Abstract

Shipping by sea is the most cost-effective way of shipping globally; yet, ship emissions make up 10% of global emissions. That means ocean freight is key to maintaining the global economy that we are accustomed to and if we do not deal with the emission problems of ships, the global industrial economy of the shipping industry will not be sustainable. In view of the importance of marine environmental conservation, the International Maritime Organization (IMO) has adopted a comprehensive set of regulations to support the implementation of emission standards for marine fuel oil, limiting sulfur to 0.5% or less. For this paper, a survey was conducted by Taiwanese carriers based on quality management system architectures, to explore the following factors using the Kano two-dimensional quality model, the importance performance analysis (IPA), and the revised decision-making trial and evaluation laboratory (RDEMATEL) to define the attributes, importance, satisfaction, and correlation that influence carriers’ choice of installing scrubber. The China Ship Building Corporation, Taiwan (CSBC) is the largest ship builder in Taiwan. Finally, the complete infrastructure is the primary area of service quality improvement for CSBC scrubber installation; the operators’ technical skill is the most influential factor, and shipyard operational efficiency is the main affected factor.

1. Introduction

According to 2014 International Maritime Organization (IMO) statistics, ship emissions account for 10% of the overall atmospheric pollution and are thus one of the main pollution sources, posing a serious risk to human health. Marine transportation is a cost-effective way of transporting goods internationally, and reducing sulfur emissions from marine fuels to less than 0.50% will improve air quality, reduce the risk of respiratory diseases, and reduce acid rain. In response, the IMO’s Marine Environment Protection Committee (MEPC) met in 1973 and 1978 to develop the International Convention for the Prevention of Pollution from Ships (MARPOL), which adopted a wide range of preventive measures for environmental conservation. In 2005, the MARPOL 73/78 Convention was updated to set the emission targets for ships with sulfur content not exceeding 4.5% and, in some areas, not exceeding 1.5%.

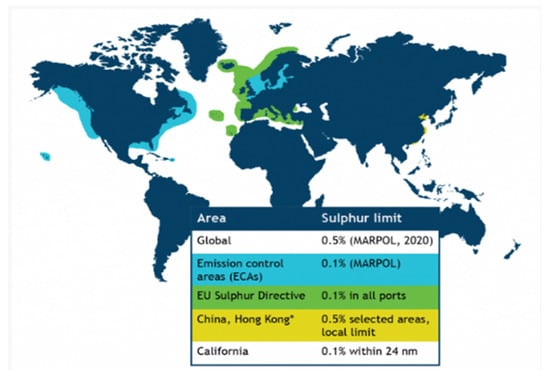

Environmental sustainability plays an increasingly significant role in today’s maritime industry. Green strategies such as speed reduction, fuel switching, and alternative fuels can effectively decrease the harmful emissions from ships and increase environmental sustainability [1]. However, the installation of scrubber systems is also an option. In 2008, the IMO’s MEPC passed another MARPOL amendment, further requiring the sulfur content of marine fuel to be reduced from 4.5% to 3.5% from 1 January 2012, and from 3.5% to 0.5% from 1 January 2020, This requirement is in addition to the 0.1% m/m sulfur limit in the North American, US Caribbean, North Sea and Baltic Sea Sulfur Emission Control Areas (SECAs) [2]. To support the implementation and monitoring of the sulfur limit, the IMO developed the Port State Control (PSC) guidelines in 2019 to provide guidance to maritime authorities on ship emissions control and global sulfur limits now and in the future as shown in Figure 1.

Figure 1.

Global sulfur limits now and in the future [3].

In order to comply with the IMO 2020 sulfur limit, global carriers are actively seeking alternative solutions for bringing their ships into compliance. Laxmana [4] points out that, according to the IMO Air Pollution and Energy Efficiency Study, the implementation of low-sulfur fuel oil policies has reduced environmental damage through the use of scrubbers, ultra-low-sulfur fuel oil (ULSFO), very-low-sulfur fuel oil (VLSFO) or liquefied natural gas (LNG). Among these, the use of VLSFO will be limited by the equipment and technology of the refineries in each country, and its quality is relatively unstable. Ammar and Seddiek [5] compared the emissions of marine gas oil (MGO), low sulfur fuel oil (LSFO) and LNG for RO-RO vessels in the Red Sea region from an environmental and economic standpoints and showed that LNG was the best solution, reducing NOx, SOx, and CO2 emissions by 77.6%, 92.5%, and 14.5%. However, the cost of converting existing vessels into LNG-powered vessels is very high and the installation period is long, which will affect marine transportation operations for a long time. Moreover, the current LNG refueling facilities in ports around the world are not ideal, making it fairly difficult to provide LNG fueling.

The adoption of alternative fuels on ships can reduce pollutant emissions originating from ships as well as improve fuel consumption efficiency. Due to a number of barriers including a lack of funding, insufficient incentives for using alternative energy sources and improving energy efficiency, limited shipyard and design capabilities, and the uncertainties associated with connecting to new technologies, the implementation of the relevant technologies may only proceed slowly [6]. Thus, the installation of desulfurization equipment is the safest and most reliable way for the shipping industry to minimize its harmful impact on the environment at this stage. Since this study began, fuel costs have continued to rise. As the cost of fuel rises, the benefits to shipping companies from installing scrubbers have become even greater. While alternative fuels may seem attractive, the costs of developing and converting to alternative fuels remains far higher, making scrubber installation the most attractive alternative at this time.

Research by Zhu et al. [7] points out that scrubbing equipment loses its attractiveness when the price of heavy fuel oil (HFO) moves in the same direction and the price differential is equal to or less than USD 56 per ton, or when the price of HFO increases while the price of LSFO decreases. However, according to the International Energy Agency (IEA), if the demand for 2.2 million barrels of marine fuel oil per day is drastically reduced due to carriers’ positive response to the sulfur emission restriction policy, the demand will shift to low-sulfur fuel oil, causing its daily demand to surge to 4 million barrels. This would lead to a surge in the price of low-sulfur fuel oil and widen the price differential between HFO and LSFO to more than USD 400 per ton; in addition, there is still a lot of uncertainty as to whether the global refining industry will be able to meet market demand in a timely manner.

Regarding the use of LSFO, many ports are currently unable to supply enough LSFO in time to replace the high demand for HSFO, and the International Energy Agency (IEA) estimates that a surge in demand for LSFO will result in a significant increase in short-term oil prices, which will unquestionably result in a significant increase in operating costs for carriers. As a result, the only real choice global carriers have is to choose between installing scrubbers and using low-sulfur fuel. Because of the uncertainty of both prices and supply of low-sulfur fuel, the main issue for carriers considering using scrubbers is whether doing so would be cost-effective.

VLSFO is limited by the equipment and technology of national refineries, and its quality is relatively unstable; in addition, the price and supply of LSFO is highly variable. Scrubber systems are more reliable than zero-emission fuels, LNG, VLSFO, and LSFO, making scrubbers more attractive to carriers in most cases. Although the initial investment cost is high, it is still relatively low in terms of ship life and operating cost, leading carriers to tend to retrofit ships with scrubbers. The impact of the implementation of the sulfur restrictions on the maritime transport industry has not been fully established; however, judging from the level of commitment of carriers and shipbuilders, it is clear that the installation of scrubbers will be an irreversible trend over the next 5 to 10 years.

In the past three years, with crude oil supply and demand, the COVID-19 pandemic, and the war between Russia and Ukraine, the difference in price between high- and low-sulfur fuel oil has been very volatile. The IEA 2023 forecast for the next two years, based on the price differential between HFO and LSFO over the past three years, is that the minimum and average fuel price differentials between the two will be USD 150/ton and USD 170/ton, while the daily fuel consumption of various types of bulk vessels ranges from 22 to 60 tons depending on the size of the vessel, meaning that, after the conversion to LSFO, bulk carriers will face increased fuel costs ranging from USD 2700 to USD 7140 per day; in addition, given the limited supply of low sulfur oil in the short term, the operating costs for bulk shipping will certainly further increase. Moreover, due to the sulfur restriction regulations, there will be a long-term demand for the installation of desulfurization equipment on both new and old ships. Moreover, as a practical matter for shippers, carriers will generally choose to install desulfurization equipment on their ships when they take into account the fuel cost and the cost of installing desulfurization equipment. In order to meet the requirements of IMO regulations, CSBC, as the largest shipbuilder in Taiwan, should make use of its shipbuilding and ship-repairing experience to improve the quality of desulfurization equipment and services and actively explore business opportunities for desulfurization equipment installation.

The China Ship Building Corporation was originally a state-owned shipyard in Taiwan and was one of the top ten construction projects in Taiwan’s early days. In 2007, due to a government renaming policy, it was renamed CSBC Corporation, Taiwan (hereafter abbreviated as CSBC) and was successfully privatized in 2008. For a long time, shipbuilding has been CSBC’s largest business; however, in 2013, it began venturing into the offshore wind energy industry, and in 2016, it started promoting indigenous defense warships in line with the government’s national shipbuilding program. The shipbuilding business is still the most important part of CSBC’s business and includes the manufacture of various types of merchant ships, as well as ship maintenance, repair and conversion, while the desulfurization equipment business will increase in 2019 due to the 2020 IMO announcement on sulfur restrictions.

In line with IMO’s determination to preserve the environment, international transportation-related environmental policies are constantly being updated and expanded. In this paper, we combine the results of forward and reverse questionnaire models to cross-reference the attributes of each service quality, and replace the traditional one-dimensional concept of the Kano model with the IPA that provides users or consumers with priority ranking of attributes related to a specific product or service through their degree of importance and performance in order to clarify the attributes and the importance and satisfaction levels between key device technologies and service quality. In addition, although a combination of the Kano model and IPA can establish the factor attributes and their importance and satisfaction levels, the establishment of a correlation between the factors will be more helpful for understanding the main reasons for the device’s technology and its improvement in service quality [8]. Therefore, by using the RDEMATEL, which improves the initial direct relationship matrix of the traditional DEMATEL which has no convergence effect, the direct, indirect, and combined effects of the factors are calculated to clarify the nature of the problem through the comparison of the interrelationships between the factors. This will help to develop countermeasures for related problems, solve complex and entangled problems, and improve the understanding of special problems. Finally, the analysis results of this paper can provide a basis for the practical upgrading of the technology and service quality of scrubber devices for the managers of CSBC.

2. Literature Review

2.1. ISO 9001 Quality Management System Components Subsection

ISO 9001 is an internationally recognized standard for creating rules, strategies, processes, and procedures to provide products and services that meet customer needs and improve customer satisfaction. The quality management system (QMS) defines how a company achieves the creation and delivery of products and services to its customers. The QMS is maintained by the International Organization for Standardization and is recognized as a globally applicable industry assessment standard for this process. Companies must produce high-quality products and services through a series of quality management processes and repeated continuous improvement. The implementation of QMS is based on the steps of customer-oriented thinking, quality products and people, physical equipment resources, manufacturing process management, and measurement analysis and improvement. Since QMS ISO 9001 has been widely applied in many fields, this paper is based on this workflow as an evaluation criterion which is expected to provide an important reference for CSBC when making decisions on scrubber installation and prioritizing improvements in technical and service quality.

2.2. Shipyard Installation Maintenance Technology and Service Quality Assessment Criteria

Before the implementation of the sulfur restriction, Celik et al. [9] evaluated the influence of shipyard berth size, shipyard pier size, shipyard transfer costs, room for discussion of cost, routine operation procedures, regular updating of materials, completeness of mechanical equipment, operator technical skill, real-time consultation services, pre-assessment surveys, electrical, pipefitter, engine, underwater, boiler technical skill, shipyard berth lead time, length of warranty, shipyard reputation, and geographical advantages, etc., on long-term cooperation with shipyards from the standpoint of ship management companies and shipowners. Bruno and Tenold [10] also conducted a comparative analysis of the shipbuilding industries in South Korea, Japan, and the United Kingdom, in which the key factors for the success of shipyards between 1970 and 1990 were whether they entered into alliances or strategic alliances with other shipyards, and the level of government financial support.

With the innovation and continuous change in the industry, the fourth industrial revolution has had an increasing impact on the manufacturing process and on the future development of the traditional manufacturing industry. The shipbuilding industry is also affected by Industry 4.0, in the sense that the industry is continuously improving through new machinery, system software, and organizational restructuring. In the shipbuilding Industry 4.0 boom, the research of Stanić et al. [11] showed that shipyard operational efficiency, operational safety management, and emphases on cost efficiency and on environmental conservation can create new value in the shipbuilding industry, reducing production and operational costs while increasing productivity. Joe and Chan [12] analyzed the factors influencing operational safety in shipyards in terms of equipment and material quality, quality of operating machinery, emergency management, supervisory center control, and lighted warning signs.

In terms of corporate social responsibility, occupational health management and environmental conservation in the shipbuilding industry, Para-González and Mascaraque-Ramírez [13] found that compliance with environmental management, corporate social responsibility, quality management, occupational health and safety standards, and the shipbuilding industry’s safety assessment systems will help improve corporate performance. Among these, the correlation between corporate social responsibility in the shipbuilding industry and the performance of the shipbuilding industry has again been verified in the research of Para-González et al. [14]. Feng and Feng [15] successfully constructed the key indicators of shipbuilding technology and maintenance capability of shipyards using factors such as experience rate of maintenance human resources, operability of maintenance equipment resources, and availability of maintenance facility resources.

There have been many previous studies on the influences affecting the development of the shipbuilding industry; however, no study has been conducted on the technology and service quality in the installation of scrubbers for the shipbuilding industry. Animah et al. [16] conducted a study from the perspective of the shipping industry on the negative environmental and health impacts of sulfur dioxide emissions from ships in the Gulf of Guinea. The results of the study indicated that the lack of infrastructure and environmental protection-related legal regulations in the region, as well as the increase in the cost of scrubber installation and shipping operators’ operating costs, are the biggest obstacles to the installation of scrubber in that region. The cost of installation, after-sales service, and shipyard infrastructure are considered the key factors affecting the installation of scrubbers.

2.3. Related Literature and Research Methods

In literature related to the Kano two-dimensional quality model, Min and Park [17] argue that, under the global supply chain system, ports are no longer the origin and destination of transportation, but a part of the whole transportation supply chain, and their service quality should be different due to their changing roles. Therefore, the Kano model was used to analyze the service quality of three major ports in the Asia–Pacific market, Busan, Incheon, and Gwangyang of South Korea, in order to provide port management and terminal operators in South Korea with port marketing and investment strategies for the future. Tang et al. [18] conducted a study on the sequence of service quality improvement in logistics centers using the failure mode and effect analysis (FMEA) and the Kano model for logistics experts and logistics center employees, respectively. In service quality, the level of concern and satisfaction varies depending on the identity of the person filling out the form; however, damaged incoming goods and a shortfall in the quantities of delivered goods were commonly identified as priority items for improvement.

In literature related to the importance performance analysis method, Nunes et al. [19] conducted an importance and satisfaction analysis of carbon emissions in the area of the ports of Leixões, Setúbal, Sines, and Viana in Portugal, using the importance performance analysis method. The study found that the satisfaction and importance levels of social and environmental factors varied significantly, indicating that social issues needed to be overcome in order to comply with and smoothly implement a low-sulfur fuel policy in the future. Lirn et al. [20], through an extensive literature review, categorized twelve green performance indicators into four underlying assessment criteria, namely shipowners’ green policy, cooperation between green shipping stakeholders, reverse logistics management, and green design and promise. Among these, the shipowners’ green design and promise is the most important criteria, followed by the shipowners’ green policy, cooperation among shipping stakeholders, and reverse logistics management.

According to Ho et al. [21] and Lin et al. [22], given the increasing professionalism of the global shipping market, outsourcing allows carriers to focus more on their core business and gain the best experience and competitiveness of third-party services. Using the marketing SAVE framework, an evaluation model of the key factors influencing carriers’ selection of ship management companies was constructed and FAHP and RDEMATEL were used to analyze the correlation between those key factors for Taiwan container carriers and bulk carriers, respectively. Professional management personnel and corporate image and reputation were the main influencing and affected factors for container and bulk shippers in Taiwan when selecting ship management companies. Hsu and Ho [23] also used RDEMATEL to analyze the correlation between the key factors for shippers in high-tech industries in choosing container shipping companies with freight tariffs as the main influencing factor and timely delivery as the main affected factor.

3. Research Methodology and Evaluation Framework

3.1. The Kano Model

The Kano two-dimensional quality model is an idea proposed by Kano and Takahashi [24] with reference to Herzberg et al.’s [25] two-factor theory. The one-dimensional concept of customer satisfaction is replaced by Kano’s two-dimensional quality model to understand the characteristics of different service qualities from the customer’s perspective, which is helpful for service quality classification and strategic application. The difference between two-dimensional quality and one-dimensional quality lies in the difference of the thinking logic. Two-dimensional quality breaks through the general linear thinking space to better understand customers, discover potential customer needs, and encourage innovation and attention to customer complaints thus eliminating an unsatisfactory monistic quality focus. The establishment of Kano’s two-dimensional model replaces the traditional one-dimensional concept of whether the quality attribute is satisfied with a different perception of customer satisfaction [26]. Kano et al. [27] distinguish all qualities into attractive qualities, one-dimensional qualities, mandatory qualities, indifferent qualities, and reverse qualities according to the degree of quality satisfaction.

The Kano model not only provides a multidimensional quality concept, but also a practical application. The Kano model questionnaire contains a set of questions about the respondents’ needs for the assessment items, which they fill in in the form of positive (sufficient) and negative (not sufficient). The questions are answered in such a way that customers can choose from “like”, “as expected”, “no opinion”, “tolerable”, and “don’t like” [27,28]. The results of the positive and negative questionnaire modes are then cross-referenced to obtain the attribute of each service quality attribute. Because the Kano model is not a model for measuring customer satisfaction, it is not generally used for that purpose. It only focuses on customer needs or classification of performance indicators, usually in the pre-satisfaction evaluation stage as an auxiliary research model. Its purpose is to help enterprises identify the entry point for improving customer satisfaction by differentiating between customers’ different needs.

Compared with other methods, the Kano model is concise, objective, and practical, and can effectively compare the importance of customer perceptions with the satisfaction level of the company’s operations. In this way, problems and gaps can be identified and actively improved to achieve the goal of satisfying all aspects of customer needs. According to Kuo et al. [29], combining the Kano model and IPA can avoid the Kano model’s limitation of not being able to evaluate attribute importance and satisfaction, and IPA’s shortcoming of only considering one dimension of quality. Since its lack of differential quality elements and reverse quality elements will not help to improve the satisfaction of shipping companies, if only the variance index of IPA is used as the basis for the improvement sequence of the technical and service quality of CSBC’s installation, it will increase the cost of improvement due to the inability to understand their quality attributes. In view of this, this paper separates the technical and service quality attributes of CSBC’s installation of scrubber devices using the Kano model, and conducts a survey on the importance and satisfaction of the device technology and service quality using the IPA method, categorizing the technical and service quality attributes through the variance indexes of importance and satisfaction in order to explore the items to be improved and the priority of the improvements in terms of the technology and service quality for CSBC in installing scrubber devices while considering the constraints of limited budgets.

3.2. Importance Performance Analysis Method

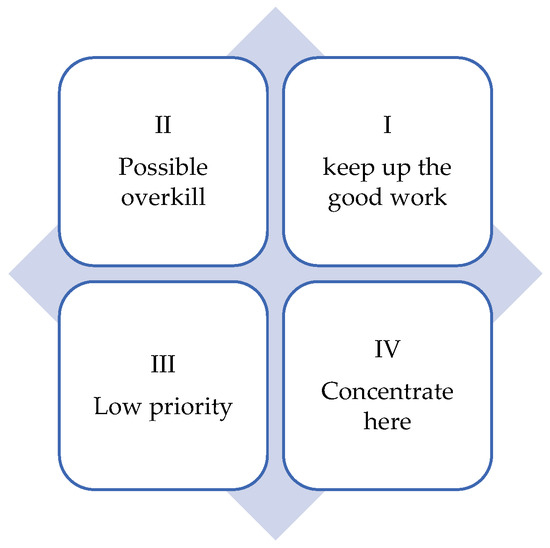

Importance performance analysis is a technique proposed by Martilla and James [30] to provide users or consumers with a prioritized ranking of attributes related to a specific product or service to test its level of “importance” and “performance.” The vertical axis of the matrix indicates the importance of the managed item to the consumer, while the horizontal axis of the matrix is the satisfaction level of the managed item to the consumer. Second, the median of importance and satisfaction is considered the central coordinate of this strategy matrix, which is divided into four quadrants. In this way, managed items can be grouped into quadrants according to their evaluations and receive corresponding strategy recommendations. On the other hand, Hollenhorst et al. [31] thinks that using the overall mean of the importance performance analysis as the separation point is more judicious than using the median. Based on this, the total mean proposed by Hollenhorst is used as the separation point for subsequent research analysis.

The steps for implementing the importance performance analysis method are to list the product or service attributes, develop the questionnaire type, and rate the importance and performance of the product or service. With importance as the vertical axis and satisfaction as the horizontal axis, the ratings of each attribute are marked in the two-dimensional space [32]. The importance and satisfaction model is as shown in Figure 2.

Figure 2.

Importance and satisfaction model.

3.3. Decision-Making Trial and Evaluation Laboratory Method

The decision-making trial and evaluation laboratory (DEMATEL) is a method developed by the Battelle Society of the Geneva Research Center between 1972 and 1976. It is a method that combines linear algebra and questionnaires of experts to determine the causal relationships of complex problems. By looking at the degree of influence between two factors and using matrix and related mathematical theory to calculate the causality and strength of influence among all factors, we can effectively understand their complex causal relationships and the directionality of factor influence [33]. DEMATEL can be used to calculate the direct, indirect, and combined effects of factors by comparing the interrelationships between factors to clarify the nature of the problem, which will help to develop countermeasures for related problems, solve complex and tangled problems, and improve the understanding of specific issues [34]. The DEMATEL computation steps are as follows:

Step 1: Define the factors and determine the relationship.

In this paper, we list the influencing factors through the literature and, using the Kano model and IPA, filter out the relevant factors such as its attractive, one-dimensional, and mandatory factors that affect the technology and service quality of CSBC installation, then combining this with the variance index to prioritize the improvement sequence and supplemented with the RDEMATEL to understand the correlation between the factors.

Step 2: Generate the direct correlation matrix and find the average matrix.

If the number of criteria is , the matrix can be obtained by comparing the criteria with each other according to their influence relationship and degree, which can also be called direct-relation matrix. Assuming that experts provide opinions on criteria, 0 (no effect), 1 (low effect), 2 (moderate effect), 3 (high effect), and 4 (very high effect) are used to represent the extent to which they think factor affects factor . The ratio of factor to factor provided by expert is denoted by . Each expert’s opinion can be formed as a non-negative matrix of by the numbers 0~4 , so that represent the matrix formed by the answers of experts, and the diagonal of matrix is 0, which means that neither factor nor factor will affect itself. The average matrix is calculated by averaging the opinions of experts, as shown in Equation (1).

where is the initial direct-relation matrix, which shows the relationship between the initial performance directly influencing other factors and affected by other factors.

Step 3. Calculate the normalized direct relationship matrix.

The initial direct relationship matrix of matrix is normalized and denoted by , and the calculation is shown in Equations (2) and (3):

Let

and you obtain

where each element of the matrix will be between 0 and 1.

Step 4: Calculate the total relational matrix of direct/indirect effects.

After the initial direct correlation matrix, is normalized, and the order of the matrix is denoted by , which can be used to represent the effect after interactions. The total influence and total relationship can be obtained by summing , and will converge to a zero matrix. The total correlation matrix is given in Equation (4).

where is the unit matrix.

Step 5: Draw a cause-and-effect relationship.

The impact relation map (IRM) can simplify complex cause-effect relationships into an easy-to-understand structure that allows decision makers to gain insight into problems and provide direction for solutions, as well as to plan optimal decisions based on causal relationships. Let be the factor in the total matrix . The sum of columns and rows is denoted by and , and is called the prominence, which indicates the sum of the influencing and affected factors; is called the degree of causality, and a positive value indicates that it is an influencing factor, while a negative value indicates that it is an affected factor. The horizontal axis of the relationship diagram is and the vertical axis is .

DEMATEL is widely used in transportation as it has been found to be effective in addressing the issue of criterion relevance assessment in past literature [35]. Peng et al. [36] conducted a study on shippers’ choice of container carriers from the perspective of environmental conservation, analyzing the relevance of 17 environmental factors that affect their choice and exploring the most important key influencing factors using DEMATEL. Kuo and Chen [37] first applied multi-criteria decision-making (MCDM) to evaluate the decision-making process of transportation policy, and then examined the interdependence between various transportation policy criteria and used DEMATEL to build an impact relation map (IRM) and network relation map (NRM) to explore the causal relationships affecting transportation policy decisions.

3.4. Revised Decision-Making Trial and Evaluation Laboratory Method

In summary, although DEMATEL can be used to understand the causal relationships and the degree of influence among key influencing factors through the input from the respondents based on their practical experience, the initial direct relationship matrix of traditional DEMATEL does not have a convergent effect, while the RDEMATEL will improve upon this problem [38]. In general, RDEMATEL and DEMATEL share the same steps and operations for defining factors and adjudicating relationships, generating direct relationship matrices, calculating standardized direct relationship matrices, and plotting influence relationships, except for the calculation of direct/indirect and total relationship matrices.

The original DEMATEL assumes that the initial direct correlation matrix will converge to zero; however, the assumption of is not correct; therefore, a very small positive value of is added to Equation (2) to converge the initial direct correlation matrix of the original DEMATEL to zero. The modified algorithm is shown in Equation (5).

A comprehensive study of research methods has found that Kano’s two-dimensional quality model can replace the one-dimensional concept of customer satisfaction and thus help to classify and strategically apply aspects the service quality through an understanding of the characteristics of different service qualities from the customer’s perspective. IPA is a technique for prioritizing the evaluation criteria for a specific product or service in terms of its importance and satisfaction level. The RDEMATEL method can be used to understand the causal relationship and the degree of influence among key influencing factors through the opinions provided by the respondents based on their practical experience, thus improving the characteristics of the traditional DEMATEL’s initial direct relationship matrix which does not have a convergence effect. Therefore, this paper adopts the Kano model, IPA, and RDEMATEL, combined with the ISO 9001 quality management system framework, to construct a prioritized improvement sequence and a correlation assessment model for application to the technology and service quality for CSBC’s installation of scrubbers.

As you can see from the above description, Kano can identify the technical and service quality attributes of the desulfurization equipment; IPA can determine the service qualities that fall in the “Concentrate Here” and “Low Priority” categories; the variance index can establish the priority improvement sequence; and RDEMATEL can investigate the main factors affecting the prioritization of improvement factors for CSBC. Therefore, this combination of research methods can enable other shipyards to examine their own service quality issues regarding the installation of desulfurization facilities, which can be useful for discovering the real reasons behind poor service quality and developing future improvement strategies. It is hoped that the results of this study will provide insight into the nature of CSBC’s desulfurization equipment installation technology and service quality, the priority of improvement items, and a clear understanding of the key factors affecting the priority of each improvement, which will facilitate CSBC’s understanding of the major issues in its efforts to improve the quality of its desulfurization equipment installation and service.

3.5. Framework for Assessment of Influencing Factors

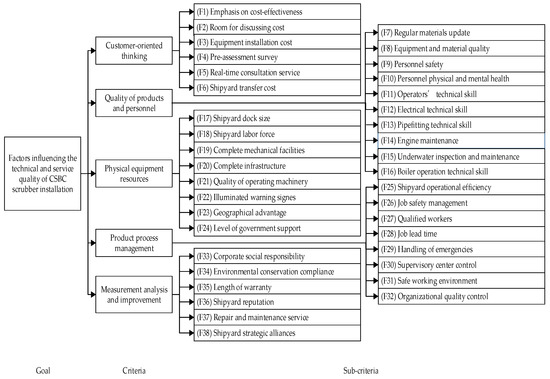

The above literature and the relevance of the research method are summarized in Table 1, showing the factors influencing the technical and service quality relating to the installation of scrubbers for CSBC.

Table 1.

Factors influencing the technical and service quality of CSBC scrubber installation.

As can be seen from Table 1, this paper, based on a review of the literature, constructs a framework of factors influencing the installation of scrubbers and CSBC’s installation technology and service quality, and divides the research components into five categories: customer-oriented thinking, quality of products and personnel, physical equipment resources, product process management, and measurement analysis and improvement. In terms of evaluation criteria, customer-oriented thinking includes six items: emphasis on cost-effectiveness, room for discussing cost, equipment installation cost, pre-assessment survey, real-time consultation service and shipyard transfer cost. Quality of products and personnel includes ten items: regular materials update, quality of equipment and material, personnel safety, personnel physical and mental health, operators’ technical skill, electrical technical skill, pipefitting technical skill, engine maintenance, underwater inspection and maintenance, and boiler operation technical skill. Physical equipment resources includes eight items: shipyard dock size, shipyard labor force, complete mechanical facilities, complete infrastructure, quality of operating machinery, illuminated warning signs, geographical advantage and level of government support. Product process management includes eight items: shipyard operational efficiency, job safety management, qualified workers, job lead time, handling of emergencies, supervisory center control, safe working environment and organizational quality control. Measurement analysis and improvement includes six items: corporate social responsibility, environmental conservation compliance, length of warranty, shipyard reputation, repair and maintenance service, and shipyard strategic alliances. The research framework is shown in Figure 3.

Figure 3.

CSBC scrubber installation and service quality assessment framework.

4. Analysis of Research Results

4.1. Questionnaire Results

This paper evaluates CSBC’s scrubber installation technology and service quality and the correlation between factors from the standpoint of Taiwan carriers. For convenient sampling, questionnaires were sent by email to those who are mainly responsible for the selection of scrubber devices in the sales, purchasing and public works departments of the listed container shipping companies in Taiwan, including the general manager, vice president, assistant managers, and managers. A total of 37 questionnaires were distributed and 32 were returned, 32 of which were valid, amounting to an 86.48% valid questionnaire return rate.

4.2. Analysis of Influencing Factor Attributes

According to the Kano model, the 38 evaluation criteria are categorized into: (A) attractive qualities—when the service quality is adequate, customers will be content; however, when it is not adequate, customers will accept the service quality as a matter of course; (O) one-dimensional qualities—when the service quality is adequate, it can improve customer satisfaction; however, when the service quality is poor, customers will feel dissatisfied; (M) mandatory qualities—when the service quality is adequate, customer satisfaction will not increase; however, when the service quality is poor, customers will feel dissatisfied; (I) indifferent qualities—customer satisfaction is not affected regardless of whether this attribute is provided or not; and (R) reverse qualities—when a service with this attribute is provided, the customer will feel dissatisfied; however, if a service lacks this attribute, it can make the customer satisfied. The technical and service quality attributes and importance and satisfaction levels of CSBC’s installation of scrubber devices are shown in Table 2.

Table 2.

CSBC installation of desulfurization tower equipment.

As can be seen from Table 2, these values are obtained from the evaluations of shipping companies based on the CSBC’s installation of desulfurization equipment using a five-point scale: 5 meaning very important (very satisfied), 4 important (satisfied), 3 average (average), 2 unimportant (unsatisfied), and 1 very unimportant (very unsatisfied). The average of importance (rank) reduces the average of satisfaction (rank) equal to the difference (rank variation), and emphasis on cost-effectiveness, regular materials update, personnel physical and mental health, underwater inspection and maintenance, boiler operation technical skill, shipyard dock size, illuminated warning signs, supervisory center control, organizational quality control, corporate social responsibility, and length of warranty are attractive qualities, indicating that having them or not does not affect the satisfaction of shipowners. Equipment installation cost, shipyard transfer cost, geographical advantage, level of government support, environmental conservation compliance, repair and maintenance services, and shipyard strategic alliances are indifferent qualities, indicating that the satisfaction of carriers is not affected regardless of whether these attributes are provided.

In addition, room for discussing costs, pre-assessment survey, real-time consultation service, equipment and material quality, personnel safety, operators’ technical skill, electrical technical skill, pipefitting technical skill, engine maintenance, shipyard labor force, complete mechanical facilities, complete infrastructure, quality of operating machinery, shipyard operational efficiency, job safety management, qualified workers, job lead time, handling of emergencies, safe working environment, shipyard reputation, and repair and maintenance service are one-dimensional qualities, indicating that when the quality is adequate, shipowners’ satisfaction with the technical and service quality of CSBC’s desulfurization equipment will improve; if it is not, their satisfaction will decrease. There are no mandatory qualities (M) or reverse qualities (R) in the 38 items evaluated by CSBC, and since the indifferent quality elements and reverse quality elements do not help improve customer satisfaction, relevant research should place emphasis on the exploration of attractive qualities, one-dimensional qualities, and mandatory qualities [39].

4.3. Importance and Satisfaction Analysis

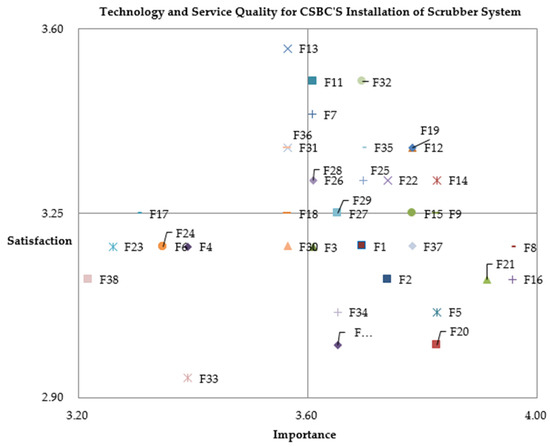

This section will analyze the importance, satisfaction matrix, and variance index of the 38 evaluation criteria to provide a reference for the improvement prioritization of technical and service quality of scrubber installation at CSBC. The importance and satisfaction matrices are shown in Figure 4.

Figure 4.

Importance and satisfaction matrix analysis.

As shown in Figure 2, there are fifteen evaluation criteria, including regular materials update, personnel safety and operators’ technical skills that belong to the continuous maintenance area; eleven evaluation criteria including emphasis on cost-effectiveness, room for discussion of costs, and equipment installation cost that belong to the priority improvement area; three evaluation criteria including pipefitting technical skill, safe working environment and shipyard reputation, that belong to the over-investment area; and nine evaluation criteria, including pre-assessment survey, shipyard transfer cost and shipyard dock size, that belong to the secondary improvement area.

In terms of importance, the equipment and material quality, boiler operation technical skill, and the quality of operating machinery are relatively more important. Shipyard strategic alliances, geographical advantage, and shipyard dock size are less important service qualities. In terms of satisfaction, pipefitting technical skill, organizational quality control, and operators’ technical skill are relatively more important. Corporate social responsibility, personnel physical and mental health, and complete infrastructure are the service qualities with lower satisfaction levels.

In terms of the variance index, emphasis on cost-effectiveness, room for discussing costs, equipment installation cost, real-time consultation service, equipment and material quality, personnel physical and mental health, engine maintenance, underwater inspection and maintenance, boiler operation technical skill, complete infrastructure, quality of operating machinery, organizational quality control, corporate social responsibility, environmental conservation compliance, and repair and maintenance service are the priority improvement areas. In the main improvement area, the assessment factors room for discussing costs, real-time consultation service, equipment and material quality, complete infrastructure, and quality of operating machinery are one-dimensional qualities. The remaining factors in the primary and secondary improvement areas are attractive qualities and indifferent qualities.

However, when resources are limited, priority should be given to improving the critical qualities in the primary and secondary improvement areas, especially those that are one-dimensional [40]. After combining the variance indices, the variance indices of F4 pre-assessment survey and F18 shipyard labor force are positive, indicating that their satisfaction level is greater than their importance level, which is still within the acceptable range for carriers. The largest variance index between the primary and secondary improvement areas is in F20 complete infrastructure (−32), which means that this is the primary area for service quality improvement for CSBC scrubber installation, followed, in order, by F5 real-time consultation service (−30), F8 equipment and material quality (−27), F21 quality of operating machinery (−27) and F2 room for discussion of cost (−18).

4.4. Correlation Analysis of Influencing Factors Subsection

To better understand how to improve CSBC’s scrubber installation technology and service quality, this paper uses RDEMATEL to understand the correlation analysis between the factors affecting the priority of improvement projects. To determine the factors influencing the priority of improvement items and their degree of influence and to preserve the stronger factors while avoiding the complexity of a cause-effect diagram, this paper uses 0.10 as the threshold value for factors and service qualities affecting shipping companies’ choice of scrubber installation facilities, mainly aiming to preserve the influencing and affected factors of room for discussion of costs, real-time consultation service, equipment and material quality, complete infrastructure and quality of operating machinery while omitting less relevant factors. indicates the total degree of influence of the factor on other factors, and indicates the total degree to which the factor is affected by other factors. indicates the intensity of the relationship between the factor and other factors; the larger the value, the greater the factor’s total influence. indicates the degree of the factor’s influence and the degree to which it is affected. When is a positive value, it indicates that the factor is an influencing factor, and when it is a negative value, it indicates that the factor is an affected factor. The causal relationship values after setting the quality assessment thresholds for CSBC’s scrubber installation technical and service quality factors are shown in Table 3.

Table 3.

Correlation analysis of key factors influencing the technology and service quality of CSBC scrubber installation.

As shown in Table 3, after the threshold value is set, the factors that are highly correlated with the service quality of CSBC’s scrubber installation include 21 factors: emphasis on cost effectiveness, room for discussing costs, equipment installation cost, pre-assessment survey, real-time consultation service, regular materials update, equipment and material quality, personnel safety, operators’ technical skill, electrical technical skill, pipefitting technical skill, engine maintenance, underwater inspection and maintenance, boiler operation technical skill, complete mechanical facilities, complete infrastructure, quality of operating machinery, shipyard operational efficiency, job safety management, qualified workers, and a safe working environment. A chart showing the causality relationship between the key factors influencing the service quality of CSBC scrubber installation after the evaluation threshold values were set is presented in Figure 5.

Figure 5.

Causality relationship of key factors affecting the service quality of CSBC scrubber installation.

In terms of major influencing factors, operators’ technical skill, engine maintenance, equipment and material quality, qualified workers, pipefitting technical skill, personnel safety, and a safe working environment are the major influencing factors. The main reason for these is that labor technical skill and safety has always been the top priority of every enterprise’s operation, and shipbuilding, installation, and maintenance teams have a great impact on the future navigation safety of ships. Moreover, shipyard operations have a certain degree of continuity and danger. The quality of machinery and equipment, personnel operating skill, and substandard machinery maintenance capabilities or malfunctions will affect the efficiency of subsequent operations.

As for the main affected factors, shipyard operational efficiency is the main factor. This factor is mainly one-dimensionally affected by personnel safety, operators’ technical skill, electrical technical skill, engine maintenance, job safety management, and qualified workers. This shows that shipping companies, as they consider the efficiency of CSBC, will consider the adequacy of CSBC’s worker safety, machinery operation, and whether its maintenance technology and equipment are adequate. Therefore, the continuous promotion and supervision of personnel safety and equipment maintenance management systems will reduce the number of injuries and deaths of personnel or damage to machinery caused by a lack of skill and equipment or improper attitudes. It will also increase the professionalism and accuracy of scrubber installation scheduling and pre-installation assessment and surveying, thus enhancing the willingness of carriers to use CSBC for scrubber installation.

Regarding the correlation of priority improvement factors, the complete infrastructure is affected by equipment and material quality, personnel safety, electrical technical skill, pipefitting technical skill, engine maintenance, job safety management, and qualified workers, among which only equipment and material quality is in the priority improvement area and its differential index is negative. In addition to personnel safety, equipment completeness, and relevant operating techniques, CSBC’s procurement department and its equipment and material manufacturers, contractors, and suppliers should strengthen material quality control and delivery inspection and the operation should be supervised according to a supervision plan. This will help the subsequent installation and maintenance process to proceed smoothly and be effective in reducing damage to equipment and infrastructure.

The factor equipment and material quality is subject to a pre-assessment survey, electrical technical skill, pipefitting technical skill, engine maintenance, job safety management, and a safe working environment, of which only engine maintenance has a differential index that is negative, mainly because the scrubber is to clean the exhaust gas emitted by engine machinery and boilers. No matter whether a set of generators and boilers are paired with a set of scrubbers, or all engines and boilers with a set of scrubbers, if the engine maintenance work is not performed properly and sulfur emissions increase, this will place a burden on the scrubber and increase the wear on the scrubber materials.

Furthermore, the main factor affecting engine maintenance is operators’ technical skill, which can be found with real-time consultation service, quality of operating machinery, and room for discussing costs among the main priority improvement factors affecting the CSBC scrubber installation service quality. In terms of scrubber installation cost, the CSBC has already provided shippers with very favorable prices; however, if we can further refine the skills of the operators, it is expected that we can increase the room for discussion with the shippers on the installation costs.

4.5. Comprehensive Discussions

The tightening of maritime regulations toward managing sustainability has heightened the demand for LSF consumption. The price difference between HSF and LSF poses a burden on ship operators’ profits pursuing sustainability. Therefore, it is paramount for policymakers to find ways to improve current market conditions in the pursuit of maximum social welfare [41]. The technological maturity of ship engines built for installation of scrubber systems is critical until the government has come up with an effective subsidy policy for ship operators to minimize environmental impact or maximize social welfare.

As we know, environmental sustainability plays an increasingly significant role in today’s maritime industry. Each shipping operator can choose to adopt a green strategy, which is able to reduce the emission during the shipping process, or a non-green strategy, which is cost-effective. Furthermore, in a more environmentally friendly market, green-concern shipping lines should increase their green efforts before equilibrium to gain greater market demand; in addition, given the growth of the competition level regarding green effort, there will be a payoff loss for shipping operators whose competitors adopt green strategies [1]. Similarly, it can be proved that the installation of scrubber systems is very helpful to environmental sustainability.

The shipbuilding industry must combine high-tech software and hardware equipment with smart technology to establish and monitor production standards; examine and test samples of preliminary products; develop and implement product tracking and quality control systems; analyze production, quality control, maintenance and other operation reports; and establish a work experience sharing platform to ensure the quality of the infrastructure, equipment materials and real-time consultation services for improving CSBC’s scrubber installation technology and service quality in the short term. By strengthening employees’ basic practical skills and training them in ship repair, ship component manufacturing, ship welding, electrical engineering, and other professional skills, we can not only improve the quality of operating equipment and increase the room for cost discussion, but also improve CSBC’s installation technology and service quality.

However, at present, the shipbuilding industry is greatly affected by the low birth rate, leading to a serious shortage of relevant professionals in the shipbuilding industry. Although, at this stage, the operators’ technical skills are in the continuing maintenance area and its satisfaction level is higher than its importance level, its impact on CSBC’s five priority improvement factors is very broad. In the long run, in addition to strengthening employees’ basic practical skills and their training in professional skills, talent cultivation is the long-term plan for CSBC to enhance its competitiveness.

5. Conclusions and Recommendations

5.1. Conclusions

- To comply with the IMO 2020 regulations on sulfur limits, global shipping companies are actively looking for shipyards that can install scrubbers on ships. In this paper, we explore the priority of influencing factors from the standpoint of Taiwan’s bulk shipping industry and the correlation between those factors and the technology and service quality of CSBC’s installation of scrubbers on ships by examining the attributes of CSBC’s installation technology and service quality items and the importance and satisfaction levels of shipping companies along with their correlation with CSBC’s installation technology and service quality factors.

- In terms of factor attributes, importance, and satisfaction analysis, of the 38 CBSC scrubber installation facility service quality factors, 11 are of attractive quality (A), 20 are of one-dimensional quality (O), 7 are of indifferent quality (I), and none are of mandatory quality (M) or reverse quality (R). This means that overall, CSBC still has room for improvement. If the installation technology and service quality of attributes (A) and (O) can be improved, carrier satisfaction with CSBC will also increase.

- In terms of variance index analysis, one-dimensional (O) factors with lower satisfaction level in the primary and secondary improvement areas at this stage—room for discussion of costs, real-time consultation service, equipment and material quality, shipyard labor force, complete infrastructure, quality of operating machinery, environmental conservation compliance, and repair and maintenance service—are a higher priority for improvement.

- In terms of factor correlation, the operators’ technical skill is the most influential of the total influencing factors, and the main influencing factor, shipyard operational efficiency, is the main affected factor. Increasing equipment and material quality and engine maintenance are short-term strategies for improving CSBC scrubber installation and service quality, while increasing operators’ technical skill is a long-term strategy for improving CSBC scrubber installation and service quality.

- The installation of desulfurization equipment in shipyards is an internationally competitive industry. Through the results of this study, we can not only understand the factors that need to be improved in terms of the technology and service quality of CSBC’s desulfurization equipment, as well as the key reasons that affect the technology and service quality, but also provide other shipyards with an understanding of their own competitive advantages from the shortcomings of CSBC, and effectively strengthen and consolidate their own competitive niches in the industry.

- In terms of limitations, this study was hampered by the difficulty in obtaining more concrete data concerning both technical and competitive trade secrets, including data on installation price, ship type and number of ships, cost of the various assembly components, and equipment selected. In compiling and analyzing the study results, the limitations placed on the study became more and more clear.

5.2. Recommendations

The familiar topic of global sulfur cap is highly relevant to the global shipping industry, as there are many long-term plans underway to address issues such as pollution emissions from ships. Although the research process and conclusions of this study have reached a certain level of sophistication and demonstrate that the choice of scrubber equipment for ships is a concrete and good choice, due to commercial confidentiality, this study was unable to obtain definitive values for the actual number of scrubber installations at CSBC, installation experience, installation price, ship type and number of ships, installation process, and cost of the various assembly components and equipment selected. With better data on costs and scalability, future studies could deliver more refined and accurate conclusions in terms of installation benefits and reference value.

Author Contributions

Conceptualization, T.-C.H.; methodology, H.-S.L.; software, T.-C.H. and H.-S.L.; validation, T.-C.H.; formal analysis, T.-C.H.; investigation, T.-C.H.; resources, T.-C.H.; data curation, T.-C.H. and H.-S.L.; writing—original draft preparation, T.-C.H.; writing—review and editing, T.-C.H. and H.-S.L.; visualization, T.-C.H.; supervision, H.-S.L.; project administration, T.-C.H.; funding acquisition, T.-C.H. and H.-S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science and Technology Council, Taiwan (110-2410-H-346 -002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The funders had no role in the design of the study, in the collection, analyses, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

References

- Lin, D.Y.; Juan, C.J.; Ng, M.W. Evaluation of Green Strategies in Maritime Liner Shipping Using Evolutionary Game Theory. J. Clean. Prod. 2021, 279, 123268. [Google Scholar] [CrossRef]

- Stathatou, P.M.; Bergeron, S.; Fee, C.; Jeffrey, P.; Triantafyllou, M.; Gershenfeld, N. Towards Decarbonization of Shipping: Direct Emissions and Life Cycle Impacts from a Biofuel Trial aboard an Ocean-Going Dry Bulk Vessel. Sustain. Energy Fuels 2022, 6, 1687–1697. [Google Scholar] [CrossRef]

- Deltamarin. Future Fuel Options and Emission Control. Available online: https://deltamarin.com/current-challenges/future-fuel-options-and-emission-control/ (accessed on 8 March 2023).

- International Maritime Organization. New IMO 2020 Regulations Help Reduce Marine Sulphur Emissions. Available online: https://www.chrobinson.com/blog/new-imo-2020-regulations-help-reduce-marine-sulphur-emissions/ (accessed on 13 December 2020).

- Ammar, N.R.; Seddiek, I.S. Eco-Environmental Analysis of Ship Emission Control Methods: Case Study RO-RO Cargo Vessel. Ocean Eng. 2017, 137, 166–173. [Google Scholar] [CrossRef]

- Huang, D.Y.; Hua, J. Development Trend of Marine Alternative Fuels. Mar. Technol. 2021, 54, 62–84. [Google Scholar]

- Zhu, M.; Li, K.X.; Lin, K.C.; Shi, W.; Yang, J. How can Shipowners Comply with the 2020 Global Sulphur Limit Economically? Transp. Res. Part D Transp. Environ. 2020, 79, 102234. [Google Scholar] [CrossRef]

- Hu, K.C.; Lee, P.T.W.; Chiu, C.W. Applying Kano’s Model and Importance-Performance Analysis to Explore the Service Quality of Major Container Ports in Asia. J. Chin. Inst. Transp. 2011, 23, 129–164. [Google Scholar]

- Celik, M.; Kahraman, C.; Cebi, S.; Er, I.D. Fuzzy Axiomatic Design-Based Performance Evaluation Model for Docking Facilities in Shipbuilding Industry: The Case of Turkish Shipyards. Expert Syst. Appl. 2009, 36, 599–615. [Google Scholar] [CrossRef]

- Bruno, L.; Tenold, S. The Basis for South Korea’s Ascent in the Shipbuilding Industry, 1970–1990. Mar. Mirror 2011, 97, 201–217. [Google Scholar] [CrossRef]

- Stanić, V.; Hadjina, M.; Fafandjel, N.; Matulja, T. Toward Shipbuilding 4.0—An Industry 4.0 Changing the Face of the Shipbuilding Industry. Brodogradnja 2018, 69, 111–128. [Google Scholar] [CrossRef]

- Joe, T.; Chang, H. A Study on User-Oriented and Intelligent Service Design in Sustainable Computing: A Case of Shipbuilding Industry Safety. Sustainability 2017, 9, 544. [Google Scholar] [CrossRef]

- Para-González, L.; Mascaraque-Ramírez, C. The Importance of Official Certifications in Globalized Companies’ Performance: An Empirical Approach to the Shipbuilding Industry. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 408–415. [Google Scholar] [CrossRef]

- Para-González, L.; Mascaraque-Ramírez, C.; Cubillas-Para, C. Maximizing Performance through CSR: The Mediator Role of the CSR Principles in the Shipbuilding Industry. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2804–2815. [Google Scholar] [CrossRef]

- Feng, X.; Feng, L. Technology of Ship Maintenance Support Resource Capability Based on Fuzzy Hierarchy Method. Acad. J. Manuf. Eng. 2020, 18, 209–217. [Google Scholar]

- Animah, I.; Lamptey, A.A.; Korsah, F.; Sackey, J.S. Compliance with MARPOL Annex VI Regulation 14 by Ships in the Gulf of Guinea Sub-Region: Issues, Challenges and Opportunities. Transp. Res. Part D Transp. Environ. 2018, 62, 441–455. [Google Scholar] [CrossRef]

- Min, H.; Park, B.I. A Two-Dimensional Approach to Assessing the Impact of Port Selection Factors on Port Competitiveness Using the Kano Model. Marit. Econ. Logist. 2020, 22, 353–382. [Google Scholar] [CrossRef]

- Tang, L.L.; Chen, S.H.; Lin, C.C. Integrating FMEA and the Kano Model to Improve the Service Quality of Logistics Centers. Processes 2021, 9, 51. [Google Scholar] [CrossRef]

- Nunes, R.A.O.; Alvim-Ferraz, M.C.M.; Martins, F.G.; Sousa, S.I.V. Environmental and Social Valuation of Shipping Emissions on Four Ports of Portugal. J. Environ. Manag. 2019, 235, 62–69. [Google Scholar] [CrossRef]

- Lirn, T.C.; Wong, C.W.Y.; Shang, K.C.; Li, Y.T. Identifying Green Assessment Criteria for Shipping Industries. In Environmental Sustainability in Asian Logistics and Supply Chains; Liu, X., Ed.; Springer: Singapore, 2019; pp. 21–44. [Google Scholar]

- Ho, T.C.; Chung, C.C.; Lee, H.S.; Wang, S.C. An Evaluation of the Key Influential Factors for Container Shipping Lines Selecting Ship Management Companies in Taiwan. Transp. Plan. J. 2016, 45, 217–234. [Google Scholar]

- Lin, T.Y.; Chung, C.C.; Ho, T.C. An Evaluation of the Key Influencing Factors for Tramp Shipping Corporations Selecting Ship Management Companies. J. Mar. Sci. Technol. 2019, 27, 133–143. [Google Scholar]

- Hsu, C.L.; Ho, T.C. Evaluating Key Factors of Container Shipping Lines from the Perspective of High-Tech Industry Shippers. J. Mar. Sci. Technol. 2021, 29, 30–41. [Google Scholar] [CrossRef]

- Kano, N.; Takahashi, F. Nippon QC Gakkai. In Proceedings of the 9th Annual Presentation Meeting, Leuven, Belgium, 10–13 September 1979. [Google Scholar]

- Herzberg, F.; Bernard, M.; Snyderman, B.B. The Motivation to Work; John Wiley and Sons: New York, NY, USA, 1959. [Google Scholar]

- Yang, C.C. The Refined Kano’s Model and Its Application. Total Qual. Manag. 2005, 16, 1127–1137. [Google Scholar] [CrossRef]

- Kano, N.; Seraku, N.; Takahashi, F.; Tsuji, S. Attractive Quality and Must-be Quality. J. Jpn. Soc. Qual. Control 1984, 14, 39–48. [Google Scholar]

- Matzler, K.; Hinterhuber, H.H. How to Make Product Development Projects More Successful by Integrating Kano’s Model of Customer Satisfaction into Quality Function Deployment. Technovation 1998, 18, 25–38. [Google Scholar] [CrossRef]

- Kuo, Y.F.; Chen, J.Y.; Deng, W.J. IPA-Kano Model: A New Tool for Categorising and Diagnosing Service Quality Attributes. Total Qual. Manag. Bus. Excell. 2012, 23, 731–748. [Google Scholar] [CrossRef]

- Martilla, J.A.; James, J.C. Importance-Performance Analysis. J. Mark. 1977, 41, 77–79. [Google Scholar] [CrossRef]

- Hollenhorst, S.; Olson, D.; Fortney, R. Use of Importance-Performance Analysis to Evaluate State Park Cabins: The Case of the West Virginia State Park System. J. Park Recreat. Adm. 1992, 10, 1–11. [Google Scholar]

- O’Sullivan, E.L. Marketing for Parks, Recreation, and Leisure; Venture: State College, PA, USA, 1991. [Google Scholar]

- Hsu, C.W.; Kuo, T.C.; Chen, S.H.; Hu, A.H. Using DEMATEL to Develop a Carbon Management Model of Supplier Selection in Green Supply Chain Management. J. Clean. Prod. 2013, 56, 164–172. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Chiang, C.H.; Li, C.W. Evaluating Intertwined Effects in e-learning Programs: A Novel Hybrid MCDM Model Based on Factor Analysis and DEMATEL. Expert Syst. Appl. 2007, 32, 1028–1044. [Google Scholar] [CrossRef]

- Lee, P.T.W.; Lin, C.W. The Cognition Map of Financial Ratios of Shipping Companies Using DEMATEL and MMDE. Marit. Policy Manag. 2013, 40, 133–145. [Google Scholar] [CrossRef]

- Peng, J.; Kannan, G.; Devika, K. Identification and Evaluation of Influential Criteria for the Selection of an Environmental Shipping Carrier using DEMATEL: A Case from India. Int. J. Shipp. Transp. Logist. 2015, 7, 719–741. [Google Scholar]

- Kuo, S.Y.; Chen, C.C. Transportation Policy Making Using MCDM Model: The Case of Hualien. Transp. Plan. J. 2015, 44, 25–44. [Google Scholar]

- Lee, H.S.; Tzeng, G.H.; Yeih, W.C.; Wang, Y.J. Revised DEMATEL: Resolving the Infeasibility of DEMATEL. Appl. Math. Model. 2013, 37, 6746–6757. [Google Scholar] [CrossRef]

- Matzler, K.; Bailom, F.; Hinterhuber, H.H.; Renzl, B.; Pichler, J. The Asymmetric Relationship between Attribute-Level Performance and Overall Customer Satisfaction: A Reconsideration of the Importance-Performance Analysis. Ind. Mark. Manag. 2004, 33, 271–277. [Google Scholar] [CrossRef]

- Chang, Y.N. Applying Kano Model to a Case University for Teaching Quality Improvement. J. Educ. Pract. Res. 2011, 24, 129–162. [Google Scholar]

- Zhou, Q.; Yuen, K.F. Low-Sulfur Fuel Consumption: Marine Policy Implications Based on Game Theory. Mar. Policy 2021, 124, 104304. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).