Support Control Design of Mining Roadway under Goaf of Close-Distance Coal Seam

Abstract

:1. Introduction

2. Engineering Background

3. Failure Mechanism and Integrity Discrimination of Close Distance Coal Seam Floor

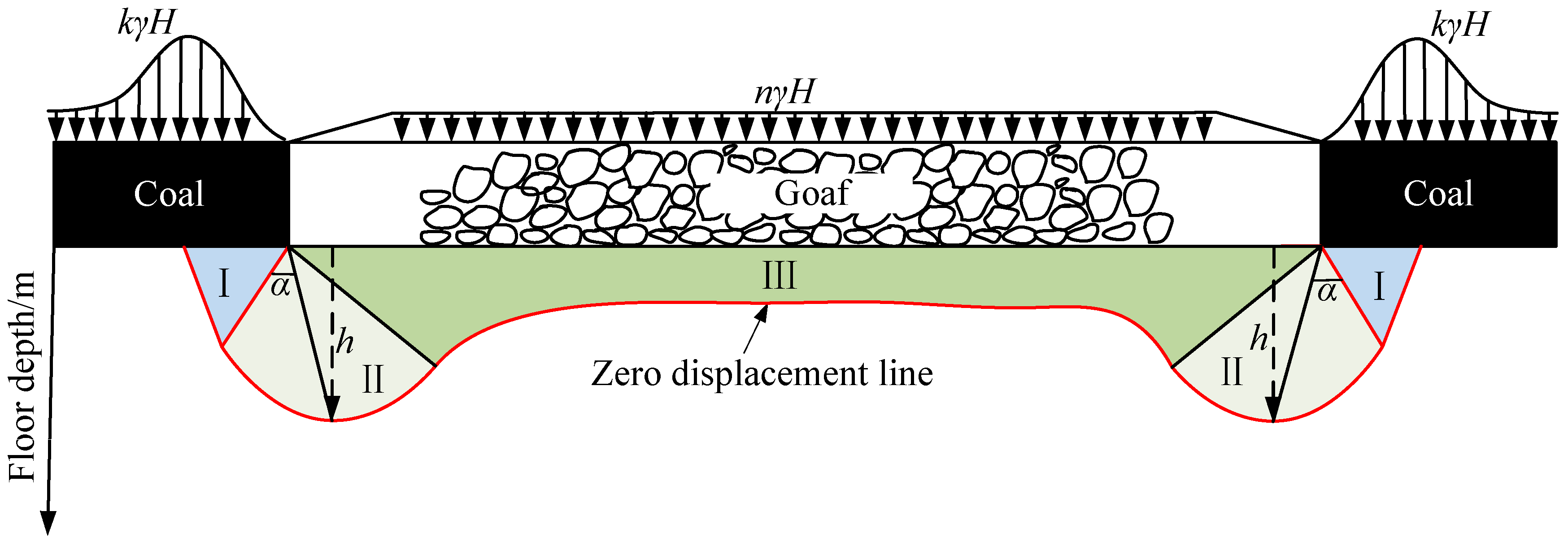

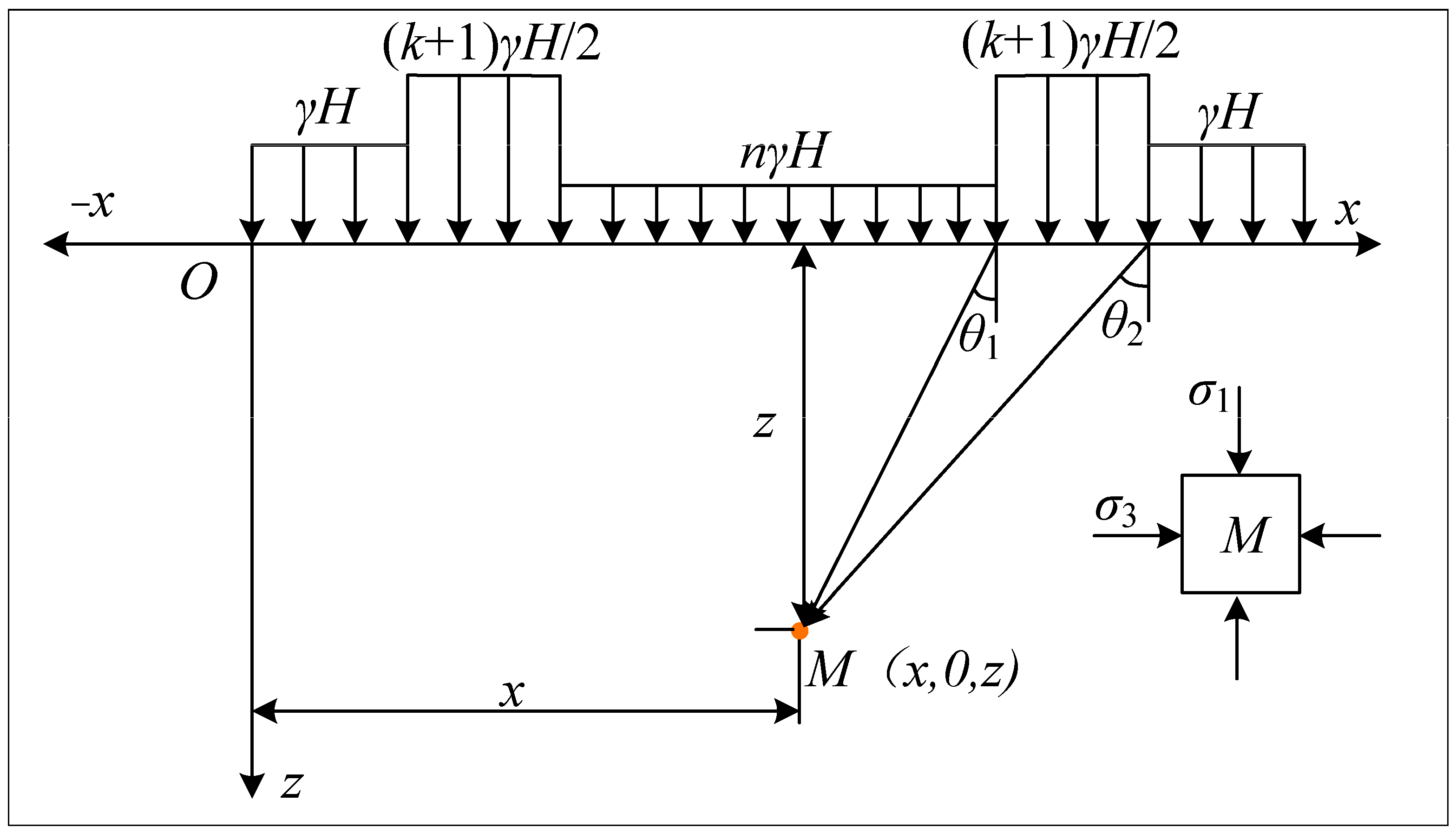

3.1. Failure Mechanism of upper Coal Seam Floor

3.2. Analysis of Occurrence State of Lower Coal Seam Roof

4. Design of Supporting Parameters of Mining Roadway in 29204 Working Faces

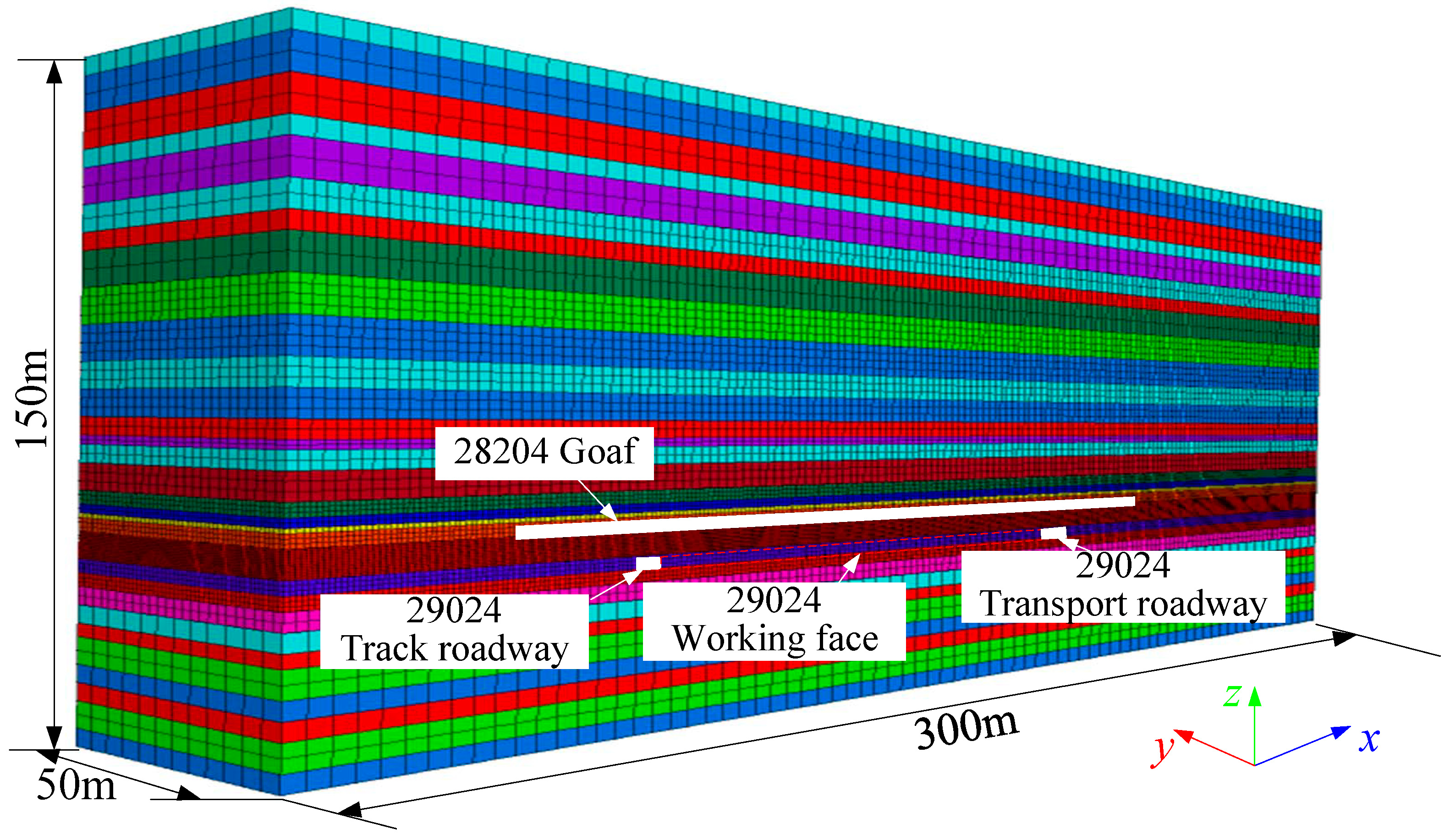

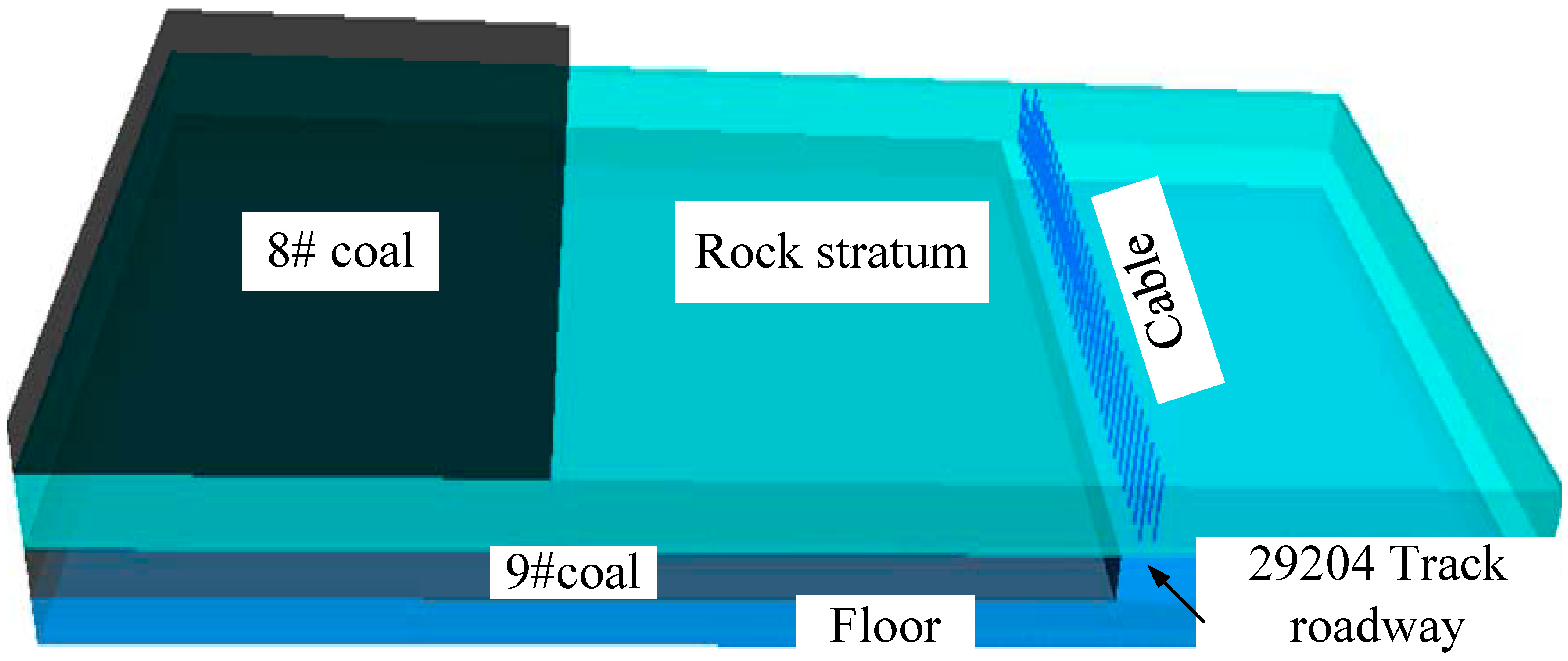

4.1. Numerical Model

4.2. Simulation Scheme

4.3. Result Analysis

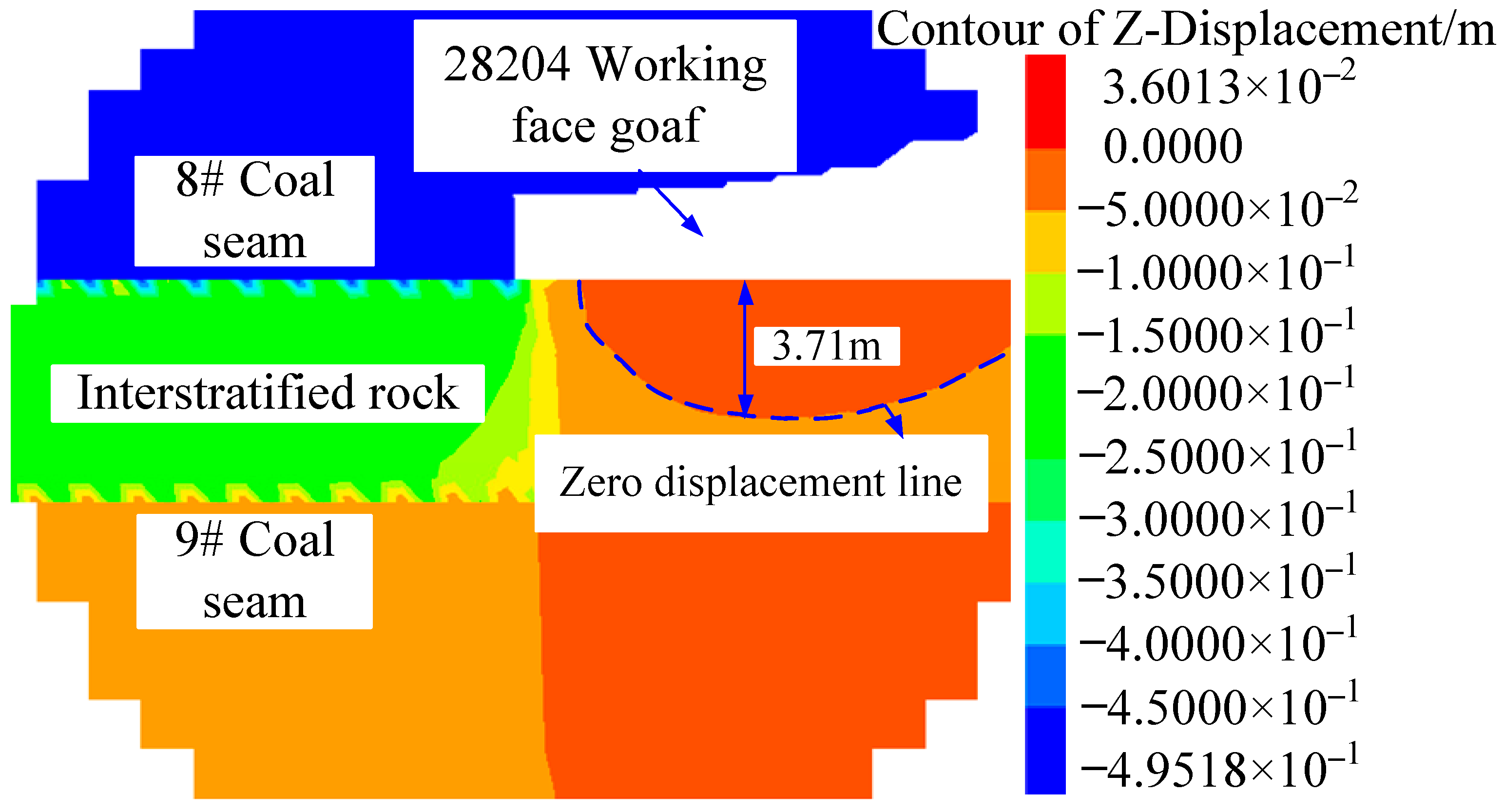

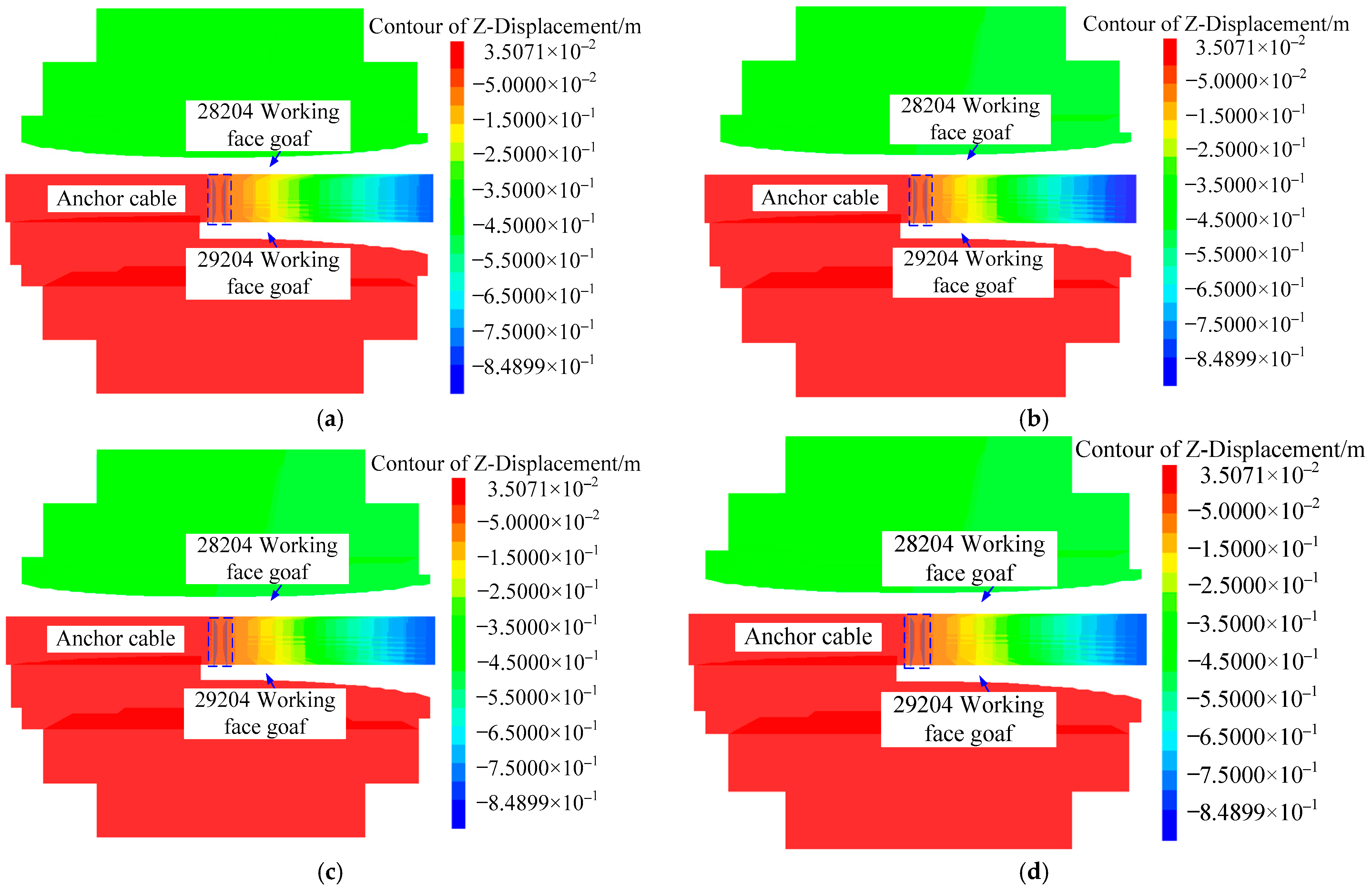

4.3.1. Simulation Verification of Floor Failure Mechanism

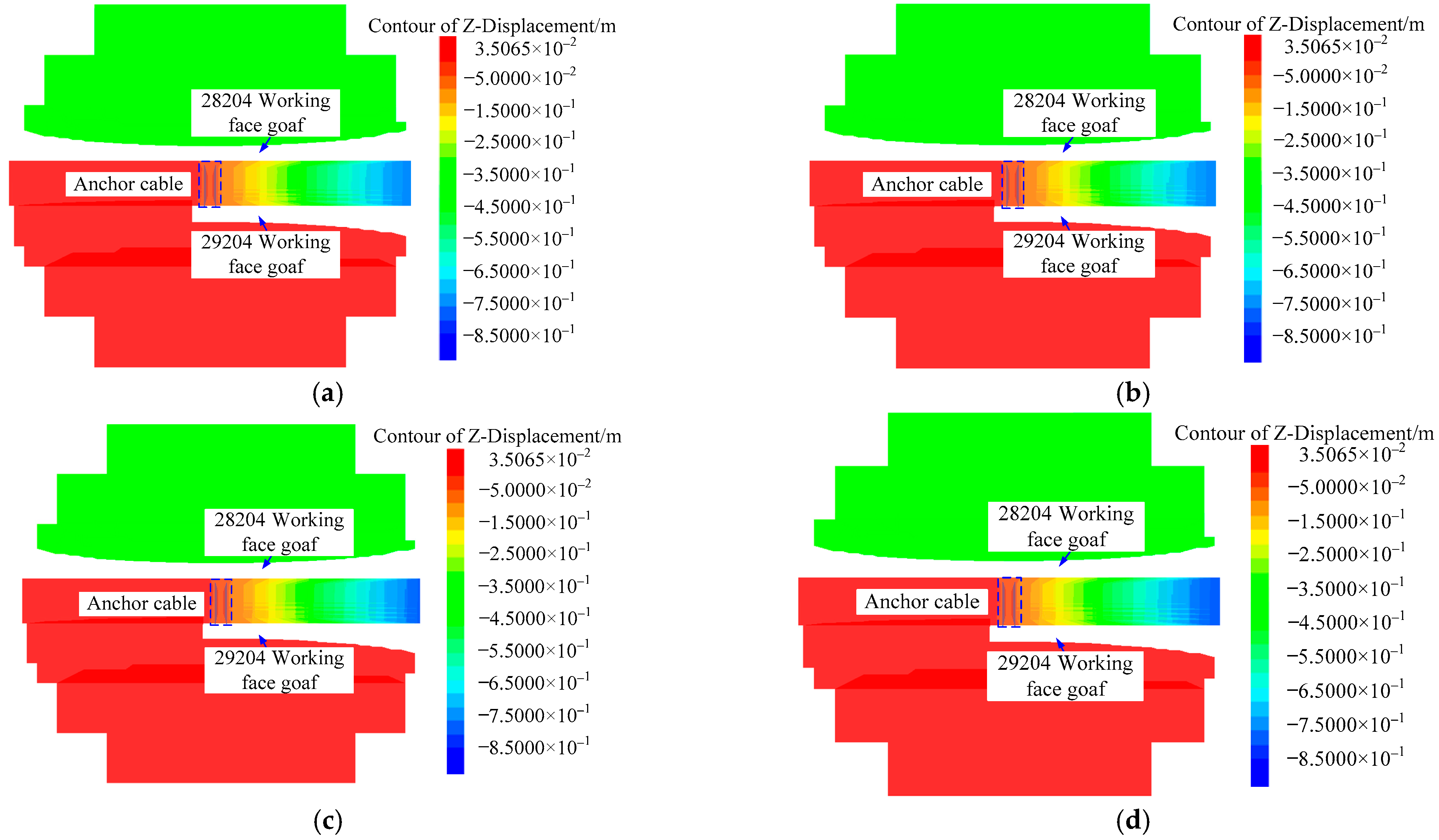

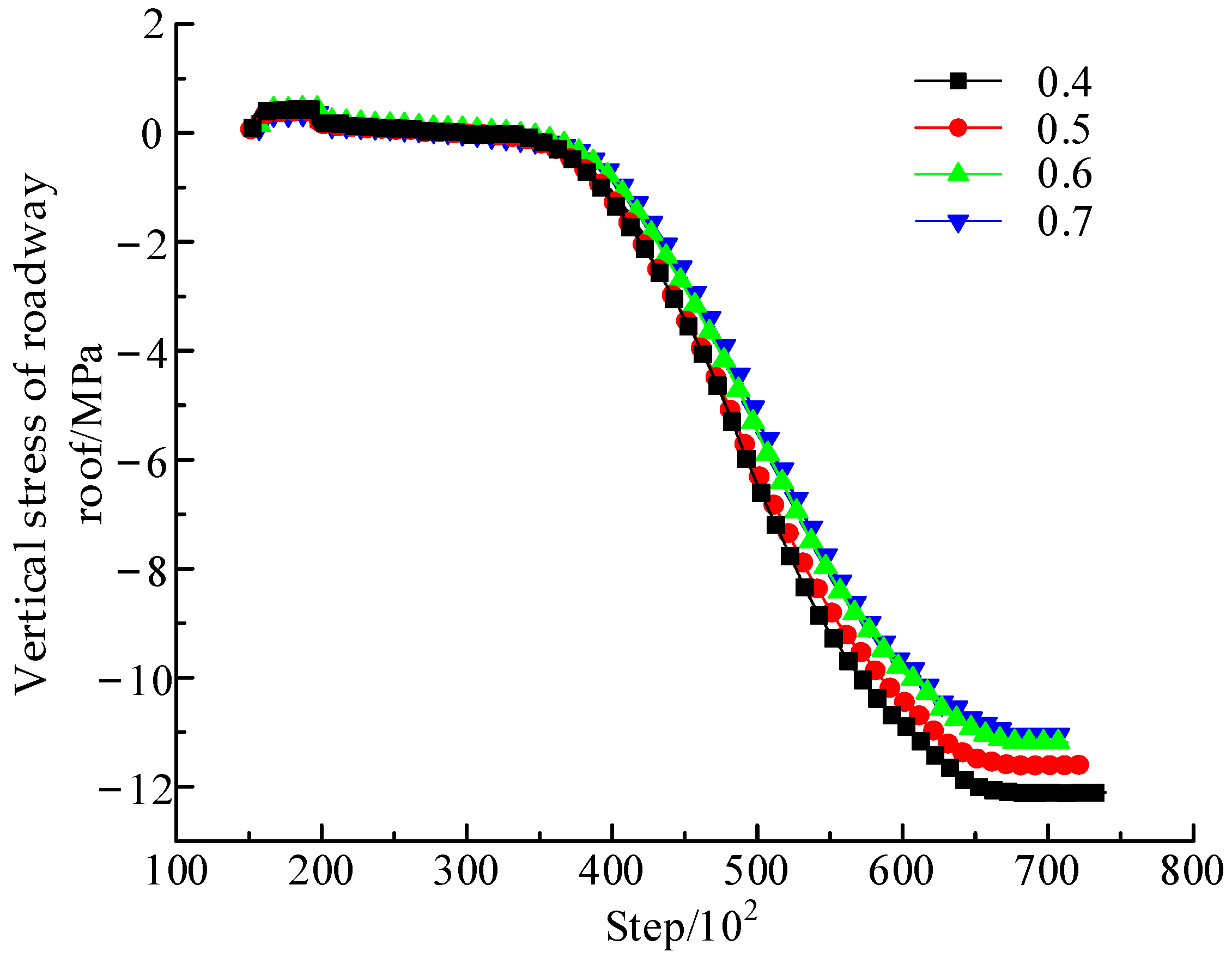

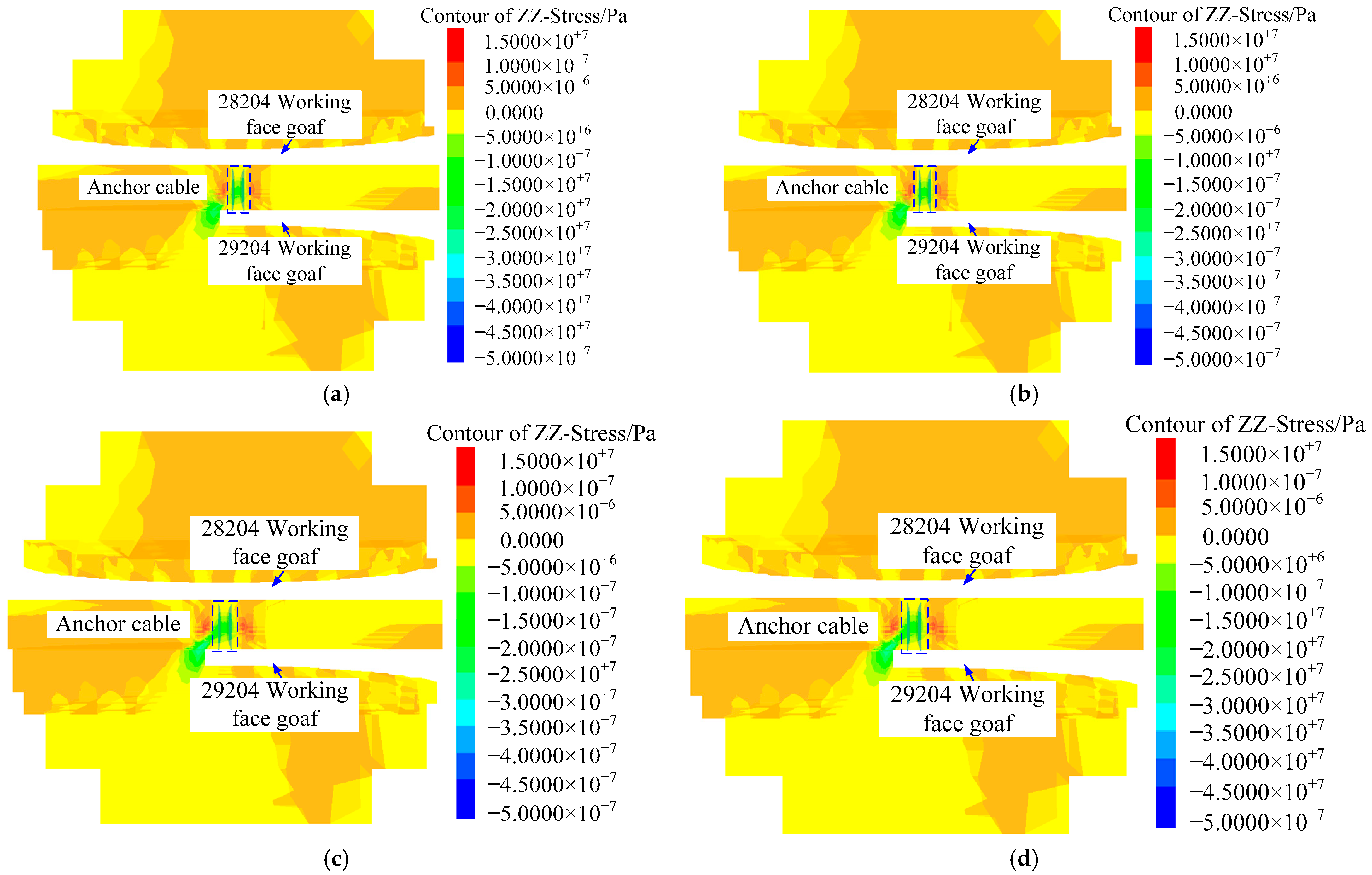

4.3.2. Deformation and Stress Distribution Law of Roadway Surrounding Rock under Different Water–Cement

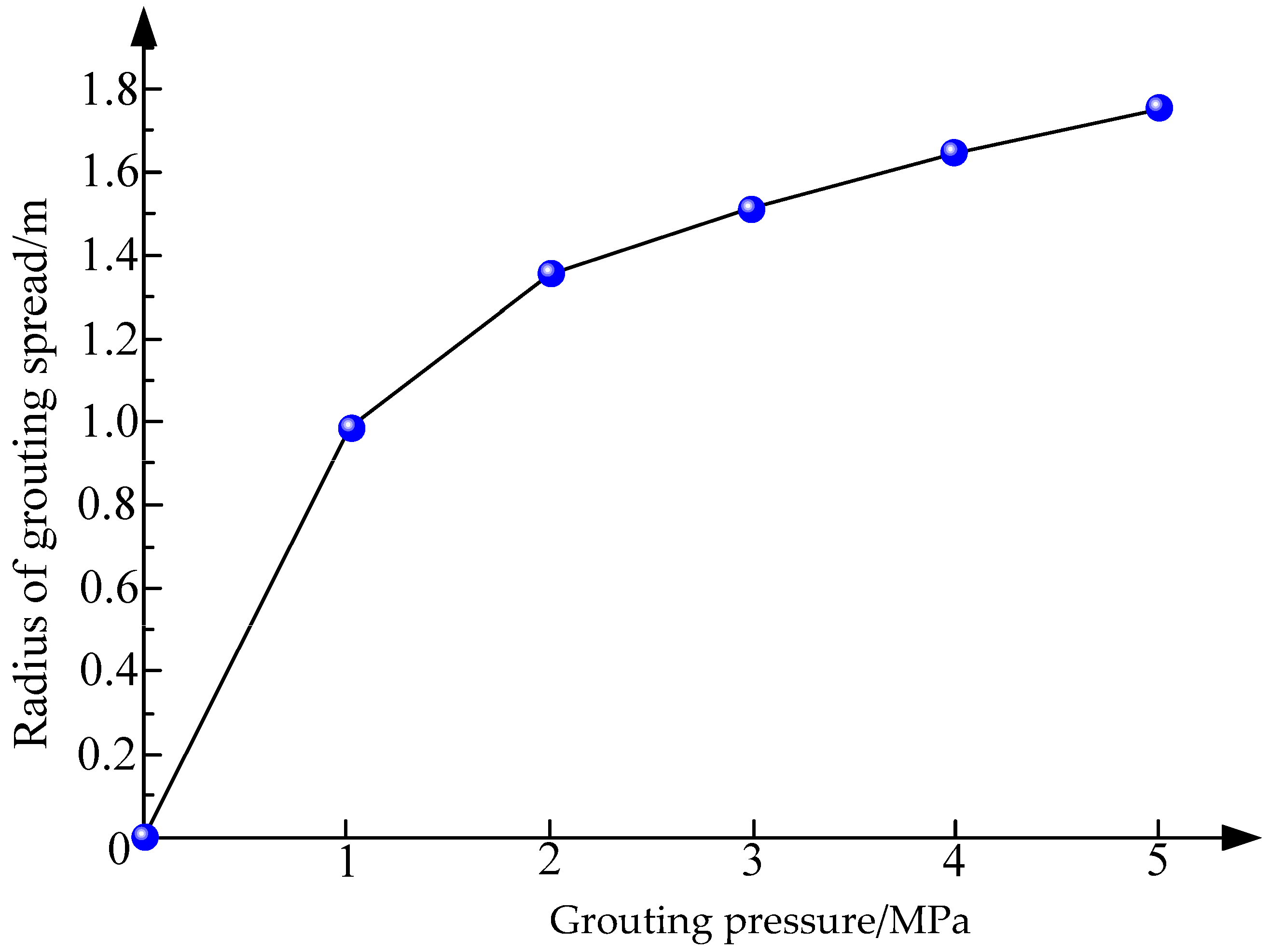

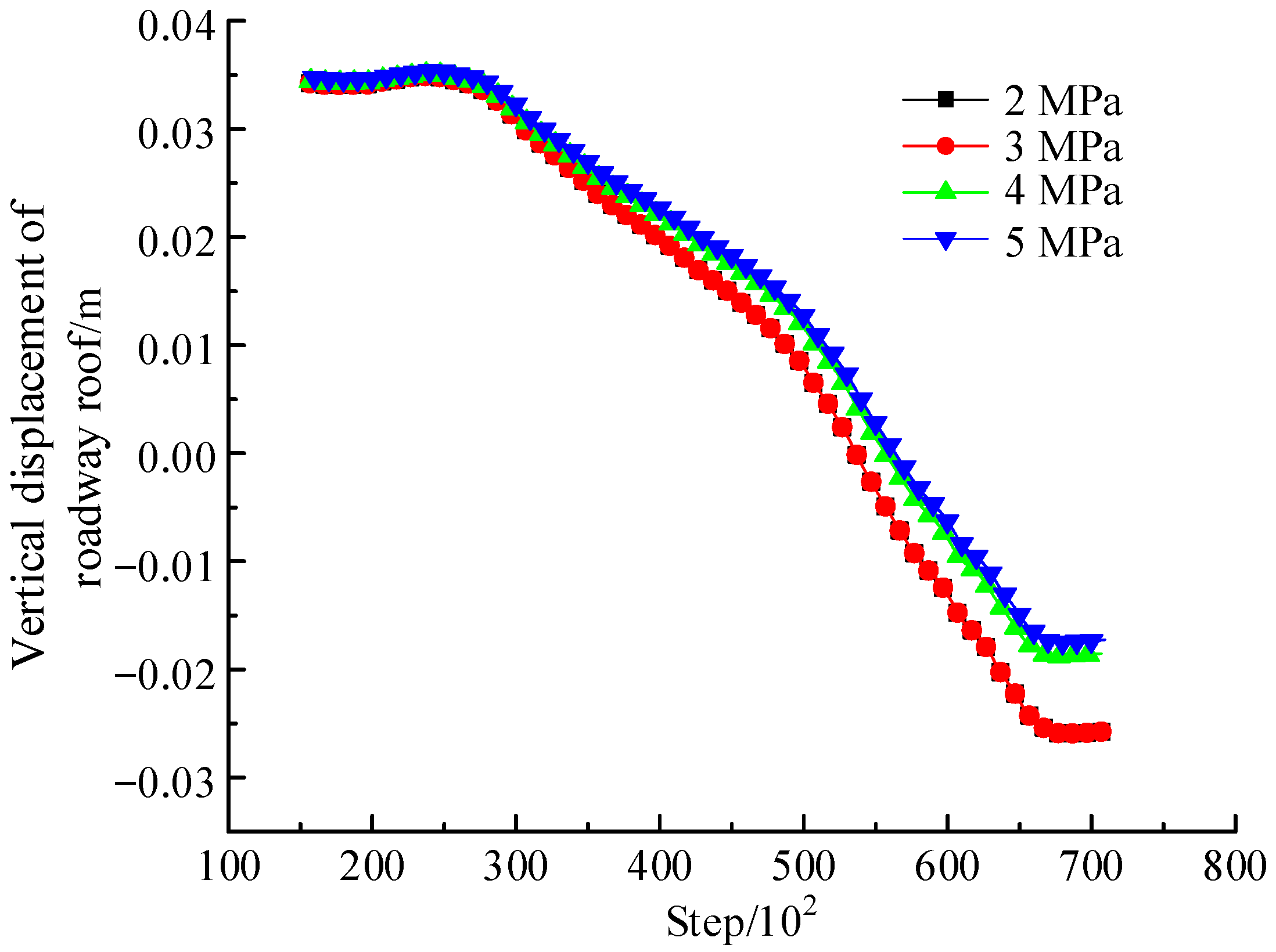

4.3.3. Deformation and Stress Distribution Law of Roadway Surrounding Rock under Different Grouting Pressure

5. Field Application

6. Conclusions

- (1)

- A mechanical model for the failure of coal seams in close distances was developed, and the floor failure mechanism based on the zero displacement line was revealed. The method for theoretical calculation of floor failure was developed, and a method for evaluating the level of occurrence of lower seam roofs was proposed using yield ratios.

- (2)

- FLAC 3D numerical simulation was used to verify and optimize parameters. According to the results, the floor failure showed obvious ‘zero displacement line’ characteristics, which verified the feasibility of the model. At the same time, the vertical displacement and stress variation of roadway roofs under the influence of different water–cementation and grouting pressure were obtained, and the optimal water–cement ratio was 0.6 and the optimal grouting pressure was 4 MPa.

- (3)

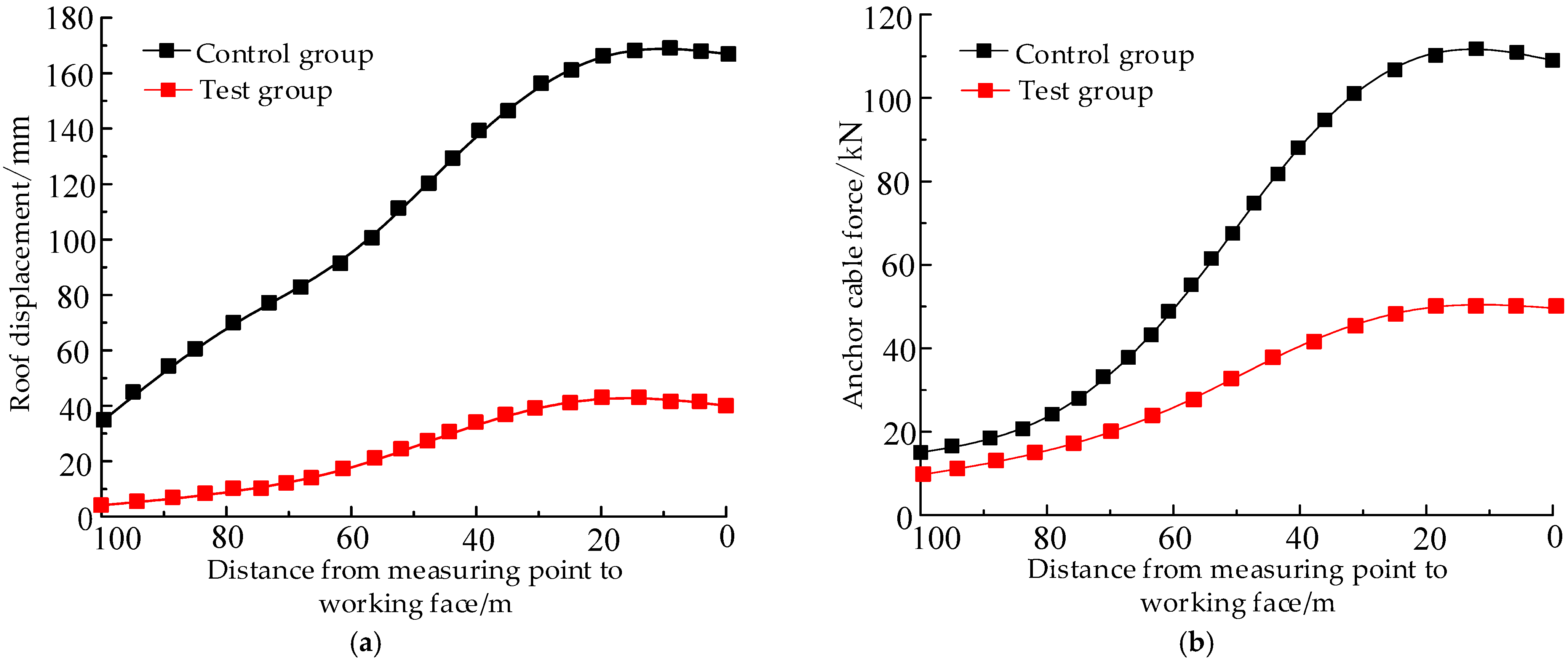

- A field application was conducted for the 29204 roadway. As a result of monitoring, the maximum roof displacement of the 29204 working face was about 42 mm, which was 73.48% lower than that of the control group. About 50.68% of the maximum force of the cable was lower than that of the control group. Clearly, anchor grouting support had an impressive design effect. In the future, attention should be paid to the use of grouting anchor cable in the support selection of mining engineering, and the support parameters should be optimized and designed around factors such as mining and geological conditions, which are very beneficial to the safe mining of coal mines and the sustainable development of resources.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.Z.; Deng, M.; Bai, J.B.; Yan, S.; Yu, X.Y. Stability control of gob-side entry retained under the gob with close distance coal seams. Int. J. Min. Sci. Technol. 2020, 31, 321–332. [Google Scholar] [CrossRef]

- Tan, Y.L.; Zhao, T.B.; Xiao, Y.X. In situ investigations of failure zone of floor strata in mining close distance coal seams. Int. J. Rock Mech. Min. 2010, 47, 865–870. [Google Scholar] [CrossRef]

- Yang, X.L.; Wen, G.C.; Dai, L.C.; Sun, H.T.; Li, X.L. Ground subsidence and surface cracks evolution from shallow-buried close-distance multi-seam mining: A case study in Bulianta Coal Mine. Rock Mech. Rock Eng. 2019, 52, 2835–2852. [Google Scholar] [CrossRef]

- Ma, Q.; Tan, Y.L.; Liu, X.S.; Gu, Q.H.; Li, X.B. Effect of coal thicknesses on energy evolution characteristics of roof rock-coal-floor rock sandwich composite structure and its damage constitutive model. Compos. Part B-Eng. 2020, 198, 108086. [Google Scholar] [CrossRef]

- Song, D.Q.; Chen, Z.; Dong, L.H.; Tan, G.J.; Zhang, K.L.; Wang, H. Monitoring analysis of influence of extra-large complex deep foundation pit on adjacent environment: A case study of Zhengzhou City, China. Geomat. Nat. Hazards Risk 2020, 11, 2036–2057. [Google Scholar] [CrossRef]

- Li, S.F.; Chen, J.F. Research on supporting technology of roadway surrounding rock for downward mining in extreme contiguous seams. Min. Saf. Environ. Prot. 2022, 49, 127–131. [Google Scholar]

- Zheng, W.X.; Bu, Q.W.; Hu, Y.Q. Plastic failure analysis of roadway floor surrounding rocks based on unified strength theory. Adv. Civ. Eng. 2018, 2018, 7475698. [Google Scholar] [CrossRef]

- Liang, Z.Z.; Song, W.C. Theoretical and numerical investigations of the failure characteristics of a faulted coal mine floor above a confined aquifer. Mine Water Environ. 2021, 40, 456–465. [Google Scholar] [CrossRef]

- Huang, Q.X.; Hao, G.Q. Research on the floor failure range and its effects of entry. J. Xian Uni. Sci. Technol. 2018, 38, 51–58. [Google Scholar]

- Cheng, H.; Zhao, H.B.; Zhang, H.; Qin, F.Y.; Li, J.Y. Study on mechanism and prevention technology of floor heave of mining roadway in close distance coal seam. J. Cent. South Univ. 2022, 53, 1392–1405. [Google Scholar]

- Liu, C.K.; Ren, J.X.; Gao, B.L.; Song, Y.J. Support design and practice for floor heave of deeply buried roadway. IOP Conf. Ser. Earth Environ. Sci. 2017, 64, 1232. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.G.; Zhao, G.M. Stress distribution and failure characteristics for workface floor of a tilted coal seam. KSCE J. Civ. Eng. 2019, 23, 3793–3806. [Google Scholar] [CrossRef]

- Chen, P. Analysis on stress characteristics of roadway floor and evolution law of arch structure. Coal Technol. 2020, 39, 79–81. [Google Scholar]

- Zhao, H.B.; Liu, Y.H.; Li, J.Y.; Xu, J.F. Analysis of damage process and zonal failure characteristics of rock mass under floor of isolated coal pillar. J. China Uni. Min. Technol. 2021, 50, 963–974. [Google Scholar]

- Jiang, Y.L.; Cai, T.T.; Zhang, X.Q. A multifactor coupling prediction model for the failure depth of floor rocks in fully mechanized caving mining: A numerical and in situ study. R. Soc. Open Sci. 2019, 6, 190528. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.X.; Liu, J.N.; Feng, G.R. Stress distribution and failure characteristics of a longwall panel floor with a negative gate pillar. Chin. J. Rock Mech. Eng. 2023, 42, 194–211. [Google Scholar]

- Mo, S.; Sheffield, P.; Corbett, P.; Ramandi, H.L.; Oh, J.; Canbulat, L.; Saydam, S. A numerical investigation into floor buckling mechanisms in underground coal mine roadways. Tunn. Undergr. Space Technol. 2020, 103, 103497. [Google Scholar] [CrossRef]

- Liu, S.L.; Liu, W.T.; Shen, J.J. Stress evolution law and failure characteristics of mining floor rock mass above confined water. KSCE J. Civ. Eng. 2017, 21, 2665–2672. [Google Scholar] [CrossRef]

- Yin, S.X.; Meng, H.P.; Qian, S.B. Failure analysis of deep coal seam floor considering strain softening of surrounding rock and formation contact in goaf. Coal Geol. Explor. 2022, 50, 95–102. [Google Scholar]

- Ma, K.; Sun, X.Y.; Tang, C.A.; Yuan, F.Z.; Wang, S.J.; Chen, T. Floor water inrush analysis based on mechanical failure characters and microseismic monitoring. Tunn. Undergr. Space Technol. 2021, 108, 103698. [Google Scholar] [CrossRef]

- Lu, Y.L.; Wang, L.G. Numerical simulation of mining-induced fracture evolution and water flow in coal seam floor above a confined aquifer. Comput. Geotech. 2015, 67, 157–171. [Google Scholar] [CrossRef]

- Guo, G.Q. Floor failure law of extra-thick coal seam in fully mechanized caving mining. Coal Geol. Explor. 2022, 50, 107–115. [Google Scholar]

- Guo, G.Q.; Wang, Z.M.; Qu, S.B.; Li, H.; Zhou, Y.; Lyu, H.J.; He, Y. Study on explicit-implicit simulation and in-situ measurement of floor failure law in extra-thick coal seams. Minerals 2023, 12, 1511. [Google Scholar] [CrossRef]

- Meng, X.X.; Liu, W.T.; Zhao, J.Y.; Ding, X.Y. In situ investigation and numerical simulation of the failure depth of an inclined coal seam floor: A case study. Mine Water Environ. 2019, 38, 686–694. [Google Scholar] [CrossRef]

- Ning, J.G.; Wang, J.; Tan, Y.L.; Xu, Q. Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int. J. Min. Sci. Technol. 2020, 30, 207–215. [Google Scholar] [CrossRef]

- Hu, Y.B.; Li, W.P.; Liu, S.L.; Wang, Q.Q. Prediction of floor failure depth in deep coal mines by regression analysis of the multi-factor influence index. Mine Water Environ. 2021, 40, 497–590. [Google Scholar] [CrossRef]

- Liu, Y.B.; Wang, E.Y.; Jiang, C.B.; Zhang, D.M.; Li, M.H.; Yu, B.C.; Zhao, D. True triaxial experimental study of anisotropic mechanical behavior and permeability evolution of initially fractured coal. Nat. Resour. Res. 2023, 32, 567–585. [Google Scholar] [CrossRef]

- Liu, Y.B.; Wang, E.Y.; Li, M.H.; Song, Z.L.; Zhang, L.; Zhao, D. Mechanical response and gas flow characteristics of pre-drilled coal subjected to true triaxial stresses. J. Nat. Gas Sci. Eng. 2023, 111, 204927. [Google Scholar] [CrossRef]

- Lei, M.F.; Peng, L.M.; Shi, C.H. Calculation of the surrounding rock pressure on a shallow buried tunnel using linear and nonlinear failure criteria. Autom. Constr. 2014, 37, 191–195. [Google Scholar] [CrossRef]

- Xu, H.F.; Gen, H.S.; Li, C.F.; Chen, W.; Wang, C. Estimating strength of grouting reinforced bodies in broken rock mass. Chin. J. Geotech. Eng. 2013, 35, 2018–2022. [Google Scholar]

- Wang, L.G.; Miao, X.X.; Dong, J.T.; Tan, X.N. Numerical simulation research of bolt-grouting support in deep soft roadway. Rock Soil Mech. 2005, 26, 983–985. [Google Scholar]

- Li, L.H. Study on the Application of Advance Support Technology with Grouting and Cable in Mining Roadway. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, June 2020. [Google Scholar]

- Song, D.Q.; Liu, X.L.; Huang, J.; Zhang, Y.F.; Zhang, J.M.; Benedict Nganteh, N. Seismic cumulative failure effects on a reservoir bank slope with a complex geological structure considering plastic deformation characteristics using shaking table tests. Eng. Geol. 2021, 286, 106085. [Google Scholar] [CrossRef]

| Title | Parting | Broken, Crack Penetration | Block Fracture |

|---|---|---|---|

| Yield ratio β | β ≥ 1 | β < 1 | |

| Interlayer spacing z (m) | z ≤ 0.5 | 0.5 ≤ z ≤ 1.5 | 1.5 < z ≤ f·h |

| Lithologic Characters | Density/kg/m3 | Bulk Modulus/GPa | Shear Modulus/GPa | Angle of Internal Friction/° | Cohesion/MPa | Tensile Strength/MPa |

|---|---|---|---|---|---|---|

| sandy mudstone | 2520 | 5.7 | 2.52 | 28.4 | 3.86 | 4.57 |

| limestone | 2650 | 6.2 | 3.43 | 29.4 | 2.19 | 2.32 |

| medium sandstone | 2580 | 6.8 | 3.98 | 33.6 | 2.59 | 2.67 |

| siltstone | 2620 | 6.7 | 3.82 | 32.8 | 2.78 | 2.51 |

| limestone | 2650 | 6.2 | 3.43 | 29.4 | 2.19 | 2.32 |

| marl | 2240 | 5.1 | 2.78 | 30.2 | 2.17 | 3.18 |

| mudstone | 2450 | 3.8 | 2.13 | 26.7 | 1.72 | 2.13 |

| 8#coal | 1600 | 3.1 | 1.57 | 24.2 | 1.65 | 1.52 |

| sandy mudstone | 2520 | 5.7 | 2.52 | 28.4 | 3.86 | 4.57 |

| 9#coal | 1600 | 3.1 | 1.57 | 24.2 | 1.65 | 1.52 |

| sandy mudstone | 2520 | 5.7 | 2.52 | 28.4 | 3.86 | 4.57 |

| Scheme | Water–Cement Ratio | Bulk Modulus/GPa | Shear Modulus/GPa | Angle of Internal Friction/° | Cohesion/MPa | Tensile Strength/MPa |

|---|---|---|---|---|---|---|

| 1 | 0.4 | 461.7 | 204.12 | 44.4 | 61.76 | 73.12 |

| 2 | 0.5 | 153.9 | 68.04 | 40.4 | 30.88 | 36.56 |

| 3 | 0.6 | 51.3 | 22.68 | 36.4 | 15.44 | 18.28 |

| 4 | 0.7 | 17.1 | 7.56 | 32.4 | 7.72 | 9.14 |

| Scheme | Grouting Pressure/MPa | Radius of Grouting Spread/m |

|---|---|---|

| 1 | 2 | 1.3 |

| 2 | 3 | 1.5 |

| 3 | 4 | 1.65 |

| 4 | 5 | 1.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, G.; Ni, P. Support Control Design of Mining Roadway under Goaf of Close-Distance Coal Seam. Sustainability 2023, 15, 5420. https://doi.org/10.3390/su15065420

Lu G, Ni P. Support Control Design of Mining Roadway under Goaf of Close-Distance Coal Seam. Sustainability. 2023; 15(6):5420. https://doi.org/10.3390/su15065420

Chicago/Turabian StyleLu, Guozhi, and Ping Ni. 2023. "Support Control Design of Mining Roadway under Goaf of Close-Distance Coal Seam" Sustainability 15, no. 6: 5420. https://doi.org/10.3390/su15065420

APA StyleLu, G., & Ni, P. (2023). Support Control Design of Mining Roadway under Goaf of Close-Distance Coal Seam. Sustainability, 15(6), 5420. https://doi.org/10.3390/su15065420