Abstract

In this study, compression mechanical properties of five giant bamboo species from different continents were investigated based on the ISO 22157:2019 standard. The selected species have been used for rural construction for centuries. The chosen bamboo species for this study, which are considered strong candidates to be used in modern construction as well, are as follows: Phyllostachys edulis (Moso), Guadua angustifolia (Guadua), Gigantochloa apus (Tali), Gigantochloa atroviolacea (Black Java), and Phyllostachys bambusoides (Madake). The excellent properties of bamboo species in tension are well established. Hence, this article principally focuses on the behaviour of selected giant species in compression to be used as structural members. In this study, the mentioned bamboo species were gathered from different continents of origin to be critically assessed, analysed, and compared with one another to better understand their compression behaviour as structural columns. The compression properties of these bamboo species have not been evaluated and compared with one another in an academic study so far. The results show that all tested species were able to provide mean compressive strengths greater than 50 MPa, which makes them highly promising construction material candidates for modern construction. The Guadua test series was able to provide outstanding consistency in the presented compression behaviour and strengths among all the tested species. The specimens with the maximum sustained load belonged to the Tali species. The greatest average failure load belonged to the Moso species. The greatest mean compressive strength measured was 88.9 MPa, reported for Madake species with smaller diameters compared to the other test series. Among the specimens with larger diameters, the greatest mean ultimate strengths were for Moso, Guadua, and Tali species with 69.9 MPa, 60.7 MPa, and 59.1 MPa compressive strengths, respectively.

1. Introduction

In recent years, a growing emphasis has been put on climate change and its dramatic effects on the planet. The correlation between anthropogenic carbon emissions and climate change has been extensively documented [1,2]. In December 2015, 195 countries adopted the Paris Agreement [3], a global accord within the United Nations Framework Convention on Climate Change. The Paris Agreement’s principal objective is to hold the increase in the global average temperature to well below 2 °C above pre-industrial levels. Additional efforts are recommended for limiting the temperature increase to just 1.5 °C and reducing the risks and impact of climate change [1]. In order to achieve this target, emissions of carbon dioxide (CO2) need to be limited and the overall man-made greenhouse gas emissions need to become net zero [4]. The construction industry has been identified as one of the major contributors, mainly due to the greenhouse gas emissions linked to the extraction and manufacturing of steel and concrete [5]. Numerous studies have analysed the life cycle of different construction projects and verified that a significant amount of the greenhouse gases due to construction are released mainly from the extraction and production of raw materials, rather than from operational practices [6].

Concrete is by far the most utilized material in civil engineering and one of the most produced and consumed substances in the world, second only to water [7]. One of the key components of concrete is cement, whose production accounts alone for about 5–6% of the total CO2 emitted from human activities [8]. Steel is another common material in civil engineering that embeds high levels of CO2 emissions. It is believed that the steel industry is responsible for 7–9% of all the global direct emissions from fossil fuels [9]. Current trends in material choices are not considered sustainable and a different approach may be needed to mitigate the negative impact of the construction industry on climate change [10].

Considering such an unsustainable scenario, strong steps should be taken to decarbonize the construction industry as much as possible. One way of achieving such a major objective is to shift towards renewable bio-based construction materials.

Among existing bio-based construction material alternatives, bamboo has recently gained popularity for being one of the organic rapidly renewable materials with the highest potential to take the lead in the sustainable structural materials panorama [11]. Bamboo has been praised for its competitive mechanical properties, rapid growth rate, negative carbon footprint and cost-effectiveness [12,13,14,15].

Bamboo is a form of giant grass native to almost all continents (Antarctica excluded) that proliferates in tropical, subtropical and temperate climates, up to 3500 m of altitude [14,15]. More than 1000 species exist, categorized into two main “tribes”: herbaceous and woody. Only fewer than 100 are suitable for construction and they all belong to the latter tribe [14]. Woody bamboo, as opposed to trees, only grows vertically and emerges from the ground with its final diameter that does not change throughout its lifespan. The anatomy of bamboo consists of a hollow culm segmented into nodes and internodes; the wall of the culm is made of longitudinal fibres that run aligned in a soft lignin matrix and are responsible for the strength of the culm [15]. Bamboo has a fast-growing rate: it reaches full maturity in 3–5 years and starts deteriorating after 6 years [14].

It is clear that bamboo is widely recognized as a sustainable material [15]. A study by Van der Lugt et al. [16] confirms that bamboo is more sustainable than steel, concrete, masonry and timber, even when imported to Europe from far distances. It has been shown that due to its fast growth rate, bamboo has a very high potential to act as a carbon sink for carbon retention, making bamboo forests an ideal ecosystem that can help mitigate climate change [17]. Bamboo forests are also excellent for erosion control, landslide prevention and water conservation [18]. Additionally, bamboo plays a role in improving air quality and maintaining wildlife biodiversity [18].

The use of bamboo in construction dates from far in the past. Chung and Yu [19] report that basic frames made of bamboo were common in China 2000 years ago and hypothesize older applications in scaffolding up to 5000 years ago. Bamboo for scaffolding is still widely adopted in Southern China and Hong Kong as a preferred choice over more modern options such as metal ones [19]. Historically, bamboo has also been largely adopted as an alternative to timber, mainly in South Asia, India and Latin America due to the wide distribution of local bamboo forests [20].

Despite bamboo having been used in construction for thousands of years, data about its structural properties have only started to be gathered recently. The first documented paper that includes the mechanical properties of such material dates back to 1923 [15]. The last two decades have seen a rapid increase in contribution toward the characterization of bamboo species, but much research has still to be conducted to cover many existing gaps due to the anisotropic nature of this material [15].

Bhagat et al. [12] suggest that most of the bamboo species suitable for construction have a tensile strength of around 120 MPa and compression strength of around 55 MPa, both parallel to the grain. Mitch et al. [21] provide allowable shear stresses of around 1.2 MPa, a value that could be additionally reduced due to bamboo’s weak matrix prone to split. Oka et al. [22] studied the effect of nodes on some mechanical properties of Black Java bamboo, following the guidelines of ISO 22157-2:2004 [23]. The study shows how the presence of a node does not impact greatly the compressive strength and shear strength, reporting average compressive strengths of 50.50 MPa for samples containing a node and 52.57 MPa for internode samples (node-free), and shear strengths of 7.77 MPa and 7.60 MPa, respectively. Tensile strengths, however, decreased from 254.30 MPa at the internode to 109.88 MPa at the node.

A previous study by Dixon and Gibson [24] indicates some of the main mechanical properties of Moso bamboo. In particular, Dixon and Gibson [24] provide stress–strain curves for axial, radial and tangential directions under axial compression. Along the fibres, the compressive strength of a bamboo wall segment was found equal to 69.1 MPa. A comparison with North American softwoods indicates that Moso bamboo is stronger in axial compression and significantly denser [24].

Several papers report the lack of standardization as a main limiting factor in the adoption and worldwide diffusion of bamboo for structural application [11,12,13,14,15]. Some attempts have been made recently to provide international standards. The first attempt dates to 1973 and was published by the Bureau of Indian Standards [25]. A more recent set of guidelines was provided in 2004 by the International Standards Organisation (ISO) with the release of three main documents: ISO 22157-1:2004: Bamboo: Determination of physical and mechanical properties—Part 1: requirements [26]; ISO 22157-2:2004: Bamboo: Determination of physical and mechanical properties—Part 2: laboratory manual [23]; and ISO 22156:2004: Bamboo: Structural design [27]. These standards provide fundamental provisions for testing bamboo for several mechanical properties and offer some guidance on structural design. These ISO standards have recently been updated with additional test methods and published recently as ISO 22157:2019 [28] and ISO 22156:2021 [29].

Until now, the extensive use of bamboo as a mainstream construction material has been hindered due to a lack of widespread knowledge on the excellent potentials of bamboo as a structural material in the modern era. The current unprecedented study has gathered five recognized giant bamboo species that are known for suitability in construction from different continents. For the first time, the behaviour of these bamboo species has been critically assessed and compared to one another under compression. For this matter, ISO 22157:2019 [28] has been considered as the testing reference standard. The objective of this study is to investigate the behaviour of different species in compression in form of full culms to be used as structural columns in modern buildings.

2. Materials and Methods

2.1. Materials

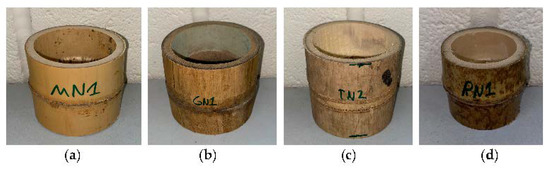

Out of the 100 species of bamboo suitable for construction, five mostly recognized were shortlisted for this project as follows: Phyllostachys edulis (Moso), Guadua angustifolia (Guadua), Gigantochloa apus (Tali), Gigantochloa atroviolacea (Black Java) and Phyllostachys bambusoides (Madake). Overall, 30 specimens have been chosen from different species with 50% of specimens from each species containing a node as per instructed by the ISO 22157:2019 standard [28]. By choosing each specimen from different bamboo culms, the natural variability was observed by comparing the coefficient of variations (CoV) of the measured properties. Figure 1a–e depicts all test specimens in this study from different species.

Figure 1.

Bamboo test series: (a) Moso; (b) Guadua; (c) Tali; (d) Black Java; and (e) Madake.

The origin of procured Moso and Madake species was China, whereas Tali and Black Java species were shipped from Indonesia. Guadua bamboo was purchased from Colombia. The diameters of the specimens were chosen in a way to provide a comparable platform for mechanical properties measurements by avoiding the size effect on the specimens’ mechanical property comparison procedure. This excludes Madake species of similar sizes to other giant bamboo species not available at the time of testing.

From an appearance perspective, Moso bamboo has a bright pale yellow to ochre colour with a satin sheen and smooth glassy skin surface finish. Moso bamboo normally owns medium to thick walls with open cell structures. Moso nodes are fairly prominent with gentle lips on larger diameters of bamboo through a single joint line (Figure 2a).

Figure 2.

Giant bamboo species evaluated in this study: (a) Moso; (b) Guadua; (c) Tali; and (d) Madake.

Guadua bamboo has a dull mid to light beige colour with dark brown spotting and a matt surface finish. Guadua bamboo has a woody thick wall and nodes that are flat with double line joints (Figure 2b).

Tali bamboo has a dull mid to light beige colour with a satin sheen and smooth glassy skin surface finish. Tali has woody thick walls with fairly flat nodes and double line joints. (Figure 2c).

Black Java bamboo has a very dark brown to mid-chocolate brown colour with a satin to matt surface finish. Black Java has woody thick walls with fairly flat nodes, i.e., no prominent lips at nodes (Figure 1d).

Madake bamboo has a speckled external colour with mid-brown and pale beige colour spots with satin to matt surface finish and smooth skin. The large splodges of brown resemble daubes of paint. Similar to Moso bamboo, Madake has medium to thick walls with open cell structures and nodes that are rather noticeable with a mild lip on larger diameters through a single joint line (Figure 2d).

Following harvesting and prior to shipping, Guadua specimens were dipped in a Borax solution, as an insect repellent and preservative. The internal nodes were pierced to allow the treatment to run through the poles, but this also helps prevent the poles from splitting or cracking. Similarly, Tali and Java Black species have the internal nodes pierced which is a traditional approach by the farmers to help prevent the poles from splitting or cracking. In addition, all shipping containers of all tested species have been fumigated for up to 24 h once they were loaded in their country of origin.

The cross-sectional dimensions of the bamboo specimens were measured to the precision of 0.1 mm. It should be pointed out that where samples obtained a variation in cross-sectional diameters, 6 measurements were taken, three at the top and three at the bottom. The mean of these measurements was used. The aim of this approach was to better account for the natural variations in the bamboo’s anatomy. The specimen lengths were cut based on the standard provisionss by ISO 22157:2019 section 10.2 [28] and measured accordingly. An overview of the averaged physical properties of bamboo specimens can be found in Table 1.

Table 1.

Averaged physical properties of bamboo specimens.

The rationale behind the labelling terminology of the specimens is as follows: the first letter denotes the species, the second letter confirms whether the specimen is internodal or nodal, and the final digit is the number of the specimen. In this manner, the coding for bamboo species is chosen as follows: “M” for Moso, “G” for Guadua, “T” for Tali, “B” for Black Java and “P” for Phyllostachys bambusoides, i.e., Madake. The coding for nodal and internodal specimens is “N” and “I”, respectively. An example of this can be found in the specimen MN1 which corresponds to Moso species, Nodal, and Sample No. 1.

The samples have been stored for a year in an environment, which was away from sunlight and water, and were given appropriate air circulation to reach the equilibrium moisture content with the laboratory environment, i.e., 15.8% on average.

2.2. Methods

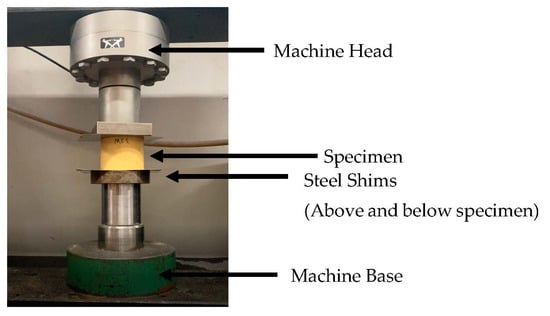

The chosen equipment to test and measure the compression properties of bamboo specimens was an Instron universal testing machine with 250 kN maximum loading capacity in compression and a displacement measurement accuracy of ±0.01 mm (Figure 3). The bottom loading platen of the machine was equipped with a spherical bearing able to ensure the load was concentrically applied by allowing necessary rotations. The end planes of each specimen were adjusted with sandpaper to ensure the load was transferred to the specimens uniformly. In addition, in between the loading platens and the specimen ends, an intermediate metallic sheet was added to minimize friction. The vertical load and displacement were automatically recorded by a computerized system at 1 second intervals. A loading rate of 2.0 kN/s was utilized after a few trials to ensure the failure of the specimens was reached within 300 ± 120 s, as instructed by ISO 22157:2019 [28]. According to the ISO standard, the length of the specimen to be tested in compression is taken as the lesser of the outer diameter, Douter, or 10 times the wall thickness, 10t.

Figure 3.

The test setup used for compression testing of the bamboo specimens.

3. Results

The test results of 30 bamboo specimens across varying species under axial compression loading are provided in this section. Table 2 summarizes the experimental results obtained from the tests for all the specimens.

Table 2.

Physical and mechanical properties of bamboo samples tested.

The results are presented in terms of the axial loads attained at the peak (Fult), the axial compressive stress reached at the peak (fc,0), the measured axial deformation at ultimate (ΔLc,0), the axial compressive strain reached the peak (fc,0), and the modulus of elasticity of specimens in compression parallel to the fibres (Εc,0). The modulus of elasticity was calculated using the following Equation (1) which is provided by ISO 22157:2019 [29]:

The equation calculates the secant modulus of elasticity between the points corresponding to the applied load and compressive strain of 60% and 20% of failure. In this manner, F60 and F20 are the applied load at 60% and 20% of the load at peak, correspondingly, whereas ε60 and ε20 are the compressive strain corresponding to 60% and 20% of the load at peak, respectively.

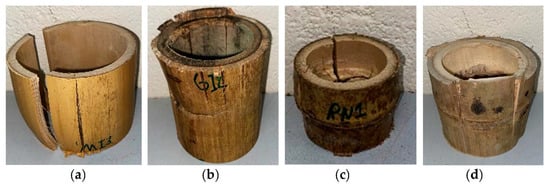

3.1. Failure Modes

The failure modes of the tested bamboo species are discussed in this section. In general, longitudinal cracking was distinct across both nodal and internodal specimens. In some cases of internodal specimens, the parallel longitudinal cracking resulted in the separation of a bamboo slice leading to a failure (Figure 4a,d). Another common failure mode for internodal specimens was local buckling, as can be seen in specimens GI2 (Figure 4b). For nodal specimens, top longitudinal cracking was the initiation point of crack propagations; however, the longitudinal cracking was stopped in some specimens at the node, starting a transverse development afterwards (Figure 4c).

Figure 4.

Bamboo specimens after failure: (a) MI3; (b) GI2; (c) PI1; and (d) TN2.

3.2. Displacement Response

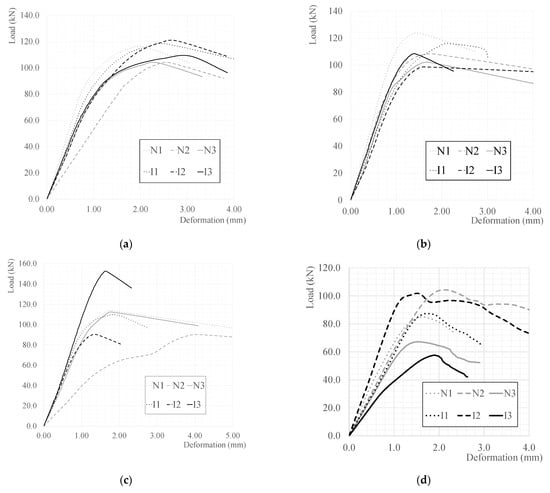

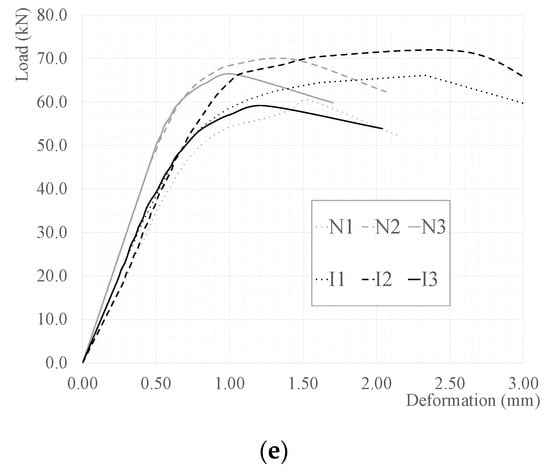

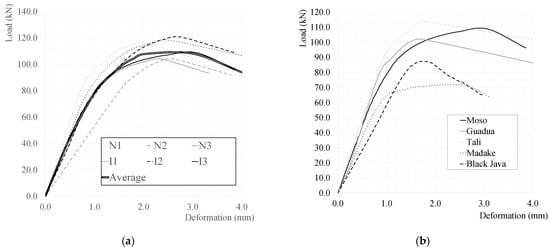

Figure 5a–e show the curves representing the load versus the end-shortening of the tested specimens divided into separate figures based on their species.

Figure 5.

Load versus end-shortening of specimens of test series: (a) Moso; (b) Guadua; (c) Tali; (d) Black Java; and (e) Madake.

For the Moso test series (Figure 5a), the displacement response can be divided into three stages. An elastic stage can be observed with a linear response in the load-deformation curve in the first phase which continues up to loads around 60 kN for Moso specimens. Upon development of cracking in the specimens, the plastic stage begins, in which the axial compressive rigidity of the specimens decreases. This is observed by the decreases in the slope of the load-deformation curves in the second stage until it reaches the ultimate load (Figure 5a). The maximum load resisted by the specimens was 120.7 kN by specimen MI2. As can be seen in Figure 5, Moso specimens could sustain considerable deformation in the plastic stage before reaching the ultimate compared to the other species (2.21 mm on average). For this matter, the next in line is the Madake series which comes from a similar genus of Asian bamboo as Moso (Figure 5e). The third stage of the Moso series displacement response corresponds to a smooth softening behaviour following reaching the ultimate load. For Moso specimens, the mean resistance of all specimens was 112.1 kN, CoV = 6.59%. In that, the mean resistance of nodal specimens is equal to 108.1 kN, and that of internodal specimens is equal to 116.0 kN (Table 2). Meanwhile, the mean deformation value at ultimate is equal to 2.55 mm, which is the greatest among other species. This corresponds to the superior deformability and the ability to absorb the applied energy compared to the rest of the species.

Similar to the Moso series, for the Guadua test series, the displacement response can be divided into three stages (Figure 5b). However, the elastic stage in the Guadua series reaches as high as around 80 kN on average for all the specimens in the series. Meanwhile, the nonlinear ascending stage of the displacement response, i.e., stage 2, corresponds to shorter deformations (Figure 5b) than those of the Moso series (0.81 mm on average). The maximum load resisted by the specimens was 123.8 kN by specimen GN1. The third stage of the Guadua series displacement response depicts a softening stage with a descending shallow slope which corresponds to a structurally desirable none-brittle failure. For Guadua specimens, the mean resistance of all specimens was 109.5 kN, with CoV = 8.38%. It should be mentioned that the mean resistance of nodal specimens is equal to 111.1 kN, and that of internodal specimens is equal to 107.7 kN (Table 2). The mean deformation value at ultimate is equal to 1.68 mm.

As with other species of bamboo tested in the study, the Tali test series displacement response includes three stages (Figure 5c). The elastic stage in the Tali series ends at forces around 65 kN on average for all the specimens in the series. Similar to the Guadua series, the plastic stage is rather short, corresponding to an average end-shortening of 0.85 mm. The maximum load resisted by the specimens was 152.4 kN by specimen TI3, which was the greatest resisted load among all tested specimens. The specimen owned the largest cross-sectional area with considerably thick walls (12.7 mm) among all specimens (Table 2). For the internodal specimens of the Tali series, the third stage corresponds to a sudden failure. This could be due to the sudden detachment of a bamboo wall slice at the ultimate (Figure 4d). As Figure 5c clearly shows, specimen TN2 presented a significantly softer behaviour compared to the rest of the specimens in the test series. The mean resisting ultimate load of all Tali specimens was 111.4 kN, with CoV = 18.60%. The mean resistance of nodal specimens is equal to 105.5 kN, and that of internodal specimens is equal to 117.3 kN. The mean deformation value at the ultimate is equal to 2.12 mm.

The elastic stage in the Black Java series continued up to a load of around 60 kN on average for all the specimens in the series except for the BI3 which failed prematurely (Figure 5d). In addition, the plastic stage of the displacement response was rather short corresponding to an average deformation of 0.73 mm. The maximum load resisted by the specimens was 104.4 kN by specimen BN2. The third stage of the Black Java series displacement response illustrates a smooth softening stage corresponding to a none-brittle failure (Figure 5d). For Black Java specimens, the mean resistance of all specimens was 83.9 kN, with CoV = 22.13%. The mean resistance of nodal specimens is equal to 85.6 kN, and that of internodal specimens is equal to 82.3 kN. In addition, the mean deformation value at ultimate is equal to 1.73 mm (Table 2).

The displacement response of Madake specimens is similar to those of the Moso series but on a smaller scale, considering the smaller size of Madake specimens (Figure 5e). The elastic stage in the Madake series continued up to a load of around 40 kN on average for all the specimens. Meanwhile, the plastic stage of the displacement response is the second longest corresponding to an average deformation of 1.78 mm (Figure 5e). The maximum load resisted by the specimens was 71.6 kN by specimen PI2. The third stage of the Madake series displacement response corresponds to a smooth softening stage. For Madake specimens, the mean resistance of all specimens was 65.6 kN, with CoV = 7.54%. The mean resistance of nodal specimens is equal to 65.5 kN, and that of internodal specimens is equal to 65.7 kN. The mean deformation value at ultimate for the Madake test series is equal to 1.67 mm (Table 2).

In addition, in order to be able to compare the displacement response of different species, one specimen from each species with the behaviour representing the average behaviour of the specimens in each species is selected. To do so, the average resisted force for different deformation instalments was calculated and drawn versus deformations in the form of a load-deformation of a hypothetical average specimen for each species. Figure 6a shows the load-deformation graph of such a hypothetical average specimen for the Moso test series along with the behaviour of the tested specimens in the series. It is clear that the closest specimen’s behaviour to that of the hypothetical average specimen for the Moso series is the MI3 specimen. Except for the Madake test series, specimens GN3, TN1 and BI1 were respectively chosen as the representatives of the Guadua, Tali and Black Java test series in a similar manner. For the Madake test series with the smaller diameters compared to the rest of the test series, the specimen with the greatest area of the cross-section (PI2) was chosen to minimize the size effect when comparing the behaviour of the responses of different bamboo species. The load versus deformation of specimens representing each species is shown in Figure 6b.

Figure 6.

Load versus deformation of (a) the specimens in the Moso series versus the hypothetical average specimen of the whole Moso series; (b) the representing specimens from each species.

3.3. Strain Response

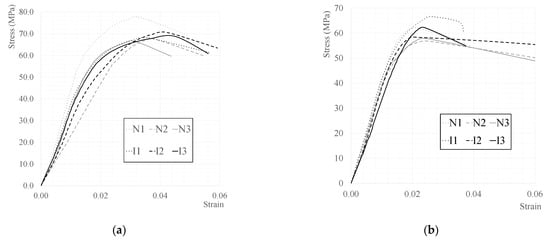

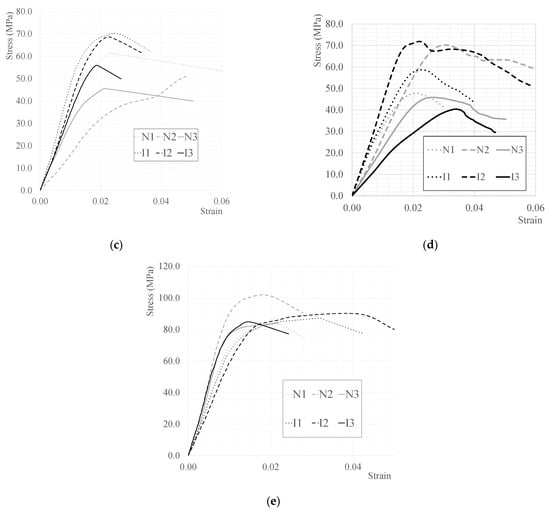

Figure 7a–e show the curves representing the sustained compressive stress versus the average axial strain of the tested specimens shown in separate figures based on their species. The calculated stress is derived by dividing the applied force by the area of the cross-section of each specimen, whereas the axial strain is calculated by dividing the end-shortening by the initial length of the specimens.

Figure 7.

Compressive stress versus axial strain of specimens of test series: (a) Moso; (b) Guadua; (c) Tali; (d) Black Java; and (e) Madake.

In all test series, the strain response can be divided into three stages. However, in the Moso and Madake series, the three stages are distinctively separable from one another (Figure 7a,e). In the Guadua, Tali and Black Java series, stage 2 can only briefly be observed (Figure 7b–d) and the material’s behaviour is very close to bi-linear behaviour.

For the Moso series, the specimens showed elastic behaviour up to an average stress of 51.5 MPa. The maximum compressive stress sustained by a Moso specimen was 77.6 MPa (specimen MN1) while the average strength of the Moso specimens was equal to 69.9 MPa with CoV = 5.25%. The mean strength of nodal specimens is equal to 70.5 MPa, and that of internodal specimens is equal to 69.2 MPa. The average strain value at ultimate for the Moso test series is equal to 0.0374.

The elastic stage for the Guadua specimens lasted up to a stress level equal to 48.9 MPa on average for all the tested specimens in this series. The maximum compressive stress experienced by a Guadua specimen was 66.7 MPa (specimen GI1) while the average strength of the Guadua specimens was equal to 60.7 MPa with CoV = 5.53%. In addition, the average strength of nodal specimens is equal to 59.0 MPa, and that of internodal specimens is equal to 62.5 MPa. The mean strain value at ultimate for the Guadua test series is equal to 0.0235.

For the Tali test series, the elastic behaviour was observed up to an average stress of 44.5 MPa. The maximum compressive stress sustained by a Tali specimen was 69.9 MPa (specimen TI1) while the average strength of the Tali specimens was equal to 59.1 MPa with CoV = 14.46%. The mean strength of nodal specimens for Tali specimens is equal to 53.4 MPa, and that of internodal specimens is equal to 64.8 MPa. The average strain value at ultimate for the Tali test series is equal to 0.0279.

For the Black Java test series, the elastic stage lasted up to a stress level equal to 44.7 MPa on average for all the tested specimens. The maximum stress experienced by a Black Java specimen was 71.9 MPa (specimen BI2) while the average strength of the Black Java specimens was equal to 54.6 MPa with CoV = 20.98%. In addition, the average strength of nodal specimens is equal to 52.6 MPa, and that of internodal specimens is equal to 56.7 MPa. The mean strain value at ultimate for the Black Java test series is equal to 0.0249.

For the Madake test series, the elastic behaviour was observed up to an average stress of 61.5 MPa. The maximum stress sustained by a Madake specimen was 101.5 MPa (specimen PN2) while the average strength of the Madake specimens was equal to 88.9 MPa with CoV = 6.65%. The mean strength of nodal specimens for Madake specimens is equal to 90.5 MPa, and that of internodal specimens is equal to 87.3 MPa. The average strain value at ultimate for the Madake test series is equal to 0.0250.

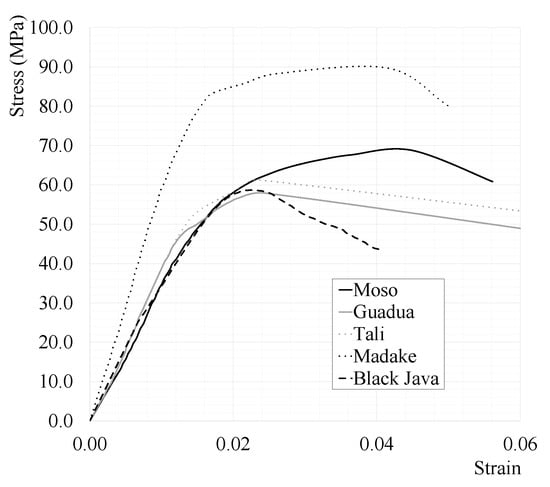

Moreover, to be able to compare the strain response of different species to one another, one specimen from each test series with the behaviour representing the average behaviour of the series is chosen. The average stress versus axial deformation of specimens representing each species is shown in Figure 8.

Figure 8.

Average stress versus strain of the representing specimens from each species.

As for the case for displacement response, for the Madake series, specimen PI2 with the greatest cross-section was chosen to minimize the size effect in comparison to the responses. In this regard, the chosen specimens to represent their series are as follows: MI3, GN3, TN1, BI1 and PI2.

4. Discussion

Following the sample preparations, testing and gathering of the test results, analysis of the results has been carried out with the purpose of better understanding the mechanical properties of the different bamboo species under compression loading till failure.

4.1. Displacement Response

The maximum average deformation experienced by a tested series belonged to the Moso series with 2.55 mm, whereas the minimum average deformation experienced by the tested series belonged to the Madake and Guadua series, with 1.67 mm and 1.68 mm end-shortening, respectively (Figure 6b).

When it comes to comparing the maximum carried load, the greatest load sustained by a test specimen was 152.4 kN by specimen TI3 from the Tali test series. The maximum average load in a test series, however, belongs to Moso, Tali and Guadua test series with 112.1 kN, 111.4 kN and 109.5 kN, respectively.

4.2. Strain Response

Figure 8 reveals the average compressive stress of the specimens representing each test series versus axial strain. The strain response of the tested species follows the same pattern as their displacement response when it comes to different stages of the loading. Stage one: a linear stage that was extended beyond the 50 MPa limit for most of the test series. Stage two: the linear stage is followed by a nonlinear ascending stage which was relatively brief for Guadua, Tali and Black Java specimens. It can be seen while the strain at maximum stress is equal to 0.0448 and 0.0415 for Moso and Madake specimens, respectively, that for Guadua, Tali and Black Java specimens is significantly lower: 0.0243, 0.0232 and 0.0207, correspondingly (Figure 8). Considering the fact that the representing specimens from all series, except the Madake series, follow the same linear stage (see Figure 8), i.e., almost similar “Stage 1”s, the aforementioned difference in the strain at ultimate corresponds to the rather brittle response of Guadua, Tali and Black Java compared to that of Moso and Madake specimens. Stage three: the ultimate failure was followed by a softening stage with a shallow negative slope. A sudden brittle failure was not a common failure mode in the tested specimens of all tested species. For Guadua specimens, the similarity of the stress–strain graphs of the tested specimens (Figure 7b) reveals an element of repeatability in the provided test results, which is remarkable for a raw natural product with a hollow shape.

The maximum sustained compressive stresses belonged to Madake specimens with a smaller diameter compared to the rest of the tested species, reaching an average compressive strength of 88.9 MPa. Among the specimens with larger diameters, the greatest average ultimate strengths were as follows: Moso, Guadua and Tali with 69.9 MPa, 60.7 MPa and 59.1 MPa compressive strengths, respectively. It should be noted that the compressive strength of Brazilian Phyllostachys edulis was measured at 59.5 MPa and 57.5 MPa for nodal and internodal specimens, respectively, by Gauss et al. [30]. Meanwhile, experimental testing of Kenneth and Uzodimma [31] on Guadua bamboo resulted in compressive strength of 74.4 MPa and 64.1 MPa on average for nodal and internodal samples, respectively.

It should be noted that for Moso and Madake test series, the nodal specimens have greater compressive strengths compared to those of the internodal specimens (Table 2). Conversely, for Guadua, Tali and Black Java test series, the internodal specimens provided greater compressive strengths compared to those of the nodal specimens in the same test series. Therefore, no certain conclusion can be derived in this matter.

4.3. Modulus of Elasticity in Compression

The Madake species was the species that provided the greatest modulus of elasticity, as can be seen in Figure 8. The average modulus of elasticity of the Madake test series is equal to 8.49 MPa with CoV = 20.59%. Among the rest of the species that had larger diameters compared to those of the Madake test series, the greatest modulus of elasticity on average belonged to the Guadua species with Ec,0 = 4.11 GPa (CoV = 7.92%) and Moso species with Ec,0 = 3.65 GPa (CoV = 21.58%). The average modulus of elasticity for Tali and Black Java species was equal to 3.54 GPa and 2.74 GPa with coefficients of variation equal to 30.24% and 32.16%, respectively.

The effect of the presence of node on the compressive modulus of elasticity of the specimens was also investigated in this study. For Moso specimens, the mean moduli of elasticity of nodal and internodal specimens were equal to 4.77 MPa and 3.56 MPa, respectively. These values for Guadua specimens were equal to 4.26 MPa and 3.96 MPa for nodal and internodal specimens, correspondingly. For Tali, Black Java and Madake species, the mean modulus of elasticity of nodal specimens were equal to 2.81 MPa, 2.57 MPa, 9.48 MPa, versus those values for internodal values as follows: 4.27 MPa, 2.90 MPa and 7.49 MPa. A previous study by Oka et al. [22] showed a 60% decrease in the compressive modulus elasticity of Black Java specimens; however, the presence of nodes had a decreasing effect on the modulus of elasticity of the specimens when compared to those of internodal specimens; the decrease level was limited to 12%. In the current study, for the Moso, Guadua and Madake specimens, the presence of the nodes increased the modulus of elasticity by 34%, 8% and 27%, respectively.

4.4. Reliability as a Construction Material

Guadua specimens were able to present excellent reliability in compression as a construction material by providing high compressive strength (Table 2) with a remarkably low variation in the compression behaviour and strength of the materials. This was evidenced by a low CoV for compressive strengths and moduli of elasticity that were respectively equal to 5.53% and 7.92%, and considerably similar load-deformation and stress-strain curves in Guadua specimens (see Figure 5b and Figure 7b). In addition, Moso and Madake specimens were able to provide reliable compressive strengths with the coefficient of variations of 5.25% and 6.65%, respectively.

Indeed, for in-depth reliability analysis, several more compressive tests need to be conducted on each of the giant bamboo species. However, the outstanding consistency of the Guadua, Moso and Madake species in compressive strength is worth mentioning. Moreover, the reliability of bamboo, based on other important properties needed for a reliable construction material, should be assessed in future studies.

5. Conclusions

The compression behaviour of five different giant bamboo species from different continents has been analysed in this experimental investigation. In total, 30 specimens from Moso, Guadua, Tali, Black Java and Madake species have been tested in compression according to the ISO 22157:2019 standard. Interestingly, all of the tested specimens were able to provide average compressive strengths greater than 50 MPa. Particular conclusions related to each species and their remarkable characteristics can be listed as follows:

- The greatest load sustained by a test specimen in this study was 152.4 kN in specimen TI3 from the Tali test series.

- The maximum average load in a test series belongs to Moso, Tali and Guadua test series with 112.1 kN, 111.4 kN and 109.5 kN, respectively.

- The maximum sustained compressive stresses belonged to Madake specimens with a smaller diameter compared to the rest of the tested species reaching an average compressive strength of 88.9 MPa.

- Among the specimens with larger diameters, the greatest average ultimate strengths achieved were as follows for Moso, Guadua and Tali with 69.9 MPa, 60.7 MPa and 59.1 MPa compressive strengths, respectively.

- The presence of the nodes did not seem to have a significant effect on the compressive strength of bamboo specimens. In fact, for Moso and Madake test series, nodal specimens have greater compressive strengths compared to those of the internodal specimens, whereas for Guadua, Tali and Black Java test series, the internodal specimens provided greater compressive strengths compared to those of the nodal specimens in the same test series.

- Guadua test series was able to provide outstanding consistency in the provided compressive behaviour and strength among all the tested specimens. This was evidenced by rather low CoV for compressive strength and modulus of elasticity that are respectively equal to 5.53% and 7.92%, and considerably similar load-deformation and stress–strain curves of Guadua specimens. Moso and Madake specimens were able to provide reliable compressive strengths with the CoVs of 5.25% and 6.65%, respectively.

Author Contributions

Conceptualization, A.M.; methodology, B.D., C.P., M.R., L.S., O.S., S.F. and A.M.; validation, A.M.; formal analysis, B.D., C.P., M.R., L.S., O.S., S.F. and A.M.; investigation, B.D., C.P., M.R., L.S., O.S., S.F. and A.M.; resources, A.M.; data curation, B.D., C.P., M.R., L.S., O.S., S.F. and A.M.; writing—original draft preparation, B.D., C.P., M.R., L.S., O.S., S.F. and A.M.; writing—review and editing, A.M.; visualization, A.M.; supervision, A.M.; project administration, A.M.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by the Brock Library Open Access Publishing Fund.

Acknowledgments

The authors gratefully appreciate the cooperation of the sales executive at UK Bamboo Supplies Limited, Jenny Warren, for the valuable information on the origin of the investigated bamboo species. The authors acknowledge the generous contribution of Brock University to the APC through the Brock Library Open Access Publishing Fund.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Intergovernmental Panel on Climate Change: Climate Change 2014: Synthesis Report. In Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change Report; Pachauri, R.K., Meyer, L., Eds.; World Meteorological Organization: Geneva, Switzerland, 2015. [Google Scholar]

- Jiang, J.; Du, J.; Li, H.; Mei, C.; Gong, X. Hydrophobicity improvement on wood for a better application of this bio-based material. Coatings 2022, 12, 1465. [Google Scholar] [CrossRef]

- Paris Agreement to the United Nations Framework Convention on Climate Change. In Treaties and Other International Acts Series (TIAS) No. 16-1104; U.S. Department of State: Washington, DC, USA, 2015.

- Matthews, H.; Caldeira, K. Stabilizing climate requires near-zero emissions. Geophys. Res. Lett. 2008, 35, 323. [Google Scholar] [CrossRef]

- Arioğlu Akan, M.Ö.; Dhavale, D.G.; Sarkis, J. Greenhouse gas emissions in the construction industry: An analysis and evaluation of a concrete supply chain. J. Clean. Prod. 2017, 167, 1195–1207. [Google Scholar] [CrossRef]

- Giesekam, J.; Tingley, D.; Cotton, I. Aligning carbon targets for construction with (inter)national climate change mitigation commitments. Energy Build. 2018, 165, 106–117. [Google Scholar] [CrossRef]

- Klee, H. Briefing: The cement sustainability initiative. Proc. Inst. Civ. Eng.—Eng. Sustain. 2004, 157, 9–11. [Google Scholar] [CrossRef]

- Rodrigues, F.; Joekes, I. Cement industry: Sustainability, challenges and perspectives. Environ. Chem. Lett. 2010, 9, 151–166. [Google Scholar] [CrossRef]

- World Steel Association. Steel’s Contribution to a Low-Carbon Future and Climate Resilient Societies; World Steel Association: Brussels, Belgium, 2020; Report. 6. [Google Scholar]

- Khatib, J.M. Sustainability of Construction Materials, 2nd ed.; Woodhead Publishing: Sawston, UK, 2016; 742p. [Google Scholar]

- Nunes, N. Nonwood bio-based materials. Perform. Bio-Based Build. Mater. 2017, 3, 97–186. [Google Scholar]

- Harries, K.A.; Sharma, B.; Richard, M. Structural Use of Full Culm Bamboo: The Path to Standardization. Int. J. Archit. Eng. Constr. 2012, 1, 66–75. [Google Scholar] [CrossRef]

- Bhagat, D.; Maheshwari, A.; Bhalla, S. Composite bamboo beam elements for structural applications. In Proceedings of the UK-India Education and Research Initiative (UKIERI) Congress on Innovations in Concrete Construction, Jalandhar, India, 5 August 2013. [Google Scholar]

- Kaminski, S.; Lawrence, A.; Trujillo, D. Structural use of bamboo. Part 1: Introduction to bamboo. Struct. Eng. 2016, 98, 40–43. [Google Scholar]

- Trujillo, D.; López, L.F. Bamboo material characterisation. In Nonconventional and Vernacular Construction Materials, 2nd ed.; Harries, K.A., Sharma, B., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 365–392. [Google Scholar]

- Van der Lugt, P.; Abrahams, R.; Van den Dobbelsteen, A. Bamboo as a building material alternative for Western Europe? A study of the environmental performance, costs and bottlenecks of the use of bamboo (products) in Western Europe. J. Bamboo Ratt. 2003, 2, 205–223. [Google Scholar] [CrossRef]

- Yiping, L.; Yanxia, L.; Buckingham, K.; Henley, K.; Guomo, Z. Bamboo and climate change mitigation. In International Network for Bamboo and Rattan; Technical Report No. 32, 2010; INBAR: Beijing, China, 2010; p. 32. [Google Scholar]

- Song, X.; Zhou, G.; Jiang, H.; Yu, S.; Fu, J.; Li, W.; Wang, W.; Ma, Z.; Peng, C. Carbon sequestration by Chinese bamboo forests and their ecological benefits: Assessment of potential, problems, and future challenges. Environ. Rev. 2011, 19, 418–428. [Google Scholar] [CrossRef]

- Chung, K.; Yu, W. Mechanical properties of structural bamboo for bamboo scaffoldings. Eng. Struct. 2002, 24, 429–442. [Google Scholar] [CrossRef]

- Huang, Z.; Sun, Y.; Musso, F. Assessment of bamboo application in building envelope by comparison with reference timber. Constr. Build. Mater. 2017, 156, 844–860. [Google Scholar] [CrossRef]

- Mitch, D.; Harries, K.; Sharma, B. Characterization of splitting behavior of bamboo culms. J. Mater. Civ. Eng. 2010, 22, 1195–1199. [Google Scholar] [CrossRef]

- Oka, G.M.; Triwiyono, A.; Awaludin, A.; Siswosukarto, S. Effects of node, internode and height position on the mechanical properties of Gigantochloa Atroviolacea bamboo. Procedia Eng. 2014, 95, 31–37. [Google Scholar] [CrossRef]

- ISO 22157-2:2004; Bamboo—Determination of Physical and Mechanical Properties—Part 2: Laboratory Manual. International Standards Organization: Geneva, Switzerland, 2004.

- Dixon, P.G.; Gibson, L.J. The structure and mechanics of Moso bamboo material. J. R. Soc. Interface 2014, 11, 20140321. [Google Scholar] [CrossRef] [PubMed]

- IS 6874:1973; Methods of Tests for Round Bamboos. Bureau of Indian Standards: Old Delhi, India, 1973.

- ISO 22157-1:2004; Bamboo—Determination of Physical and Mechanical Properties—Part 1: Requirements. International Standards Organization: Geneva, Switzerland, 2004.

- ISO 22156:2004; Bamboo—Structural Design. International Standards Organization: Geneva, Switzerland, 2004.

- ISO 22157:2019; Bamboo structures—Determination of Physical and Mechanical Properties of Bamboo Culms—Test Methods. International Standards Organization: Geneva, Switzerland, 2019.

- ISO 22156:2021; Bamboo—Structural Design. International Standards Organization: Geneva, Switzerland, 2021.

- Gauss, C.; Savastano, H., Jr.; Harries, K. Use of ISO 22157 mechanical test methods and the characterisation of Brazilian, P. edulis bamboo. Constr. Build. Mater. 2019, 228, 116728. [Google Scholar] [CrossRef]

- Kenneth, O.I.; Uzodimma, U.O. Evaluation of the Compressive Strength of Bamboo Culms under Node and Internode Conditions. Saudi J. Civ. Eng. 2021, 5, 251–258. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).