Sewage Sludge Management and Application in the Form of Sustainable Fertilizer

Abstract

1. Introduction

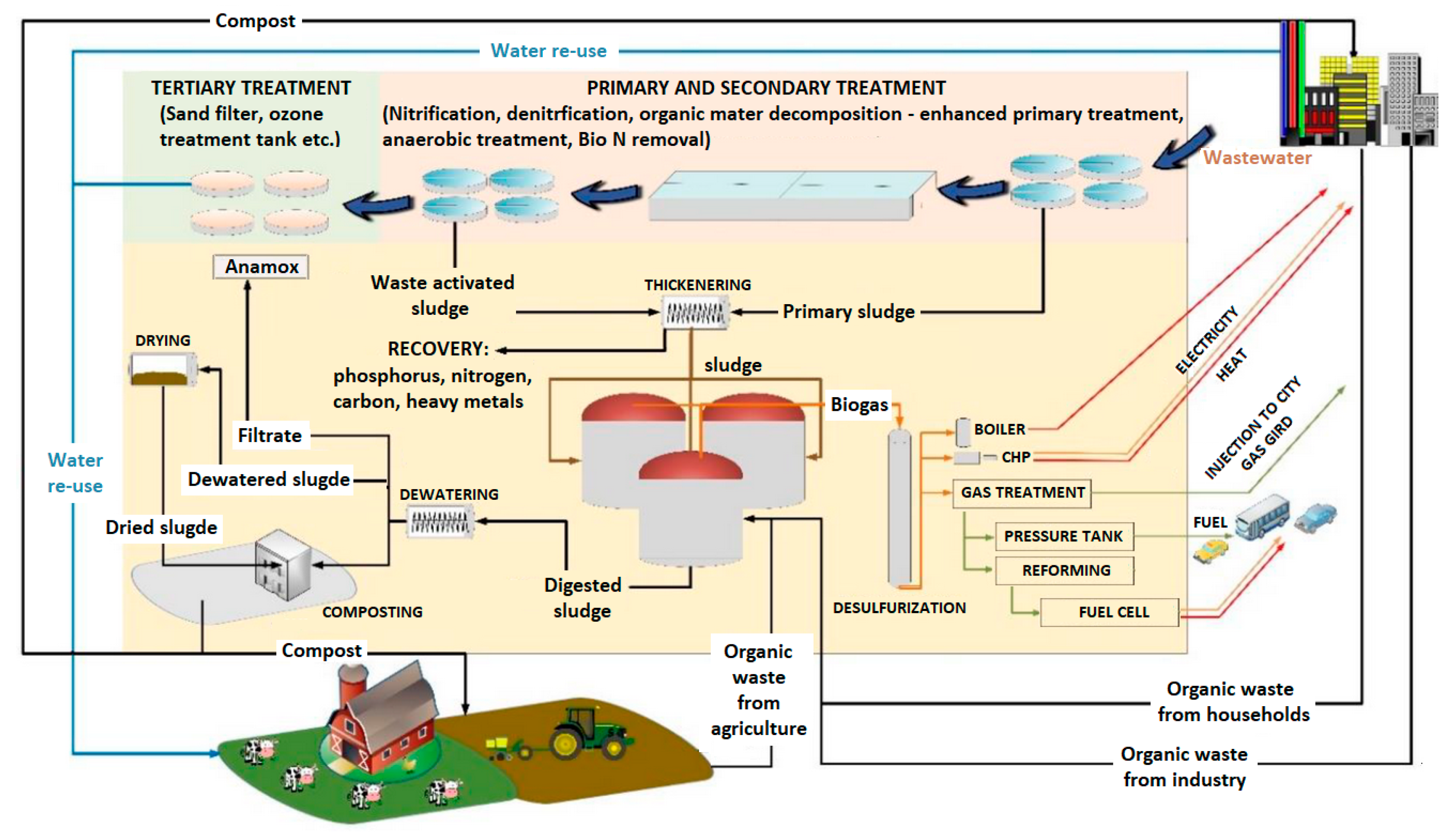

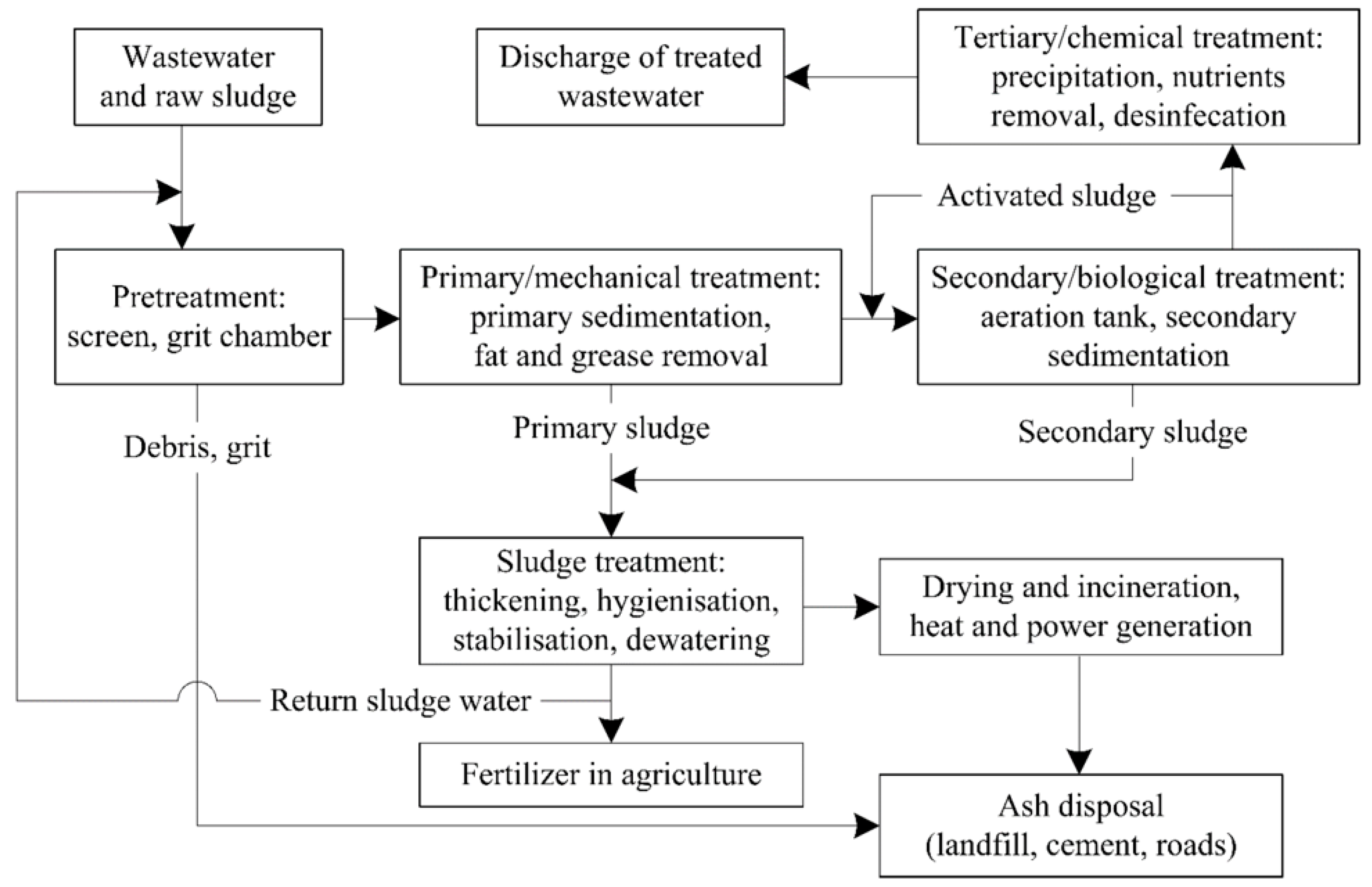

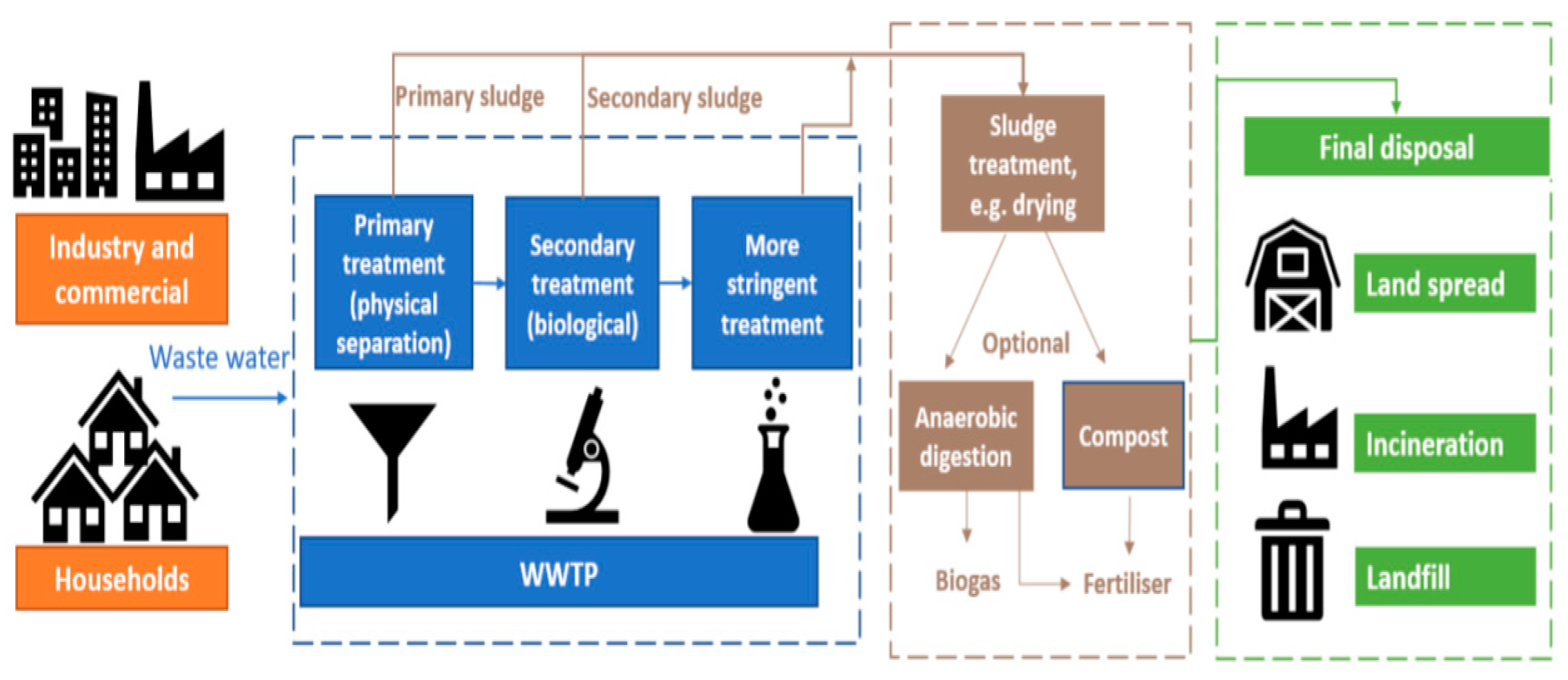

2. Sewage Sludge Production and Management

2.1. Treatment and Disposal Strategies for Sewage Sludge

2.1.1. Anaerobic Digestion

2.1.2. Composting

2.1.3. Pyrolysis

2.2. Application of Treated Sewage Sludge as Fertilizer

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ungureanu, N.; Vlăduț, V.; Voicu, G. Water Scarcity and Wastewater Reuse in Crop Irrigation. Sustainability 2020, 12, 9055. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Inglezakis, V.J. Sewage Sludge Management: From the Past. to Our Century; Nova Science Publishers, Inc.: New York, NY, USA, 2012; ISBN 9781613243930. [Google Scholar]

- Inglezakis, V.J.; Zorpas, A.A.; Karagiannidis, A.; Samaras, P.; Voukkali, I.; Sklari, S. European Union Legislation on Sewage Sludge Management. Fresenius Environ. Bull. 2014, 23, 635–639. [Google Scholar]

- Basel Convention. Available online: http://www.basel.int/Countries/StatusofRatifications/PartiesSignatories/tabid/4499/Default.aspx (accessed on 7 February 2023).

- Stockholm Convention. Available online: http://chm.pops.int/Countries/StatusofRatifications/PartiesandSignatoires/tabid/4500/Default.aspx (accessed on 7 February 2023).

- European Commission. Environmental, Economic and Social Impacts of the Use of Sewage Sludge on Land; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Guangyin, Z.; Youcai, Z. Sewage Sludge Generation and Characteristics. Pollution Control and Resource Recovery; Elsevier: Oxford, UK, 2017; ISBN 978-0-12-811639-5. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The Possible Use of Sewage Sludge Ash (SSA) in the Construction Industry as a Way towards a Circular Economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- European Environmental Agency. More from Less—Material Resource Efficiency in Europe. 2016. Available online: https://www.eea.europa.eu/publications/more-from-less (accessed on 1 January 2023).

- Wiechmann, B.; Dienemann, C.; Kabbe, C.; Brandt, S.; Vogel, I.; Roskosch, A. Sewage Sludge Management in Germany; Umweltbundesamt (UBA): Dessau-Roßlau, Grmany, 2013. [Google Scholar]

- Neczaj, E.; Grosser, A.; Grobelak, A.; Celary, P.; Singh, B.R. Conversion of Sewage Sludge and Other Biodegradable Waste into High-Value Soil Amendment within a Circular Bioeconomy Perspective. Energies 2021, 14, 6953. [Google Scholar] [CrossRef]

- Inglezakis, V.J.J.; Poulopoulos, S.G.G.; Arkhangelsky, E.; Zorpas, A.A.A.; Menegaki, A.N.N. Aquatic Environment; Elsevier B.V.: Amsterdam, The Netherlands, 2016; ISBN 9780444627339. [Google Scholar] [CrossRef]

- García, L.; Leyva-Díaz, J.C.; Díaz, E.; Ordóñez, S. A Review of the Adsorption-Biological Hybrid Processes for the Abatement of Emerging Pollutants: Removal Efficiencies, Physicochemical Analysis, and Economic Evaluation. Sci. Total. Environ. 2021, 780, 146554. [Google Scholar] [CrossRef] [PubMed]

- Shooner, F.; Tyagi, R.D. Thermophilic Microbial Leaching of Heavy Metals from Municipal Sludge Using Indigenous Sulphur-Oxidizing Microbiota. Appl. Microbiol. Biotechnol. 1996, 45, 440–446. [Google Scholar] [CrossRef]

- Jaynes, W.F.; Zartman, R.E.; Sosebee, R.E.; Wester, D.B. Biosolids Decomposition after Surface Applications in West Texas. J. Environ. Qual. 2003, 32, 1773–1781. [Google Scholar] [CrossRef]

- Stylianou, M.A.; Kollia, D.; Haralambous, K.J.; Inglezakis, V.J.; Moustakas, K.G.; Loizidou, M.D. Effect of Acid Treatment on the Removal of Heavy Metals from Sewage Sludge. Desalination 2007, 215, 73–81. [Google Scholar] [CrossRef]

- Zorpas, A.A.A.; Inglezakis, V.J.V.J.; Loizidou, M. Heavy Metals Fractionation before, during and after Composting of Sewage Sludge with Natural Zeolite. Waste Manag. 2008, 28, 2054–2060. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Inglezakis, V.; Loizidou, M.; Grigoropoulou, H. Particle Size Effects on Uptake of Heavy Metals from Sewage Sludge Compost Using Natural Zeolite Clinoptilolite. J. Colloid Interface Sci. 2002, 250, 1–4. [Google Scholar] [CrossRef]

- McClellan, K.; Halden, R.U. Pharmaceuticals and Personal Care Products in Archived U.S. Biosolids from the 2001 EPA National Sewage Sludge Survey. Water Res. 2010, 44, 658–668. [Google Scholar] [CrossRef] [PubMed]

- Đurđević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef]

- European Commission. A European Green Deal. 2020. Available online: https://commission.europa.eu/document/download/daef3e5c-a456-4fbb-a067-8f1cbe8d9c78_en (accessed on 1 January 2023).

- Anderson, N.; Snaith, R.; Madzharova, G.; Bonfait, J.; Doyle, L.; Godley, A.; Lam, M.; Day, G.; Neilson, R.; Fribourg-Blanc, B. Sewage Sludge and the Circular Economy; European Environment Agency (EEA): Strasbourg, France, 2021. [Google Scholar]

- Iticescu, C.; Georgescu, P.L.; Arseni, M.; Rosu, A.; Timofti, M.; Carp, G.; Cioca, L.I. Optimal Solutions for the Use of Sewage Sludge on Agricultural Lands. Water 2021, 13, 585. [Google Scholar] [CrossRef]

- Smirnov, Y.D.; Suchkova, M.V. Beneficial Use of Sewage Sludge Incineration Ash in the National Economy. Water Ecol. 2019, 24, 16–25. [Google Scholar] [CrossRef]

- Kominko, H.; Gorazda, K.; Wzorek, Z.; Wojtas, K. Sustainable Management of Sewage Sludge for the Production of Organo-Mineral Fertilizers. Waste Biomass Valorization 2018, 9, 1817–1826. [Google Scholar] [CrossRef]

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Union: Brussels, Belgium, 2008. [Google Scholar]

- Mohanakrishna, G.; Srikanth, S.; Pant, D. Bioprocesses for Waste and Wastewater Remediation for Sustainable Energy. Bioremediat. Bioeconomy 2016, 537–565. [Google Scholar] [CrossRef]

- Wehner, M.; Lichtmannegger, T.; Robra, S.; do Carmo Precci Lopes, A.; Ebner, C.; Bockreis, A. Determination of the Dewatered Digestate Amounts and Methane Yields from the Co-Digestion of Biowaste as a Basis for a Cost-Benefit Analysis. Waste Manag. 2021, 126, 632–642. [Google Scholar] [CrossRef]

- Manu, M.K.; Li, D.; Liwen, L.; Jun, Z.; Varjani, S.; Wong, J.W.C. A Review on Nitrogen Dynamics and Mitigation Strategies of Food Waste Digestate Composting. Bioresour. Technol. 2021, 334, 125032. [Google Scholar] [CrossRef]

- Rincón, C.A.; de Guardia, A.; Couvert, A.; le Roux, S.; Soutrel, I.; Daumoin, M.; Benoist, J.C. Chemical and Odor Characterization of Gas Emissions Released during Composting of Solid Wastes and Digestates. J. Environ. Manag. 2019, 233, 39–53. [Google Scholar] [CrossRef]

- Ting, C.; Lee, D. Production of Hydrogen and Methane from Wastewater Sludge Using Anaerobic Fermentation. Int. J. Hydrogen Energy 2007, 32, 677–682. [Google Scholar] [CrossRef]

- Yang, G.; Wang, J. Fermentative Hydrogen Production from Sewage Sludge. Crit. Rev. Environ. Sci. Technol. 2017, 47, 1219–1281. [Google Scholar] [CrossRef]

- Wieringa, K.T. The Formation of Acetic Acid from Carbon Dioxide and Hydrogen by Anaerobic Spore-Forming Bacteria. Antonie van Leeuwenhoek 1939, 6, 251–262. [Google Scholar] [CrossRef]

- Fontaine, F.E.; Peterson, W.H.; McCoy, E.; Johnson, M.J.; Ritter, G.J. A New Type of Glucose Fermentation by Clostridium Thermoaceticum. J. Bacteriol. 1942, 43, 701–715. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Zhang, G.; Zhuan, R.; Yang, A.; Wang, Y. Transformations, Inhibition and Inhibition Control Methods of Sulfur in Sludge Anaerobic Digestion: A Review. Curr. Org. Chem. 2016, 20, 2780–2789. [Google Scholar] [CrossRef]

- Demirel, B.; Scherer, P. The Roles of Acetotrophic and Hydrogenotrophic Methanogens during Anaerobic Conversion of Biomass to Methane: A Review. Rev. Environ. Sci. Biotechnol. 2008, 7, 173–190. [Google Scholar] [CrossRef]

- Guo, X.M.; Trably, E.; Latrille, E.; Carrère, H.; Steyer, J.-P. Hydrogen Production from Agricultural Waste by Dark Fermentation: A Review. Int. J. Hydrog. Energy 2010, 35, 10660–10673. [Google Scholar] [CrossRef]

- Horta, C.; Carneiro, J.P. Use of Digestate as Organic Amendment and Source of Nitrogen to Vegetable Crops. Appl. Sci. 2022, 12, 248. [Google Scholar] [CrossRef]

- Tani, M.; Sakamoto, N.; Kishimoto, T.; Umetsu, K. Utilization of Anaerobically Digested Dairy Slurry Combined with Other Wastes Following Application to Agricultural Land. Int. Congr. Ser. 2006, 1293, 331–334. [Google Scholar] [CrossRef]

- Tambone, F.; Genevini, P.; D’Imporzano, G.; Adani, F. Assessing Amendment Properties of Digestate by Studying the Organic Matter Composition and the Degree of Biological Stability during the Anaerobic Digestion of the Organic Fraction of MSW. Bioresour. Technol. 2009, 100, 3140–3142. [Google Scholar] [CrossRef]

- International Energy Agency. Outlook for Biogas and Biomethane: Prospects for Organic Growth; IEA: Paris, France, 2020. [Google Scholar]

- Anwar, Z.; Irshad, M.; Fareed, I.; Saleem, A. Characterization and Recycling of Organic Waste after Co-Composting—A Review. J. Agric. Sci. 2015, 7, 68–79. [Google Scholar] [CrossRef]

- Stylianou, M.A.A.; Inglezakis, V.J.J.; Moustakas, K.G.G.; Loizidou, M.D.D. Improvement of the Quality of Sewage Sludge Compost by Adding Natural Clinoptilolite. Desalination 2008, 224, 240–249. [Google Scholar] [CrossRef]

- Al-Rumaihi, A.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Environmental Impact Assessment of Food Waste Management Using Two Composting Techniques. Sustainability 2020, 12, 1595. [Google Scholar] [CrossRef]

- Soudejani, H.T.; Kazemian, H.; Inglezakis, V.J.; Zorpas, A.A. Application of Zeolites in Organic Waste Composting: A Review. Biocatal. Agric. Biotechnol. 2019, 22, 101396. [Google Scholar] [CrossRef]

- Hamidpour, M.; Afyuni, M.; Khadivi, E.; Zorpas, A.; Inglezakis, V. Composted Municipal Waste Effect on Chosen Properties of Calcareous Soil. Int. Agrophys. 2012, 26, 365–374. [Google Scholar] [CrossRef]

- Wong, J.W.C.; Selvam, A. Speciation of Heavy Metals during Co-Composting of Sewage Sludge with Lime. Chemosphere 2006, 63, 980–986. [Google Scholar] [CrossRef]

- Kästner, M.; Mahro, B. Microbial Degradation of Polycyclic Aromatic Hydrocarbons in Soils Affected by the Organic Matrix of Compost. Appl. Microbiol. Biotechnol. 1996, 44, 668–675. [Google Scholar] [CrossRef]

- Kominko, H.; Gorazda, K.; Wzorek, Z. Potentiality of Sewage Sludge-Based Organo-Mineral Fertilizer Production in Poland Considering Nutrient Value, Heavy Metal Content and Phytotoxicity for Rapeseed Crops. J. Environ. Manag. 2019, 248, 09283. [Google Scholar] [CrossRef]

- Lasaridi, K.E.; Manios, T.; Stamatiadis, S.; Chroni, C.; Kyriacou, A. The Evaluation of Hazards to Man and the Environment during the Composting of Sewage Sludge. Sustainability 2018, 10, 2618. [Google Scholar] [CrossRef]

- Zhang, D.; Luo, W.; Li, Y.; Wang, G.; Li, G. Performance of Co-Composting Sewage Sludge and Organic Fraction of Municipal Solid Waste at Different Proportions. Bioresour. Technol. 2018, 250, 853–859. [Google Scholar] [CrossRef]

- Wu, C.; Li, W.; Wang, K.; Li, Y. Usage of Pumice as Bulking Agent in Sewage Sludge Composting. Bioresour. Technol. 2015, 190, 516–521. [Google Scholar] [CrossRef]

- Asses, N.; Farhat, A.; Cherif, S.; Hamdi, M.; Bouallagui, H. Comparative Study of Sewage Sludge Co-Composting with Olive Mill Wastes or Green Residues: Process Monitoring and Agriculture Value of the Resulting Composts. Process Saf. Environ. Prot. 2018, 114, 25–35. [Google Scholar] [CrossRef]

- Dumontet, S.; Dinel, H.; Baloda, S.B. Pathogen Reduction in Sewage Sludge by Composting and Other Biological Treatments: A Review. Biol. Agric. Hortic. 1999, 16, 409–430. [Google Scholar] [CrossRef]

- Lasaridi, K.E.; Stentiford, E.I.; Evans, T. Windrow Composting of Wastewater Biosolids: Process Performance and Product Stability Assessment. Water Sci. Technol. 2000, 42, 217–226. [Google Scholar] [CrossRef]

- Peigné, J.; Girardin, P. Environmental Impacts of Farm-Scale Composting Practices. Water Air Soil. Pollut. 2004, 153, 45–68. [Google Scholar] [CrossRef]

- Cao, L.; Liao, L.; Su, C.; Mo, T.; Zhu, F.; Qin, R.; Li, R. Metagenomic Analysis Revealed the Microbiota and Metabolic Function during Co-Composting of Food Waste and Residual Sludge for Nitrogen and Phosphorus Transformation. Sci. Total. Environ. 2021, 773, 145561. [Google Scholar] [CrossRef]

- Xiao, Y.; Zeng, G.M.; Yang, Z.H.; Shi, W.J.; Huang, C.; Fan, C.Z.; Xu, Z.Y. Continuous Thermophilic Composting (CTC) for Rapid Biodegradation and Maturation of Organic Municipal Solid Waste. Bioresour. Technol. 2009, 100, 4807–4813. [Google Scholar] [CrossRef]

- Jiang, Z.; Zheng, H.; Xing, B. Environmental Life Cycle Assessment of Wheat Production Using Chemical Fertilizer, Manure Compost, and Biochar-Amended Manure Compost Strategies. Sci. Total. Environ. 2021, 760, 143342. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, G.; Chen, T.; Shi, X.; Wang, Y.; Nie, E.; Liu, J. Effect of Phosphate Amendments on Improving the Fertilizer Efficiency and Reducing the Mobility of Heavy Metals during Sewage Sludge Composting. J. Environ. Manag. 2019, 235, 124–132. [Google Scholar] [CrossRef]

- Raheem, A.; Sikarwar, V.S.; He, J.; Dastyar, W.; Dionysiou, D.D.; Wang, W.; Zhao, M. Opportunities and Challenges in Sustainable Treatment and Resource Reuse of Sewage Sludge: A Review. Chem. Eng. J. 2018, 337, 616–641. [Google Scholar] [CrossRef]

- Frišták, V.; Pipíška, M.; Soja, G. Pyrolysis Treatment of Sewage Sludge: A Promising Way to Produce Phosphorus Fertilizer. J. Clean. Prod. 2018, 172, 1772–1778. [Google Scholar] [CrossRef]

- Morshedi, L.; Lashgarara, F.; Hosseini, S.J.F.; Najafabadi, M.O. The Role of Organic Farming for Improving Food Security from the Perspective of Fars Farmers. Sustainability 2017, 9, 2086. [Google Scholar] [CrossRef]

- Mattos, D.; Hippler, F.W.R.; Boaretto, R.M.; Stuchi, E.S.; Quaggio, J.A. Soil Boron Fertilization: The Role of Nutrient Sources and Rootstocks in Citrus Production. J. Integr. Agric. 2017, 16, 1609–1616. [Google Scholar] [CrossRef]

- Xu, G. Analysis of Sewage Sludge Recovery System in EU—in Perspectives of Nutrients and Energy Recovery Efficiency, and Environ-Mental Impacts. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2014. [Google Scholar]

- Hartenstein, R.; Leaf, A.L.; Neuhauser, E.F.; Bickelhaupt, D.H. Composition of the Earthworm Eisenia Foetida (Savigny) and Assimilation of 15 Elements from Sludge during Growth. Comp. Biochem. Physiol. Part. C Comp. Pharmacol. 1980, 66, 187–192. [Google Scholar] [CrossRef]

- Villar, L.D.; Garcia, O. Assessment of Anaerobic Sewage Sludge Quality for Agricultural Application after Metal Bioleaching. Environ. Technol. 2003, 24, 1553–1559. [Google Scholar] [CrossRef]

- Vigneswaran, S.; Sundaravadivel, M. Wastewater Recycle, Reuse, and Reclamation; UNESCO: London, UK, 2004; pp. 48–75. [Google Scholar]

- Ekane, N.; Barquet, K.; Rosemarin, A. Resources and Risks: Perceptions on the Application of Sewage Sludge on Agricultural Land in Sweden, a Case Study. Front. Sustain. Food Syst. 2021, 5, 647780. [Google Scholar] [CrossRef]

- Urra, J.; Alkorta, I.; Mijangos, I.; Epelde, L.; Garbisu, C. Application of Sewage Sludge to Agricultural Soil Increases the Abundance of Antibiotic Resistance Genes without Altering the Composition of Prokaryotic Communities. Sci. Total. Environ. 2019, 647, 1410–1420. [Google Scholar] [CrossRef]

- Joseph, C.-A.; Khiari, L.; Gallichand, J.; Hébert, M.; Beecher, N. Influence of Sludge Incineration Ash on Ryegrass Growth and Soil Phosphorus Status. Pedosphere 2019, 29, 70–81. [Google Scholar] [CrossRef]

- Antolín, M.C.; Pascual, I.; García, C.; Polo, A.; Sánchez-Díaz, M. Growth, Yield and Solute Content of Barley in Soils Treated with Sewage Sludge under Semiarid Mediterranean Conditions. Field Crops Res. 2005, 94, 224–237. [Google Scholar] [CrossRef]

- Đurđević, D.; Trstenjak, M.; Hulenić, I. Sewage Sludge Thermal Treatment Technology Selection by Utilizing the Analytical Hierarchy Process. Water 2020, 12, 1255. [Google Scholar] [CrossRef]

- Kurniawan, T.; Hakiki, R.; Sidjabat, F.M. Wasterwater Sludge as an Alternative Energy Resource: A Review. J. Environ. Eng. Waste Manag. 2018, 3, 1–12. [Google Scholar] [CrossRef]

- Slepetiene, A.; Kochiieru, M.; Jurgutis, L.; Mankeviciene, A.; Skersiene, A.; Belova, O. The Effect of Anaerobic Digestate on the Soil Organic Carbon and Humified Carbon Fractions in Different Land-Use Systems in Lithuania. Land 2022, 11, 133. [Google Scholar] [CrossRef]

- Bartkowska, I.; Biedka, P.; Tałałaj, I.A. Production of Biosolids by Autothermal Thermophilic Aerobic Digestion (ATAD) from a Municipal Sewage Sludge: The Polish Case Study. Energies 2020, 13, 6258. [Google Scholar] [CrossRef]

- Khan, M.J.; Qasim, M.; Umar, M. Utilization of Sewage Sludge as Organic Fertiliser in Sustainable Agriculture. J. Appl. Sci. 2006, 6, 531–535. [Google Scholar] [CrossRef]

- Umlauf, G.; Christoph, E.H.; Lanzini, L.; Savolainen, R.; Skejo, H.; Bidoglio, G.; Clemens, J.; Goldbach, H.; Scherer, H. PCDD/F and Dioxin-like PCB Profiles in Soils Amended with Sewage Sludge, Compost, Farmyard Manure, and Mineral Fertilizer since 1962. Environ. Sci. Pollut. Res. 2011, 18, 461–470. [Google Scholar] [CrossRef]

- de Corato, U. Agricultural Waste Recycling in Horticultural Intensive Farming Systems by On-Farm Composting and Compost-Based Tea Application Improves Soil Quality and Plant Health: A Review under the Perspective of a Circular Economy. Sci. Total. Environ. 2020, 738, 139840. [Google Scholar] [CrossRef] [PubMed]

- Wijesekara, H.; Colyvas, K.; Rippon, P.; Hoang, S.A.; Bolan, N.S.; Manna, M.C.; Thangavel, R.; Seshadri, B.; Vithanage, M.; Awad, Y.M.; et al. Carbon Sequestration Value of Biosolids Applied to Soil: A Global Meta-Analysis. J. Environ. Manag. 2021, 284, 112008. [Google Scholar] [CrossRef]

- Bolan, N.S.; Kunhikrishnan, A.; Naidu, R. Carbon Storage in a Heavy Clay Soil Landfill Site after Biosolid Application. Sci. Total. Environ. 2013, 465, 216–225. [Google Scholar] [CrossRef]

- Panuccio, M.R.; Romeo, F.; Mallamaci, C.; Muscolo, A. Digestate Application on Two Different Soils: Agricultural Benefit and Risk. Waste Biomass Valori. 2021, 12, 4341–4353. [Google Scholar] [CrossRef]

- García-Sánchez, M.; Siles, J.A.; Cajthaml, T.; García-Romera, I.; Tlustoš, P.; Száková, J. Effect of Digestate and Fly Ash Applications on Soil Functional Properties and Microbial Communities. Eur. J. Soil. Biol. 2015, 71, 1–12. [Google Scholar] [CrossRef]

- Muscolo, A.; Settineri, G.; Papalia, T.; Attinà, E.; Basile, C.; Panuccio, M.R. Anaerobic Co-Digestion of Recalcitrant Agricultural Wastes: Characterizing of Biochemical Parameters of Digestate and Its Impacts on Soil Ecosystem. Sci. Total. Environ. 2017, 586, 746–752. [Google Scholar] [CrossRef]

- Riva, C.; Orzi, V.; Carozzi, M.; Acutis, M.; Boccasile, G.; Lonati, S.; Tambone, F.; D’Imporzano, G.; Adani, F. Short-Term Experiments in Using Digestate Products as Substitutes for Mineral (N) Fertilizer: Agronomic Performance, Odours, and Ammonia Emission Impacts. Sci. Total. Environ. 2016, 547, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Sogn, T.A.; Dragicevic, I.; Linjordet, R.; Krogstad, T.; Eijsink, V.G.H.; Eich-Greatorex, S. Recycling of Biogas Digestates in Plant Production: NPK Fertilizer Value and Risk of Leaching. Int. J. Recycl. Org. Waste Agric. 2018, 7, 49–58. [Google Scholar] [CrossRef]

- Tambone, F.; Orzi, V.; D’Imporzano, G.; Adani, F. Solid and Liquid Fractionation of Digestate: Mass Balance, Chemical Characterization, and Agronomic and Environmental Value. Bioresour. Technol. 2017, 243, 1251–1256. [Google Scholar] [CrossRef] [PubMed]

- Tambone, F.; Orzi, V.; Zilio, M.; Adani, F. Measuring the Organic Amendment Properties of the Liquid Fraction of Digestate. Waste Manag. 2019, 88, 21–27. [Google Scholar] [CrossRef] [PubMed]

| Material | Source | Method for Obtaining Fertilizer | Results Obtained, Fertilizer Effect | References |

|---|---|---|---|---|

| SS | WWTPs | Undigested sludge and anaerobically digested sludge | The soil quality was improved, SS contributed to the maintenance and improvement. | [23] |

| SS | - | Treated with a mixture of calcite and dolomite | The particle size distribution of degraded soils was improved. | [70] |

| Ash from SS incineration | Municipal and agri-food industries | Thermally dried and anaerobically digested | The soil properties were improved, with higher values of organic matter, total potassium, nitrogen, and minerals. | [71,72,73,74] |

| Dehydrated fresh SS | - | Burning | The germination index showed that the composts were safe for agricultural use. The addition of phosphate additives contributed to higher temperatures, decomposition of organic matter, and increased fertilizer efficiency, as well as reduced mobility of heavy metals. | [60] |

| Sludge from municipal and industrial sewage | WWTPs | Composting using a reactor | The application of pyrolysis products to soils deficient in phosphorus and contaminated with toxic metals effectively reduced the mobility of pollutants and added available phosphorus. | [62] |

| Digestate | - | AD | A more positive influence was found on the increase in soil organic carbon (SOC). The content of mobile humic substances (MHS) tended to increase in pastures and field crop rotations in soil treated with digestate. | [75] |

| Dehydrated SS | Municipal WWTPs | Autothermal thermophilic aerobic decomposition (ATAD) | The process produces a sludge that does not rot and does not contain pathogenic microorganisms, parasites, and fungi. The sludge is sanitary, hygienically safe, and contains valuable nutrients. The product has a positive effect on the physical, chemical, and biological properties of soils. | [76] |

| SS | - | - | The process significantly increased the yield of barley grain, and improved soil microbiological properties, such as basal respiration, microbial biomass, and the activity of several soil enzymes (urease, dietary protease, phosphatase, and β-glucosidase) that promote nutrient reuse for crops. | [72] |

| SS | Sewer channels of the city | Air dried, crushed and passed through a 4 mm sieve | The process increased soil pH, organic matter content, ECe, NPK, Ca + Mg, and trace elements (Fe, Cu, Mn, and Zn). It increased soil productivity, yield, and the quality of wheat. A significant increase in straw yield was noted. | [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sugurbekova, G.; Nagyzbekkyzy, E.; Sarsenova, A.; Danlybayeva, G.; Anuarbekova, S.; Kudaibergenova, R.; Frochot, C.; Acherar, S.; Zhatkanbayev, Y.; Moldagulova, N. Sewage Sludge Management and Application in the Form of Sustainable Fertilizer. Sustainability 2023, 15, 6112. https://doi.org/10.3390/su15076112

Sugurbekova G, Nagyzbekkyzy E, Sarsenova A, Danlybayeva G, Anuarbekova S, Kudaibergenova R, Frochot C, Acherar S, Zhatkanbayev Y, Moldagulova N. Sewage Sludge Management and Application in the Form of Sustainable Fertilizer. Sustainability. 2023; 15(7):6112. https://doi.org/10.3390/su15076112

Chicago/Turabian StyleSugurbekova, Gulnar, Elvira Nagyzbekkyzy, Ainur Sarsenova, Gaziza Danlybayeva, Sandugash Anuarbekova, Rabiga Kudaibergenova, Céline Frochot, Samir Acherar, Yerlan Zhatkanbayev, and Nazira Moldagulova. 2023. "Sewage Sludge Management and Application in the Form of Sustainable Fertilizer" Sustainability 15, no. 7: 6112. https://doi.org/10.3390/su15076112

APA StyleSugurbekova, G., Nagyzbekkyzy, E., Sarsenova, A., Danlybayeva, G., Anuarbekova, S., Kudaibergenova, R., Frochot, C., Acherar, S., Zhatkanbayev, Y., & Moldagulova, N. (2023). Sewage Sludge Management and Application in the Form of Sustainable Fertilizer. Sustainability, 15(7), 6112. https://doi.org/10.3390/su15076112