Machine Learning-Based Flexural Capacity Prediction of Corroded RC Beams with an Efficient and User-Friendly Tool

Abstract

1. Introduction

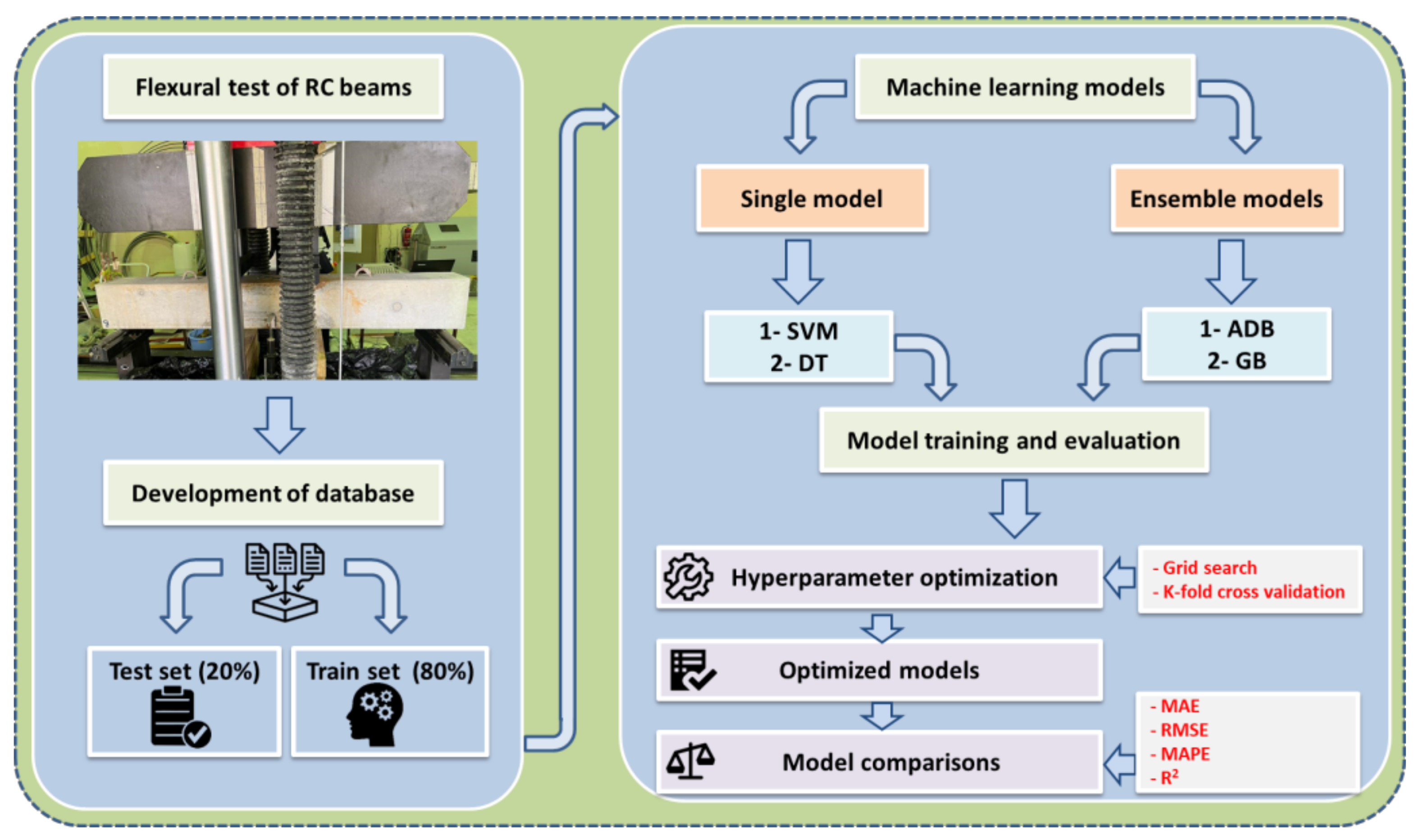

2. Research Significance

- To develop ML predictive models that can accurately estimate the flexural capacity of corroded RC beams.

- To evaluate and compare the performance of various ML models using statistical indices such as mean absolute error (MAE), mean absolute percent error (MAPE), root mean squared error (RMSE), and coefficient of determination (R2) and select the most accurate and reliable predictive model.

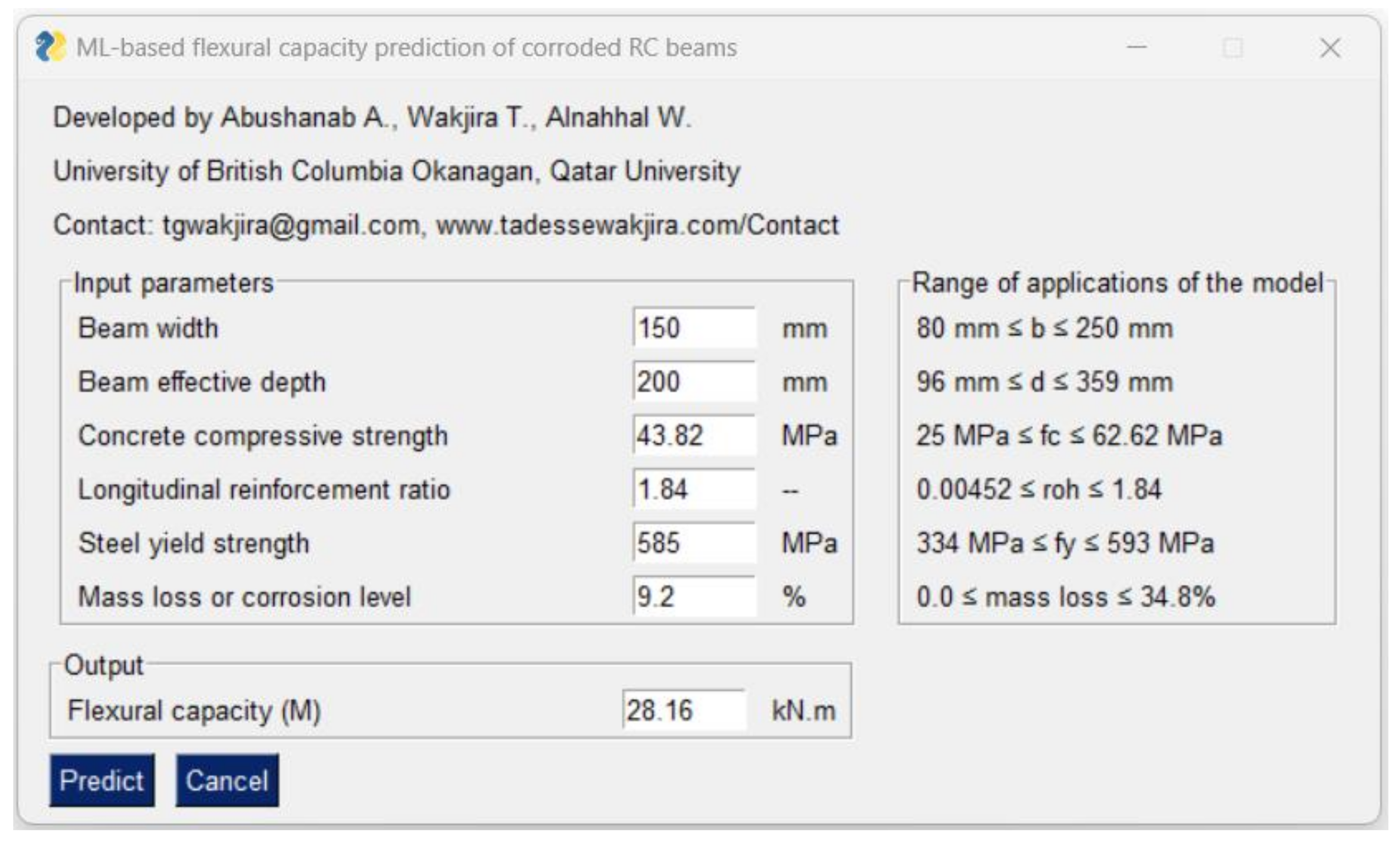

- To develop a graphical user interface for the best predictive model, which facilitates its practical implementation and enables fast, accurate, and intelligent prediction of the flexural capacity of corroded RC beams.

3. Material and Methods

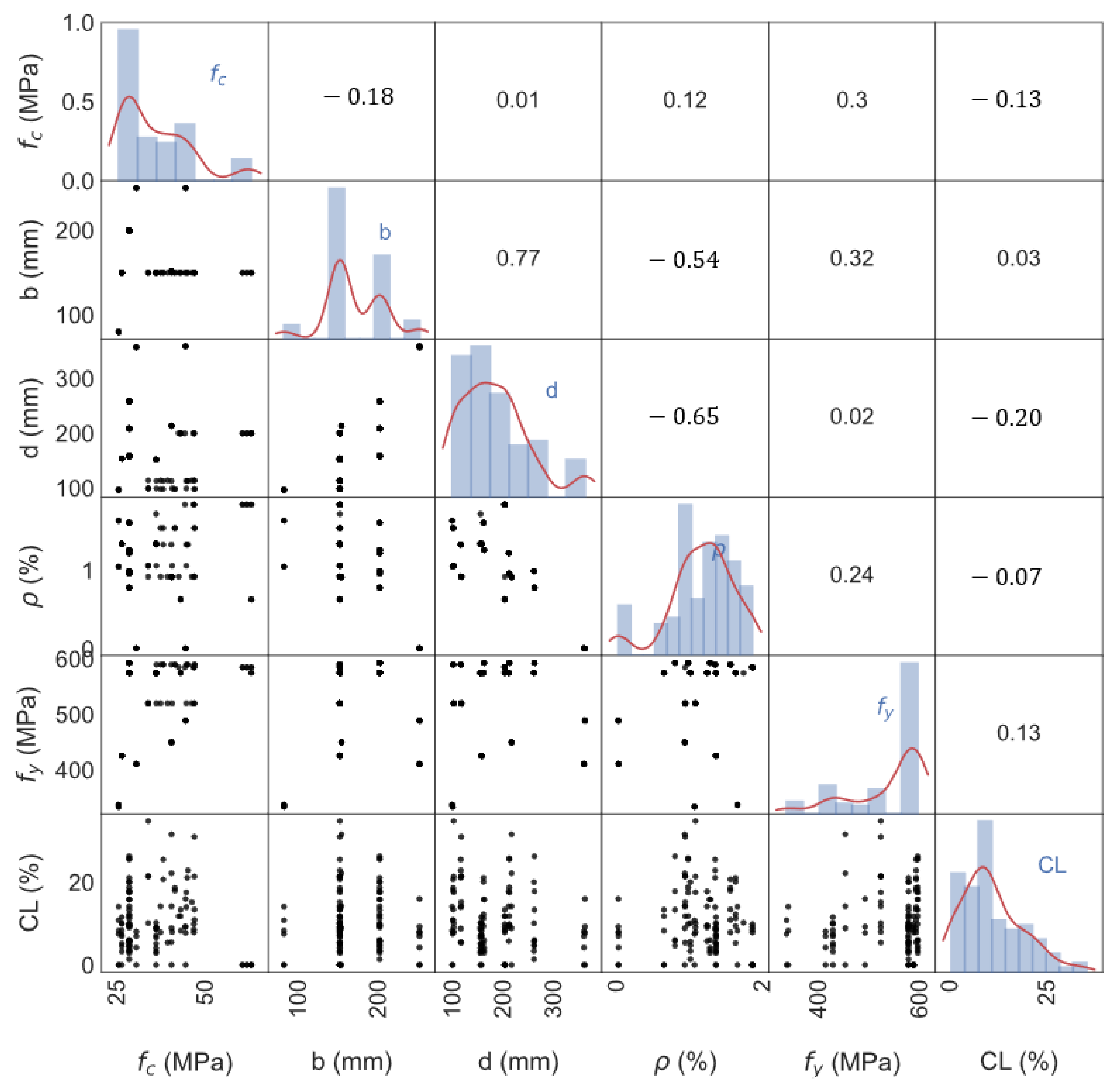

3.1. Research Database

- Concrete compressive strength: the beams considered in this database had concrete compressive strength in the range of 25 MPa 62.62 MPa.

- Beam geometry: the beams’ widths ranged between 80 mm and 250 mm, and the beams’ effective depths were in the range of 96 mm to 359 mm.

- Reinforcement characteristics: the yield strength of steel reinforcement varied from 334 MPa to 593 MPa.

- Reinforcement ratio: the beams’ reinforcement ratios ranged between 0.0045% and 1.84%.

- Mass loss: the mass loss of the beams, which was expressed as the CL, varied between 0% and 34.8%.

3.2. Machine Learning Models

3.2.1. Single ML Models

Support Vector Machine

Decision Tree

3.2.2. Ensemble ML Models

Adaptive Boosting

Gradient Boosting

4. Results and Discussion

4.1. Hyperparameter Optimization Results

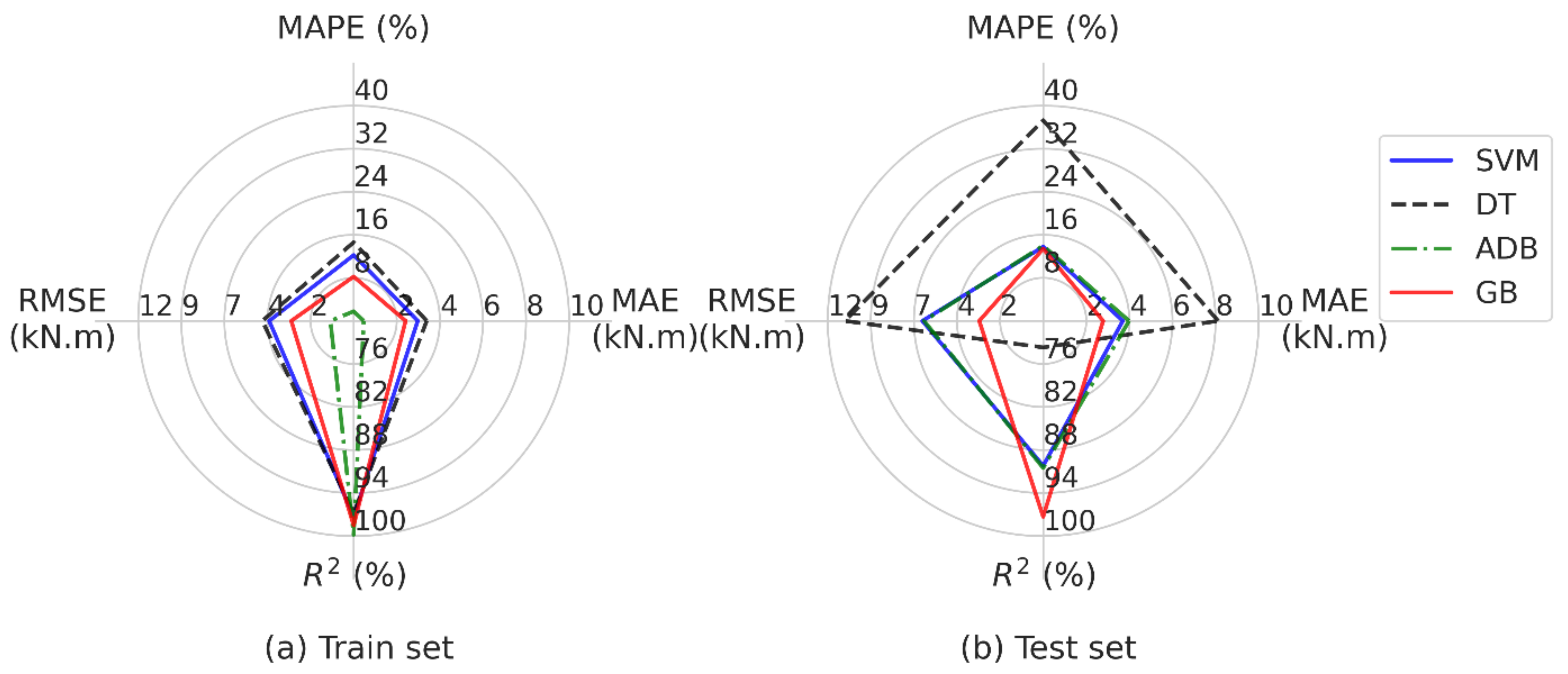

4.2. Model Performance

4.3. Comparison of Predictive Models

4.4. An Intelligent Prediction Tool with Fast and Accurate Results

5. Conclusions

- The DT model exhibited overfitting, with significantly higher values on the test set compared to the training set, indicating that it may not generalize well to new data. Specifically, on the training set, it achieved an MAE of 3.39 kN.m, MAPE of 14.61%, RMSE of 5.09 kN.m, and R2 of 96.8%. However, it showed overfitting with an MAE of 8.12 kN.m, MAPE of 37.29%, RMSE of 11.05 kN.m, and R2 of 73.70% on the test dataset.

- The SVM model achieved a relatively good performance with an MAE of 3.70 kN.m, MAPE of 13.79%, RMSE of 6.73 kN.m, and R2 of 90.20% on the test set.

- The ADB model showed high performance on the training set with an MAE of 0.47 kN.m, MAPE of 1.78%, RMSE of 1.30 kN.m, and R2 of 99.8%. However, it experienced a significant drop in the predictive performance on the test set, indicating some overfitting and less generalization capability.

- The GB model outperformed the other models with the lowest MAE of 2.78 kN.m, MAPE of 13.40%, and RMSE of 3.56 kN.m, and the highest R2 of 97.30% on the test set. Consequently, the developed gradient boosting model can be used to accurately predict the flexural capacity of corroded RC beams.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abushanab, A.; Alnahhal, W.; Farraj, M. Structural Performance and Moment Redistribution of Basalt FRC Continuous Beams Reinforced with Basalt FRP Bars. Eng. Struct. 2021, 240, 112390. [Google Scholar] [CrossRef]

- Peng, J.; Yan, G.; Zandi, Y.; Sadighi Agdas, A.; Pourrostam, T.; Ezz El-Arab, I.; Denic, N.; Nesic, Z.; Cirkovic, B.; Amine Khadimallah, M. Prediction and Optimization of the Flexural Behavior of Corroded Concrete Beams Using Adaptive Neuro Fuzzy Inference System. Structures 2022, 43, 200–208. [Google Scholar] [CrossRef]

- Basaran, B. Effect of Steel–FRP Ratio and FRP Wrapping Layers on Tensile Properties of Glass FRP-Wrapped Ribbed Steel Reinforcing Bars. Mater. Struct. 2021, 54, 188. [Google Scholar] [CrossRef]

- Jnaid, F.; Aboutaha, R.S. Residual Flexural Strength of Corroded Reinforced Concrete Beams. Eng. Struct. 2016, 119, 198–216. [Google Scholar] [CrossRef]

- Malumbela, G.; Moyo, P.; Alexander, M. Behaviour of RC Beams Corroded under Sustained Service Loads. Constr. Build. Mater. 2009, 23, 3346–3351. [Google Scholar] [CrossRef]

- Imperatore, S.; Rinaldi, Z.; Spagnuolo, S. Influence of Corrosion on the Experimental Behaviour of R.C. Ties. Eng. Struct. 2019, 198, 109458. [Google Scholar] [CrossRef]

- Almusallam, A.A.; Al-Gahtani, A.S.; Aziz, A.R.; Dakhil, F.H. Rasheeduzzafar Effect of Reinforcement Corrosion on Flexural Behavior of Concrete Slabs. J. Mater. Civ. Eng. 1996, 8, 123–127. [Google Scholar] [CrossRef]

- Rodriguez, J.; Ortega, L.; Casal, J. Load Carrying Capacity of Concrete Structures with Corroded Reinforcement. Constr. Build. Mater. 1997, 11, 239–248. [Google Scholar] [CrossRef]

- Mangat, P.S.; Elgarf, M.S. Flexural Strength of Concrete Beams with Corroding Reinforcement. ACI Struct. J. 1999, 96, 149–158. [Google Scholar] [CrossRef]

- Huang, R.; Yang, C.C. Condition Assessment of Reinforced Concrete Beams Relative to Reinforcement Corrosion. Cem. Concr. Compos. 1997, 19, 131–137. [Google Scholar] [CrossRef]

- Abushanab, A.; Alnahhal, W.; Farraj, M. Experimental and Finite Element Studies on the Structural Behavior of BFRC Continuous Beams Reinforced with BFRP Bars. Compos. Struct. 2021, 281, 114982. [Google Scholar] [CrossRef]

- Azad, A.K.; Ahmad, S.; Azher, S.A. Residual Strength of Corrosion-Damaged Reinforced Concrete Beams. ACI Mater. J. 2007, 104, 40–47. [Google Scholar]

- Azad, A.K.; Ahmad, S.; Al-Gohi, B.H.A. Flexural Strength of Corroded Reinforced Concrete Beams. Mag. Concr. Res. 2010, 62, 405–414. [Google Scholar] [CrossRef]

- Cai, B.; Pan, G.; Fu, F. Prediction of the Postfire Flexural Capacity of RC Beam Using GA-BPNN Machine Learning. J. Perform. Constr. Facil. 2020, 34, 04020105. [Google Scholar] [CrossRef]

- Cao, W.; Wang, A.; Yu, D.; Liu, S.; Hou, W. Establishment and Implementation of an Asphalt Pavement Recycling Decision System Based on the Analytic Hierarchy Process. Resour. Conserv. Recycl. 2019, 149, 738–749. [Google Scholar] [CrossRef]

- Solhmirzaei, R.; Salehi, H.; Kodur, V.; Naser, M.Z. Machine Learning Framework for Predicting Failure Mode and Shear Capacity of Ultra High Performance Concrete Beams. Eng. Struct. 2020, 224, 111221. [Google Scholar] [CrossRef]

- Fu, B.; Chen, S.-Z.; Liu, X.-R.; Feng, D.-C. A Probabilistic Bond Strength Model for Corroded Reinforced Concrete Based on Weighted Averaging of Non-Fine-Tuned Machine Learning Models. Constr. Build. Mater. 2022, 318, 125767. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Abushanab, A.; Ebead, U.; Alnahhal, W. FAI: Fast, Accurate, and Intelligent Approach and Prediction Tool for Flexural Capacity of FRP-RC Beams Based on Super-Learner Machine Learning Model. Mater. Today Commun. 2022, 33, 104461. [Google Scholar] [CrossRef]

- Truong, G.T.; Choi, K.K.; Kim, C.S. Implementation of Boosting Algorithms for Prediction of Punching Shear Strength of RC Column Footings. Structures 2022, 46, 521–538. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Rahmzadeh, A.; Alam, M.S.; Tremblay, R. Explainable Machine Learning Based Efficient Prediction Tool for Lateral Cyclic Response of Post-Tensioned Base Rocking Steel Bridge Piers. Structures 2022, 44, 947–964. [Google Scholar] [CrossRef]

- Kutty, A.A.; Wakjira, T.G.; Kucukvar, M.; Abdella, G.M.; Onat, N.C. Urban Resilience and Livability Performance of European Smart Cities: A Novel Machine Learning Approach. J. Clean. Prod. 2022, 378, 134203. [Google Scholar] [CrossRef]

- Kourehpaz, P.; Molina Hutt, C. Machine Learning for Enhanced Regional Seismic Risk Assessments. J. Struct. Eng. 2022, 148, 04022126. [Google Scholar] [CrossRef]

- El Maaddawy, T.; Soudki, K.; Topper, T. Long-Term Performance of Corrosion-Damaged Reinforced Concrete Beams. ACI Struct. J. 2005, 102, 649–656. [Google Scholar] [CrossRef]

- Xia, J.; Jin, W.-L.; Li, L.-Y. Effect of Chloride-Induced Reinforcing Steel Corrosion on the Flexural Strength of Reinforced Concrete Beams. Mag. Concr. Res. 2012, 64, 471–485. [Google Scholar] [CrossRef]

- Wang, L.; Ma, Y.; Ding, W.; Zhang, J.; Liu, Y. Comparative Study of Flexural Behavior of Corroded Beams with Different Types of Steel Bars. J. Perform. Constr. Facil. 2015, 29, 04014163. [Google Scholar] [CrossRef]

- Tan, N.N.; Nguyen, N.D. An Experimental Study on Flexural Behavior of Corroded Reinforced Concrete Beams Using Electrochemical Accelerated Corrosion Method. J. Sci. Technol. Civ. Eng. NUCE 2019, 13, 1–11. [Google Scholar] [CrossRef]

- Yalciner, H.; Kumbasaroglu, A.; El-Sayed, A.K.; Balkıs, A.P.; Dogru, E.; Turan, A.I.; Karimi, A.; Kohistani, R.; Mermit, M.F.; Bicer, K. Flexural Strength of Corroded Reinforced Concrete Beams. ACI Struct. J. 2020, 117, 29–41. [Google Scholar] [CrossRef]

- Vapnik, V.N. The Nature of Statistical Learning Theory; Springer: New York, NY, USA, 2000; ISBN 978-1-4419-3160-3. [Google Scholar]

- Yu, H.; Kim, S. SVM Tutorial-Classification, Regression and Ranking. Handb. Nat. Comput. 2012, 1–4, 479–506. [Google Scholar] [CrossRef]

- Chang, C.; Lin, C. LIBSVM: A Library for Support Vector Machines. ACM Trans. Intell. Syst. Technol. 2011, 2, 1–27. [Google Scholar] [CrossRef]

- Sutton, C.D. Classification and Regression Trees, Bagging, and Boosting. Handb. Stat. 2005, 24, 303–329. [Google Scholar] [CrossRef]

- Breiman, L.; Friedman, J.H.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; Wadsworth: Belmont, CA, USA, 1984; Volume 432, p. 9. [Google Scholar]

- Shrestha, D.L.; Solomatine, D.P. Experiments with AdaBoost.RT: An Improved Boosting Scheme for Regression. Neural Comput. 2006, 18, 1678–1710. [Google Scholar] [CrossRef]

| Model | Tuned Hyperparameters | |

|---|---|---|

| Name | Value | |

| Support vector machine | Regularization parameter, C | 30 |

| Epsilon, ε | 10−5 | |

| Kernel type | RBF | |

| Decision tree | Maximum tree depth | 5 |

| Maximum number of randomly chosen input features | 4 | |

| Minimum sample required to split an internal node | 2 | |

| Minimum sample required at the leaf node | 1 | |

| Adaptive boosting | Number of estimators or base learners | 10 |

| Learning rate | 0.15 | |

| Base learner | Decision tree | |

| Maximum depth of base learner | 10 | |

| Maximum number of randomly selected input features for base learner | 3 | |

| Minimum sample required to split an internal node | 2 | |

| Minimum sample required at the leaf node | 1 | |

| Gradient boosting machine | Number of base learners or estimators | 20 |

| Maximum depth | 5 | |

| Fraction of samples used to fit each base learner | 30% | |

| Learning rate | 0.25 | |

| Model | Training Set | Test Set | ||||||

|---|---|---|---|---|---|---|---|---|

| MAE (kN.m) | MAPE (%) | RMSE (kN.m) | R2 (%) | MAE (kN.m) | MAPE (%) | RMSE (kN.m) | R2 (%) | |

| SVM | 2.97 | 12.23 | 4.71 | 97.3 | 3.70 | 13.79 | 6.73 | 90.20 |

| DT | 3.39 | 14.61 | 5.09 | 96.8 | 8.12 | 37.29 | 11.05 | 73.70 |

| ADB | 0.47 | 1.78 | 1.3 | 99.8 | 3.99 | 13.98 | 6.64 | 90.50 |

| GB | 2.41 | 8.24 | 3.48 | 98.5 | 2.78 | 13.40 | 3.56 | 97.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abushanab, A.; Wakjira, T.G.; Alnahhal, W. Machine Learning-Based Flexural Capacity Prediction of Corroded RC Beams with an Efficient and User-Friendly Tool. Sustainability 2023, 15, 4824. https://doi.org/10.3390/su15064824

Abushanab A, Wakjira TG, Alnahhal W. Machine Learning-Based Flexural Capacity Prediction of Corroded RC Beams with an Efficient and User-Friendly Tool. Sustainability. 2023; 15(6):4824. https://doi.org/10.3390/su15064824

Chicago/Turabian StyleAbushanab, Abdelrahman, Tadesse Gemeda Wakjira, and Wael Alnahhal. 2023. "Machine Learning-Based Flexural Capacity Prediction of Corroded RC Beams with an Efficient and User-Friendly Tool" Sustainability 15, no. 6: 4824. https://doi.org/10.3390/su15064824

APA StyleAbushanab, A., Wakjira, T. G., & Alnahhal, W. (2023). Machine Learning-Based Flexural Capacity Prediction of Corroded RC Beams with an Efficient and User-Friendly Tool. Sustainability, 15(6), 4824. https://doi.org/10.3390/su15064824