A Vulnerability Assessment Framework for Product-Service Systems Based on Variation Mode and Effect Analysis

Abstract

1. Introduction

2. Literature Review

2.1. PSS and PSS Design

2.2. The Concept of Vulnerability and the Vulnerability of PSS

2.3. Vulnerability Assessment Methods and Their Applications in PSS

2.4. The Variation Mode and Effect Analysis (VMEA)

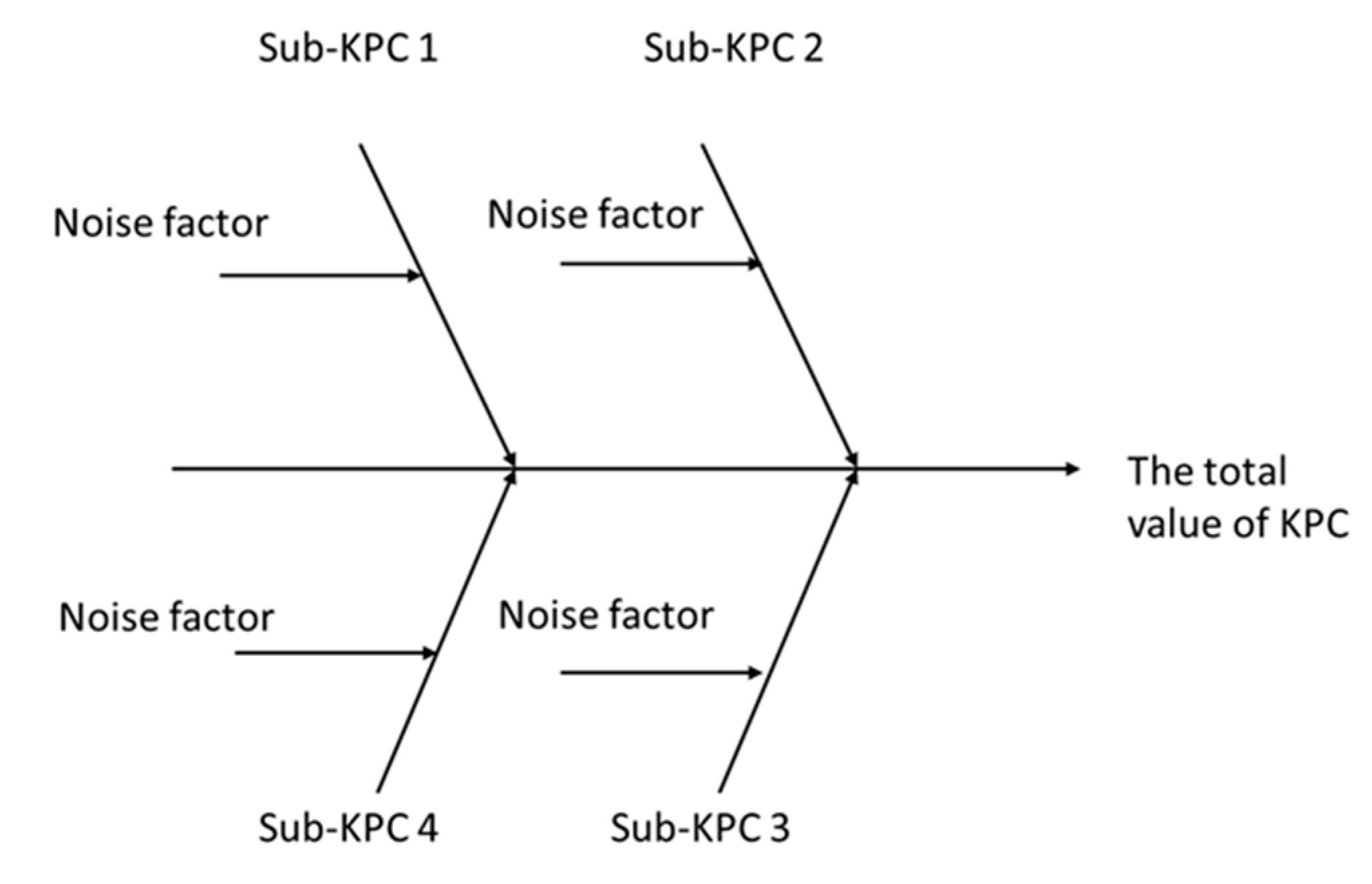

2.4.1. KPC Causal Breakdown

2.4.2. Sensitivity Assessment

2.4.3. Variation Size Assessment

2.4.4. Variation Risk Assessment and Prioritizing

2.5. Research Gap

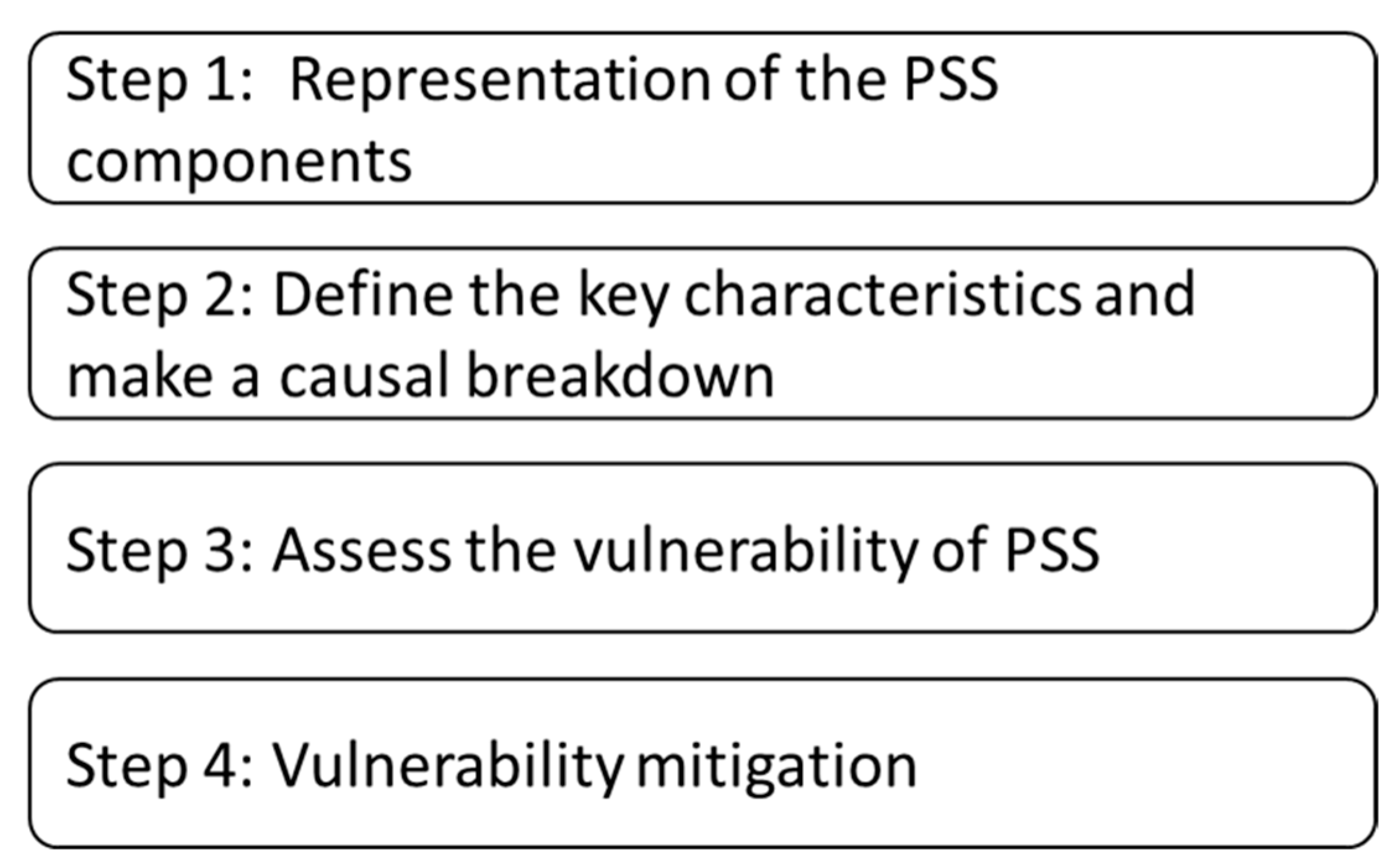

3. Methodology

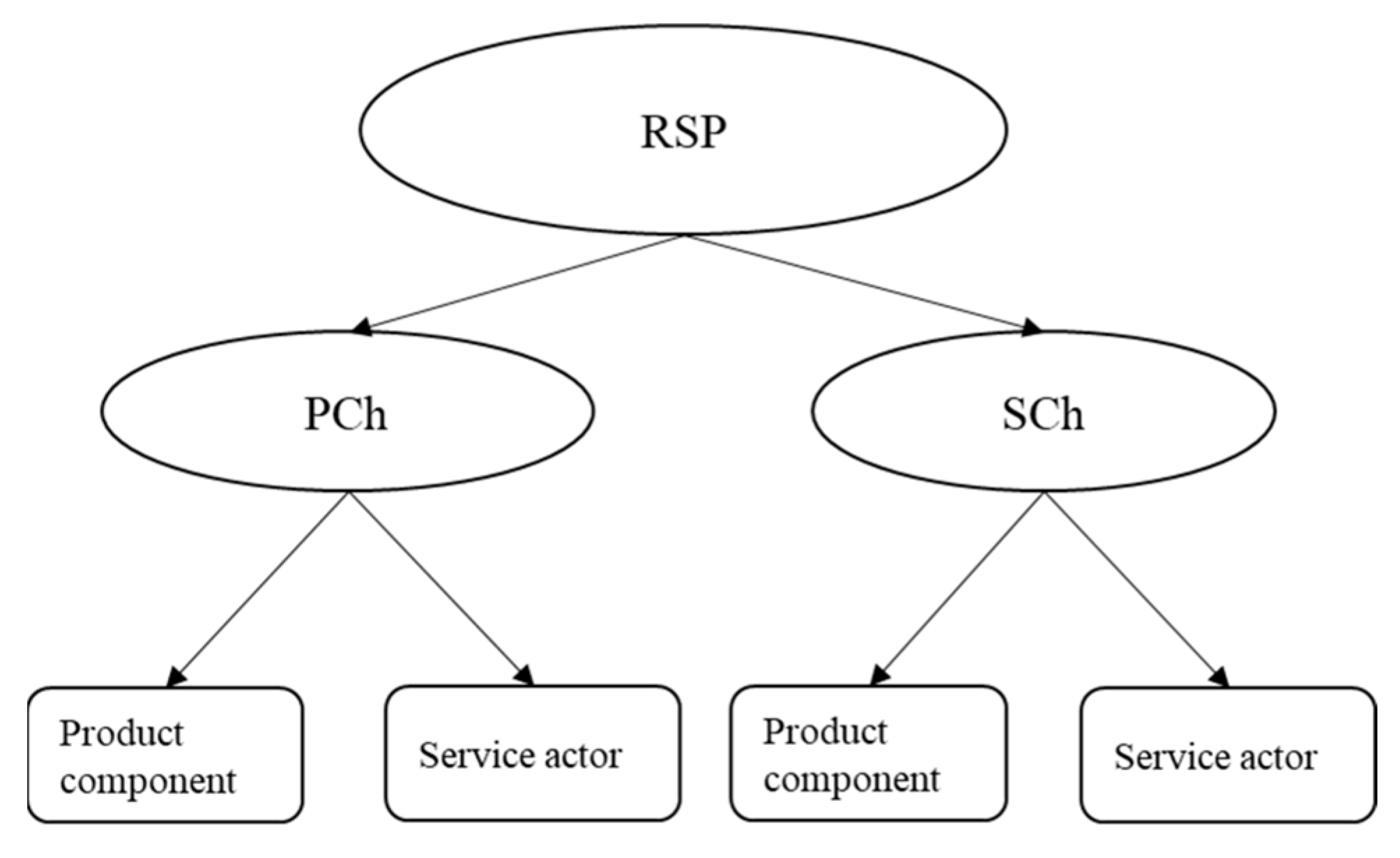

3.1. Representation of the PSS Components

3.2. Define the Key Characteristics and Make a Causal Breakdown

3.2.1. Define the RSP of the Targeted PSS

- The selected RSP has a positive or negative impact on one or several stakeholders.

- If the performance of the selected RSP deteriorates, one or more stakeholders may suffer significant losses at the economic, social, and environmental levels. The loss should be direct and observable.

3.2.2. Dividing RSP into PChs and SChs

3.2.3. Identifying the Noise Factor for Each PCh and SCh

- Behavioral perturbation: any event relating to the customer’s adverse behavior that leads to product breakdown. Due to the lack of legal and contractual constraints, customer behavior may cause physical damage to PSS products or machines, thereby reducing availability and efficiency.

- Social perturbation: any event relating to the adverse social attitude from various stakeholders, including customers, managers, staff, government, and the local community, that reduces the acceptance and satisfaction towards the targeted PSS. The adverse social attitude can be mainly divided into two types, namely insensitivity toward sharing or renting and resistance toward PSS novelty.

- Environmental perturbation: any event relating to the lack of environmental prerequisites, which reduces the support from the legal environment, market, and micro-economy.

- Competence perturbation: any event relating to the lack of the specific competence to overtake the basic function of PSS and the ability of service actors to maintain the system against accidental events, which weakens the performance of tasks and the availability of products.

- Resource perturbation: any event relating to the shortage of resources, including investment, component, human resources, materials, and infrastructure, which could lead to disruption and even bankruptcy.

- Organizational perturbation: any event relating to the structural problem that originates from the organization that reduces efficiency.

3.3. Assess the Vulnerability of PSS

3.4. Vulnerability Mitigation

- Risk avoidance: take actions to avoid the responsibility of the risk, which requires PSS providers to not provide PSS or not be responsible for the machine. This type of action is only adopted when the resource and contract support is poor for the current PSS.

- Risk reduction: take actions to reduce the probability of the risk, which requires PSS providers to improve their technical ability including monitoring and data collecting. This type of strategy has a strict requirement on whether customers are willing to abide by the contract.

- Risk sharing: take actions to share the risk with other stakeholders, including customers, manufacturers, insurance firms, and local government. This type of strategy also depends on the willingness of various stakeholders and their preference toward risk.

- Risk retention: take no actions to solve the risk. Instead, let the user pay for the loss of the risk. This type of strategy has a high-level requirement on the relationship between providers and customers. The legal rules and customers’ moral standards also play an important role in this context.

- Will this action reduce the benefit or increase the cost?

- Will this action be hindered by stakeholders?

- Will this action lead to further risk of damaging the machine?

- Will this action lead to the environmental risk, including pollution and waste?

4. Illustration of the Application Example

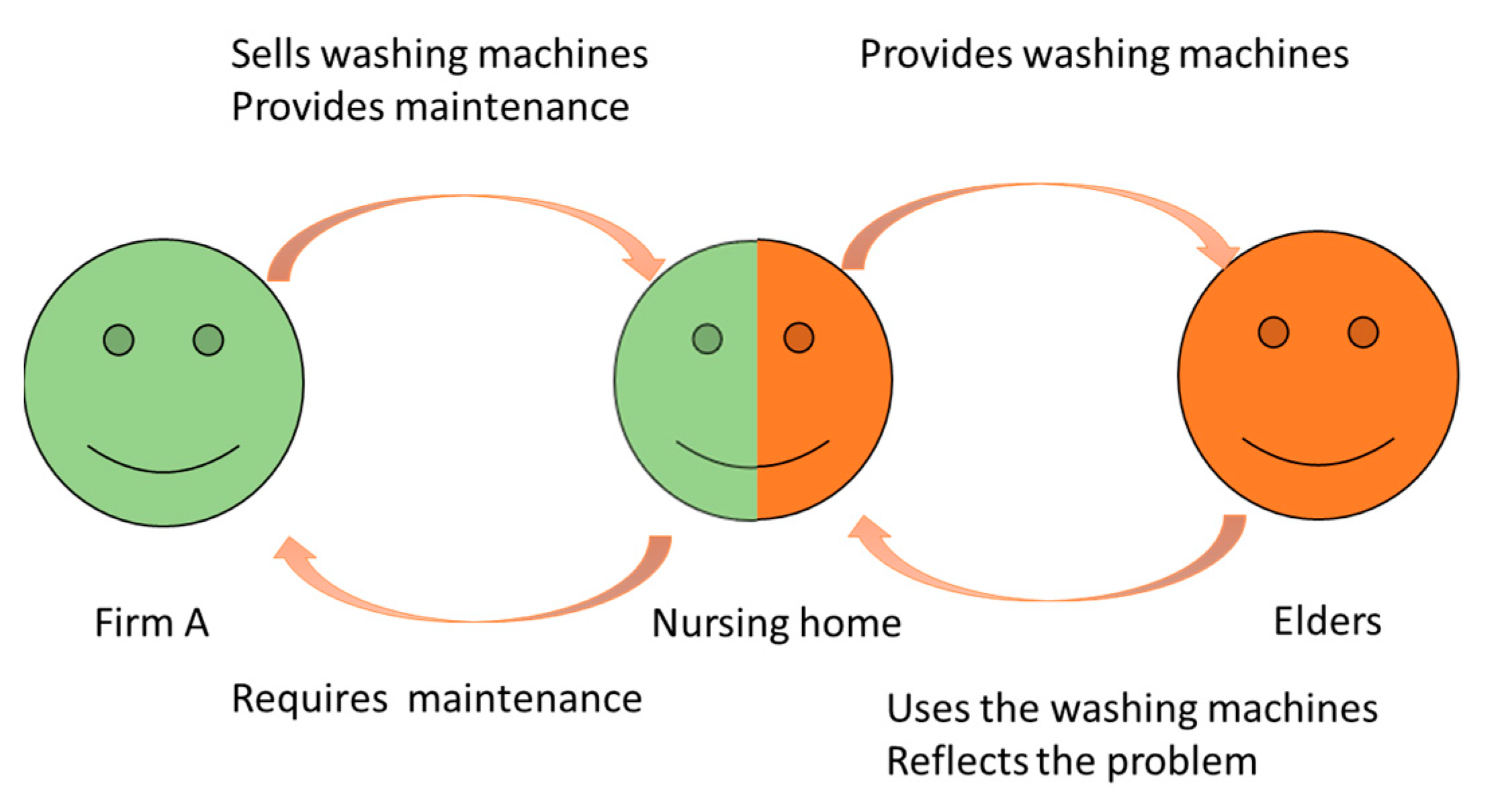

4.1. Representation of the PSS Model

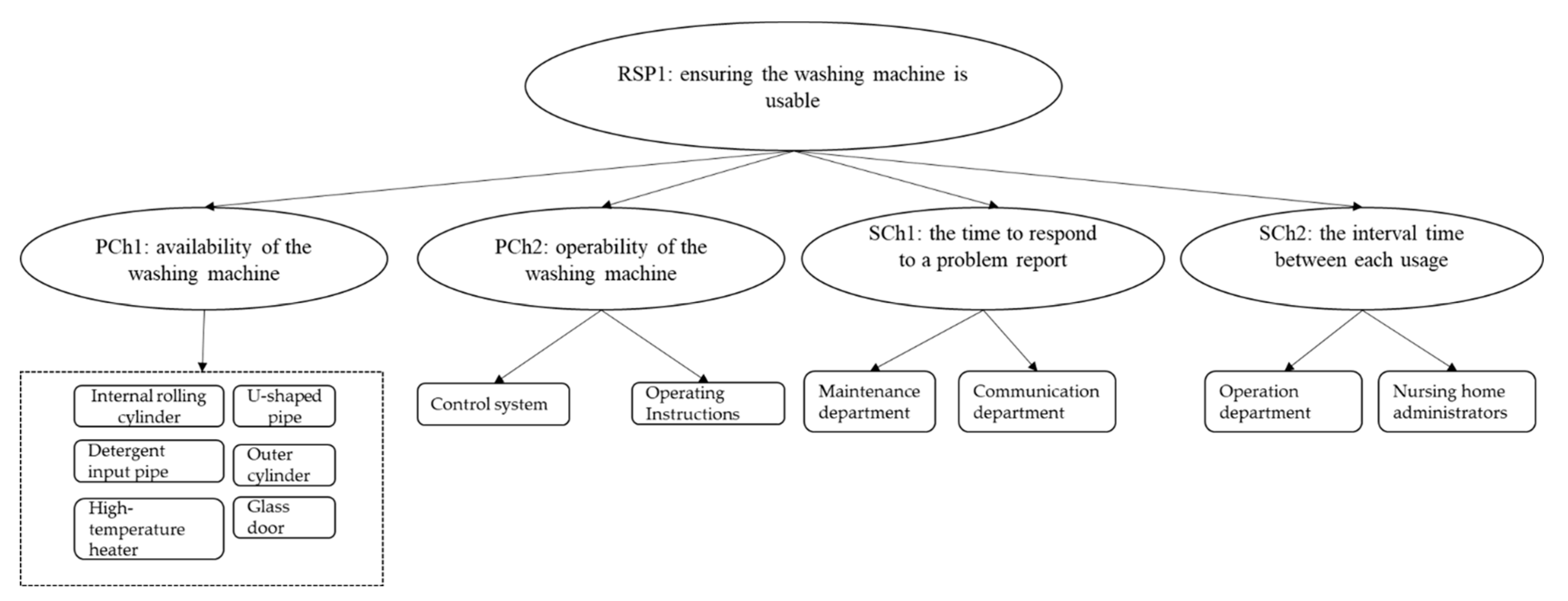

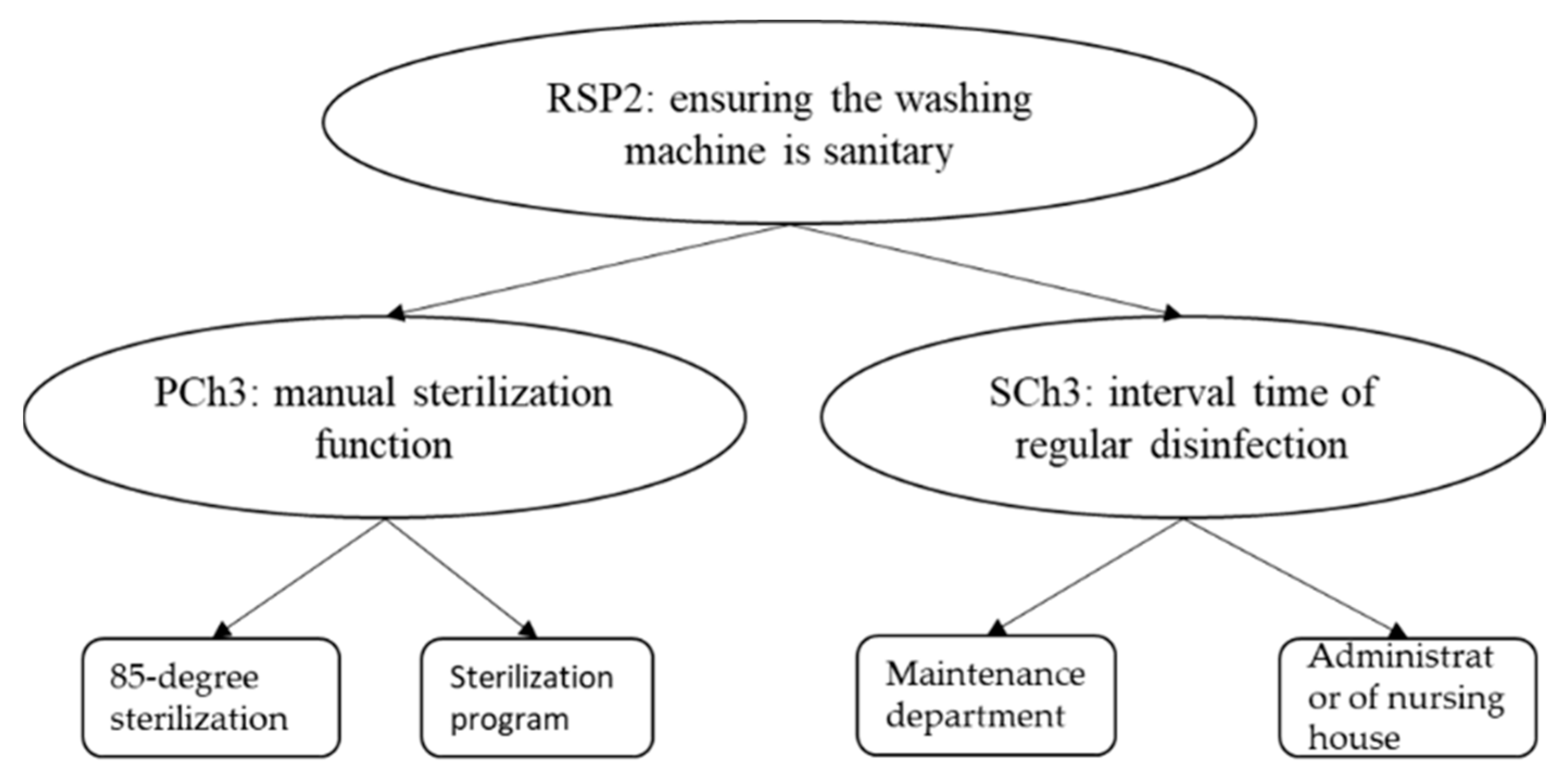

4.2. Define the Key Characteristics and Provide a Causal Breakdown

4.3. Vulnerability Assessment

4.4. Recommendation on Mitigation

5. Discussion

5.1. Effectiveness of the Proposed Method

5.2. The Theoretical Implication of This Research

5.3. Limitations

6. Conclusions and Future Direction

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oliva, R.; Kallenberg, R. Managing the transition from products to services. Int. J. Serv. Ind. Manag. 2003, 14, 160–172. [Google Scholar] [CrossRef]

- Vezzoli, C.; Ceschin, F.; Diehl, J.C.; Kohtala, C. New design challenges to widely implement ‘Sustainable Product–Service Systems’. J. Clean. Prod. 2015, 97, 1–12. [Google Scholar] [CrossRef]

- Goedkoop, M.; van Halen, C.; te Riele, H.; Rommens, P. Product Service Systems, Ecological and Economic Basics; VROM: The Hague, The Netherlands, 1999. [Google Scholar]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Haase, R.P.; Pigosso DC, A.; McAloone, T.C. Product/service-system origins and trajecto-ries: A systematic literature review of PSS definitions and their characteristics. Pro-Cedia Cirp 2017, 64, 157–162. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Sjödin, D.R. Risk management for product-service system operation. Int. J. Oper. Prod. Manag. 2016, 36, 665–686. [Google Scholar] [CrossRef]

- Sakao, T.; Rönnbäck, A.Ö.; Sandström, G.Ö. Uncovering benefits and risks of integrated product service offerings—Using a case of technology encapsulation. J. Syst. Sci. Syst. Eng. 2013, 22, 421–439. [Google Scholar] [CrossRef]

- Wang, H.; Mitake, Y.; Tsutsui, Y.; Alfarisi, S.; Shimomura, Y. An ontology for the vulnerability of Product-Service System. Procedia CIRP 2022, 107, 338–343. [Google Scholar] [CrossRef]

- Wang, H.; Mitake, Y.; Tsutsui, Y.; Alfarisi, S.; Shimomura, Y. A Taxonomy of Product–Service System Perturbations through a Systematic Literature Review. J. Risk Financ. Manag. 2022, 15, 443. [Google Scholar] [CrossRef]

- Taguchi, G. System of Experimental Design; Engineering Methods to Optimize Quality and Minimize Costs; UNIPUB/Kraus International Publications: New York, NY, USA, 1987; ISBN 978-0527916213. [Google Scholar]

- Hasenkamp, T.; Arvidsson, M.; Gremyr, I. A review of practices for robust design methodology. J. Eng. Des. 2009, 20, 645–657. [Google Scholar] [CrossRef]

- Martinez, V.; Neely, A.; Velu, C.; Leinster-Evans, S.; Bisessar, D. Exploring the journey to services. Int. J. Prod. Econ. 2017, 192, 66–80. [Google Scholar] [CrossRef]

- Kimita, K.; Sakao, T.; Shimomura, Y. A failure analysis method for designing highly reliable product-service systems. Res. Eng. Des. 2018, 29, 143–160. [Google Scholar] [CrossRef]

- Russo, D.; Birolini, V.; Ceresoli, R. Fit: A triz based failure identification tool for product-service systems. Procedia CIRP 2016, 47, 210–215. [Google Scholar] [CrossRef]

- Song, W.; Zheng, J.; Niu, Z.; Wang, Q.; Tang, Y.; Zheng, P. Risk evaluation for industrial smart product-service systems: An integrated method considering failure mode correlations. Adv. Eng. Inform. 2022, 54, 101734. [Google Scholar] [CrossRef]

- Chakhunashvili, A.; Johansson, P.M.; Bergman, B.L.S. Variation mode and effect analysis. In Annual Symposium Reliability and Maintainability, 2004-RAMS; IEEE: New York, NY, USA, 2004; pp. 364–369. [Google Scholar]

- Cronholm, K. Design of experiment based on VMEA (Variation Mode and Effect Analysis). Procedia Eng. 2013, 66, 369–382. [Google Scholar] [CrossRef]

- Arai, T.; Shimomura, Y. Proposal of service CAD system-a tool for service engineering. CIRP Ann. 2004, 53, 397–400. [Google Scholar] [CrossRef]

- Shimomura, Y.; Tomiyama, T. Service modeling for service engineering. In International Working Conference on the Design of Information Infrastructure Systems for Manufacturing; Springer: Boston, MA, USA, 2002; pp. 31–38. [Google Scholar]

- Phillips, J.; Simmonds, L. Using fishbone analysis to investigate problems. Nurs. Times 2013, 109, 18–20. [Google Scholar]

- Mont, O.K. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- D’Agostin, A.; de Medeiros, J.F.; Vidor, G.; Zulpo, M.; Moretto, C.F. Drivers and barriers for the adoption of use-oriented product-service systems: A study with young consumers in medium and small cities. Sustain. Prod. Consum. 2020, 21, 92–103. [Google Scholar] [CrossRef]

- Lindahl, M.; Sundin, E.; Sakao, T. Environmental and economic benefits of Integrated Product Service Offerings quantified with real business cases. J. Clean. Prod. 2014, 64, 288–296. [Google Scholar] [CrossRef]

- Kühl, C.; Tjahjono, B.; Bourlakis, M.; Aktas, E. Implementation of Circular Economy principles in PSS operations. Procedia CIRP 2018, 73, 124–129. [Google Scholar] [CrossRef]

- Coreynen, W.; Matthyssens, P.; Van Bockhaven, W. Boosting servitization through digitization: Pathways and dynamic resource configurations for manufacturers. Ind. Mark. Manag. 2017, 60, 42–53. [Google Scholar] [CrossRef]

- Dmitrijeva, J.; Schroeder, A.; Bigdeli, A.Z.; Baines, T. Paradoxes in servitization: A processual perspective. Ind. Mark. Manag. 2022, 101, 141–152. [Google Scholar] [CrossRef]

- Moro, S.; Cauchick-Miguel, P.A.; de Sousa Mendes, G.H. Product-service systems benefits and barriers: An overview of literature review papers. Int. J. Ind. Eng. Manag. 2020, 11, 61. [Google Scholar] [CrossRef]

- Maussang, N.; Zwolinski, P.; Brissaud, D. Product-service system design methodology: From the PSS architecture design to the products specifications. J. Eng. Des. 2009, 20, 349–366. [Google Scholar] [CrossRef]

- Muto, K.; Kimita, K.; Shimomura, Y. A guideline for product-service-systems design process. Procedia CIRP 2015, 30, 60–65. [Google Scholar] [CrossRef]

- Akasaka, F.; Nemoto, Y.; Kimita, K.; Shimomura, Y. Development of a knowledge-based design support system for Product-Service Systems. Comput. Ind. 2012, 63, 309–318. [Google Scholar] [CrossRef]

- Kimita, K.; Shimomura, Y. Design method for modular product-service system architecture. In Proceedings of the DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; pp. 979–988. [Google Scholar]

- Song, W.; Sakao, T. A customization-oriented framework for design of sustainable product/service system. J. Clean. Prod. 2017, 140, 1672–1685. [Google Scholar] [CrossRef]

- Sakao, T.; Song, W.; Matschewsky, J. Creating service modules for customising product/service systems by extending DSM. CIRP Ann. 2017, 66, 21–24. [Google Scholar] [CrossRef]

- Vezzoli, C.; Ceschin, F.; Osanjo, L.; M’Rithaa, M.K.; Moalosi, R.; Nakazibwe, V.; Diehl, J.C. Designing Sustainable Energy for All: Sustainable Product-Service System Design Applied to Distributed Renewable Energy; Springer Nature: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Hara, T.; Arai, T.; Shimomura, Y. Integrated representation of function, service activity, and product behavior for service development. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Brooklyn, NY, USA, 3–6 August 2008; pp. 67–76. [Google Scholar]

- Cong, J.-C.; Chen, C.-H.; Zheng, P.; Li, X.; Wang, Z. A holistic relook at en-gineering design methodologies for smart product-service systems development (Nov.). J. Clean. Prod. 2020, 272, 122737. [Google Scholar] [CrossRef]

- Kuo, T.C.; Wang, M.L. The optimisation of maintenance service levels to support the product service system. Int. J. Prod. Res. 2012, 50, 6691–6708. [Google Scholar] [CrossRef]

- Wang, N.; Ren, S.; Liu, Y.; Yang, M.; Wang, J.; Huisingh, D. An active preventive maintenance approach of complex equipment based on a novel product-service system operation mode. J. Clean. Prod. 2020, 277, 123365. [Google Scholar] [CrossRef]

- Garetti, M.; Rosa, P.; Terzi, S. Life cycle simulation for the design of product–service systems. Comput. Ind. 2012, 63, 361–369. [Google Scholar] [CrossRef]

- Sundin, E. Life-cycle perspectives of product/service-systems: In design theory. In Introduction to Product/Service-System Design; Springer: London, UK, 2009; pp. 31–49. [Google Scholar]

- Yang, L.; Xing, K.; Lee, S.H. A new conceptual life cycle model for Result-Oriented Product-Service System development. In Proceedings of the 2010 IEEE International Conference on Service Operations and Logistics, and Informatics, Qingdao, China, 15–17 July 2010; IEEE: New York, NY, USA, 2010; pp. 23–28. [Google Scholar]

- Clayton, R.J.; Backhouse, C.J.; Dani, S. Evaluating existing approaches to product-service system design: A comparison with industrial practice. J. Manuf. Technol. Manag. 2012, 23, 272–298. [Google Scholar] [CrossRef]

- Ball, R.E. Aircraft Combat Survivability: Susceptibility and Reduction; Lecture Notes; Department of Aeronautics, Naval Postgraduate School: Monterey, CA, USA, 1979. [Google Scholar]

- Turner, B.L.; Kasperson, R.E.; Matson, P.A.; McCarthy, J.J.; Corell, R.W.; Christensen, L.; Eckley, N.; Kasperson, J.X.; Luers, A.; Martello, M.L.; et al. A framework for vulnerability analysis in sustainability science. Proc. Natl. Acad. Sci. USA 2003, 100, 8074–8079. [Google Scholar] [CrossRef]

- Adger, W.N. Vulnerability. Glob. Environ. Change 2006, 16, 268–281. [Google Scholar] [CrossRef]

- Qiu, Q.A.; Cui, L.R.; Kong, D.J. Availability and maintenance modeling for a two-component system with dependent failures over a finite time horizon. Proc. Inst. Mech. Eng. O J. Risk Reliab. 2019, 233, 200–210. [Google Scholar] [CrossRef]

- Li, Y.F.; Liu, Y.; Huang, T.D.; Huang, H.Z.; Mi, J.H. Reliability assessment for systems suffering common cause failure based on Bayesian networks and proportional hazards model. Qual. Reliab. Eng. Int. 2020, 36, 2509–2520. [Google Scholar] [CrossRef]

- Zhang, Y.G.; Yu, T.X.; Song, B.F. A reliability allocation method of mechanism considering system performance reliability. Qual. Reliab. Eng. Int. 2019, 35, 2240–2260. [Google Scholar] [CrossRef]

- Estrada, A.; Romero, D. A system quality attributes ontology for product-service systems functional measurement based on a holistic approach. Procedia CIRP 2016, 47, 78–83. [Google Scholar] [CrossRef]

- Umeda, Y.; Daimon, T.; Kondoh, S. Proposal of Decision Support Method for Life Cycle Strategy by Estimating Value and Physical Lifetimes—Case Study. In Proceedings of the 4th International Symposium on Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 12–14 December 2005; pp. 606–613. [Google Scholar]

- Cooper, T. Inadequate life? Evidence of consumer attitudes to product obsolescence. J. Consum. Policy 2004, 27, 421–449. [Google Scholar] [CrossRef]

- Smith, A.K.; Bolton, R.N. An experimental investigation of customer reactions to service failure and recovery encounters: Paradox or peril? J. Serv. Res. 1998, 1, 65–81. [Google Scholar] [CrossRef]

- Besch, K. Product-service systems for office furniture: Barriers and opportunities on the European market. J. Clean. Prod. 2005, 13, 1083–1094. [Google Scholar] [CrossRef]

- Hou, C.; Jo, M.S.; Sarigöllü, E. Feelings of satiation as a mediator between a product’s perceived value and replacement intentions. J. Clean. Prod. 2020, 258, 120637. [Google Scholar] [CrossRef]

- Reim, W.; Sjödin, D.; Parida, V. Mitigating adverse customer behaviour for product-service system provision: An agency theory perspective. Ind. Mark. Manag. 2018, 74, 150–161. [Google Scholar] [CrossRef]

- de Medeiros, J.F.; Marcon, A.; Ribeiro JL, D.; Quist, J.; D’Agostin, A. Consumer emotions and collaborative consumption: The effect of COVID-19 on the adoption of use-oriented product-service systems. Sustain. Prod. Consum. 2021, 27, 1569–1588. [Google Scholar] [CrossRef]

- Hara, T.; Sakao, T.; Fukushima, R. Customization of product, service, and product/service system: What and how to design. Mech. Eng. Rev. 2019, 6, 18–00184. [Google Scholar] [CrossRef]

- Munoz Lopez, N.; Santolaya Saenz, J.L.; Biedermann, A.; Serrano Tierz, A. Sustainability assessment of product–service systems using flows between systems approach. Sustainability 2020, 12, 3415. [Google Scholar] [CrossRef]

- Asbjornslett, B.E. Assess the vulnerability of your production system. Prod. Plan. Control 1999, 10, 219–229. [Google Scholar] [CrossRef]

- DeSmit, Z.; Elhabashy, A.E.; Wells, L.J.; Camelio, J.A. Cyber-physical vulnerability assessment in manufacturing systems. Procedia Manuf. 2016, 5, 1060–1074. [Google Scholar] [CrossRef]

- Anton, P.S.; Anderson, R.H.; Mesic, R.; Scheiern, M. The Vulnerability Assessment & Mitigation Methodology. Rand National Defense Research Inst Santa Monica Ca. 2003. Available online: https://www.rand.org/content/dam/rand/pubs/monograph_reports/2005/MR1601.pdf (accessed on 9 March 2023).

- Zhang, J.; Zhao, X.; Song, Y.; Qiu, Q. Joint optimization of maintenance and spares ordering policy for a use-oriented product-service system with multiple failure modes. Appl. Stoch. Model. Bus. Ind. 2021, 37, 1123–1142. [Google Scholar] [CrossRef]

- Flax, L.K.; Jackson, R.W.; Stein, D.N. Community vulnerability assessment tool methodology. Nat. Hazards Rev. 2002, 3, 163–176. [Google Scholar] [CrossRef]

- Mahl, T.; Köhler, C.; Arnold, D.; Lins, D.; Kuhlenkötter, B. PSS-FMEA: Towards an integrated FMEA method to support the development of product-service systems in SMEs. Proc. Des. Soc. 2021, 1, 2501–2510. [Google Scholar] [CrossRef]

- Johansson, P.; Chakhunashvili, A.; Barone, S.; Bergman, B. Variation mode and effect analysis: A practical tool for quality improvement. Qual. Reliab. Eng. Int. 2006, 22, 865–876. [Google Scholar] [CrossRef]

- Bellinello, M.M.; Michalski, M.A.; Melani, A.H.; Netto, A.C.; Murad, C.A.; Souza, G.F. PAL-VMEA: A Novel Method for Enhancing Decision-Making Consistency in Maintenance Management. Appl. Sci. 2020, 10, 8040. [Google Scholar] [CrossRef]

- Goetz, S.; Hartung, J.; Schleich, B.; Wartzack, S. Robustness evaluation of product concepts based on function structures. In Proceedings of the Design Society: International Conference on Engineering Design, Delft University of Technology, Delft, The Netherlands, 5–8 August 2019; Cambridge University Press: Cambridge, UK, 2019; Volume 1, pp. 3521–3530. [Google Scholar]

- Pavasson, J.; Karlberg, M. Variation mode and effect analysis compared to FTA and FMEA in product development. In Proceedings of the 19th AR2TS Advances in Risk and Reliability Technology Symposium, Stratford-upon-Avon, UK, 12–14 April 2011; pp. 252–260. [Google Scholar]

- Sakao, T.; Birkhofer, H.; Panshef, V.; Dorsam, E. An effective and efficient method to design services: Empirical study for services by an investment-machine manufacturer. Int. J. Internet Manuf. Serv. 2009, 2, 95–110. [Google Scholar] [CrossRef]

- Haber, N.; Fargnoli, M.; Sakao, T. Integrating QFD for product-service systems with the Kano model and fuzzy AHP. Total Qual. Manag. Bus. Excell. 2020, 31, 929–954. [Google Scholar] [CrossRef]

- Ishikawa, K.; Loftus, J.H. Introduction to Quality Control; 3A Corporation: Tokyo, Japan, 1990. [Google Scholar]

- Reim, W.; Parida, V.; Sjödin, D.R. Managing risks for product-service systems provision: Introducing a practical decision tool for risk management. In Practices and Tools for Servitization; Palgrave Macmillan: Cham, Switzerland, 2018; pp. 249–266. [Google Scholar]

- Daiwa Corporation. Available online: https://www.daiwa-corp.com/ (accessed on 12 December 2022).

- Example of Commercial Laundry Equipment Shipment. Available online: https://www.daiwa-corp.com/business/record.php/ (accessed on 12 December 2022).

- Song, W. Requirement management for product-service systems: Status review and future trends. Comput. Ind. 2017, 85, 11–22. [Google Scholar] [CrossRef]

| Weight | Criteria |

|---|---|

| 0–2 | There is a very low-level contribution that the RSP could contribute to the benefit of the stakeholders of the targeted PSS |

| 3–4 | There is a low-level contribution that the RSP could contribute to the benefit of the stakeholders of the targeted PSS |

| 5–6 | There is a moderate-level contribution that the RSP could contribute to the benefit of the stakeholders of the targeted PSS |

| 7–8 | There is a high-level contribution that the RSP could contribute to the benefit of the stakeholders of the targeted PSS |

| 9–10 | There is a very high-level contribution that the RSP could contribute to the benefit of the stakeholders of the targeted PSS |

| Root Cause | RSP 1 | |

|---|---|---|

| PCh 1 | SCh 1 | |

| Organization | ||

| Society | ||

| Resource | ||

| Behavior | ||

| Competence | ||

| Environment | ||

| Weight | Criteria |

|---|---|

| 0–2 | Extremely low contribution to the variation of the RSP performance that could be made by the impact of the product characteristic/service characteristic |

| 3–4 | Low contribution to the variation of the RSP performance that could be made by the impact of the product characteristic/service characteristic |

| 5–6 | Moderate contribution to the variation of the RSP performance that could be made by the impact of the product characteristic/service characteristic |

| 7–8 | High contribution to the variation of the RSP performance that could be made by the impact of the product characteristic/service characteristic |

| 9–10 | Extremely high contribution to the variation of the RSP performance that could be made by the impact of the product characteristic/service characteristic |

| RSP | PCh | SCh |

|---|---|---|

| Ensuring the washing machine is usable | The availability of the washing machine | The time to respond to a problem report |

| The operability of the washing machine | The interval time between each usage | |

| Ensuring the washing machine is sanitary | Manual sterilization function, | The interval time of regular disinfection |

| Root Cause | RSP1 | |||

|---|---|---|---|---|

| PCh1 | PCh2 | SCh1 | SCh2 | |

| Organization | NF9: Lack of communication between the liaison department and maintenance department | |||

| Society | NF1: Elderly people’s resistance to technological products | NF13: poor understanding of sharing mode of elders | ||

| Resource | NF2: Power shortage | NF7: electronic component failure | NF10: Lack of replacement parts | |

| NF3: aging components | ||||

| Behavior | NF4: Careless customer behavior | NF11: Frequent vandalism | NF14: Elders refuse to take out clothes timely | |

| NF5: Adverse customer behavior | ||||

| Competence | NF6: Mismanagement | NF8: Lack of experience in instructing old users | NF12: Lack of training on serving elders | NF15: Lack of co-operation with nursing administrators |

| Environment | NF16: Lack of policy about timely taking out | |||

| Root Cause | RSP2 | |

|---|---|---|

| PCh3 | SCh3 | |

| Organization | NF22: Poor communication between administrator and maintenance department | |

| Society | ||

| Resource | NF17: Heater aging | NF23: Lack of effective fungicides |

| NF18: Bacteria in water pipes | ||

| Behavior | NF19: The user has not used the sterilization function | |

| NF20: Patient using washing machine | ||

| Competence | NF24: Insufficient anti-bactericidal Experience | |

| Environment | NF21: The appearance of a new flu | |

| Code of RSP | Importance |

|---|---|

| RSP1 | 10 |

| RSP2 | 6 |

| Code of Characteristics | Weight |

|---|---|

| PCh1 (RSP1) | 10 |

| PCh2 (RSP1) | 5 |

| PCh3 (RSP2) | 8 |

| SCh1 (RSP1) | 6 |

| SCh2 (RSP1) | 3 |

| SCh3 (RSP2) | 3 |

| Code of RSP | The Weight of RSP | Code of Characteristics | The Weight of Characteristics | Code of Noise Factor | Variation of NF | Sensitivity of Characteristic to NF | VRPN of NF | VRPN of Each RSP | Total VRPN |

|---|---|---|---|---|---|---|---|---|---|

| RSP1 | 10 | PCh1 | 10 | NF1 | 2 | 6 | 1200 | 11,400 | 29,424 |

| NF2 | 8 | 1 | 800 | ||||||

| NF3 | 8 | 6 | 4800 | ||||||

| NF4 | 6 | 6 | 3600 | ||||||

| NF5 | 8 | 2 | 1600 | ||||||

| NF6 | 2 | 2 | 400 | ||||||

| PCh2 | 5 | NF7 | 8 | 4 | 800 | 1000 | |||

| NF8 | 2 | 2 | 200 | ||||||

| SCh1 | 6 | NF9 | 5 | 4 | 1200 | 5420 | |||

| NF10 | 8 | 4 | 1920 | ||||||

| NF11 | 8 | 2 | 960 | ||||||

| NF12 | 4 | 6 | 1440 | ||||||

| SCh2 | 3 | NF13 | 2 | 8 | 480 | 4260 | |||

| NF14 | 8 | 4 | 960 | ||||||

| NF15 | 5 | 6 | 900 | ||||||

| NF16 | 8 | 8 | 1920 | ||||||

| RSP2 | 6 | PCh3 | 8 | NF17 | 8 | 3 | 1152 | 6576 | |

| NF18 | 6 | 2 | 576 | ||||||

| NF19 | 5 | 2 | 480 | ||||||

| NF20 | 8 | 6 | 2304 | ||||||

| NF21 | 9 | 5 | 2040 | ||||||

| SCh3 | 3 | NF22 | 2 | 4 | 144 | 792 | |||

| NF23 | 10 | 2 | 360 | ||||||

| NF24 | 4 | 4 | 288 |

| Code of NF | Mitigation Strategy | Potential Side Effect | |||

|---|---|---|---|---|---|

| Risk Avoidance | Risk Reduction | Risk Sharing | Risk Retention | ||

| NF1 | Education on elders about using washing machine | ||||

| NF3 | Monthly examination | Improved cost of human resource | |||

| NF4 | Strengthen collaboration with nursing home administrators | ||||

| NF5 | Set up monitoring system | High technical competence is required | |||

| NF9 | Integration of maintenance and liaison departments | ||||

| NF10 | Spare parts for Nursing Homes | ||||

| NF12 | Post a description of the main problem characteristics at the washing machine work site | ||||

| NF16 | Ask administrators to guide the per-usage time | ||||

| NF17 | Provide a periodic examination on the condition of heater | ||||

| NF20 | Infected people are prohibited from using washing machines | ||||

| NF21 | Ask administrators to take charge of managing epidemic patients | Further infection caused by the poor competence of administrators | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Mitake, Y.; Tsutsui, Y.; Alfarisi, S.; Shimomura, Y. A Vulnerability Assessment Framework for Product-Service Systems Based on Variation Mode and Effect Analysis. Sustainability 2023, 15, 5092. https://doi.org/10.3390/su15065092

Wang H, Mitake Y, Tsutsui Y, Alfarisi S, Shimomura Y. A Vulnerability Assessment Framework for Product-Service Systems Based on Variation Mode and Effect Analysis. Sustainability. 2023; 15(6):5092. https://doi.org/10.3390/su15065092

Chicago/Turabian StyleWang, Hanfei, Yuya Mitake, Yusuke Tsutsui, Salman Alfarisi, and Yoshiki Shimomura. 2023. "A Vulnerability Assessment Framework for Product-Service Systems Based on Variation Mode and Effect Analysis" Sustainability 15, no. 6: 5092. https://doi.org/10.3390/su15065092

APA StyleWang, H., Mitake, Y., Tsutsui, Y., Alfarisi, S., & Shimomura, Y. (2023). A Vulnerability Assessment Framework for Product-Service Systems Based on Variation Mode and Effect Analysis. Sustainability, 15(6), 5092. https://doi.org/10.3390/su15065092