, with 43.5% undergraduates, 32% post-graduates, 20.6% holding certificates, and 4% with diplomas, indicating a well-educated sample that is likely knowledgeable about the study topic. The classifications of educational levels were chosen based on the classifications approved in Saudi Arabia.

Figure 5.

Education levels of respondents.

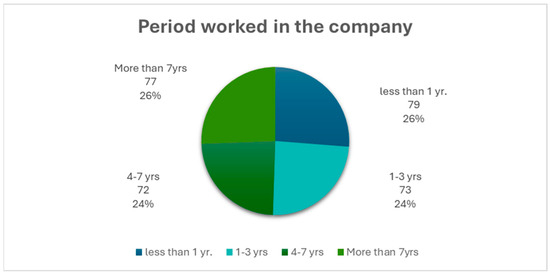

Figure 6 displays the respondents’ tenure at their company, with 26.2% employed for less than one year, 25.6% for over seven years, 24.3% for 1–3 years, and 23.9% for 4–7 years. On average, the respondents had worked for more than four years, indicating their familiarity with automation-related company changes. The “Period worked in the company” classifications were chosen based on the average job turnover in Saudi companies.

Figure 6.

Period worked in the company.

4.2. Descriptive Analysis

4.2.1. Automation Used

In regard to automation used in the manufacturing companies, Table 1 below shows that the respondents agreed with all the statements as follows: “Automation has become an integral part of the company manufacturing process in the firm” (mean = 4.1196), “The company uses Business Automation to improve the quality of products, services, or operating in the company” (mean = 4.1628), “The company plans to invest in business automation technology in the next year” (mean = 4.0698), “The company uses automation in managing its manufacturing operations” (mean = 3.7741), “The company uses automation in planning its inventories” (mean = 3.7674), “The company uses automation in planning its inventories” (mean = 3.7674), “Business automation has replaced human labor in the manufacturing operations of the company” (mean = 3.4452), and “The company has invested in Business automation technology in the past one year” (mean = 3.9236). These results suggest that the manufacturing companies in the study have embraced automation in different areas.

Table 1.

Automation used: descriptive statistics.

4.2.2. Impact on Corporate Performance

Table 2 below shows what the respondents think regarding how automation has affected the performance of their companies. The data show that the majority of the respondents in the survey agreed with the following statements: “Automation has improved efficiency of our operations” (mean = 4.1528), “Automation has increased the profitability of the company” (mean = 3.9070), “The automation has increased the employees’ productivity” (mean = 3.7209), “Automation has increased customers’ satisfaction” (mean = 3.8904), “Automation has increased the innovation of the company” (mean = 3.9834), and “Automation has improved market share of the company” (mean = 3.7375). According to the results of descriptive studies, it is clear that automation has an essential role in improving the performance of companies in terms of efficiency, profitability, productivity, customer satisfaction, innovation, and increasing market share.

Table 2.

Impact on corporate performance: descriptive statistics.

4.3. Correlation Analysis

Correlation analysis is a statistical procedure used to measure the strength and direction of a relationship between two factors. In the context of this study, correlation analysis was used to examine the connection between automation and the corporate performance of the firms in the manufacturing sector. The correlation coefficient is shown to be r = 0.689 as in Table 3, which indicates that there is a moderately strong and positive relationship between automation and corporate performance. Its p-value is 0.000, which means this correlation is significant due to a priori set alpha of 0.05. Therefore, the correlation was found to be statistically reliable and positive, which means that the development of automation in enterprises positively affects their performance.

Table 3.

Correlations.

4.4. Regression Analysis

Regression analysis was used to understand and quantify the relationship between automation and corporate performance. Table 4 below shows the model summary, showing an R-squared of 0.475. This indicates that about 47.5% of the variability in the corporate performance of manufacturing companies in the KSA can be attributed to the automation variable.

Table 4.

Model summary.

Table 5 below shows the ANOVA model. The p-value is 0.000, which is less than 0.05. This indicates that the model is statistically significant and that automation has a significant effect on predicting the corporate performance of manufacturing companies.

Table 5.

ANOVA a.

Table 6 below shows the coefficients used to represent the anticipated impact of automation on company performance when other factors are held constant. The data show that for automation, B = 0.674, with a p-value of 0.000 (less than 5). This shows that for a unit increase in automation levels in KSA manufacturing companies, there is an associated 0.674 unit increase in corporate performance. The p-value of 0.00 shows a significant relationship between automation in KSA manufacturing companies and their corporate performance.

Table 6.

Coefficients.

5. Discussion and Conclusions

5.1. Discussion

Establihing the extent to which automation is used in the operations of Saudi Arabian manufacturing companies.

The first goal of this study is to determine the extent of the use of automation in the operations and activities of Saudi industrial companies. The descriptive data provided showed that most respondents agreed that automation is an integral part of the operation (mean = 4.1196), and that they use it in managing their manufacturing operations (mean = 3.7741). There was also agreement among the respondents on the necessity of using automation in the planning process for warehouses, using it to replace human labor, and the necessity of permanent investment in automation. These findings indicate the widespread adoption of automation in Saudi industrial companies and are consistent with a study by [14], which explained that automation has become very important for different economies and modern companies. This is consistent with the Kingdom of Saudi Arabia’s adoption of technology to achieve Vision 2030, and of course, automation raises the level of services and sustainable performance in general. This is what ref. [6] indicated: the use of information technology has become necessary for all companies that seek to remain competitive in a highly competitive market. In order to deal effectively with intense competition in markets and to obtain a competitive advantage, industrial companies must invest more in automation in order to improve production, increase operational efficiency, and at the same time, they must improve quality and raise productivity. Overall, it can be concluded that the industrial sector in the Kingdom has become more automated.

Determining the effect of business process automation on the operational performance of manufacturing companies in Saudi Arabia.

The second goal of this study was to determine the impact of automation on the operational performance of industrial companies. The correlation analysis showed a moderate relationship, r = 0.689, while the regression analysis showed a coefficient value (B) of 0.674, which means that automation positively affects operational performance. Moreover, returning to the descriptive statistics, the participants in the questionnaire agreed that automation had improved their performance, and this is consistent with the study by [14], which states that automation through the application of information technology technologies makes the business sector more productive. It also supports reducing costs and improving production quality. At the same time, it increases customer satisfaction, improves business profitability in the long term, and certainly improves operational performance. Also, Ref. [26] noted that many manufacturing industries in developing countries use modern technologies, which help transform the production in these manufacturing industries into an industrial pattern, but it is competitive and dynamic, and therefore, automation contributes to improving production capacity and sustainability.

Establishing the impact of business process automation on corporate performance.

The descriptive analysis shows that the respondents of this study agreed that “business process automation has improved efficiency in their firms (mean = 4.1528), “business process automation has increased profitability” (mean = 3.9070), “business process automation has increased employees’ productivity” (mean = 3.7209), “business process automation has increased customers satisfaction” (mean = 3.8904), “business process automation has increased the innovation” (mean = 3.9834) and “improved market share” (mean = 3.7375). Correlation analysis has confirmed a positive relationship between automation and performance, and this is consistent with the results of some studies, such as [14,25,37]. All of these studies reported that the positive role of automation in various operational and administrative aspects leads to improved performance.

Determining the benefits of automation in Saudi Arabia’s industrial companies and whether they exceed costs.

The fourth objective of this study was to determine the benefits of automation for Saudi industrial companies. Descriptive statistics indicated largely positive perceptions among the questionnaire respondents regarding the benefits of automation. The most significant focus was improving efficiency, with an average of 4.1528, followed by increasing innovation, with an average of 3.9834, and then increasing profitability, with an average of 4.1528. The figure of 3.9070 is the increase in customer satisfaction, with an average of 3.8904. These results indicate generally positive perceptions of the benefits of automation in the manufacturing sector, which is consistent with other studies. Ref. [8] has also shown that improving performance through improved output and lowering costs from automation has been critical to the KSA manufacturing sector. In general, as the statistical analysis showed, the benefits of automation are more significant than its costs [25].

5.2. Managerial Implications

The results of this study are important to many stakeholders. Managers and executives in Saudi manufacturing companies can use them to develop their companies’ businesses as their knowledge of the positive impact of automation will be an incentive for them to introduce more automation. It can also be recommended that automation be introduced into all industrial companies in Saudi Arabia, regardless of the size of the companies so that automation becomes an integral part of the activity of any manufacturing company. At the same time, a portion of the companies’ capital and retained earnings should be allocated in order to achieve a good level of automation. Decision-makers should also pay attention to the importance of integrating automation decisions into the company’s long-term strategies, and this is another very important aspect for companies and their decision-makers. Emphasis should also be placed on the importance of innovation in companies as the development of automation is usually accompanied by an expansion of innovation. On the other hand, automation trends in Saudi Arabia can be supported by the government through the enactment of legislation and laws that encourage automation and the provision of facilities for that purpose. At the same time, consideration must be given by the government to employment and unemployment rates as automation is typically associated with the reduction in the number of workers in industrial companies. Suppliers who deal with industrial companies can also benefit. Saudi manufacturing companies benefit from this research with the increased availability of high-tech products and means of production. Automation will also contribute to achieving a higher level of sustainability, which is consistent with the Kingdom of Saudi Arabia’s Vision 2030. At the same time, this study highlights the need for the Saudi government to deal effectively with employment problems associated with the increasing use of automation by directing education and training towards advanced technical fields.

5.3. Theoretical Implications

This paper provided empirical evidence on the positive effects of automation on performance in companies, and thus enriches areas of knowledge and provides a basis for other future research that addresses the impact of automation in the Saudi market in particular and in the GCC market in general. Also, highlighting the importance of automation in business is an important aspect that enriches research on sustainability. This study also covers the integration of technological progress with business strategies, and at the same time addresses the state of innovation and work efficiency in the context of developing economies. All of this provides a high theoretical value to this paper.

5.4. Limitations

The methodology and the results of this research were of high value. Still, future studies can discuss many other aspects of this research by using mixed methods to obtain quantitative and qualitative data. It is possible to enhance the conceptual or mathematical models, and future research should also be based on stratified samples. To ensure that all business sectors are included in the study and that quantitative data can be supplemented with other qualitative data through other data collection methods such as interviews or focus groups, we also recommend the inclusion of additional control variables such as company size, industry, or location to account for potential confounding factors. Also, the impact of automation on unemployment rates is an important topic that can be covered in the future in any research, whether at the level of Saudi Arabia or at the level of other countries.

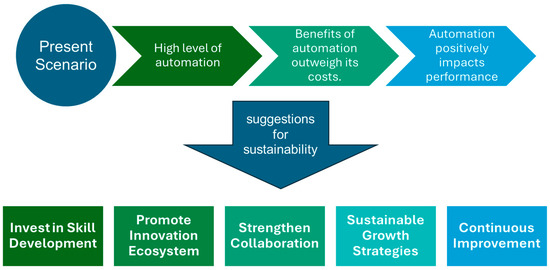

6. Conclusions

The primary objective of this study is to determine the impact of automation on the performance of manufacturing companies in the Kingdom of Saudi Arabia:

- The results of this study have shown that automation has an important role in improving performance as companies operating in the manufacturing sector in the Kingdom of Saudi Arabia were able to improve their performance in the dimensions of profitability, market share, operational efficiency, and productivity.

- The study showed that there is a high level of automation application in manufacturing companies in the Kingdom of Saudi Arabia

- Based on statistics, regression, and correlation analysis, it can be concluded that automation positively impacts the performance of manufacturing companies in the Kingdom of Saudi Arabia.

- The study showed that the benefits of applying automation in Saudi manufacturing companies exceed its costs or burdens, and this reinforces the relative importance of applying automation in this sector.

- It is necessary to constantly think about improving employment, along with developing automation. This can be achieved through training in the skills necessary to deal with and integrate with automation, as well as promoting entrepreneurship and innovation.

Please see Figure 7 to see the main suggestions for sustainability as a main recommendation of this paper.

Figure 7.

Gear Up for Development.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data used to support the findings of this study are available from the author upon request.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Hayes, R.H.; Upton, D.M. Operations-based strategy. Calif. Manag. Rev. 1998, 40, 8–25. [Google Scholar] [CrossRef]

- Aljuhani, N.; Alshahrani, F.; Alharbi, A.; Aldini, N.; Albalawi, H.; Elhag, S. Robotic process automation and reengineering using Bizagi and UiPath: A case study on mortgage request process. Int. J. Simul. Process Model. 2021, 17, 166–177. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and microfoundations of (sustainable) enterprise performance. Strateg. Manag. J. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Grover, V.; Malhotra, M.K. Business process reengineering: A tutorial on the concept, evolution, method, technology and application. J. Oper. Manag. 1997, 15, 193–213. [Google Scholar] [CrossRef]

- Amoako-Gyampah, K.; Acquaah, M. Manufacturing strategy, competitive strategy and firm performance: An empirical study in a developing economy environment. Int. J. Prod. Econ. 2008, 111, 575–592. [Google Scholar] [CrossRef]

- Cunningham, M.T.; Culligan, K.L. Competition and competitive groupings: An exploratory study in information technology markets. J. Mark. Manag. 1988, 4, 148–173. [Google Scholar] [CrossRef]

- Hsieh, L.F.; Lin, L.H. A performance evaluation model for international tourist hotels in Taiwan—An application of the relational network DEA. Int. J. Hosp. Manag. 2010, 29, 14–24. [Google Scholar] [CrossRef]

- AlShathry, O. Business process management: A maturity assessment of Saudi Arabian organizations. Bus. Process Manag. J. 2016, 22, 507–521. [Google Scholar] [CrossRef]

- Efthymiou, O.K.; Ponis, S.T. Industry 4.0 technologies and their impact in contemporary logistics: A systematic literature review. Sustainability 2021, 13, 11643. [Google Scholar] [CrossRef]

- Mahnashi, I.; Salah, B.; Ragab, A.E. Industry 4.0 Framework Based on Organizational Diagnostics and Plan–Do–Check–Act Cycle for the Saudi Arabian Cement Sector. Sustainability 2023, 15, 11261. [Google Scholar] [CrossRef]

- Ng, T.C.; Lau, S.Y.; Ghobakhloo, M.; Fathi, M.; Liang, M.S. The application of industry 4.0 technological constituents for sustainable manufacturing: A content-centric review. Sustainability 2022, 14, 4327. [Google Scholar] [CrossRef]

- Muzafar, S.; Jhanjhi, N.Z. Success stories of ICT implementation in Saudi Arabia. In Employing Recent Technologies for Improved Digital Governance; IGI Global: Hershey, PA, USA, 2020; pp. 151–163. [Google Scholar]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Alsafouri, S.; Ayer, S.K. Review of ICT implementations for facilitating information flow between virtual models and construction project sites. Autom. Constr. 2018, 86, 176–189. [Google Scholar] [CrossRef]

- Cirillo, V.; Molero Zayas, J. Digitalizing industry? Labor, technology and work organization: An introduction to the Forum. J. Ind. Bus. Econ. 2019, 46, 313–321. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; Crown: Danvers, MA, USA, 2017. [Google Scholar]

- Richardson, S. Cognitive automation: A new era of knowledge work? Bus. Inf. Rev. 2020, 37, 182–189. [Google Scholar] [CrossRef]

- Wong, P.K.; Ngin, P.M. Automation and organizational performance: The case of electronics manufacturing firms in Singapore. Int. J. Prod. Econ. 1997, 52, 257–268. [Google Scholar] [CrossRef]

- Taouab, O.; Issor, Z. Firm performance: Definition and measurement models. Eur. Sci. J. 2019, 15, 93–106. [Google Scholar] [CrossRef]

- Voss, C.A.; Åhlström, P.; Blackmon, K. Benchmarking and operational performance: Some empirical results. Int. J. Oper. Prod. Manag. 1997, 17, 1046–1058. [Google Scholar] [CrossRef]

- Srinivasan, M.; Mukherjee, D.; Gaur, A.S. Buyer–supplier partnership quality and supply chain performance: Moderating role of risks, and environmental uncertainty. Eur. Manag. J. 2011, 29, 260–271. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Kobu, B. Performance measures and metrics in logistics and supply chain management: A review of recent literature (1995–2004) for research and applications. Int. J. Prod. Res. 2007, 45, 2819–2840. [Google Scholar] [CrossRef]

- Baird, K.; Jia Hu, K.; Reeve, R. The relationships between organizational culture, total quality management practices and operational performance. Int. J. Oper. Prod. Manag. 2011, 31, 789–814. [Google Scholar] [CrossRef]

- Modgil, S.; Sharma, S. Total productive maintenance, total quality management and operational performance: An empirical study of Indian pharmaceutical industry. J. Qual. Maint. Eng. 2016, 22, 353–377. [Google Scholar] [CrossRef]

- Fernández, M.A.; Becerra, R. An analysis of Spanish hotel efficiency. Cornell Hosp. Q. 2015, 56, 248–257. [Google Scholar] [CrossRef]

- Szalavetz, A. Digitalisation, automation and upgrading in global value chains–factory economy actors versus lead companies. Post-Communist Econ. 2019, 31, 646–670. [Google Scholar] [CrossRef]

- Zahraee, S.M. A survey on lean manufacturing implementation in a selected manufacturing industry in Iran. Int. J. Lean Six Sigma 2016, 7, 136–148. [Google Scholar] [CrossRef]

- Lewis, T.E.; Slack, R.D. Whooping Cranes and Human Disturbance: An Historical Perspective and Literature Review; Texas A&M University: College Station, TX, USA, 2008. [Google Scholar]

- Watzenig, D.; Horn, M. (Eds.) Automated Driving: Safer and More Efficient Future Driving; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Dodel, M.; Mesch, G.S. Perceptions about the impact of automation in the workplace. Inf. Commun. Soc. 2020, 23, 665–680. [Google Scholar] [CrossRef]

- Bacon-Shone, J.H. Introduction to Quantitative Research Methods; Graduate School, The University of Hong Kong: Hong Kong, China, 2013. [Google Scholar]

- Gunter, B. The quantitative research process. In A Handbook of Media and Communication Research; Routledge: London, UK, 2013; pp. 251–278. [Google Scholar]

- Siedlecki, S.L. Understanding descriptive research designs and methods. Clin. Nurse Spec. 2020, 34, 8–12. [Google Scholar] [CrossRef] [PubMed]

- Etikan, I.; Musa, S.A.; Alkassim, R.S. Comparison of convenience sampling and purposive sampling. Am. J. Theor. Appl. Stat. 2016, 5, 1–4. [Google Scholar] [CrossRef]

- Fuller, D.; Colwell, E.; Low, J.; Orychock, K.; Tobin, M.A.; Simango, B.; Buote, R.; Van Heerden, D.; Luan, H.; Cullen, K.; et al. Reliability and validity of commercially available wearable devices for measuring steps, energy expenditure, and heart rate: Systematic review. JMIR mHealth uHealth 2020, 8, e18694. [Google Scholar] [CrossRef]

- Keskinbora, K.H. Medical ethics considerations on artificial intelligence. J. Clin. Neurosci. 2019, 64, 277–282. [Google Scholar] [CrossRef]

- Peron, M.; Fragapane, G.; Sgarbossa, F.; Kay, M. Digital facility layout planning. Sustainability 2020, 12, 3349. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).