AGRI|gen: Analysis and Design of a Parametric Modular System for Vertical Urban Agriculture

Abstract

:1. Research Summary

1.1. Introduction

1.2. Problem Definition

1.3. Research Objectives

1.4. Research Questions

- How much can a (MAVFFS) produce in terms of yield per year? And how much can it fulfil from local consumption?

- To what extent can MAVFFS save lands?

- What are the MAVFFS basic expected costs?

- How would the modular unit patterns change in the façade according to its position?

- How would the MAVFFS look on one building and a neighbourhood?

1.5. Research Hypothesis

- Growing crops on the facades and roofs of a neighbourhood can fulfil its local consumption of these crops.

- All the facades and roofs have enough natural light to properly grow the selected crops on them.

- The basic MAVFFS cost will be less than constructing a vertical farm for the same available farming area.

1.6. Research Methodology

- To answer the research questions, this research used the following techniques in each stage:

1.6.1. Data Collection

1.6.2. Data Analysis

1.6.3. Research by Design

1.7. Expected Outcomes

2. Literature Review

2.1. Global Challenges

2.1.1. Climate Change

2.1.2. Water Scarcity

2.1.3. Rapid Urbanisation

2.2. Urban Farming

2.2.1. Urban Agriculture

2.2.2. Vertical Farming

- local case study: proposed vertical farm in Nablus

2.2.3. Brief Definition of Vertical Greenery Systems

- International case study (1): Proposed productive facade in Singapore:

2.3. General Hydroponic Crops Growing Requirements

- Oxygen(O2) and carbon dioxide (CO2): Like most other creatures, plants need oxygen in the air, but having it in the water enhances nutrient absorption. Moreover, carbon dioxide is also needed for the photosynthesis process. Both gases exist within the normal breathable air at an acceptable rate for plant growth.

- Water (H2O): Water works as a solvent solution for the nutrients and oxygen as it also has a role in metabolic operations; water with 5.00–7.00 pH is generally required.

- Nutrients: Nutrients represent the needed food for plants. Phosphorus (P), Potassium (K), and Nitrogen (N) are the most needed nutrients, and they are commercially available in many formulas.

- Temperature: Temperature is an important factor in hydroponic systems as it affects both the dissolved oxygen in the water and the metabolic activity of the plants. Ideally, the water and ambient temperature should be maintained between 18–25 °C to ensure optimal growth and development.

- Light: Light intensity, spectrum, and duration are one of the most affecting factors. These will be explained in detail in the next section [35].

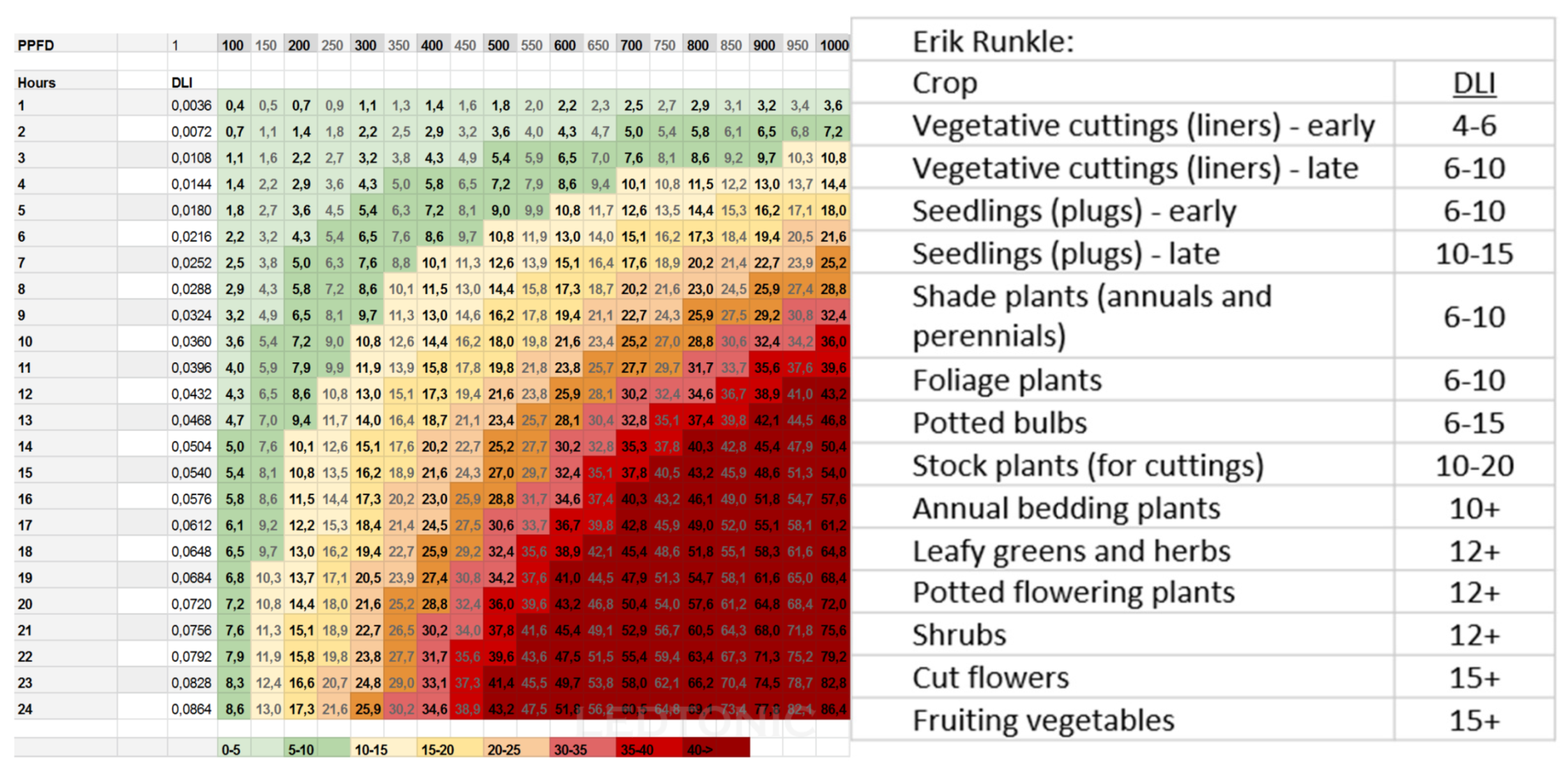

2.3.1. Crops Light Requirements

- International case study (2): 3D city models for urban farming site identification in buildings.

2.3.2. Possible Crops for Vertical Farming:

2.4. Parametric and Modular Architecture

3. Case Study

3.1. Site Selection

3.1.1. Site Selection Criteria

- (A)

- Country scale:

- (B)

- City Scale:

- (C)

- Neighbourhood Scale:

3.1.2. Chosen Country Analysis

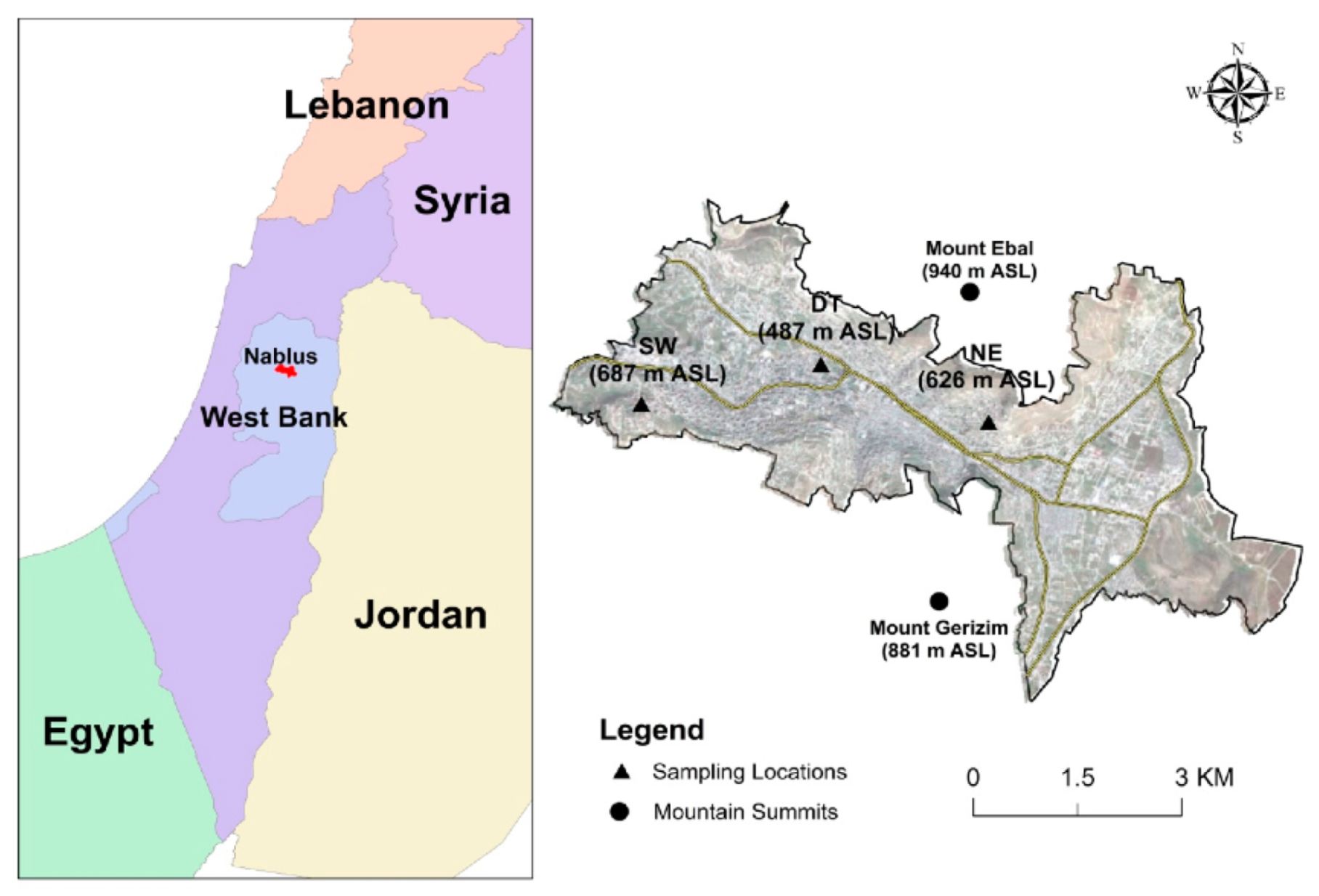

3.1.3. City Analysis

3.1.4. Neighbourhood Analysis

3.2. Crops Selection

3.2.1. Crops Selection Criteria

- Hydroponic farming possibility:

- Available natural DLI:

- Acceptable Plant growing conditions:

- Local consideration:

3.2.2. Selected Crops Requirements, Productivity, and Consumption

4. Analysis Process

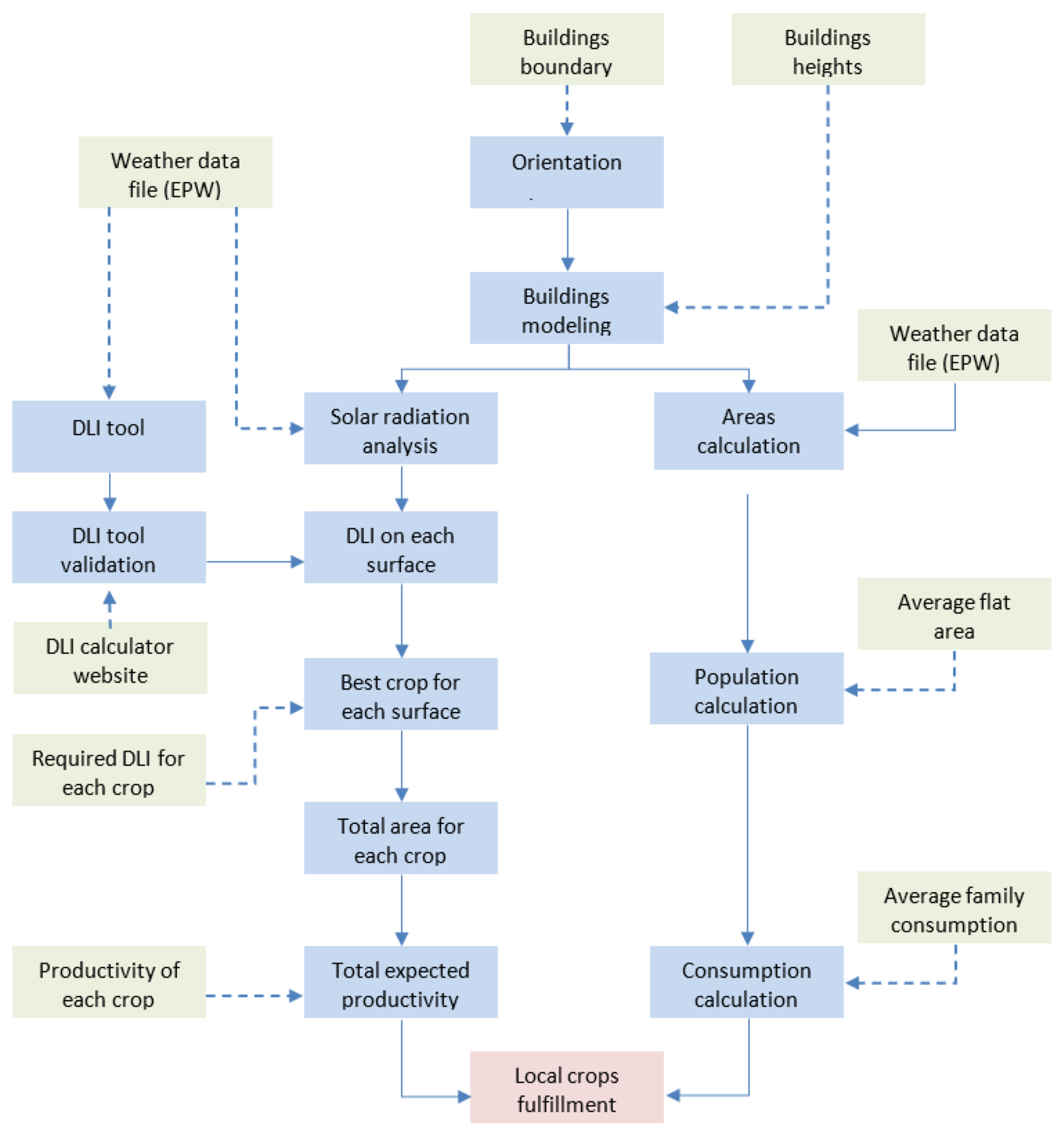

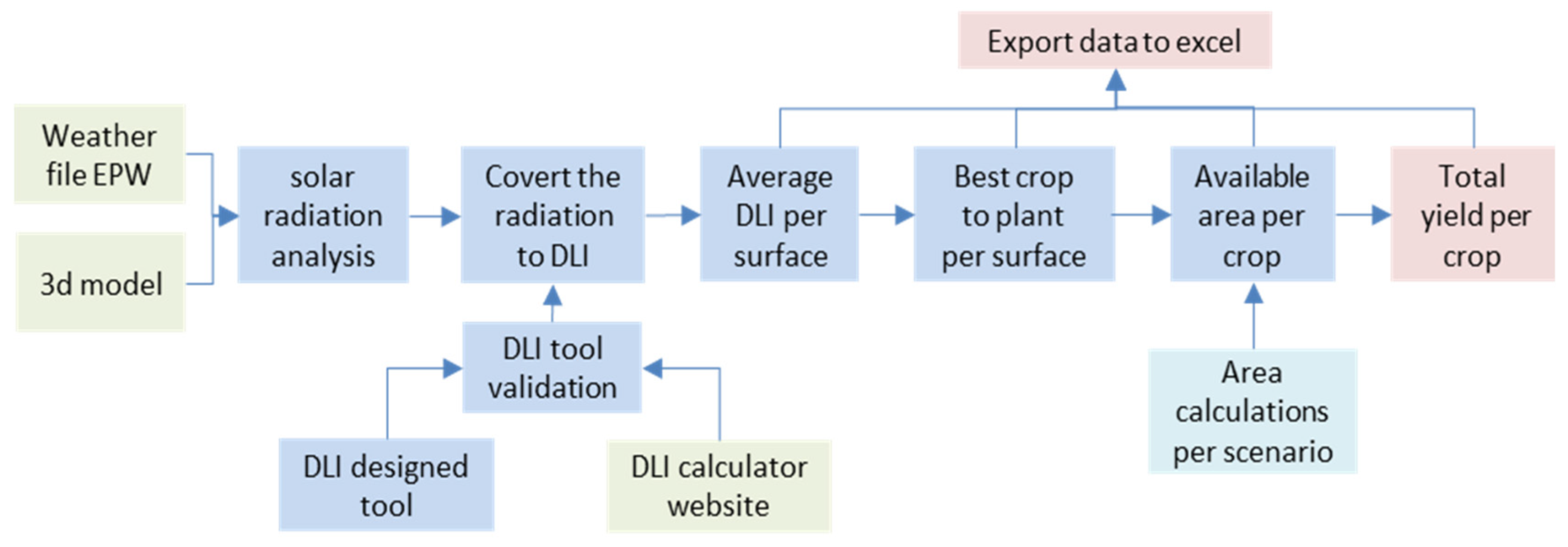

4.1. General Diagram for the Capacity Analyzing Tool

4.2. Analysis Tool Basic Inputs

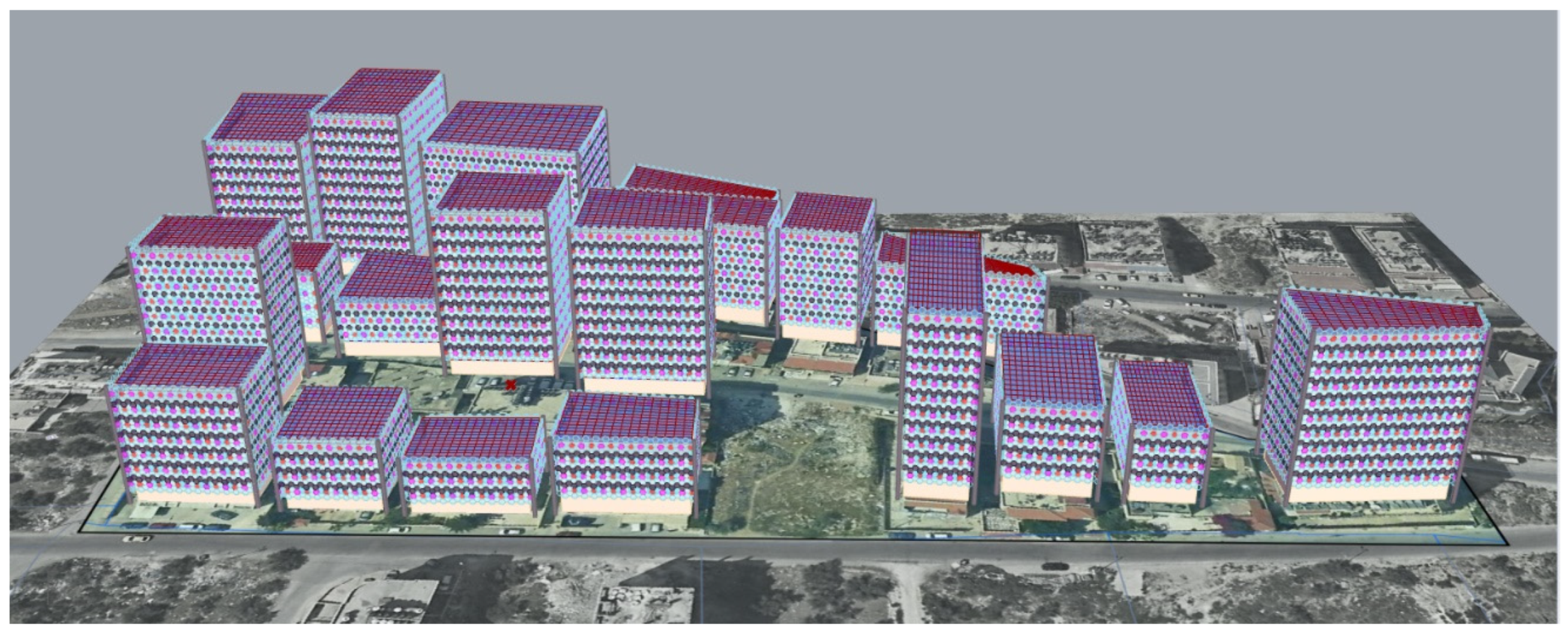

4.2.1. Neighbourhood Buildings Boundaries

4.2.2. Neighbourhood Buildings Data

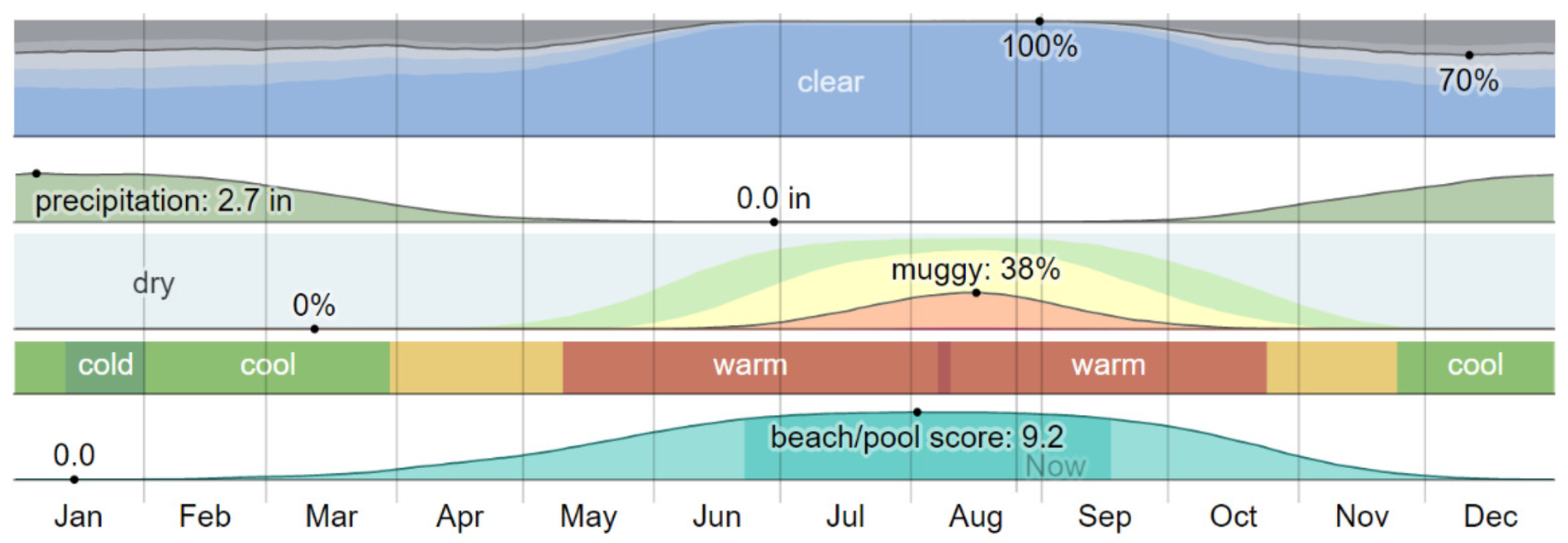

4.2.3. Neighbourhood Weather File (EPW)

4.2.4. Neighbourhood Local Statistics

4.3. Site Modelling

4.3.1. Reading Excel Data

4.3.2. Orientation Detection

4.3.3. Buildings Modelling

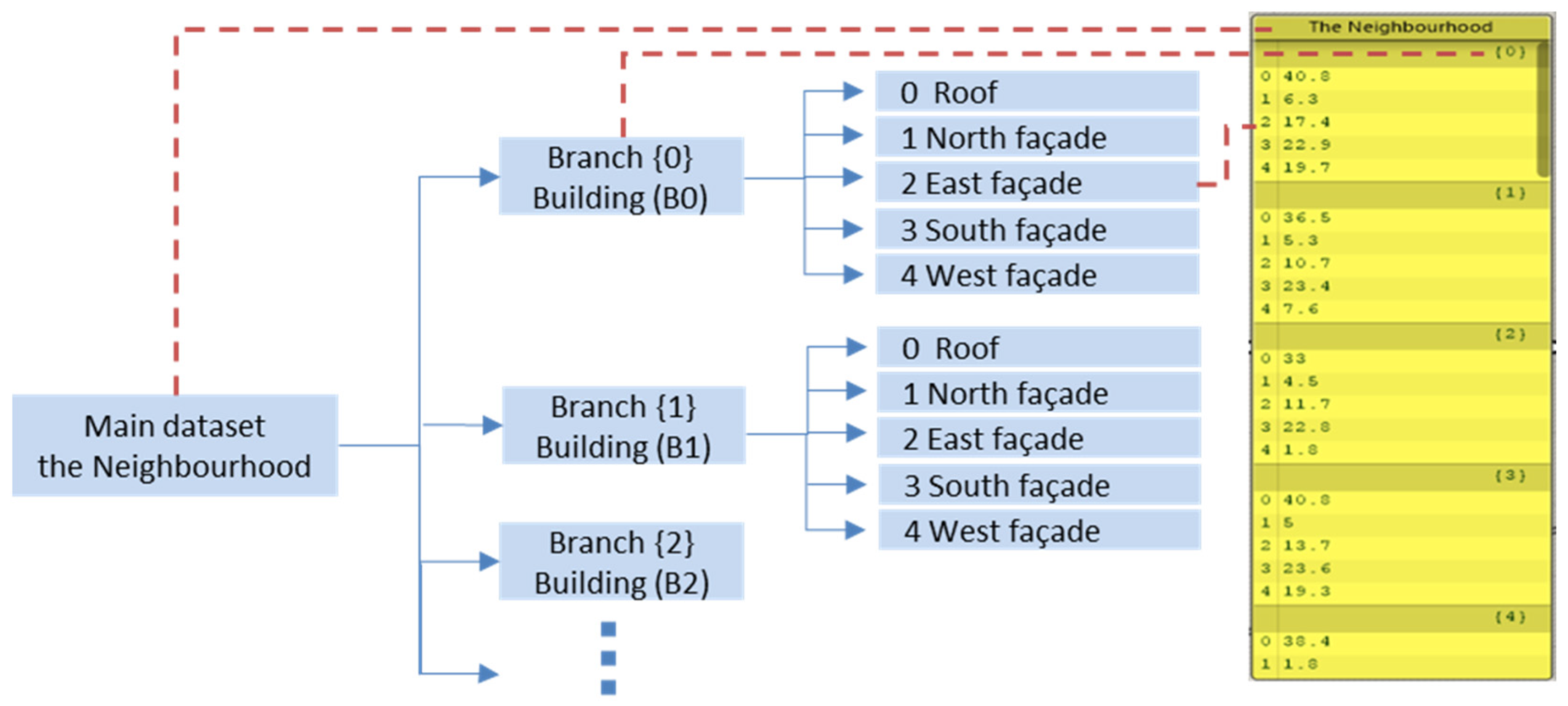

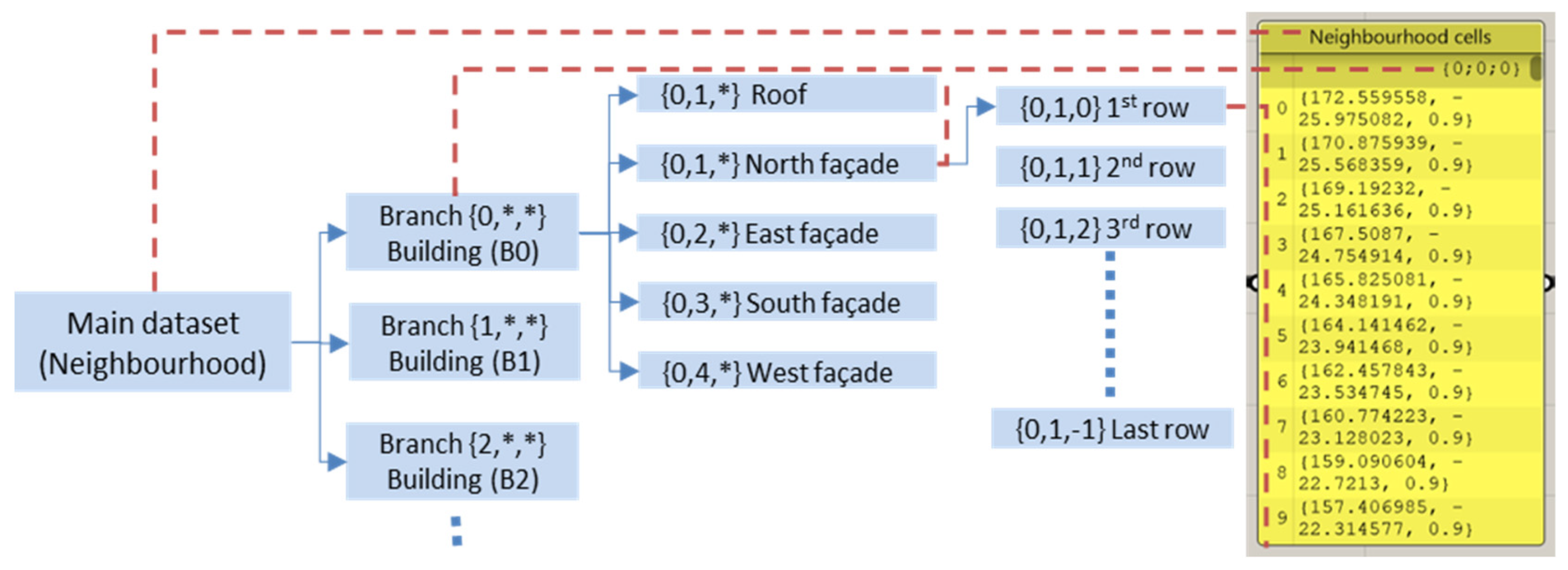

4.3.4. Data Tree Structure

4.4. Neighbourhood Consumption Analysis

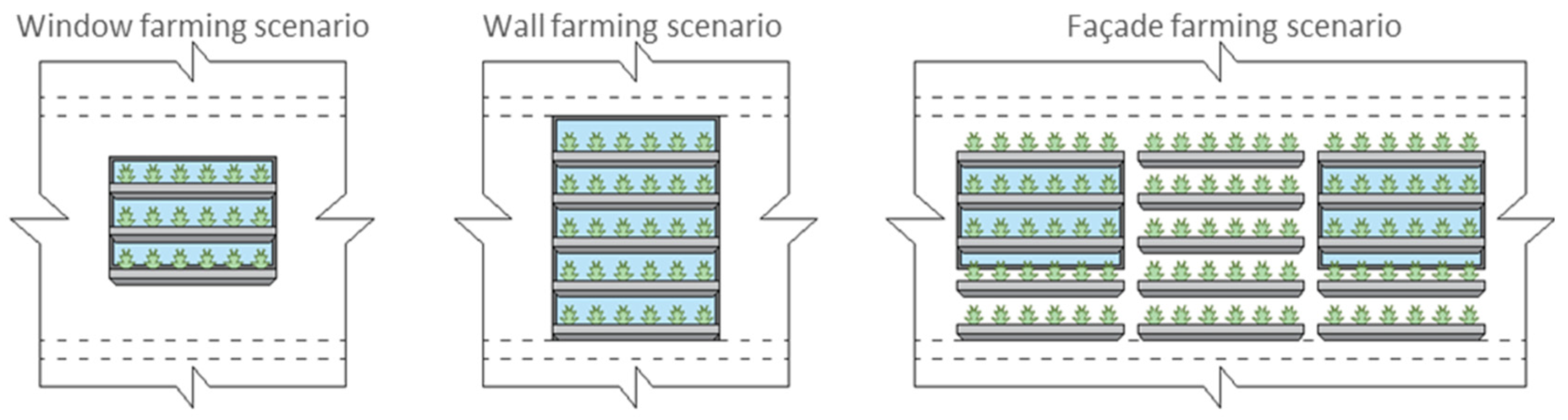

4.4.1. Areas Calculations

4.4.2. Population Calculation

4.4.3. Consumption Calculation

4.5. Neighbourhood Production Analysis

4.5.1. Solar Radiation Calculation

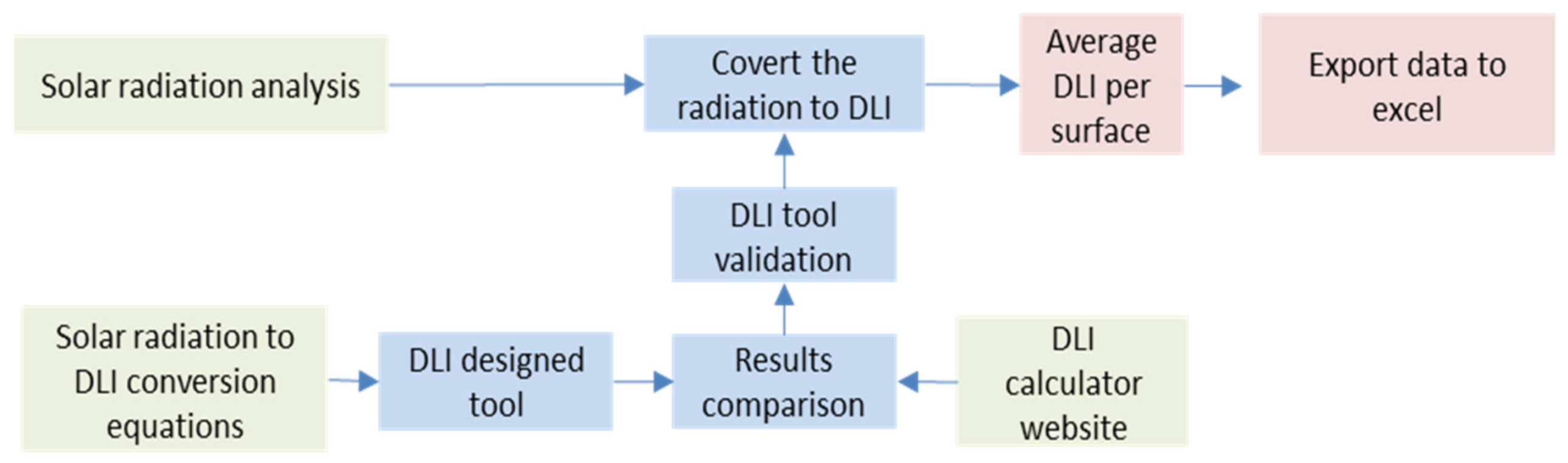

4.5.2. DLI Values on Different Surfaces

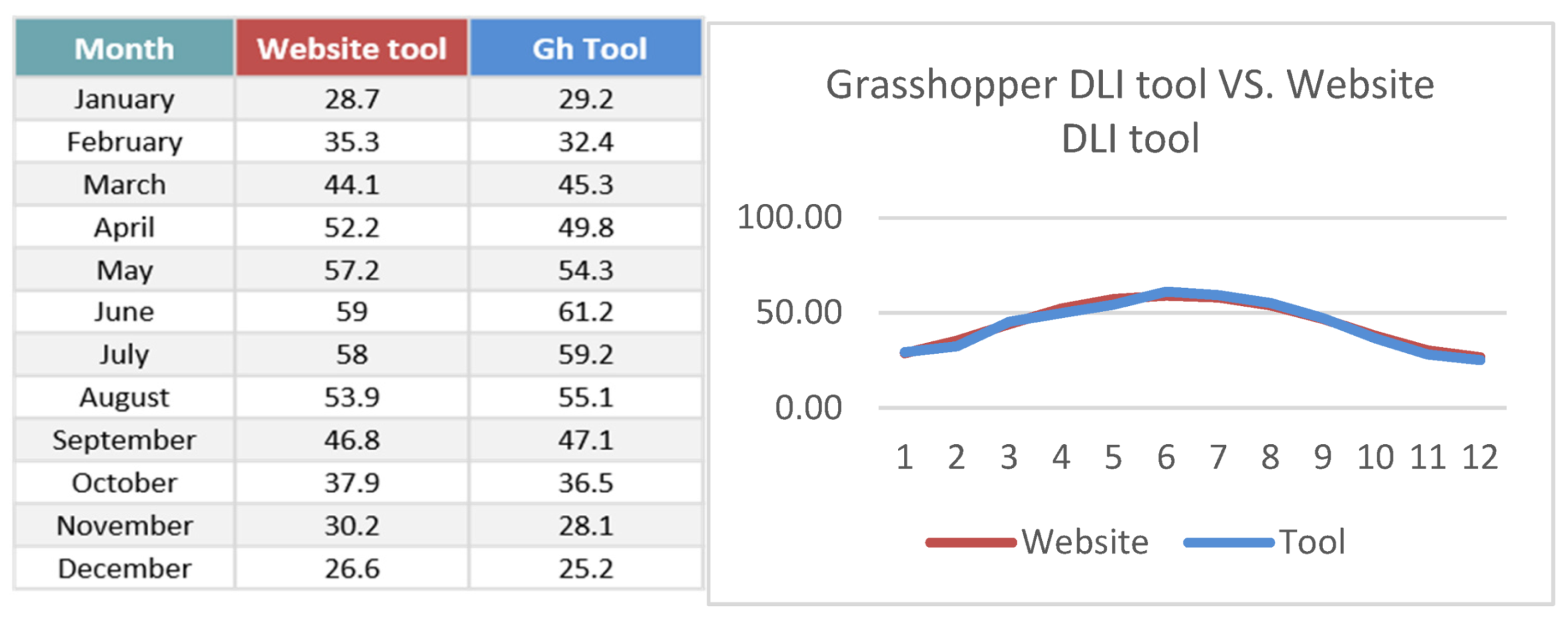

- DLI calculator website

- DLI designed tool

- DLI tool validation

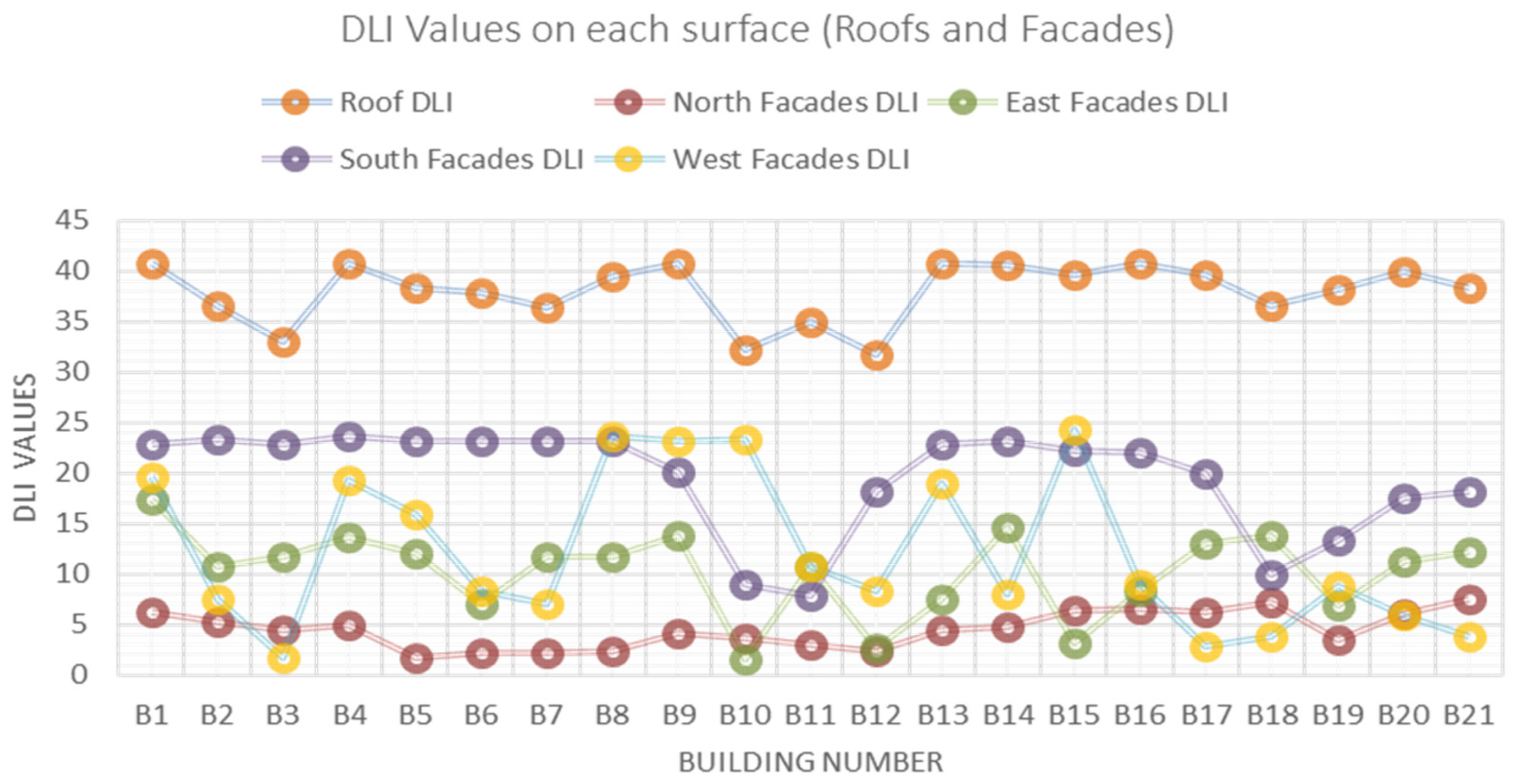

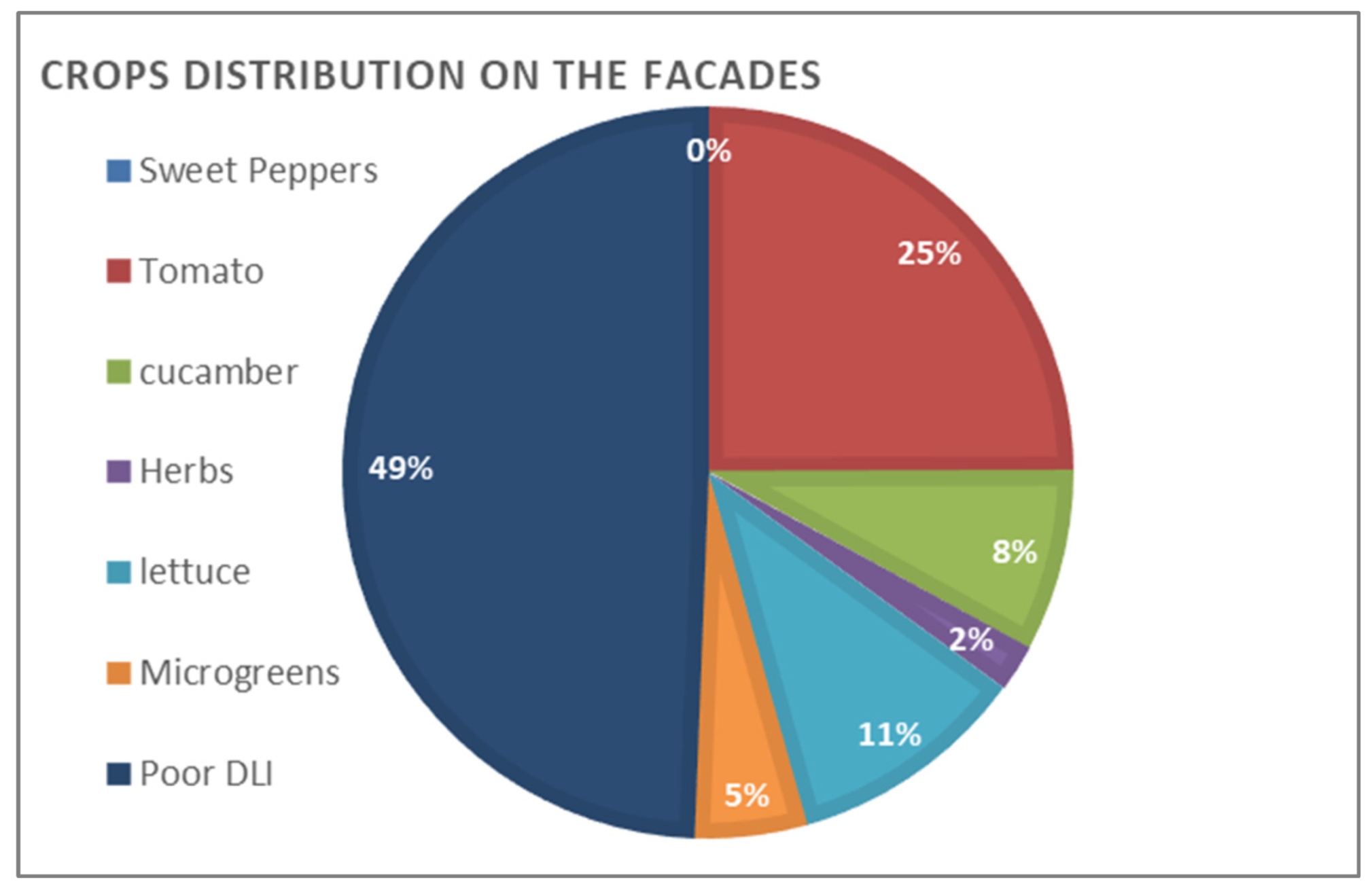

- DLI values on different surfaces

4.5.3. Best Crop for Each Surface (Decision Making)

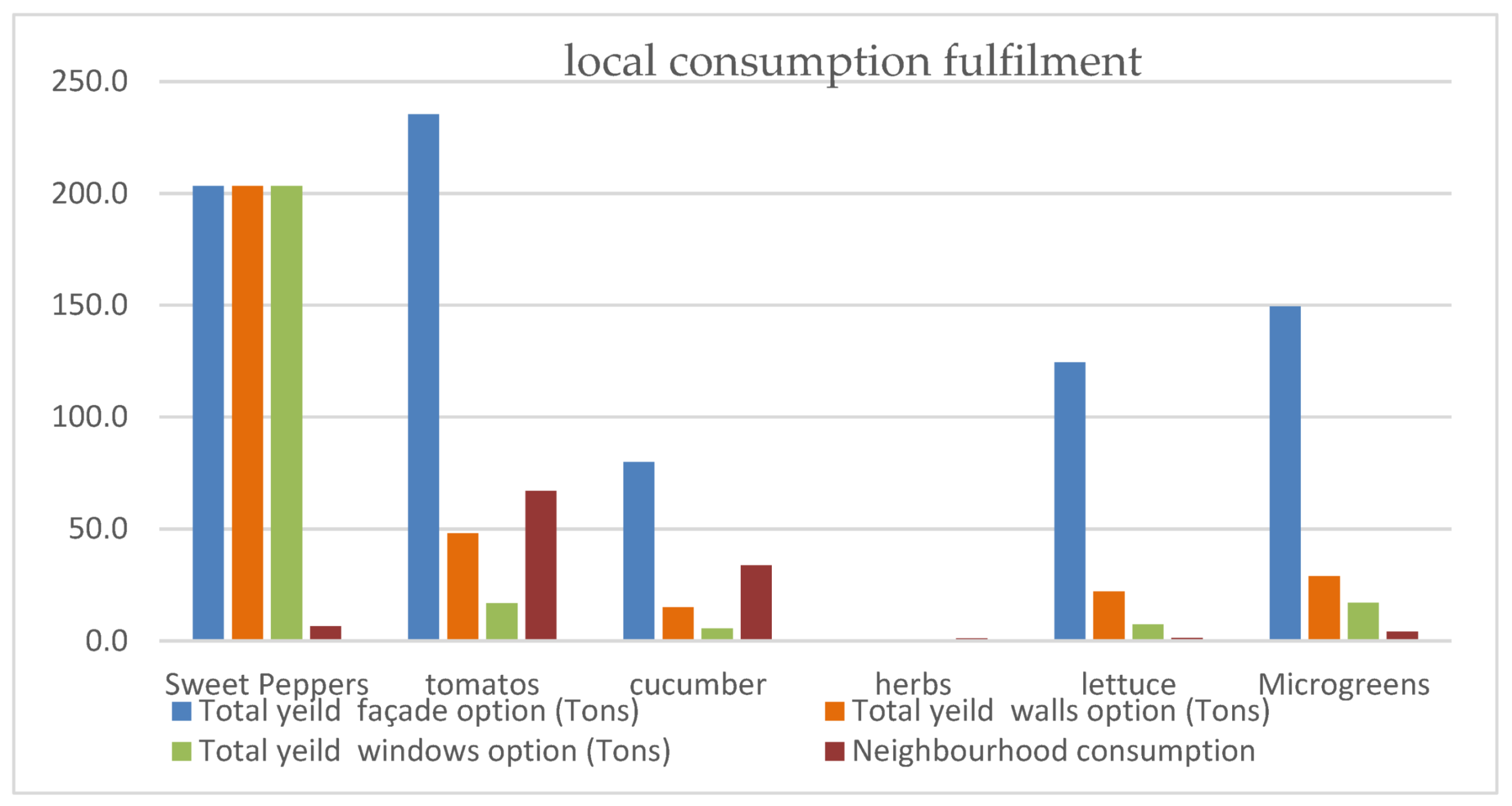

4.5.4. Total Productivity

4.6. AGRI|gen\Analysis Tool Output and Findings

5. The Design Process

5.1. Design Concept

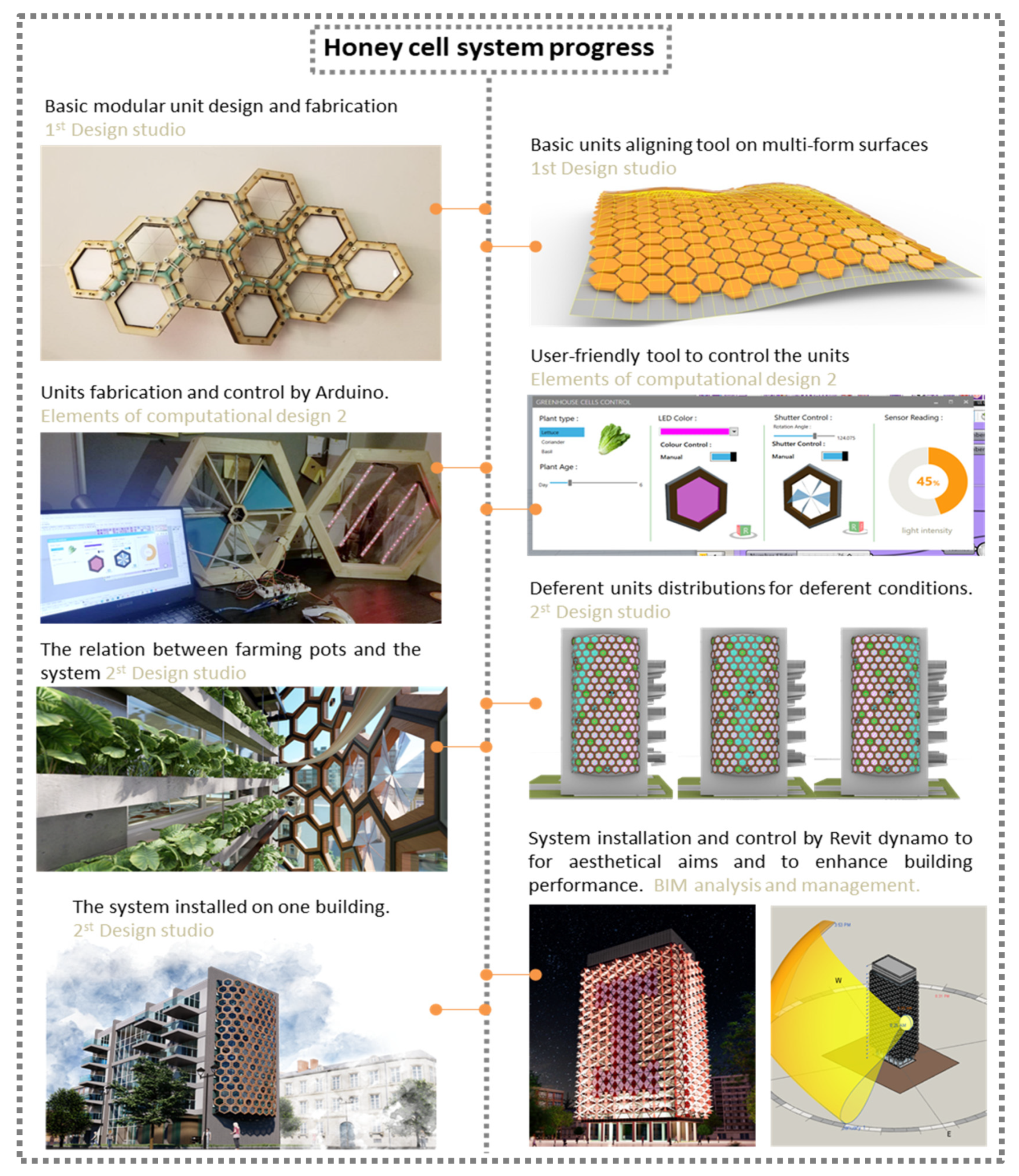

5.1.1. Previous Related Work

5.1.2. AGRI|gen\Design Tool Target

5.1.3. Units Definition

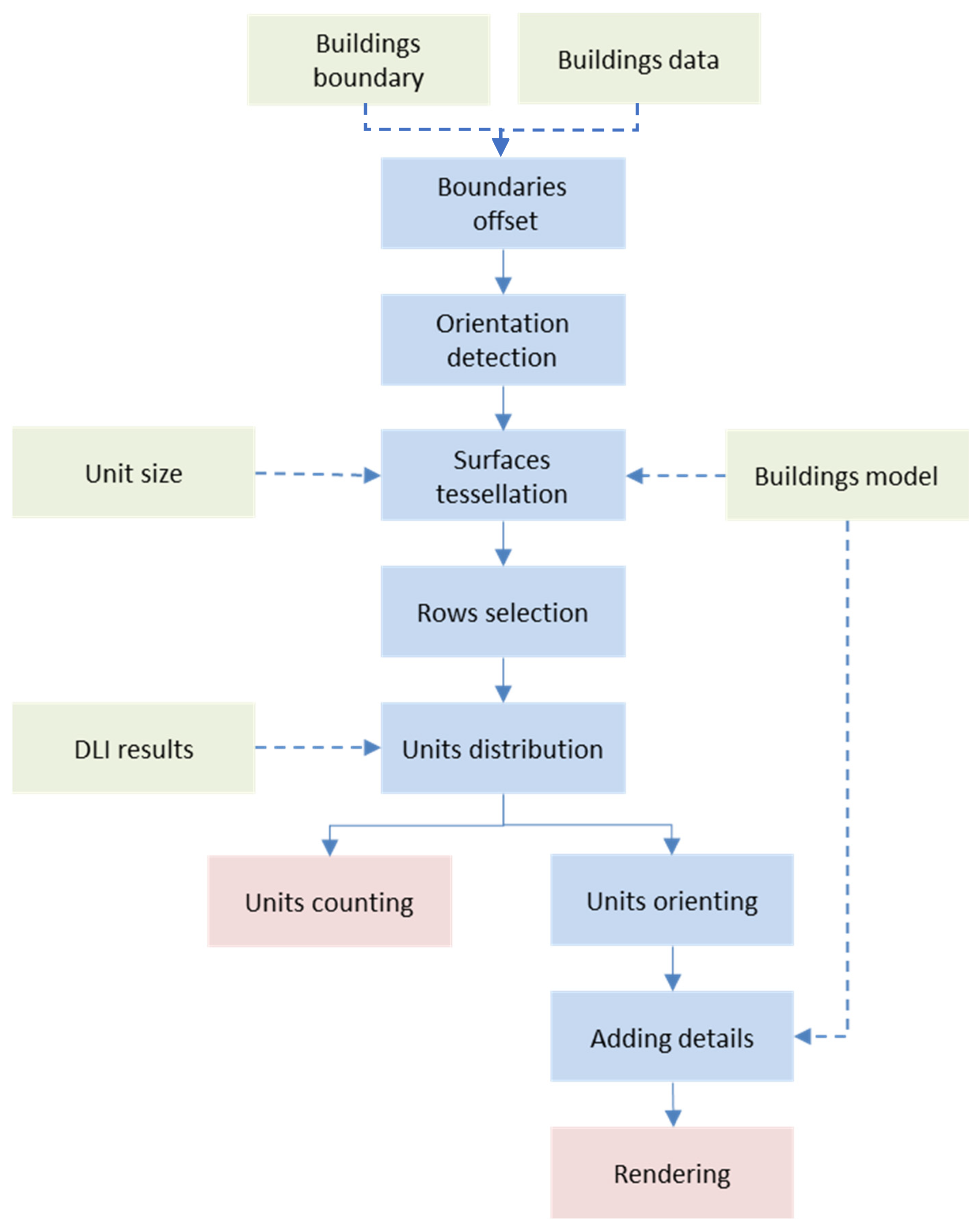

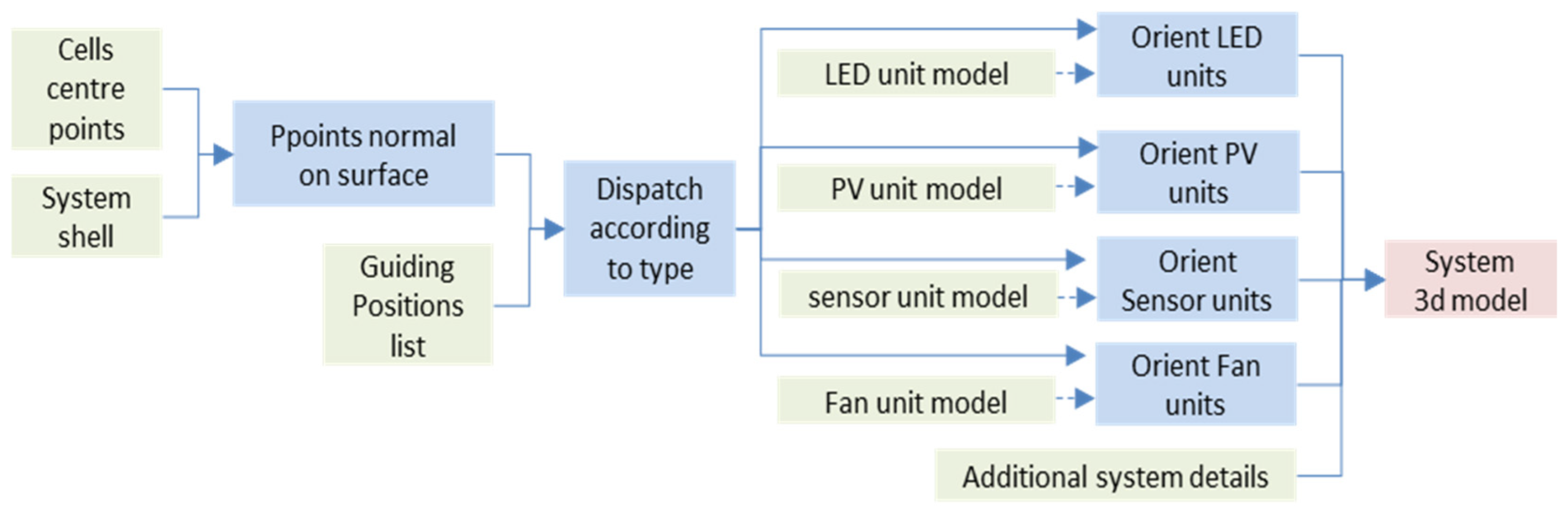

5.2. General AGRI|gen\Design Tool Algorithm

5.3. AGRI|gen\Design Tool Inputs

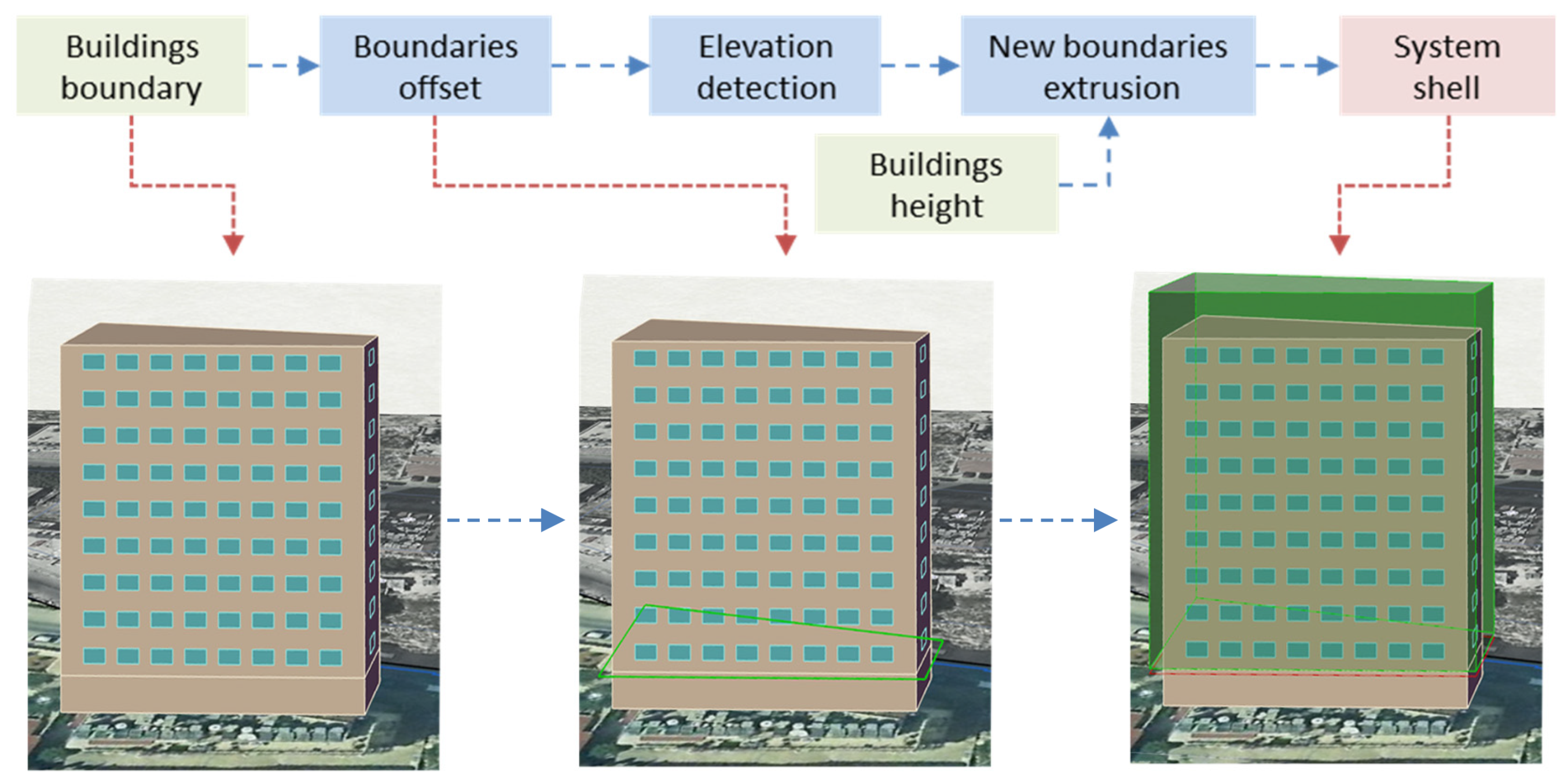

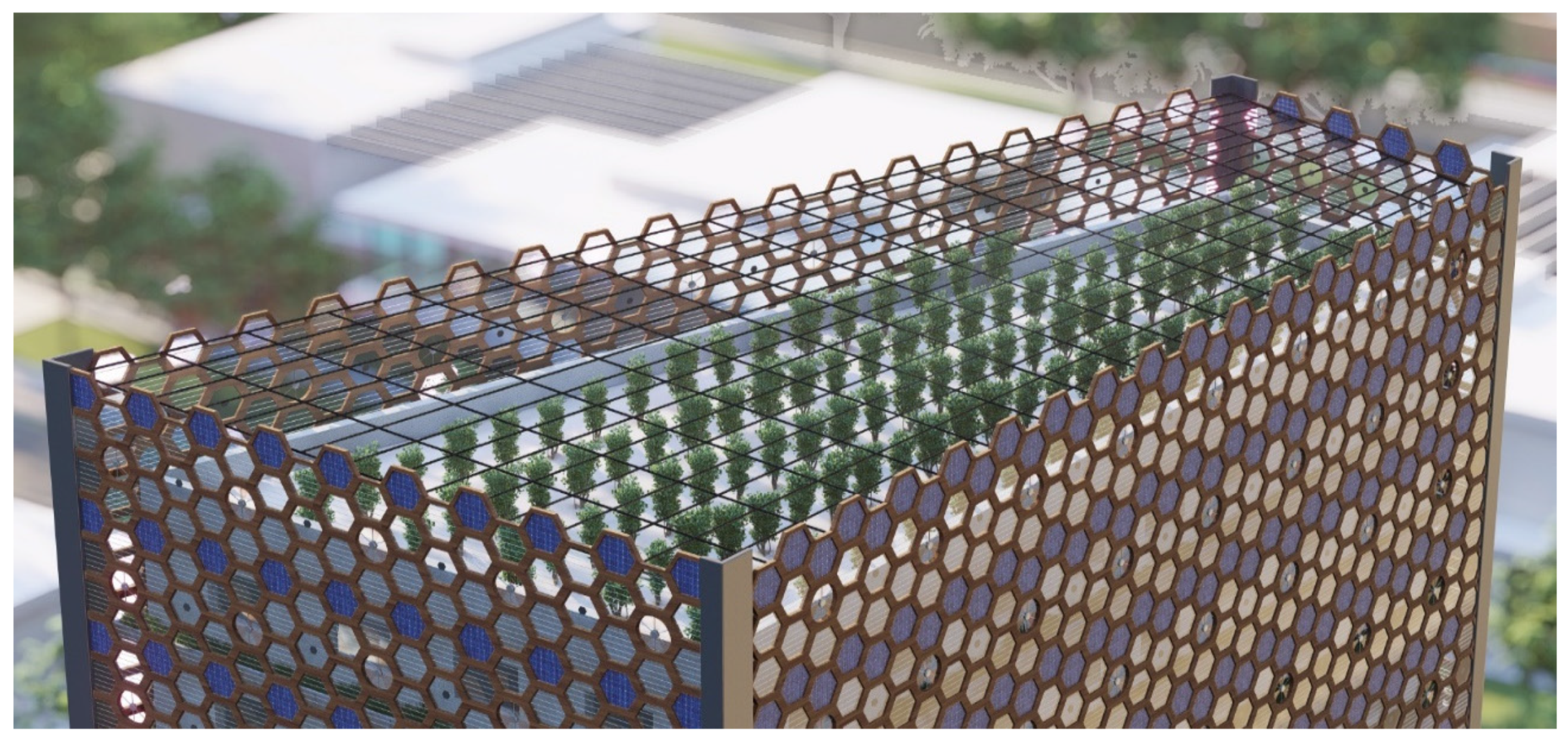

5.4. Shell Modelling

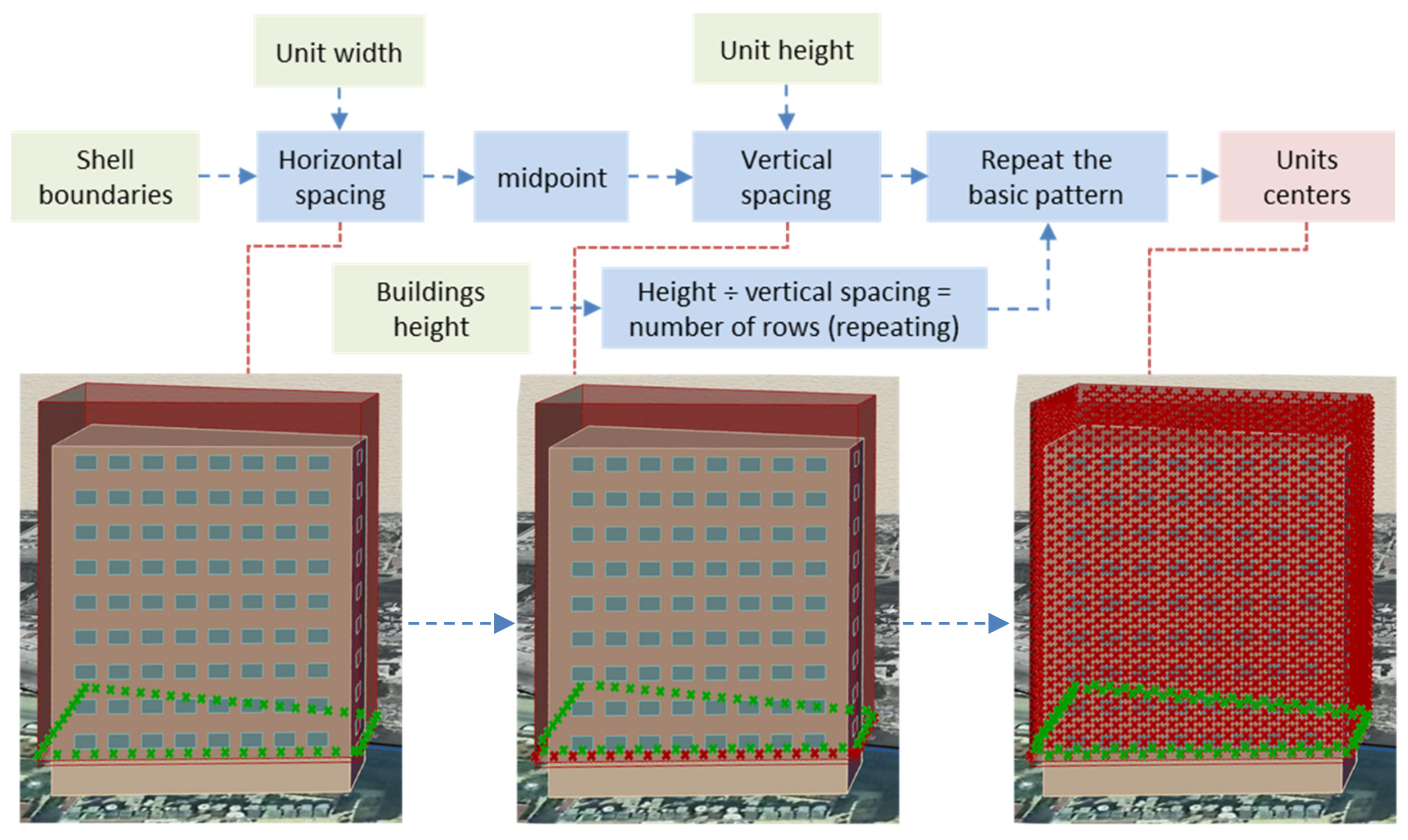

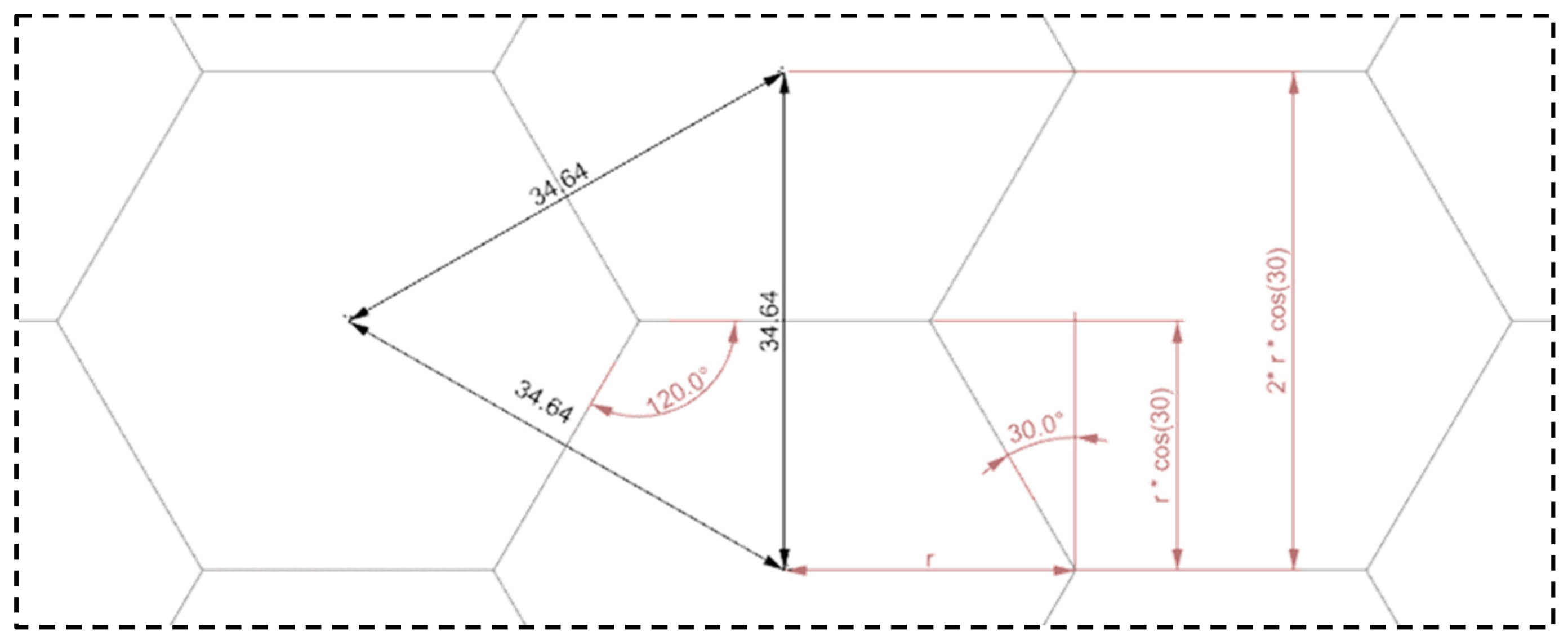

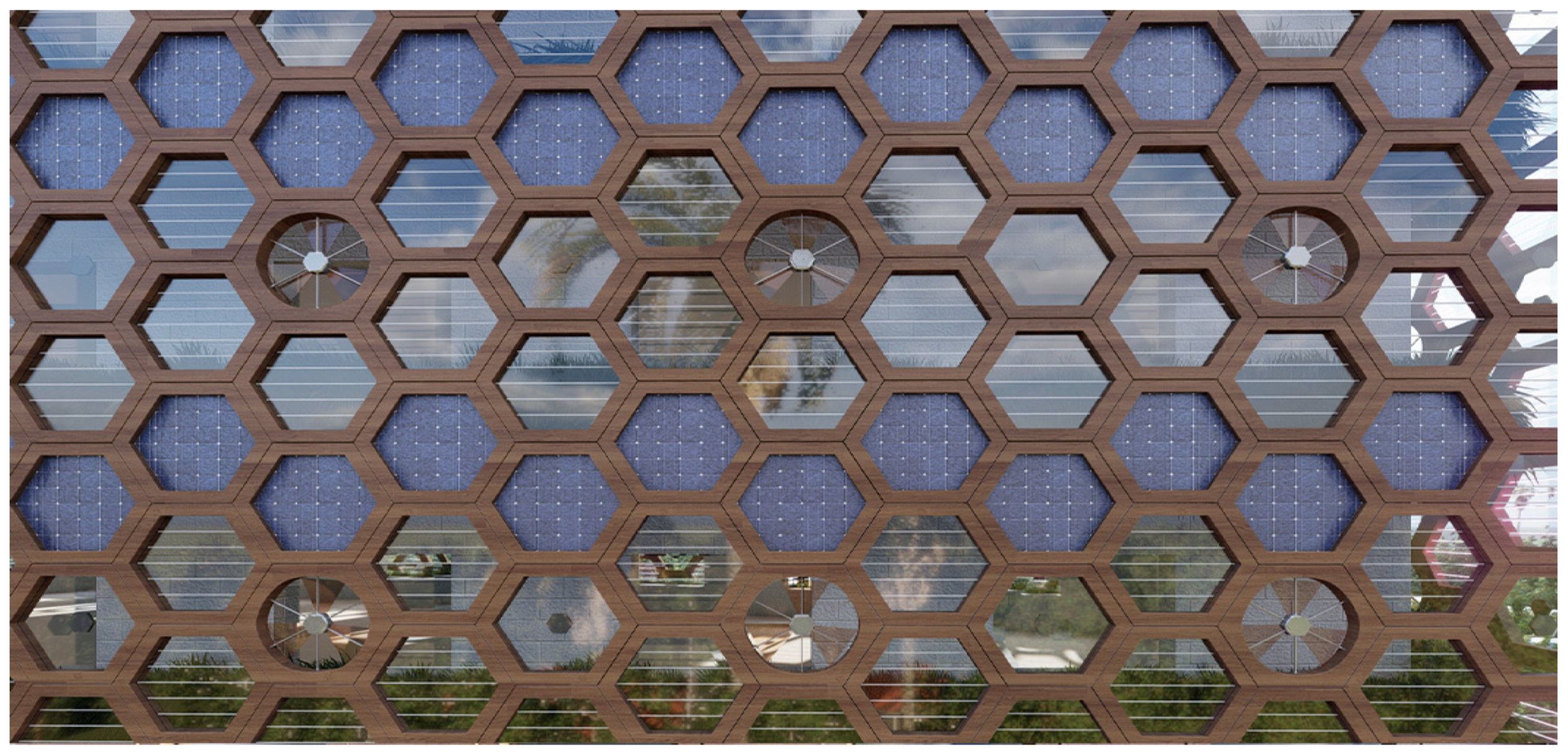

5.5. Facade Tessellation

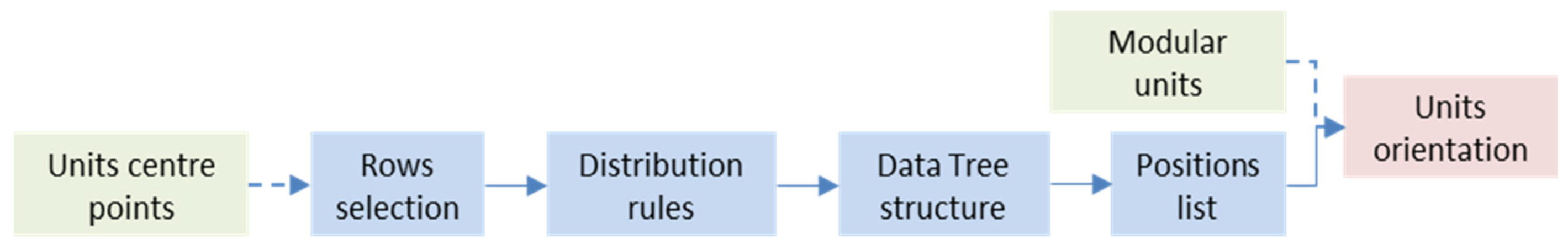

5.6. Units Distribution

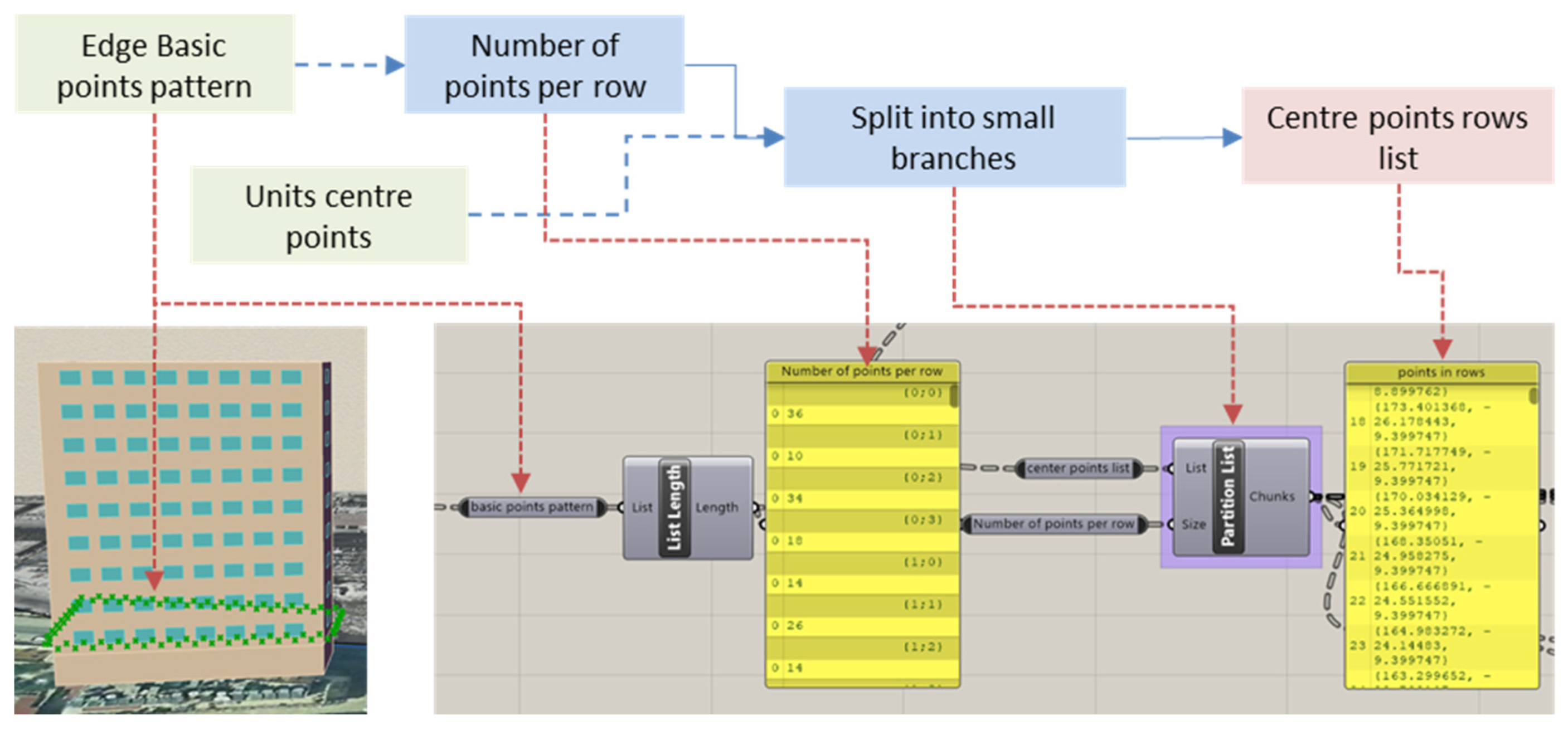

5.6.1. Rows Selection

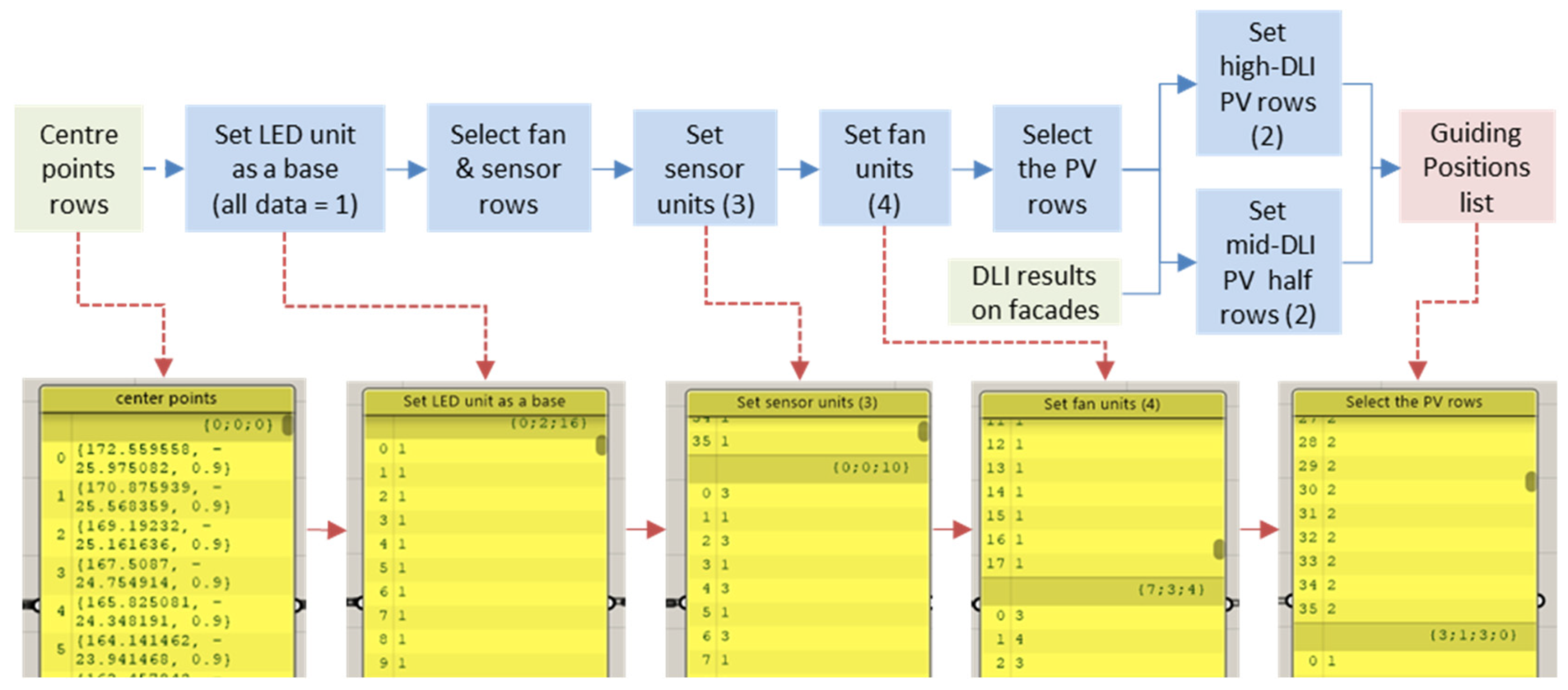

5.6.2. Distribution Rules

- Each facade is divided into equal rows; to have a repeatable pattern on each floor.

- LED units should be the default unit for all point centres (to serve as a primary basis).

- PV units should not be in front of windows; in order not to block the view and ventilation.

- PV units should take a full row in high DLI facades, half a row in mid-DLI facades, and no rows in low DLI facades; as their main role is to provide shading (for the residents) and generate electricity.

- Sensor and fan units should be placed at a fixed distance in the row (to be evenly distributed).

- Technically, to implement those rules the following algorithm was used (see Figure 30).

5.6.3. Data Tree Structure

5.6.4. Units Orientation

5.7. Roof Design

5.8. Final Results Analysis

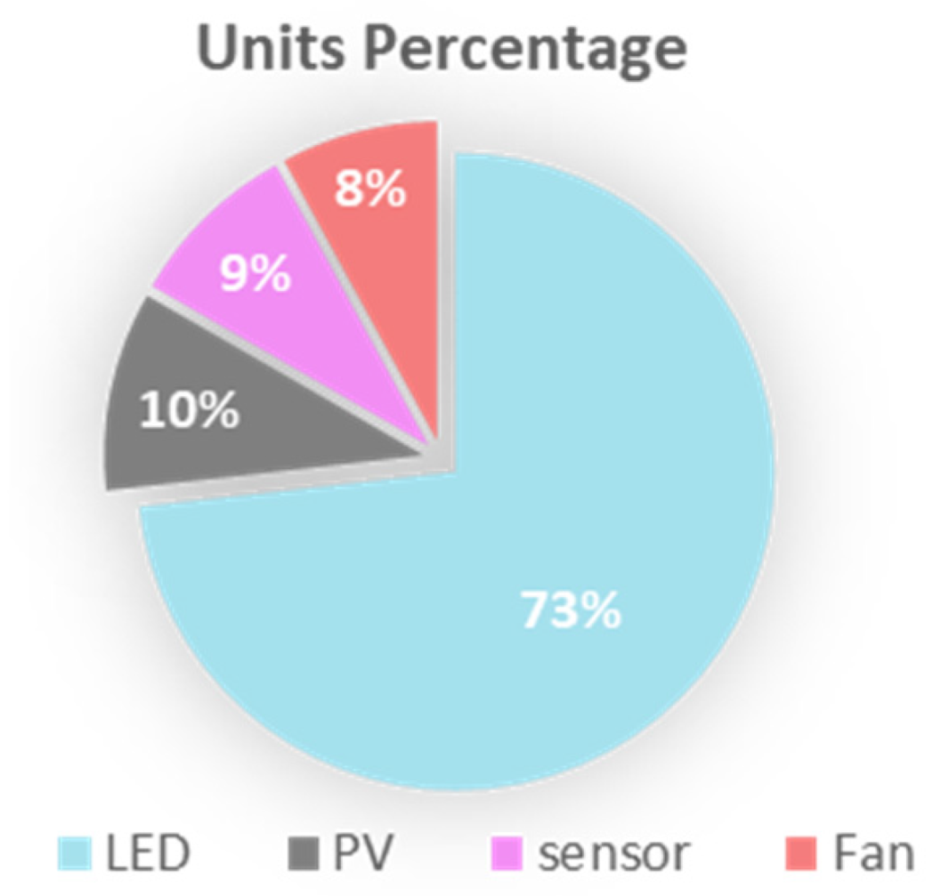

5.8.1. Units Count and Costs

5.8.2. Facade Patterns

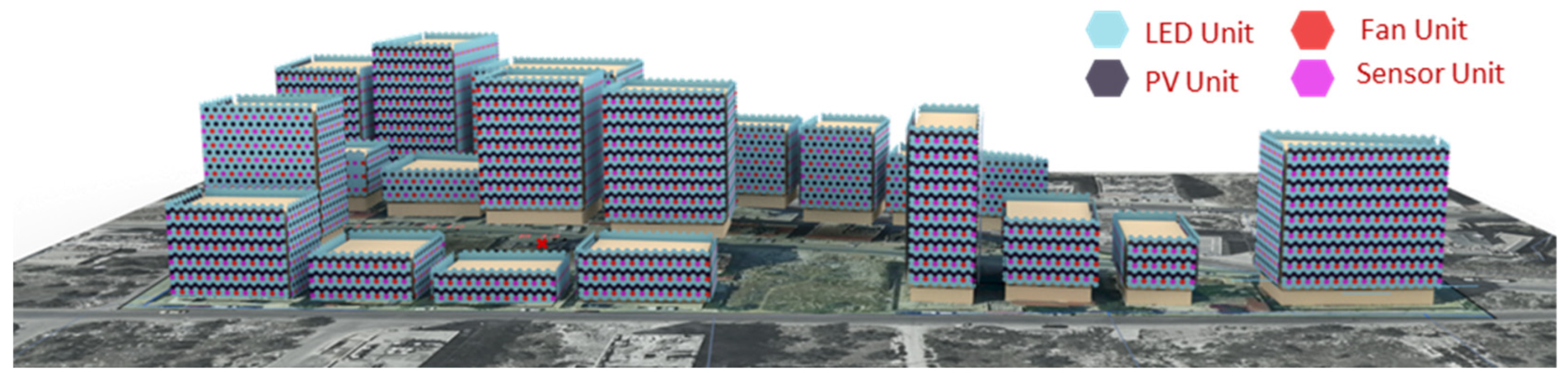

5.8.3. Visualisation

6. Conclusions and Recommendations

6.1. Conclusions

6.2. Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lorenz, K.; Lal, R. Carbon Sequestration in Agricultural Ecosystems, 1st ed.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Despommier, D. The Vertical Farm: Feeding the World in the 21st Century, 1st ed.; Macmillan: New York, NY, USA, 2010. [Google Scholar]

- Despommier, D. Vertical Farms in Horticulture BT-Encyclopedia of Food and Agricultural Ethics; Thompson, P.B., Kaplan, D.M., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 1791–1799. [Google Scholar] [CrossRef]

- Haworth, T. How Much Does Vertical Farming Cost? (2022 Start-Ups Costs & Profit Return). Available online: https://cambridgehok.co.uk/news/how-much-does-vertical-farming-cost (accessed on 25 August 2022).

- Bustami, R.A.; Belusko, M.; Ward, J.; Beecham, S. Vertical greenery systems: A systematic review of research trends. Build. Environ. 2018, 146, 226–237. [Google Scholar] [CrossRef]

- Tablada, A.; Kosorić, V.; Huang, H.; Chaplin, I.K.; Lau, S.K.; Yuan, C.; Lau, S.S.Y. Design optimisation of productive Façades: Integrating photovoltaic and farming systems at the tropical technologies laboratory. Sustainability 2018, 10, 3762. [Google Scholar] [CrossRef] [Green Version]

- Jabi, W. Parametric Design for Architecture; Laurence King: London, UK, 2013. [Google Scholar]

- Bradley, S. The Benefits of Modular Design—Vanseo Design. Available online: https://vanseodesign.com/web-design/modular-benefits/ (accessed on 31 August 2022).

- Palestinian Central Bureau of Statistics. Palestine Statistical Yearbook 2017; Palestinian Central Bureau of Statistics: Ramallah, Palestine, 2017.

- Robert McNeel and Associates. Rhino Grasshopper 7.0; Robert McNeel and Associates: Seattle, WA, USA, 2020. [Google Scholar]

- Roudsari, M.S.; Mackey, C. Ladybugtools 0.0.69; Ladybug Tools LLC: Fairfax, VA, USA, 2017. [Google Scholar]

- Sevaldson, B. Discussions & Movements in Design Research: A systems approach to practice research in design. Form Akad. 2010, 3, 8–35. [Google Scholar] [CrossRef] [Green Version]

- Morrison, A.; Sevaldson, B. Getting Going Research by Design. FORMakademisk 2010, 3, 1–7. [Google Scholar] [CrossRef]

- Davidová, M. Systemic Approach to Architectural Performance: The Media Mix in the Creative Design Process. FormAkademisk-Res. J. Des. Des. Educ. 2017, 10, 1–25. [Google Scholar] [CrossRef]

- Schön, D.A. The Reflective Practitioner: How Professionals Think in Action; Basic Books: London, UK, 1992. [Google Scholar]

- Cross, N. Design Thinking: Understanding How Designers Think and Work; Berg Publishers: Oxford, UK, 2011. [Google Scholar]

- FAO. Proceedings of the Expert Meeting on How to Feed the World in 2050; FAO: Rome, Italy, 2009; p. 35. [Google Scholar]

- Vermeulen, S.J.; Campbell, B.M.; Ingram, J.S.I. Climate change and food systems. Annu. Rev. Environ. Resour. 2012, 37, 195–222. [Google Scholar] [CrossRef] [Green Version]

- Karimi, L.; Ghassemi, A. Rural Desalination. In A Multidisciplinary Introduction to Desalination; River Publishers: New York, NY, USA, 2022; pp. 531–558. [Google Scholar]

- Ungureanu, N.; Vlăduț, V.; Voicu, G. Water scarcity and wastewater reuse in crop irrigation. Sustainability 2020, 12, 9055. [Google Scholar] [CrossRef]

- Dankova, R. Agriculture Holds the Key to Tackling Water Scarcity. 2016. Available online: https://blogs.worldbank.org/water/agriculture-holds-key-tackling-water-scarcity (accessed on 31 August 2022).

- Ritchie, H.; Roser, M. Urbanization—Our World Data. Available online: https://ourworldindata.org/urbanization (accessed on 24 October 2022).

- Nadal, A.; Cerón Palma, I.; Cuerva Contreras, E.; Gabarrell Durany, X.; Josa Garcia-Tornel, A.; Rieradevall Pons, J.; Pons Valladares, O.; Sanyé-Mengual, E. Urban agriculture in the framework of sustainable urbanism. Temes Disseny 2015, 31, 92–103. [Google Scholar]

- Campos Mühlenhoff, S. Food System Transformations: Social Movements, Local Economies, Collaborative Networks; Cambridge University Press: Cambridge, UK, 2022; Volume 37. [Google Scholar] [CrossRef]

- Armstrong, D. A survey of community gardens in upstate New York: Implications for health promotion and community development. Health Place 2000, 6, 319–327. [Google Scholar] [CrossRef] [PubMed]

- Pirog, R.; Van Pelt, T.; Enshayan, K.; Cook, E. Food, Fuel, and Freeways: An Iowa perspective on how far food travels, fuel usage, and greenhouse gas emissions. Leopold Cent. Sustain. Agric. 2001, 209, 37. [Google Scholar]

- What Is Urban Agriculture? Types and Benefits of Urban Agriculture—Conserve Energy Future n.d. Available online: https://www.conserve-energy-future.com/types-and-benefits-urban-agriculture.php (accessed on 31 August 2022).

- Taib, N.; Prihatmanti, R. Optimising balcony for green spaces: Application of edible biofaçade on urban high-rise setting. Plan. MALAYSIA 2018, 16, 98–109. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Kalantari, F.; Ting, K.C.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–12. [Google Scholar] [CrossRef]

- Derbas, G. The Planning and Design of Vertical farms: Prospects for Urban Farming in Palestine. Master Dissertation, The University of Jordan, Amman, Jordan, 2012. [Google Scholar]

- Safikhani, T.; Abdullah, A.M.; Ossen, D.R.; Baharvand, M. A review of energy characteristic of vertical greenery systems. Renew. Sustain. Energy Rev. 2014, 40, 450–462. [Google Scholar] [CrossRef]

- Ottelé, M. Vertical greening systems and the effect on air flow and temperature on the building envelope. Build. Environ. 2011, 46, 2287–2294. [Google Scholar]

- Perini, K.; Ottelé, M.; Haas, E.M.; Raiteri, R. Vertical greening systems, a process tree for green façades and living walls. Urban Ecosyst. 2013, 16, 265–277. [Google Scholar] [CrossRef]

- Manso, M.; Castro-Gomes, J. Green wall systems: A review of their characteristics. Renew. Sustain. Energy Rev. 2015, 41, 863–871. [Google Scholar] [CrossRef]

- Walch, J. Hydroponic-Urban-Gardening Hydroponic: Hydroponics—Optimal Growing Conditions n.d. Available online: https://www.hydroponic-urban-gardening.com/hydroponics-guide/hydroponics-optimal-growing-conditions/?L=1 (accessed on 19 August 2020).

- Eden Green Technology 10 Benefits of Hydroponics|Eden Green n.d. Available online: https://www.edengreen.com/blog-collection/benefits-of-hydroponics (accessed on 19 November 2022).

- Ćavar Zeljković, S.; Aucique-Perez, C.E.; Štefelová, N.; De Diego, N. Optimizing growing conditions for hydroponic farming of selected medicinal and aromatic plants. Food Chem. 2022, 375, 131845. [Google Scholar] [CrossRef] [PubMed]

- McCree, K.J. Photosynthetically Active Radiation BT—Physiological Plant Ecology I: Responses to the Physical Environment; Lange, O.L., Nobel, P.S., Osmond, C.B., Ziegler, H., Eds.; Springer: Berlin/Heidelberg, Germany, 1981; pp. 41–55. [Google Scholar] [CrossRef]

- DLI (Daily Light Integral) Chart—Understand Your Plants’ PPFD & Phot—LEDTonic n.d. Available online: https://www.ledtonic.com/blogs/guides/dli-daily-light-integral-chart-understand-your-plants-ppfd-photoperiod-requirements (accessed on 5 October 2022).

- Palliwal, A.; Song, S.; Tan, H.T.W.; Biljecki, F. 3D city models for urban farming site identification in buildings. Comput. Environ. Urban Syst. 2021, 86, 101584. [Google Scholar] [CrossRef]

- Mary wickison 25 of the Best Plants for Indoor Hydroponic Gardens—Dengarden. 2022. Available online: https://dengarden.com/gardening/indoor-hydroponic-garden (accessed on 19 November 2022).

- Day, M. Rhino Grasshopper—AEC Magazine; X3DMedia: London, UK, 2009; pp. 49–56. [Google Scholar]

- Shi, X.; Yang, W. Performance-driven architectural design and optimization technique from a perspective of architects. Autom. Constr. 2013, 32, 125–135. [Google Scholar] [CrossRef]

- Grasshopper 3D—c—We Think Forward n.d. Available online: http://www.sentragrafika.com/grasshopper-and-learning-session.html (accessed on 24 October 2022).

- UN Habitat. National Report on Housing and Sustainable Urban Development; UN Habitat: Ramallah, Palestine, 2014. [Google Scholar]

- Abdelnour, S.; Agha, Z.; Baconi, T.; Dajani, M.; Kattan, V.; Sansour, V.; Tartir, A.; Zurayk, R. Focus On: Palestine’s Natural Resources—Al-Shabaka. Available online: https://al-shabaka.org/focuses/focus-on-palestines-natural-resources/ (accessed on 31 August 2022).

- Palestine GDP from Agriculture Forestry and Fishing—2022 Data—2023 Forecast. Available online: https://tradingeconomics.com/palestine/gdp-from-agriculture (accessed on 18 November 2022).

- Ministry of Foreign Affairs of the Netherlands. Climate Change Profile: Palestinian Territories; Ministry of Foreign Affairs of the Netherlands: Rotterdam, The Netherlands, 2018.

- Khader, A.; Martin, R.S. Use of Low-Cost Ambient Particulate Sensors in Nablus, Palestine with Application to the Assessment of Regional Dust Storms. Atmosphere 2019, 10, 539. [Google Scholar] [CrossRef] [Green Version]

- Nablus Municipality. Available online: http://nablus.org/index.php/en/nablus-city (accessed on 3 September 2020).

- An-Najah National University An-Najah National University: Nablus City. An-Najah Natl Univ 2022. Available online: https://www.najah.edu/en/about/history-and-traditions/nablus-city/ (accessed on 12 February 2023).

- Nablus Climate, Weather by Month, Average Temperature (Palestinian Territories)—Weather Spark. Available online: https://weatherspark.com/y/98966/Average-Weather-in-Nablus-Palestinian-Territories-Year-Round (accessed on 18 November 2022).

- Geomolg Geospatial Web Mapping Application In Palestine n.d. Available online: https://geomolg.ps/ (accessed on 10 August 2022).

- Marcelis, L.F.M.; Broekhuijsen, A.G.M.; Meinen, E.; Nijs, E.M.F.M.; Raaphorst, M.G.M. Quantification of the growth response to light quantity of greenhouse grown crops. In Proceedings of the Acta Horticulturae, Lillehammer, Norway, 21–24 June 2005; International Society for Horticultural Science (ISHS): Leuven, Belgium, 2006; pp. 97–104. [Google Scholar] [CrossRef]

- ASHRAE. 2015 ASHRAE HANDBOOK; ASHRAE: Atlanta, GA, USA, 2015. [Google Scholar]

- Climate.Onebuilding.org n.d. Available online: https://climate.onebuilding.org (accessed on 31 August 2022).

- WEATHER DATA|EnergyPlus n.d. Available online: https://energyplus.net/weather (accessed on 12 September 2022).

- Living Standards in the Palestinian Territory Expenditure, Consumption, Poverty, 2011; Palestinian Central Bureau of Statistics: Ramallah, Palestine, 2011.

- DLI Calculator—Agritecture n.d. Available online: https://www.agritecture.com/dli-calculator (accessed on 31 August 2022).

- Van Iersel, M. Can I Convert PAR (Photo Active Radiation) Value of Micro Mole/M2/S to Solar Radiation in Watt/m2? 2017. Available online: https://www.researchgate.net/post/Can-I-convert-PAR-photo-active-radiation-value-of-micro-mole-M2-S-to-Solar-radiation-in-Watt-m2 (accessed on 22 November 2022).

- Reem Abu-Laban What Are the Differences in the Prices of a Dunum of Land between the Palestinian Governorates? Aliqtisadi n.d. Available online: https://www.aliqtisadi.ps/article/5255/ما-هي-الاختلافات-في-أسعار-دونم-الأرض-بين-المحافظات-الفلسطينية؟ (accessed on 31 August 2022).

| Common Name | Latin Name |

|---|---|

| Tarragon | Artemisia dracunculus L. |

| Peppermint | Mentha x piperita L. |

| Green Mint | Mentha L. [such as: Mentha x piperita L. Mentha spicata L. Mentha pulegium L.] |

| Oregano | Origanum vulgare L. |

| Basil | Ocimum basilicum L. |

| Sage | Salvia officinalis L. |

| Stevia | Stevia rebaudiana (Bertoni) Hemsl. |

| Lemon Balm | Melissa officinalis L. |

| Rosemary | Rosmarinus officinalis L. |

| Common Name | Latin Name |

|---|---|

| Lettuce | Lactuca sativa L. |

| Spinach | Spinacia oleracea L. |

| Bok Choy | Brassica chinensis L. |

| Tomatoes | Solanum lycopersicum L. |

| Peppers | Capsicum annuum L. |

| Cucumber | Cucumis sativus L. |

| Celery | Apium graveolens L. |

| Crop | Required DLI | Required Temperature | Consumption kg\Family per Month | Productivity kg\m2 per Year |

|---|---|---|---|---|

| Sweet peppers | 25–50 | 17–24° | 1.556 | 27.7 |

| Tomatoes | 20–50 | 17–19° | 16.128 | 33 |

| Cucumber | 20–35 | 17–27° | 8.107 | 35 |

| Herbs | 15–20 | 15–24° | 0.243 | 0.6 |

| Lettuce | 12–18 | 15–25° | 0.289 | 41 |

| Microgreens | 10–20 | 18–24° | 1.002 | 105.2 |

| Crop | Consumption (kg\Family per Month) |

|---|---|

| Tomato | 16.128 |

| Cucumber | 8.107 |

| Sweet peppers | 1.556 |

| Herbs | 0.243 |

| Lettuce | 0.289 |

| Microgreens (Spinach) | 1.002 |

| Crops | Family Consumption kg\Month | Neighbourhood Consumption kg\Month | Ton\Year |

|---|---|---|---|

| Tomatoes | 16.128 | 5580 | 66.96 |

| Cucumber | 8.107 | 2805 | 33.66 |

| Green peppers | 1.556 | 538 | 6.456 |

| Lettuce | 0.289 | 100 | 1.2 |

| Spinach | 1.002 | 347 | 4.164 |

| Thyme | 0.243 | 84.078 | 1.008936 |

| Total Planting Areas | |||||

|---|---|---|---|---|---|

| Elevations | Roof | ||||

| Plant | Facade Area | Walls Area | Windows Area | Plant | Area |

| Sweet Peppers | 0 | 0 | 0 | Sweet Peppers | 7339.9 |

| Tomato | 7130.7 | 1452.5 | 510 | Tomato | 0 |

| cucumber | 2279.6 | 430 | 156 | cucumber | 0 |

| Herbs | 593.3 | 90 | 42 | Herbs | 0 |

| lettuce | 3036.1 | 537.5 | 180 | lettuce | 0 |

| Microgreens | 1421.7 | 275 | 162 | Microgreens | 0 |

| Poor DLI | 14,107.6 | 2685 | 1188 | Poor DLI | 0 |

| Total area | 28,569 | 5470 | 2238 | Total area | 7339.9 |

| Total Crops Yields | |||||

|---|---|---|---|---|---|

| Crop | Yield kg\m2 | Total Yield Façade Option (Tons) | Total Yield Walls Option (Tons) | Total Yield Windows Option (Tons) | |

| Facade | Roof | ||||

| Sweet Peppers | - | 27.7 | 203.3 | 203.3 | 203.3 |

| Tomato | 33 | - | 235.3 | 47.9 | 16.8 |

| Cucumber | 35 | - | 79.8 | 15.1 | 5.5 |

| Herbs | 0.6 | - | 0.4 | 0.1 | 0.03 |

| Lettuce | 41 | - | 124.5 | 22.0 | 7.4 |

| Microgreens | 105.2 | - | 149.6 | 28.9 | 17.0 |

| Local Consumption Fulfilment % | ||||

|---|---|---|---|---|

| Crop | Neighbourhood Consumption | Fulfilment % Facade Option | Fulfilment % Walls Option | Fulfilment % Windows Option |

| Sweet Peppers | 6.456 | 3149.24 | 3149.24 | 3149.24 |

| Tomato | 66.96 | 351.42 | 71.58 | 25.13 |

| cucumber | 33.66 | 237.04 | 44.71 | 16.22 |

| herbs | 1.01 | 35.28 | 5.35 | 2.50 |

| lettuce | 1.2 | 10,373.34 | 1836.46 | 615.00 |

| Microgreens | 4.164 | 3591.81 | 694.76 | 409.28 |

| Unit | LED | PV | Sensor | Fan | Total |

|---|---|---|---|---|---|

| Count | 29,896 | 4124 | 3557 | 3247 | 40,824 |

| percentage | 73.23% | 10.10% | 8.71% | 7.95% | 100% |

| expected cost\unit | 38.5 | 57.5 | 43.5 | 47.5 | - |

| Total cost $ | 1,150,996 | 237,130 | 154,729.5 | 154,232.5 | 1,697,088 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghazal, I.; Mansour, R.; Davidová, M. AGRI|gen: Analysis and Design of a Parametric Modular System for Vertical Urban Agriculture. Sustainability 2023, 15, 5284. https://doi.org/10.3390/su15065284

Ghazal I, Mansour R, Davidová M. AGRI|gen: Analysis and Design of a Parametric Modular System for Vertical Urban Agriculture. Sustainability. 2023; 15(6):5284. https://doi.org/10.3390/su15065284

Chicago/Turabian StyleGhazal, Iyad, Reema Mansour, and Marie Davidová. 2023. "AGRI|gen: Analysis and Design of a Parametric Modular System for Vertical Urban Agriculture" Sustainability 15, no. 6: 5284. https://doi.org/10.3390/su15065284

APA StyleGhazal, I., Mansour, R., & Davidová, M. (2023). AGRI|gen: Analysis and Design of a Parametric Modular System for Vertical Urban Agriculture. Sustainability, 15(6), 5284. https://doi.org/10.3390/su15065284