Smart and Sustainable Human-Centred Workstations for Operators with Disability in the Age of Industry 5.0: A Systematic Review

Abstract

:1. Introduction

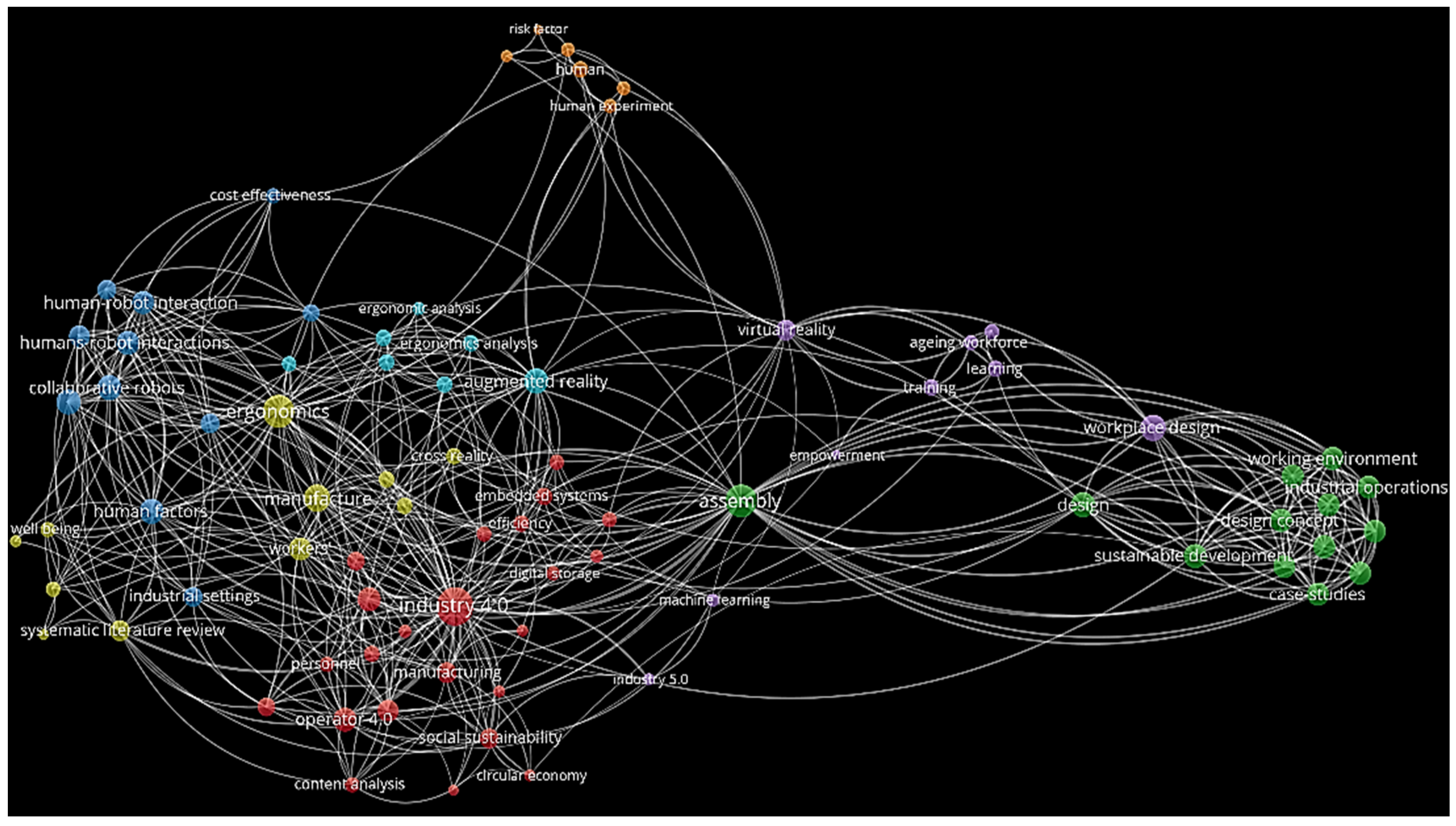

- Discipline 1: Workstation Design.

- Discipline 2: Disability in Manufacturing.

- Discipline 3: Industry 4.0 and Industry 5.0.

- Discipline 4: Sustainability and Social Sustainability.

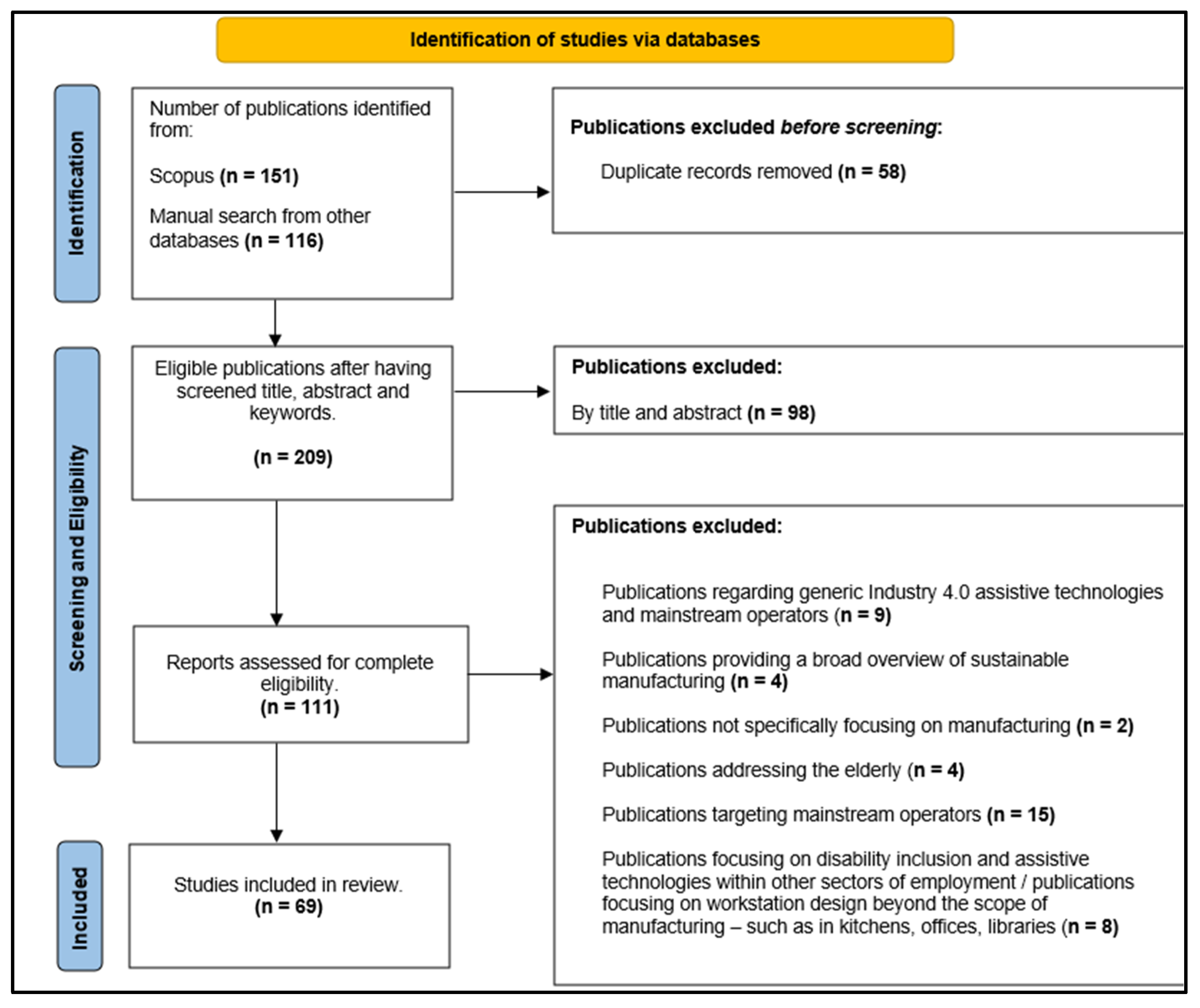

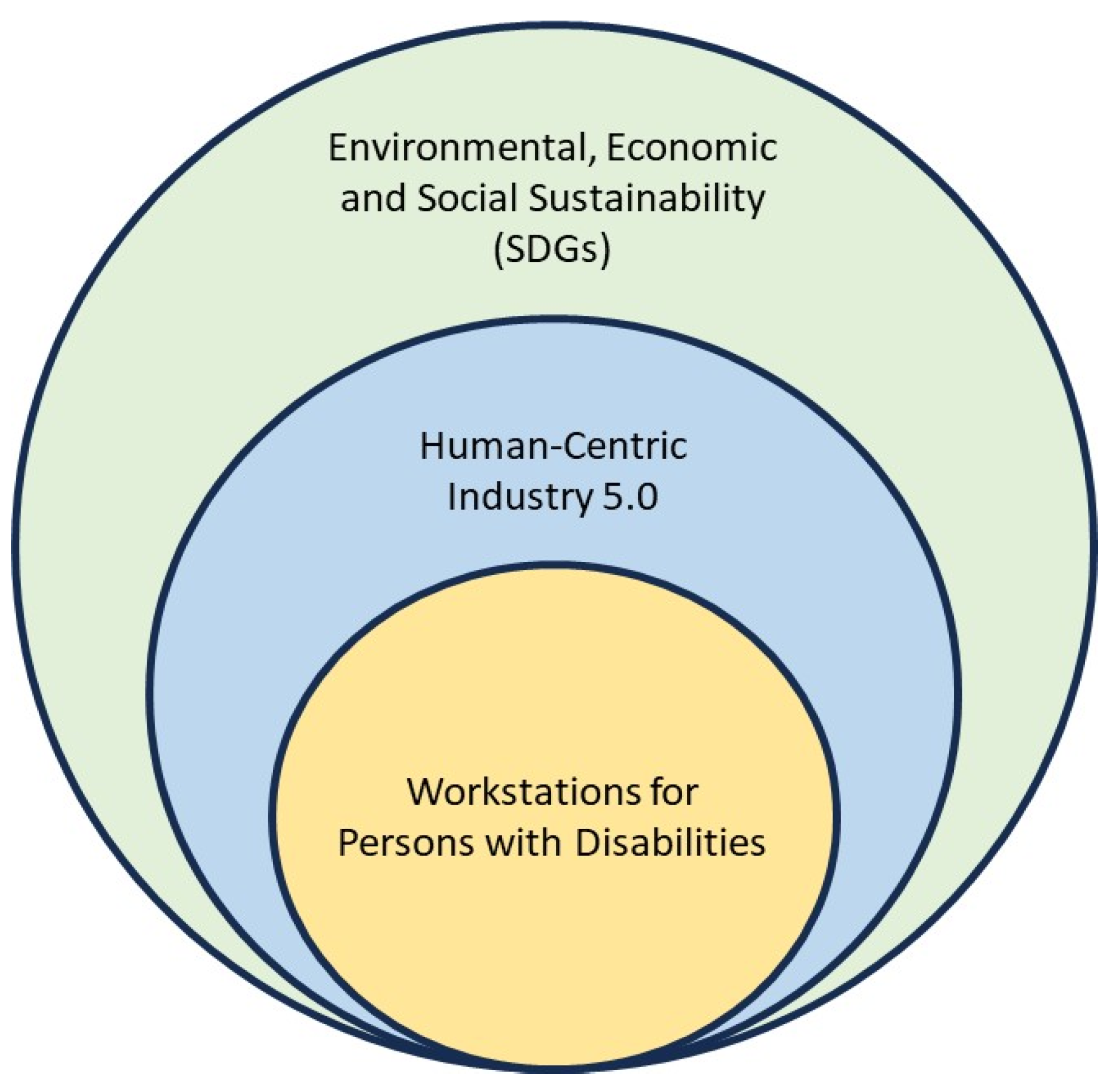

2. Setting the Scene for the PRISMA Systematic Review

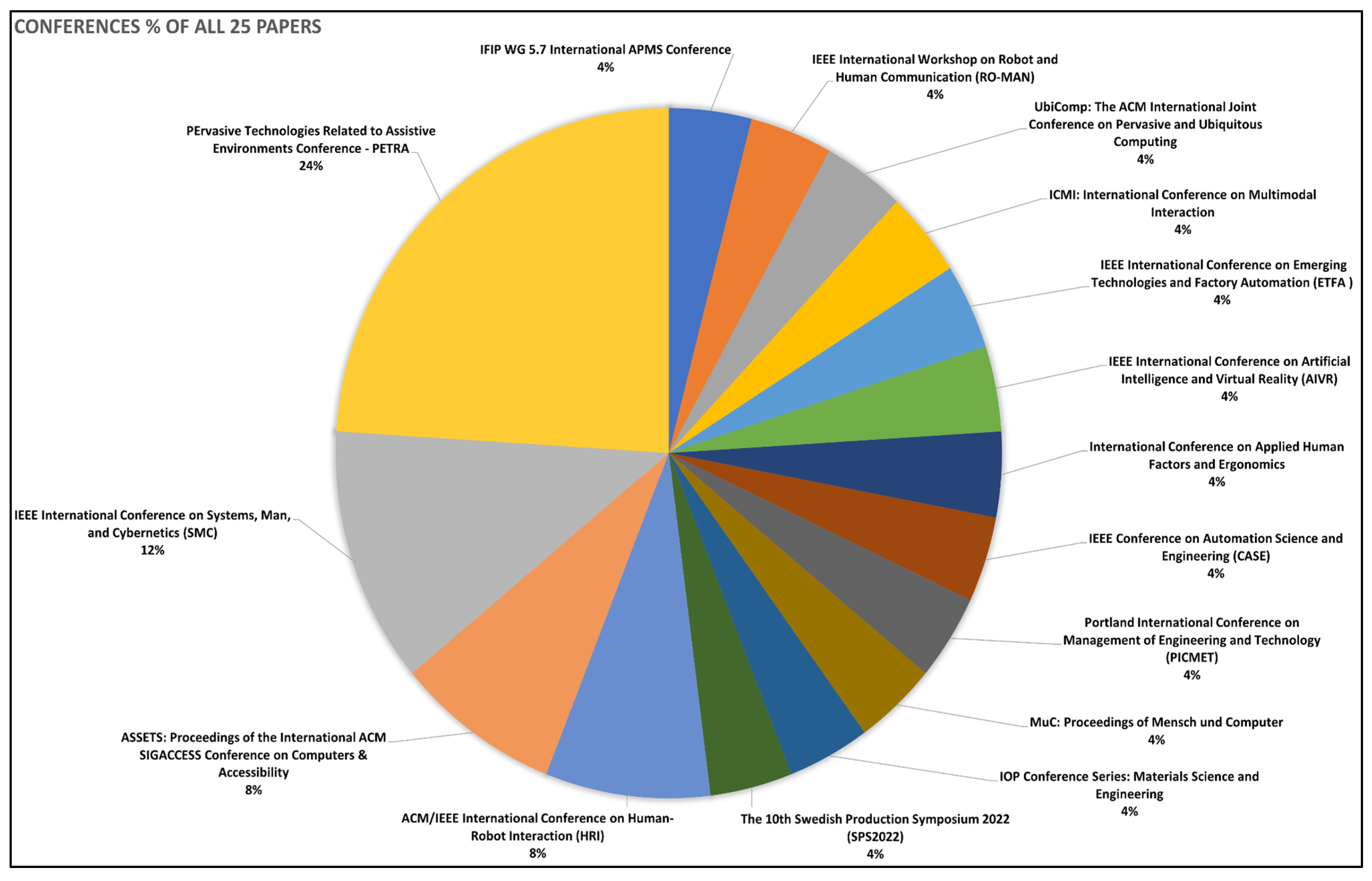

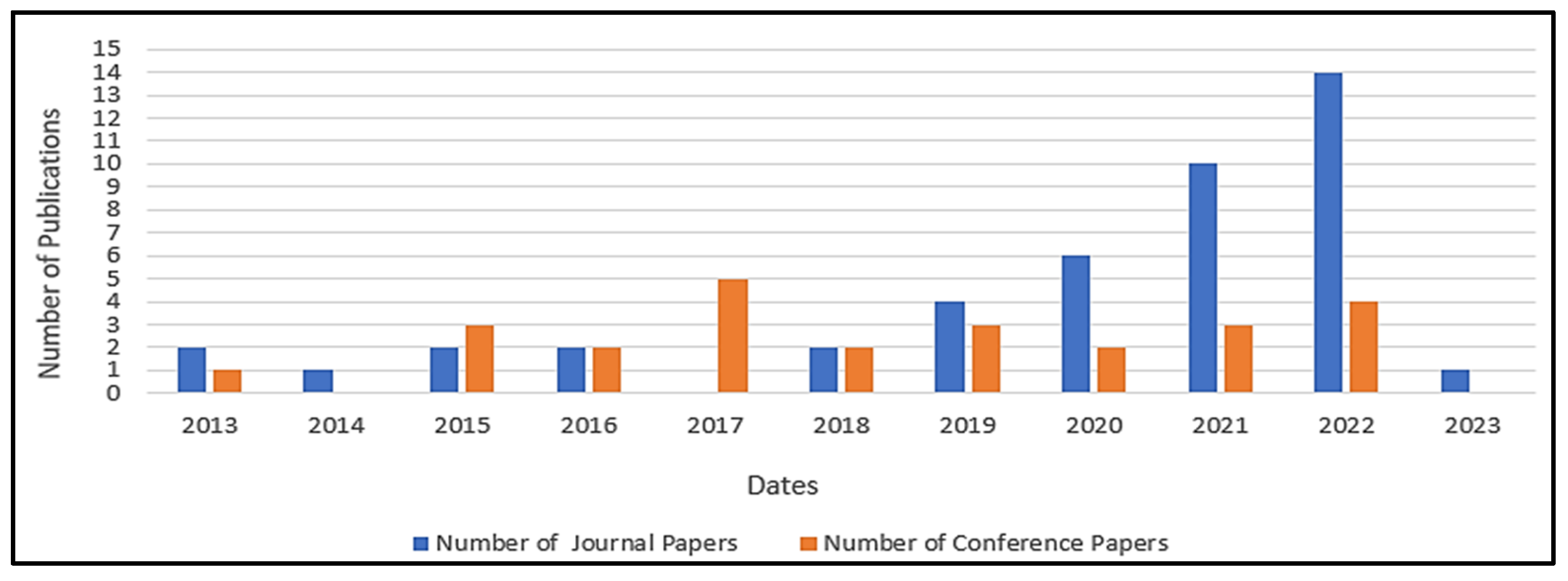

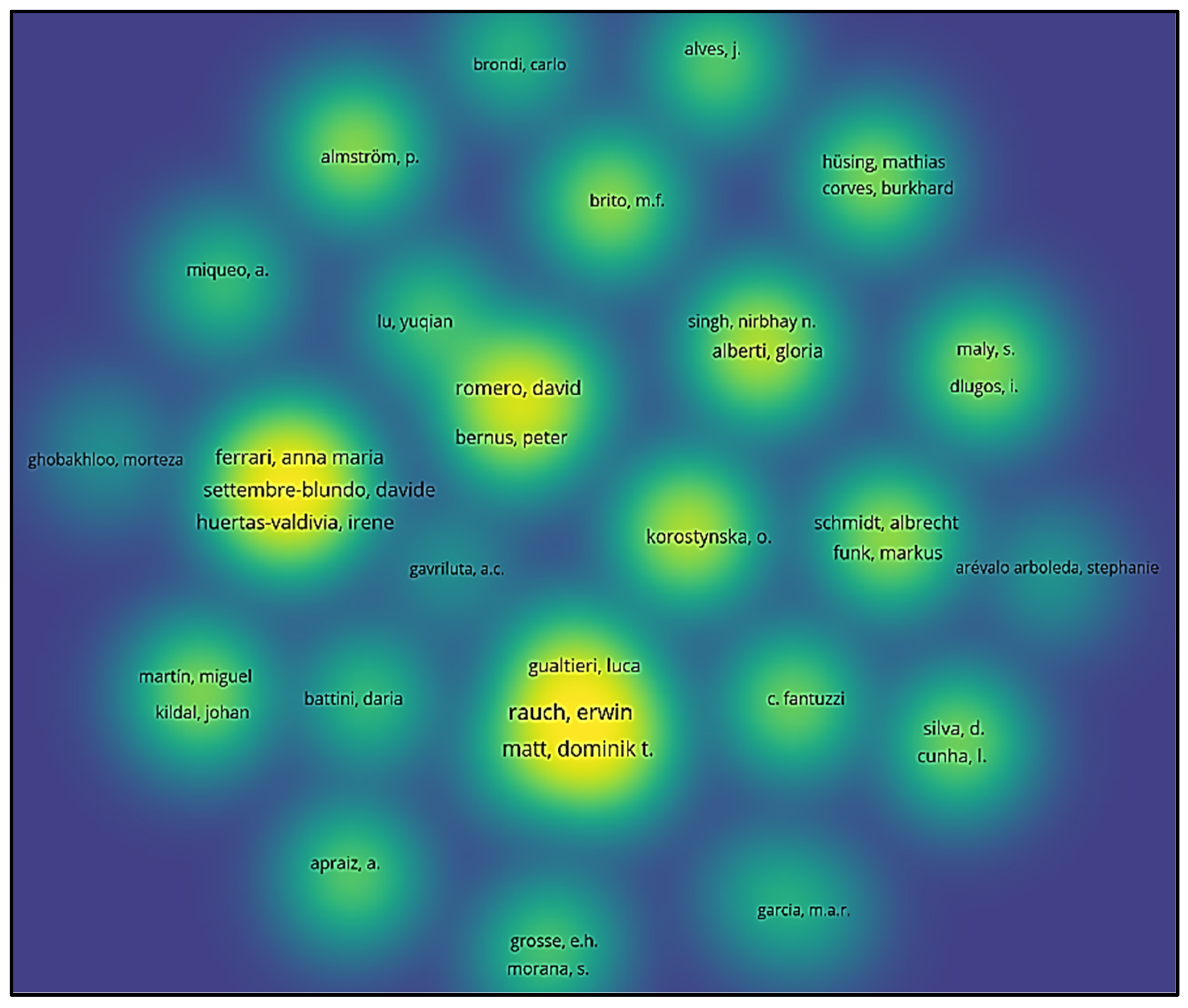

3. Statistical Detail following the Identification of the Literature

4. Workstation Design for Heterogenous Operators on the Manufacturing Shop Floor

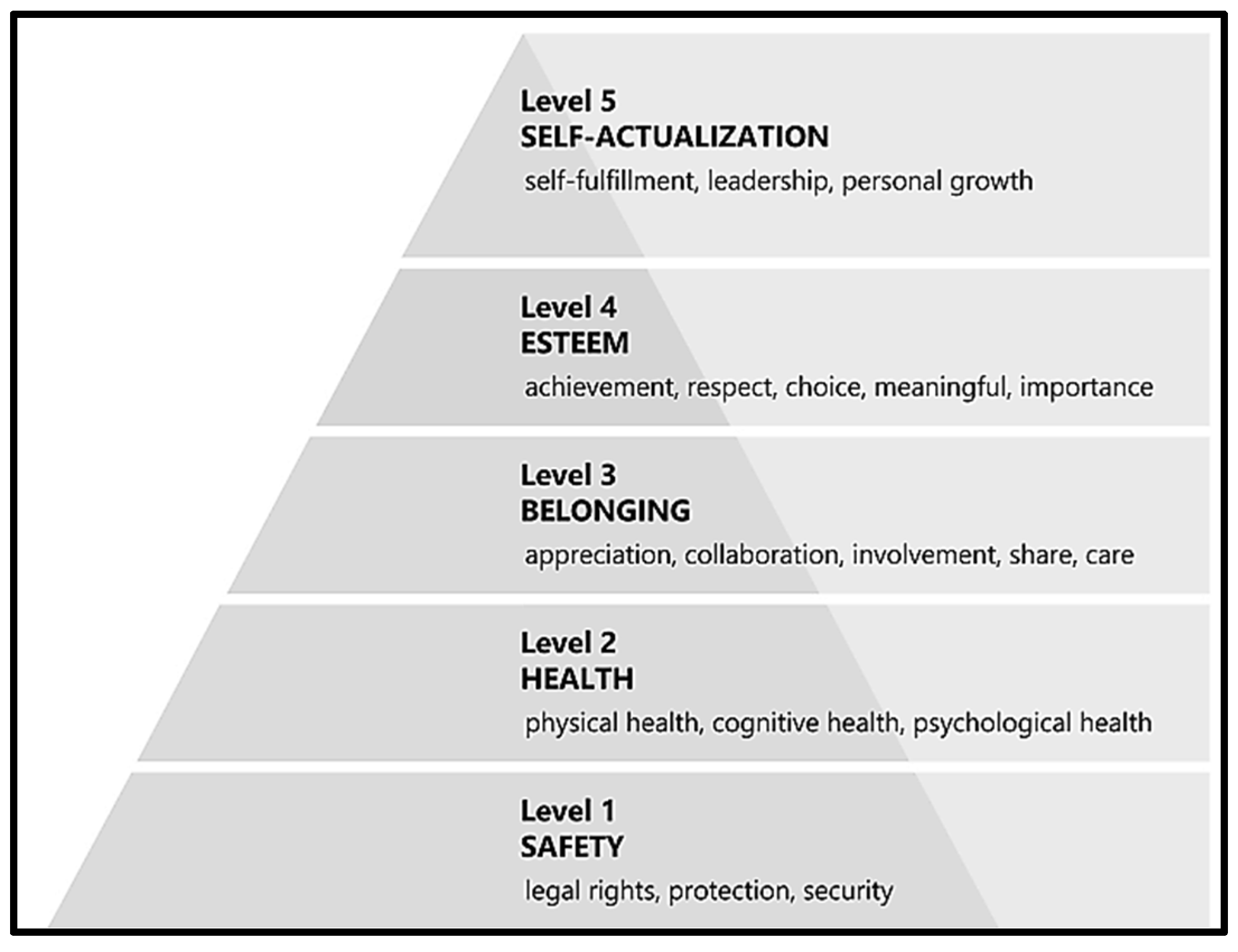

4.1. Designing Workstations That Empower Operators with Disabilities as Smart Learners

4.2. Workstation Design for, with, and by Operators with Disabilities

4.3. Balancing the Task-Skill Dynamic for Operators with Disabilities on the Shop Floor

4.4. Adapting, Accommodating, and Adjusting Workstations to Suit Operators with Disabilities

4.5. Key Takeaways from Section 4

5. Industry 4.0, Industry 5.0, and the Impact on Inclusive Manufacturing Shop Floors

5.1. Investigating Industry 4.0 Assistive Technologies for the Shop Floor

5.2. Augmenting the Workspace of Operators with Disabilities on the Shop Floor

Disability vs. Simulation

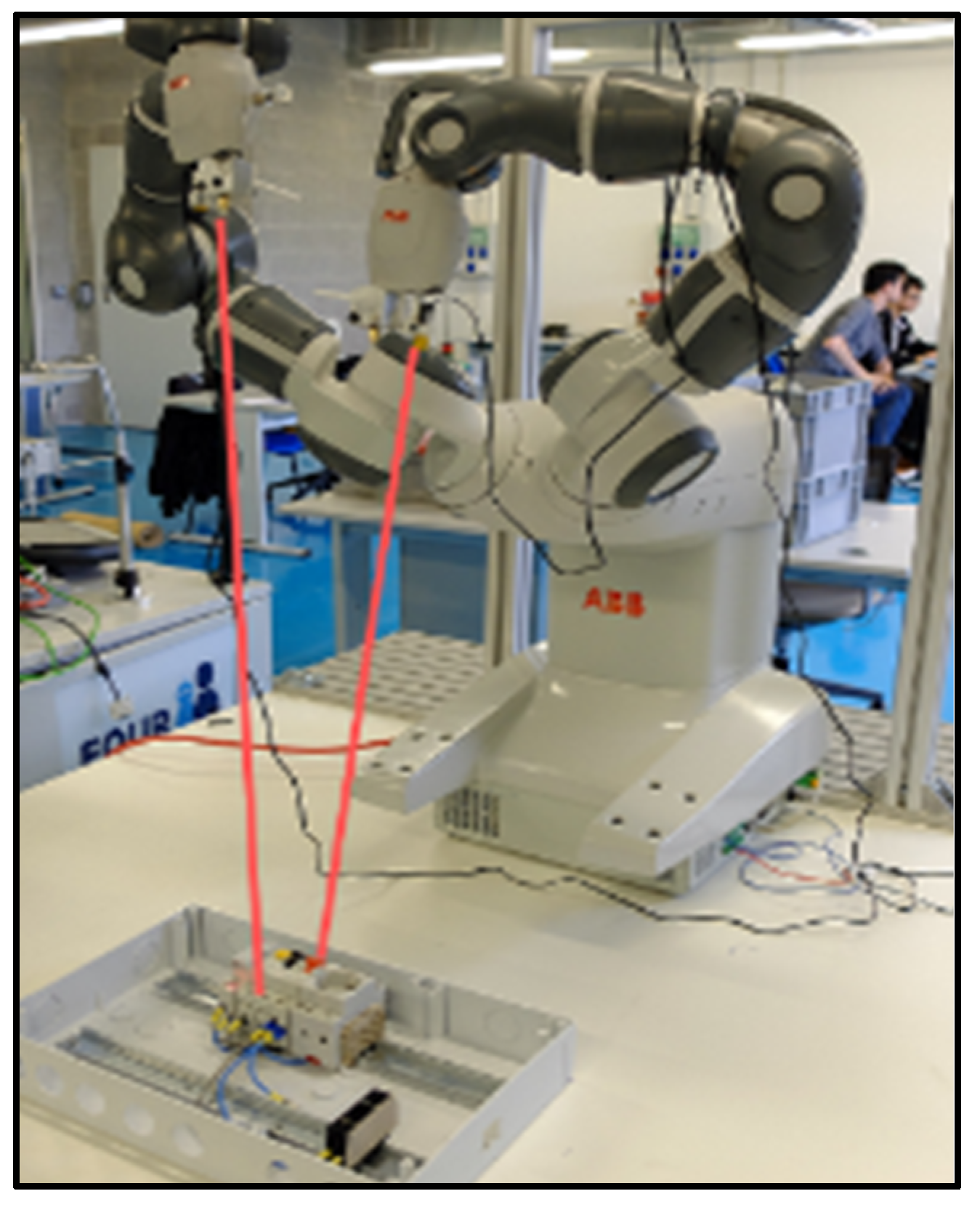

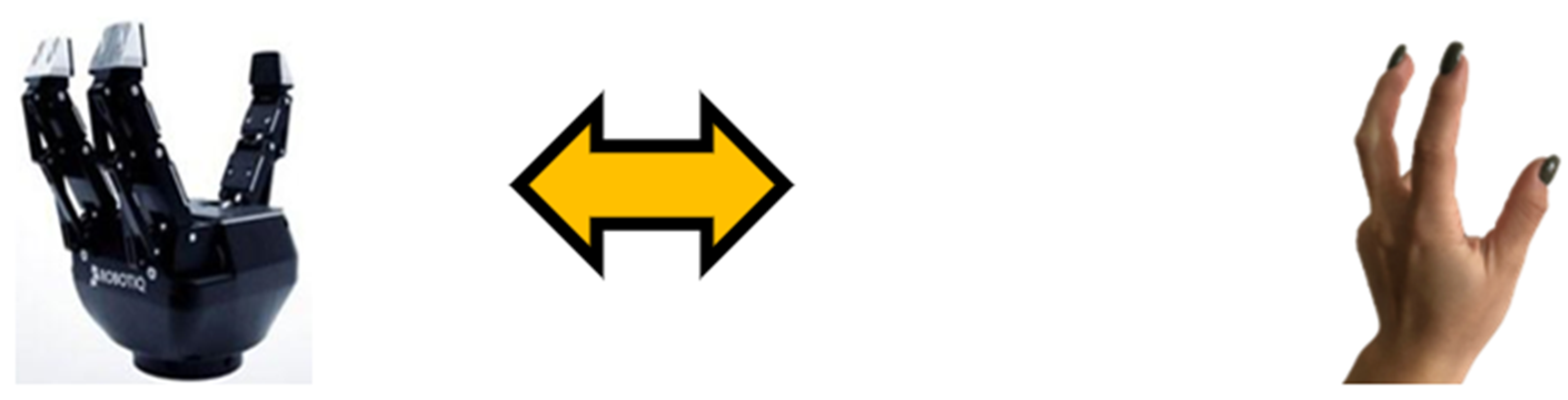

5.3. The Uprise of Robots Collaborating with Operators with Disabilities

5.4. Cognitive Ergonomics for Inclusivity in Industry 4.0

5.5. Key Takeaways from Section 5

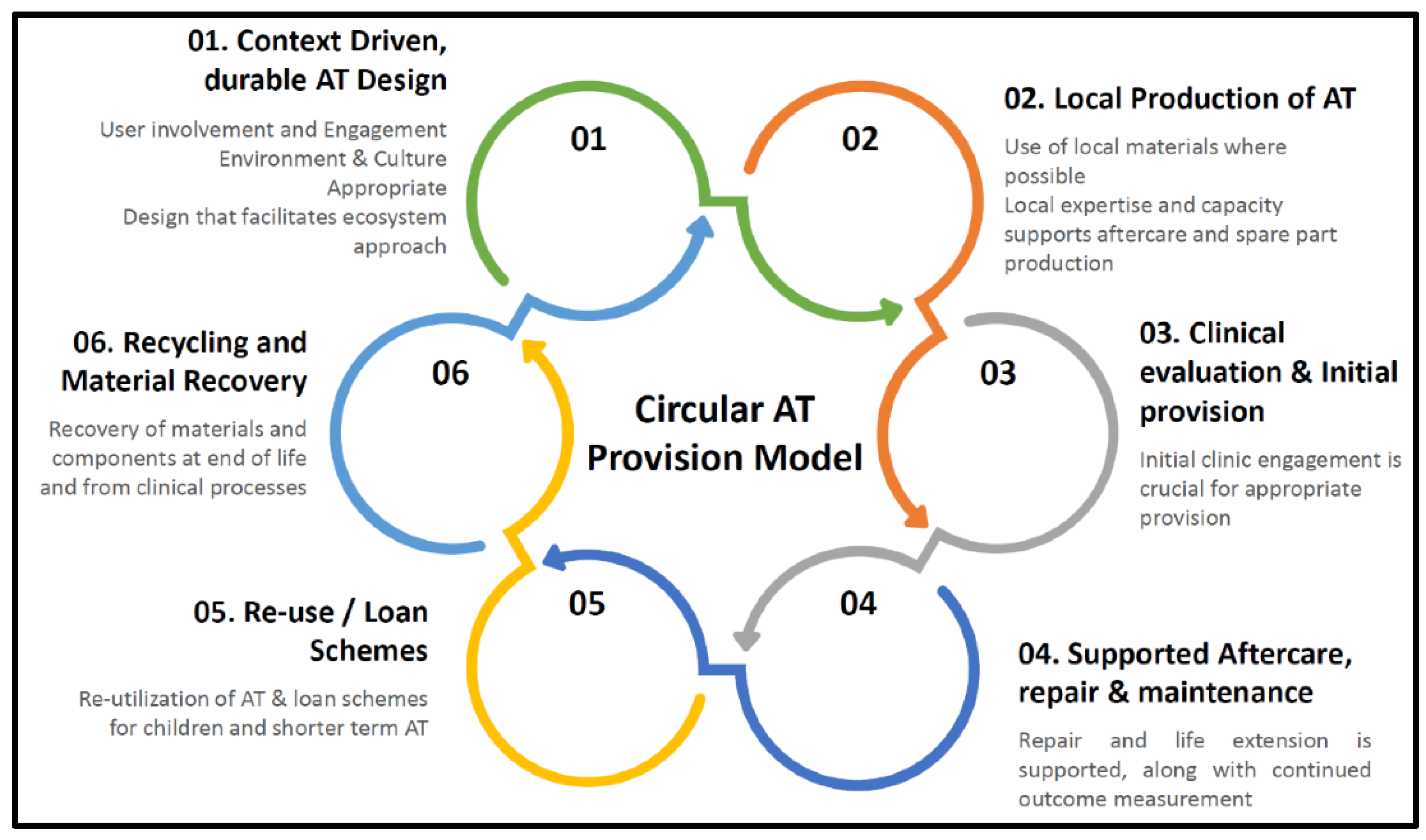

6. Sustainability on the Manufacturing Shop Floor and Industry 5.0

6.1. Industry 4.0 for Sustainability, or Sustainability for Industry 4.0?

6.2. A New Outlook towards Sustainability in the Age of Industry 5.0

6.3. Socially Sustainable Considerations for Operators with Disability on the Shop Floor

6.4. Key Takeaways from Section 6

7. Identified Research Gaps and Future Work

7.1. Main Research Question and the Main Outcomes of This Review

7.2. A Bright Future for Inclusivity on the Shop Floor in the Age of Industry 5.0: Future Work

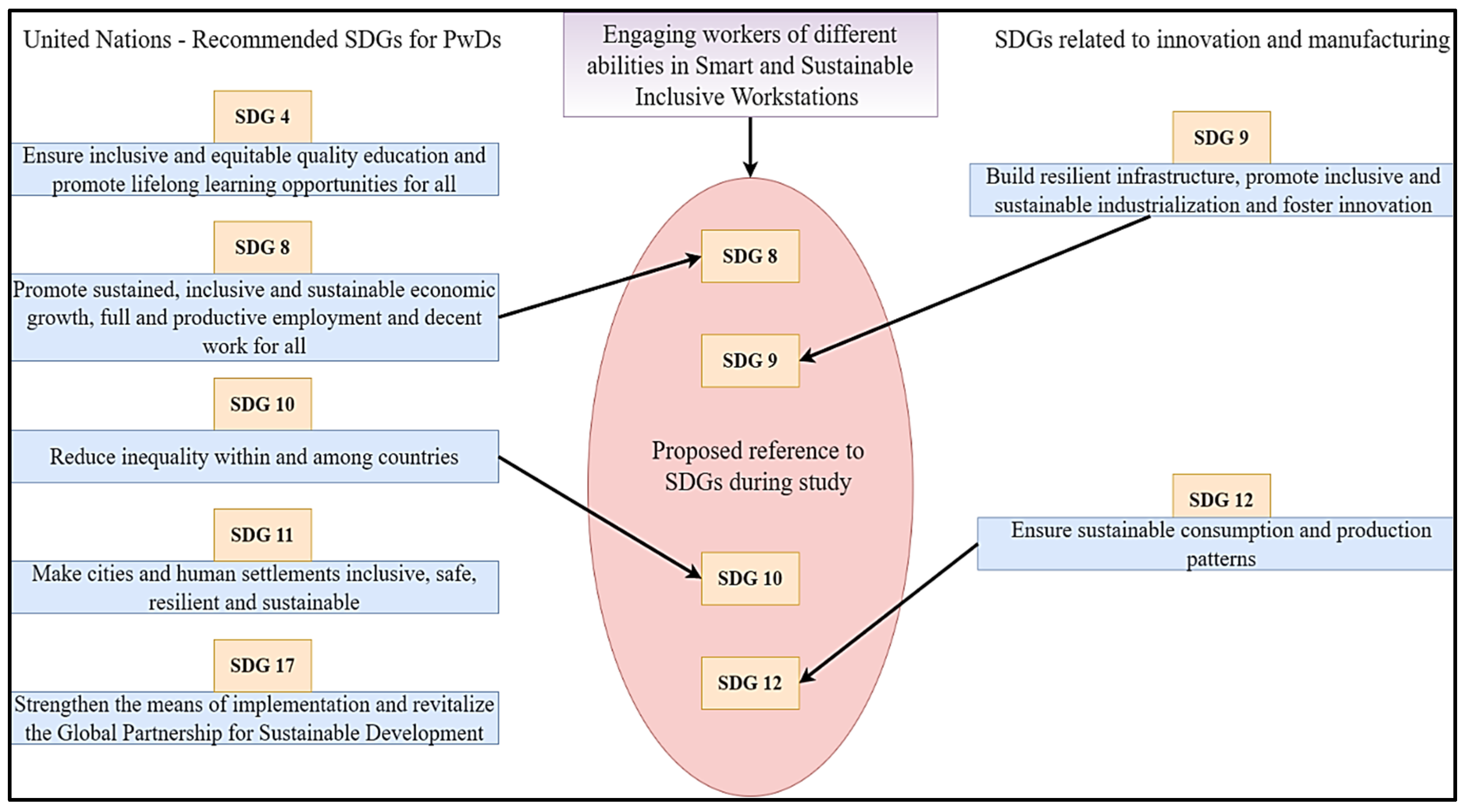

7.3. Shifting the Direction towards a Holistically Sustainable Design Approach: Adopting the SDGs for Future Work

- -

- SDG 8—Decent Work and Economic Growth (primarily addressing Disciplines 2 and 4).

- -

- SDG 9—Industry, Innovation, and Infrastructure (primarily addressing Disciplines 1, 3 and 4; also recommended by [29] in pursuit of adopting SDGs towards Industry 5.0.).

- -

- SDG 10—Reduce inequality within and among countries (primarily addressing Disciplines 2 and 4).

- -

- SDG 12—Responsible Consumption and Production (primarily addressing Disciplines 3 and 4; also recommended by [29] in pursuit of adopting SDGs towards Industry 5.0.).

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Four Disciplines | Subtopics Identified | Corresponding Literary Work References |

|---|---|---|

| Workstation design | Human skills in manufacturing | [2,4,5,6,7,9,10,12,18,19,20,25,29,33,34,38,40,42,43,45,48,49,50,51,52,55,58,59,61,64,66,71,78,90,91,92] |

| Cognitive ergonomics | [4,5,6,10,11,19,20,29,34,37,39,43,48,50,61,63,64,66,69,71,74,75,76,77,80,90] | |

| Physical ergonomics | [2,4,5,6,7,19,20,25,29,37,45,48,49,61,63,66,69,70,80] | |

| User-centreed design/human-centred in manufacturing | [2,4,9,10,11,12,18,20,25,29,31,32,35,37,38,40,43,44,45,48,51,54,58,60,63,64,74,75,76,78,81] | |

| Universal design in manufacturing | [4,7,40,43] | |

| Participatory design in manufacturing | [7,10,18,34,38,47,62,68] | |

| Assembly line balancing and job allocation | [2,5,10,19,22,24,33,37,38,39,44,45,46,48,59,71,76] | |

| Inclusive workstation design for shop floor | [7,35,36,39,43,44,46,47,49,50,53,55,56,57,59,61,62,63,64,66,70,71,74,75,76,77,80,90] | |

| Industry 4.0 and Industry 5.0 | Industry 4.0 in manufacturing | [2,6,7,9,12,18,22,29,31,32,33,35,36,37,39,40,43,44,45,48,51,54,58,60,61,63,65,66,69,71,75,76,78,80,81] |

| Automation in manufacturing | [2,4,6,7,9,10,12,20,25,29,31,33,37,43,47,51,58,63,66,71,74,75,78,90,92] | |

| I4.0 ATs for disabled operators | [4,11,18,19,20,22,33,35,36,37,39,40,42,43,44,47,50,51,53,54,58,59,60,61,62,63,64,65,66,69,71,74,75,77,80,90,91] | |

| I4.0 ATs for mainstream operators | [2,6,9,10,12,25,33,35,37,39,40,48,51,71,76,78] | |

| Human–robot collaboration | [18,19,29,37,44,47,48,54,58,59,62,63,65,68,80] | |

| Accessibility | [4,6,7,11,12,14,18,20,29,34,36,42,43,44,46,51,58,60,61,62,63,64,65,70,74,75,80,90] | |

| Industry 5.0 in manufacturing | [7,9,10,12,29,45,48,78,81,92] | |

| Sustainability and social sustainability | Sustainability and Industry 4.0/5.0 | [7,9,10,31,32,45,78,81] |

| Socially sustainable manufacturing | [2,6,7,9,10,12,18,25,29,31,32,34,36,38,42,43,45,48,65,66,69,78,81,92] | |

| Social dimension of sustainability (generic) | [2,6,9,10,12,14,18,25,29,31,32,34,36,38,42,43,45,48,54,62,65,66,69,78,81,91,92] | |

| Economically sustainable manufacturing | [7,9,10,29,31,32,34,78,81] | |

| Economic sustainability (generic) | [9,10,29,31,32,34,78,81] | |

| Environmentally sustainable manufacturing | [9,10,29,31,32,34,42,78,81] | |

| Environmental sustainability (generic) | [9,10,29,31,32,34,38,42,78,81] | |

| Sustainable development goals (SDGs) | [7,32,34,42] | |

| Disability in manufacturing and disability studies | Disability and Industry 4.0 | [4,11,14,19,20,22,33,35,37,39,40,43,44,45,50,54,61,62,63,64,65,68,71,75,76,78,80,91] |

| Disability in manufacturing | [4,5,6,7,11,18,19,20,21,22,23,24,33,34,35,36,37,39,40,41,42,43,44,45,46,47,49,50,51,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,74,75,76,77,78,80,90,91] | |

| Psychology and behaviour studies | [14,19,37,55,56,64] | |

| Universal design and disability | [7,18] | |

| Physical disability | [4,14,37,47,51,55,63,64,65,66,68,69,70,77,91] | |

| Sensory disability | [4,14,20,41,55,56,63,91] | |

| Cognitive disability | [4,11,14,20,22,35,36,37,39,41,44,47,50,51,53,54,55,56,57,58,60,61,63,64,65,66,68,74,76,91] | |

| Short-term memory loss | [53,65,76] | |

| Learning disability | [11,14,47,56,65,68] | |

| Visual | [42,51,53,55,56,57,63,65,68] | |

| Disability in employment and accommodations | [4,7,11,14,19,20,21,22,37,40,42,43,44,46,47,49,50,51,53,55,57,59,61,63,66,68,69,70,71,75,80] | |

| Sheltered workshops | [22,36,47,60,64,65,66,68,74,75,76,77] |

References

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Engel, P.; Harnisch, M.; Justus, J. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; The Boston Consulting Group: Boston, MA, USA, 2015. [Google Scholar]

- Kaasinen, E.; Schmalfuß, F.; Özturk, C.; Aromaa, S.; Boubekeur, M.; Heilala, J.; Heikkilä, P.; Kuula, T.; Liinasuo, M.; Mach, S.; et al. Empowering and engaging industrial workers with Operator 4.0 solutions. Comput. Ind. Eng. 2020, 139, 105678. [Google Scholar] [CrossRef]

- Mark, B.G.; Rauch, E.; Matt, D.T. Industrial Assistance Systems to Enhance Human–Machine Interaction and Operator’s Capabilities in Assembly. In Implementing Industry 4.0 in SMEs; Matt, D.T., Modrák, V., Zsifkovits, H., Eds.; Springer: Cham, Switzerland, 2021; pp. 129–161. [Google Scholar]

- Villani, V.; Sabattini, L.; Czerniaki, J.N.; Mertens, A.; Vogel-Heuser, B.; Fantuzzi, C. Towards modern inclusive factories: A methodology for the development of smart adaptive human-machine interfaces. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–7. [Google Scholar]

- Katiraee, N.; Calzavara, M.; Finco, S.; Battini, D.; Battaïa, O. Consideration of workers’ differences in production systems modelling and design: State of the art and directions for future research. Int. J. Prod. Res. 2021, 59, 3237–3268. [Google Scholar] [CrossRef]

- Matt, D.T.; Orzes, G.; Rauch, E.; Dallasega, P. Urban production—A socially sustainable factory concept to overcome shortcomings of qualified workers in smart SMEs. Comput. Ind. Eng. 2020, 139, 105384. [Google Scholar] [CrossRef]

- Mattsson, S.; Kurdve, M.; Almström, P.; Skagert, K. Synthesis of Universal Workplace Design in Assembly—A Case Study. In Advances in Transdisciplinary Engineering; Ng, A.H.C., Syberfeldt, A., Hogberg, D., and Holm, M., Eds.; IOS Press BV: Amsterdam, The Netherlands, 2022; pp. 184–196. [Google Scholar]

- Katiraee, N.; Finco, S.; Battaïa, O.; Battini, D. Assembly Line Balancing with Inexperienced and Trainer Workers. Advances in Production Management Systems. In Proceedings of the Artificial Intelligence for Sustainable and Resilient Production Systems: IFIP WG 5.7 International Conference, APMS 2021, Nantes, France, 5–9 September 2021; pp. 497–506. [Google Scholar]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Grund, J.; Umfahrer, M.; Buchweitz, L.; Gay, J.; Theil, A.; Korn, O. A gamified and adaptive learning system for neurodivergent workers in electronic assembling tasks. In Proceedings of the Mensch und Computer 2020, Association for Computing Machinery, Magdeburg, Germany, 6–9 September 2020; pp. 491–494. [Google Scholar]

- Grybauskas, A.; Stefanini, A.; Ghobakhloo, M. Social sustainability in the age of digitalization: A systematic literature Review on the social implications of industry 4.0. Technol. Soc. 2022, 70, 101997. [Google Scholar] [CrossRef]

- UN. Convention on the Rights of Persons with Disabilities; United Nations: New York, NY, USA, 2006. [Google Scholar]

- Adigun, O.; Nzima, D. The Fourth Industrial Revolution and Persons with Disabilities: Peeping Into The Future Through The Lens Of The Present. Multicult. Educ. 2021, 7, 2021. [Google Scholar]

- Zahidaha, A.A.; Nasirab, R.D. Decreasing the Digital Divide for People with Disabilities in the 4th Industrial Revolution: Case Study Kerjabilitas Users. In Proceedings of the 11th Conference of Indonesian Students Association in South Korea (CISAK) 2019At: Korea Matirime and Ocean University, Busan, Republic of Korea, 30–31 March 2019; p. 5. [Google Scholar]

- Council of the European Union General Secretariat. Disability in the EU: Facts and Figures. 4 July 2022. Available online: https://www.consilium.europa.eu/en/infographics/disability-eu-facts-figures/ (accessed on 27 November 2023).

- Eurostat—Statistics Explained. Businesses in the Manufacturing Sector. February 2023. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Businesses_in_the_manufacturing_sector (accessed on 27 November 2023).

- Mark, B.G.; Hofmayer, S.; Rauch, E.; Matt, D.T. Inclusion of Workers with Disabilities in Production 4.0: Legal Foundations in Europe and Potentials Through Worker Assistance Systems. Sustainability 2019, 11, 5978. [Google Scholar] [CrossRef]

- Mandischer, N.; Gürtler, M.; Weidemann, C.; Hüsing, E.; Bezrucav, S.-O.; Gossen, D.; Brünjes, V.; Hüsing, M.; Corves, B. Toward Adaptive Human–Robot Collaboration for the Inclusion of People with Disabilities in Manual Labor Tasks. Electronics 2023, 12, 1118. [Google Scholar] [CrossRef]

- Sabattini, L.; Villani, V.; Czerniak, J.; Mertens, A.; Fantuzzi, C. Methodological Approach for the Design of a Complex Inclusive Human-Machine System. In Proceedings of the 2017 13th IEEE Conference on Automation Science and Engineering (CASE), Xi’an, China, 1 August 2017. [Google Scholar]

- Kuznetsova, Y.; Bento, J.P.C. Workplace Adaptations Promoting the Inclusion of Persons with Disabilities in Mainstream Employment: A Case-Study on Employers. Responses in Norway. Soc. Incl. 2018, 6, 34–45. [Google Scholar] [CrossRef]

- Kosch, T.; Abdelrahman, Y.; Funk, M.; Schmidt, A. One size does not fit all: Challenges of providing interactive worker assistance in industrial settings. In Proceedings of the 2017 ACM International Joint Conference on Pervasive and Ubiquitous Computing and Proceedings of the 2017 ACM International Symposium on Wearable Computers, Maui, HI, USA, 11–15 September 2017; pp. 1006–1011. [Google Scholar]

- Bonello, A.; Francalanza, E.; Refalo, P. The realities of achieving a Smart, Sustainable, and Inclusive shopfloor in the age of Industry 5.0. Procedia Comput. Sci. 2024, in press. [Google Scholar]

- Litwin, P.; Antonelli, D.; Stadnicka, D. Disabled employees on the manufacturing line: Simulations of impact on performance and benefits for companies. IFAC-PapersOnLine 2022, 55, 848–853. [Google Scholar] [CrossRef]

- Romero, D.; Noran, O.; Stahre, J.; Bernus, P.; Fast-Berglund, Å. Towards a Human-Centred Reference Architecture for Next Generation Balanced Automation Systems: Human-Automation Symbiosis. In Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth; Umeda, S., Nakano, M., Mizuyama, H., Hibino, H., Kiritsis, D., von Cieminski, G., Eds.; Springer: Tokyo, Japan, 2015; pp. 556–566. [Google Scholar]

- ‘Disability Inclusion Overview’, World Bank. 2022. Available online: https://www.worldbank.org/en/topic/disability (accessed on 25 March 2023).

- United Nations Department of Economic and Social Affairs, ‘Disability—Inclusive; Sustainable Development Goals—2030 Agenda for Sustainable Development’. 2018. Available online: https://social.desa.un.org/issues/disability/sustainable-development-goals-sdgs-and-disability#:~:text=Closely%20linked%20is%20Goal%2010,settlements%20inclusive%2C%20safe%20and%20sustainable (accessed on 25 March 2023).

- Page, M.; McKenzie, J.; Bossuyt, P.; Boutron, I.; Hoffman, T.; Mulrow, C. The PRISMA 2020 Statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 15906. [Google Scholar] [CrossRef] [PubMed]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Centre for Science and Technology Studies, Leiden University, The Netherlands, ‘VOSviewer—Visualizing Scientific Landscapes’, VOSviewer. 2023. Available online: https://www.vosviewer.com// (accessed on 20 March 2023).

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Funk, M.; Bächler, A.; Bächler, L.; Kosch, T.; Heidenreich, T.; Schmidt, A. Working with Augmented Reality? A Long-Term Analysis of In-Situ Instructions at the Assembly Workplace. In Proceedings of the 10th International Conference on PErvasive Technologies Related to Assistive Environments, Association for Computing Machinery, Island of Rhodes, Greece, 21–23 June 2017; pp. 222–229. [Google Scholar]

- Sutherland, J.W.; Richter, J.S.; Hutchins, M.J.; Dornfeld, D.; Dzombak, R.; Mangold, J.; Robinson, S.; Hauschild, M.Z.; Bonou, A.; Schönsleben, P.; et al. The role of manufacturing in affecting the social dimension of sustainability. CIRP Ann. 2016, 65, 689–712. [Google Scholar] [CrossRef]

- Büttner, S.; Mucha, H.; Funk, M.; Kosch, T.; Aehnelt, M.; Robert, S.; Röcker, C. The Design Space of Augmented and Virtual Reality Applications for Assistive Environments in Manufacturing: A Visual Approach. In Proceedings of the 10th International Conference on PErvasive Technologies Related to Assistive Environments, Association for Computing Machinery, Island of Rhodes, Greece, 21–23 June 2017; pp. 433–440. [Google Scholar]

- Funk, M.; Mayer, S.; Schmidt, A. Using In-Situ Projection to Support Cognitively Impaired Workers at the Workplace. In Proceedings of the ASSETS ’15: Proceedings of the 17th International ACM SIGACCESS Conference on Computers & Accessibility, Lisbon, Portugal, 26–28 October 2015; pp. 185–192. [Google Scholar]

- Simões, A.C.; Pinto, A.; Santos, J.; Pinheiro, S.; Romero, D. Designing human-robot collaboration (HRC) workspaces in industrial settings: A systematic literature review. J. Manuf. Syst. 2022, 62, 28–43. [Google Scholar] [CrossRef]

- Berlin, C.; Barletta, I.; Fantini, P.; Georgoulias, K.; Hansich, C.; Lanz, M.; Latokartano, J.; Pinzone, M.; Schönborn, G.; Stahre, J.; et al. Prerequisites and Conditions for Socially Sustainable Manufacturing in Europe’s Future Factories—Results Overview from the SO SMART Project. In Advances in Ergonomics of Manufacturing: Managing the Enterprise of the Future; Advances in Intelligent Systems and Computing; Schlick, C., Trzcieliński, S., Eds.; Springer: Yulee, FL, USA, 2016; Volume 490, pp. 319–330. [Google Scholar]

- Funk, M.; Bächler, A.; Bächler, L.; Korn, O.; Krieger, C.; Heidenreich, T.; Schmidt, A. Comparing projected in-situ feedback at the manual assembly workplace with impaired workers. In Proceedings of the 8th ACM International Conference on PErvasive Technologies Related to Assistive Environments, Corfu, Greece, 1–3 July 2015; Association for Computing Machinery: New York, NY, USA; p. 1. [Google Scholar]

- Villani, V.; Sabattini, L.; Barańska, P.; Callegati, E.; Czerniak, J.N.; Debbache, A. The INCLUSIVE System: A General Framework for Adaptive Industrial Automation. IEEE Trans. Autom. Sci. Eng. 2021, 18, 1969–1982. [Google Scholar] [CrossRef]

- Desideri, L.; Lancioni, G.; Malavasi, M.; Gherardini, A.; Cesario, L. Step-Instruction Technology to Help People with Intellectual and Other Disabilities Perform Multistep Tasks: A literature review. J. Dev. Phys. Disabil. 2021, 33, 857–886. [Google Scholar] [CrossRef]

- Oldfrey, B.; Barbareschi, G.; Morjaria, P.; Giltsoff, T.; Massie, J.; Miodownik, M.; Holloway, C. Could Assistive Technology Provision Models Help Pave the Way for More Environmentally Sustainable Models of Product Design, Manufacture and Service in a Post-COVID World? Sustainability 2021, 13, 10867. [Google Scholar] [CrossRef]

- Correia de Barros, A. Inclusive design within industry 4.0: A literature review with an exploration of the concept of complexity. Des. J. 2022, 25, 849–866. [Google Scholar] [CrossRef]

- Kildal, J.; Ipiña, I.; Martín, M.; Maurtua, I. Collaborative assembly of electrical cabinets through multimodal interaction between a robot and a human worker with cognitive disability. Procedia CIRP 2020, 97, 184–189. [Google Scholar] [CrossRef]

- Battini, D.; Berti, N.; Finco, S.; Zennaro, I.; Das, A. Towards industry 5.0: A multi-objective job rotation model for an inclusive workforce. Int. J. Prod. Econ. 2022, 250, 108619. [Google Scholar] [CrossRef]

- Araújo, F.F.; Costa, A.M.; Miralles, C. Balancing parallel assembly lines with disabled workers. Eur. J. Ind. Eng. 2015, 9, 344–365. [Google Scholar] [CrossRef]

- Arévalo Arboleda, S.; Pascher, M.; Lakhnati, Y.; Gerken, J. Understanding Human-Robot Collaboration for People with Mobility Impairments at the Workplace, a Thematic Analysis. In Proceedings of the 2020 29th IEEE International Conference on Robot and Human Interactive Communication (RO-MAN), Naples, Italy, 31 August–4 September 2020; pp. 561–566. [Google Scholar]

- Lu, Y.; Zheng, H.; Chand, S.; Xia, W.; Liu, Z.; Xu, X.; Wang, L.; Qin, Z.; Bao, J. Outlook on human-centric manufacturing towards Industry 5.0. J. Manuf. Syst. 2022, 62, 612–627. [Google Scholar] [CrossRef]

- Vujica Herzog, N.; Harih, G. Decision support system for designing and assigning ergonomic workplaces to workers with disabilities. Ergonomics 2019, 63, 225–236. [Google Scholar] [CrossRef] [PubMed]

- Mihailidis, A.; Melonis, M.; Keyfitz, R.; Lanning, M.; Van Vuuren, S.; Bodine, C. A nonlinear contextually aware prompting system (N-CAPS) to assist workers with intellectual and developmental disabilities to perform factory assembly tasks: System overview and pilot testing. Disabil. Rehabil. Assist. Technol. 2016, 11, 604–612. [Google Scholar] [CrossRef]

- Villani, V.; Sabattini, L.; Zanelli, G.; Callegati, E.; Bezzi, B.; Barańska, P.; Mockałło, Z.; Żołnierczyk-Zreda, D.; Czerniak, J.N.; Nitsch, V.; et al. A User Study for the Evaluation of Adaptive Interaction Systems for Inclusive Industrial Workplaces. IEEE Trans. Autom. Sci. Eng. 2022, 19, 3300–3310. [Google Scholar] [CrossRef]

- Moore, R.; Williams, A.B. Towards a Learning Architecture to Support Social Scaffolding for an Artificially Intelligent Disability Assistant. In Proceedings of the Companion of the 2021 ACM/IEEE International Conference on Human-Robot Interaction, Boulder, CO, USA, 8–11 March 2021; pp. 467–469. [Google Scholar]

- Lancioni, G.E.; Singh, N.N.; O’Reilly, M.F.; Green, V.A.; Oliva, D.; Campodonico, F. Two men with multiple disabilities carry out an assembly work activity with the support of a technology system. Dev. Neurorehabilit. 2013, 16, 332–339. [Google Scholar] [CrossRef]

- Williams, A.B.; Williams, R.M.; Moore, R.E.; McFarlane, M. AIDA: A Social Co-Robot to Uplift Workers with Intellectual and Developmental Disabilities. In Proceedings of the 2019 14th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Daegu, Republic of Korea, 11–14 March 2019; pp. 584–585. [Google Scholar]

- Lancioni, G.; Singh, N.; O’Reilly, M.; Sigafoos, J.; Campodonico, F.; Zimbaro, C.; Alberti, G.; Trubia, G.; Zagaria, T. Helping people with multiple disabilities manage an assembly task and mobility via technology-regulated sequence cues and contingent stimulation. Life Span Disabil. 2018, 21, 143–163. [Google Scholar]

- Lancioni, G.E.; Singh, N.N.; O’Reilly, M.F.; Sigafoos, J.; Alberti, G.; Perilli, V.; Laporta, D.; Campodonico, F.; Oliva, D.; Groeneweg, J. People with multiple disabilities learn to engage in occupation and work activities with the support of technology-aided programs. Res. Dev. Disabil. 2014, 35, 1264–1271. [Google Scholar] [CrossRef] [PubMed]

- Lancioni, G.E.; Singh, N.N.; O’Reilly, M.F.; Sigafoos, J.; Alberti, G.; Boccasini, A.; Civita, L.; Tedone, R.; La Martire, M.L.; Trubia, G. Assistive Technology to support occupational engagement and mobility in persons with multiple disabilities. Life Span Disabil. 2015, 18, 119–139. [Google Scholar]

- Kildal, J.; Martín, M.; Ipiña, I.; Maurtua, I. Empowering assembly workers with cognitive disabilities by working with collaborative robots: A study to capture design requirements. Procedia CIRP 2019, 81, 797–802. [Google Scholar] [CrossRef]

- Hüsing, E.; Weidemann, C.; Lorenz, M.; Corves, B.; Hüsing, M. Determining Robotic Assistance for Inclusive Workplaces for People with Disabilities. Robotics 2021, 10, 44. [Google Scholar] [CrossRef]

- Kosch, T.; Kettner, R.; Funk, M.; Schmidt, A. Comparing Tactile, Auditory, and Visual Assembly Error-Feedback for Workers with Cognitive Impairments. In Proceedings of the 18th international ACM SIGACCESS Conference on Computers and Accessibility, Reno, NV, USA, 23–26 October 2016; pp. 53–60. [Google Scholar]

- Simões, B.; de Amicis, R.; Segura, A.; Martín, M.; Ipiña, I. A cross reality wire assembly training system for workers with disabilities. Int. J. Interact. Des. Manuf. 2021, 15, 429–440. [Google Scholar] [CrossRef]

- Arévalo Arboleda, S.; Becker, M.; Gerken, J. Does One Size Fit All? A Case Study to Discuss Findings of an Augmented Hands-Free Robot Teleoperation Concept for People with and without Motor Disabilities. Technologies 2022, 10, 4. [Google Scholar] [CrossRef]

- Stöhr, M.; Schneider, M.; Henkel, C. Adaptive Work Instructions for People with Disabilities in the Context of Human Robot Collaboration. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 301–308. [Google Scholar]

- Korn, O.; Schmidt, A.; Hörz, T. Augmented manufacturing: A study with impaired persons on assistive systems using in-situ projection. In Proceedings of the 6th International Conference on PErvasive Technologies Related to Assistive Environments—PETRA ’13, Rhodes, Greece, 29 June 2013; pp. 1–8. [Google Scholar]

- Drolshagen, S.; Pfingsthorn, M.; Gliesche, P.; Hein, A. Acceptance of Industrial Collaborative Robots by People With Disabilities in Sheltered Workshops. Front. Robot. AI 2021, 7, 541741. [Google Scholar] [CrossRef] [PubMed]

- Mark, B.G.; Rauch, E.; Matt, D.T. Systematic selection methodology for worker assistance systems in manufacturing. Comput. Ind. Eng. 2022, 166, 107982. [Google Scholar] [CrossRef]

- Arévalo Arboleda, S.; Miller, S.; Janka, M.; Gerken, J. What’s behind a choice? Understanding Modality Choices under Changing Environmental Conditions. In Proceedings of the ICMI ’19: 2019 International Conference on Multimodal Interaction, Suzhou, China, 14–18 October 2019; pp. 291–301. [Google Scholar]

- Arévalo Arboleda, S.; Pascher, M.; Baumeister, A.; Klein, B.; Gerken, J. Reflecting upon Participatory Design in Human-Robot Collaboration for People with Motor Disabilities: Challenges and Lessons Learned from Three Multiyear Projects. In Proceedings of the PErvasive Technologies Related to Assistive Environments Conference—PETRA 2021, Corfu, Greece, 29 June 2021; pp. 147–155. [Google Scholar]

- Zheng, T.; Glock, C.H.; Grosse, E.H. Opportunities for using eye tracking technology in manufacturing and logistics: Systematic literature review and research agenda. Comput. Ind. Eng. 2022, 171, 108444. [Google Scholar] [CrossRef]

- Budziszewski, P.; Grabowski, A.; Milanowicz, M.; Jankowski, J. Workstations for people with disabilities: An example of a virtual reality approach. Int. J. Occup. Saf. Ergon. 2016, 22, 367–373. [Google Scholar] [CrossRef]

- Segura, Á.; Diez, H.V.; Barandiaran, I.; Arbelaiz, A.; Álvarez, H.; Simões, B.; Posada, J.; García-Alonso, A.; Ugarte, R. Visual computing technologies to support the Operator 4.0. Comput. Ind. Eng. 2020, 139, 105550. [Google Scholar] [CrossRef]

- Ventana Systems, ‘Vensim’. 2022. Available online: https://vensim.com/ (accessed on 20 January 2023).

- ‘FlexSim—Problem Solved’, FlexSim. 2022. Available online: https://www.flexsim.com/ (accessed on 20 January 2023).

- Jost, M.; Luxenburger, A.; Knoch, S.; Alexandersson, J. PARTAS: A Personalizable Augmented Reality Based Task Adaption System for Workers with Cognitive Disabilities. In Proceedings of the 15th International Conference on PErvasive Technologies Related to Assistive Environments, Association for Computing Machinery, Corfu, Greece, 29 June 2022; pp. 159–168. [Google Scholar]

- Aksu, V.; Jenderny, S.; Martinetz, S.; Röcker, C. Providing context-sensitive mobile assistance for people with disabilities in the workplace. In AHFE 2018: Advances in Design for Inclusion; Di Bucchianico, G., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 3–14. [Google Scholar]

- Knoch, S.; Mohr, J.; Wolf, M.; Alexandersson, J.; Jost, R.; Posselt, K. Augmented Reality-based Worker Assistance for People with Cognitive Disabilities. In Proceedings of the 2022 IEEE International Conference on Artificial Intelligence and Virtual Reality (AIVR), Virtual, 12–14 December 2022; pp. 216–218. [Google Scholar]

- Weidemann, C.; Hüsing, E.; Freischlad, Y.; Mandischer, N.; Corves, B.; Hüsing, M. RAMB: Validation of a Software Tool for Determining Robotic Assistance for People with Disabilities in First Labor Market Manufacturing Applications. In Proceedings of the 2022 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Prague, Czech Republic, 9–12 October 2022; pp. 2269–2274. [Google Scholar]

- Grabowska, S.; Saniuk, S.; Gajdzik, B. Industry 5.0: Improving humanization and sustainability of Industry 4.0. Scientometrics 2022, 127, 3117–3144. [Google Scholar] [CrossRef] [PubMed]

- Universal Robots, ‘UR+ | Robotiq 3-Finger for Universal Robots’. 2023. Available online: https://robotiq.com/products/3-finger-adaptive-robot-gripper (accessed on 27 November 2023).

- Mark, B.G.; Rauch, E.; Brown, C.A.; Matt, D.T. Design of an Assembly Workplace for Aging Workforce and Worker with Disabilities. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1174, 1. [Google Scholar] [CrossRef]

- Majerník, M.; Daneshjo, N.; Malega, P.; Drábik, P.; Barilová, B. Sustainable Development of the Intelligent Industry from Industry 4.0 to Industry 5.0. Adv. Sci. Technol. Res. J. 2022, 16, 12–18. [Google Scholar] [CrossRef]

- United Nations, ‘Goal 8’, United Nations | Department of Economic and Social Affairs. 2022. Available online: https://sdgs.un.org/goals/goal8 (accessed on 25 March 2023).

- United Nations. Goal 10; Department of Economic and Social Affairs, United Nations: New York, NY, USA, 2022. [Google Scholar]

- Andreasen, M.M.; Hein, L. Integrated Product Development; Springer: Berlin, Germany; New York, NY, USA, 1987. [Google Scholar]

- Francalanza, E.; Borg, J.; Vella, P.; Farrugia, P.; Constantinescu, C. An ‘Industry 4.0’ digital model fostering integrated product development. In Proceedings of the 2018 IEEE 9th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 10–13 February 2018; pp. 95–99. [Google Scholar]

- Axiak, J.; Refalo, P.; Francalanza, E. An Integrated Product Development Approach to Improving Sustainability Using Simulated Experiments: Manufacturing Case Study. In Sustainable Design and Manufacturing 2016. SDM 2016. Smart Innovation, Systems and Technologies; Setchi, R., Howlett, R., Liu, Y., Theobald, P., Eds.; Springer: Cham, Switzerland, 2016; Volume 52. [Google Scholar]

- Giddings, R.; Hopwood, B.; O’Brien, G. Environment, economy and society: Fitting them together into sustainable development. Sust. Dev. 2002, 10, 187–196. [Google Scholar] [CrossRef]

- OMRON TAIYO Co. Ltd. ‘Japan’s First Factory to Empower People with Disabilities Leads the Next 50 Years of Change | OMRON Exploring “Work Styles of the Future” to Build a Sustainable Society’, OMRON Long-Term Vision Shaping the Future 2030. Available online: https://www.omron.com/global/en/edge-link/news/566.html (accessed on 27 November 2023).

- Roser, C. Disabled Employees in Manufacturing—Omron Taiyo in Japan—Part 2. Available online: https://www.allaboutlean.com/disabled-employees-in-manufacturing-omron-taiyo-in-japan-part-2/ (accessed on 27 November 2023).

- Simões, B.; de Amicis, R.; Barandiaran, I.; Posada, J. Cross reality to enhance worker cognition in industrial assembly operations. Int. J. Adv. Manuf. Technol. 2019, 105, 3965–3978. [Google Scholar] [CrossRef]

- Mark, B.G.; Gualtieri, L.; De Marchi, M.; Rauch, E.; Matt, D.T. Function-Based Mapping of Industrial Assistance Systems to User Groups in Production. Procedia CIRP 2021, 96, 278–283. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J. Towards the Resilient Operator 5.0: The Future of Work in Smart Resilient Manufacturing Systems. Procedia CIRP 2021, 104, 1089–1094. [Google Scholar] [CrossRef]

| “inclusive” AND “manufacturing” AND “workstation” AND “Industry 4.0” AND “disabilit” |

| “industry 4.0” AND “disabilit” AND “workstation” AND “manufacturing” |

| “smart” AND “sustainab” AND “workstation” AND “manufacturing” AND “disabilit” |

| “sustainab” AND “workstation” AND “industry 4.0” AND “disabilit” |

| “sustainab” AND “workstation” AND “industry 5.0” AND “disabilit” |

| “industry 5.0” AND “disabilit” AND “manufacturing” |

| “industry 4.0” AND “sustainab” AND “manufacturing” |

| “industry 5.0” AND “sustainab” AND “manufacturing” |

| Rank | Publication Title | Author | Date |

|---|---|---|---|

| 1st | Industry 4.0, digitization, and opportunities for sustainability | M. Ghobakhloo [31] | 2020 |

| 2nd | Industry 4.0 technologies assessment: A sustainability perspective | C. Bai [32] | 2020 |

| 3rd | Industry 5.0: A survey on enabling technologies and potential applications | P. Maddikunta [10] | 2022 |

| 4th | Industry 4.0 and Industry 5.0—Inception, conception and perception | X. Xu [9] | 2021 |

| 5th | Empowering and engaging industrial workers with Operator 4.0 solutions | E. Kaasinen [2] | 2020 |

| 6th | Working with Augmented Reality?: A Long-Term Analysis of In-Situ Instructions at the Assembly Workplace | M. Funk [33] | 2017 |

| 7th | The role of manufacturing in affecting the social dimension of sustainability | J. Sutherland [34] | 2016 |

| 8th | The Design Space of Augmented and Virtual Reality Applications for Assistive Environments in Manufacturing: A Visual Approach | S. Büttner [35] | 2017 |

| 9th | Towards a Human-Centred Reference Architecture for Next Generation Balanced Automation Systems: Human-Automation Symbiosis | D. Romero [25] | 2015 |

| 10th | Using In-Situ Projection to Support Cognitively Impaired Workers at the Workplace | M. Funk [36] | 2015 |

| Assistive System Category | Technology | Purpose of Technology for Operators with Different Disabilities | Reference |

|---|---|---|---|

| Sensorial assistive systems | Warning lights | Exemplar for people with hearing disabilities, since such warning lights can allow for timely reaction. | [18,50,60] |

| Audible signals | Idem to above purpose, with the exception that audible signals are suitable for people with vision disabilities. | [18,50,53,60,61] | |

| Visual instructions | Ideal for people with vision disabilities; useful to convey warnings easily and reliably. | [11,18,50,60] | |

| Smart watches | When amalgamating sensors such as heart monitoring sensors, real-time evaluation of the operator’s wellbeing is just a tap away. | [18] | |

| Physical assistive systems | Exoskeletons | Physically worn by the user; practical for people with physical disabilities; promotes mobility to upper limbs, forearms, and whole-body movement. | [18] |

| Collaborative robots and attachments | Integrated within the workstation to act as an extension of the operator, to sustain the operator during heavy load lifting—stimulates an ergonomically-conscious environment. Also suitable for tasks demanding a high degree of precision. | [18,59,62,63] | |

| Virtual reality and head-mounted displays (HMDs) | Provides hands-free control for people with restricted dexterity and motor skills. | [35,62] | |

| Cognitive assistive systems | Projectors and thermography technology | Used to avail operators of guidance during assembly tasks, whilst ensuring that an acceptable quality is simultaneously attained. | [11,33,36,44,58,61,63,64] |

| Digital supportive services such as contour visualisation | Feasible for people with cognitive disabilities and provision of workload relief as opposed to having to recall everything by memory. Clear outlining of contours and instructions was also recognised as a beneficial implementation. | [11,33,36,63,64] | |

| Collaborative robots and attachments | Supplement guidance during cognitively demanding tasks, such as laser-pointing and tracking. | [44,58,65] |

| Areas of Commonality between Industry 4.0 and Sustainability, as Displayed by Ghobakhloo [31] | Economical | Environmental | Social |

|---|---|---|---|

| Upscaling of business framework | ✓ | ||

| Cutting down on CO2 emissions | ✓ | ||

| Enhancing company profitability | ✓ | ||

| Adopting economic growth | ✓ | ||

| Resource management and energy efficiency | ✓ | ✓ | |

| Consciousness towards the environment | ✓ | ✓ | |

| Strengthening human resources | ✓ | ✓ | |

| Prioritising efficiency in production | ✓ | ✓ | |

| Provision of novel occupations | ✓ | ✓ | |

| Decreasing costs to manufacture | ✓ | ||

| Augmentation of manufacturing flexibility | ✓ | ✓ | |

| Adaptable production | ✓ | ✓ | |

| Ease of production versatility | ✓ | ✓ | |

| Upgrading safety control through cobots | ✓ | ||

| Managing supply chains | ✓ | ✓ | |

| Enriching social consciousness | ✓ | ||

| TOTAL | 13 | 8 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonello, A.; Francalanza, E.; Refalo, P. Smart and Sustainable Human-Centred Workstations for Operators with Disability in the Age of Industry 5.0: A Systematic Review. Sustainability 2024, 16, 281. https://doi.org/10.3390/su16010281

Bonello A, Francalanza E, Refalo P. Smart and Sustainable Human-Centred Workstations for Operators with Disability in the Age of Industry 5.0: A Systematic Review. Sustainability. 2024; 16(1):281. https://doi.org/10.3390/su16010281

Chicago/Turabian StyleBonello, Amberlynn, Emmanuel Francalanza, and Paul Refalo. 2024. "Smart and Sustainable Human-Centred Workstations for Operators with Disability in the Age of Industry 5.0: A Systematic Review" Sustainability 16, no. 1: 281. https://doi.org/10.3390/su16010281

APA StyleBonello, A., Francalanza, E., & Refalo, P. (2024). Smart and Sustainable Human-Centred Workstations for Operators with Disability in the Age of Industry 5.0: A Systematic Review. Sustainability, 16(1), 281. https://doi.org/10.3390/su16010281