Compressive Strength, Permeability, and Abrasion Resistance of Pervious Concrete Incorporating Recycled Aggregate

Abstract

1. Introduction

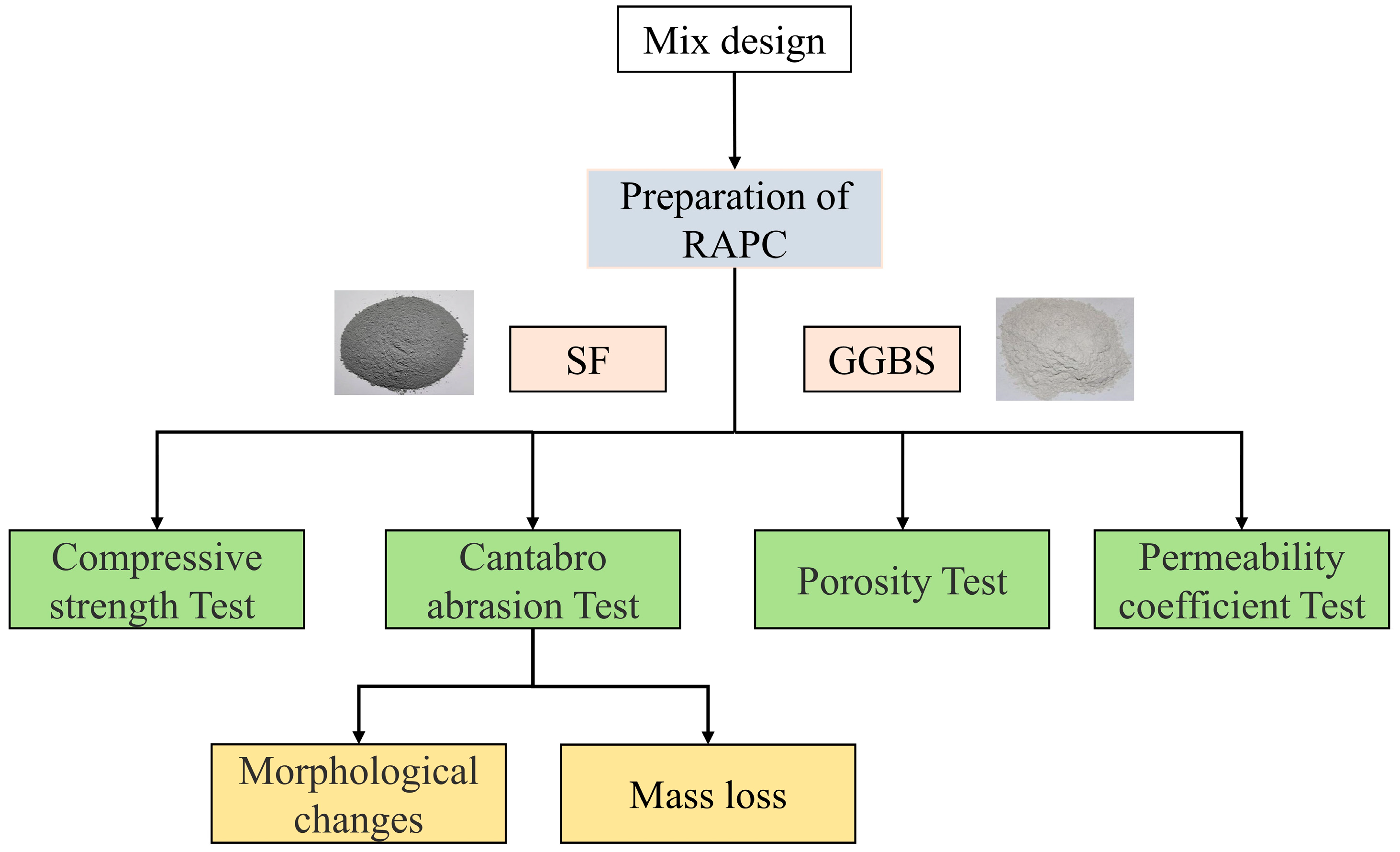

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Design

2.3. Preparation of RAPC

2.4. Performance Test

2.4.1. Compressive Strength

2.4.2. Permeability Coefficient

2.4.3. Porosity

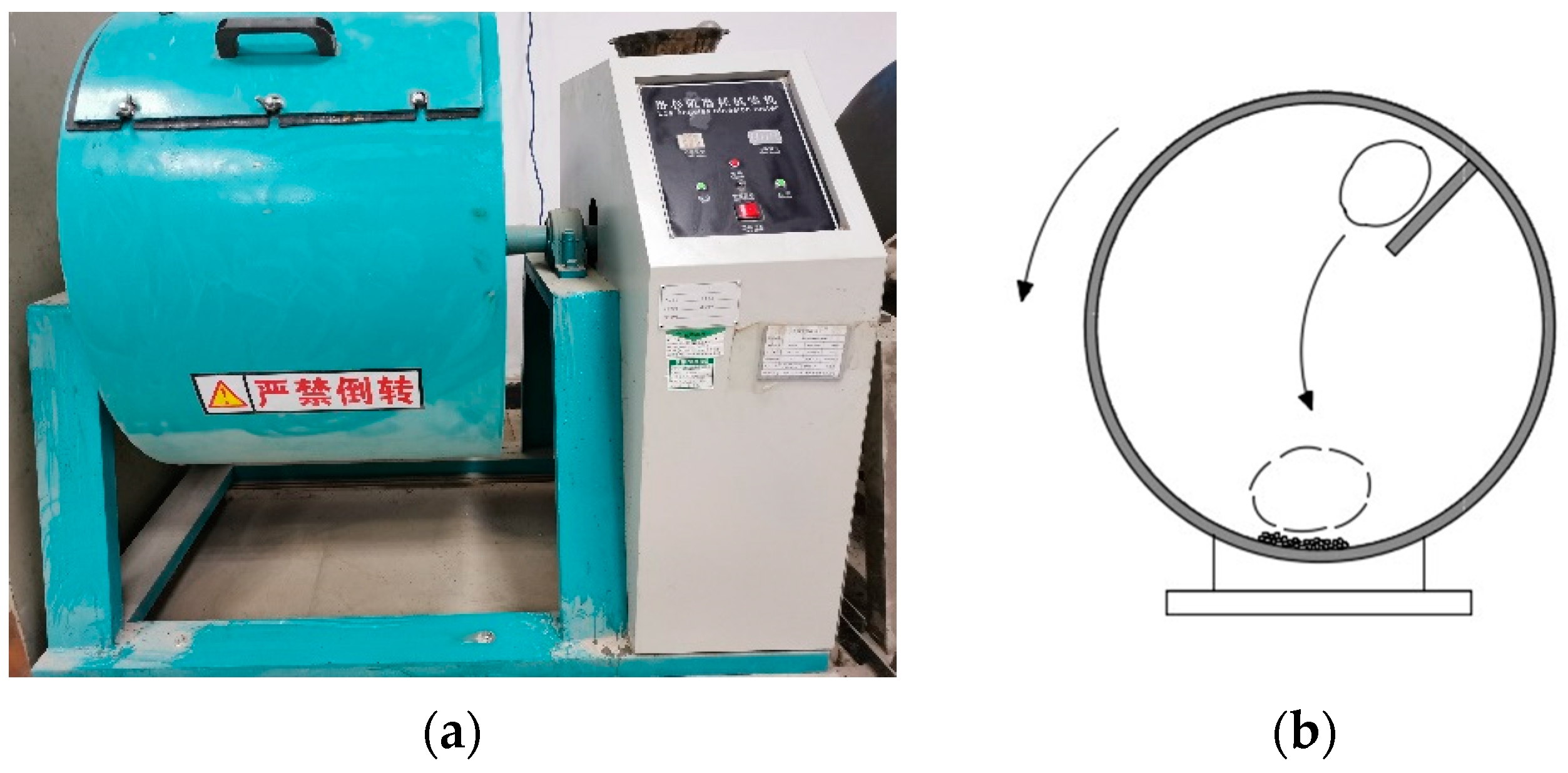

2.4.4. Cantabro Abrasion Test

3. Results

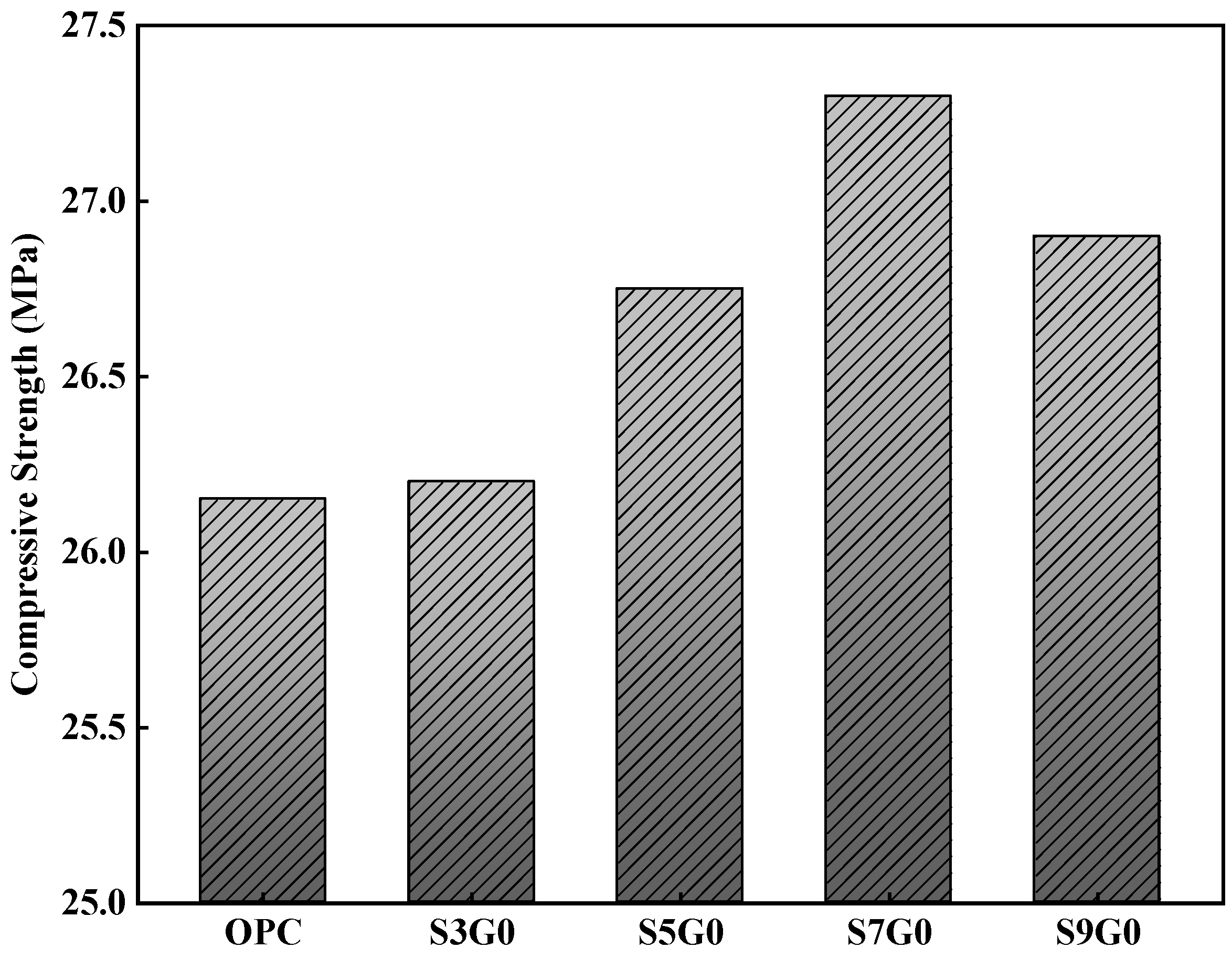

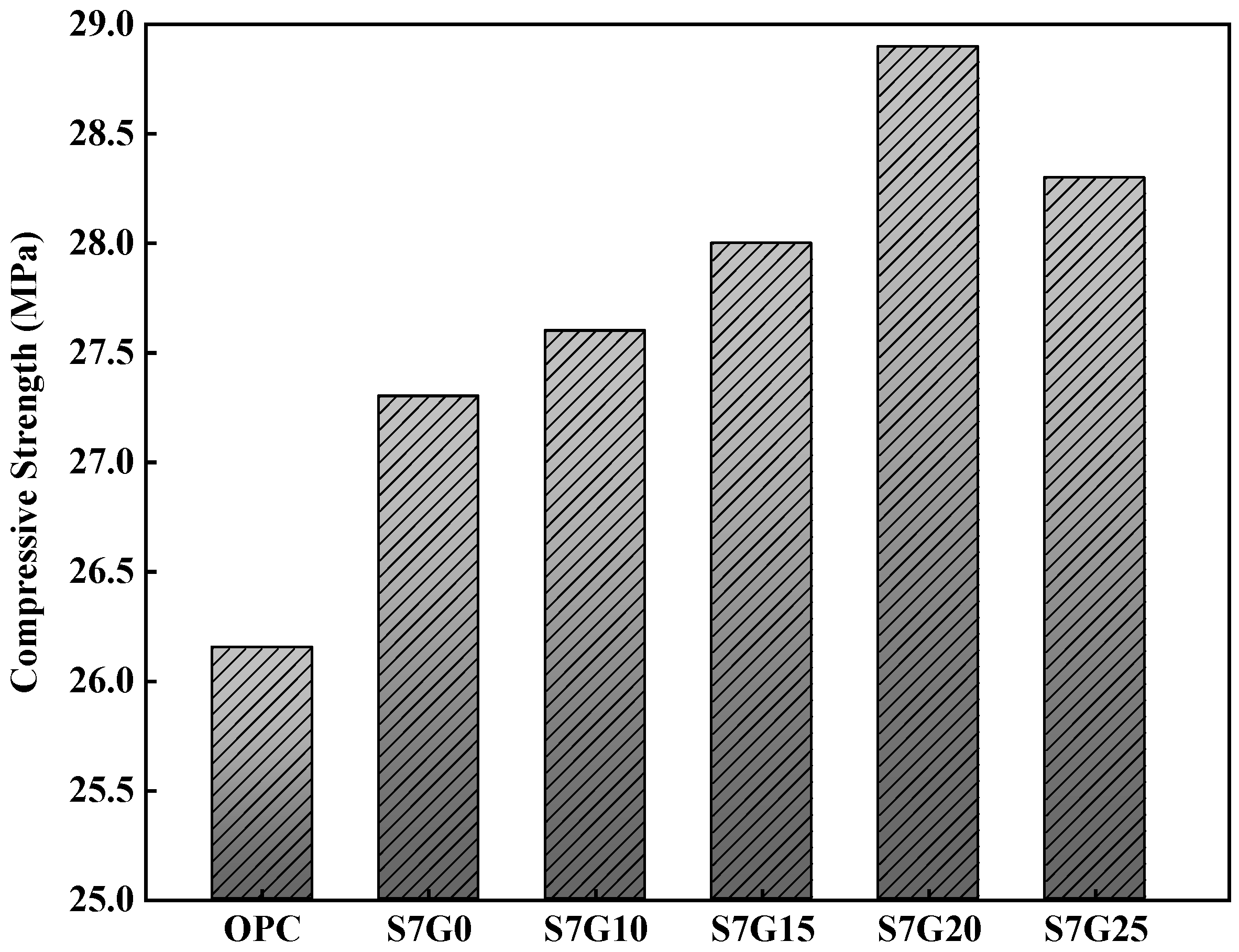

3.1. Compressive Strength

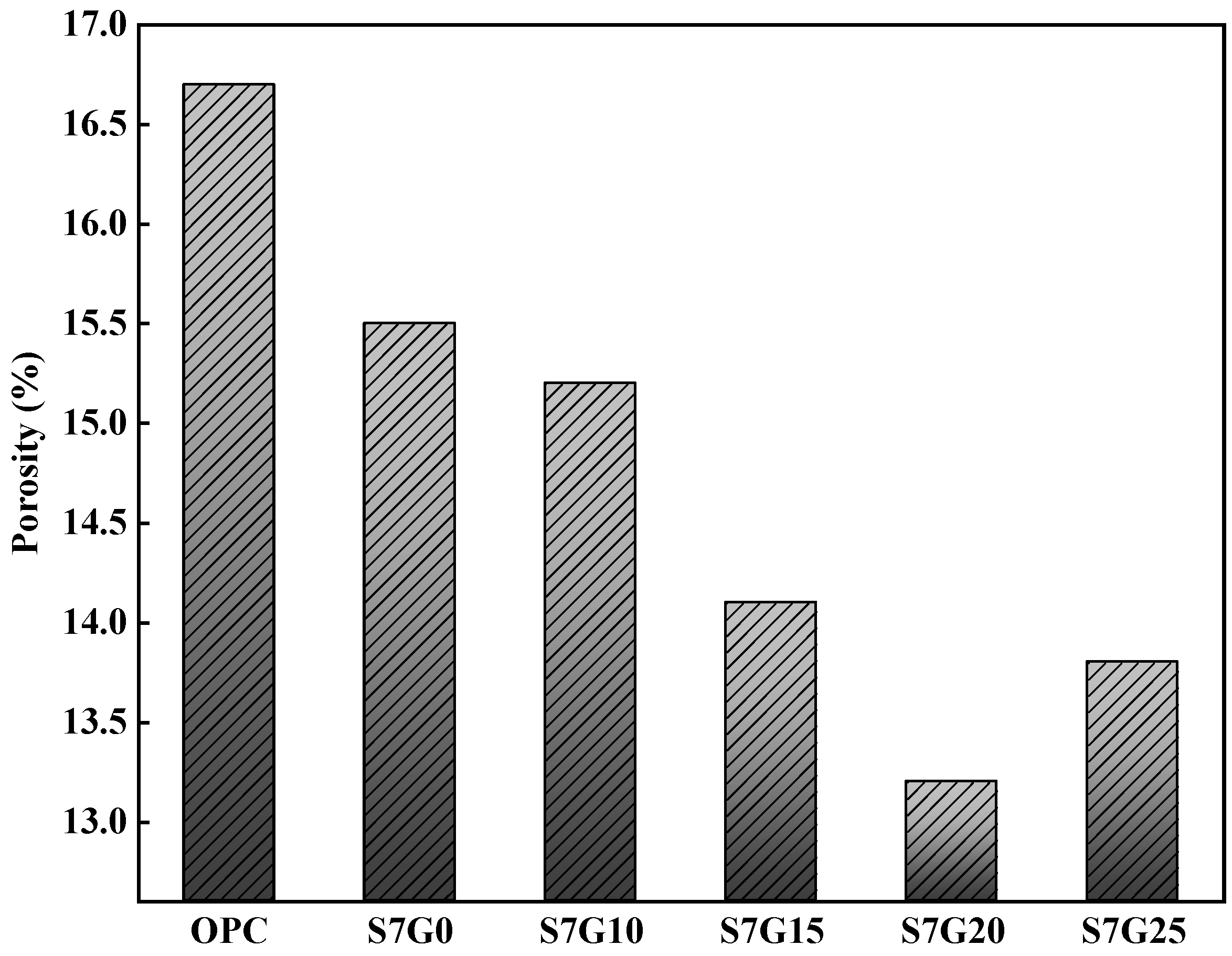

3.2. Porosity

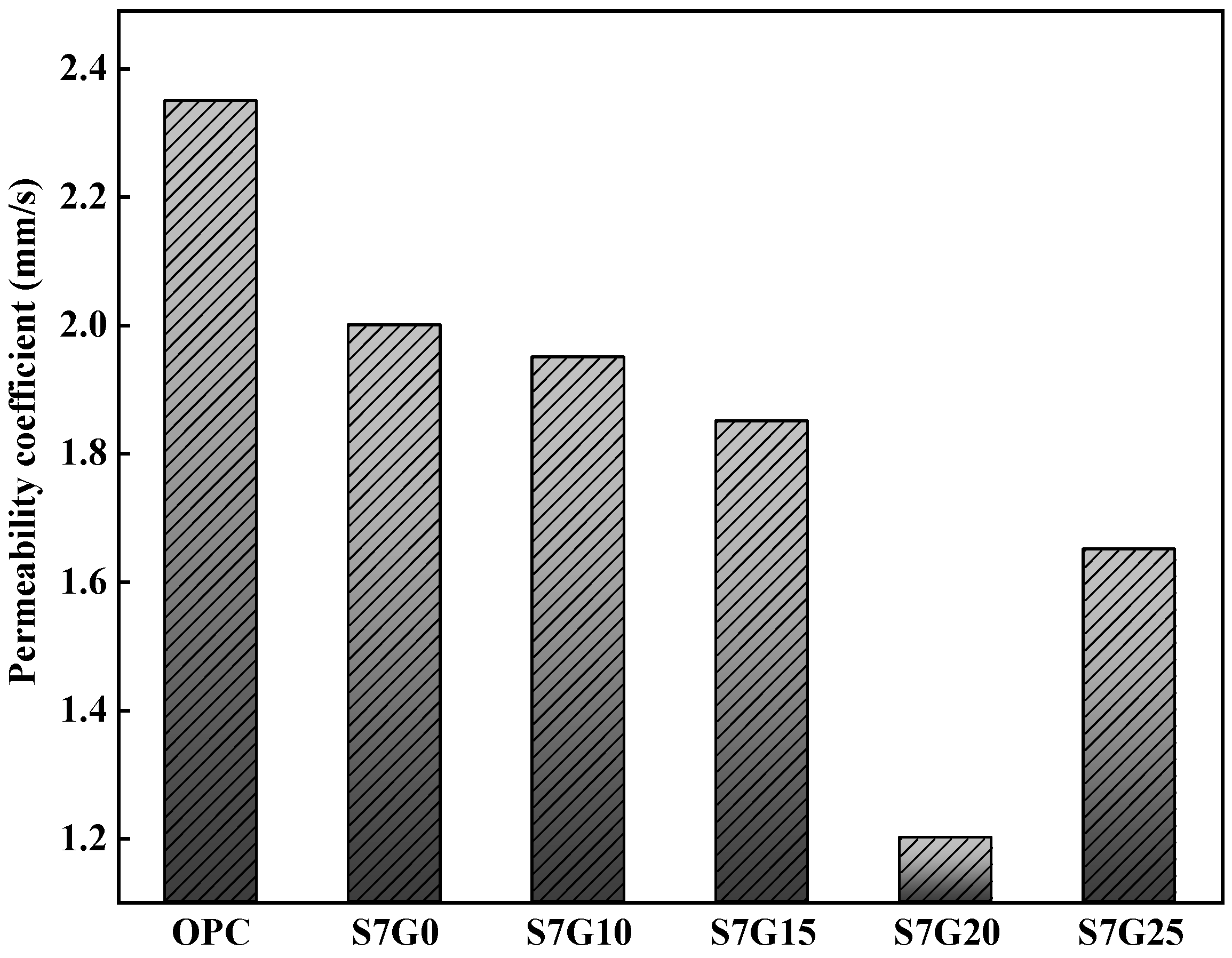

3.3. Permeability Coefficient

3.4. Abrasion Resistance

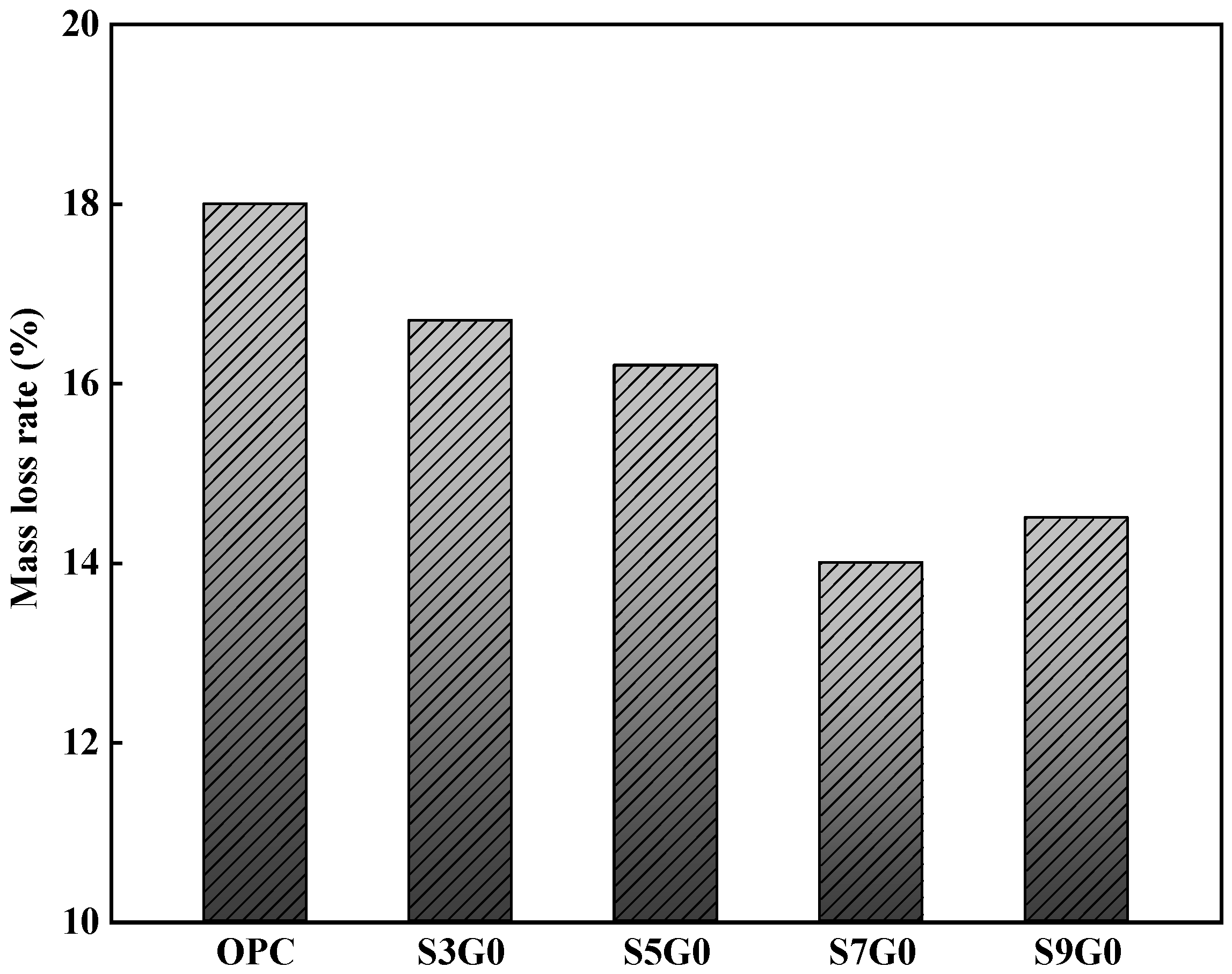

3.4.1. Effect of SF and GGBS on the Mass Loss Rate of RAPC

3.4.2. Effect of the Number of Revolutions on the Morphological Changes in RAPC

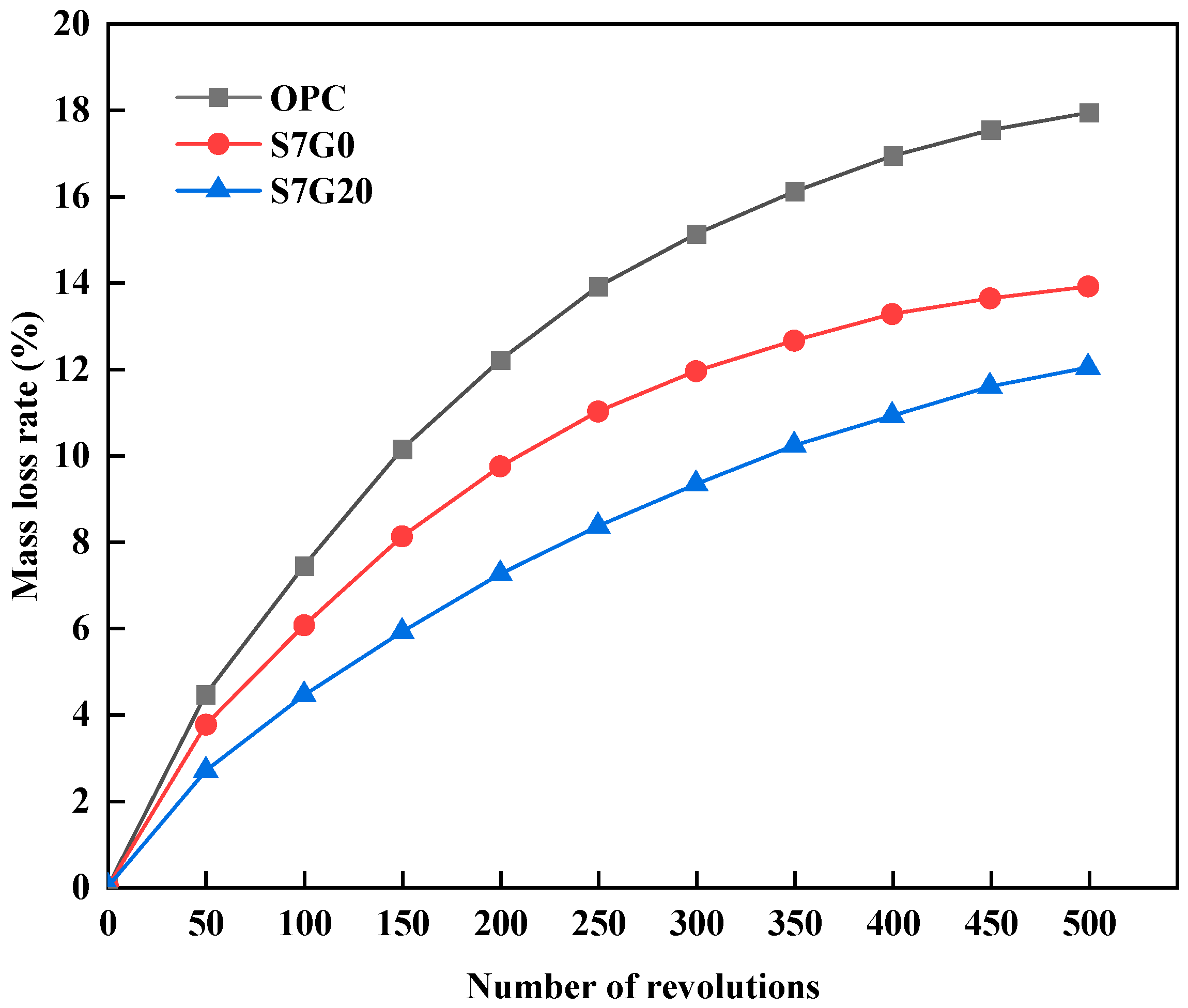

3.4.3. Effect of the Number of Revolutions on the Rate of RAPC Mass Loss

3.5. Relationship between Mechanical Properties and Abrasion Resistance of RAPC

3.6. Discussion

4. Conclusions

- Compared with the control PCs prepared with pure cement, the compressive strength of recycled aggregate pervious concrete firstly increased and then decreased with the content of SF increase. The combination of SF and GGBS showed a similar tendency. The addition of 7% SF and 20% GGBS exhibited the highest compressive strength, which reached 28.9 MPa at 28 days.

- The permeability coefficient and porosity of recycled aggregate pervious concrete were firstly reduced and then slightly increased. The incorporation of SCMs could enhance the compressive strength, while significantly reducing the permeability and porosity of the PCs correspondingly. However, the lowest permeability coefficient (1.2 mm/s) of recycled aggregate pervious concrete with SCMs also meets the design requirements.

- The mass loss of the recycled aggregate pervious concrete was firstly decreased and then declined with the increase in SF and GGBS content. The incorporation of 7% SF and 20% GGBS showed the excellent abrasion resistance of recycled aggregate pervious concrete in the Cantabro test.

- Considering their superior compressive strength and excellent permeability, PCs with 50% RCA as coarse aggregate, and 7% SF and 20% GGBS as SCMs, are practical for the production of eco-friendly permeable paving blocks, which seems to be promising for application in building construction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, X.; Wu, K.H.; Huang, W.K.; Yu, J.M.; Yu, H.Y. Application of recycled concrete aggregates and crushed bricks on permeable concrete road base. Road Mater. Pavement Des. 2021, 22, 2181–2196. [Google Scholar] [CrossRef]

- Strieder, H.L.; Dutra, V.F.P.; Graeff, Â.G.; Núñez, W.P.; Merten, F.R.M. Performance evaluation of pervious concrete pavements with recycled concrete aggregate. Constr. Build. Mater. 2022, 315, 125384. [Google Scholar] [CrossRef]

- Wijayasundara, M.; Mendis, P.; Crawford, R.H. Integrated assessment of the use of recycled concrete aggregate replacing natural aggregate in structural concrete. J. Clean. Prod. 2018, 174, 591–604. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Compression response of normal and high strength pervious concrete. Constr. Build. Mater. 2016, 109, 177–187. [Google Scholar] [CrossRef]

- AlShareedah, O.; Nassiri, S. Pervious concrete mixture optimization, physical, and mechanical properties and pavement design: A review. J. Clean. Prod. 2021, 288, 125095. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef]

- Yang, L.X.; Kou, S.C.; Song, X.F.; Lu, M.R.; Wang, Q. Analysis of properties of pervious concrete prepared with difference paste-coated recycled aggregate. Constr. Build. Mater. 2021, 269, 121244. [Google Scholar] [CrossRef]

- Liu, T.J.; Wang, Z.Z.; Zou, D.J.; Zhou, A.; Du, J.Z. Strength enhancement of recycled aggregate pervious concrete using a cement paste redistribution method. Cem. Concr. Res. 2019, 122, 72–82. [Google Scholar] [CrossRef]

- Wang, R.J.; Yu, N.N.; Li, Y. Methods for improving the microstructure of recycled concrete aggregate: A review. Constr. Build. Mater. 2020, 242, 118164. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Chen, L.; Zhang, W.L.; Zhang, K. Environmental compatibility of pervious concrete with recycled coarse aggregate applying in riparian buffer area. Constr. Build. Mater. 2024, 411, 134590. [Google Scholar] [CrossRef]

- Huang, J.D.; Zhang, Y.; Sun, Y.T.; Ren, J.L.; Zhao, Z.D.; Zhang, J.F. Evaluation of pore size distribution and permeability reduction behavior in pervious concrete. Constr. Build. Mater. 2021, 290, 123228. [Google Scholar] [CrossRef]

- Tran, T.N.H.; Kaur, H.; Sukcharoen, T.; Pulngern, T.; Sata, V.; Jaturapitakkul, C.; Ban, C.C.; Tangchirapat, W. Application of ultra high-performance mortar for producing high-performance pervious concrete with low carbon emissions and cost. J. Build. Eng. 2024, 86, 108847. [Google Scholar] [CrossRef]

- Chen, X.Y.; Wu, X.X.; Bian, X.Y.; Wu, Q.Y.; Cheng, S.K.; Ren, C.Q. Evaluating the physicochemical properties of pervious recycled aggregate concrete incorporating pozzolanic additives under acid rain attack. Constr. Build. Mater. 2024, 411, 134507. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P.; Tavakoli, D.; El-Mir, A.; Dehkordi, R.S. Synergic effect of recycled aggregates, waste glass, and slag on the properties of pervious concrete. Dev. Built Environ. 2023, 15, 100189. [Google Scholar] [CrossRef]

- Machado da França, A.P.; Bianchi Pereira da Costa, F. Evaluating the effect of recycled concrete aggregate and sand in pervious concrete paving blocks. Road Mater. Pavement Des. 2023, 24, 560–577. [Google Scholar] [CrossRef]

- Li, F.; Cai, X.; Zhang, Y.N.; Guo, X.W.; Jiang, M.M. Mechanical and Permeability Analysis and Optimization of Recycled Aggregate Pervious Concrete Based on Response Surface Method. J. Renew. Mater. 2023, 11, 1745–1762. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesolu, M.; Kareem, Q.; Ipek, S. Effect of different substitution of natural aggregate by recycled aggregate on performance characteristics of pervious concrete. Mater. Struct. 2016, 49, 521–536. [Google Scholar] [CrossRef]

- Lund, M.S.M.; Kevern, J.T.; Schaefer, V.R.; Hansen, K.K. Mix design for improved strength and freeze-thaw durability of pervious concrete fill in Pearl-Chain Bridges. Mater. Struct. 2017, 50, 42. [Google Scholar] [CrossRef]

- dos Santos Lima, G.T.; Rocha, J.C.; Cheriaf, M. Investigation of the properties of pervious concrete with a recycled aggregate designed with a new combination of admixture. Constr. Build. Mater. 2022, 340, 127710. [Google Scholar] [CrossRef]

- Tamimi, A.; Tabsh, S.W.; El-Emam, M. Pervious Concrete Made with Recycled Coarse Aggregate and Reinforced with Date Palm Leaves Fibers. Materials 2023, 16, 7496. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, M.; Fawzy, A.M. Experimental investigation on permeability indices and strength of modified pervious concrete with recycled concrete aggregate. Constr. Build. Mater. 2018, 193, 105–127. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Vieira, G.L.; Schiavon, J.Z.; Borges, P.M.; da Silva, S.R.; de Oliveira Andrade, J.J. Influence of recycled aggregate replacement and fly ash content in performance of pervious concrete mixtures. J. Clean. Prod. 2020, 271, 122665. [Google Scholar] [CrossRef]

- Elahi, M.M.A.; Shearer, C.R.; Reza, A.N.R.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Golewski, G.L. Fracture performance of cementitious composites based on quaternary blended cements. Materials 2022, 15, 6023. [Google Scholar] [CrossRef]

- Debbarma, S.; Ransinchung, G.; Singh, S. Improving the properties of RAP-RCCP mixes by incorporating supplementary cementitious materials as part addition of portland cement. J. Mater. Civ. Eng. 2020, 32, 04020229. [Google Scholar] [CrossRef]

- Ganesh, P.; Murthy, A.R. Tensile behaviour and durability aspects of sustainable ultra-high performance concrete incorporated with GGBS as cementitious material. Constr. Build. Mater. 2019, 197, 667–680. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- İpek, S.; Diri, A.; Mermerdaş, K. Recycling the low-density polyethylene pellets in the pervious concrete production. J. Mater. Cycles Waste Manag. 2021, 23, 272–287. [Google Scholar] [CrossRef]

- Furkan Ozel, B.; Sakallı, Ş.; Şahin, Y. The effects of aggregate and fiber characteristics on the properties of pervious concrete. Constr. Build. Mater. 2022, 356, 129294. [Google Scholar] [CrossRef]

- CJJ/T 135-2009. Available online: https://www.codeofchina.com/standard/CJJT135-2009.html (accessed on 21 March 2024).

- ASTM C39/C39M. Available online: https://www.astm.org/astm-tpt-174.html (accessed on 21 March 2024).

- ASTM C1754-12. Available online: https://www.google.com.hk/url?sa=t&source=web&rct=j&opi=89978449&url=https://cdn.standards.iteh.ai/samples/80784/2c1aef8915e04a468a527cb22a534e86/ASTM-C1754-C1754M-12.pdf&ved=2ahUKEwjV3IzI24mGAxWR_7sIHXU9AB4QFnoECBUQAQ&usg=AOvVaw1zYUmHGKZPEtFOy0TRIb3J (accessed on 21 March 2024).

- Jike, N.; Xu, C.J.; Yang, R.J.; Qi, Y.X.; Dai, Y.Q.; Peng, Y.; Wang, J.Y.; Zhang, M.Z.; Zeng, Q. Pervious concrete with secondarily recycled low-quality brick-concrete demolition residue: Engineering performances, multi-scale/phase structure and sustainability. J. Clean. Prod. 2022, 341, 130929. [Google Scholar] [CrossRef]

- Singh, A.; Biligiri, K.P.; Sampath, P.V. Engineering properties and lifecycle impacts of Pervious All-Road All-weather Multilayered pavement. Resour. Conserv. Recycl. 2022, 180, 106186. [Google Scholar] [CrossRef]

- Shen, P.L.; Lu, J.X.; Zheng, H.B.; Liu, S.H.; Sun Poon, C. Conceptual design and performance evaluation of high strength pervious concrete. Constr. Build. Mater. 2020, 269, 121342. [Google Scholar] [CrossRef]

- Xie, X.G.; Zhang, T.S.; Wang, C.; Yang, Y.M.; Bogush, A.; Khayrulina, E.; Huang, Z.M.; Wei, J.X.; Yu, Q.J. Mixture proportion design of pervious concrete based on the relationships between fundamental properties and skeleton structures. Cem. Concr. Compos. 2020, 113, 103693. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Yang, K.H.; Jung, Y.B.; Cho, M.S.; Tae, S.H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Khalid, N.H.A.; Fediuk, R.; Ozbakkaloglu, T.; Lee, Y.H.; Haruna, S.; Lee, Y.Y. Slag uses in making an ecofriendly and sustainable concrete: A review. Constr. Build. Mater. 2021, 272, 121942. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of silica fume in concrete: Review of hardened properties. Resour. Conserv. Recycl. 2011, 55, 923–932. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

| Density (kg/m3) | Water for Standard Consistency (%) | Stability | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3 d | 28 d | 3 d | 28 d | |||

| 3150 | 28.1 | qualified | 231 | 296 | 25.3 | 47.9 | 4.8 | 7.9 |

| Aggregate Type | Aggregate Size (mm) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Water Absorption (%) | Crushing Value (%) |

|---|---|---|---|---|---|

| NCA | 9.50–16 | 2700 | 1510 | 0.7 | 2.3 |

| RCA | 4.75–9.50 | 2670 | 1266 | 4.3 | 8.6 |

| RCA | 9.50–16 | 2631 | 1269 | 9.3 | 12.3 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Ignition Loss | |

|---|---|---|---|---|---|---|---|

| SF | 92.8 | 2.10 | 0.50 | 0.48 | 0.61 | — | 2.20 |

| GGBS | 21.5 | 7.2 | 1.48 | 50.1 | 0.4 | 3.32 | 1.98 |

| Cement | 23.42 | 6.35 | 4.65 | 63.4 | 1.86 | 2.65 | 1.72 |

| NO. | Water | Cement | NCA | RCA | SF | GGBS | SP |

|---|---|---|---|---|---|---|---|

| OPC | 127.76 | 425.86 | 739.9 | 739.9 | 0.00 | 0.00 | 4.69 |

| S3G0 | 127.76 | 413.08 | 739.9 | 739.9 | 12.78 | 0.00 | 4.69 |

| S5G0 | 127.76 | 404.57 | 739.9 | 739.9 | 21.29 | 0.00 | 4.69 |

| S7G0 | 127.76 | 396.05 | 739.9 | 739.9 | 29.81 | 0.00 | 4.69 |

| S9G0 | 127.76 | 387.53 | 739.9 | 739.9 | 38.33 | 0.00 | 4.69 |

| S7G10 | 127.76 | 353.45 | 739.9 | 739.9 | 29.81 | 42.59 | 4.69 |

| S7G15 | 127.76 | 332.17 | 739.9 | 739.9 | 29.81 | 63.88 | 4.69 |

| S7G20 | 127.76 | 310.88 | 739.9 | 739.9 | 29.81 | 85.17 | 4.69 |

| S7G25 | 127.76 | 289.59 | 739.9 | 739.9 | 29.81 | 106.5 | 4.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, X.; Zhou, H.; Bian, X.; Chen, X.; Ren, C. Compressive Strength, Permeability, and Abrasion Resistance of Pervious Concrete Incorporating Recycled Aggregate. Sustainability 2024, 16, 4063. https://doi.org/10.3390/su16104063

Bai X, Zhou H, Bian X, Chen X, Ren C. Compressive Strength, Permeability, and Abrasion Resistance of Pervious Concrete Incorporating Recycled Aggregate. Sustainability. 2024; 16(10):4063. https://doi.org/10.3390/su16104063

Chicago/Turabian StyleBai, Xixuan, Heng Zhou, Xiaoya Bian, Xuyong Chen, and Chengqiang Ren. 2024. "Compressive Strength, Permeability, and Abrasion Resistance of Pervious Concrete Incorporating Recycled Aggregate" Sustainability 16, no. 10: 4063. https://doi.org/10.3390/su16104063

APA StyleBai, X., Zhou, H., Bian, X., Chen, X., & Ren, C. (2024). Compressive Strength, Permeability, and Abrasion Resistance of Pervious Concrete Incorporating Recycled Aggregate. Sustainability, 16(10), 4063. https://doi.org/10.3390/su16104063