1. Introduction

Humidity is one of the essential factors of the greenhouse microclimate that should be maintained for optimum plant growth. Excessive humidity sometimes combines with the appearance of free water (condensation) to create favorable conditions for the development of fungal diseases and enhance leaf necrosis, as well as promoting the formation of soft and thin leaves [

1]. For these reasons, controlling the humidity inside greenhouses is a fundamental concern for better crop cultivation. The conventional method used to control the humidity level within a considerable range consumes significant energy. The primary concern of consuming significant energy is maintaining the low-cost dehumidifier, ventilation, and air conditioning system [

2,

3,

4]. Many energy-saving humidity control systems are being developed to reduce greenhouse energy utilization [

5,

6]. However, it is very challenging to achieve uniform humidity inside a greenhouse because it is directly related to the operational time and HVAC system [

2].

With respect to the control and uniformity of the inside greenhouse humidity level, the primary goal is to either “keep the humidity in” or “keep the humidity out” based on the plant growth threshold level [

5]. Research on the development of humidity-control techniques for greenhouses began in the 1940s [

7]. Researchers have attempted to establish the optimum humidity range for crop growth and define sustainable humidity ranges for the prevention of crop damage. Researchers have also reported several types of dehumidification systems (e.g., liquid desiccant dehumidification systems [

8,

9], solar desalination systems [

10,

11,

12], and compressor-type dehumidification systems [

13,

14]) to maintain a healthy relationship between crops and the inside greenhouse environment. In maximum greenhouses, stand-alone high-energy-consuming dehumidifiers are used to create the desired humidity level inside [

15]. However, a group of small dehumidifiers can provide a more uniform humidity distribution. Recently, for large greenhouses, some multizone independent control techniques with dehumidifiers have been introduced to control different zone environments using small independent control systems [

16]. A detailed experiment including humidity response and variability is needed to know the performance of the small dehumidifiers. Therefore, in this research, two different mediums (a closed chamber and a small greenhouse) were used to evaluate the performance of a single unit dehumidifier that could provide useful key outcomes for the management of advanced conditions such as large greenhouses with multizone dehumidifiers.

The humidity response and variability in greenhouses vitally influence the measurement of humidity uniformity in crop growth [

17]. Boulard et al. [

18] clarified that humidity usually drops on the greenhouse surface and in areas just above the floor and below the roof. Several researchers have focused on achieving uniform humidity distribution with various techniques. Considerable work has been conducted to improve the efficiency of natural ventilation in greenhouses by using the variability method to measure the uniformity level [

17,

19,

20,

21]. Kempkes and Van de Braak [

22] and Kempkes et al. [

23] checked the environmental uniformity to evaluate the effect of different component positions. Ahmed et al. [

24] and Al-Helal et al. [

25] investigated the spatial distribution of temperature and relative humidity by studying several greenhouses covers. The humidity response plays a crucial role in evaluating the humidity distribution over time. Different layers and planes’ humidity levels are needed to find the humidity distribution at different conditions. Therefore, humidity response and variability were studied using the humidity condition for the dehumidifier operation, which is typically used to analyze different layers on spatial and vertical planes.

Recently, different dehumidifying techniques have been used, including vapor compression [

26] and desiccant dehumidifier [

27]. The conventional type of dehumidifier is located in one or two locations in a greenhouse. This type of dehumidifier needs a high electric load (5–20 kW), space, and operational cost. On the other hand, this study used a condensation system. The main advantages of this approach include compact, safe, low power (0.5 kW), and noiseless technology that can have a significant impact on dehumidifying the greenhouse as well as on sustainable agriculture. Previously, the low-powered dehumidifier was mainly used to generate freshwater from ambient air and an irrigation system in a greenhouse [

28]. We developed and evaluated the performance of the small-scale suspension-type dehumidifier to control the status of individual actuating components [

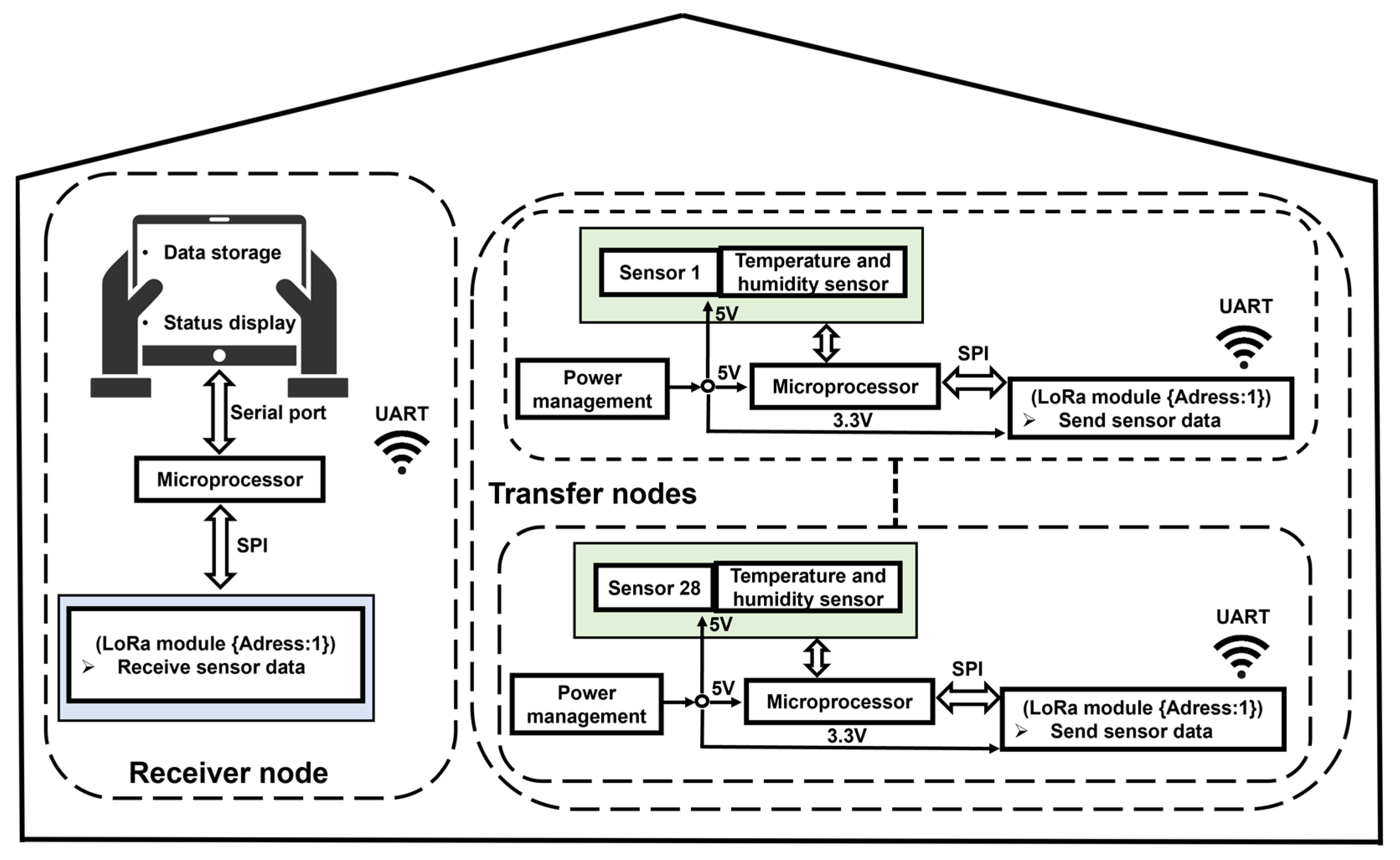

6] in the greenhouse. The basic performance of the suspension-type dehumidifier with a condensation cooling system was evaluated in greenhouses with regard to the remote monitoring and control of the components, the required time to achieve the target humidity, and the spatial and vertical variability of humidity to assist the dehumidifying process for the greenhouse.

Based on the previous research, this type of dehumidifier was designed to maintain low power, but the major challenge is keeping the humidity uniform due to the low efficiency [

29]. Before placing the dehumidifier modules in a commercial greenhouse, evaluation was necessary to investigate the dehumidifying behavior. The process of the low-powered suspension type is to install the units at multiple heights and locations in greenhouses to improve the response time and uniformity of the humidity control. Therefore, the objective of this study was to evaluate a low-powered suspension-type dehumidifier module in terms of humidity response and variability in a closed chamber without interaction with the outside, and a small greenhouse with interaction with the outside, to determine suitable conditions for various working environments.

4. Discussion

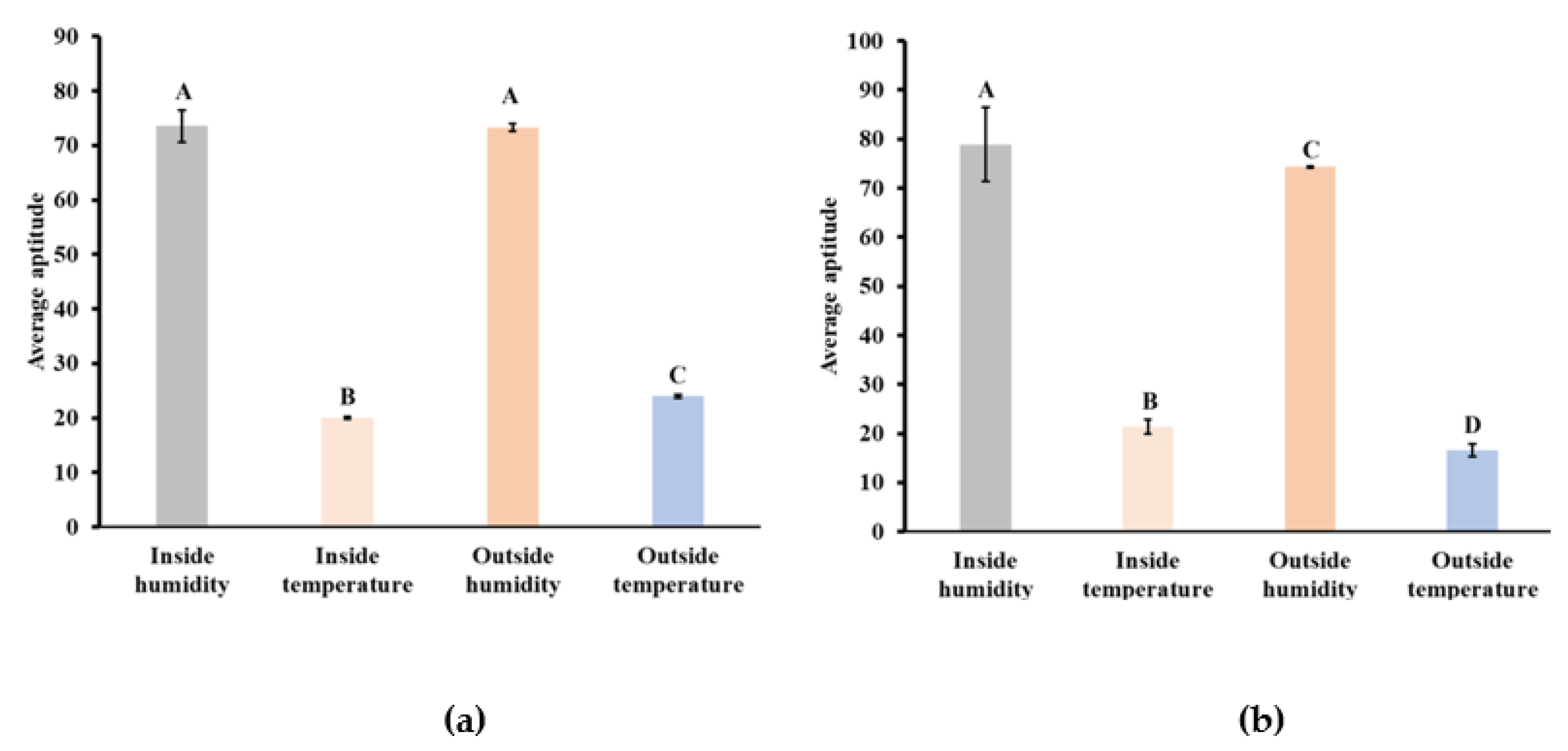

Figure 10 shows the temperature and humidity comparison when the humidity level was reduced from 80% to 70% and 90% to 70% for the small greenhouse. The 80% to 70% operation was taken only 18 min. Due to the short period of operation; the moisture removal rate was low, and no statistically significant difference was found between the inside and outside humidity. During the experiment, the indoor temperature remained constant for both test sites, and the performance of the low-powered dehumidifier module was affected by the humidity ratio of indoor air. The evaporator performance was also a key factor in maintaining the dehumidifier performance [

37]. A higher humidity ratio indicates a higher moisture removal rate. In the same manner, the dew point temperature and the evaporating temperature become higher accordingly. As a result, the coefficient of performance of the evaporator increases, which decreases the power and enhances the efficiency of the dehumidification system. The outside temperature shows less impact on the performance of the dehumidifier module. On the other hand, in the 90% to 70% condition, the operation time and moisture removal rate were higher than 80% to 70%. As a result, there has a significant difference between the inside and outside humidity.

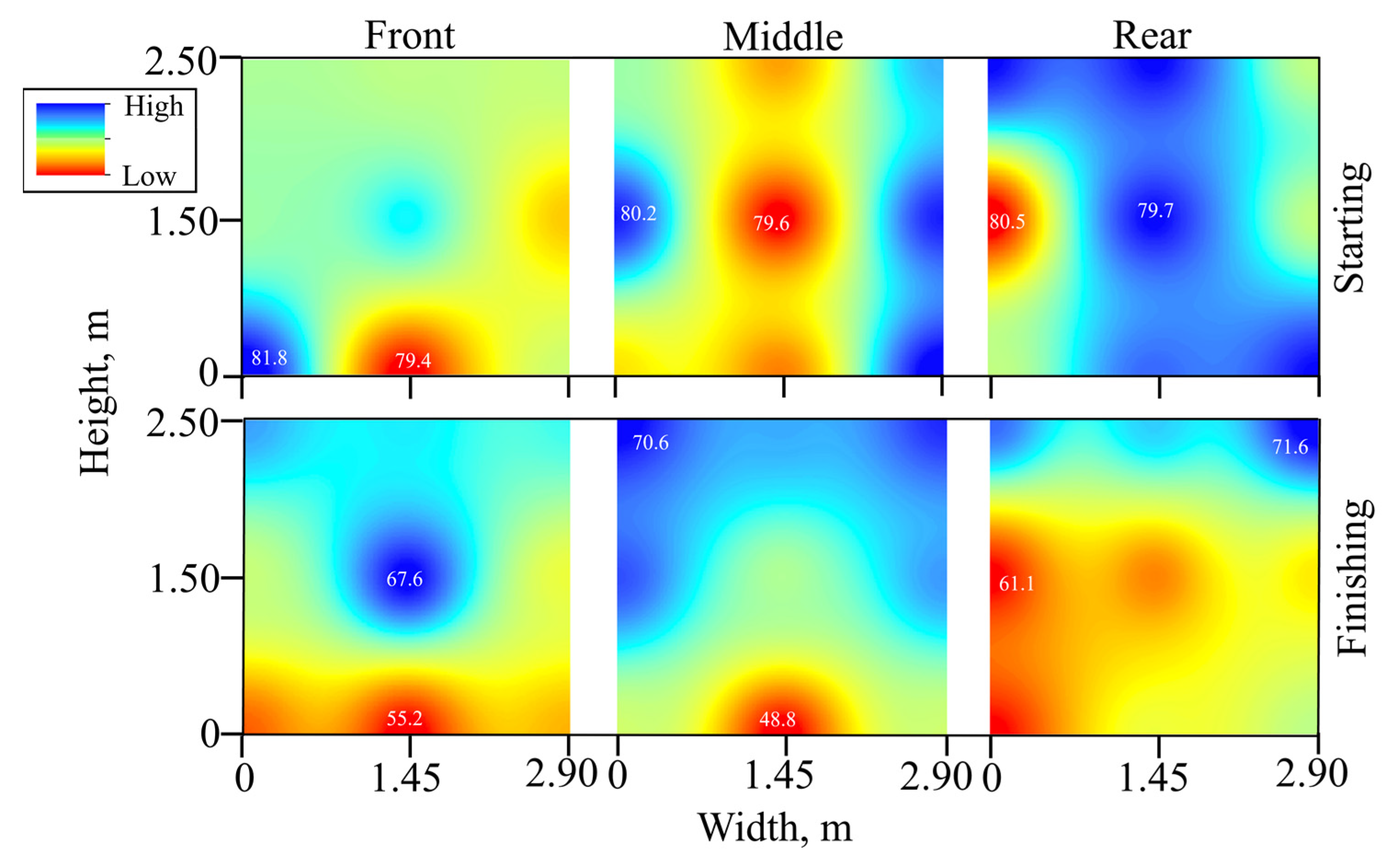

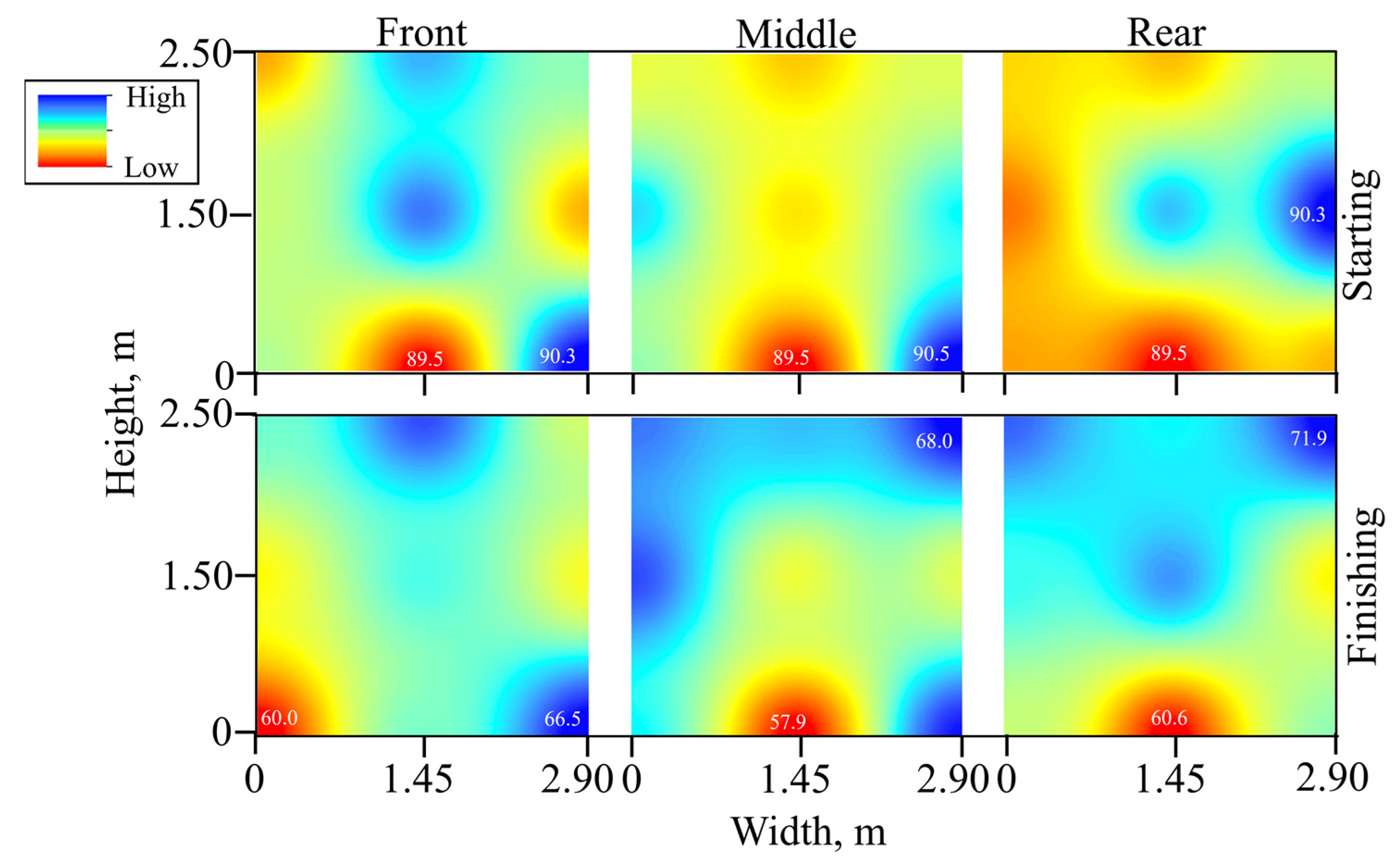

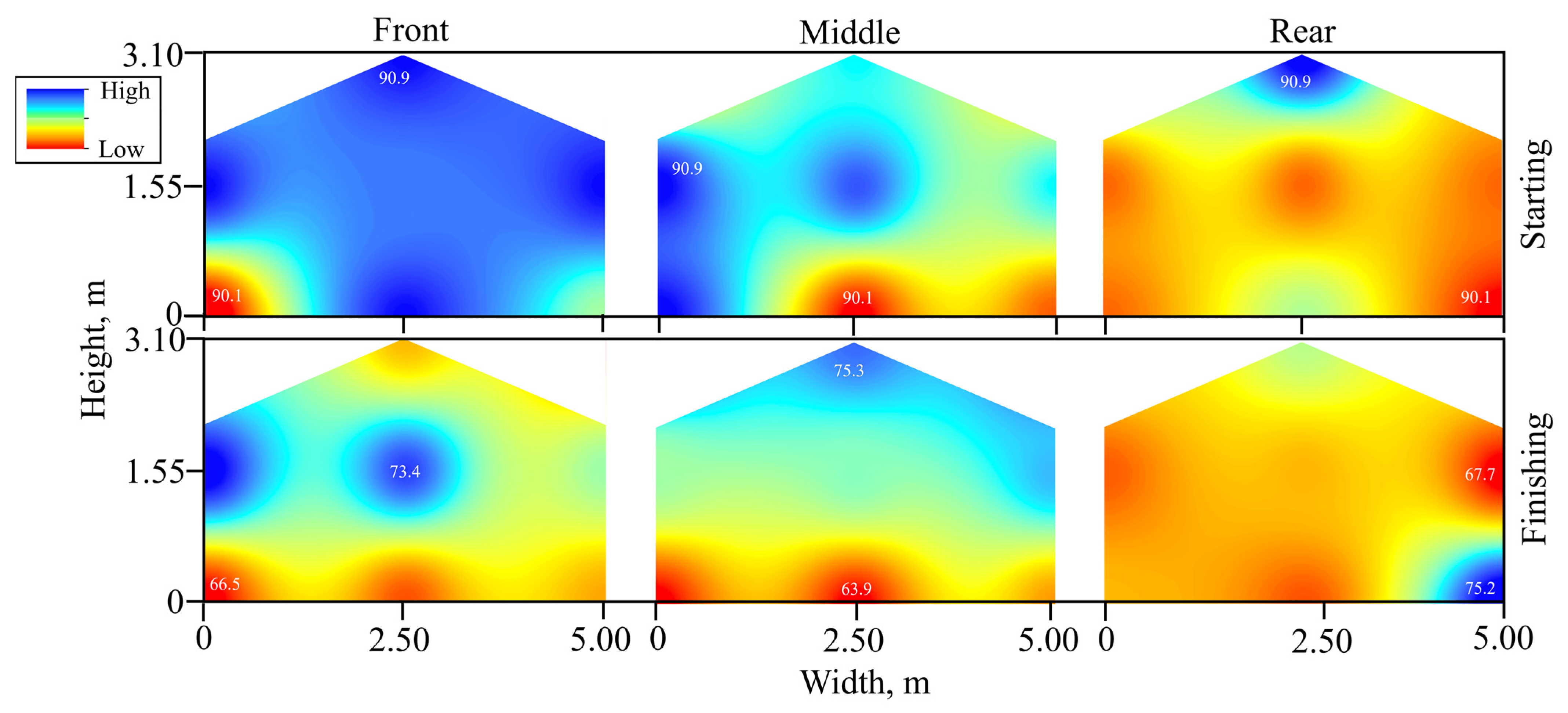

The number of dehumidifiers, fan speed, and direction are the primary concerns for providing sufficient dehumidification. According to previous research, the humidity uniformity was also uneven even though it uses different high-powered and large-scale dehumidifiers [

38,

39]. Based on the spatial and vertical variability, the top and middle layers accrued relatively higher uniformity using the low-powered suspension-type dehumidifier. In contrast, bottom layer uniformity was lower for all conditions. Based on the result of using the same dehumidifier module in a crop condition [

6], the bottom layer humidity level was an issue with uniform distribution. Therefore, to improve the uniformity level of the whole greenhouse, an additional dehumidifier module in the bottom layer would be a promising solution.

Table 8 shows the comparison of power consumption of various greenhouse dehumidifier studies and the present study. Based on the literature, the condensation cooling dehumidifier (current study) used the least power consumption than the other commercial greenhouse dehumidifier. On the other hand, the per-area power consumption was higher when using the heat pump dehumidification system. According to the analysis, the proposed low-powered condensation cooling system dehumidifier may depending on climate conditions, reduce power consumption from 20 to 700%.

5. Directions for Further Research

Based on the spatial and vertical variability of humidity, an extra dehumidifier is required at the bottom layer to make the uniform humidity distribution. However, in the future, an artificial simulation is necessary before installing this dehumidifier in large greenhouses with crops. For that purpose, we have to adapt the climatical status in order to secure an optimum environment for the crop. The artificial simulation needs to consider inside greenhouse water vapor transfer including air exchange processes through vents or leakage, plant transpiration, condensation, and evaporation. To analyze and predict the humidity condition, computational fluid dynamics (CFD) will be an effective method to simulate the dehumidification status inside greenhouses. CFD and the real test including our proposed dehumidifier would aid in the measure of the location of the multiple dehumidifiers for different crop conditions.

In addition, solar modules will be installed to act as the main power source for various sensors and dehumidifiers. The main purpose of using this low-powered dehumidifier is to use solar-generated electricity as well as deploy agrivoltaic systems.

6. Conclusions

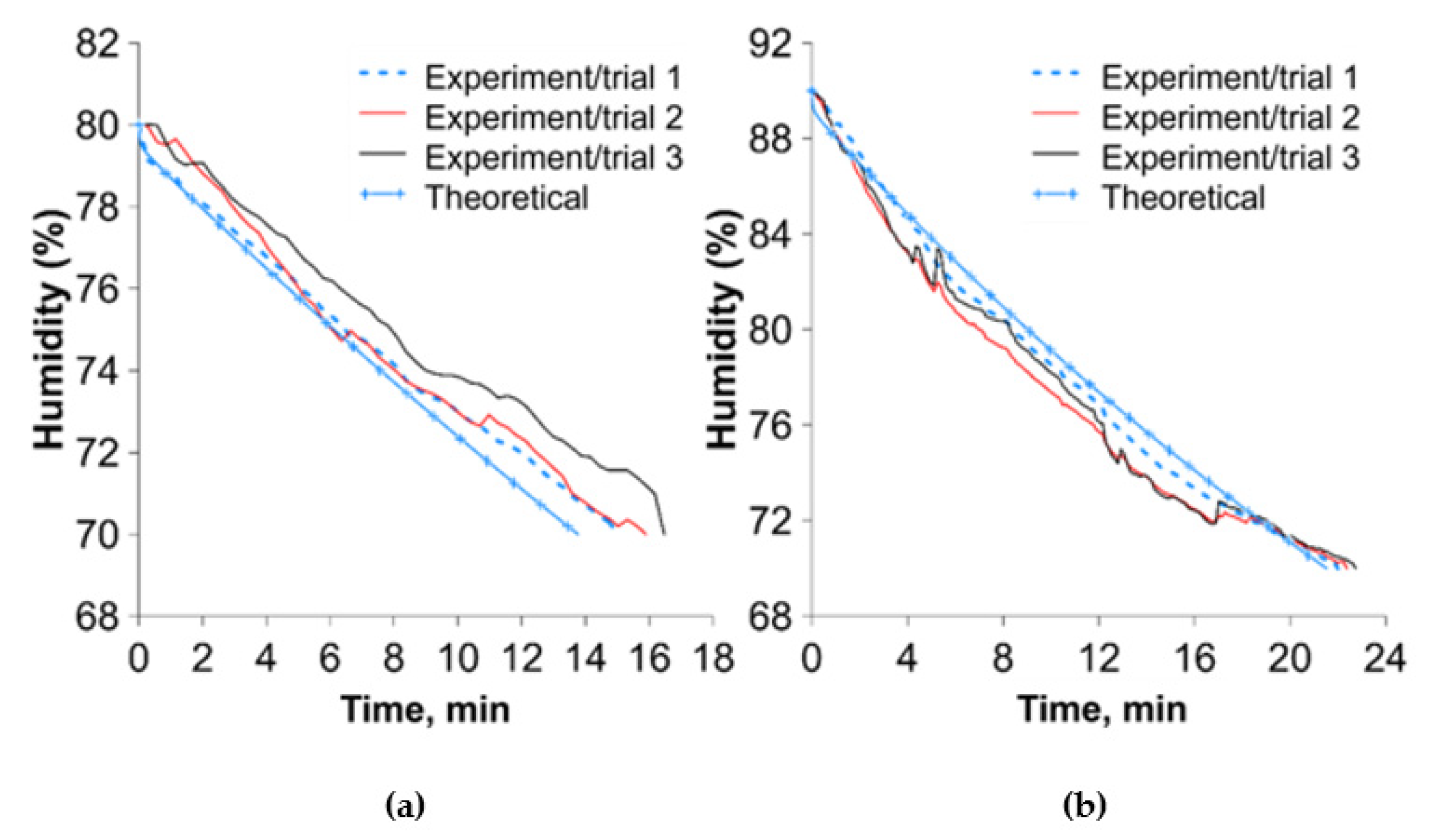

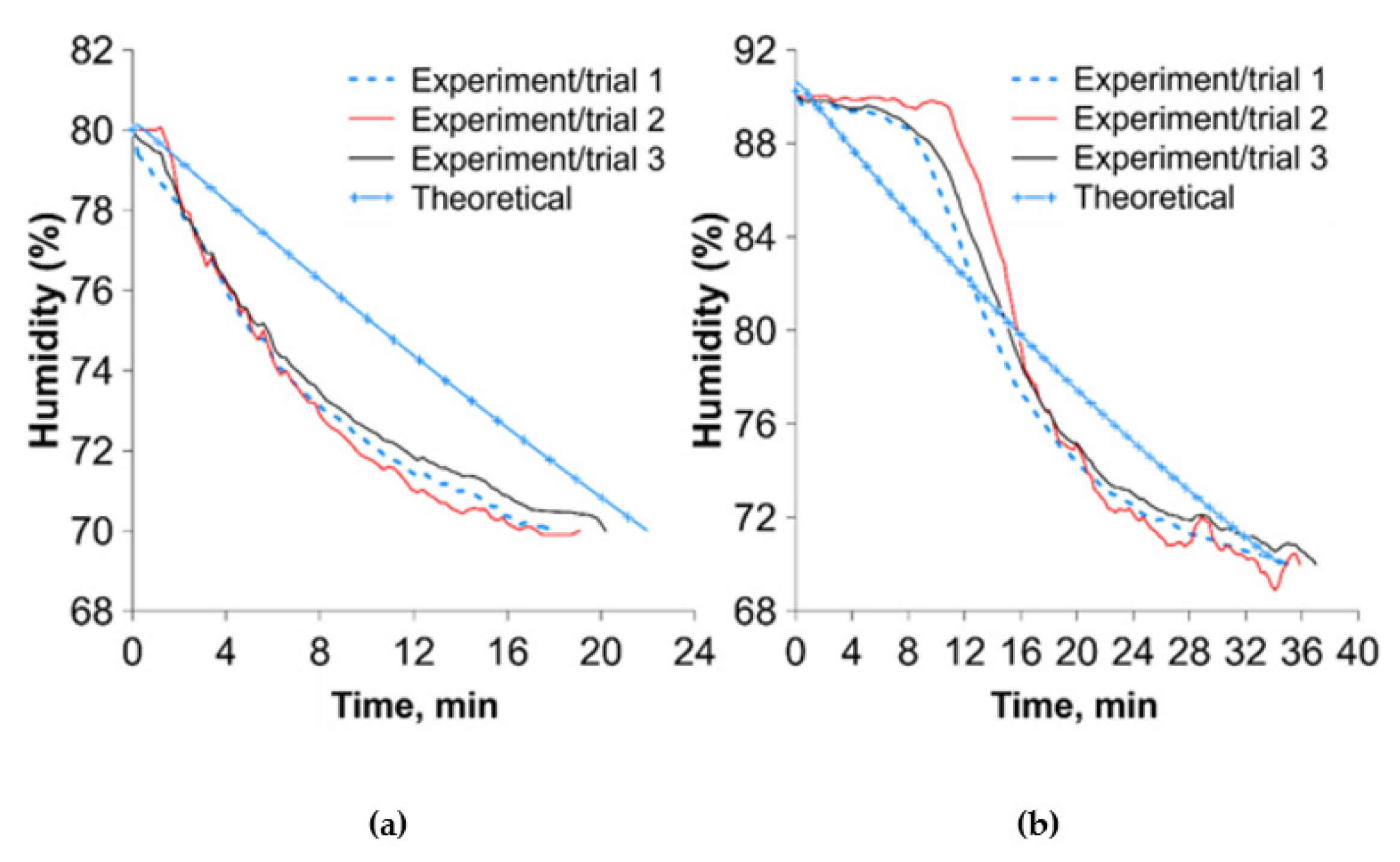

In this study, we evaluated the performance of a low-powered suspension-type dehumidifier module in terms of the humidity changes over time and investigated the humidity distributions by spatial and vertical variability analysis for a closed chamber and a small greenhouse. A mass balance method was used to calculate the humidity response theoretically. The moisture removal rate, experimental area, condensation on the area cover, and the inner airspeed were considered in the theoretical calculations. The humidity response of the dehumidifier module indicated that the difference between the theoretical and experimental humidity response times for both 90% to 70% and 80% to 70% humidity reductions was 1 min. According to the spatial and vertical variability, the humidity change range at the top layer was greater than that at the middle and bottom layers. For the 90% to 70% and 80% to 70% operating conditions, the average humidity level decreased while maintaining the humidity response time. However, uniformity was not maintained because the dehumidifier air did not reach all the enclosed space, especially in the bottom layer. The results of this study would provide useful information for the development of low-power dehumidifier modules and demonstrate the feasibility of controlling humidity in various greenhouses using the presented guidelines.