Evaluating the Efficiencies of Logistics Centers with Fuzzy Logic: The Case of Turkey †

Abstract

1. Introduction

2. Literature Review

3. Materials, Variables and Methodology

3.1. Materials

3.2. DMUs Used and Selection of Variables

- Output-Total Revenue (turnover): the data obtained concerning revenue from LC activities was scrutinized. This included the annual overall revenue generated by various activities conducted by LC, comprising domestic and international transportation revenues, along with other incomes categorized under the ‘other’ section. The annual total revenue (turnover) was calculated in Turkish Lira (TL) for this study. Within this scope, this variable was considered the output, aiming to assess how effectively LCs utilized their inputs to generate this output.

- Input-Installed area : this variable indicates the current size of the LC area (in ), encompassing warehouses, terminals, road-rail connections, container loading-unloading, and stock areas, among others.

- Input-Capacity (tons): it denotes the maximum total cargo capacity (inbound and outbound cargo) that an LC can handle within a year, expressed in tons.

- Input-Number of personnel: this variable signifies the total permanent personnel actively working within the LC, including maintenance, management, and support staff.

- Input-Number of railway lines: it reflects the total count of railway tracks within the LC, encompassing loading-unloading ramp lines, main ramps, running lines, platforms, train formation, maneuvering, dispatch lines, and weighing lines.

- Input-Total number of engaged companies: this variable denoted the number of companies collaborated with, a result of the LC’s conducted activities and offered services.

- Input-Total railway transportations: this variable represents the total amount of railway cargo transported from the LC in 2022, measured in tons.

- Input-Total handled cargo quantity (nett): based on 2022 data, this variable signified the total handled cargo quantity (inbound and outbound cargo) in nett tons within the LC. (netton: the ton loaded on a wagon in proportion to its capacity).

- Input-Total handled cargo quantity (netton-km): derived from 2022 data, this variable represented the distance (in km) that the total handled cargo traveled after leaving the LC in nettons. (netton-km: distance traveled in km by nettons).

- Input-Number of loaded/unloaded wagons: this variable indicated the total number of loaded and unloaded wagons for inbound and outbound cargo within the LC during 2022.

3.3. Methodology

3.3.1. Classical DEA Model

- CCR (Charnes, Cooper, and Rhodes) Model: this model is based on the principle of “constant returns to scale” and calculates the efficiency level between the system’s inputs and outputs, aiming to achieve the best state by altering inputs to reduce or outputs to increase. This model considers only strategies for reducing inputs or increasing outputs for each business.

- BCC (Banker, Charnes, and Cooper) Model: In this model, based on the principle of “variable returns to scale” the system had the flexibility to employ strategies for both reducing inputs and increasing outputs. The BCC model calculates efficiency levels by allowing businesses to make balanced changes to inputs and outputs.

- input-oriented DEA: in input-oriented DEA, a system’s efficiency is assessed from the perspective of how effectively it uses the given input quantity to achieve maximum output-essentially, how efficiently it utilizes resources to generate more output. This evaluation aims to minimize the system’s inputs proportionally while keeping outputs constant. The input-oriented efficiency of a system reflects its success in obtaining the highest possible output with the given input quantity.

- output-oriented DEA: on the other hand, output-oriented DEA examines a system’s ability to maximize output, focusing on how effectively it can use input to achieve the desired output quantity. This assessment aims to maximize the system’s outputs proportionally while keeping inputs constant. The output-oriented efficiency of a system reflects how little input it needs to achieve the highest possible output.

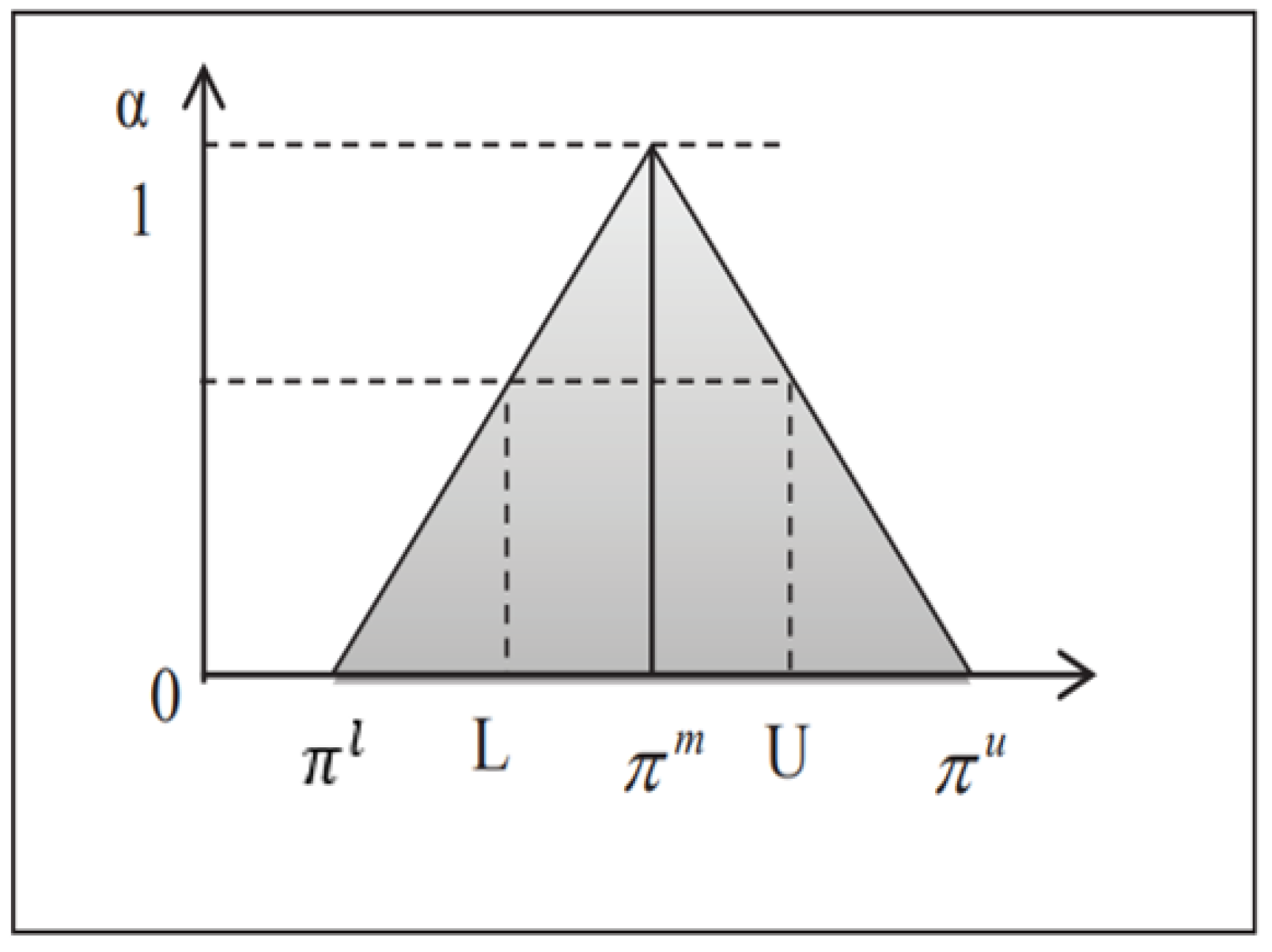

3.3.2. Fuzzy DEA Model

- identification of decision units (alternatives) involved in the research problem.

- Classification of relevant variables for decision units into input and output variables.

- Computation of various descriptive statistical information for input and output variables.

- Calculation of fuzzy lower and upper bounds (intervals) of variables using symmetric triangular membership functions with standard errors for input and output variables.

- Clarification and refinement of fuzzy lower and upper bounds of the fuzzified input and output variables using -cut levels, followed by the computation of lower and upper bound efficiencies using classical DEA models.

- Since there are two efficiency values for each -cut, obtaining the final efficiencies and rankings by combining these efficiencies with the Chen–Klein Index.

- Statistical testing of the relationship between rankings of classical DEA efficiencies and Fuzzy-DEA efficiencies using the ‘Spearman Rank Correlation’ test for each -cut.

4. Results

- the main aim behind adopting the “variable returns to scale” approach in measuring the efficiencies of LCs is as follows. In assessing efficiency using the variable returns to scale approach, it is asserted the proportional change in inputs differs from the change in outputs. Specifically, the notion that when inputs double, outputs also double proportionally forms the basis of the “constant returns to scale (CCR Model)” approach. Conversely, the principle underlying the “variable returns to scale” approach emerges when the doubling of inputs results in a more or less than twofold change in outputs (a proportional differentiation) [40]. This understanding, considering similar efficiency measurement studies in the literature mentioned in previous sections, led to the adoption of the “variable returns to scale” approach in assessing the efficiencies of LCs in this study, considering the selected inputs (such as installed area, capacity, personnel number, etc.) and outputs (total revenue). This conclusion was influenced by the realization that changes in inputs, whether increased or decreased, might not correspond proportionally to changes in total revenue due to various internal and external factors.

- The primary purpose behind adopting the input-oriented approach is as follows. In input-oriented Fuzzy-DEA, a system is evaluated from the perspective of how efficiently it utilizes a given amount of input to achieve maximum output, i.e., how effectively it utilizes resources to generate more output. This approach is aimed at proportionally minimizing the system’s inputs while keeping the outputs constant [87]. Hence, considering the relevant literature provided in the previous sections, the adoption of the input-oriented Fuzzy-DEA model in the study is aimed at determining to what extent the inputs should be minimized to achieve the output data (total revenue) for LCs in the year 2022.

5. Discussion

6. Conclusions

- it is imperative to identify the LCs as are highlighted in these and similar studies and strategize plans to enhance the efficiency of these centers. Ensuring the efficient utilization of resources in these centers is crucial.

- The expedited execution of studies aiming to establish nine new centers in addition to the existing twelve LCs was of significant importance for completing essential railway connections among all LCs in Turkey.

- Formulating regional logistics master plans could contribute to new LC establishment plans that would be based on needs and offered a more balanced distribution, rather than being driven solely by political decisions.

- Facilitating a tighter integration, particularly through the establishment of railway connections, between LCs and production centers is essential. Various incentives should be provided in this context.

- Investments in modern equipment and cutting-edge technology tailored to the industry’s needs should be made in LCs. Technologies such as automation, monitoring systems, and data analytics are pivotal in enhancing the appeal of these centers.

- Embracing a more proactive approach in managing LCs in Turkey is crucial to establish a competitive ecosystem. Increasing collaboration between the public and private sectors is vital for swiftly meeting customer needs. Furthermore, such collaboration can facilitate the more effective utilization of public resources and maximize leveraging the experiences of the private sector.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

Appendix A

References

- Kristiansen, J.; Johannsen, H.H.W.; Hansen, L.G.; Hansen, C.J. Transport system concepts and definitions. In Sutranet; Department of Development and Planning, Aalborg University: Aalborg, Denmark, 2005; pp. 1–20. Available online: https://vbn.aau.dk/ws/portalfiles/portal/4783616/JK_HHWJ_LGH_CJH_Transport_systems_concepts_working_paper_2006.pdf (accessed on 15 December 2023).

- The European Logistic Platforms Association (Europlatforms). Available online: https://europlatforms.eu/Logistic%20Center%20Definition.html (accessed on 15 December 2023).

- Higgins, C.D.; Ferguson, M.; Kanaroglou, P.S. Varieties of logistics centers: Developing standardized typology and hierarchy. Transp. Res. Rec. 2012, 2288, 9–18. [Google Scholar] [CrossRef]

- Eygü, H.; Karabacak, E. Türkiye’de ulaştırma hizmetlerinden duyulan memnuniyetin genelleştirilmiş sıralı logit modelleri ile analizi. J. Acad. Value Stud. 2020, 6, 117–135. [Google Scholar] [CrossRef]

- Eygü, H.; Karabacak, E. Afet lojistik yönetimi temelinde risk yönetim endeksi verileriyle Türkiye ile AB ülkelerinin karşılaştırılması. Atatürk Üniversitesi İktisadi İdari Bilim. Derg. 2017, 31, 627–648. [Google Scholar]

- Tadić, S.; Krstić, M.; Brnjac, N. Selection of efficient types of inland intermodal terminals. J. Transp. Geogr. 2019, 78, 170–180. [Google Scholar] [CrossRef]

- Mahilange, P.K. Effective supply chain management equilibrates the supply and demand management of an organization. Asian J. Manag. 2016, 7, 231–235. [Google Scholar] [CrossRef]

- Miškić, S.; Tadić, S.; Stević, Ž.; Krstić, M.; Roso, V. A novel hybrid model for the evaluation of industry 4.0 technologies’ applicability in logistics centers. J. Math. 2023, 2023, 3532862. [Google Scholar] [CrossRef]

- Ulutaş, A.; Karakuş, C.B.; Topal, A. Location selection for logistics center with fuzzy SWARA and CoCoSo methods. J. Intell. Fuzzy Syst. 2020, 38, 4693–4709. [Google Scholar] [CrossRef]

- Bounie, N.; Blanquart, C. Logistics centers and agglomeration economies: Logistics clusters or Co-located logistics activities? The French case. In World Conference on Transport Research (WCTR 2016); Elsevier: Shanghai, China, 2016; Volume 25, Available online: https://hal.science/hal-01590275/document (accessed on 15 December 2023).

- Wang, Y.; Wang, X.; Wei, Y.; Sun, Y.; Fan, J.; Wang, H. Two-echelon multi-depot multi-period location-routing problem with pickup and delivery. Comput. Ind. Eng. 2023, 182, 109385. [Google Scholar] [CrossRef]

- Sbihi, A.; Eglese, R.W. Combinatorial optimization and green logistics. Ann. Oper. Res. 2010, 175, 159–175. [Google Scholar] [CrossRef]

- Vermeulen, W.J.; Seuring, S. Sustainability through the market-the impacts of sustainable supply chain management: Introduction. Sustain. Dev. 2009, 17, 269–273. [Google Scholar] [CrossRef]

- European Commission, The Transport Research and Innovation Monitoring and Information System (TRIMIS), FV-2000—Quality of Freight Villages Structure and Operations. Available online: https://trimis.ec.europa.eu/system/files/project/documents/fv2000.pdf (accessed on 15 December 2023).

- Vleugel, J. Modelling goods city distribution in the Netherlands. Eur. Transp. 2004, 28, 20–33. [Google Scholar]

- Heuer, F.; Furusawa, Y.; Bockel, R.; Visser, J.G.S.N. Delivering the Goods, 21st Century Challenges to Urban Goods Transport; OECD: Parijs, France, 2003; 156p, Available online: https://research.tudelft.nl/en/publications/delivering-the-goods-21st-century-challenges-to-urban-goods-trans (accessed on 15 December 2023).

- Wu, J. Sustainable Freight Village Concepts for Agricultural Products Logistics-A Knowledge Management-Oriented Study. Ph.D. Dissertation, Fachbereich Wirtschaftswissenschaft, Universität Bremen, Bremen, Germany, 2013. Available online: http://nbn-resolving.de/urn:nbn:de:gbv:46-00103227-16 (accessed on 15 December 2023).

- Taniguchi, E.; Noritake, M.; Yamada, T.; Izumitani, T. Optimal size and location planning of public logistics terminals. Transp. Res. Part E Logist. Transp. Rev. 1999, 35, 207–222. [Google Scholar] [CrossRef]

- Republic of Turkey Ministry of Transport and Infrastructure. Available online: https://uhdgm.uab.gov.tr/lojistik-merkezler (accessed on 15 December 2023).

- Turkish State Railways (TCDD). Available online: https://www.tcdd.gov.tr/kurumsal/lojistik-merkezler (accessed on 15 December 2023).

- Meidute, I. Comparative analysis of the definitions of logistics centres. Transport 2005, 20, 106–110. [Google Scholar] [CrossRef]

- Özden, Ü. Veri zarflama analizi (VZA) ile Türkiye’deki vakıf üniversitelerinin etkinliğinin ölçülmesi. İstanbul Üniversitesi İşletme Fakültesi Derg. 2008, 37, 167–185. [Google Scholar]

- Yeşilyurt, C. Performans ölçümünde kullanılan parametreli ve parametresiz etkinlik ölçüm yöntemlerinin karşılaştırılması. Atatürk Üniversitesi Sos. Bilim. Enstitüsü Derg. 2018, 22, 2941–2953. [Google Scholar]

- Yu, M.C.; Su, M.H. Using fuzzy DEA for green suppliers’ selection considering carbon footprints. Sustainability 2017, 9, 495. [Google Scholar] [CrossRef]

- He, M.; Shen, J.; Wu, X.; Luo, J. Logistics space: A literature review from the sustainability perspective. Sustainability 2018, 10, 2815. [Google Scholar] [CrossRef]

- Demir, E.; Hrušovský, M.; Jammernegg, W.; Van Woensel, T. Green intermodal freight transportation: Bi-objective modelling and analysis. Int. J. Prod. Res. 2019, 57, 6162–6180. [Google Scholar] [CrossRef]

- Paul, A.; Shukla, N.; Paul, S.K.; Trianni, A. Sustainable supply chain management and multi-criteria decision-making methods: A systematic review. Sustainability 2021, 13, 7104. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Lu, C. Evaluating the effects of logistics center location: An analytical framework for sustainable urban logistics. Sustainability 2023, 15, 3091. [Google Scholar] [CrossRef]

- Tadić, S.; Krstić, M.; Roso, V.; Brnjac, N. Dry port terminal location selection by applying the hybrid grey MCDM model. Sustainability 2020, 12, 6983. [Google Scholar] [CrossRef]

- Shoukhbaf, B.; Kamalabadi, I.N. Logistics network design considering the location of logistics hubs: A case study of western Iran. Int. J. Innov. Eng. 2021, 1, 74–89. [Google Scholar] [CrossRef]

- Feng, X.; Zhou, Y.; Gao, M. A research on warehouse operation optimization of logistics center. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 632, p. 022055. [Google Scholar] [CrossRef]

- Saruchera, F. Determinants of effective high-risk cargo logistics at sea ports: A case study. J. Transp. Supply Chain Manag. 2020, 14, 1–13. [Google Scholar] [CrossRef]

- Tadić, S.; Krstić, M.; Zečević, S. Defining the typical structures of the intermodal terminals. In Quantitative Methods in Logistics; University of Belgrade: Belgrade, Serbia, 2020; pp. 67–86. [Google Scholar] [CrossRef]

- Tadić, S.; Krstić, M.; Roso, V.; Brnjac, N. Planning an intermodal terminal for the sustainable transport networks. Sustainability 2019, 11, 4102. [Google Scholar] [CrossRef]

- Parola, F.; Satta, G.; Buratti, N.; Vitellaro, F. Digital technologies and business opportunities for logistics centres in maritime supply chains. Marit. Policy Manag. 2021, 48, 461–477. [Google Scholar] [CrossRef]

- Khan, A.; Chen, C.C.; Suanpong, K.; Ruangkanjanases, A.; Kittikowit, S.; Chen, S.C. The impact of CSR on sustainable innovation ambidexterity: The mediating role of sustainable supply chain management and second-order social capital. Sustainability 2021, 13, 12160. [Google Scholar] [CrossRef]

- Şahan, D.; Tuna, O. Policy implications on transport infrastructure–trade dynamics: Case of Turkey. Logistics 2021, 5, 47. [Google Scholar] [CrossRef]

- He, Z.; Sun, L.; Wang, Y.; Zhu, C. Empirical study on efficiency of regional freight logistics in China. Int. J. Logist. Syst. Manag. 2006, 2, 302. [Google Scholar] [CrossRef]

- Markovits-Somogyi, R.; Gecse, G.; Bokor, Z. Basic efficiency measurement of Hungarian logistics centres using data envelopment analysis. Period. Polytech. Soc. Manag. Sci. 2011, 19, 97–101. [Google Scholar] [CrossRef]

- Kapucu, Y. Lojistik Merkezlerinin Etkinlik Analizi: TCDD. Master’s Thesis, Institute of Science-Gazi University, Ankara, Turkey, 2018. [Google Scholar]

- Dumlu, H.; Wolff, A. Türkiye’deki lojistik köylerin potansiyel etkinliklerine göre değerlendirilmesi: MOORA yöntemi ile bir uygulama. Kafkas Üniversitesi İktisadi İdari Bilim. Fakültesi Derg. 2021, 12, 1000–1026. [Google Scholar] [CrossRef]

- Keleş, N.; Pekkaya, M. Evaluation of logistics centers in terms of sustainability via MCDM methods. J. Adv. Manag. Res. 2023, 20, 291–309. [Google Scholar] [CrossRef]

- Ballis, A.; Mavrotas, G. Freight village design using the multicriteria method PROMETHEE. Oper. Research. Int. J. 2007, 7, 213–232. [Google Scholar] [CrossRef]

- Erturgut, R.; Oğuz, S. Lojistik merkezlerin ihracata etkisi: AB ülkeleri üzerine yatay kesit veriler ile regresyon analizi. Aksaray Üniversitesi İktisadi İdari Bilim. Fakültesi Derg. 2022, 14, 423–430. [Google Scholar] [CrossRef]

- Elevli, B. Logistics freight center locations decision by using Fuzzy-PROMETHEE. Transport 2014, 29, 412–418. [Google Scholar] [CrossRef]

- Kazançoğlu, Y.; Özbiltekin, M.; Özkan-Özen, Y.D. Sustainability benchmarking for logistics center location decision: An example from an emerging country. Manag. Environ. Qual. 2020, 31, 1239–1260. [Google Scholar] [CrossRef]

- Awasthi, A.; Chauhan, S.S.; Goyal, S.K. A multi-criteria decision-making approach for location planning for urban distribution centers under uncertainty. Math. Comput. Model. 2011, 53, 98–109. [Google Scholar] [CrossRef]

- He, Y.; Wang, X.; Lin, Y.; Zhou, F.; Zhou, L. Sustainable decision making for joint distribution center location choice. Transp. Res. Part D Transp. Environ. 2017, 55, 202–216. [Google Scholar] [CrossRef]

- Essaadi, I.; Grabot, B.; Féniès, P. Location of global logistic hubs within Africa based on a fuzzy multi-criteria approach. Comput. Ind. Eng. 2019, 132, 1–22. [Google Scholar] [CrossRef]

- Kumar, A.; Anbanandam, R. Location selection of multimodal freight terminal under STEEP sustainability. Res. Transp. Bus. Manag. 2019, 33, 100434. [Google Scholar] [CrossRef]

- Uyanik, C.; Tuzkaya, G.; Kalender, Z.T.; Oguztimur, S. An ıntegrated DEMATEL–IF-TOPSIS methodology for logistics centers’ location selection problem: An application for Istanbul metropolitan area. Transport 2020, 35, 548–556. [Google Scholar] [CrossRef]

- Stojanović, I.; Puška, A. Logistics performances of Gulf Cooperation Council’s countries in global supply chains. Decis. Mak. Appl. Manag. Eng. 2021, 4, 174–193. [Google Scholar] [CrossRef]

- Jaržemskis, A. Research on public logistics centre as tool for cooperation. Transport 2007, 22, 50–54. [Google Scholar] [CrossRef][Green Version]

- Kaynak, M.; Zeybek, H. Intermodal terminallerin gelişiminde lojistik merkezler, dağıtım parkları ve Türkiye’deki durum. Gazi Üniversitesi İİbf Derg. 2007, 9, 39–58. [Google Scholar]

- Council of Higher Education of Türkiye-Thesis Center, Yöktez. Available online: https://tez.yok.gov.tr/UlusalTezMerkezi// (accessed on 15 December 2023).

- Sancaklı, A. Uluslararası Lojistik Şirketlerinde Karşılaştırmalı Ölçüm (Benchmarking) Uygulamaları. Master’s Thesis, Institute of Science-Istanbul University, Istanbul, Turkey, 2006. [Google Scholar]

- Ting, C.J.; Fang, H.L. Using Data Envelopment Analysis to Evaluate the Performance of Third Party Distribution Centers. In Proceedings of the 11th IMHRC, Milwaukee, WI, USA, 2010; Available online: https://digitalcommons.georgiasouthern.edu/pmhr_2010/37 (accessed on 15 December 2023).

- Chandraprakaikul, W.; Suebpongsakorn, A. Evaluation of Logistics Companies Using Data Envelopment Analysis. In Proceedings of the 4th IEEE International Symposium on Logistics and Industrial Informatics, Smolenice, Slovakia, 5–7 September 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 81–86. Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=6319466 (accessed on 15 December 2023).

- Güner, S. Liman etkinliği ölçümünde iki aşamalı bir model önerisi ve Türk limanları üzerinde bir uygulama. Alphanumeric J. 2015, 3, 99–106. [Google Scholar]

- Park, H.G.; Lee, Y.J. The efficiency and productivity analysis of large logistics providers services in Korea. Asian J. Shipp. Logist. 2015, 31, 469–476. [Google Scholar] [CrossRef]

- Ateş, A.; Esmer, S.; Çakır, E.; Balcı, K. Karadeniz konteyner terminallerinin göreceli etkinlik analizi. Dokuz Eylül Üniversitesi Denizcilik Fakültesi Derg. 2013, 5, 1–22. [Google Scholar]

- Okursoy, A.; Bircan, K. Konteyner Limanlarının Etkinlik Ölçümlerinde Veri Zarflama Analizinin Kullanılması ve Alternatif Değişkenler için Öneriler. In Proceedings of the National Logistics and Supply Chain Congress, Aksaray, Türkiye, 16–18 May 2013; pp. 64–74. Available online: https://www.researchgate.net/profile/Algin-Okursoy/publication/258511086_Konteyner_Limanlarinin_Etkinlik_Olcumlerinde_Veri_Zarflama_Analizinin_Kullanilmasi_Ve_Alternatif_Degiskenler_Icin_Oneriler/links/568687b308aebccc4e139f76/Konteyner-Limanlarinin-Etkinlik-Oelcuemlerinde-Veri-Zarflama-Analizinin-Kullanilmasi-Ve-Alternatif-Degiskenler-Icin-Oeneriler.pdf (accessed on 15 December 2023).

- Ateş, A.; Esmer, S. Farklı yöntemler ile Türk konteyner limanlarının verimliliği. Veriml. Derg. 2014, 1, 61–76. [Google Scholar]

- Almawshekı, E.S.; Shah, M.Z. Technical efficiency analysis of container terminals in the middle eastern region. Asian J. Shipp. Logist. 2015, 31, 477–486. [Google Scholar] [CrossRef]

- Altın, F.G.; Şahin, Y.; Karaatlı, M.; Yıldız, Ö. Avrupa Birliği ülkeleri ve Türkiye’deki limanların etkinliklerinin veri zarflama analizi ile değerlendirilmesi. Süleyman Demirel Üniversitesi İktisadi İdari Bilim. Fakültesi Derg. 2017, 22, 21–30. [Google Scholar]

- Yüksekyıldız, E.; Tunçel, A.L. Determining the relative efficiency of container terminals in Turkey using fuzzy data envelopment analysis. Mar. Sci. Technol. Bull. 2020, 9, 103–113. [Google Scholar] [CrossRef]

- Acer, A. Lojistik faaliyetlerde antrepoların etkinliğinin veri zarflama analizi ile belirlenmesi. İşletme Araştırmaları Derg. 2021, 13, 2976–2989. [Google Scholar] [CrossRef]

- Dinçel, S. Roadmap of organized ındustrial zones in the logistics center establishment: Example of preliminary survey and determination of the ınfrastructure and superstructure unit area. In Administrative and Economics Sciences: Theory, Current Researches and New Trends/5; Gürder, F., Ed.; IVPE: Cetinje, Montenegro, 2022; pp. 128–146. Available online: https://www.uakb.org/source/2022%20EK%C4%B0M/ADMINISTRATIVE%20AND%20ECONOMICS%20SCIENCES%20Theory,%20Current%20Researches%20and%20New%20Trends%205.pdf (accessed on 15 December 2023).

- Nehir, E.M. Global Liman İşletmelerinde Verimlilik Ölçümü: Bulanık Analitik Hiyerarşi Prosesi ve Bulanık Veri Zarflama Analizi. Master’s Thesis, Institute of Business-Sakarya University, Sakarya, Turkey, 2022. Available online: https://tez.yok.gov.tr/UlusalTezMerkezi/tezSorguSonucYeni.jsp (accessed on 18 December 2023).

- Sun, H.; Gao, Z.; Wu, J. A bi-level programming model and solution algorithm for the location of logistics distribution centers. Appl. Math. Model. 2008, 32, 610–616. [Google Scholar] [CrossRef]

- Kengpol, A. Design of a decision support system to evaluate logistics distribution network in greater mekong subregion countries. Int. J. Prod. Econ. 2008, 115, 388–399. [Google Scholar] [CrossRef]

- Aksoy, O. Lojistik Köy Yerlerinin Belirlenmesi Için Bir Tam Sayılı Programlama Modeli: TCDD Için Bir Uygulama. Master’s Thesis, Institute of Science-Gazi University, Ankara, Turkey, 2012. [Google Scholar]

- Aksoy, O.; Özyörük, B. The ımportance of freight villages: An implementation in TCDD. Appl. Math. Model. 2015, 39, 6043–6049. [Google Scholar] [CrossRef]

- Karaşan, A. Lojistik Köy Yer Seçiminde Sezgisel Bulanık Bütünleşik Bir Çok Ölçütlü Yöntem Önerisi. Ph.D. Thesis, Institute of Science-Istanbul Thecnichal University, Istanbul, Turkey, 2016. Available online: http://hdl.handle.net/11527/17452 (accessed on 18 December 2023).

- Dıng, Z.Y.; Jo, G.S.; Wang, Y.; Yeo, G.T. The relative efficiency of container terminals in small and medium-sized ports in China. Asian J. Shipp. Logist. 2015, 31, 231–251. [Google Scholar] [CrossRef]

- Yang, C.; Taudes, A.; Dong, G. Efficiency analysis of European freight villages: Three peers for benchmarking. Cent. Eur. J. Oper. Res. 2017, 25, 91–122. [Google Scholar] [CrossRef][Green Version]

- Demirci, A.; Tarhan, D.B. Karayolu taşımacılığı optimizasyonu (veri zarflama analizi ile Mersin ilinde bir uygulama). Toros Üniversitesi İİsbf Sos. Bilim. Derg. 2017, 4, 112–131. [Google Scholar]

- Liu, M. Analysis of Regional Logistics Efficiency Based on SE-DEA Model and FCM Algorithm. In Lecture Notes in Mechanical Engineering, Proceedings of the International Conference on Advances in Materials and Manufacturing, Bhopal, India, 22–26 November 2022; Springer: Singapore, 2022; pp. 789–798. [Google Scholar] [CrossRef]

- Çevik, V.; Yılmaz, M. Lojistik köy konsepti ve Kayseri Boğazköprü Lojistik Köyü puanlandırması. Uluslararası İktisadi Ve İdari Bilim. Derg. 2016, 2, 52–70. [Google Scholar]

- Çekerol, G.; Nalçakan, M. Lojistik sektörü içerisinde Türkiye demiryolu yurtiçi yük taşıma talebinin Ridge regresyonla analizi. Marmara Üniversitesi İktisadi İdari Bilim. Derg. 2011, 31, 321–344. [Google Scholar]

- Özdemir, S.; Keskin, B.; Eren, T.; Özcan, E. Türkiye’deki lojistik merkezleri yatırım önceliklerinin değerlendirilmesinde çok ölçütlü bir karar modeli önerisi. Demiryolu Mühendisliği 2020, 12, 83–94. [Google Scholar] [CrossRef]

- Hamzaçebi, C.; İmamoğlu, G.; Alçı, A. Selection of logistics center location with MOORA method for Black Sea Region of Turkey. J. Econ. Bibliogr. 2016, 3, 74–82. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision-making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. Ser. A Gen. 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale inefficiencies in data envelopment analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Gündüz, O. Bulanık veri zarflama ile kuru kayısı yetiştiren işletmelerin etkinlik analizi. J. Agric. Sci. 2015, 21, 525–537. [Google Scholar] [CrossRef]

- Cook, W.D.; Seiford, L.M. Data envelopment analysis (DEA)–thirty years on. Eur. J. Oper. Res. 2009, 192, 1–17. [Google Scholar] [CrossRef]

- Guo, P.; Tanaka, H. Fuzzy DEA: A perceptual evaluation method. Fuzzy Sets Syst. 2001, 119, 149–160. [Google Scholar] [CrossRef]

- Kuosmanen, T.; Post, T.; Scholtes, S. Non-parametric tests of productive efficiency with errors-in-variables. J. Econom. 2007, 136, 131–162. [Google Scholar] [CrossRef]

- Sengupta, J.K. A fuzzy systems approach in data envelopment analysis. Comput. Math. Appl. 1992, 24, 259–266. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets. Inf. Control 1965, 8, 338–350. [Google Scholar] [CrossRef]

- Lertworasirikul, S.; Fang, S.C.; Joines, J.A.; Nuttle, H.L. Fuzzy data envelopment analysis (DEA): A possibility approach. Fuzzy Sets Syst. 2003, 139, 379–394. [Google Scholar] [CrossRef]

- Karsak, E.E. Using data envelopment analysis for evaluating flexible manufacturing systems in the presence of imprecise data. Int. J. Adv. Manuf. Technol. 2008, 35, 867–874. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Emrouznejad, A.; Tavana, M. A taxonomy and review of the fuzzy data envelopment analysis literature: Two decades in the making. Eur. J. Oper. Res. 2011, 214, 457–472. [Google Scholar] [CrossRef]

- Azadeh, A.; Alem, S.M. A flexible deterministic, stochastic and fuzzy Data Envelopment Analysis approach for supply chain risk and vendor selection problem: Simulation analysis. Expert Syst. Appl. 2010, 37, 7438–7448. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Saati, S.; Tavana, M. An ideal-seeking fuzzy data envelopment analysis framework. Appl. Soft Comput. 2010, 10, 1062–1070. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Mustafa, A. Fuzzy assessment of performance of a decision-making unit using DEA: A non-radial approach. Expert Syst. Appl. 2010, 37, 5153–5157. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Agrell, P.J.; Fukuyama, H.; Gholami, K.; Khoshnevis, P. The role of multiplier bounds in fuzzy data envelopment analysis. Ann. Oper. Res. 2017, 250, 249–276. [Google Scholar] [CrossRef]

- Soleimani-Damaneh, M. Establishing the existence of a distance-based upper bound for a fuzzy DEA model using duality. Chaos Solitons Fractals 2009, 41, 485–490. [Google Scholar] [CrossRef]

- Jahanshahloo, G.R.; Lotfi, F.H.; Shahverdi, R.; Adabitabar, M.; Rostamy-Malkhalifeh, M.; Sohraiee, S. Ranking DMUs by l1-norm with fuzzy data in DEA. Chaos Solitons Fractals 2009, 39, 2294–2302. [Google Scholar] [CrossRef]

- Wen, M.; You, C.; Kang, R. A new ranking method to fuzzy data envelopment analysis. Comput. Math. Appl. 2010, 59, 3398–3404. [Google Scholar] [CrossRef]

- Khanjani Shiraz, R.; Tavana, M.; Fukuyama, H. A random-fuzzy portfolio selection DEA model using value-at-risk and conditional value-at-risk. Soft Comput. 2020, 24, 17167–17186. [Google Scholar] [CrossRef]

- Qin, R.; Liu, Y.K. Modeling data envelopment analysis by chance method in hybrid uncertain environments. Math. Comput. Simul. 2010, 80, 922–950. [Google Scholar] [CrossRef]

- Wang, Y.M.; Luo, Y.; Liang, L. Fuzzy data envelopment analysis based upon fuzzy arithmetic with an application to performance assessment of manufacturing enterprises. Expert Syst. Appl. 2009, 36, 5205–5211. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Mustafa, A.; Al-Eraqi, A.S. Aggregating preference ranking with fuzzy data envelopment analysis. Knowl. Based Syst. 2010, 23, 512–519. [Google Scholar] [CrossRef]

- Wen, M.; Li, H. Fuzzy data envelopment analysis (DEA): Model and ranking method. J. Comput. Appl. Math. 2009, 223, 872–878. [Google Scholar] [CrossRef]

- Ecer, F. Üyelik fonksiyonu olarak üçgen bulanık sayılar mı yamuk bulanık sayılar mı? Gazi Üniversitesi İktisadi İdari Bilim. Fakültesi Derg. 2007, 9, 161–180. [Google Scholar]

- Toprak, Z.F. Flow discharge modeling in open canals using a new fuzzy modeling technique (SMRGT). CLEAN–Soil Air Water 2009, 37, 742–752. [Google Scholar] [CrossRef]

- Günal, A.Y.; Mehdi, R. Application of a new fuzzy logic model known as “SMRGT” for estimating flow coefficient rate. Turk. J. Eng. 2024, 8, 46–55. [Google Scholar] [CrossRef]

- Mugera, A.W. Measuring technical efficiency of dairy farms with ımprecise data: A fuzzy data envelopment analysis approach. Aust. J. Agric. Resour. Econ. 2013, 57, 501–520. [Google Scholar] [CrossRef]

- Kao, C.; Liu, S.T. Fuzzy efficiency measures in data envelopment analysis. Fuzzy Sets Syst. 2000, 113, 427–437. [Google Scholar] [CrossRef]

- Chen, C.; Klein, C.M. A simple approach to ranking a group of aggregated fuzzy utilities. IEEE Trans. Syst. Man Cybern B Cybern 1997, 27, 26–35. [Google Scholar] [CrossRef]

- Gauthier, T.D. Detecting trends using Spearman’s rank correlation coefficient. Environ. Forensics 2001, 2, 359–362. [Google Scholar] [CrossRef]

- Miran, B. Verimlilik ve Etkinlik Analizleri, Google Books. 2022. Available online: https://www.google.com.tr/books/edition/Verimlilik_ve_Etkinlik_Analizleri/-htkEAAAQBAJ?hl=tr&gbpv=0 (accessed on 19 December 2023).

- Güneş, T. Bulanık Veri Zarflama Analizi. Master’s Thesis, Institute of Science-Ankara University, Ankara, Turkey, 2006. [Google Scholar]

- Karadeniz, V.; Akpınar, E. Türkiye’de lojistik köy uygulamalari ve yeni bir lojistik köy önerisi. Marmara Coğrafya Derg. 2011, 24, 49–71. [Google Scholar]

| No | DMUs (LCs) | City | Geographical Region |

|---|---|---|---|

| 1 | Gelemen | Samsun | Black Sea |

| 2 | Kosekoy/Izmit | Kocaeli | Marmara |

| 3 | Usak | Usak | Aegean |

| 4 | Halkali | Istanbul | Marmara |

| 5 | Hasanbey | Eskisehir | Central Anatolia |

| 6 | Gokkoy | Balikesir | Marmara |

| 7 | Kaklik | Denizli | Aegean |

| 8 | Turkoglu | Kahramanmaras | Mediterranean |

| 9 | Palandoken | Erzurum | Eastern Anatolia |

| 10 | Kayacik | Konya | Central Anatolia |

| 11 | Yenice | Mersin | Mediterranean |

| 12 | Kars | Kars | Eastern Anatolia |

| Variables | Abbreviations | Previous References | |

|---|---|---|---|

| Output | Total revenue (turnover) | [39,40,56,57,58,59,60] | |

| Inputs | Installed area | [40,41,59,61,62,63,64,65,66,67,68,69] | |

| Capacity (tons) | [40,41,66,70,71,72,73,74] | ||

| Number of personnel | [39,59,60,67,68,74,75,76,77,78] | ||

| Number of railway lines | [40,68,79] | ||

| Total number of engaged companies | [68,71,76] | ||

| Total railway transportations | [68,72,73,80,81] | ||

| Total handled cargo quantity (netton) | [39,40,61,62,63,64,65,66,67,73,75,76] | ||

| Total handled cargo quantity (netton-km) | [68,73,77,82] | ||

| Number of loaded/unloaded wagons | [40,59,65,67,69,75] |

| Variables | Minimum | Maximum | Mean | Standard Deviation | ||

|---|---|---|---|---|---|---|

| Total revenue (turnover) | 1,042,228 | 84,727,941 | 35,345,916.4 | 32,585,147.2 | 9,406,521.7 | |

| Installed area | 40,000 | 1,000,000 | 421,666.7 | 289,352.7 | 83,528.9 | |

| Capacity (tons) | 246,000 | 2,000,000 | 1,137,300 | 657,153.2 | 189,703.8 | |

| Number of personnel | 2 | 181 | 73 | 63.2 | 18.3 | |

| Number of railway lines | 1 | 26 | 15 | 7.7 | 2.2 | |

| Total number of engaged companies | 1 | 15 | 8 | 4.9 | 1.4 | |

| Total railway transportations | 18,056 | 1,155,079 | 401,787.8 | 397,100.8 | 114,633.1 | |

| Total handled cargo quantity (in tons) | 3111.1 | 1,070,691.7 | 420,360.9 | 372,199.5 | 107,444.7 | |

| Total handled cargo quantity (in ton-km) | 2,511,443 | 455,606,727 | 174,562,974.9 | 151,237,390 | 43,658,473.9 | |

| Number of loaded/unloaded wagons | 286 | 52,382 | 15,201 | 15,503.6 | 4475.5 |

| -Cut Levels | ||||||

| DMUs (LCs) | 0 | 0.25 | 0.50 | 0.75 | 1 | Mean |

| Gelemen/Samsun | 0.487 | 0.560 | 0.643 | 0.726 | 0.800 | 0.643 |

| Kosekoy/Izmit | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Usak | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Halkali/Istanbul | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Hasanbey/Eskisehir | 0.978 | 1.000 | 1.000 | 1.000 | 1.000 | 0.996 |

| Gokkoy/Balikesir | 0.664 | 0.754 | 0.849 | 0.911 | 0.957 | 0.827 |

| Kaklik/Denizli | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Turkoglu/Kahramanmaras | 1.000 | 1.000 | 1.000 | 1.000 | 0.905 | 0.981 |

| Palandoken/Erzurum | 0.170 | 0.265 | 0.388 | 0.697 | 0.902 | 0.484 |

| Kayacik/Konya | 0.567 | 0.769 | 0.882 | 0.940 | 0.909 | 0.813 |

| Yenice/Mersin | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Kars | 0.066 | 0.119 | 1.000 | 1.000 | 1.000 | 0.637 |

| mean | 0.744 | 0.789 | 0.897 | 0.940 | 0.956 | 0.865 |

| -Cut Levels | ||||||

| DMUs (LCs) | 0 | 0.25 | 0.50 | 0.75 | 1 | Mean |

| Gelemen/Samsun | 0.657 | 0.685 | 0.717 | 0.756 | 0.800 | 0.723 |

| Kosekoy/Izmit | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Usak | 0.251 | 0.303 | 0.389 | 0.574 | 1.000 | 0.504 |

| Halkali/Istanbul | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Hasanbey/Eskisehir | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Gokkoy/Balikesir | 0.788 | 0.821 | 0.859 | 0.903 | 0.957 | 0.866 |

| Kaklik/Denizli | 0.633 | 0.704 | 0.838 | 1.000 | 1.000 | 0.835 |

| Turkoglu/Kahramanmaras | 0.518 | 0.569 | 0.638 | 0.742 | 0.905 | 0.674 |

| Palandoken/Erzurum | 0.255 | 0.306 | 0.390 | 0.554 | 0.902 | 0.481 |

| Kayacik/Konya | 0.807 | 0.828 | 0.852 | 0.880 | 0.909 | 0.855 |

| Yenice/Mersin | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Kars | 0.103 | 0.131 | 0.186 | 0.335 | 1.000 | 0.351 |

| mean | 0.668 | 0.696 | 0.739 | 0.812 | 0.956 | 0.774 |

| Rank | DMUs (LCs) | ||

|---|---|---|---|

| 1 | Kosekoy/Izmit | 1.000 | 1.000 |

| 2 | Halkali/Istanbul | 1.000 | 1.000 |

| 3 | Yenice/Mersin | 1.000 | 1.000 |

| 4 | Kaklik/Denizli | 1.000 | 1.000 |

| 5 | Usak | 1.000 | 1.000 |

| 6 | Hasanbey/Eskisehir | 0.995 | 1.000 |

| 7 | Turkoglu/Kahramanmaras | 0.968 | 0.905 |

| 8 | Gokkoy/Balikesir | 0.815 | 0.957 |

| 9 | Kayacik/Konya | 0.801 | 0.909 |

| 10 | Gelemen/Samsun | 0.635 | 0.800 |

| 11 | Palandoken/Erzurum | 0.423 | 0.902 |

| 12 | Kars | 0.406 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karabacak, E.; Kutlu, H.A. Evaluating the Efficiencies of Logistics Centers with Fuzzy Logic: The Case of Turkey. Sustainability 2024, 16, 438. https://doi.org/10.3390/su16010438

Karabacak E, Kutlu HA. Evaluating the Efficiencies of Logistics Centers with Fuzzy Logic: The Case of Turkey. Sustainability. 2024; 16(1):438. https://doi.org/10.3390/su16010438

Chicago/Turabian StyleKarabacak, Ebubekir, and Hüseyin Ali Kutlu. 2024. "Evaluating the Efficiencies of Logistics Centers with Fuzzy Logic: The Case of Turkey" Sustainability 16, no. 1: 438. https://doi.org/10.3390/su16010438

APA StyleKarabacak, E., & Kutlu, H. A. (2024). Evaluating the Efficiencies of Logistics Centers with Fuzzy Logic: The Case of Turkey. Sustainability, 16(1), 438. https://doi.org/10.3390/su16010438