Abstract

Traditional safety planning methods that rely on manual inspections result in labour-intensive, time-consuming, and inadequate information transmission, which has significant negative social and economic effects on our society, as well as financial and schedule losses for construction projects. Building information modelling (BIM) is useful for analysing workplace safety issues, preventing risks and hazards, and improving safety throughout the project’s life cycle. This study intends to pinpoint health and safety concerns and to understand the role of BIM adoption in enhancing health and safety in Malaysian building construction projects. Following a survey of 302 Malaysian construction industry professionals, statistical data analysis using the relative importance index, reliability, validity, and correlation measures was performed. The results show that implementing BIM can prevent accidents on construction sites by detecting physical spatial clashes, anticipating project dangers, and providing a wealth of parametric data throughout the entire life cycle of structures. A framework was created to improve the application of BIM to enhance health and safety linked with construction projects. The study found that construction industry stakeholders believe that BIM implementation in construction projects can improve health and safety and reduce accident rates in Malaysia.

1. Introduction

The construction industry cannot disregard the importance of health and safety (H&S) on construction sites [1,2]. Over 26,000 construction workers in the United States have died at work in the last two decades. That equates to approximately five deaths each working day [3]. Falls from height, slips, being struck by large and heavy construction equipment, lifting operations, electrocution, and becoming entangled in or between objects are among the most common accidents on construction sites. The problems of the industry’s distinctive character, human behaviour, tough site circumstances, inadequate safety management, and inadequate integration of occupational health and safety are all important causes of accidents, resulting in the occurrence of accidents and fatalities in construction projects [4,5,6,7,8,9].

Traditional safety planning in Malaysia is mostly labour-intensive, time-consuming, and inefficient since it depends on regular manual observations [3,10,11,12]. In addition, the traditional safety planning method to be used in the construction sector, such as two-dimensional drawings and schedules, face-to-face meetings, written declarations, and even usage of telecommunication tools like email, fax, and cell phones to understand safety aspects, are inefficient processes with poor information exchange quality [13,14,15,16]. Traditionally, construction and safety have been controlled independently [17,18]. Safety is always considered a deterrent to working productivity and further capital investment. On the other side, construction management that prioritises productivity rather than safety management is likely to neglect the safety restrictions within the construction development, resulting in a consistently high accident rate in Malaysia [2,19].

The construction industry is characterised by continuous changes, the bombardment of differing technologies, terrible working conditions, and the participation and necessity for coordination of several interdependent trades and operations [20,21]. Due to the hazardous nature of the workplace, the construction sector is highly concerned about safety. Even though Malaysia has extensive occupational health and safety regulations that are frequently reinforced by rigorous safety inspections and audits by the Department of Occupational Safety and Health (DOSH), site accident rates are still alarming. Construction accidents may cause project delays, budget overruns, waste of time, and loss of economic resources. In the worst cases, construction accidents can result in the loss of human life. The contractors, safety specialists, and even some stakeholders contribute significantly to ensuring that the safety management policies are practised successfully to achieve zero incidents in the construction industry in Malaysia. Traditional safety planning, which depends on manual observation and the usage of traditional communication methods, results in low efficiency of the process. Safety accidents negatively affect our society on a social and economic level and result in considerable cost and schedule losses for construction projects [22]. Considerations for safety throughout the design and construction stage can avert the occurrence of accidents. However, the lack of adaptable equipment and technologies makes it difficult to support and improve occupational health and safety during construction.

Therefore, a method or technology, building information modelling (BIM), is proposed and used in the construction sector to prevent and reduce injuries and accidents from happening. BIM is the highly encouraging latest advancement in the architectural, engineering, and construction (AEC) sector [23]. It is a technology that can lower project costs, boost productivity and quality, speed up project delivery, and even enhance the health and safety aspects of the construction industry. BIM functions to replicate the construction project in a simulated environment, and a BIM model can be constructed digitally with BIM technology [24]. BIM is the holistic information production and management process for a constructed asset. A computerised depiction of an asset throughout its life cycle, from conception, construction, and operation, can be created using BIM by integrating structured and multidisciplinary data [25,26,27]. Through BIM, a safer workplace is created with the improvement of safety communications and safety planning in the construction industry in Malaysia.

This study aims to devise a BIM-based theoretical framework to manage H&S issues of the construction project. To attain this, the study identifies the health and safety issues of the construction industry from the literature and the perspective of construction industry stakeholders. Moreover, the study also discusses the adoption of BIM technology in improving safety as evaluated in the construction industry. The scope of this study covers the effects and impacts of the implementation of traditional health and safety management in construction projects in Malaysia. In addition, the BIM concept and theory related to health and safety in construction projects were studied, and this study researched the health and safety of building construction projects with the adoption of the BIM application in Malaysia.

2. Literature Review

The adoption of traditional safety planning and its effects on health and safety in building construction projects were the main topics of the literature review. In addition, it examined the BIM safety applications used in building projects for safety rule verification, safety design validation, and safety communications.

2.1. Traditional Safety Planning

The construction sector is infamous for its track record of health and safety, and compared to other industries, it has a higher rate of workplace injuries and fatal accidents [10,28,29]. However, despite the efforts of regulatory and governmental organizations and professionals, there has not been a discernible decline in the number of accidents, injuries, and fatalities that occur in the construction sector.

Traditional safety planning can be summarised by three facts. Traditional safety planning mostly relies on regular manual observations, which are labour-intensive and highly time-consuming. Project execution and safety planning may communicate what will be built and what safety precautions are required. However, the connection between safety planning and job task execution is frequently weak. The observed findings on safety might typically be prone to mistakes due to subjective assessments of the decision-maker, since they use manual observation and depend on their own experiences. Next, it is difficult to impart safety knowledge and information only through safety regulations. The existing safety rules and practices have been shown to have an impact. It becomes more challenging for personnel or workers who are newly hired by companies to adapt to a new safety culture. Workers find it difficult to gain knowledge related to the new safety regulations in a short period and follow the rules when designing, planning, and executing work tasks. Besides that, contractors are frequently solely responsible for construction site safety [3,30]. The project stakeholders, especially designers, should pay more attention to safety since there is a connection between construction methods and the schedule on-site. Designers are frequently unaware of how their work impacts construction methods, the schedule, and, most critically, safety.

Traditional occupational safety planning is dependent on the scale of the work system of the construction site and the project delivery method. In a survey of incidents at various firm sizes, it was revealed that accidents were more common and more severe in small firms [28,31]. A traditional safety analysis is made by estimating the risk situation and modifying the schedule to prevent the risk peaks by referring to the safety history records [3,14].

The factors influencing safety performance in building construction projects include the labourers, lack of skilled labour, limited experience, availability of resources, inadequate safety attitudes, project size, contract value, budget, time, etc., for construction projects [28,32,33]. In addition, inappropriate work planning, insufficiency of necessary equipment, communication between partners, training, and leadership are also major obstacles related to effective safety planning [6,34]. Due to poor coordination and integration between the designers and engineers or safety coordinators, they may face challenges in analysing the type, moment, place, and reason for implementing effective safety measures [3,4,35]. The workers and even the inexperienced managers are also unaware of and ignore the safety requirements and knowledge during the construction phase [28]. From the statement above, we can realise that health and safety issues are fairly disregarded by most of the contractors and stakeholders, causing time and economic resources to be lost with the occurrence of accidents [3].

Construction design and management (CDM) and publications like the Egan and the Latham Reports have all been created to improve health and safety in the construction sector, among other changes [10]. Production planning management has been integrated with a safety planning and control model (SPC) [36]. To identify and evaluate the probability of likely loss-of-control events, the construction job safety analysis (CJSA) tool has also been created [3,6,14]. Despite the modifications showing positive development in H&S over the years, many improvements still need to be made.

2.2. BIM-Related Safety Applications

Since the bulk of the construction sector has these safety concerns, practitioners and researchers are worried about coming up with a creative solution. Designers or architects, construction managers or project managers, and contractors can all use building information modelling (BIM) to solve these issues, as BIM simplifies the project. Using BIM to improve health and safety in the construction sector has the potential to increase practitioner understanding of the sites, which would reduce the likelihood of accidents occurring while construction is being carried out. The majority of H&S data may be produced directly in a single environment with the development of BIM and the implementation of the project’s life cycle in a single integrated environment. The use of an integrated strategy is studied for its potential benefits to the health and safety of the majority of site workers.

2.2.1. BIM for Safety Rule-Checking and Design Validation

BIM has gained extensive interest from the architectural, engineering, and construction (AEC) sector. The planning of safety risks and identification of hazards in the construction industry can be enhanced with BIM adoption. BIM helps in detecting and determining physical spatial clashes on the construction site [11,37]. Four-dimensional BIM can help to visualise, analyse, and avoid project hazards throughout the construction project life cycle, aiming to enhance project management [35,38]. Falls, cave-ins, and congestion hazards can also be identified with the combination of BIM and laser scanning and point cloud generation by modelling occupancy of the construction sites through BIM [1,3,14]. The method above can automatically recognise the fall and cave-in hazards and visualises the pits, hazards, and the necessary personal protective equipment in a BIM model. BIM is a tool that can be used as a design and rule algorithm. BIM can be utilised for automated safety checking of construction models and schedules on construction sites [3]. BIM is an object-oriented, semantic approach that enables the handling of complex information systems, including 3D visual assistance [27,35]. BIM may be utilised as a tool for systematic risk management, as well as a platform for other BIM-related technologies and a source of core data for undertaking additional risk analysis in the development phase [37]. By incorporating H&S data into BIM, the emphasis on detecting high-risk projects and promoting awareness may be increased, which will help to reduce risks and accidents in the future. [10].

BIM can be adopted as a rule check software to detect and mitigate safety concerns and optimise their design during the planning and design process [37]. BIM allows users to visualise and predict occupational hazards throughout construction, allowing them to adjust design options and incorporate or connect the safety process in the model, achieving the goals of designing for safety with BIM development [35,39]. BIM can help designers comprehend the consequences of design choices and decisions by automatically recognising and highlighting the possible safety risks [1,40]. By embedding the data and hazardous materials into the BIM models, the ability to visualise particular construction scenarios can be performed, and it helps designers make judgments about further actions or construction techniques [10,11]. Suggestions on how to improve their designs are given to designers and contractors to make them safer to construct with the development of designs for construction worker safety tools [1,4]. BIM can regulate how the design affects safety on the job site and when it is best to have an impact on construction safety during the planning and design stages [40,41]. The construction phase that is connected by BIM and schedules may be extracted and explained in real-time, giving all operatives on construction sites a greater understanding [13]. Through simulation-based scheduling, a thorough, in-depth, and precise understanding of site conditions and all construction stages may be provided by examining the site’s environmental characteristics and visualising the project dangers [35,42].

2.2.2. BIM for Safety Communication

Safety communication helps managers or workers to monitor what is happening around the construction site. All employees should be able to understand the safety information provided by communication by letting them know when risks are on the horizon or by asking for assistance with something. Teamwork—especially safety teamwork—cannot be performed or work without timely and efficient communication. Communication at work concerning safety should be improved, whether the information is urgent or simply preventative. BIM is a significant advancement in technology for site communication, as it has the potential to replace traditional communication methods, such as physical meetings, paper-based methods, telecommunication systems, and so on [13]. BIM can enhance stakeholders’ communication as it can help in increasing the transfer of information between parties. There is a need for a solution to streamline collaboration between stakeholders at the final stage of the investment; hence, BIM can help and be adopted for this need. BIM allows one to share relevant and accurate information with different groups of people, such as civil engineers, architects, contractors, stakeholders, etc. Using cloud technology, different teams can work together and communicate at the same time if there is anything urgent happening at the site, from those in the office to those in the workshop and on-site.

BIM provides a lot of parametric data and enables collaborative projects to access information sharing on safety at the construction site [34,43]. At all project stages, communication is essential for distributing and comprehending technology options and safety precautions [13,44]. BIM adoption in construction projects results in increasing communication among individuals participating in a project, which benefits more efficiently by eliminating the ineffective paper-based method of distributing project data and information [10]. With BIM authoring tools, virtual reality (VR) is utilised for virtual danger assessments and visualisation, as well as professional training and design for safety [3,44]. BIM can be used to improve construction safety by establishing a strong connection between safety concerns and construction planning, as well as providing site layouts and safety plans to aid safety communication [4,45]. Table 1 below shows all the identified factors from the literature related to traditional safety planning and BIM safety application.

Table 1.

Literature-based identified factors related to traditional and BIM safety planning.

3. Methodology

This study intends to evaluate how Malaysian construction industry professionals view BIM and how it may be applied to building construction projects to improve health and safety. The study adopted a descriptive methodology. This study comprised data collection and subject observation over a study period in order to assess the state of accident occurrences. A qualitative and quantitative survey approach was used in this study to ascertain and investigate the health and safety improvement with the adoption of BIM in building construction projects from the viewpoint of consultants, contractors, and specialists from a construction academic background.

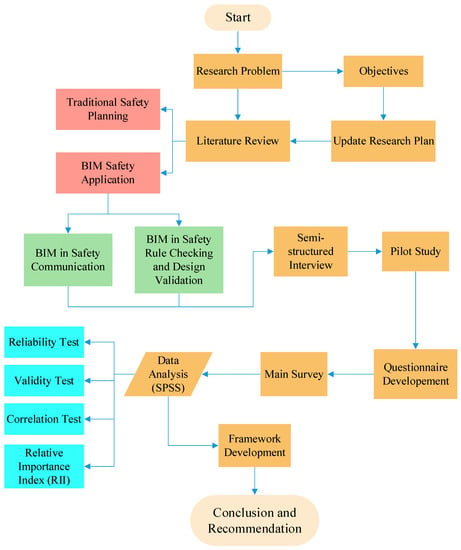

The goals of the study and the challenges associated with construction projects in terms of health and safety have been determined. A literature survey was carried out to better comprehend BIM and its current adaptability and safety use in the research and building construction industries. From the literature research, assessment questions were devised to gauge how the specialists in building construction projects evaluate BIM in terms of safety. Additionally, it was established how BIM was used in building construction projects for safety purposes. The second phase of the research involved developing and creating a questionnaire. Pilot research was conducted to assess the respondents’ degree of understanding of the prepared questionnaire. Finally, the data were descriptively analysed using the statistical packages for social sciences (SPSS) programme to assess reliability, validity, and correlation. In addition to statistical analysis, Microsoft Excel was used to generate the relative importance index (RII). To verify the F-distribution for the null hypothesis, the F-test was run. Figure 1 depicts the progression of the study to its conclusion.

Figure 1.

Research flowchart.

3.1. Semi-Structure Interview

In a semi-structured interview, questions were posed within a preset theme framework to collect data. The questions were often open-ended, allowing for flexibility. This semi-structured interview was conducted by recruiting 10–15 experts from contractors, consultants, and academic personnel with construction backgrounds to obtain feedback on the draft questionnaire. This semi-structured interview was conducted online or in-person.

3.2. Pilot Survey

Before distributing the questionnaire to the entire sample group, a pilot test was undertaken to evaluate the viability of the key research factors. A small sample size was used in the pilot test to verify whether the respondents were aware of the questionnaire’s purpose or not. Following the results of an effective pilot test, a large-scale distribution was conducted. However, in the pilot survey, various factors were advised to be discarded; a summary of the discarded factors is shown below in Table 2.

Table 2.

Discarded factors during the pilot survey.

3.3. Development of the Questionnaire

A survey was created to assess how BIM adoption has improved health and safety and to examine the variables that affect BIM use and understanding in building construction projects. The developed questionnaire has three sections. The questionnaire’s initial section concentrated on the profiles of the respondents. The second section focused on contemporary safety concerns and the results of using conventional safety planning in building construction projects. The third portion focused on the use of safety BIM to enhance health and safety in construction projects for buildings.

3.4. Target Population and Sample Size

In this study, academic university personnel, as well as building project contractors and consultants were the target populations. The quickest and easiest method of data collection for this study was a questionnaire methodology.

The sample size is frequently divided into subgroups based on demographics, such as age, gender, and location, to ensure that the overall sample accurately represents the entire population. The sample size was determined using Andrew Fisher’s calculation [57,58] for the unknowable population.

Equation (1) shows the formula of the sample size calculation. The ‘z-score’, usually referred to as the “standard score,” is related to the degree of confidence. The confidence level is the likelihood that, after many random sample selections, the actual population parameter will fall inside the confidence interval. A z-score is a statistic that indicates the number of standard deviations below or above the population means that a raw score or percentage of confidence level falls. The level of confidence is 90 because there are doubtful specialists in the general community in the building business, which reduces the level of confidence. A confidence level of 90 has a z-score of 1.65 with a standard deviation of 0.5. The confidence interval additionally displays the error margin, which is 5%. In this study, 273 sample sizes were selected. However, the questionnaires were distributed more widely than the sample size to obtain better findings.

3.5. Data Analysis

Expert interviews were conducted to gather qualitative data, and a quantitative technique was used to analyse the findings. In addition, the statistic packages for social science (SPSS) software was used for further data analysis, as discussed below.

3.5.1. Reliability Test

The consistency of the questionnaire was taken into consideration using reliability analysis. The higher value of reliability reflects a higher degree of internal consistency. To determine how closely connected a group of items are to one another, the internal consistency—or Cronbach’s alpha—is measured. It is regarded as a gauge for the dependability of scales. The average inter-correlation between the test items and the total number of test items may be used. Equation (2) below shows the formula of Cronbach’s alpha calculation for conceptual purposes:

where:

N: number of items;

Ć: average inter-item covariance among the items;

Ύ: average variance.

3.5.2. Validity Test

A validity test is essential in research data collection. It serves as an indicator of the research instrument’s level of validity. An instrument is deemed to be legitimate if it can expose the data of the variable’s research and can measure what is to be measured or intended. The validity test is categorised into two main groups: face validity and statistical validity.

Face Validity

The extent to which an instrument is seen to include the notion it intends to measure is known as face validity. If an instrument appears to measure what it is supposed to measure, it may be said to have validity. It is altered and discussed in a number of positive and important ways.

Statistical Validity

Statistical validity is the degree to which research study results may be considered accurate and dependable based on the statistical test. It is crucial for researchers to have enough data and to use the appropriate statistical method to evaluate that data to attain statistical validity. Internal validity and structure validity are categorised as statistical validity.

Internal Validity

Internal validity is the extent to which a research study establishes a trustworthy cause-and-effect relationship. This is about the validity of results within or internal to a study. It focuses on accuracy and strong research methods. It usually concerns causality.

Structure Validity

Structural validity is the degree to which ratings on a scale constitute a sufficient indication of dimensionality research.

3.5.3. Correlation Test

Correlation is a statistical technique that shows how closely two variables are related to one another or how much of a connection there is between them. The correlation coefficient, which always ranges from -1 to 1, is used to quantify correlation.

3.5.4. Relative Importance Index (RII)

The relative importance index (RII) is calculated using Equation (3) below. Based on the input obtained, the relative importance index (RII) is computed for each type and subtype to assess the significance of each element. A factor’s significance increases with its RII value. As a result of its simplicity in prioritising each element, RII is preferred for factor ranking.

where:

W: the weight of each factor;

A: the height and weight of the factor;

N: the sum of the respondents.

4. Results and Discussion

4.1. Info about the Participants

The findings in Table 3 display general information about respondents who are Malaysian construction industry professionals. The survey was distributed using the Microsoft form platform for this investigation, and 302 replies were obtained. The findings indicate that 79.1% of respondents had earned a Bachelor’s degree. The respondents’ experience ranges from none to more than 30 years. Regarding education and years of experience, 38.7% of the respondents had 5 to 10 years of experience in the construction industry. The majority of responders (55.3%) work for contractor companies. According to their work title, the majority of respondents (36.1%) in the construction business were from other groups, such as planners, drafters, quantity surveyors, administrators, trainees, and so forth. Site engineers made up the majority of the additional 35.4% of respondents. In terms of institution size, it was discovered that 43.4% of respondents worked for medium-sized organisations with 50 to 200 people.

Table 3.

Respondents’ demographic profiles.

4.2. Factors to Implement BIM

The analysis in this part focused on aspects that can enhance health and safety through the adoption of BIM in the construction industry. The determination of a few factors was made. These elements can be examined for health and safety improvement in the construction sector by reducing the possibility of hazard exposure and injuries during building projects. On a five-point Likert scale, where 1 indicates high disagreement, 2 indicates disagreement, 3 indicates neutrality, 4 indicates agreement, and 5 indicates strong agreement, the respondents were asked to rate the degree of BIM implementation and utilisation in construction projects. The Cronbach’s alpha test was used to examine the data for consistency and dependability; the results are detailed below.

4.2.1. Reliability

The statistical approach of Cronbach’s alpha was used to guarantee precision and dependability. A value of 0.9 is considered very dependable, 0.7 to 0.9 is regarded as reliable, 0.5 to 0.7 is considered fairly reliable, and 0.5 or less is considered extremely unreliable. With N = 48 and a test value of 0.915, it is clear that the reliability is high. The data dependability for this investigation is shown in Table 4 below.

Table 4.

Data reliability summary.

4.2.2. Validity

Table 5 shows the data validity and correlation for this study. The correlation and p-value were evaluated for each variable. For the hypothesis test, our p-value equals < 0.001, which is less than the reasonable significance level (0.05), so it can be concluded that all the factors in this survey were valid. In addition, based on the correlation coefficient obtained for all the factors being greater than the r table product moment 0.1126, it can be concluded that all the factors were valid. Consequently, the null hypothesis is rejected, and it can be concluded that all the factors were beneficial to be used for this study.

Table 5.

Data validity and correlation summary.

4.2.3. Correlation

Based on the results in Table 5, the p-value obtained for all the factors is <0.001, which is less than the reasonable significance level (0.05). It can be concluded that there is a significant relationship between each factor. However, the Pearson correlation values obtained for a few factors were in the range of 0.21–0.40, meaning they have a low correlation with each other. The remaining factors have a correlation coefficient within the range of 0.41–0.60, meaning that they have a moderate correlation. Consequently, the result of the correlation is still acceptable, and there is a less significant relationship between each factor.

4.2.4. Ranking by RII

The quantification and significance of each aspect are evaluated using RII for traditional safety planning and health and safety improvement with the use of BIM. This mechanism is a method based on science that is mostly used to assess how the components in this survey study are ranked. The RII is calculated using the formula above, where W stands for each factor’s intensity (which ranges from 1 to 5), A stands for the highest weight (in this example, 5), and N stands for the number of respondents (i.e., 302 in this case).

Traditional Safety Planning

This section examines the implementation of traditional safety planning in the construction industry, the factors that prevent accidents from happening, and the impacts of accidents on the projects and people.

- A.

- Implementation of Traditional Safety Planning

Based on the results shown in Table 6, “traditional safety planning is labour-intensive and highly time-consuming” was ranked at the first position, which equals 88.54%, implying that this factor is statistically significant. This means that there is sufficient evidence that traditional safety planning is labour-intensive and highly time-consuming to a high degree. Most of the respondents in this study agree that traditional safety planning relies strongly on 2D paper-based information to determine hazard prevention techniques, which is often complex and difficult to understand for the workers. They require a long time to understand the surroundings of the site, and thus, this method is highly inefficient. Hence, the connection between planning and execution is often weak, as execution does not always go with the flow. The obtained results agree with Ruikar [10], who found that traditional safety planning has a major impact on the time and construction progress.

Table 6.

RII and ranking of factors for the implementation of traditional safety planning.

“The construction site size, work system, and project delivery method are factors that influence occupational safety” was ranked in the second position, which equals 82.19%. In other words, there is evidence that the construction site size, work system, and project delivery method are factors that influence occupational safety to a high degree. It was revealed that small-scale construction sites have a higher number of occupational accidents. The small-scale construction sites mostly lack technical support, which may be a reason for site accidents. In addition, the government is generally focused on large-scale construction sites more than small-scale construction sites. The media repeat the exposure to large-scale construction sites; thus, the public will likely neglect accidents happening at small-scale construction sites. For this reason, the safety management system is neglected or ignored by the contractors who are involved in small-scale construction. The obtained results agree with Arewa and Farrell [31].

“Safety knowledge is difficult to share and transfer by safety regulations alone” was ranked at the third position, which equals 82.05%. This means that this factor is statistically significant. This directs that the respondents agree to a high degree that safety knowledge is difficult to share and transfer by safety regulations alone. It is agreed that the newly hired workers find it difficult to adapt to a new safety culture since the improvement of existing safety rules and regulations has slowed down in recent years. The workers are commanded to acquire the knowledge in a short time and follow the rules when designing, planning, and executing the projects.

“Contractors are frequently solely responsible for construction site safety” was ranked at the last position, which equals 80.07%. This indicates that the respondents agree to a high degree that the contractors are solely responsible for construction site safety. Safety at the site, which is responsibly taken care of by every team member, helps to solve improving health and safety in the construction industry. The obtained results agree with Malekitabar and Ardeshir [30], who found that responsibility for safety needs to be taken on by everyone, not just the contractors.

In general, it was found that all factors in this group are statistically significant with their RII weight of over 80%. This designated that the respondents agree to a high degree with the traditional safety planning. The results are presented in Table 6.

- B.

- Factors and Impacts of Higher Accident Rates

“The unique nature of the industry, human behaviour, difficult site conditions, and poor safety management are causes of an accident” was ranked at the first position, which equals 90.00%. This designated that respondents agree to a high degree that the unique nature of the industry, human behaviour, difficult site conditions, and poor safety management are causes of an accident. The feedback from the respondents strongly agreed that the irresponsible attitude of the workers during working or handling machines and discipline issues results in decreased safety. Many accidents happen because of the irresponsible attitudes of the workers, apart from their negligence and carelessness. Concerning alcoholic beverages, some of the workers may exhibit discipline issues when they go for a drink after work. This condition may affect their safety performance during work the following day, resulting in accidents.

“The availability of skilled labour and resources, limited experience, poor safety attitudes, project size, time, and budget are factors that influence safety” was ranked at the second position, which equals 89.40%. This indicates that the respondents agree to a high degree that the availability of skilled labour and resources, limited experience, poor safety attitudes, project size, time, and budget are factors that influence safety. This result may be due to contractors, site engineers, or health and safety department officers failing to provide safety knowledge-sharing sessions and training to the workers. A smaller project size may lack workers with construction experience, intensive use of temporary workers, and contractors not properly providing PPE. The obtained results agree with Gopang and Nebhwani [32].

Additionally, “inappropriate work planning, insufficiency of necessary equipment, communication between partners, training, and leadership” was ranked at the third position, which equals 88.81%, based on the respondents’ responses. In other words, there is evidence that inappropriate work planning, insufficiency of necessary equipment, communication between partners, training, and leadership are the factors that influence health and safety issues to a high degree. This factor results in an increase in the accident and fatalities number and causes injuries at the construction site. The obtained results agree with Cortés-Pérez and Cortés-Pérez [34], who found that lacking necessary equipment and training might contribute to a failure in health and safety in a construction project.

“Time and economic resources are lost with an accident’s occurrence” was ranked the first position for the impacts of higher accidents rate group, which equals 87.15%. This is an indication that it is statistically significant, meaning that there is sufficient evidence that time and economic resources are lost to an accident’s occurrence to a high degree. Accidents lead to construction delays and cost overruns, which decrease the productivity of the economic resources available, restricting the growth potential and reducing economic profitability.

In general, it was found that all factors are significant statistically, with all the RII weight of factors over 80%. This means that there is high approval from the respondents about these causes and impacts of influence on the higher rate of accidents in the construction industry. The results of these groups of factors are presented in Table 7.

Table 7.

RII and ranking of factors causing site accidents.

BIM-Related Safety Applications

This group consists of two items related to BIM applications: BIM for safety rule checking and design validation and BIM in safety communications.

- A.

- BIM for Safety Rule Checking and Design Validation

All the factors for BIM in safety checking and design validation were ranked with the help of RII, as shown in Table 8 below. “BIM that can help detect and determine physical spatial clashes on a construction site” were found to be the most influential factor; hence it was ranked in the first position, which equals 92.65%. It is evidence that BIM can help detect and determine physical spatial clashes on a construction site to a high degree. BIM allows architects to preview a series of potential scenarios and identify specific places where different models may overlay by using the techniques of visualisation, detection, and virtual prototyping before the construction starts. Once the construction is in process, BIM assists the site managers in reducing the on-site risks. Clash detection via BIM can help provide accurate estimates for the entire construction phase by identifying clashes between several models during the design and construction stages, resulting in keeping accidents at bay daily at the construction site. In short, BIM can help identify risks early on, help avoid accidents during construction, and create a safer working environment for everyone involved in the construction process. The obtained results agree with Lu and Gong [11] and Zou and Kiviniemi [37].

Table 8.

RII and ranking of factors related to BIM safety rule checking and design validation.

“BIM visualises, analyses, and prevents project hazards throughout the life cycle of the construction project” was ranked in the second position, which equals 87.88%. In other words, there is evidence that BIM visualises, analyses, and prevents project hazards throughout the life cycle of the construction project to a high degree. The reason for this result is that the visualisation techniques of BIM employ conflict detection, allowing design errors to be spotted and amended before and during the project execution, hence, accidents can be avoided. The obtained results agree with Hartmann and Van Meerveld [38], who found that project hazards can be visualised, analysed, and avoided via 4D BIM to enhance project management.

“Monitoring of confined spaces can be improved on construction sites” was ranked at the third position, which equals 87.35%, implying that this factor is statistically significant. This directs that the respondents agree to a high degree that the monitoring of confined spaces can be improved on construction sites. BIM can be used to control the hazards of working in confined spaces and monitor air dust in real-time for the protection of workers. “Time and cost are reduced” was also ranked at the third position, also equal to 87.35%. This indicates that it is statistically significant, meaning that there is sufficient evidence that time and cost are reduced to a high degree. There is no cost overrun and project delay with a lower number of accidents and fatalities on the construction sites, as we can complete and hand over the projects before the due date. When accidents happen on-site, additional time, manpower, and cost are needed to repair the situation so that the projects can be continued. In addition, contractors or other parties are entitled to workers’ compensation if any worker suffers an injury during their employment. The obtained results agree with Rodrigues and Estrada [44].

“BIM can generate necessary temporary structures automatically and assess the safety risks” was ranked in the fifth position, which equals 87.02%. In other words, there is evidence that BIM generates necessary temporary structures automatically and assesses the safety risks to a high degree. The obtained results agree with Kim and Cho [46], who found that a temporary structure plan can be created automatically with a BIM-based application to facilitate proactive management of temporary structures by exploiting the detailed information included in the digital building models. This scope was limited to temporary stair towers used during roof construction.

“Decisions about upcoming tasks or construction techniques can be made and decided easily based on the situation” was ranked at the last position, which equals 74.64%. In other words, there is evidence that the decision about upcoming tasks or construction techniques can be made and decided easily based on the situation to a moderate degree. This result is due to the respondents assuming that the decisions can also be made and decided with critical thinking, even though BIM has not functioned in a construction project.

In general, it was found that all the factors are statistically significant, with each having an RII weight of over 70%. This designated that the respondents agree to a high degree with these factors. The results are presented in Table 8.

- B.

- BIM for Safety Communications

In another influential factor group, BIM for safety communications, “communication is critical at all stages of the project for clear understanding and safety measures” was ranked at the first position, which equals 90.40%. There is an indication that communication is critical at all stages of the project for clear understanding and safety measures with a high degree. Most of the respondents in this survey agree that safety communication is one of the main predictors of success in construction projects. Construction consists of many elements, including different roles, tasks, and collaboration throughout the projects. By improving coordination and communication, BIM has the potential to make construction sites safer for everyone involved. BIM allows for collaboration between the contractors and the construction team instead of the use of conventional safety planning. Through BIM and the common data platform, everyone involved in the projects has a better understanding of the surroundings of the site to reduce any potential risks and hazards. The obtained results agree with Ganah and John [13], who found that communication is key to avoiding misunderstandings that could cause the occurrence of accidents at the construction site.

“BIM provides a lot of parametric data and enables collaborative projects” was ranked at the second position, which equals 87.81%. This means that the factor is statistically significant. This directs that the respondents agree to a high degree that BIM provides a lot of parametric data and enables collaborative projects. It is indicated that BIM is a collaborative way for multidisciplinary information storing, sharing, exchanging, and managing throughout the entire project lifecycle, including the planning, design, construction, operation, maintenance, and demolition phase. BIM can be used to coordinate and plan with all parties before the construction starts; hence, hazards and risks can be determined earlier and overcome before it is too late. Conversely, when the safety hazards are not effectively communicated and responsive safety measures are not identified, risky behaviours and the likelihood of injuries can increase. The obtained results agree with Goedert and Meadati [43].

“Construction safety is improved by establishing a strong relationship between safety issues and construction planning and providing site layouts and safety plans to aid safety communication” was ranked at the third position, which equals 82.72%. In other words, there is evidence that construction safety is improved by establishing a strong relationship between safety issues and construction planning and providing site layouts and safety plans to aid safety communication to a high degree. A proper site layout is a useful and important function that can influence all aspects of work on a construction site, including construction methods, health, and safety. It can prevent or minimise construction site accidents through appropriate site layout design since a proper site layout consists of complete and detailed information about the site and workers can identify which points are potential hazards and risks through the site layout.

“With BIM authoring tools, virtual reality (VR) is utilised for virtual danger assessment, professional training, and design for safety” was ranked at the last position, which equals 72.05%. This indicates that the respondents agree to a moderate degree that virtual reality (VR) is utilised for virtual danger assessment, professional training, and design for safety, with BIM authoring tools. Virtual danger assessment can be adopted with virtual reality (VR) and BIM authoring tools to determine and identify potential hazards and risks. These obtained results agree with Zhang and Teizer [3], who found that virtual reality (VR) can help to improve health and safety in a construction project by combining BIM authoring tools.

In general, it was found that all the factors are statistically significant, with an RII weight of all factors over 70%. This designates that the respondents agree to a high degree about these factors. The results of RII for this group are presented in Table 9.

Table 9.

RII and ranking of BIM safety communications factors.

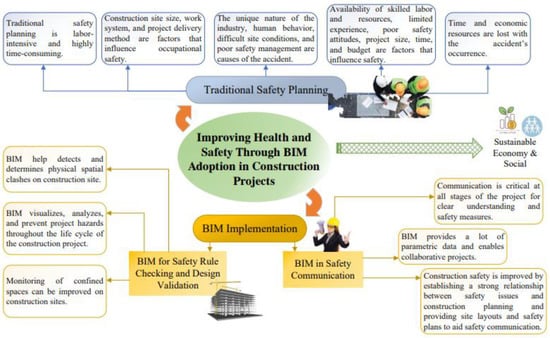

4.3. Framework Development

Figure 2 shows a framework based on the evaluation of traditional safety planning and BIM implementation in safety rule-checking, design validation, and safety communication. The diagram illustrates the impact of a higher rate of accidents with traditional safety planning to promote BIM implementation in construction projects in Malaysia. Traditional safety planning, BIM implementation in safety rule-checking and design validation, and safety communication are directly related to each other because BIM is to be utilised due to the ineffective traditional safety planning, which results in a higher number of occupational accidents and fatalities. BIM can help to overcome these health and safety issues in the construction industry. Traditional safety planning is labour-intensive and time-consuming; thus, BIM implementation can help by detecting and determining the potential hazards in a short period throughout the life cycle of the construction project. This is due to traditional hazard visualisation techniques being mostly based on the observation and experience of the experts; hence, it takes a long time compared with the utilisation of BIM. The factors influencing accident rates include human behaviours, poor safety management, lack of integration, etc. This indicates that communication is critical at all stages of the project for clear understanding and safety measures. BIM can be utilised in this case, as it provides a lot of parametric data and allows for collaboration between the contractors and the construction team using cloud technology. The higher occupational accident rate results in a loss of time and economic resources, leading to economic breakouts. Meanwhile, the company’s image and reputation are affected, and the injured workers might lose their life in the accidents. BIM must be adopted in planning, designing, and executing projects to improve health and safety in the construction industry. Hence, a safer working environment can be created for the workers to promote social sustainability.

Figure 2.

Framework development.

5. Conclusions

This research has undertaken a thorough and critical literature assessment on BIM in safety communication, design validation, and rule checking, and discusses the current state and challenges of implementation of traditional safety planning in building construction projects. Responses were collected from professionals through questionnaires, and the data were analysed using reliability, validity, correlation, and RII ranking. The study concludes that traditional safety planning implementation is labour-intensive and time-consuming, as it primarily relies on human observation, as well as the expertise and quantitative analysis of the experts, which reduces its effectiveness in the real environment. BIM technology might be useful in this case since it can be utilised for systematic risk management, as a source of essential data, and as a platform for other BIM-based applications to perform further risk assessments. BIM can detect, visualise, determine, analyse, and prevent project hazards and physical spatial clashes on construction sites. Furthermore, BIM can be used as a tool for automated safety checks (rule checking) and knowledge-based systems throughout the building construction life cycle. Overall, the RII rated “traditional safety planning is labour-intensive and highly time-consuming (B2/0.8854)” and “safety requirements and knowledge are ignored by workers and inexperienced managers (C7/0.8728)” as the top factors to be considered under traditional safety planning, whereas, “BIM help detects and determines physical spatial clashes on construction site (E15/0.9256)” and “Communication is critical at all stages of the project for clear understanding and safety measures (J44/0.9040)” are highly rated under BIM-related safety applications.

Since construction is a continuous process, there should not be any safety gaps between phases. The number of intricate building projects is increasing, and because of the urgency with which they must be completed, so are the occupational dangers associated with their execution. Accidents that have significant economic and societal implications must be avoided. BIM adoption is thus recommended for planning, design, and execution, as well as for effective stakeholder communication about safety at all stages of the process.

Author Contributions

Conceptualization, W.S.A. and Y.P.E.; methodology, W.S.A., M.A.M., Y.P.E. and A.H.Q.; software, Y.P.E., M.A.M., M.A.S. and K.M.A.; validation, K.M.A., A.H.Q., W.S.A. and S.A.K.; resources, W.S.A. and A.H.Q.; data curation, Y.P.E.; writing—original draft preparation, Y.P.E., and M.A.M.; writing—review and editing, W.S.A., S.A.K. and M.A.S.; supervision, W.S.A.; funding acquisition, W.S.A. and A.H.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to appreciate the YUTP-FRG 1/2021 (cost center # 015LC0-369) in Universiti Teknologi PETRONAS (UTP) awarded to Wesam Salah Alaloul for the support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mihić, M.; Vukomanović, M.; Završki, I. Review of previous applications of innovative information technolo-gies in construction health and safety. Organ. Technol. Manag. Constr. Int. J. 2019, 11, 1952–1967. [Google Scholar]

- Alaloul, W.S.; Saad, S.; Qureshi, A.H. Construction Sector: IR 4.0 Applications. In Handbook of Smart Materials, Technologies, and Devices; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–50. ISBN 9783030586751. [Google Scholar]

- Zhang, S.; Teizer, J.; Lee, J.-K.; Eastman, C.M.; Venugopal, M. Building Information Modeling (BIM) and Safety: Automatic Safety Checking of Construction Models and Schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Akram, R.; Thaheem, M.J.; Nasir, A.R.; Ali, T.H.; Khan, S. Exploring the role of building information modeling in construction safety through science mapping. Saf. Sci. 2019, 120, 456–470. [Google Scholar] [CrossRef]

- Benjaoran, V.; Bhokha, S. An integrated safety management with construction management using 4D CAD model. Saf. Sci. 2010, 48, 395–403. [Google Scholar] [CrossRef]

- Sulankivi, K.; Kähkönen, K.; Mäkelä, T.; Kiviniemi, M. 4D-BIM for construction safety planning. In Proceedings of the W099-Special Track 18th CIB World Building Congress, Salford, UK, 10–13 May 2010. [Google Scholar]

- Ahmadi, H.R.; Mahdavi, N.; Bayat, M. A novel damage identification method based on short time Fourier transform and a new efficient index. Structures 2021, 33, 3605–3614. [Google Scholar] [CrossRef]

- Ahmadi, H.R.; Mahdavi, N.; Bayat, M. A new index based on short time Fourier transform for damage detec-tion in bridge piers. Comput. Concr. 2021, 27, 447–455. [Google Scholar]

- Musarrat, M.A.; Inderyas, O.; Khan, S.; Shah, A. Causes of delay in the execution phase of construction projects in khyber pukhtoonkhwa pakistan. Sarhad Univ. Int. J. Basic Appl. Sci. 2016, 4, 62–70. [Google Scholar]

- Ruikar, D. Using BIM to mitigate risks associated with health and safety in the construction and maintenance of infrastructure assets. WIT Trans. Ecol. Environ. 2016, 204, 873–884. [Google Scholar]

- Lu, Y.; Gong, P.; Tang, Y.; Sun, S.; Li, Q. BIM-integrated construction safety risk assessment at the design stage of building projects. Autom. Constr. 2021, 124, 103553. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Liew, M. Inflation rate and labours’ wages in construction projects: Economic relation investigation. Eng. Constr. Arch. Manag. 2021, 29, 2461–2494. [Google Scholar] [CrossRef]

- Ganah, A.; John, G.A. Integrating building information modeling and health and safety for onsite construc-tion. Saf. Health Work. 2015, 6, 39–45. [Google Scholar] [CrossRef]

- Zhang, S.; Sulankivi, K.; Kiviniemi, M.; Romo, I.; Eastman, C.M.; Teizer, J. BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 2015, 72, 31–45. [Google Scholar] [CrossRef]

- Collado-Mariscal, D.; Cortés-Pérez, J.; Cortés-Pérez, A.; Cuevas-Murillo, A. Proposal for the Integration of Health and Safety into the Design of Road Projects with BIM. Buildings 2022, 12, 1753. [Google Scholar] [CrossRef]

- Maqsoom, A.; Khan, K.; Musarat, M.; Mubasit, H.; Umer, M. Influence of internal workforce diversity fac-tors on labor productivity in construction projects: Empirical evidence from Pakistan. In Proceedings of the 2020 2nd International Sustainability and Resilience Conference: Technology and Innovation in Building Designs (51154), Sakhir, Bahrain, 11–12 November 2020. [Google Scholar]

- Maqsoom, A.; Musarat, M.A.; Mubbasit, H.; Alaloul, W.S.; Ashraf, H.; Rabbani, M.B.A.; Shaheen, I. Extrinsic workforce diversity factors: An impact of employee characteristics on productivity. Ain Shams Eng. J. 2023, 102170. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Irfan, M.; Sreenivasan, P.; Rabbani, M.B.A. Health and Safety Improvement through Industrial Revolution 4.0: Malaysian Construction Industry Case. Sustainability 2022, 15, 201. [Google Scholar] [CrossRef]

- Chan, I.Y.S.; Leung, H.Y.; Fung, I.W.H.; Leung, M. How can BIM support Construction Safety Management? Development of SIM. MATEC Web Conf. 2016, 66, 00018. [Google Scholar] [CrossRef]

- Illahi, M.; Ashri, M. Study of Safety Management & Professional to Achive Zero Accident in Construction Site. Bachelor’s Thesis, Universiti Malaysia Pahang, Pekan, Malaysia, 2010. [Google Scholar]

- Altaf, M.; Musarat, M.A.; Khan, A.; Shoukat, Z.; Salahuddin, U. Change order impact on construction industry of Pakistan. In AWAM International Conference on Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Matthei, J. The impact of implementing Building Information Modeling (BIM) on Occupational Health and Safe-ty (OHS) during construction. In Proceedings of the 32 Forum Bauinformatik, Darmstadt, German, 9–10 September 2021. [Google Scholar]

- Hire, S.; Sandbhor, S.; Ruikar, K.; Amarnath, C.B. BIM usage benefits and challenges for site safety application in Indian construction sector. Asian J. Civ. Eng. 2021, 22, 1249–1267. [Google Scholar] [CrossRef]

- Kubba, S. Handbook of Green Building Design and Construction: LEED, BREEAM, and Green Globes; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Autodesk What Is BIM|Building Information Modeling|Autodesk. Available online: https://www.autodesk.com/industry/aec/bim (accessed on 6 March 2023).

- Akram, R.; Thaheem, M.; Khan, S.; Nasir, A.; Maqsoom, A. Exploring the Role of BIM in Construction Safe-ty in Developing Countries: Toward Automated Hazard Analysis. Sustainability 2022, 14, 12905. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Building information modelling (BIM) to enhance occupational safety in construc-tion activities: Research trends emerging from one decade of studies. Buildings 2020, 10, 98. [Google Scholar] [CrossRef]

- Pham, K.-T.; Vu, D.-N.; Hong, P.; Park, C. 4D-BIM-based workspace planning for temporary safety facili-ties in construction SMEs. Int. J. Environ. Res. Public Health 2020, 17, 3403. [Google Scholar] [CrossRef]

- Riaz, Z.; Arslan, M.; Kiani, A.K.; Azhar, S. CoSMoS: A BIM and wireless sensor based integrated solution for worker safety in confined spaces. Autom. Constr. 2014, 45, 96–106. [Google Scholar] [CrossRef]

- Malekitabar, H.; Ardeshir, A.; Sebt, M.H.; Stouffs, R. Construction safety risk drivers: A BIM approach. Saf. Sci. 2016, 82, 445–455. [Google Scholar] [CrossRef]

- Arewa, A.O.; Farrell, P. A review of compliance with health and safety regulations and economic perfor-mance in small and medium construction enterprises. In Proceedings of the 28th Annual ARCOM Conference, Edinburgh, UK, 3–5 September 2012; pp. 423–432. [Google Scholar]

- Gopang, M.A.; Nebhwani, M.; Khatri, A.; Marri, H.B. An assessment of occupational health and safety measures and performance of SMEs: An empirical investigation. Saf. Sci. 2017, 93, 127–133. [Google Scholar] [CrossRef]

- Kheni, N.A.; Gibb, A.; Dainty, A. Health and safety management within small-and medium-sized enter-prises (SMEs) in developing countries: Study of contextual influences. J. Constr. Eng. Manag. 2010, 136, 1104–1115. [Google Scholar] [CrossRef]

- Cortés-Pérez, J.P.; Cortés-Pérez, A.; Prieto-Muriel, P. BIM-integrated management of occupational hazards in building construction and maintenance. Autom. Constr. 2020, 113, 103115. [Google Scholar] [CrossRef]

- Rodrigues, F.; Baptista, J.S.; Pinto, D. BIM Approach in Construction Safety—A Case Study on Preventing Falls from Height. Buildings 2022, 12, 73. [Google Scholar] [CrossRef]

- Saurin, T.A.; Formoso, C.; Guimarães, L. Safety and production: An integrated planning and control model. Constr. Manag. Econ. 2004, 22, 159–169. [Google Scholar] [CrossRef]

- Zou, Y.; Kiviniemi, A.; Jones, S.W. A review of risk management through BIM and BIM-related technologies. Saf. Sci. 2017, 97, 88–98. [Google Scholar] [CrossRef]

- Hartmann, T.; van Meerveld, H.; Vossebeld, N.; Adriaanse, A. Aligning building information model tools and construction management methods. Autom. Constr. 2012, 22, 605–613. [Google Scholar] [CrossRef]

- Wetzel, E.M.; Thabet, W. The use of a BIM-based framework to support safe facility management pro-cesses. Autom. Constr. 2015, 60, 12–24. [Google Scholar] [CrossRef]

- Kamardeen, I. 8D BIM modelling tool for accident prevention through design. In Proceedings of the Association of Researchers in Construction Management 26th Annual ARCOM Conference, Leeds, UK, 6–8 September 2010. [Google Scholar]

- Marefat, A.; Toosi, H.; Hasankhanlo, R.M. A BIM approach for construction safety: Applications, barriers and solutions. Eng. Constr. Arch. Manag. 2018, 26, 1855–1877. [Google Scholar] [CrossRef]

- Hardin, B.; McCool, D. BIM and Construction Management: Proven Tools, Methods, and Workflows; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Goedert, J.D.; Meadati, P. Integrating construction process documentation into building information model-ing. J. Constr. Eng. Manag. 2008, 134, 509–516. [Google Scholar] [CrossRef]

- Rodrigues, F.; Estrada; Antunes, J.; Swuste, P. Safety through design: A BIM-based framework. In International Congress and Exhibition “Sustainable Civil Infrastructures: Innovative Infrastructure Geotechnology”, Sharm El Sheikh, Egypt, 15–19 July 2017; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Azhar, S. Role of visualisation technologies in safety planning and management at construction jobsites. Procedia Eng. 2017, 171, 215–226. [Google Scholar] [CrossRef]

- Kim, K.; Cho, Y. BIM-based planning of temporary structures for construction safety. In Proceedings of the Computing in Civil Engineering, Austin, TX, USA, 21–23 June 2015; pp. 436–444. [Google Scholar]

- Kim, H.; Ahn, H. Temporary facility planning of a construction project using BIM (Building Information Mod-eling). In Proceedings of the International Workshop on Computing in Civil Engineering, Miami, FL, USA, 19–22 June 2011; pp. 627–634. [Google Scholar]

- Shim, C.-S.; Lee, K.-M.; Kang, L.; Hwang, J.; Kim, Y. Three-dimensional information model-based bridge en-gineering in Korea. Struct. Eng. Int. 2012, 22, 8–13. [Google Scholar] [CrossRef]

- Eastman, C. Automated Assessment of Early Concept Designs. Arch. Des. 2009, 79, 52–57. [Google Scholar] [CrossRef]

- Martinez-Aires, M.D.; López-Alonso, M.; Martínez-Rojas, M. Building information modeling and safety management: A systematic review. Saf. Sci. 2018, 101, 11–18. [Google Scholar] [CrossRef]

- Smith, D.K.; Tardif, M. Building Information Modeling: A Strategic Implementation Guide for Architects, Engineers, Constructors, and Real Estate Asset Managers; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Manuele, F.A. Prevention through design addressing occupational risks in the design and redesign processes. Prof. Saf. 2008, 53, 37–44. [Google Scholar]

- Zhang, S.; Boukamp, F.; Teizer, J. Ontology-based semantic modeling of construction safety knowledge: Towards automated safety planning for job hazard analysis (JHA). Autom. Constr. 2015, 52, 29–41. [Google Scholar] [CrossRef]

- Chen, A.; Golparvar-Fard, M.; Kleiner, B. Saves: An augmented virtuality strategy for training construction hazard recognition. In Construction Research Congress 2014: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; American Society Civil Engineers: Reston, VI, USA, 2014. [Google Scholar]

- Mallasi, Z. Dynamic quantification and analysis of the construction workspace congestion utilising 4D visualisa-tion. Autom. Constr. 2006, 15, 640–655. [Google Scholar] [CrossRef]

- Qi, J.; Issa, R.R.A.; Hinze, J.; Olbina, S. Integration of safety in design through the use of building information modelling. In Proceedings of the International Workshop on Computing in Civil Engineering, Miami, FL, USA, 19–22 June 2011; pp. 698–705. [Google Scholar]

- Dattalo, P. Determining Sample Size: Balancing Power, Precision, and Practicality; Oxford University Press: Oxford, UK, 2008. [Google Scholar]

- Verma, J.P.; Verma, P. (Eds.) Determining Sample Size in Experimental Studies. In Determining Sample Size and Power in Research Studies; Springer: Singapore, 2020. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).