Efficiency of Waste as Cement Replacement in Foamed Concrete—A Review

Abstract

:1. Introduction

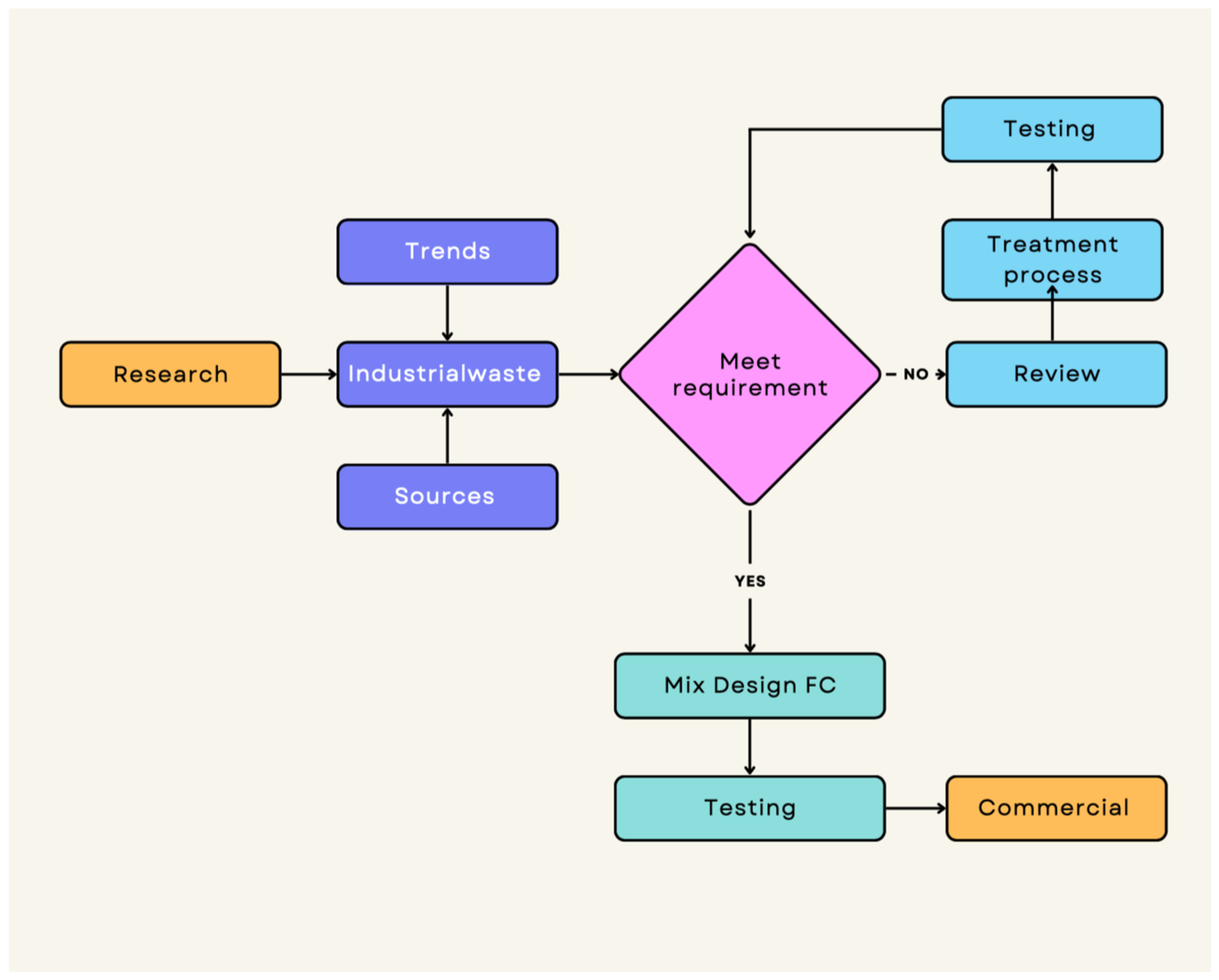

2. The Characterization Process of Waste

2.1. Chemical Composition of Pozzolan Alternatives

| Component | Portland Cement Type 1 [11] | Fly Ash [11] | Silica Fume [36] | Rice Husk Ash [12] | Slag [35] | POFA [37] | PSBE |

|---|---|---|---|---|---|---|---|

| SiO2 | 20.55 | 59.0 | 78.82 | 90.75 | 39.1 | 51.83 | 55.82 |

| Al2O3 | 4.780 | 19.58 | 0.00 | 0.75 | 12.1 | 2.32 | 13.48 |

| CaO | 63.94 | 0.54 | 2.35 | 0.87 | 38.3 | 8.10 | 6.60 |

| Fe2O3 | 3.64 | 7.23 | 0.98 | 0.08 | 1.03 | 7.60 | 8.24 |

| MgO | 1.50 | 4.64 | 6.41 | 0.63 | 8.50 | 3.13 | 5.94 |

2.2. X-ray Diffraction of Pozzolan Alternatives

2.3. Physical Characteristics of Pozzolan Alternatives

2.4. Morphology of Pozzolan Alternatives

3. Compressive Strength of FC with Pozzolan Alternatives

4. Water Absorption of FC with Pozzolan Alternatives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chinda, T. Investigation of factors affecting a construction waste recycling decision. Civ. Eng. Environ. Syst. 2016, 33, 214–226. [Google Scholar] [CrossRef]

- Breuer, A.; Janetschek, H.; Malerba, D. Translating Sustainable Development Goal (SDG) Interdependencies into Policy Advice. Sustainability 2019, 11, 2092. [Google Scholar] [CrossRef] [Green Version]

- Durastanti, C.; Moretti, L. Environmental Impacts of Cement Production: A Statistical Analysis. Appl. Sci. 2020, 10, 8212. [Google Scholar] [CrossRef]

- Rafiza, A.R.; Fazlizan, A.; Thongtha, A.; Asim, N.; Noorashikin, M.S. The Physical and Mechanical Properties of Autoclaved Aerated Concrete (AAC) with Recycled AAC as a Partial Replacement for Sand. Buildings 2022, 12, 60. [Google Scholar] [CrossRef]

- Bakhtyar, B.; Kacemi, T.; Nawaz, M.A. A Review on Carbon Emissions in Malaysian Cement Industry. Int. J. Energy Econ. Policy 2017, 7, 282–286. [Google Scholar]

- Li, G.; Zhou, C.; Ahmad, W.; Usanova, K.I.; Karelina, M.; Mohamed, A.M.; Khallaf, R. Fly Ash Application as Supplementary Cementitious Material: A Review. Materials 2022, 15, 2664. [Google Scholar] [CrossRef]

- Oginni, F.A. Continental Appplication of Foamed Concrete Technology: Lessons for Infrastructural Development in Africa. Br. J. Appl. Sci. Technol. 2015, 5, 417. [Google Scholar] [CrossRef]

- Chica, L.; Alzate, A. Cellular concrete review: New trends for application in construction. Constr. Build. Mater. 2019, 200, 637–647. [Google Scholar] [CrossRef]

- Amran, M.; Huei Lee, Y.; Vatin, N.; Fediuk, R.; Poi-Ngian, S.; Yong Lee, Y.; Murali, G. Design Efficiency, Characteristics, and Utilization of Reinforced Foamed Concrete: A Review. Crystals 2020, 10, 948. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Zhang, Z.; Yao, P.; Ma, Z. Properties and Modification of Sustainable Foam Concrete Including Eco-friendly Recycled Powder From Concrete Waste. Case Stud. Constr. Mater. 2022, 16, e00826. [Google Scholar] [CrossRef]

- Richard, A. Experimental Production of Sustainable Lightweight Foamed Concrete. Br. J. Appl. Sci. Technol. 2013, 3, 994–1005. [Google Scholar] [CrossRef]

- Bayuaji, R. The Influence of Microwave Incinerated Rice Husk Ash on Foamed Concrete Workability and Compressive Strength Using Taguchi Method. J. Teknol. 2015, 75, 265–274. [Google Scholar] [CrossRef] [Green Version]

- She, W.; Du, Y.; Zhao, G.; Feng, P.; Zhang, Y.; Cao, X. Influence of coarse fly ash on the performance of foam concrete and its application in high-speed railway roadbeds. Constr. Build. Mater. 2018, 170, 153–166. [Google Scholar] [CrossRef]

- Chen, Y.G.; Guan, L.L.; Zhu, S.Y.; Chen, W.J. Foamed concrete containing fly ash: Properties and application to backfilling. Constr. Build. Mater. 2021, 273, 121685. [Google Scholar] [CrossRef]

- Bing, C.; Zhen, W.; Ning, L. Experimental Research on Properties of High-Strength Foamed Concrete. J. Mater. Civ. Eng. 2012, 24, 113–118. [Google Scholar] [CrossRef]

- Awang, H.; Mydin, A.O.; Roslan, A.F. Microstructural Investigation of Lightweight Foamed Concrete Microstructural Investigation of Lightweight Foamed. Int. J. Acad. Res. 2012, 4, 196–200. [Google Scholar]

- Donatello, S.; Cheeseman, C.R. Recycling and recovery routes for incinerated sewage sludge ash (ISSA): A review. Waste Manag. 2013, 33, 2328–2340. [Google Scholar] [CrossRef]

- Sharipudin, S.S.; Ridzuan, A.R.M. Influence of waste paper sludge ash (WPSA) and fine recycled concrete aggregate (FRCA) on the compressive strength characteristic of foamed concrete. Adv. Mater. Res. 2013, 626, 376–380. [Google Scholar] [CrossRef]

- Tan, X.; Han, F.; Zhao, F. Preparation of autoclaved foamed concrete block from fly ash and carbide slag. MATEC Web Conf. 2018, 142, 02006. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, Y.; Zhan, B.; Xu, G. Preparation of autoclaved aerated concrete by using graphite tailings as an alternative silica source. Constr. Build. Mater. 2021, 267, 121792. [Google Scholar] [CrossRef]

- Lim, S.K.; Tan, C.S.; Lim, O.Y.; Lee, Y.L. Fresh and hardened properties of lightweight foamed concrete with palm oil fuel ash as filler. Constr. Build. Mater. 2013, 46, 39–47. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Al Muhit, B.A.; bin Jumaat, M.Z.; Jing, M.L.Y. A comparison of the thermal conductivity of oil palm shell foamed concrete with conventional materials. Mater. Des. 2013, 51, 522–529. [Google Scholar] [CrossRef]

- Cong, M.; Bing, C. Properties of a foamed concrete with soil as filler. Constr. Build. Mater. 2015, 76, 61–69. [Google Scholar] [CrossRef]

- Li, Y.; Chai, J.; Wang, R.; Zhang, X.; Si, Z. Utilization of sugarcane bagasse ash (SCBA) in construction technology: A state-of-the-art review. J. Build. Eng. 2022, 56, 104774. [Google Scholar] [CrossRef]

- Hameed, A.M.; Hamada, R.F. Using the glass and rubber waste as sustainable materials to prepare foamed concrete with improved properties. IOP Conf. Ser. Mater. Sci. Eng. 2020, 881, 012188. [Google Scholar] [CrossRef]

- Khan, Q.S.; McCarthy, T.J.; Sheikh, M.N. Experimental investigations of foamed concrete with recycled waste glass powder wall panels. Struct. Concr. 2022, 23, 3929–3944. [Google Scholar] [CrossRef]

- Dao, D.V.; Ly, H.-B.; Vu, H.-L.T.; Le, T.-T.; Pham, B.T. Investigation and Optimization of the C-ANN Structure in Predicting the Compressive Strength of Foamed Concrete. Materials 2020, 13, 1072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Calis, G.; Yildizel, S.A.; Erzin, S.; Tayeh, B.A. Evaluation and optimisation of foam concrete containing ground calcium carbonate and glass fibre (experimental and modelling study). Case Stud. Constr. Mater. 2021, 15, e00625. [Google Scholar] [CrossRef]

- Ullah, H.S.; Khushnood, R.A.; Ahmad, J.; Farooq, F. Predictive modelling of sustainable lightweight foamed concrete using machine learning novel approach. J. Build. Eng. 2022, 56, 104746. [Google Scholar] [CrossRef]

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- Ahmad, S.; Al-Amoudi, O.S.B.; Khan, S.M.; Maslehuddin, M. Effect of silica fume inclusion on the strength, shrinkage and durability characteristics of natural pozzolan-based cement concrete. Case Stud. Constr. Mater. 2022, 17, e01255. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Hasan, M.; Hossain, M.K.; Zain, M.F.M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- K Al-Chaar, G.; Alkadi, M.; Asteris, P.G. Natural Pozzolan as a Partial Substitute for Cement in Concrete. Open Constr. Build. Technol. J. 2013, 7, 33–42. [Google Scholar] [CrossRef] [Green Version]

- Nwankwo, C.O.; Bamigboye, G.O.; Davies, I.E.; Michaels, T.A. High volume Portland cement replacement: A review. Constr. Build. Mater. 2020, 260, 120445. [Google Scholar] [CrossRef]

- Nasir, M.; Al-Amoudi, O.S.B.; Maslehuddin, M. Effect of placement temperature and curing method on plastic shrinkage of plain and pozzolanic cement concretes under hot weather. Constr. Build. Mater. 2017, 152, 943–953. [Google Scholar] [CrossRef]

- Dedeloudis, C.; Zervaki, M.; Sideris, K.; Juenger, M.; Alderete, N.; Kamali-Bernard, S.; Snellings, R. Natural pozzolans. In Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials: State-of-the-Art Report of the RILEM Technical Committee 238-SCM; Springer: Berlin/Heidelberg, Germany, 2018; Volume 4, pp. 181–231. [Google Scholar]

- Zhou, Y.; Wang, Z.; Zhu, Z.; Chen, Y.; Wu, K.; Huang, H.; Xu, L. Influence of metakaolin and calcined montmorillonite on the hydration of calcium sulphoaluminate cement. Case Stud. Constr. Mater. 2022, 16, e01104. [Google Scholar] [CrossRef]

- Danner, T.; Norden, G.; Justnes, H. Characterisation of calcined raw clays suitable as supplementary cementitious materials. Appl. Clay Sci. 2018, 162, 391–402. [Google Scholar] [CrossRef]

- Valipour, M.; Pargar, F.; Shekarchi, M.; Khani, S. Comparing a natural pozzolan, zeolite, to metakaolin and silica fume in terms of their effect on the durability characteristics of concrete: A laboratory study. Constr. Build. Mater. 2013, 41, 879–888. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Dyer, T.D. Pozzolanas and pozzolanic materials. Lea’s Chem. Cem. Concr. 2019, 5, 363–467. [Google Scholar]

- Awang, H.; Aljoumaily, Z.S. Influence of granulated blast furnace slag on mechanical properties of foam concrete. Cogent Eng. 2017, 4, 1409853. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Hatungimana, D.; Ramyar, K. Effect of fly ash and silica fume on hardened properties of foam concrete. Constr. Build. Mater. 2019, 194, 1–11. [Google Scholar] [CrossRef]

- Mohamad, N.; Samad, A.A.A.; Lakhiar, M.T.; Othuman Mydin, M.A.; Jusoh, S.; Sofia, A.; Efendi, S.A. Effects of Incorporating Banana Skin Powder (BSP) and Palm Oil Fuel Ash (POFA) on Mechanical Properties of Lightweight Foamed Concrete. Int. J. Integr. Eng. 2018, 10, 69–76. [Google Scholar] [CrossRef]

- Osei, D.; Jackson, E. Compressive strength and workability of concrete using natural pozzolana as partial replacement of ordinary Portland cement. J. Adv. Appl. 2012, 3, 3658–3662. [Google Scholar]

- Ramezanianpour, A.A.; Moeini, M.A. Mechanical and durability properties of alkali activated slag coating mortars containing nanosilica and silica fume. Constr. Build. Mater. 2018, 163, 611–621. [Google Scholar] [CrossRef]

- Heikal, M.; Eldidamony, H.; El-Didamony, H.; Heikal, M.; Khalil, K.A.; El-Sanhory, A. Pozzolanic activity of silica fume with lime. J. Basic Environ. Sci. 2017, 4, 236–246. [Google Scholar]

- Ahmad, I.A.; Pertiwi, N.; Taufieq, N.A.S. Reliability of rice husk ash as substitution of Portland composite cement producing green concrete. Ecol. Environ. Conserv. 2018, 24, S56–S63. [Google Scholar]

- Ramos, T.; Matos, A.M.; Sousa-Coutinho, J. Strength and Durability of Mortar Using Cork Waste Ash as Cement Replacement. Mater. Res. 2014, 17, 893–907. [Google Scholar] [CrossRef] [Green Version]

- Nagendra, V. Ground Granulated Blast Furnace Slag (GGBS): Effect of Particle Size and Dosage on Compressive Strength with Microstructural Analysis of Concrete. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 2467–2474. [Google Scholar] [CrossRef]

- Juenger, M.C.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Karim, M.; Hossain, M.; Khan, M.; Zain, M.; Jamil, M.; Lai, F. On the Utilization of Pozzolanic Wastes as an Alternative Resource of Cement. Materials 2014, 7, 7809–7827. [Google Scholar] [CrossRef] [Green Version]

- Franus, W.; Panek, R.; Wdowin, M. SEM Investigation of Microstructures in Hydration Products of Portland Cement. In 2nd International Multidisciplinary Microscopy and Microanalysis Congress: Proceedings of InterM, Fethiye, Turkey, 16–19 October 2014; Springer: Cham, Switzerland, 2015; pp. 105–112. [Google Scholar]

- Kledyński, Z.; Machowska, A.; Pacewska, B.; Wilińska, I. Investigation of hydration products of fly ash–slag pastes. J. Therm. Anal. Calorim. 2017, 130, 351–363. [Google Scholar] [CrossRef] [Green Version]

- Elrahman, M.A.; El Madawy, M.; Chung, S.-Y.; Sikora, P.; Stephan, D. Preparation and Characterization of Ultra-Lightweight Foamed Concrete Incorporating Lightweight Aggregates. Appl. Sci. 2019, 9, 1447. [Google Scholar] [CrossRef] [Green Version]

- Atashgah, K.M.; Hashempour, H.; Rezaei, M.K. An Investigation into the Role of Nano-Silica in Improving Strength of Lightweight Concrete. Eur. Online J. Nat. Soc. Sci. 2014, 3, 1058–1067. [Google Scholar]

- Wi, K.; Lee, H.S.; Lim, S.; Song, H.; Hussin, M.W.; Ismail, M.A. Use of an agricultural by-product, nano sized Palm Oil Fuel Ash as a supplementary cementitious material. Constr. Build. Mater. 2018, 183, 139–149. [Google Scholar] [CrossRef]

- Gencel, O.; Bilir, T.; Bademler, Z.; Ozbakkaloglu, T. A Detailed Review on Foam Concrete Composites: Ingredients, Properties, and Microstructure. Appl. Sci. 2022, 12, 5752. [Google Scholar] [CrossRef]

- ASTM C513/C513M; Standard Test Method for Obtaining and Testing Specimens of Hardened Lightweight Insulating Concrete for Compressive Strength. ASTM International: West Conshohocken, PA, USA, 2011.

- Fu, Y.; Wang, X.; Wang, L.; Li, Y. Foam concrete: A state-of-the-art and state-of-the-practice review. Adv. Mater. Sci. Eng. 2020, 2020, 6153602. [Google Scholar] [CrossRef] [Green Version]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Amran, Y.M.; Rashid, R.S.; Hejazi, F.; Safiee, N.A.; Ali, A.A. Response of precast foamed concrete sandwich panels to flexural loading. J. Build. Eng. 2016, 7, 143–158. [Google Scholar] [CrossRef]

- Li, G.; Tan, H.; He, X.; Zhang, J.; Deng, X.; Zheng, Z.; Guo, Y. The influence of wet ground fly ash on the performance of foamed concrete. Constr. Build. Mater. 2021, 304, 124676. [Google Scholar] [CrossRef]

- Lee, Y.L.; Tan, C.S.; Lim, S.K.; Mohammad, S.; Lim, J.H. Strength performance on different mix of cement-sand ratio and sand condition for lightweight foamed concrete. E3S Web Conf. 2018, 65, 02006. [Google Scholar] [CrossRef]

- Kursuncu, B.; Gencel, O.; Bayraktar, O.Y.; Shi, J.; Nematzadeh, M.; Kaplan, G. Optimization of foam concrete characteristics using response surface methodology and artificial neural networks. Constr. Build. Mater. 2022, 337, 127575. [Google Scholar] [CrossRef]

- Jones, M.R.; Ozlutas, K.; Zheng, L. High-volume, ultra-low-density fly ash foamed concrete. Mag. Concr. Res. 2017, 69, 1146–1156. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Lange, D. Influence of fine inclusions on the morphology and mechanical performance of lightweight foam concrete. Cem. Concr. Compos. 2021, 124, 104264. [Google Scholar] [CrossRef]

- Juenger, M.C.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Allouzi, R.; Al Qatawna, A.; Al-Kasasbeh, T. Lightweight Foamed Concrete Mixture for Structural Use. ACI Mater. J. 2020, 117, 99–109. [Google Scholar]

- Zhang, S.; Qi, X.; Guo, S.; Zhang, L.; Ren, J. A systematic research on foamed concrete: The effects of foam content, fly ash, slag, silica fume and water-to-binder ratio. Constr. Build. Mater. 2022, 339, 127683. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Amran, Y.M.; Farzadnia, N.; Ali, A.A. Properties and applications of foamed concrete; a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Yu, X.G.; Luo, S.S.; Gao, Y.N.; Xiao, H.; Li, D.J.; Xu, H.C.; Li, F. Microstructure, Mineral Phases and Strength of the Foam Concrete. Key Eng. Mater. 2011, 492, 484–488. [Google Scholar] [CrossRef]

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- Zhao, H.; Ding, J.; Huang, Y.; Tang, Y.; Xu, W.; Huang, D. Experimental analysis on the relationship between pore structure and capillary water absorption characteristics of cement-based materials. Struct. Concr. 2019, 20, 1750–1762. [Google Scholar] [CrossRef]

- Liu, M.; Hu, Y.; Lai, Z.; Yan, T.; He, X.; Wu, J.; Lv, S. Influence of various bentonites on the mechanical properties and impermeability of cement mortars. Constr. Build. Mater. 2020, 241, 118015. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Al-Mulali, M.Z.; Shaik, S.; El Ouni, M.H.; El-Shorbagy, M.A. Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review. Buildings 2022, 12, 634. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sulfuric acid resistance of fly ash based geopolymer concrete. Constr. Build. Mater. 2017, 146, 136–143. [Google Scholar] [CrossRef]

- Othman, R.; Jaya, R.P.; Muthusamy, K.; Sulaiman, M.; Duraisamy, Y.; Abdullah, M.M.A.B.; Sandu, A.V. Relation between density and compressive strength of foamed concrete. Materials 2021, 14, 2967. [Google Scholar] [CrossRef] [PubMed]

- Othman, R.; Muthusamy, K.; Sulaiman, M.A.; Duraisamy, Y.; Jaya, R.P.; Wei, C.B.; Śliwa, A. Compressive strength and durability of foamed concrete incorporating Processed Spent Bleaching Earth. Arch. Civ. Eng. 2022, LXVIII, 627–643. [Google Scholar] [CrossRef]

| Material | Mean Size of the Particle (μm) | Surface Area (m2/kg) | Particle Shape | Specific Gravity | |

|---|---|---|---|---|---|

| [11] | Portland cement | 20–30 | 300–400 | Angular, irregular | 3.1–3.2 |

| [11] | Fly ash | 10–15 | <1000 | Spherical | 2.06 |

| [36] | Silica Fume | 0.1–0.3 | 20,000 | Spherical | 2.37 |

| [12] | Rice husk ash | 10–20 | <10,000 | Cellular, irregular | 2.0–2.3 |

| [35] | GGBS | 10–15 | <1000 | Angular, irregular | 2.63 |

| [37] | POFA | 0.1–75 | <1000 | Angular, irregular | 2.05–2.5 |

| PSBE | 0.1 | <1000 | Spherical | 2.44 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Othman, R.; Putra Jaya, R.; Duraisamy, Y.; Sulaiman, M.A.; Chong, B.W.; Ghamari, A. Efficiency of Waste as Cement Replacement in Foamed Concrete—A Review. Sustainability 2023, 15, 5163. https://doi.org/10.3390/su15065163

Othman R, Putra Jaya R, Duraisamy Y, Sulaiman MA, Chong BW, Ghamari A. Efficiency of Waste as Cement Replacement in Foamed Concrete—A Review. Sustainability. 2023; 15(6):5163. https://doi.org/10.3390/su15065163

Chicago/Turabian StyleOthman, Rokiah, Ramadhansyah Putra Jaya, Youventharan Duraisamy, Mohd Arif Sulaiman, Beng Wei Chong, and Ali Ghamari. 2023. "Efficiency of Waste as Cement Replacement in Foamed Concrete—A Review" Sustainability 15, no. 6: 5163. https://doi.org/10.3390/su15065163

APA StyleOthman, R., Putra Jaya, R., Duraisamy, Y., Sulaiman, M. A., Chong, B. W., & Ghamari, A. (2023). Efficiency of Waste as Cement Replacement in Foamed Concrete—A Review. Sustainability, 15(6), 5163. https://doi.org/10.3390/su15065163