Predictive Modeling and Validation of Carbon Emissions from China’s Coastal Construction Industry: A BO-XGBoost Ensemble Approach

Abstract

1. Introduction

2. Literature Review

3. Data Sources

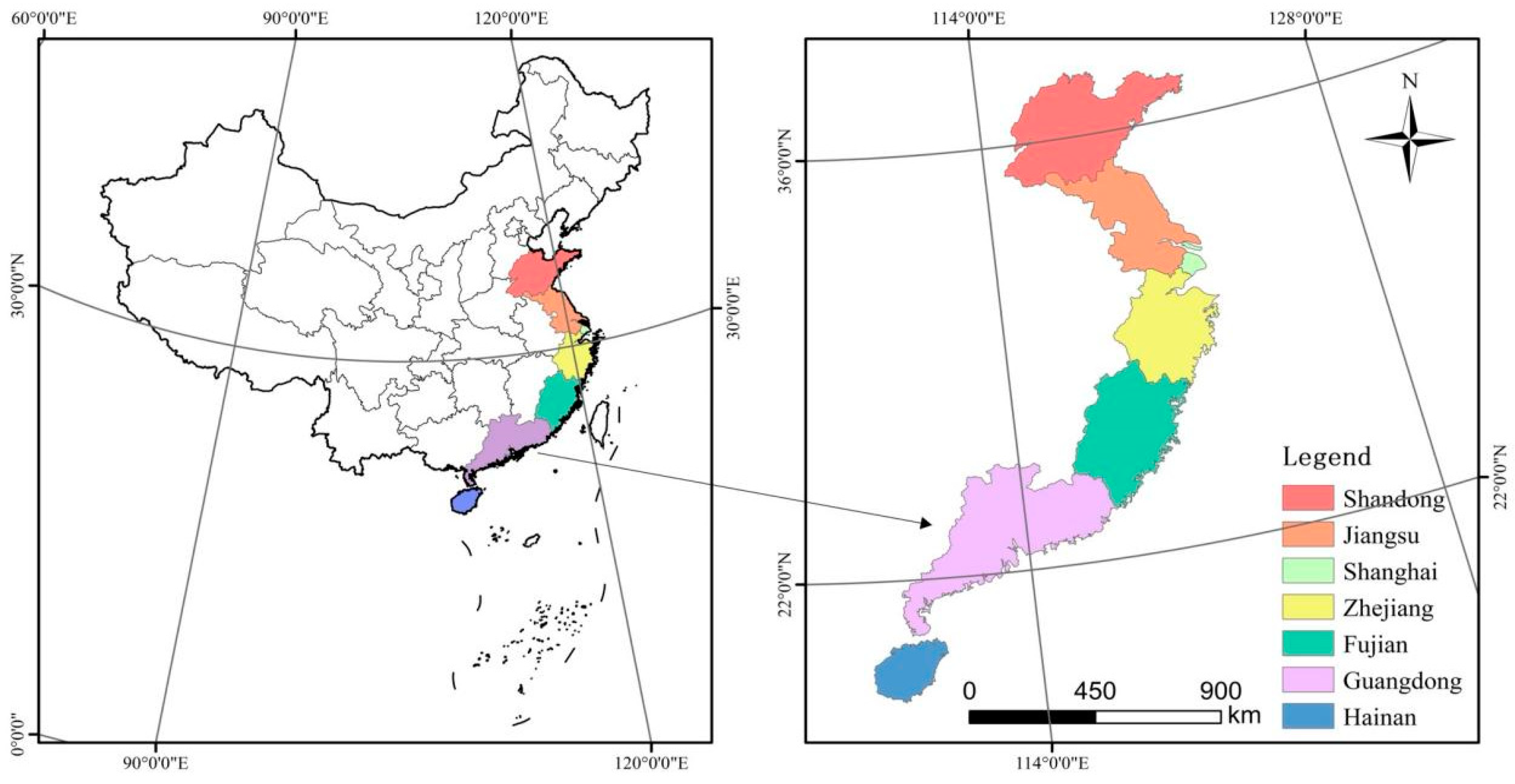

3.1. Research Area

3.2. Data Processing

3.2.1. Min–Max Normalization Method

3.2.2. Fixed-Effects Model

4. Research Approach and Methodology

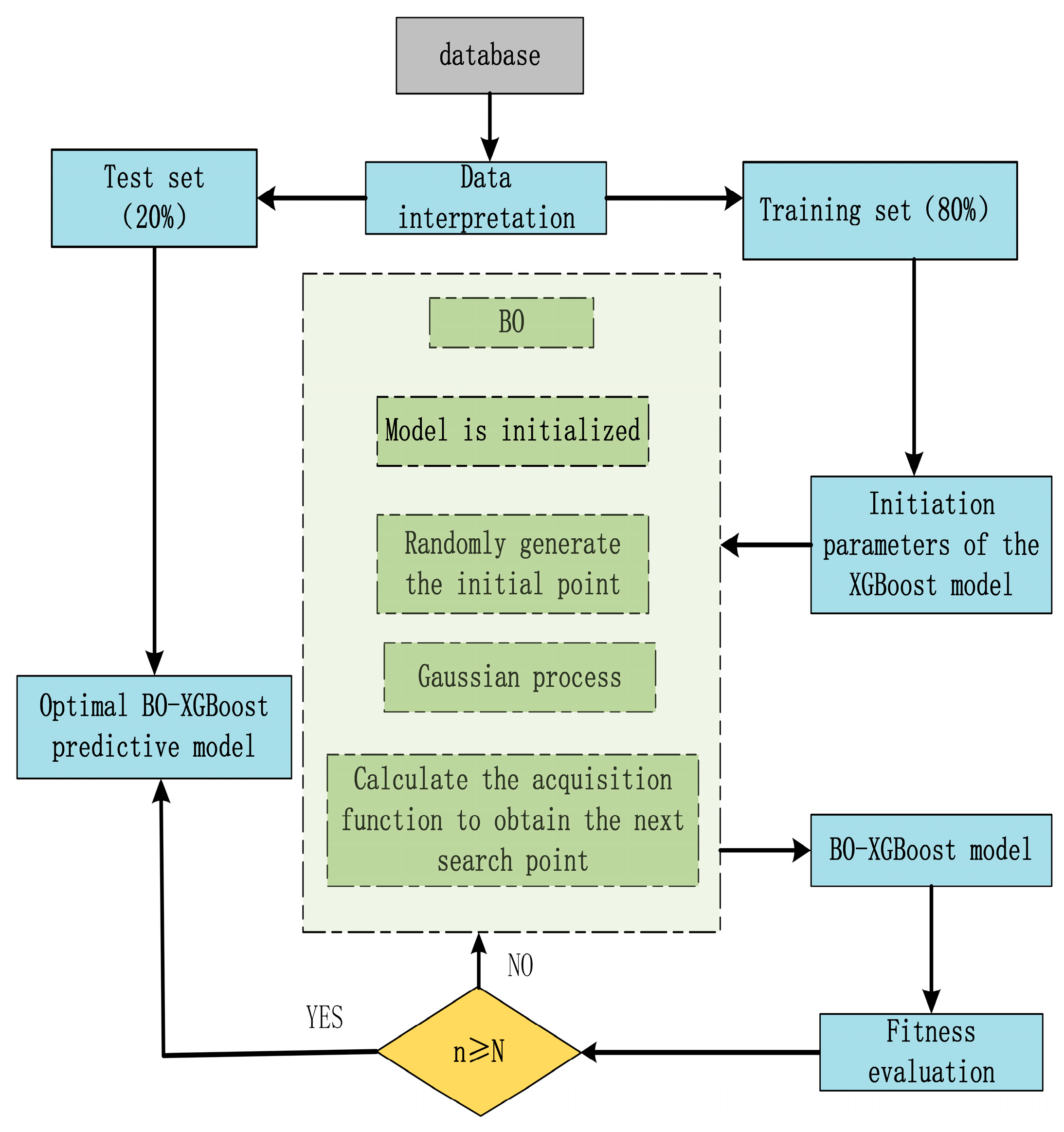

4.1. Research Approach

4.2. Accounting for CECI

4.3. Preliminary Selection of Influencing Factors on CECI

4.4. Methods for Predicting CECI

4.4.1. XGBoost Algorithm

4.4.2. Bayesian Optimization Algorithm

4.4.3. BO-XGBoost Model

4.4.4. Evaluation Indicators for Prediction Models

5. Results and Analysis

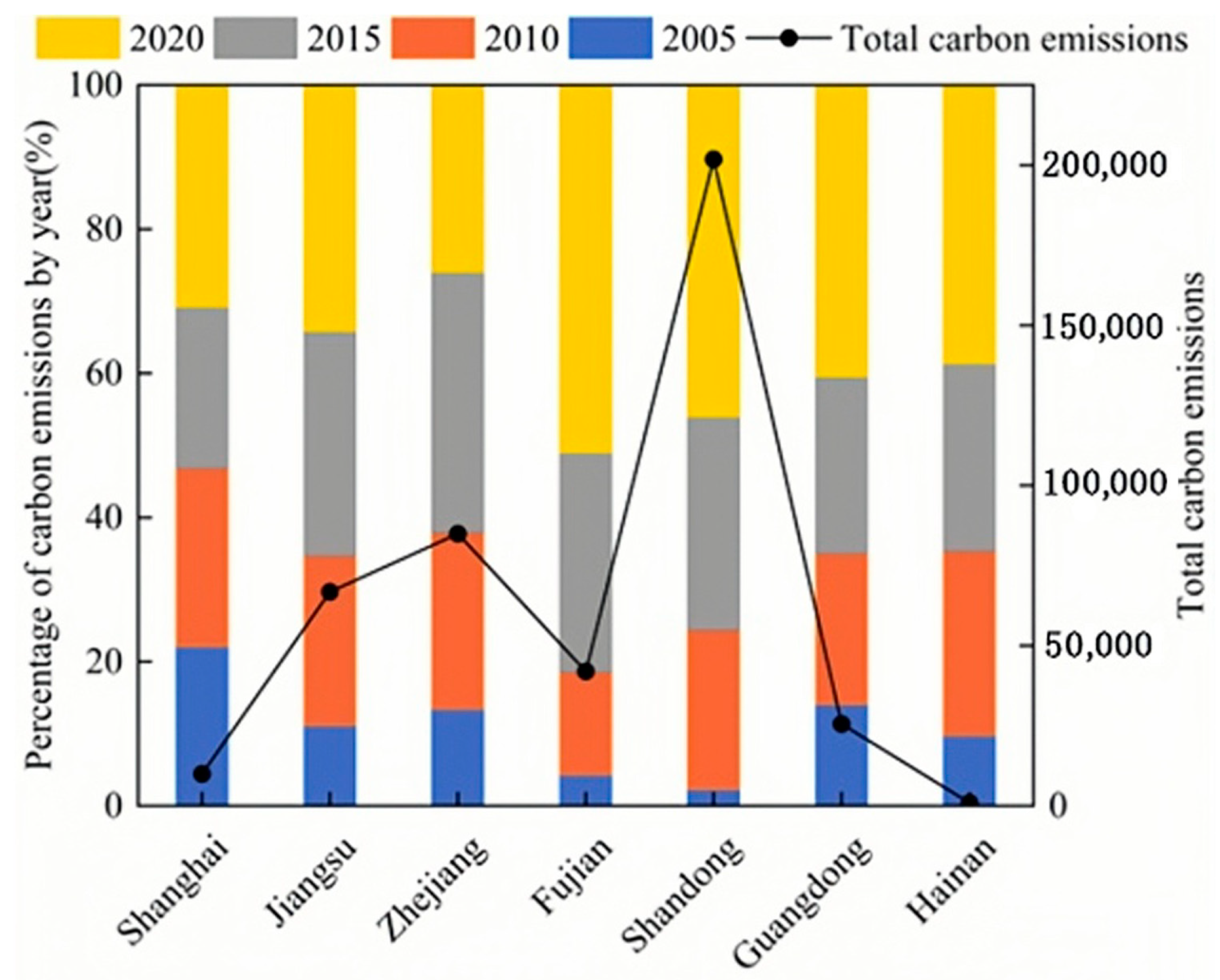

5.1. Measurement of Carbon Emissions from the Construction Industry

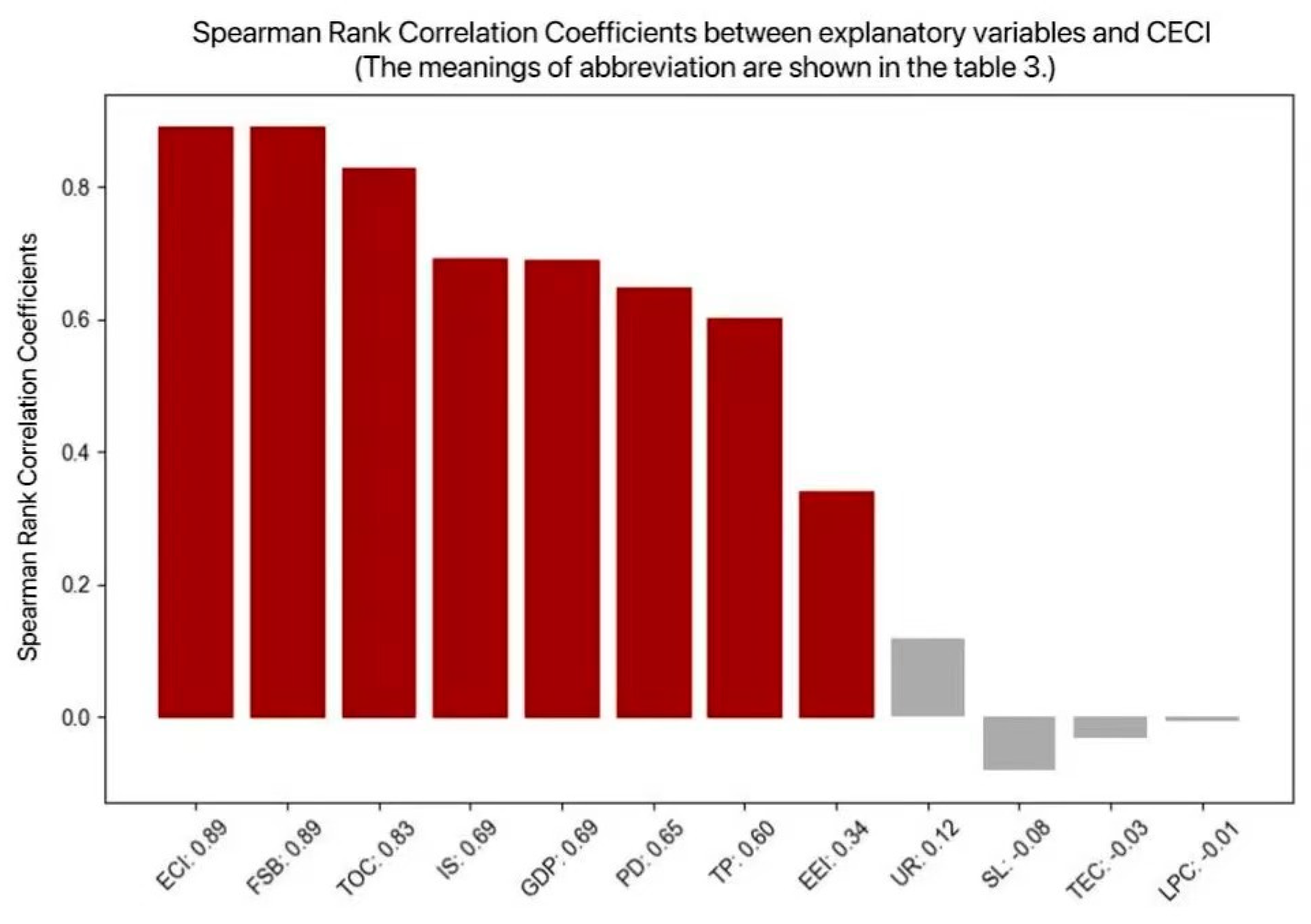

5.2. Results of Factors Influencing CECI

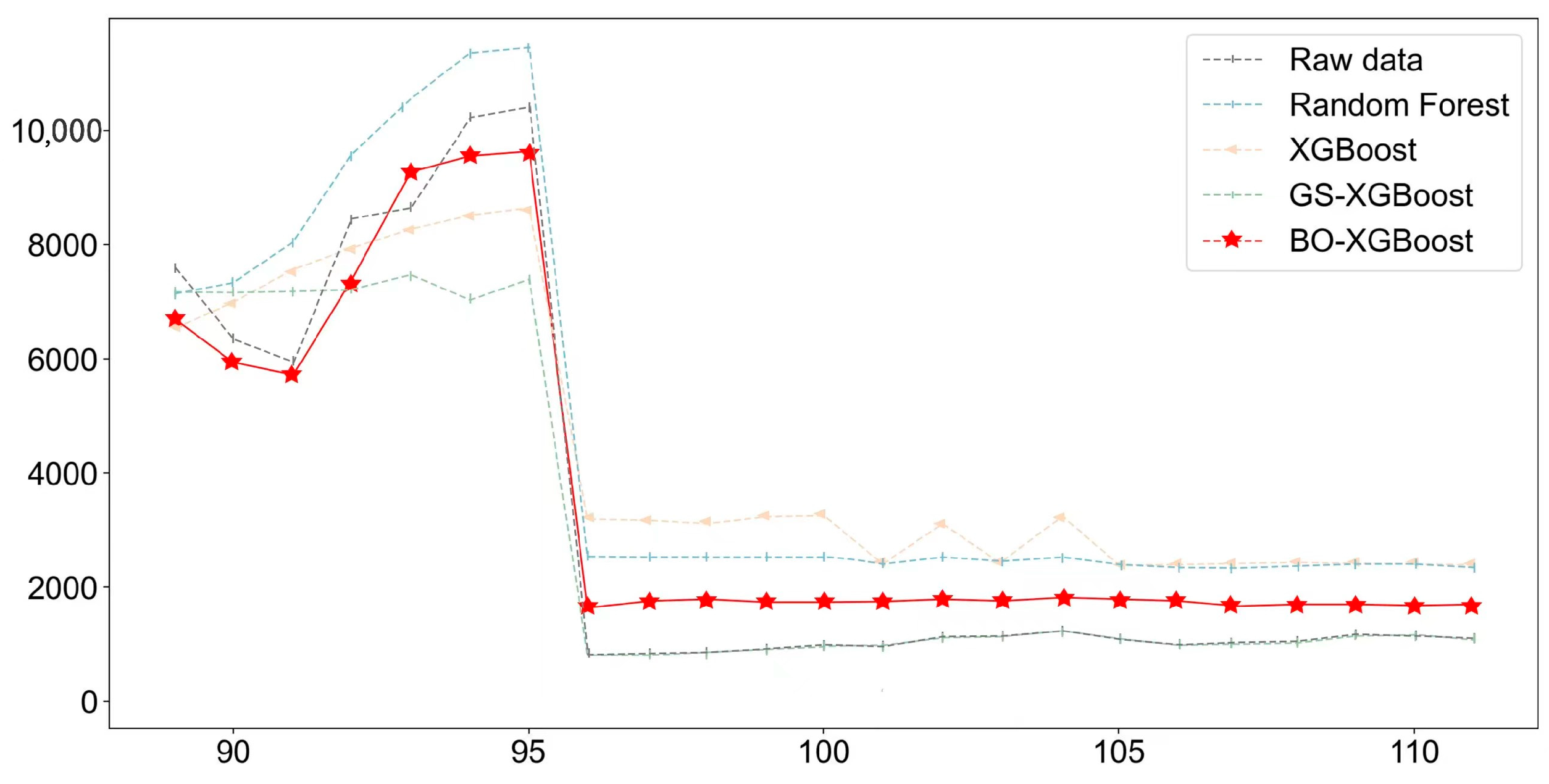

5.3. Comparison and Validation of Carbon Emission-Prediction Models

6. Conclusions and Recommendations

6.1. Conclusions

- (1)

- According to the IPCC emission factor method, spanning the years 2005 to 2020, the cumulative carbon emissions from the construction industry in the seven provinces and municipalities under scrutiny exhibited an escalating trend, surging from 310 million tons to 1.72 billion tons. Among the individual provinces and municipalities, Shandong Province emerged as the foremost emitter of carbon emissions from the construction sector, while Hainan Province registered the lowest emissions.

- (2)

- In reviewing the 12 factors influencing carbon emissions, 8 of them exhibited strong correlations with the CECI. These factors include employment in the construction industry, the floor space of buildings completed, the total output of the construction industry, industrial structure, gross domestic product, provincial disparities, the total population and the energy emission intensity. Meanwhile, it should be noted that the disparities among provinces should not be overlooked by researchers studying regional carbon emissions.

- (3)

- The Random Forest, XGBoost, BO-XGBoost and GS-XGBoost algorithms demonstrated commendable performance in fitting both the training and test sets. Notably, considering the four indicators of RMSE, MAE, and MAPE for validation, it was concluded that the BO-XGBoost model is more suitable for predicting carbon dioxide emissions in the construction industry.

6.2. Policy Recommendations

- (1)

- The demand to optimize the energy structure is vital. Currently, the main energy consumption in the construction industry comes from fossil fuels, primarily coal. The primary way to achieve carbon emission reduction involves controlling the total energy consumption and optimizing the consumption structure. It is necessary to strongly promote green energy sources, such as solar, wind and electricity, and establish a complementary multi-energy supply and utilization system. At the same time, we need to enhance the sustainable and efficient use of traditional energy sources, such as coal.

- (2)

- To address carbon emissions at their source, we must reduce energy consumption in the production of building materials. At present, the indirect carbon emissions from the construction industry primarily come from steel, timber and cement. Therefore, we need to both use these materials wisely and change the production processes of building materials, developing material transformation technology that turns waste materials into usable new materials and can reduce our reliance on raw resources, subsequently lowering carbon emissions.

- (3)

- Based on the analysis of the influencing factors of carbon emissions, the number of employees in the construction industry, the amount of completed construction area, the total output value and provincial disparities all have a strong correlation with carbon emissions. Therefore, we need to formulate policies based on local conditions, such as elevating employee skills through training and education to better meet environmental standards. It is worth noting that the government should establish a carbon emissions trading market or implement a carbon tax system to tax construction companies with higher carbon emissions, incentivizing them to reduce their emissions and improve productivity and energy efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, D.; Huang, G.; Zhu, S.; Chen, L.; Wang, J. How to peak carbon emissions of provincial construction industry? Scenario analysis of Jiangsu Province. Renew. Sustain. Energy Rev. 2021, 144, 110953. [Google Scholar] [CrossRef]

- Pu, X.; Yao, J.; Zheng, R. Forecast of energy consumption and carbon emissions in China’s building sector to 2060. Energies 2022, 15, 4950. [Google Scholar] [CrossRef]

- Wakiyama, T.; Kuramochi, T. Scenario analysis of energy saving and CO2 emissions reduction potentials to ratchet up Japanese mitigation target in 2030 in the residential sector. Energy Policy 2017, 103, 1–15. [Google Scholar] [CrossRef]

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M. Carbon footprint of construction industry: A global review and supply chain analysis. Renew. Sustain. Energy Rev. 2020, 124, 109783. [Google Scholar] [CrossRef]

- Guo, X.; Fang, C. Spatio-temporal interaction heterogeneity and driving factors of carbon emissions from the construction industry in China. Environ. Sci. Pollut. Res. 2023, 30, 81966–81983. [Google Scholar] [CrossRef] [PubMed]

- Atmaca, A.; Atmaca, N. Life cycle energy (LCEA) and carbon dioxide emissions (LCCO2A) assessment of two residential buildings in Gaziantep, Turkey. Energy Build. 2015, 102, 417–431. [Google Scholar] [CrossRef]

- Li, D.; Huang, G.; Zhang, G.; Wang, J. Driving factors of total carbon emissions from the construction industry in Jiangsu Province, China. J. Clean. Prod. 2020, 276, 123179. [Google Scholar] [CrossRef]

- Ma, M.; Cai, W. Do commercial building sector-derived carbon emissions decouple from the economic growth in Tertiary Industry? A case study of four municipalities in China. Sci. Total Environ. 2019, 650, 822–834. [Google Scholar] [CrossRef]

- Hung, C.C.; Hsu, S.-C.; Cheng, K.-L. Quantifying city-scale carbon emissions of the construction sector based on multi-regional input-output analysis. Resour. Conserv. Recycl. 2019, 149, 75–85. [Google Scholar] [CrossRef]

- Liu, B.; Wang, D.; Xu, Y.; Liu, C.; Luther, M. Embodied energy consumption of the construction industry and its international trade using multi-regional input–output analysis. Energy Build. 2018, 173, 489–501. [Google Scholar] [CrossRef]

- Wu, Y.; Chau, K.; Lu, W.; Shen, L.; Shuai, C.; Chen, J. Decoupling relationship between economic output and carbon emission in the Chinese construction industry. Environ. Impact Assess. Rev. 2018, 71, 60–69. [Google Scholar] [CrossRef]

- Jiang, T.; Huang, S.; Yang, J. Structural carbon emissions from industry and energy systems in China: An input-output analysis. J. Clean. Prod. 2019, 240, 118116. [Google Scholar] [CrossRef]

- Zheng, L.; Mueller, M.; Luo, C.; Menneer, T.; Yan, X. Variations in whole-life carbon emissions of similar buildings in proximity: An analysis of 145 residential properties in Cornwall, UK. Energy Build. 2023, 296, 113387. [Google Scholar] [CrossRef]

- Du, Q.; Lu, X.; Li, Y.; Wu, M.; Bai, L.; Yu, M. Carbon emissions in China’s construction industry: Calculations, factors and regions. Int. J. Environ. Res. Public Health 2018, 15, 1220. [Google Scholar] [CrossRef]

- Zhao, Y.; Duan, X.; Yu, M. Calculating carbon emissions and selecting carbon peak scheme for infrastructure construction in Liaoning Province, China. J. Clean. Prod. 2023, 420, 138396. [Google Scholar] [CrossRef]

- Zhang, C.-Y.; Zhao, L.; Zhang, H.; Chen, M.-N.; Fang, R.-Y.; Yao, Y.; Zhang, Q.-P.; Wang, Q. Spatial-temporal characteristics of carbon emissions from land use change in Yellow River Delta region, China. Ecol. Indic. 2022, 136, 108623. [Google Scholar] [CrossRef]

- Abdullah, L.; Pauzi, H.M. Methods in forecasting carbon dioxide emissions: A decade review. J. Teknol. 2015, 75, 67–82. [Google Scholar] [CrossRef]

- Lü, X.; Lu, T.; Kibert, C.J.; Viljanen, M. Modeling and forecasting energy consumption for heterogeneous buildings using a physical–statistical approach. Appl. Energy 2015, 144, 261–275. [Google Scholar] [CrossRef]

- Zubair, M.U.; Ali, M.; Khan, M.A.; Khan, A.; Hassan, M.U.; Tanoli, W.A. BIM-and GIS-Based Life-Cycle-Assessment Framework for Enhancing Eco Efficiency and Sustainability in the Construction Sector. Buildings 2024, 14, 360. [Google Scholar] [CrossRef]

- Yang, X.; Hu, M.; Wu, J.; Zhao, B. Building-information-modeling enabled life cycle assessment, a case study on carbon footprint accounting for a residential building in China. J. Clean. Prod. 2018, 183, 729–743. [Google Scholar] [CrossRef]

- Yan, S.; Zhang, Y.; Sun, H.; Wang, A. A real-time operational carbon emission prediction method for the early design stage of residential units based on a convolutional neural network: A case study in Beijing, China. J. Build. Eng. 2023, 75, 106994. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Pisarenko, Z. Modeling carbon emission trajectory of China, US and India. J. Clean. Prod. 2020, 258, 120723. [Google Scholar] [CrossRef]

- Jiang, W.; Yu, Q. Carbon emissions and economic growth in China: Based on mixed frequency VAR analysis. Renew. Sustain. Energy Rev. 2023, 183, 113500. [Google Scholar] [CrossRef]

- Pan, C.; Wang, H.; Guo, H.; Pan, H. How do the population structure changes of China affect carbon emissions? An empirical study based on ridge regression analysis. Sustainability 2021, 13, 3319. [Google Scholar] [CrossRef]

- Alabdullah, A.A.; Iqbal, M.; Zahid, M.; Khan, K.; Amin, M.N.; Jalal, F.E. Prediction of rapid chloride penetration resistance of metakaolin based high strength concrete using light GBM and XGBoost models by incorporating SHAP analysis. Constr. Build. Mater. 2022, 345, 128296. [Google Scholar] [CrossRef]

- Malkomes, G.; Schaff, C.; Garnett, R. Bayesian optimization for automated model selection. In Proceedings of the 30th Conference on Neural Information Processing Systems (NIPS 2016), Barcelona, Spain, 5–10 December 2016. [Google Scholar]

- Wu, J.; Chen, X.-Y.; Zhang, H.; Xiong, L.-D.; Lei, H.; Deng, S.-H. Hyperparameter optimization for machine learning models based on Bayesian optimization. J. Electron. Sci. Technol. 2019, 17, 26–40. [Google Scholar]

- Feng, B.; Wang, X.; Liu, B. Provincial variation in energy efficiency across China’s construction industry with carbon emission considered. Resour. Sci. 2014, 36, 1256–1266. [Google Scholar]

- Montes, C.; Kapelan, Z.; Saldarriaga, J. Predicting non-deposition sediment transport in sewer pipes using Random forest. Water Res. 2021, 189, 116639. [Google Scholar] [CrossRef]

- Fan, J.S.; Zhou, L. Spatiotemporal distribution and provincial contribution decomposition of carbon emissions for the construction industry in China. Resour. Sci. 2019, 41, 897–907. [Google Scholar] [CrossRef]

- Chi, Y.; Liu, Z.; Wang, X.; Zhang, Y.; Wei, F. Provincial CO2 emission measurement and analysis of the construction industry under China’s carbon neutrality target. Sustainability 2021, 13, 1876. [Google Scholar] [CrossRef]

- Zhou, W.; Yu, W. Regional variation in the carbon dioxide emission efficiency of construction industry in China: Based on the three-stage DEA model. Discret. Dyn. Nat. Soc. 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Dai, D.; Li, K.; Zhao, S.; Zhou, B. Research on prediction and realization path of carbon peak of construction industry based on EGM-BP model. Front. Energy Res. 2022, 10, 981097. [Google Scholar] [CrossRef]

- Yang, Z.; Fang, H.; Xue, X. Sustainable efficiency and CO2 reduction potential of China’s construction industry: Application of a three-stage virtual frontier SBM-DEA model. J. Asian Archit. Build. Eng. 2022, 21, 604–617. [Google Scholar] [CrossRef]

- Yang, J.; Zheng, X. The Spatiotemporal Distribution Characteristics and Driving Factors of Carbon Emissions in the Chinese Construction Industry. Buildings 2023, 13, 2808. [Google Scholar] [CrossRef]

- Chen, H.; Lu, C. Research on the Spatial Effect and Threshold Characteristics of New-Type Urbanization on Carbon Emissions in China’s Construction Industry. Sustainability 2023, 15, 15825. [Google Scholar] [CrossRef]

- Cong, X.; Zhao, M.; Li, L. Analysis of carbon dioxide emissions of buildings in different regions of China based on STIRPAT model. Procedia Eng. 2015, 121, 645–652. [Google Scholar] [CrossRef]

- Chun-Jing, S.; Jin, C.; Yan-Rong, L.; Wei-Zhi, L. Carbon emission accounting analysis and prediction research of construction industry in Hainan Province. Environ. Eng. 2016, 34, 161–165. [Google Scholar]

- Wang, Y.; Wu, X. Research on High-Quality Development Evaluation, Space–Time Characteristics and Driving Factors of China’s Construction Industry under Carbon Emission Constraints. Sustainability 2022, 14, 10729. [Google Scholar] [CrossRef]

- Tian, D.; Li, M.C.; Shi, J.; Shen, Y.; Han, S. On-site text classification and knowledge mining for large-scale projects construction by integrated intelligent approach. Adv. Eng. Inform. 2021, 49, 12. [Google Scholar] [CrossRef]

- Hui-tian, L.; Da-wei, H. Construction and Analysis of Machine Learning Based Transportation Carbon Emission Prediction Model. Environ. Sci. 2023, 44, 1–17. [Google Scholar] [CrossRef]

- Cheng, S.; Fan, W.; Meng, F.; Chen, J.; Liang, S.; Song, M.; Liu, G.; Casazza, M. Potential role of fiscal decentralization on interprovincial differences in CO2 emissions in China. Environ. Sci. Technol. 2020, 55, 813–822. [Google Scholar] [CrossRef]

| Types of Energy | Lower Heating Value * | Carbon Content Per Unit Calorific Value * | Carbon Oxidation Rate * |

|---|---|---|---|

| Raw coal | 20.908 | 25.800 | 0.899 |

| Washed anthracite | 26.344 | 25.800 | 0.899 |

| Other washed coal | 9.409 | 25.800 | 0.899 |

| Shaped coal | 16.800 | 25.800 | 0.899 |

| Coke | 28.435 | 29.200 | 0.970 |

| Coke oven gas | 17.981 | 12.100 | 0.990 |

| Other coal gas | 8.429 | 12.100 | 0.990 |

| Crude oil | 41.816 | 20.000 | 0.980 |

| Gasoline | 43.070 | 18.900 | 0.980 |

| Kerosene | 43.070 | 19.500 | 0.980 |

| Diesel | 42.625 | 20.200 | 0.980 |

| Liquefied petroleum gas | 50.179 | 17.200 | 0.990 |

| Fuel oil | 41.816 | 21.100 | 0.980 |

| Refinery dry gas | 45.998 | 15.700 | 0.990 |

| Natural gas | 38.931 | 15.300 | 0.990 |

| Other petroleum products | 40.190 | 20.000 | 0.980 |

| Other coking products | 28.435 | 29.200 | 0.970 |

| Types of Materials | Steel | Wood | Cement | Glass | Aluminum |

|---|---|---|---|---|---|

| Carbon dioxide emission factor * | 1.79 | −842.80 | 0.82 | 0.97 | 2.60 |

| Recycling rate * | 0.80 | 0.00 | 0.00 | 0.00 | 0.85 |

| Category | Influencing Factors | Abbreviation | Reference Literature |

|---|---|---|---|

| Population factors | Total Population | TP | [33] |

| Employment in the Construction Industry | ECI | [34,35,36] | |

| Economic factors | Gross Domestic Product | GDP | [34] |

| Urbanization Rate | UR | [34,36,37] | |

| Technological factors | Floor Space of Buildings Completed | FSB | [38] |

| Total Output of the Construction Industry | TOC * | [34,36] | |

| Standard Of Living | SL * | [39] | |

| Industrial Structure | IS * | [34,40,41] | |

| Energy Emission Intensity | EEI * | [37,41] | |

| Labor Productivity in the Construction Industry | LPC | [34] | |

| Technological Equipment Rate of Construction Enterprises | TEC | [36,42] | |

| Geographic factors | Provincial Disparities | PD * | [43] |

| Model Parameters | Parameter Explanation | ||

|---|---|---|---|

| max_depth | Limiting the maximum depth of a tree | (3,9) | 4 |

| gamma | Penalty term coefficient, the minimum loss | (0,1) | 1 |

| min_child_weight | Minimum leaf node sample to split the node | (0,1) | 0.119 |

| reg_alpha | L1 regularization parameters | (0,1) | 1 |

| n_estimators | Number of iterations raised | (100,200) | 193 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Liu, S. Predictive Modeling and Validation of Carbon Emissions from China’s Coastal Construction Industry: A BO-XGBoost Ensemble Approach. Sustainability 2024, 16, 4215. https://doi.org/10.3390/su16104215

Hou Y, Liu S. Predictive Modeling and Validation of Carbon Emissions from China’s Coastal Construction Industry: A BO-XGBoost Ensemble Approach. Sustainability. 2024; 16(10):4215. https://doi.org/10.3390/su16104215

Chicago/Turabian StyleHou, Yunfei, and Shouwei Liu. 2024. "Predictive Modeling and Validation of Carbon Emissions from China’s Coastal Construction Industry: A BO-XGBoost Ensemble Approach" Sustainability 16, no. 10: 4215. https://doi.org/10.3390/su16104215

APA StyleHou, Y., & Liu, S. (2024). Predictive Modeling and Validation of Carbon Emissions from China’s Coastal Construction Industry: A BO-XGBoost Ensemble Approach. Sustainability, 16(10), 4215. https://doi.org/10.3390/su16104215