Scientific Research on Bioethanol in Brazil: History and Prospects for Sustainable Biofuel

Abstract

1. Introduction

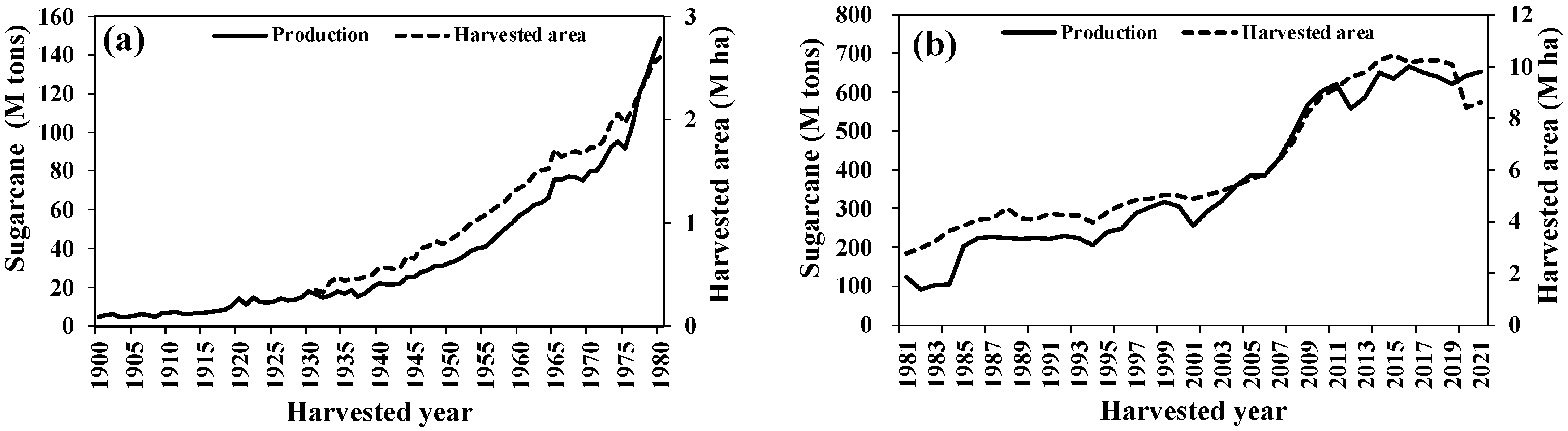

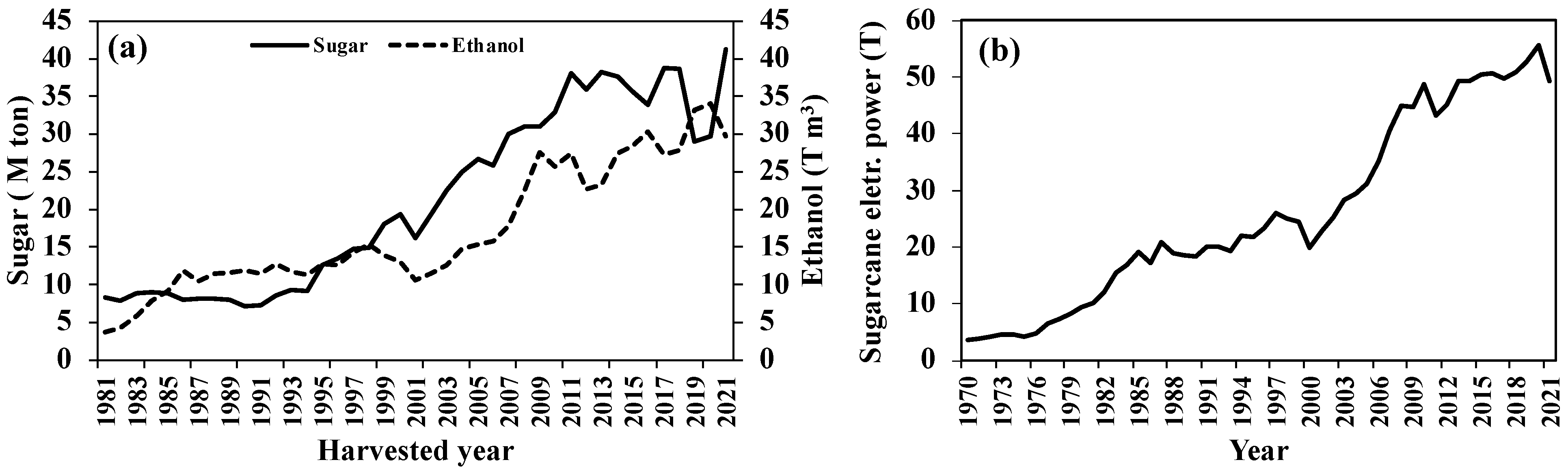

2. History of Ethanol Production from Sugarcane

3. Foundation of the Institutions and the First Investments in Sugarcane Agriculture in Brazil

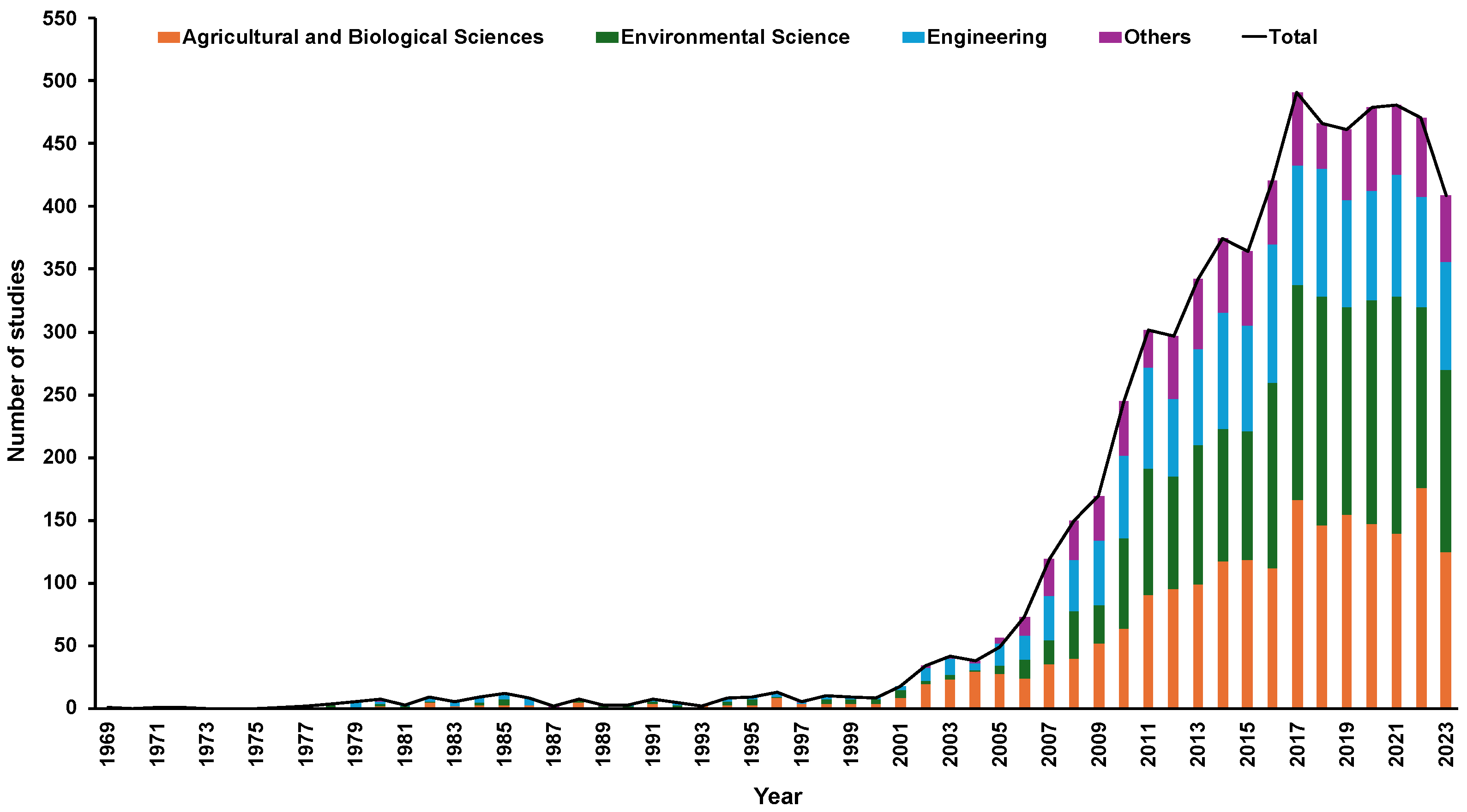

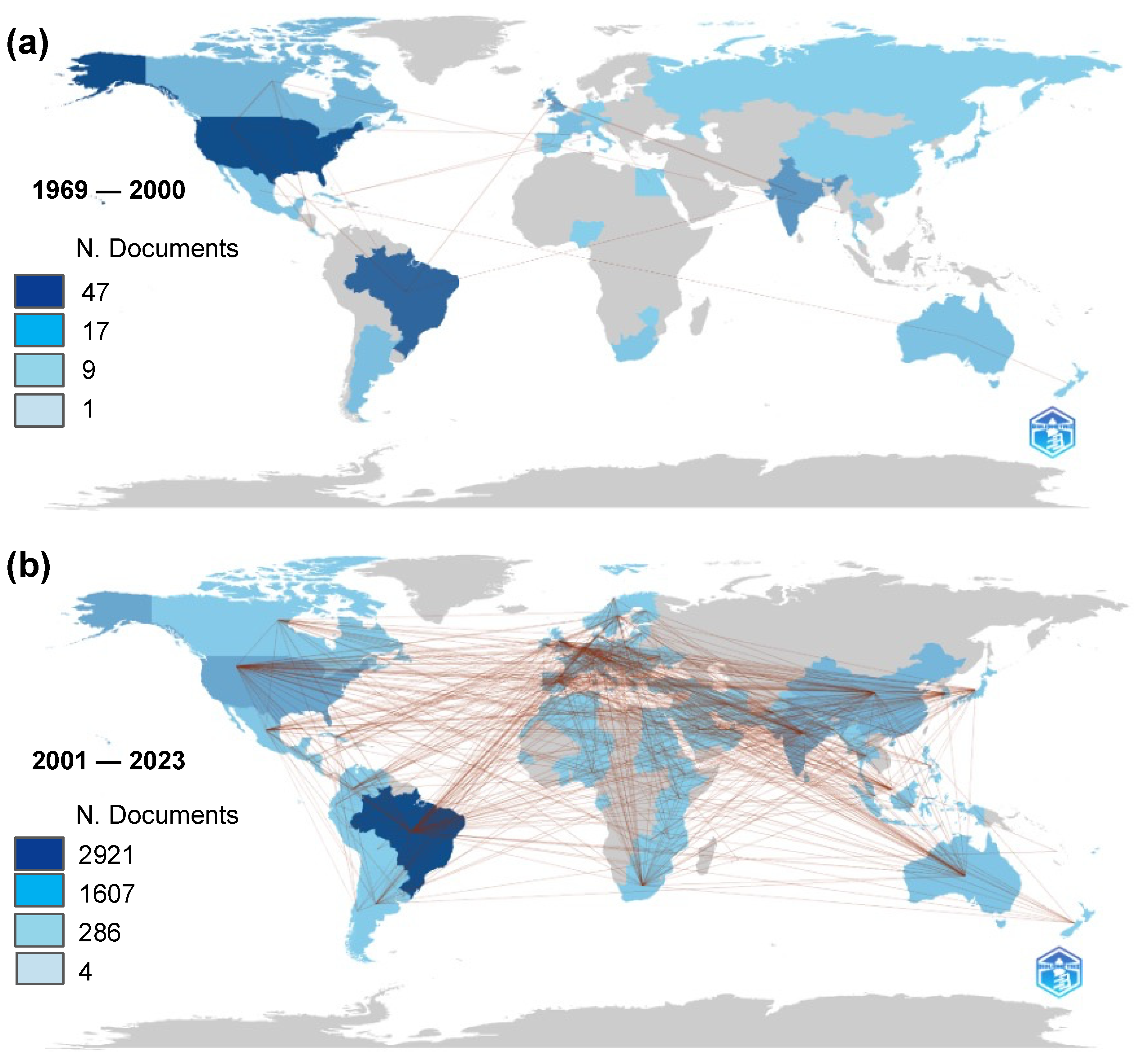

4. The First Phase of Brazilian Investments in Science and Technology in the Sugarcane Sector: An Analysis from 1969 to 2000

5. The Second Phase of Brazilian Investments in Science and Technology in the Sugarcane Sector: An Analysis from 2001 to 2023

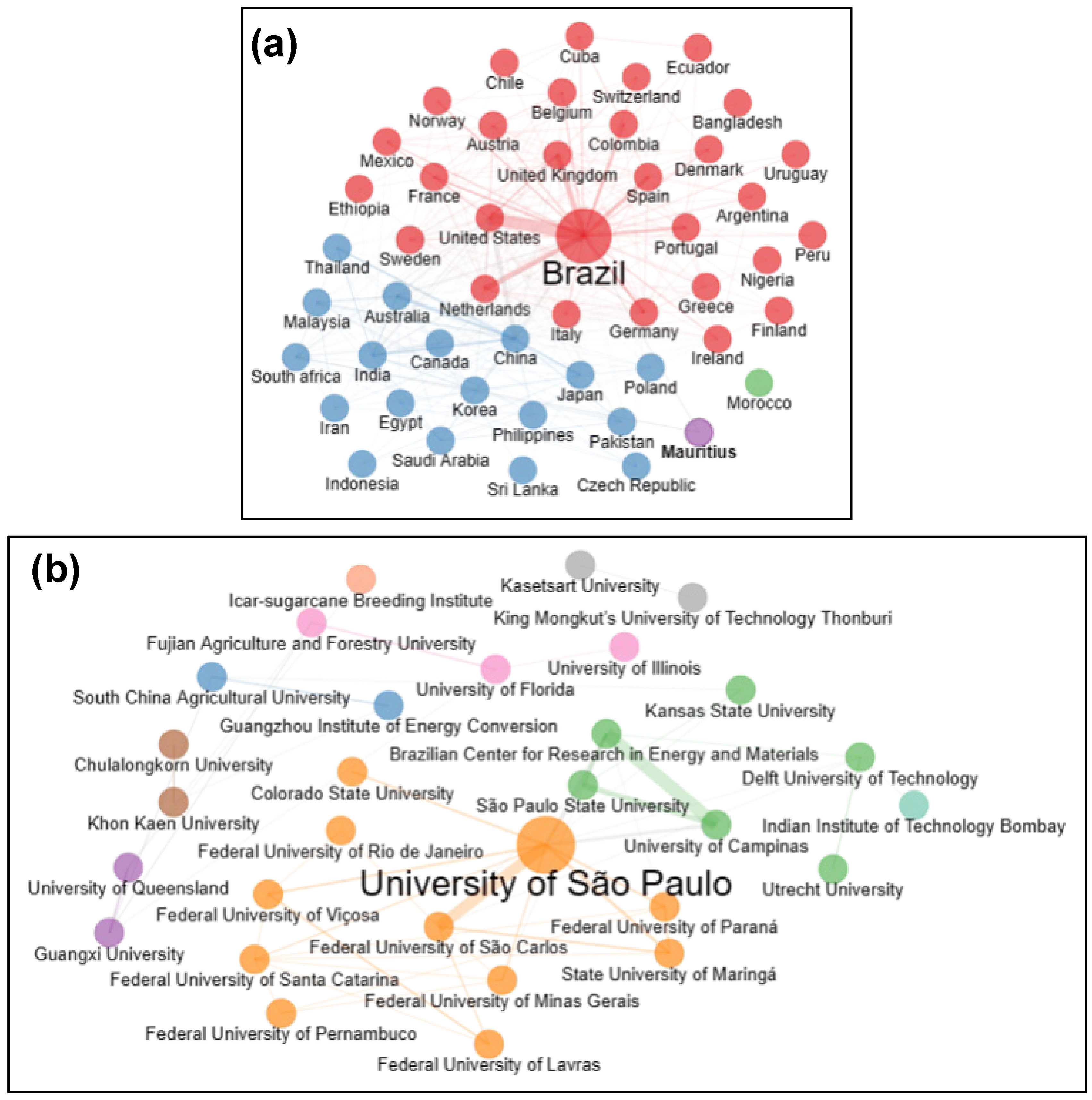

6. The Production of Scientific Knowledge in the Sugar-Energy Sector: A Bibliometrics Analysis of Phases 1 and 2

7. The Future of Brazilian Ethanol and Climate Change

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Nogueira, L.A.H.; Seabra, J.E.A.; Best, G.; Leal, M.R.L.V. Sugarcane-Based Bioethanol: Energy for Sustainable Development. In BNDES and CGEE coordination—Rio de Janeiro: BNDES. 2008; Available online: https://www.researchgate.net/publication/269038981_Sugarcane_based_bioethanol_energy_for_sustainable_development (accessed on 27 March 2024).

- Gupta, C.; Prakash, D. Duckweed: An Effective Tool for Phyto-Remediation. Toxicol. Environ. Chem. 2013, 95, 1256–1266. [Google Scholar] [CrossRef]

- Guo, B.; Dai, S.; Wang, R.; Guo, J.; Ding, Y.; Xu, Y. Combined Effects of Elevated CO2 and Cd-Contaminated Soil on the Growth, Gas Exchange, Antioxidant Defense, and Cd Accumulation of Poplars and Willows. Environ. Exp. Bot. 2015, 115, 1–10. [Google Scholar] [CrossRef]

- Wrangham, R. Pegando Fogo: Por Que Cozinhas Nos Tornou Humanos. In Editora Zahar, Rio de Janeiro. 2010, p. 226. Available online: https://www.amazon.com.br/Pegando-fogo-cozinhar-tornou-humanos/dp/8537801968 (accessed on 27 March 2024).

- Goldemberg, J. Ethanol for a Sustainable Energy Future. Science 2007, 315, 808–810. [Google Scholar] [CrossRef] [PubMed]

- Rapier, R. Fossil Fuels Still Supply 84 Percent of World Energy-and Other Eye Openers from BP’s Annual Review. Available online: https://www.forbes.com/sites/rrapier/2020/06/20/bp-review-new-highs-in-global-energy-consumption-and-carbon-emissions-in-2019/?sh=712179d466a1 (accessed on 22 March 2024).

- Energy Institute-Statistical Review of World Energy. 2023. Available online: https://www.energyinst.org/statistical-review (accessed on 23 April 2024).

- Karp, A.; Shield, I. Bioenergy from Plants and the Sustainable Yield Challenge. New Phytol. 2008, 179, 15–32. [Google Scholar] [CrossRef] [PubMed]

- McKendry, P. Energy Production from Biomass (Part 1): Overview of Biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- De Souza, A.P.; Grandis, A.; Leite, D.C.C.; Buckeridge, M.S. Sugarcane as a Bioenergy Source: History, Performance, and Perspectives for Second-Generation Bioethanol. Bioenergy Res. 2014, 7, 24–35. [Google Scholar] [CrossRef]

- FAO Food and Agriculture Organization of the United Nations. Available online: http://www.fao.Org/Faostat/En/#data (accessed on 22 March 2024).

- CONAB Companhia Nacional de Abastecimento. 2024. Available online: https://www.conab.gov.br (accessed on 22 March 2024).

- Leão, R.M. Álcool Energia Verde; Iqual Editora: Embu, São Paulo, Brazil, 2002; p. 256. ISBN 8587854062. [Google Scholar]

- Bakker, H. Sugar Cane Cultivation and Management Kluwer. In Chapter 1—The Origins of Sugar Cane; Springer Science & Business Media: Cambridge, MA, USA, 1999; pp. 1–2. [Google Scholar]

- Songstad, D.D.; Lakshmanan, P.; Chen, J.; Gibbons, W.; Hughes, S.; Nelson, R. Historical Perspective of Biofuels: Learning from the Past to Rediscover the Future. In Vitro Cell. Dev. Biol. 2009, 45, 189–192. Available online: https://link.springer.com/article/10.1007/s11627-009-9218-6 (accessed on 27 March 2024). [CrossRef]

- CGEE Relatório Final Do Contrato de Gestão. 2009. Available online: https://www.cgee.org.br/documents/10182/37920/rel-cg-2009.pdf (accessed on 22 March 2024).

- Moreira, J.R.; Goldemberg, J. The Alcohol Program. Energy Policy 1999, 27, 229–245. [Google Scholar] [CrossRef]

- Castro, M.H.M.; Schwartzman, S. Tecnologia Para a Indústria a História Do Instituto Nacional de Tecnologia; Centro Edelstein: Rio de Janeiro, Brazil, 2008; ISBN 9788599662540. [Google Scholar]

- Moraes, M.; Bacchi, M. Etanol: Do Início Às Fases Atuais de Produção. Revista de Política Agrícola. Available online: https://seer.sede.embrapa.br/index.php/RPA/article/view/950 (accessed on 27 March 2024).

- Nigro, F.; Szwarc, A. O Etanol Como Combustível. In de Sousa, E.L.L., de C. Macedo, I. (Org.). Etanol e bioeletricidade. A Cana-De-açúcar No Futuro Da Matriz Energética; Luc Projetos de Comunicação: São Paulo, Brazil, 2010; Volume 6, pp. 154–189. Available online: https://unica.com.br/wp-content/uploads/2020/10/etanol-e-bioeletricidade-a-cana-de-acucar-na-matriz-energetica-brasileira.pdf (accessed on 22 March 2024).

- He, L.-Y.; Hou, L.-Q.; Lin, H.; Du, S.-F. Biofuels or Hybrid Vehicles? A Scenario Perspective in China. Energy Sour. Part B Econ. Plan. Policy 2016, 11, 443–449. [Google Scholar] [CrossRef]

- Rodrigues, C.M. Gênese e Evolução Da Pesquisa Agropecuária No Brasil: Da Instalação Da Corte Portuguesa Ao Início Da República. Cad. Ciênc. Tecnol. 1987, 4, 21–38. [Google Scholar]

- Reifschneider, F.J.B.; Henz, G.P.; Ragassi, C.F.; dos Anjos, U.G.; Ferraz, R.M. Novos Ângulos Da História Da Agricultura No Brasil. In Embrapa Informação Tecnológica, Brasília. 2010, p. 112. Available online: https://www.embrapa.br/busca-de-publicacoes/-/publicacao/868764/novos-angulos-da-historia-da-agricultura-no-brasil (accessed on 27 March 2024).

- Ramos, P. Os Mercados Mundiais de Açúcar e a Evolução Da Agroindústria Canavieira Do Brasil Entre 1930 e 1980: Do Açúcar Ao Álcool Para o Mercado Interno. Econ. Apl. 2007, 11, 559–585. [Google Scholar] [CrossRef][Green Version]

- IAC BRASIL/Açúcar. Available online: https://www.iac.sp.gov.br/centro.php?tag=7 (accessed on 22 March 2024).

- Lima, J.A. Intervenção Governamental No Setor Açucareiro: Ênfase à Problemática Do Subsídio de Equalização; Tese de Doutorado, Universidade de São Paulo: São Paulo, Brazil, 1992. [Google Scholar]

- Cursi, D.E.; Hoffmann, H.P.; Barbosa, G.V.S.; Bressiani, J.A.; Gazaffi, R.; Chapola, R.G.; Fernandes Junior, A.R.; Balsalobre, T.W.A.; Diniz, C.A.; Santos, J.M.; et al. History and Current Status of Sugarcane Breeding, Germplasm Development and Molecular Genetics in Brazil. Sugar. Tech. 2022, 24, 112–133. [Google Scholar] [CrossRef]

- Pimentel, L.S. The Brazilian Ethanol Program. Biotechnol. Bioeng. 1980, 22, 1989–2012. [Google Scholar] [CrossRef] [PubMed]

- Furtado, A.T.; Scandiffio, M.I.G.; Cortez, L.A.B. The Brazilian Sugarcane Innovation System. Energy Policy 2011, 39, 156–166. [Google Scholar] [CrossRef]

- Furtado, A.; Scandiffio, M. The Ethanol Promise in Brazil. Sci. Am. Brazil. Ed. Braz. 2006, 53, 66–71. [Google Scholar]

- Matsuoka, S.; Ferro, J.; Arruda, P. The Brazilian Experience of Sugarcane Ethanol Industry. In Vitro Cell. Dev. Biol. Plant 2009, 45, 372–381. [Google Scholar] [CrossRef]

- Buckeridge, M.S. Seed Cell Wall Storage Polysaccharides: Models to Understand Cell Wall Biosynthesis and Degradation. Plant Physiol. 2010, 154, 1017–1023. [Google Scholar] [CrossRef] [PubMed]

- Hotta, C.T.; Lembke, C.G.; Domingues, D.S.; Ochoa, E.A.; Cruz, G.M.Q.; Melotto-Passarin, D.M.; Marconi, T.G.; Santos, M.O.; Mollinari, M.; Margarido, G.R.A.; et al. The Biotechnology Roadmap for Sugarcane Improvement. Trop. Plant Biol. 2010, 3, 75–87. [Google Scholar] [CrossRef]

- Arruda, P. Perspective of the Sugarcane Industry in Brazil. Trop. Plant Biol. 2011, 4, 3–8. [Google Scholar] [CrossRef]

- Arruda, P. Sugarcane Transcriptome: A Landmark in Plant Genomics in the Tropics. Genet. Mol. Biol. 2001, 24, 1–4. [Google Scholar] [CrossRef]

- Lima, D.U.; Santos, H.P.; Tiné, M.A.; Molle, F.R.D.; Buckeridge, M.S. Patterns of Expression of Cell Wall Related Genes in Sugarcane. Genet. Mol. Biol. 2001, 24, 191–198. [Google Scholar] [CrossRef][Green Version]

- Vettore, A.L.; da Silva, F.R.; Kemper, E.L.; Souza, G.M.; da Silva, A.M.; Ferro, M.I.T.; Henrique-Silva, F.; Giglioti, A.; Lemos, M.V.; Coutinho, L.L.; et al. Analysis and Functional Annotation of an Expressed Sequence Tag Collection for Tropical Crop Sugarcane. Genome Res. 2003, 13, 2725–2735. [Google Scholar] [CrossRef] [PubMed]

- Bernardes, R.C.; Varela, C.A.; Consoni, F.L.; Sacramento, E.S. Ensaio Sobre as Virtudes Do Capital de Risco Corporativo Para Projetos de Alta Tecnologia No Setor Agrícola: A Trajetória Inovadora Da Alellyx Applied Genomics e Da CanaVialis. Rev. Adm. 2013, 48, 327–340. Available online: https://www.revistas.usp.br/rausp/article/view/58663/61753 (accessed on 22 March 2024). [CrossRef]

- Reinach, F. Impactos Da Genômica Na Agricultura Brasileira. Rev. Pesqui. Fapesp 2008, 48, 37–41. Available online: https://revistapesquisa.fapesp.br/fernando-reinach/ (accessed on 22 March 2024).

- Watanabe, M.D.B.; Morais, E.R.; Cardoso, T.F.; Chagas, M.F.; Junqueira, T.L.; Carvalho, D.J.; Bonomi, A. Process Simulation of Renewable Electricity from Sugarcane Straw: Techno-Economic Assessment of Retrofit Scenarios in Brazil. J. Clean. Prod. 2020, 254, 120081. [Google Scholar] [CrossRef]

- Soccol, C.R.; de S. Vandenberghe, L.P.; Medeiros, A.B.P.; Karp, S.G.; Buckeridge, M.; Ramos, L.P.; Pitarelo, A.P.; Ferreira-Leitão, V.; Gottschalk, L.M.F.; Ferrara, M.A. Bioethanol from Lignocelluloses: Status and Perspectives in Brazil. Bioresour. Technol. 2010, 101, 4820–4825. [Google Scholar] [CrossRef] [PubMed]

- Buckeridge, M.S.; de Souza, A.P. Breaking the Glycomic Code of Cell Wall Polysaccharides May Improve Second-Generation Bioenergy Production from Biomass. Bioenergy Res. 2014, 7, 1065–1073. [Google Scholar] [CrossRef]

- McCann, M.; Carpita, N. Biomass recalcitrance: A multi-scale, multi-factor, and conversion-specific property. J. Exp. Bot. 2015, 66, 14. [Google Scholar] [CrossRef] [PubMed]

- Robinson, A.J.; Giuliano, A.; Abdelaziz, O.Y.; Hulteberg, C.P.; Koutinas, A.; Triantafyllidis, K.S.; Barleta, D.; De Bari, I. Techno-economic optimization of a process superstructure for lignin valorization. Bioresour. Technol. 2022, 364, 128004. [Google Scholar] [CrossRef]

- EMBRAPA. História.Empresa Brasileira de Pesquisa Agropecuária. Available online: https://www.Embrapa.Br/Agroenergia/Historia (accessed on 22 March 2024).

- LNBIO National Laboratories: Brazilian Synchrotron Light Laboratory. Available online: https://Lnbr.Cnpem.Br/Overview/ (accessed on 22 March 2024).

- Ramiro, D.A.; Melotto-Passarin, D.M.; de A. Barbosa, M.; dos Santos, F.; Gomez, S.G.P.; Massola Júnior, N.S.; Lam, E.; Carrer, H. Expression of Arabidopsis Bax Inhibitor-1 in Transgenic Sugarcane Confers Drought Tolerance. Plant Biotechnol. J. 2016, 14, 1826–1837. [Google Scholar] [CrossRef] [PubMed]

- Grassi, M.C.B.; Pereira, G.A.G. Energy-Cane and RenovaBio: Brazilian Vectors to Boost the Development of Biofuels. Ind. Crop. Prod. 2019, 129, 201–205. [Google Scholar] [CrossRef]

- MAPA Ministério de Agricultura Pecuária e Abastecimento Do Brasil. 2023. Available online: https://sistemasweb.agricultura.gov.br/ (accessed on 27 March 2024).

- Martinelli, L.A.; Filoso, S. Expansion of Sugarcane Ethanol Production in Brazil: Environmental and Social Challenges. Ecol. Appl. 2008, 18, 885–898. [Google Scholar] [CrossRef] [PubMed]

- Walter, A.; Dolzan, P.; Quilodran, O.; Gracia, J.; Da Silva, C.; Piacente, F. Sustainability Analysis of the Brazilian Ethanol. Available online: https://www.globalbioenergy.org/uploads/media/0811_Unicamp_-_A_sustainability_analysis_of_the_Brazilian_ethanol.pdf (accessed on 22 March 2024).

- Geraque, E. Produção de Hidrogênio Verde a Partir Do Etanol e Da Água Começa a Sair dos Laboratórios. In Folha de São Paulo. 2022. Available online: https://www.terra.com.br/planeta/sustentabilidade/producao-de-hidrogenio-verde-a-partir-do-etanol-e-da-agua-comeca-a-sair-dos-laboratorios,a841dd47d8a5d008b10829f4aeefce72rwmg21jl.html (accessed on 27 March 2024).

- Zupic, I.; Čater, T. Bibliometric Methods in Management and Organization. Organ. Res. Methods 2015, 18, 429–472. [Google Scholar] [CrossRef]

- Nickell, L.G.; Maretzki, A. Growth of Suspension Cultures of Sugarcane Cells in Chemically Defined Media. Physiol. Plant 1969, 22, 117–125. [Google Scholar] [CrossRef]

- Lawrence, S. Free Online Availability Substantially Increases a Paper’s Impact. Nature 2001, 411, 521. [Google Scholar] [CrossRef]

- Brennan, L.; Owende, P. Biofuels from Microalgae—A Review of Technologies for Production, Processing, and Extractions of Biofuels and Co-Products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2022. [Google Scholar]

- Buckeridge, M.S.; Grandis, A.; Tavares, E.Q.P. Disassembling the Glycomic Code of Sugarcane Cell Walls to Improve Second-Generation Bioethanol Production. In Bioethanol Production from Food Crops; Elsevier: Amsterdam, The Netherlands, 2019; pp. 31–43. [Google Scholar]

- Creutzig, F.; Ravindranath, N.H.; Berndes, G.; Bolwig, S.; Bright, R.; Cherubini, F.; Chum, H.; Corbera, E.; Delucchi, M.; Faaij, A.; et al. Bioenergy and Climate Change Mitigation: An Assessment. GCB Bioenergy 2015, 7, 916–944. [Google Scholar] [CrossRef]

- IRENA Recycle: Bioenergy. Circular Carbon Economy Report 05. The United Arab Emirates: The International Renewable Energy Agency (IRENA). Available online: https://www.irena.org/publications/2020/Sep/Recycle-Bioenergy (accessed on 22 March 2024).

- Zhang, M.; Govindaraju, M. Sugarcane Production in China. In Sugarcane-Technology and Research; InTech: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Rudorff, B.F.T.; Aguiar, D.A.; Silva, W.F.; Sugawara, L.M.; Adami, M.; Moreira, M.A. Studies on the Rapid Expansion of Sugarcane for Ethanol Production in São Paulo State (Brazil) Using Landsat Data. Remote Sens. 2010, 2, 1057–1076. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Coninck, H.; Revi, A.; Babiker, M.; Bertoldi, P.; Buckeridge, M.; Cartwright, A.; Dong, W.; Ford, J.; Fuss, S.; Hourcade, J.C.; et al. Global Warming of 1.5 °C: Summary for Policymakers; IPCC—The Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2018; pp. 313–343. [Google Scholar]

- IPCC. 2021 Summary for Policymakers. In Climate Change 2021—The Physical Science Basis; Cambridge University Press: Cambridge, UK, 2021; pp. 3–32. [Google Scholar]

- Köberle, A.C. The Value of BECCS in IAMs: A Review. Curr. Sustain./Renew. Energy Rep. 2019, 6, 107–115. [Google Scholar] [CrossRef]

- Macedo, I. Situação Atual e Perspectivas Do Etanol. Estud. Av. São Paulo 2007, 21, 157–165. [Google Scholar] [CrossRef][Green Version]

- Szymanski, M.S.E.; Balbinot, R.; Schirme, W.N. Anaerobic Digestion of Vinasse: Energy Use of Biogas and Obtaining Carbon Credits-Case Study. Available online: https://www.Uel.Br/Revistas/Uel/Index.Php/Semagrarias/Article/ViewFile/7596/6685 (accessed on 22 March 2024).

- Nakashima, R.N.; De Oliveira Junior, S. Comparative Exergy Assessment of Vinasse Disposal Alternatives: Concentration, Anaerobic Digestion and Fertirrigation. Renew. Energy 2020, 147, 1969–1978. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, A.; Pal, A. Overview of Hydrogen Production from Biogas Reforming: Technological Advancement. Int. J. Hydrogen Energy 2022, 47, 34831–34855. [Google Scholar] [CrossRef]

- MME, Governo Federal Ministério de Minas e Energia. Baseline to support the Brazilian Hydrogen Strategy. Federal Government Ministry of Mines and Energy and Empresa de Pesquisa Energética (EPE). 2021. Available online: https://epe.gov.br>sites-pt>publicacao-569 (accessed on 24 April 2024).

- EPE. 2031-Ten-year energy expansion plan. Federal Government Ministry of Mines and Energy and Empresa de Pesquisa Energética (EPE). 2021. Available online: https://www.gov.br>pde-2031 (accessed on 24 April 2024).

- Feng, X.; Zhao, Y.; Zhao, Y.; Wang, H.; Liu, H.; Zhang, Q. A mini review on recent progress of steam reforming of ethanol. RSC Adv. 2023, 13, 23991–24002. [Google Scholar] [CrossRef] [PubMed]

- Freitas, B.R.; Lago, L.; Fregadolli, A.; Lopes, M.; Lopes, G.; Junior, O.F.; Doubek, G. Hydrogen production by ethanol reform: Critical analysis and technological roadmap. AEA—Brazilian Society of Automotive Engineering. Available online: https://pdf.blucher.com.br/engineeringproceedings/simea2023/PAP12.pdf (accessed on 27 March 2024).

- Rossetti, I.; Lasso, J.; Compagnoni, M.; De Guido, G.; Pellegrini, L. H2 production from bioethanol and its use in fuel-cells. Chem. Eng. Trans. 2015, 43, 1–6, ISBN 978-88-95608-34-1. [Google Scholar]

- Capaz, R.S.; Guida, E.; Seabra, J.E.A.; Osseweijer, P.; Posada, J.A. Mitigating carbon emissions through sustainable aviation fuels: Costs and potential. Biofuels Bioprod. Biorefining 2020, 15, 502–524. [Google Scholar] [CrossRef]

- ICAO. CORSIA–Sustainability Criteria for CORSIA Eligible Fuels. Montreal. 2019. Available online: https://www.icao.int/environmental-protection/CORSIA/Documents/ICAO%20document%2005%20-%20Sustainability%20Criteria%20-%20November%202021.pdf (accessed on 27 March 2024).

- ASTM D7566-20; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. ASTM: West Conshohocken, PA, USA, 2020.

- Raj, T.; Singh, V. Natural deep eutectic solvents (NADES) assisted deconstruction of oilcane bagasse for high lipid and sugar recovery. Ind. Crop. Prod. 2024, 210, 118127. [Google Scholar] [CrossRef]

| Time 1969–2000 | Time 2001–2023 | ||||||

|---|---|---|---|---|---|---|---|

| Country | Articles | SCP | MCP | Country | Articles | SCP | MCP |

| United States | 21 | 19 | 2 | Brazil | 2237 | 1473 | 387 |

| Brazil | 19 | 17 | 2 | United States | 597 | 284 | 121 |

| India | 11 | 9 | 2 | India | 429 | 311 | 142 |

| United Kingdom | 9 | 5 | 4 | China | 373 | 261 | 69 |

| Argentina | 5 | 5 | 0 | Thailand | 147 | 101 | 28 |

| Canada | 5 | 3 | 2 | Australia | 130 | 47 | 35 |

| France | 4 | 2 | 2 | United Kingdom | 125 | 34 | 32 |

| Mexico | 4 | 3 | 1 | Mexico | 106 | 59 | 20 |

| South Africa | 3 | 3 | 0 | Japan | 105 | 34 | 24 |

| Australia | 2 | 1 | 1 | Netherlands | 102 | 30 | 29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grandis, A.; Fortirer, J.d.S.; Pagliuso, D.; Buckeridge, M.S. Scientific Research on Bioethanol in Brazil: History and Prospects for Sustainable Biofuel. Sustainability 2024, 16, 4167. https://doi.org/10.3390/su16104167

Grandis A, Fortirer JdS, Pagliuso D, Buckeridge MS. Scientific Research on Bioethanol in Brazil: History and Prospects for Sustainable Biofuel. Sustainability. 2024; 16(10):4167. https://doi.org/10.3390/su16104167

Chicago/Turabian StyleGrandis, Adriana, Janaina da Silva Fortirer, Débora Pagliuso, and Marcos S. Buckeridge. 2024. "Scientific Research on Bioethanol in Brazil: History and Prospects for Sustainable Biofuel" Sustainability 16, no. 10: 4167. https://doi.org/10.3390/su16104167

APA StyleGrandis, A., Fortirer, J. d. S., Pagliuso, D., & Buckeridge, M. S. (2024). Scientific Research on Bioethanol in Brazil: History and Prospects for Sustainable Biofuel. Sustainability, 16(10), 4167. https://doi.org/10.3390/su16104167