Life Cycle Assessment of the Sugarcane Supply Chain in the Brazilian Midwest Region

Abstract

1. Introduction

2. Literature Review

2.1. Brazilian Sugar and Ethanol Industry

2.2. Sugarcane Supply Chain Sustainability

2.3. Life Cycle Assessment (LCA) of the Sugarcane Supply Chain

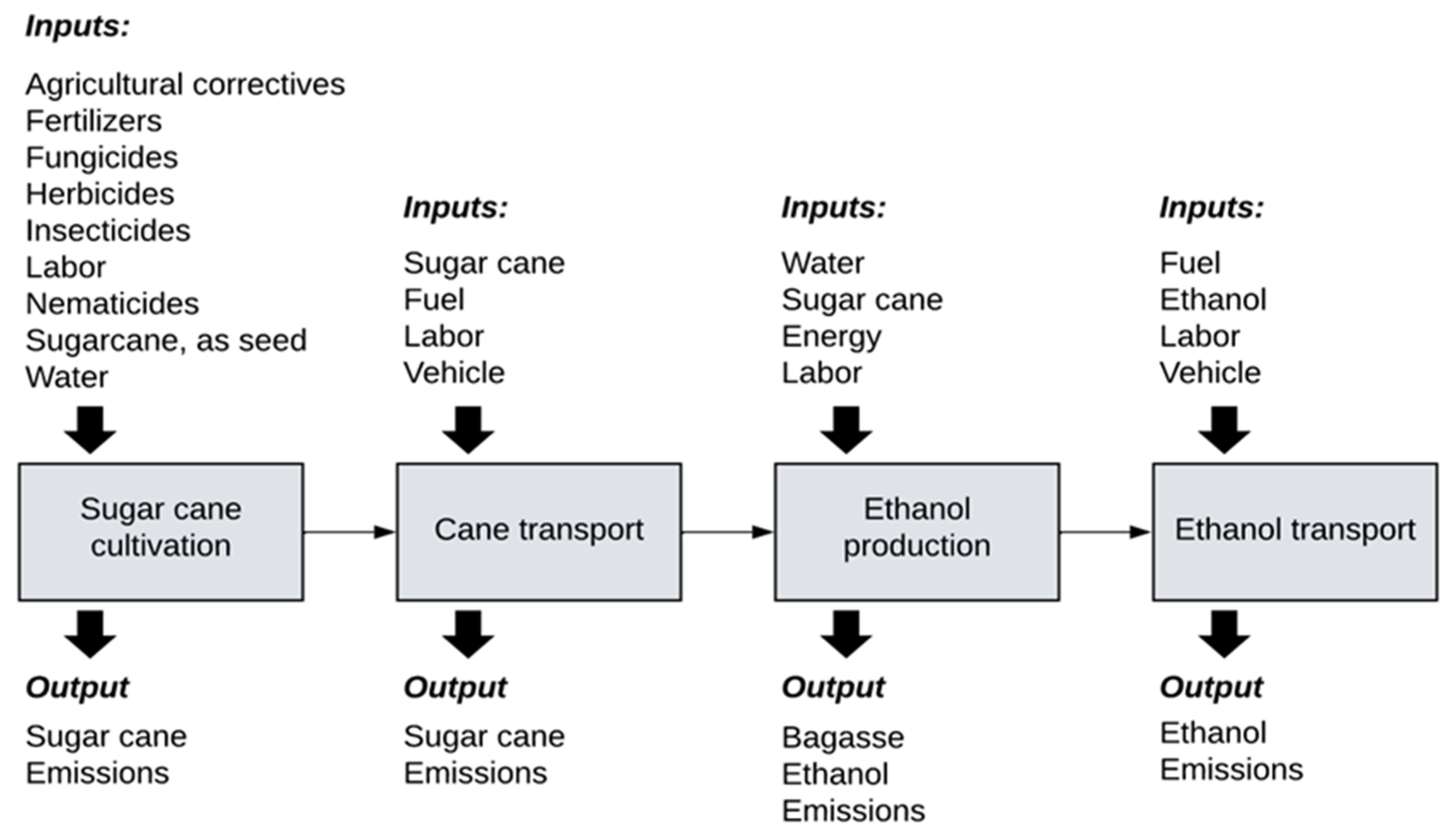

3. Materials and Methods

3.1. Research Approach

3.2. Impact Assessment

3.3. Data Collecting

4. Results Presentation and Analysis

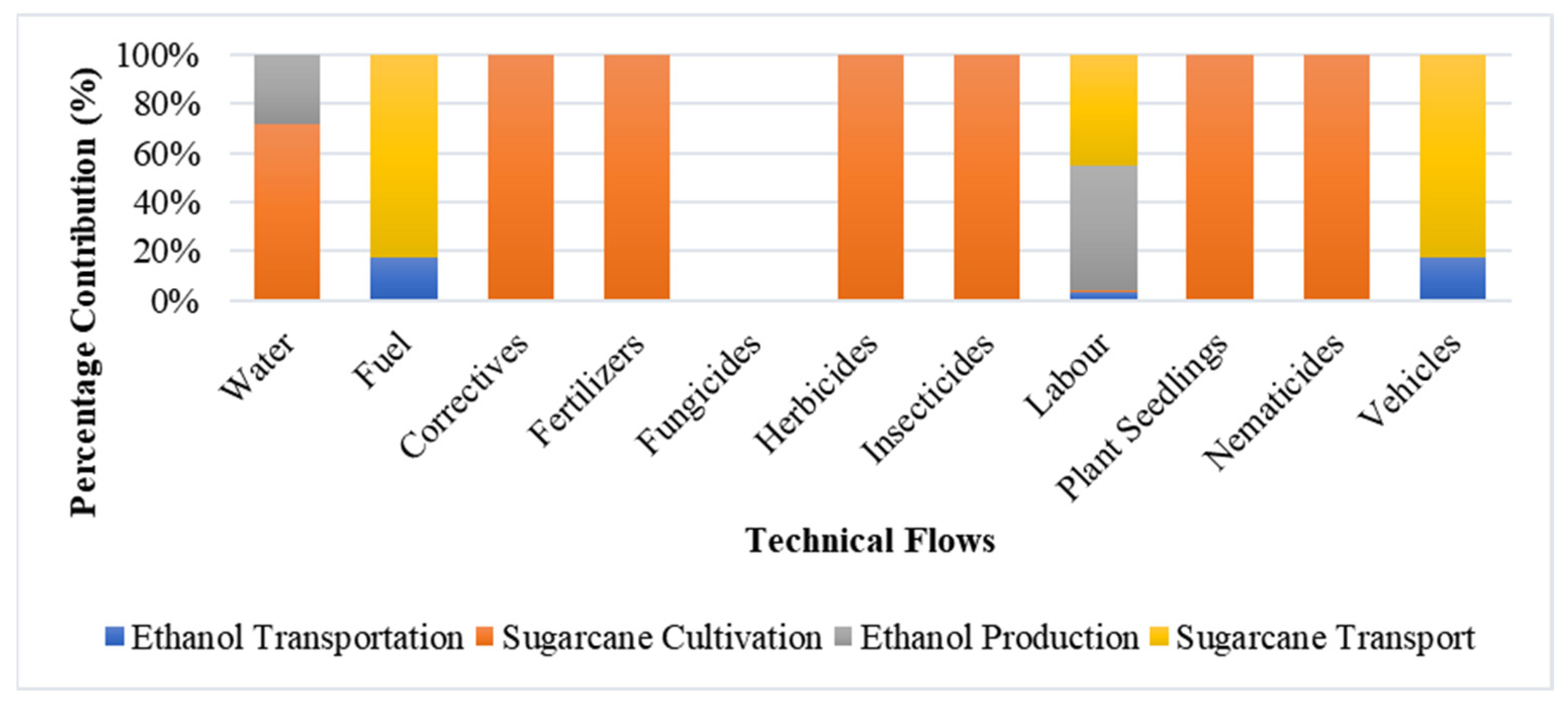

4.1. Life Cycle Inventory—Technical Flows

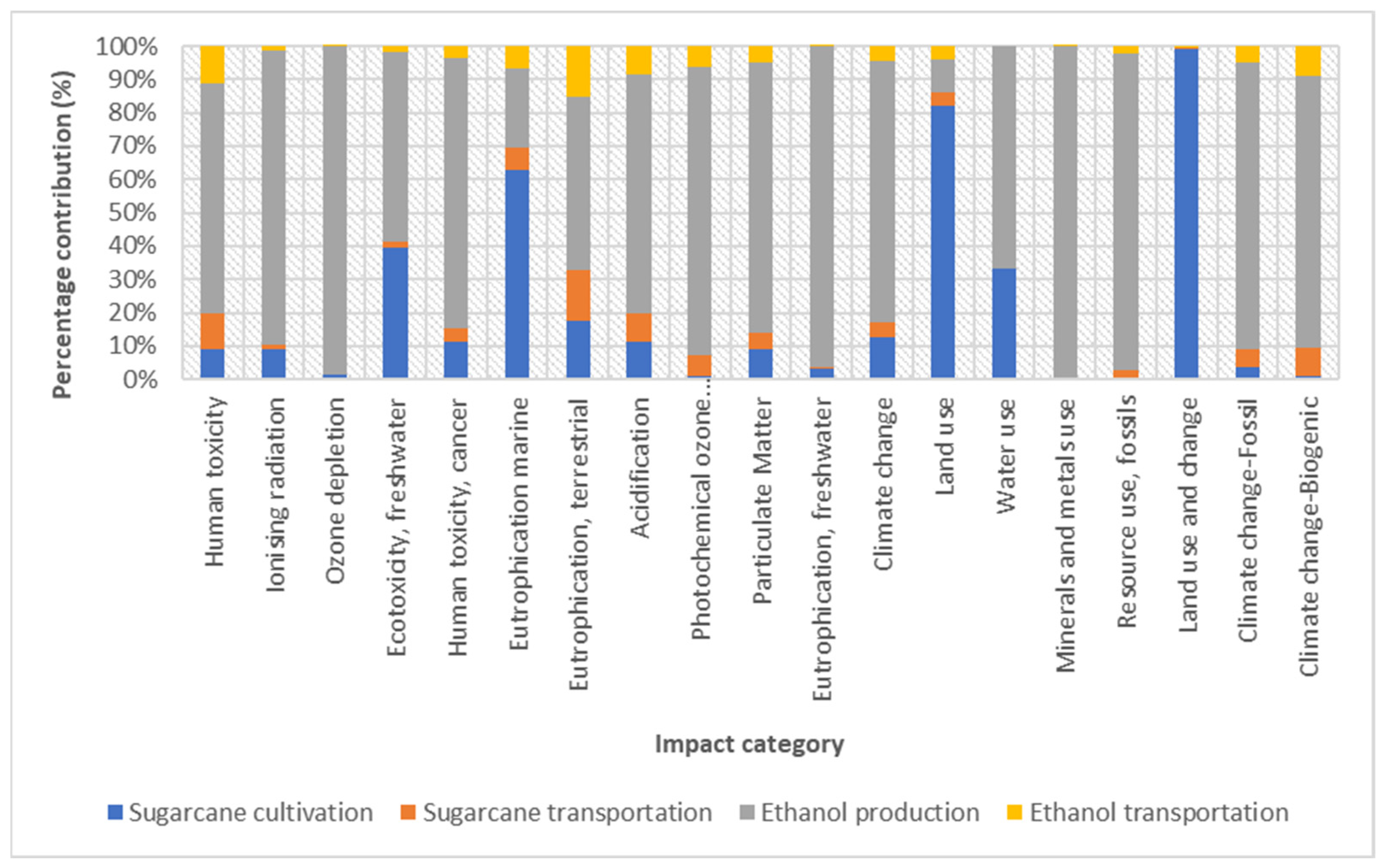

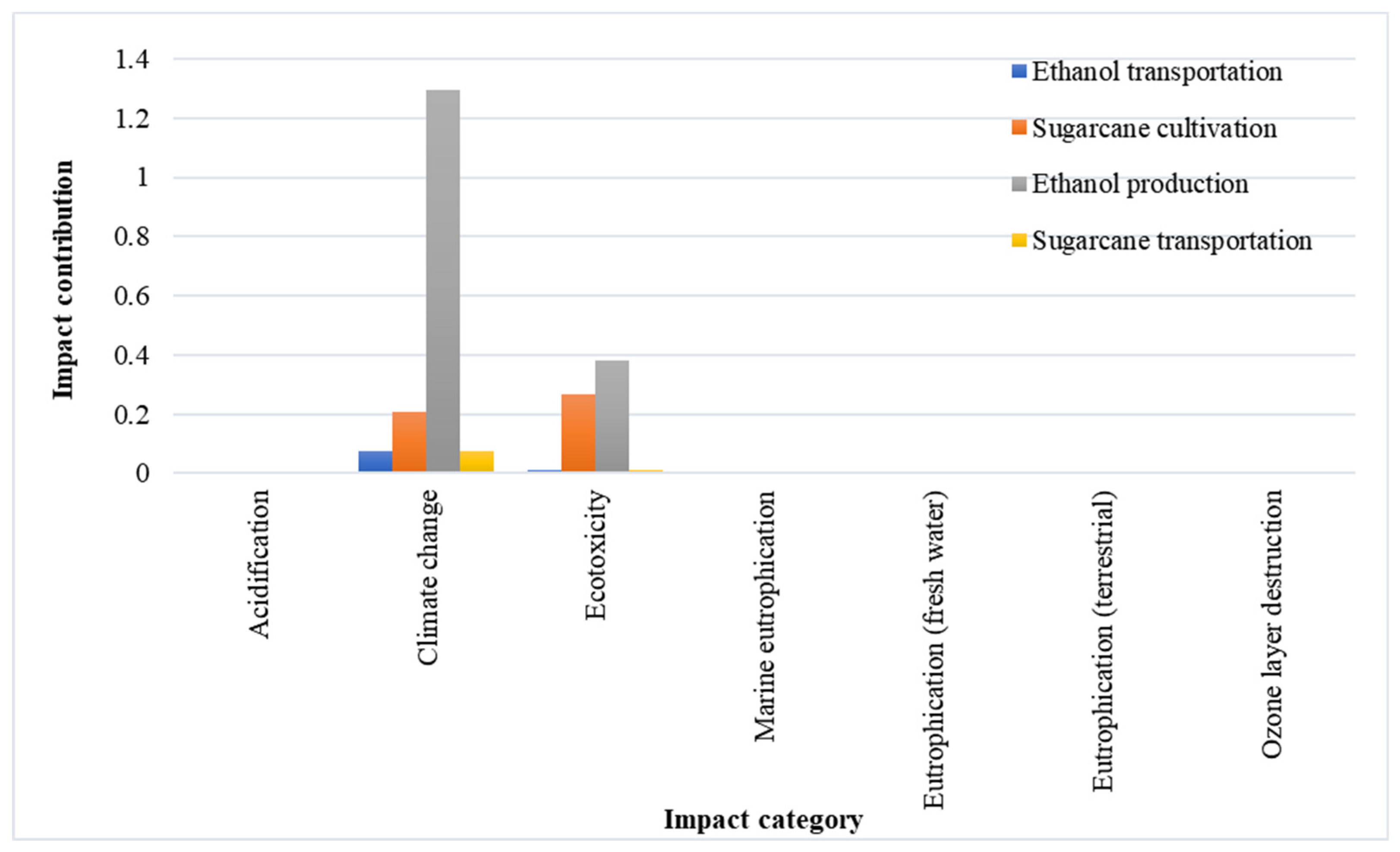

4.2. Life Cycle Impact Assessment (LCIA)—Elementary Flows

4.2.1. Ecosystem Damage

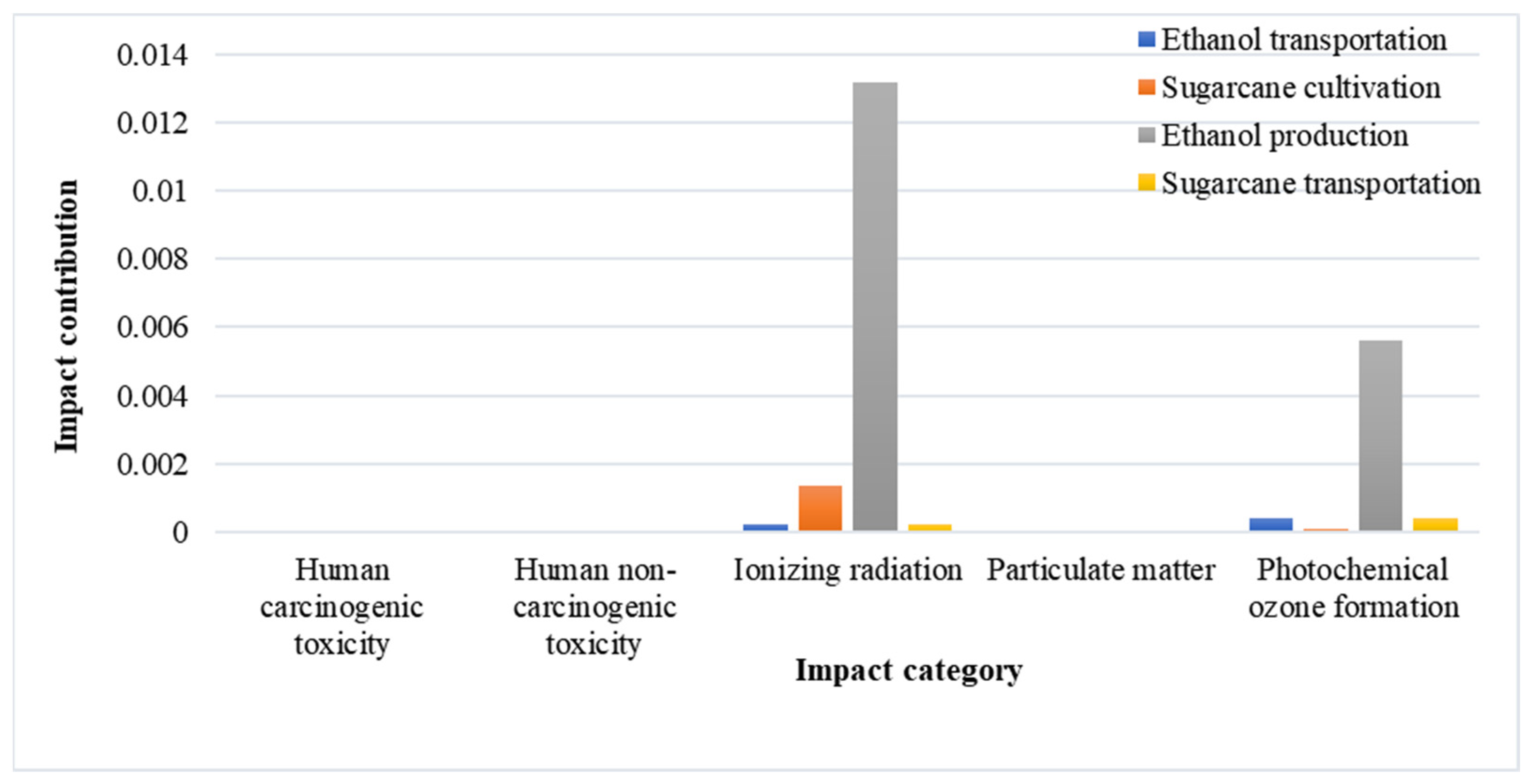

4.2.2. Human Health Damage

4.2.3. Resource Consumption

5. Discussion

5.1. Sugarcane Cultivation

5.2. Transport

5.3. Ethanol Production

5.4. Final Considerations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gilani, H.; Sahebi, H.; Oliveira, F. Sustainable sugarcane-to-bioethanol supply chain network design: A robust possibilistic programming model. Appl. Energy 2020, 278, 115653. [Google Scholar] [CrossRef]

- Jonker, J.G.G.; Junginger, H.M.; Verstegen, J.A.; Lin, T.; Rodríguez, L.F.; Ting, K.C.; Faaij, A.P.C.; Van Der Hilst, F. Supply chain optimization of sugarcane first generation and eucalyptus second generation ethanol production in Brazil. Appl. Energy 2016, 173, 494–510. [Google Scholar] [CrossRef]

- Ometto, A.R.; Hauschild, M.Z.; Roma, W.N.L. Lifecycle assessment of fuel ethanol from sugarcane in Brazil. Int. J. Life Cycle Assess. 2009, 14, 236–247. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Faaij, A.P.C.; Seabra, J.E.A.; Lundquist, L.; Schenker, U.; Briois, J.F.; Patel, M.K. Life cycle assessment of sugarcane ethanol production in India in comparison to Brazil. Int. J. Life Cycle Assess. 2014, 19, 1049–1067. [Google Scholar] [CrossRef]

- García, C.A.; García-Treviño, E.S.; Aguilar-Rivera, N.; Armendáriz, C. Carbon footprint of sugar production in Mexico. J. Clean. Prod. 2016, 112 Pt 4, 2632–2641. [Google Scholar] [CrossRef]

- Prasara-A, J.; Gheewala, S.H.; Silalertruksa, T.; Pongpat, P.; Sawaengsak, W. Environmental and social life cycle assessment to enhance sustainability of sugarcane-based products in Thailand. Clean Technol. Environ. Policy 2019, 21, 1447–1458. [Google Scholar] [CrossRef]

- Bordonal, R.O.; Carvalho, J.L.N.; Lal, R.; De Figueiredo, E.B.; De Oliveira, B.G.; Scala, N., Jr. Sustainability of sugarcane production in Brazil. A review. Agron. Sustain. Dev. 2018, 38, 13. [Google Scholar] [CrossRef]

- Fang, K.; Heijungs, R.; de Snoo, G.R. Theoretical exploration for the combination of the ecological, energy, carbon, and water footprints: Overview of a footprint family. Ecol. Indic. 2014, 36, 508–518. [Google Scholar] [CrossRef]

- De Figueiredo, E.B.; Panosso, A.R.; Romão, R.; La Scala, N., Jr. Research greenhouse gas emission associated with sugar production in southern Brazil. Carbon Balance Manag. 2010, 5, 3. [Google Scholar] [CrossRef] [PubMed]

- Khatiwada, D.; Silveira, S. Greenhouse gas Balances of Molasses Bases Ethanol in Nepal. J. Clean. Prod. 2011, 19, 1471–1485. [Google Scholar] [CrossRef]

- Renouf, M.A.; Pagan, R.J.; Wegener, M.K. Bio-production from Australian sugarcane: An environmental investigation of product diversification in an agro-industry. J. Clean. Prod. 2013, 39, 87–96. [Google Scholar] [CrossRef]

- Khatiwada, D.; Leduc, S.; Silveira, S.; McCallum, I. Optimizing ethanol and bioelectricity production in sugarcane biorefineries in Brazil. Renew. Energy 2016, 85, 371–386. [Google Scholar] [CrossRef]

- Shavazipour, B.; Stray, J.; Stewart, T.J. Sustainable planning in sugar-bioethanol supply chain under deep uncertainty: A case study of South African sugarcane industry. Comput. Chem. Eng. 2020, 143, 107091. [Google Scholar] [CrossRef]

- Abdali, H.; Sahebi, H.; Pishvaee, M. The water-energy-food-land nexus at the sugarcane-to-bioenergy supply chain: A sustainable network design model. Comput. Chem. Eng. 2021, 145, 107199. [Google Scholar] [CrossRef]

- Lemos, S.V.; Salgado, A.P., Jr.; Duarte, A.; De Souza, M.A.A., Jr.; Antunes, F.A. Agroindustrial best practices that contribute to technical efficiency in Brazilian sugar and ethanol production mills. Energy 2019, 177, 397–411. [Google Scholar] [CrossRef]

- Duarte, A.; Salgado, A.P., Jr.; Lemos, S.V.; De Souza, M.A.A., Jr.; Antunes, F.A. Proposal of operating best practices that contribute to the technical efficiency in Brazilian sugar and ethanol mills. J. Clean. Prod. 2019, 214, 173–184. [Google Scholar] [CrossRef]

- Carlucci, F.V.; Lemos, S.V.; Salgado, A.P., Jr.; Rebehy, P.C.P.W. Environmental, field and impurity factors to increase the agricultural performance of Brazilian and Australian sugarcane mills. Clean Technol. Environ. Policy 2021, 23, 2083–2100. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Srivastava, S.K.; Jangirala, S. System Dynamics Analysis of Sugarcane Supply Chain in Indian Sugar Industry. Glob. Bus. Rev. 2021, 1–20. [Google Scholar] [CrossRef]

- Monteiro, L.A.; Sentelhas, P.C. Sugarcane yield gap: Can it be determined at national level with a simple agrometeorological model? Crop Pasture Sci. 2017, 68, 272–284. [Google Scholar] [CrossRef]

- CNA—Confederação da Agricultura e Pecuária do Brasil (Brazilian Agriculture and Livestock Confederation). PIB do Agronegócio. CNA e CEPEA. 13 September 2021. Available online: https://www.cnabrasil.org.br/publicacoes/pib-do-agronegocio-avanca-no-trimestre-e-acumula-alta-de-9-81-no-primeiro-semestre-de-2021 (accessed on 26 October 2022).

- Santoro, E.; Soler, E.M.; Cherri, A.C. Route optimization in mechanized sugarcane harvesting. Comput. Electron. Agric. 2017, 141, 140–146. [Google Scholar] [CrossRef]

- Machado, R.L.; Da Cruz, T.V. An Empirical Approach Analyzing the Socioeconomic Sustainability of the International Sugarcane Trade. Sustainability 2022, 14, 2198. [Google Scholar] [CrossRef]

- CONAB—Companhia Nacional de Abastecimento (Brazilian National Supply Company). Companhia Nacional de Abastecimento. Acompanhamento da Safra Brasileira: Cana-de-Açúcar. v.7—Safra 2019/20—N.3—Terceiro levantamento. Brasília. December 2020; pp. 1–62. Available online: https://www.conab.gov.br/ (accessed on 4 May 2023).

- Gonçalves, F.; Perna, R.; Lopes, E.; Maciel, R.; Tovar, L.; Lopes, M. Strategies to improve the environmental efficiency and the profitability of sugarcane mills. Biomass Bioenergy 2021, 148, 106052. [Google Scholar] [CrossRef]

- Hussain, A.; Arif, S.M.; Aslam, M. Emerging renewable and sustainable energy technologies: State of the art. Renew. Sustain. Energy Rev. 2017, 71, 12–28. [Google Scholar] [CrossRef]

- ÚNICA—União da Indústria de Cana-de-Açúcar e Bioenergia (Brazilian Union of Sugarcane and Bioenergy). Cana-de-açúcar é fonte de 19% da Energia Consumida no Brasil. Available online: https://unica.com.br/noticias/cana-de-acucar-e-fonte-de-19-da-energia-consumida-no-brasil/ (accessed on 28 June 2022).

- Kota, K.B.; Shenbagaraj, S.; Sharma, P.K.; Sharma, A.K.; Ghodke, P.K.; Chen, W.H. Biomass torrefaction: An overview of process and technology assessment based on global readiness level. Fuel 2022, 324 Pt B, 124663. [Google Scholar] [CrossRef]

- Murphy, J.D.; McCarthy, K. Ethanol production from energy crops and wastes for use as a transport fuel in Ireland. Appl. Energy 2005, 82, 148–166. [Google Scholar] [CrossRef]

- Nie, Y.; Cai, W.; Wang, C.; Huang, G.; Ding, Q.; Yu, L.; Li, H.; Ji, D. Assessment of the potential and distribution of an energy crop at 1-km resolution from 2010 to 2100 in China—The case of sweet sorghum. Appl. Energy 2019, 239, 395–407. [Google Scholar] [CrossRef]

- Rentizelas, A.; Melo, I.C.; Alves Junior, P.N.; Campoli, J.S.; Rebelatto, D.A.N. Multi-criteria efficiency assessment of international biomass supply chain pathways using Data Envelopment Analysis. J. Clean. Prod. 2019, 237, 117690. [Google Scholar] [CrossRef]

- Cavalcanti, E.J.C.; Carvalho, M.; Da Silva, D.R.S. Energy, exergy and exergoenvironmental analyses of a sugarcane bagasse power cogeneration system. Energy Convers. Manag. 2020, 222, 113232. [Google Scholar] [CrossRef]

- Jonker, J.G.; Junginger, M.; Posada, J.; Ioiart, C.S.; Faaij, A.P.; Van Der Hilst, F. Economic performance and GHG emission intensity of sugarcane-and eucalyptus-derived biofuels and biobased chemicals in Brazil. Biofuels Bioprod. Biorefin. 2019, 13, 950–977. [Google Scholar] [CrossRef]

- Mahjoub, N.; Sahebi, H. The water-energy nexus at the hybrid bioenergy supply chain: A sustainable network design model. Ecol. Indic. 2020, 119, 106799. [Google Scholar] [CrossRef]

- Lamers, P.; Hamelinck, C.; Junginger, M.; Faaij, A. International bioenergy trade—A review of past developments in the liquid biofuel market. Renew. Sustain. Energy Rev. 2011, 15, 2655–2676. [Google Scholar] [CrossRef]

- Mozaffari, M.R.; Ostovan, S.; Wanke, P.F. A Hybrid Genetic Algorithm-Ratio DEA Approach for Assessing Sustainable Efficiency in Two-Echelon Supply Chains. Sustainability 2020, 12, 8075. [Google Scholar] [CrossRef]

- Mota, B.; Gomes, M.I.; Carvalho, A.; Barbosa-Povoa, A.P. Towards supply chain sustainability: Economic, environmental and social design and planning. J. Clean. Prod. 2015, 105, 14–27. [Google Scholar] [CrossRef]

- Neutzling, D.M.; Land, A.; Seuring, S.; DO Nascimento, L.F.M. Linking sustainability-oriented innovation to supply chain relationship integration. J. Clean. Prod. 2018, 172, 3448–3458. [Google Scholar] [CrossRef]

- Chavéz, M.M.M.; Sarache, W.; Costa, Y.; Soto, J. Multiobjective stochastic scheduling of upstream operations in a sustainable sugarcane supply chain. J. Clean. Prod. 2020, 276, 123305. [Google Scholar] [CrossRef]

- Higgins, A. Scheduling of road vehicles in sugarcane transport: A case study at an Australian sugar mill. Eur. J. Oper. Res. 2006, 170, 987–1000. [Google Scholar] [CrossRef]

- Kadwa, M.; Bezuidenhout, C.N. Modelling sugarcane supply consistency at a sugar mill. Comput. Electron. Agric. 2015, 111, 107–111. [Google Scholar] [CrossRef]

- Walters, D.; Lancaster, G. Implementing value strategy through the value chain. Manag. Decis. 2000, 38, 160–178. [Google Scholar] [CrossRef]

- Ramjeawon, T. Life cycle assessment of electricity generation from bagasse in Mauritius. J. Clean. Prod. 2008, 16, 1727–1734. [Google Scholar] [CrossRef]

- Campbell, J.E.; Lobell, D.B.; Field, C.B. Greater transportation energy and GHG offsets from bioelectricity than ethanol. Science 2009, 324, 1055–1057. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Nguyen, T.L.T.; Gheewala, S.H.; Sagisaka, M. Greenhouse gas savings potential of sugar cane bio-energy systems. J. Clean. Prod. 2010, 18, 412–418. [Google Scholar] [CrossRef]

- Cherubini, F.; Stromman, A.H. Life cycle assessment of bioenergy systems: State of the art and future challenges. Bioresour. Technol. 2011, 102, 437–451. [Google Scholar] [CrossRef] [PubMed]

- Yuttitham, M.; Gheewala, S.H.; Chidthaisong, A. Carbon footprint of sugar produced from sugarcane in eastern Thailand. J. Clean. Prod. 2011, 19, 2119–2127. [Google Scholar] [CrossRef]

- Dunkelberg, E.; Finkbeiner, M.; Hirschl, B. Sugarcane ethanol production in Malawi: Measures to optimize the carbon footprint and to avoid indirect emissions. Biomass Bioenergy 2014, 71, 37–45. [Google Scholar] [CrossRef]

- Soam, S.; Kumar, R.; Gupta, R.P.; Sharma, P.K.; Tuli, D.K.; Das, B. Life cycle assessment of fuel ethanol from sugarcane molasses in northern and western India and its impact on Indian biofuel programme. Energy 2015, 83, 307–315. [Google Scholar] [CrossRef]

- Seabra, J.E.A.; Macedo, I.C.; Chum, H.L.; Faroni, C.E.; Sarto, C.A. Life cycle assessment of Brazilian sugarcane products: GHG emissions and energy use. Biofuels Bioprod. Biorefin. 2011, 5, 519–532. [Google Scholar] [CrossRef]

- Blengini, G.A.; Busto, M. The life cycle of rice: LCA of alternative agri-food chain management systems in Vercelli (Italy). J. Environ. Manag. 2009, 90, 1512–1522. [Google Scholar] [CrossRef]

- Keyes, S.; Tyedmers, P.; Beazley, K. Evaluating the environmental impacts of conventional and organic apple production in Nova Scotia, Canada, through life cycle assessment. J. Clean. Prod. 2015, 104, 40–51. [Google Scholar] [CrossRef]

- European Commission. Analysis of Existing Environmental Footprint Methodologies for Products and Organizations: Recommendations, Rationale, and Alignment. Ispra, Italy, November 2011, Updated after Feedback by ADEME, DEFRA, WRI, ISSO. Available online: https://ec.europa.eu/environment/eussd/pdf/Deliverable.pdf (accessed on 4 May 2023).

- Pizzol, M.; Laurent, A.; Sala, S.; Weidema, B.; Verones, F.; Koffler, C. Normalisation and weighting in life cycle assessment: Quo vadis? Int. J. Life Cycle Assess. 2017, 22, 853–866. [Google Scholar] [CrossRef]

- Rebolledo-Leiva, R.; Angulo-Meza, L.; Iriarte, A.; González-Araya, M.C. Joint carbon footprint assessment and data envelopment analysis for the reduction of greenhouse gas emissions in agriculture production. Sci. Total Environ. 2017, 593–594, 36–46. [Google Scholar] [CrossRef] [PubMed]

- Mendes, N.C.; Bueno, C.; Ometto, A.R. Avaliação de impacto do ciclo de vida: Revisão dos principais métodos. Production 2016, 26, 160–175. [Google Scholar] [CrossRef][Green Version]

- EMBRAPA (Brazilian Agricultural Research Corporation). Correção e Adubação. 2022. Available online: https://www.embrapa.br/agencia-de-informacao-tecnologica/cultivos/cana/producao/correcao-e-adubacao#:~:text=Doses%20entre%2080%20e%20150,planta%20como%20para%20as%20soqueiras (accessed on 27 April 2023).[Green Version]

- Nova Cana. Uso de Pesticidas e Herbicidas no Cultivo da Cana. Available online: https://www.novacana.com/noticias/uso-pesticidas-herbicidas-cultivo (accessed on 27 April 2023).[Green Version]

- Agri-Footprint. Agri-Footprint 6 Methodology Report. Part 2: Description of Data. Gouda, NL, 15 August 2022, Version 2. Available online: https://blonksustainability.nl/tools/agrifootprint (accessed on 4 May 2023).[Green Version]

- ReCiPe Midpoint. A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization. RIVM Report 2016-0104a. Available online: https://pre-sustainability.com/legacy/download/Report_ReCiPe_2017.pdf (accessed on 4 May 2023).[Green Version]

- FAOSTAT. Technical Conversion Factors for Agricultural Commodities. 2023. Available online: https://www.fao.org/fileadmin/templates/ess/documents/methodology/tcf.pdf (accessed on 4 May 2023).[Green Version]

- Brentrup, F.; Pallière, C. Nitrogen Use Efficiency as an Agro-Environmental Indicator. In Proceedings of the OECD Workshop on Agri-Environmental Indicators, Leysin, Switzerland, 23–26 March 2010. [Google Scholar][Green Version]

- Rosas, F. World Fertilizer Model—The World NPK Model. 2011. Available online: http://ageconsearch.umn.edu/bitstream/103223/2/11-WP_520.NEW.pdf (accessed on 4 May 2023).[Green Version]

- IFA. Statistical Information. 2015. Available online: http://www.fertilizer.org/ifa/HomePage/STATISTICS/Production-and-trade (accessed on 4 May 2023).[Green Version]

- Nemecek, T.; Schnetzer, J. Methods of Assessment of Direct Field Emissions for LCIs of Agricultural Production Systems: Data v3.0; Agroscope Reckenholz-Tänikon Research Station ART: Zurich, Switzerland, 2012; 34p. [Google Scholar][Green Version]

- Amlinger, F.; Pollak, M.; Favoino, E. Heavy Metals and Organic Compounds from Wastes Used as Organic Fertilisers; European Commission: Brussels, Belgium, 2004. [Google Scholar][Green Version]

- Mels, A.; Bisschops, I.; Swart, B. Zware Metalen in Meststoffen—Vergelijking van urine en zwart Water met in Nederland Toegepaste Meststoffen; Stichting Toegepast Onderzoek Waterbeheer (STOWA): Engelsbrand, Germany, 2008; pp. 1–10. [Google Scholar][Green Version]

- Mekonnen, M.M.; Hoekstra, A.Y. The Green, Blue and Grey Water Footprint of Crops and Derived Crop Products—Volume 1: Main Report (Vol. 1); UNESCO-IHE: Delft, The Netherlands, 2010. [Google Scholar][Green Version]

- Resende, R.S.; Nascimento, T.; De Carvalho, T.B.; Amorin, J.R.A.; Rodrigues, L. Reducing sugarcane irrigation demand through planting date adjustment in Alagoas state, Brazil. Rev. Bras. Eng. Agrícola Ambient. 2021, 25, 75–81. [Google Scholar] [CrossRef]

- Carr, M.K.V.; Knox, J.W. The water relations and irrigation requirements of sugar cane (Saccharum officinarum): A review. Exp. Agric. 2011, 47, 1–25. [Google Scholar] [CrossRef]

- García, C.A.; Fuentes, A.; Hennecke, A.; Riegelhaupt, E.; Manzini, F.; Masera, O. Life-cycle and greenhouse gas emissions and energy balances of sugarcane ethanol production in Mexico. Appl. Energy 2011, 88, 2088–2097. [Google Scholar] [CrossRef]

- Acero, A.P.; Rodríguez, C.; Ciroth, A. LCIA Methods: Impact Assessment Methods in Life Cycle Assessment and Their Impact Categories. Version: 1.5.2. 2015. Available online: https://www.openlca.org/wp-content/uploads/2015/11/LCA-METHODS-v.1.5.2.pdf (accessed on 4 May 2023).

- Gunawan, T.B.; Romli, M.; Noor, E. Life Cycle Assessment of Cane-sugar in Indonesian Sugar Mill: Energy Use and GHG Emissions. IOP Conf. Ser. Mater. Sci. Eng. 2019, 536, 012059. [Google Scholar] [CrossRef]

- De Figueiredo, E.B.; La Scala, N., Jr. Greenhouse Gas Balance Due to the Conversion of Sugarcane Areas from Burned to Green Harvest in Brazil. Agric. Ecosyst. Environ. 2011, 141, 77–85. [Google Scholar] [CrossRef]

- Leal, M.R.L.V.; Galdos, M.V.; Scarpare, F.V.; Seabra, J.E.A.; Walter, A.; Oliveira, C.O.F. Sugarcane straw availability, quality, recovery and energy use: A literature review. Biomass Bioenergy 2013, 53, 11–19. [Google Scholar] [CrossRef]

| Input | Description | Data | Unit | Source |

|---|---|---|---|---|

| Water | Water use for irrigation | 50,000–80,000 | Kg/ha.day | [57] |

| Soil correction | Use of potassium (K2O) to increase productivity | 80–150 | Kg/ha | [57] |

| Fertilizer | Nitrogen fertilization to increase productivity | 30 | Kg/ha | [58] |

| Fungicide | Fungicide consumption in sugarcane cultivation | 0 | Kg/ha | [58] |

| Herbicide | Volume of herbicide in sugarcane cultivation | 200 | L/ha | [58] |

| Insecticide | Consumption of insecticides in sugarcane cultivation | 0.54 | Kg/ha | [58] |

| Labor | People per hectare of cultivated land | 0.08 | Worker/ha | [13] |

| Seedling | Quantity of sugarcane seedlings used in cultivation | 10,000–18,000 | Kg/ha | [57] |

| Nematicide | Nematicides used in sugarcane cultivation | 10 | Kg/ha | [57] |

| Output | Description | Data | Unit | Source |

| Sugarcane | Amount of harvested sugarcane | 4,560,000 | Kg/ha | Studied mill |

| Input | Description | Data | Unit | Source |

|---|---|---|---|---|

| Sugarcane | Amount of harvested sugarcane | 4,560,000 | Kg/ha | Studied mill |

| Fuel | Truck consumption with 15-ton capacity | 30 | mL/t.km | [58] |

| Labor | Number of people transporting sugarcane | 0.02 | Worker/t.km | [13] |

| Vehicle | Sugarcane transportation vehicle | 4,560,000 | Kg/km | Studied mill |

| Output | Description | Data | Unit | Source |

| Transported sugarcane | Amount of sugarcane transported from the farm to the processing plant | 4,560,000 | Kg/km | Studied mill |

| Input | Description | Data | Unit | Source |

|---|---|---|---|---|

| Sugarcane | Amount of harvested sugarcane | 4,560,000 | Kg | Studied mill |

| Water | Amount of water used in the industrial process for ethanol production | 8080 | Kg/t | [57] |

| Labor | Number of people in the production process | 22.82 | Worker/t | [13] |

| Vehicle | Sugarcane transportation vehicle | 4,560,000 | Kg/km | Studied mill |

| Output | Description | Data | Unit | Source |

| Produced ethanol | Amount of ethanol produced in the processing plant | 424,080 | L/day | Studied mill |

| Bagasse | Amount of residual bagasse from sugarcane processing | 0.28 | t/sugarcane t | Studied mill |

| Input | Description | Data | Unit | Source |

|---|---|---|---|---|

| Fuel | Truck consumption with 15-ton capacity | 30 | mL/t.km | [58] |

| Produced ethanol | Amount of transported ethanol to the marketplace | 424,080 | L/day | Studied mill |

| Labor | People transporting ethanol | 6.64 | Worker/t.km | [13] |

| Vehicle | Ethanol transportation vehicle | 424,080 | L.km | Studied mill |

| Output | Description | Data | Unit | Source |

| Transported ethanol | Amount of ethanol transported from the mill to the marketplace | 424,080 | L.km | Studied mill |

| Indicator | Sugarcane Cultivation | Sugarcane Transport | Ethanol Production | Ethanol Transport | Unit |

|---|---|---|---|---|---|

| Human, non-carcinogenic toxicity | 5.72559 × 10−9 | 7.09834 × 10−9 | 4.44575 × 10−8 | 7.09834 × 10−9 | CTUh |

| Ionizing radiation, human health | 1.36808 × 10−3 | 2.15625 × 10−4 | 1.31765 × 10−2 | 2.15625 × 10−4 | kBq U-235 eq |

| Ozone depletion | 3.59266 × 10−11 | 1.84330 × 10−13 | 2.34491 × 10−9 | 1.84330 × 10−13 | kg CFC11 eq |

| Eco-toxicity, fresh water | 2.65815 × 10−1 | 1.29910 × 10−2 | 3.82426 × 10−1 | 1.29910 × 10−2 | CTUe |

| Human toxicity, cancer | 1.47766 × 10−9 | 4.92000 × 10−10 | 1.04267 × 10−8 | 4.92000 × 10−10 | CTUh |

| Marine eutrophication | 2.00530 × 10−3 | 2.16721 × 10−4 | 7.54317 × 10−4 | 2.16721 × 10−4 | kg N eq |

| Eutrophication, terrestrial | 2.80633 × 10−3 | 2.41488 × 10−3 | 8.18517 × 10−3 | 2.41488 × 10−3 | mol N eq |

| Acidification | 6.31577 × 10−4 | 4.68065 × 10−4 | 3.99318 × 10−3 | 4.68065 × 10−4 | mol H+ eq |

| Photochemical formation of ozone | 6.84707 × 10−5 | 4.13018 × 10−4 | 5.60343 × 10−3 | 4.13018 × 10−4 | kgNMVOC eq |

| Particulate matter | 4.86557 × 10−9 | 2.51044 × 10−9 | 4.31065 × 10−8 | 2.51044 × 10−9 | disease increase |

| Eutrophication, fresh water | 1.56441 × 10−5 | 4.82532 × 10−7 | 4.41246 × 10−4 | 4.82532 × 10−7 | kg P eq |

| Climate change | 2.07715 × 10−1 | 7.65839 × 10−2 | 1.29678 × 10+0 | 7.65839 × 10−2 | kg CO2 eq |

| Land use | 1.47718 × 10+1 | 7.21686 × 10−1 | 1.75906 × 10+0 | 7.21686 × 10−1 | En |

| Water use | 1.57499 × 10−2 | −1.62203 × 10−2 | 3.16267 × 10−2 | 1.60148 × 10−4 | m3 depriv. |

| Use of mineral resources and metals | 9.90939 × 10−9 | 4.43371 × 10−9 | 4.49728 × 10−6 | 4.43371 × 10−9 | kg Sb eq |

| Use of fossil resources | 2.61173 × 10−1 | 1.04057 × 10+0 | 4.30852 × 10+1 | 1.04057 × 10+0 | MJ |

| Climate change—Land use | 1.49428 × 10−1 | 5.51236 × 10−4 | 5.31494 × 10−5 | 5.51236 × 10−4 | kg CO2 eq |

| Fossil climate change | 5.82758 × 10−2 | 7.58975 × 10−2 | 1.29549 × 10+0 | 7.58975 × 10−2 | kg CO2 eq |

| Climate-biogenic changes | 1.19096 × 10−5 | 1.35169 × 10−4 | 1.23947 × 10−3 | 1.35169 × 10−4 | kg CO2 eq |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, T.G.; Machado, R.L. Life Cycle Assessment of the Sugarcane Supply Chain in the Brazilian Midwest Region. Sustainability 2024, 16, 285. https://doi.org/10.3390/su16010285

Rodrigues TG, Machado RL. Life Cycle Assessment of the Sugarcane Supply Chain in the Brazilian Midwest Region. Sustainability. 2024; 16(1):285. https://doi.org/10.3390/su16010285

Chicago/Turabian StyleRodrigues, Thamine G., and Ricardo L. Machado. 2024. "Life Cycle Assessment of the Sugarcane Supply Chain in the Brazilian Midwest Region" Sustainability 16, no. 1: 285. https://doi.org/10.3390/su16010285

APA StyleRodrigues, T. G., & Machado, R. L. (2024). Life Cycle Assessment of the Sugarcane Supply Chain in the Brazilian Midwest Region. Sustainability, 16(1), 285. https://doi.org/10.3390/su16010285