1. Introduction

Profitability has always been considered as a meta-target of factories, ensuring the competitiveness and long-term success of manufacturing companies [

1]. However, in light of limited natural resources and the threat of climate change, factories must increasingly focus on environmental sustainability as well [

2]. The manufacturing sector is responsible for approximately 25% of the CO2 emissions worldwide and has to become CO2-neutral by 2035 at the latest in order to avoid irreversible tipping points in the climate system [

3,

4,

5]. Factory planning designs a factory based on entrepreneurial specifications, and thereby needs to play a key role in operationalizing the concept of sustainability, addressing both economic and environmental targets over the factory life cycle. A majority of the costs and impacts are determined in factory planning, but they are not activated until use stage, and effect chains often cannot be traced back to design decisions from factory planning [

6]. For example, the acquisition costs of machine tools account for about 20% of the life cycle costs, while the costs for operation represent 80% of the total life cycle costs [

7]. A life cycle-oriented system configuration can reduce total costs by about one-third over the lifetime of the machine. In particular, unplanned operating costs are reduced by 80% [

6,

8]. However, a machine tool is only a single element of a factory, which is embedded in process chains, a building structure, and supported by technical building services (TBS), storage and transport facilities. The prevailing structures and interrelationships in a factory system are numerous and multifaceted, which is why a factory is also defined as a complex socio-technical system [

9]. The life cycle costs and environmental impacts of a factory result from the dynamic interaction between the system elements with their individual life cycles, whose life cycle lengths and behavior are influenced by disturbances and change drivers in factory operation. In order to establish life cycle costing (LCC) and life cycle assessment (LCA) in factory planning, a quantitative life cycle model (LC-model) is envisioned for modeling, forecasting and design of the entire factory with its inherent factory elements so that the economic and environmental sustainability of factory configurations over the factory life cycle can be evaluated. However, a main challenge is to understand the impact path in relation to outcome values in order to support life cycle-oriented decision making in factory planning. With this regard, a model-based understanding is required that builds the basis for setting situations into context, deriving measures and evaluating solution approaches [

10]. Preliminary work showed that there is a lack of such model-based approaches for factory systems [

11,

12,

13,

14].

Against this background, the goal is to develop a generic impact path model of a factory system in order to equip factory planners with a knowledge base for economic and environmental life cycle evaluation of factory systems. The paper is structured as follow: In

Section 2, the relevant background and state of research is presented. As LCC and LCA have not become an integral part of factory planning yet, the necessary system understanding about life cycle-oriented planning of factory configurations is established first, in

Section 3, so that the impact paths in relation to the outcome values can be uncovered in

Section 4 as one of the main results of this paper. The paper concludes with a case study demonstrating the transfer of the conceptual results into practice in

Section 5 as a basis for a brief discussion in

Section 6 as well as a conclusion in

Section 7.

2. Background and State of Research

A factory is a place where products are produced and, therefore, value is created [

15]. Value creation in a factory is based on the combination of the different production factors, such as equipment, material, energy, information and personnel [

16]. The equipment forms the technical basis for the operational performance. Personnel provide working capacity and combine material and energy with the help of information systems [

17]. Taking a system perspective, the factory system can be further divided into subsystems. The main subsystem is the production system, which is also called the flow system and converts the inputs material, energy and information into products and services [

18]. Existing description models divide a factory system into individual factory elements, which, in turn, are organized in a hierarchical structure. A generic description of the factory elements has already been carried out by Nyhuis et al. [

19]. Each factory element can be assigned to the design fields technology, space or organization as well as to a hierarchical levels workstation, section, factory and plant, whereby the latter two are often merged together [

6]. Further description models of factories have been developed focusing on different factory levels. For example, Hesselbach et al. developed a holistic factory understanding, where dynamic interactions between the building, TBS and production shape the factory system [

20]. Herrmann et al. place the holistic factory understanding in a hierarchical system definition with characteristic input and output flows [

21]. A factory understanding from the perspective of industrial ecology is presented by Despeisse et al. [

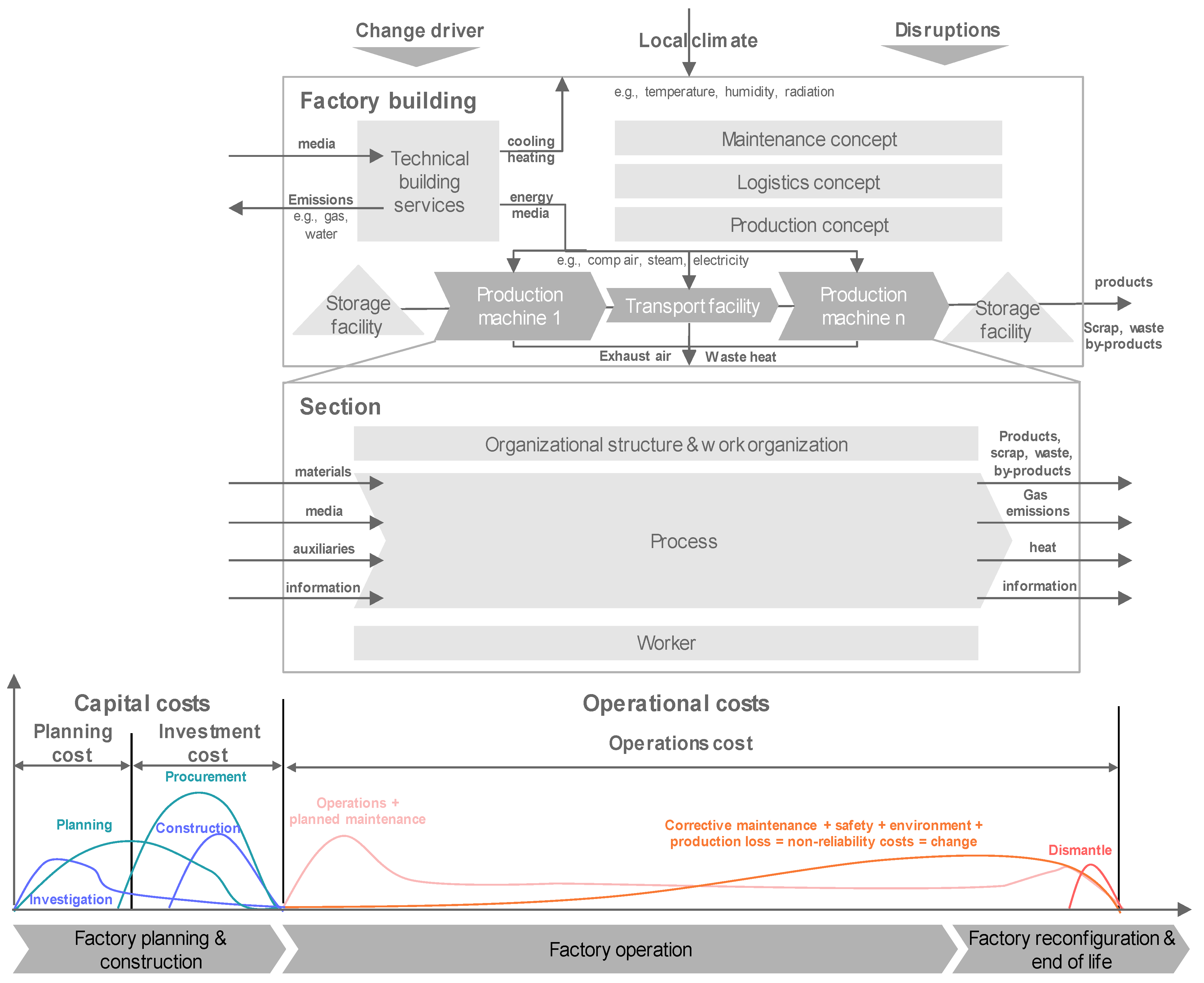

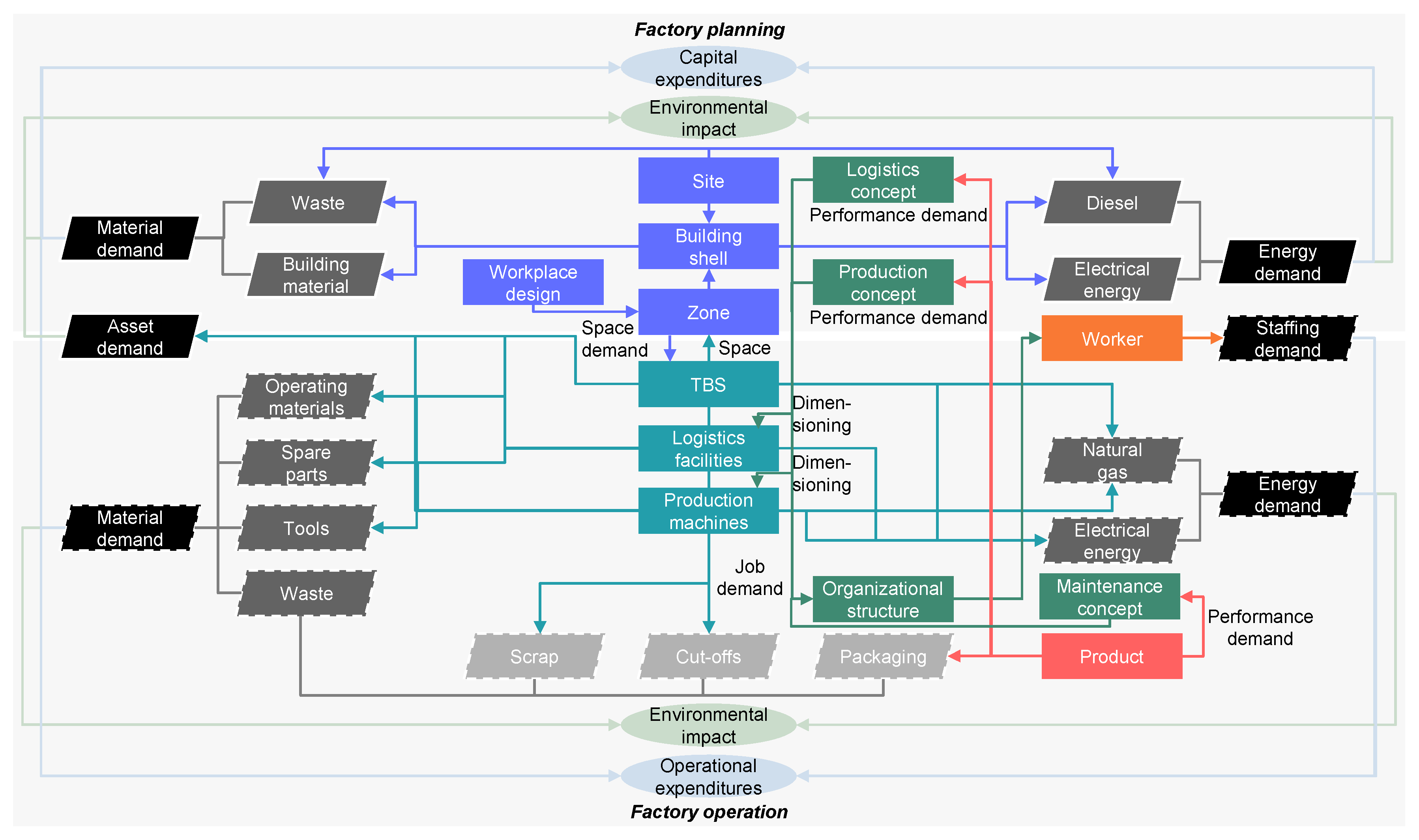

22]. In the upper half,

Figure 1 merges these models and illustrates a factory system at different levels and corresponding input/output flows. The factory system is described within its system boundaries with the following main subsystems [

1,

6,

20,

23]:

Process facilities including production, storage and transportation that accomplish the value-adding transformation process in process chains

TBS, which maintain production conditions (in terms of moisture, temperature and purity) and supply production and logistics with energy and media flows

Factory building, that is, the physical boundary of the factory system to the outside

Production organization with maintenance, logistics and production concepts that describe the functional and logical interrelationships in manufacturing, assembly and logistics

Figure 1.

Qualitative representation of the sustainability of a factory using the example of life cycle costs, following [

1,

6,

20,

24].

Figure 1.

Qualitative representation of the sustainability of a factory using the example of life cycle costs, following [

1,

6,

20,

24].

Subsystems of a factory and their elements are planned in the course of the factory planning, whose process has been described by various authors [

6,

17,

25,

26] and is based on the general problem-solving cycle. Factory planning provides design solutions and potentials from a personnel, technical-organizational, economic and environmental perspective that can be used during factory operation for different target alignments [

26]. Factory operation typically lasts for numerous decades and includes several reconfigurations by factory planning until end-of-life of the factory is reached. It represents the most relevant life cycle stage, as most of the environmental impacts and life cycle costs occur during factory operation [

27,

28,

29]. During factory operation, production management monitors, controls and manages the processes in the factory in order to ensure the company’s objectives are met through the interaction of people, technology and organization as well as cooperation within and outside the factory [

26].

The lower half of

Figure 1 shows the traditional economic perspective of factory planning. First, on the left side, capital costs arise to create the solution space of a factory system [

6]. Then, operational costs occur until end-of-life. The factory system faces increasing uncertainties during factory operation [

26]. On the one hand, there are internal and external change drivers arising from higher-level megatrends, which pose ever new requirements [

13]. On the other hand, short-term and operational disturbances have a relevant impact on performance and are difficult to anticipate [

30]. Therefore, a continuous reorganization of the factory is necessary. As a result, there is a gradual merging of factory planning and factory operation tasks [

17]. If the factory is unable to adapt its facilities and organization fast enough, it can quickly lose its competitiveness due to the variety and speed of the influencing factors leading to the end of the factory life cycle [

6]. At this point, the market requirements cannot be fulfilled anymore. Together with management, the termination of the factory can be decided. Practical experience has shown that complete dismantling is usually not carried out and resources can be reutilized so that this phase only plays a minor role from an economic and environmental perspective (e.g., 0.9 % share of the environmental impact of a modern automobile factory [

27]). Additionally, this phase is accompanied by only a few conceptual decisions. In the further course, potential activities in this phase are not considered separately, but are discussed in the course of factory planning.

Due to the increasing relevance of environmental criteria in factory planning, the concept of life cycle-oriented factory planning was shaped in previous publications [

11,

12,

13,

14]. Instead of permanently and reactively adapting the factory to quasi-static conditions, life cycle-oriented factory planning aims for a proactive planning of the factory life cycle. Factory operation is thought ahead for the long term and a factory configuration is developed from a life cycle engineering perspective. According to this concept, all factory elements must be aligned considering their individual life cycles in such a way that economic and environmental targets are achieved over a given period during the factory life cycle. Further information on life cycle engineering in factory planning and a review of associated frameworks as well as methods and tools are provided in Dér et al. [

14].

To operationalize the concept of life cycle-oriented factory planning, there is a need for a performance measure system that can be used for target setting and target monitoring. LCA is the methodology that translates energy and material flows into environmental impacts [

31]. Climate change is a relevant but not a solitary impact category [

32]. Further impact categories need to be accounted for in order to avoid problem shifting [

33]. The modeling of impact paths from elementary flows to impact categories originally come from product perspective [

34], partly extended by an economic impact path [

35]. A first application of LCA impact path models in the context of urban factories was conducted by Juraschek [

36]. Monetarily factored flows are considered in the cost structure of a factory, which can be evaluated holistically using the LCC method according to VDI 2884 [

37] or VDMA 34160 [

38] or, with regard to buildings, according to Iso 15686 [

39]. The term life cycle costs is defined as the sum of all expenses required for the intended use of a system from acquisition to disposal [

37]. By analyzing the cost progression, LCC supports the acquisition of capital goods and long-lived products with high investment costs [

40].

Different methodological approaches were presented over the years for the life cycle evaluation of factories, for example, [

11,

41,

42]. An overview of models for the life cycle evaluation of factories is provided in [

11]. Individual factory elements have already been modeled for LCC and LCA [

43,

44,

45]. In particular, machine tools have been examined in detail. The application of LCA for entire factories based on empirical data is rather nonexistent; one unique example is the LCA of an automotive factory [

27]. While the modeling, forecasting and design of individual factory elements is well established in science and practice, it has not yet been possible to transfer the methodology to an entire factory with its interconnected cycles such as product, process and building life cycles. Next to methodological questions and limited data availability during planning phases, the more important barrier is to understand the inner logic of the life cycle behavior of a factory system. In order to design and operate a factory according to sustainability targets, factory planning and operation must not only understand the life cycle behavior of single factory elements, but, more particularly, gain a comprehensive understanding of the emerging life cycle behavior of the interconnected factory elements.

3. Development of a System Understanding for Factory Life Cycle Evaluation

Based on the identified research gap, this section forms the methodological foundation for developing the impact path models as a knowledge base for the subsequent economic and environmental life cycle evaluation of factory systems. To this end, a conceptual research approach is applied that can be related to application-oriented science, which aims to “develop rules, models and procedures for practical action with the help of findings from the theoretical or fundamental sciences” [

46]. The considered research methodology includes logical-argumentative reference modeling to find suitable solutions [

47]. By creating simplified ideal representations of the system, deepening existing knowledge and developing design patterns, the life cycle evaluation on the factory level is exploited efficiently following Weick’s concept of “sensemaking” [

48]. First, an integrated control loop of factory planning and operation is developed that functions as an enabler for building up a system understanding about the factory life cycle behavior. It serves to derive life cycle stage-specific actuating and regulating variables, which function as the calculation basis for LCC and LCA. Afterwards, the functional interactions of the factory elements are analyzed, which result in life cycle data as a basis for the evaluation of economic and ecological outcome values. Therefore, the focus is on interdependencies with outcome values afterwards in order to identify the factory elements with a direct influence on the factory sustainability. These analyses outline the interdependencies on a high abstraction level. They serve to ensure valid system modeling of the impact path for evaluation on the one hand. On the other hand, the comprehensibility of the effects of factory planning decisions within one factory element and on the rest of the factory is ensured.

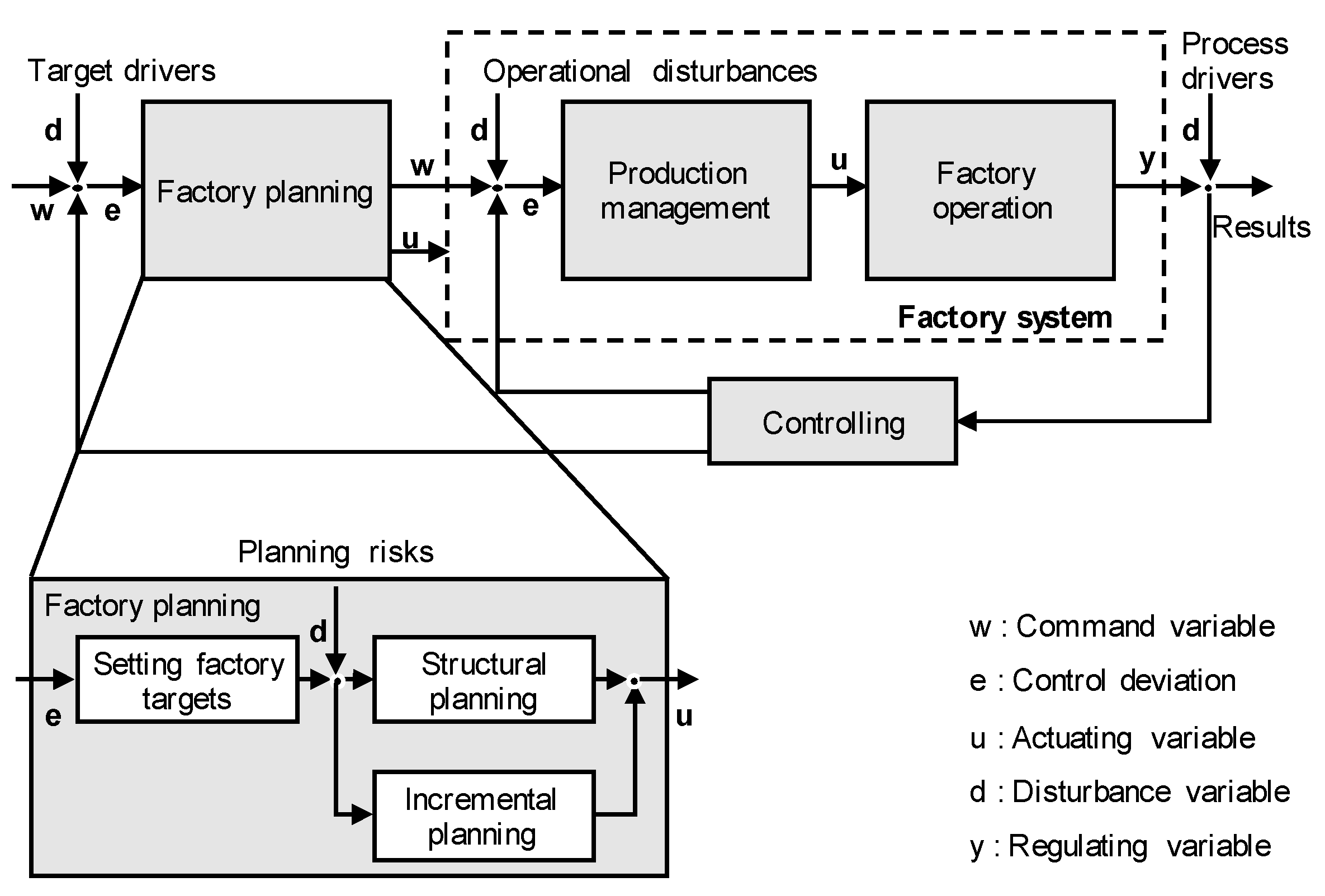

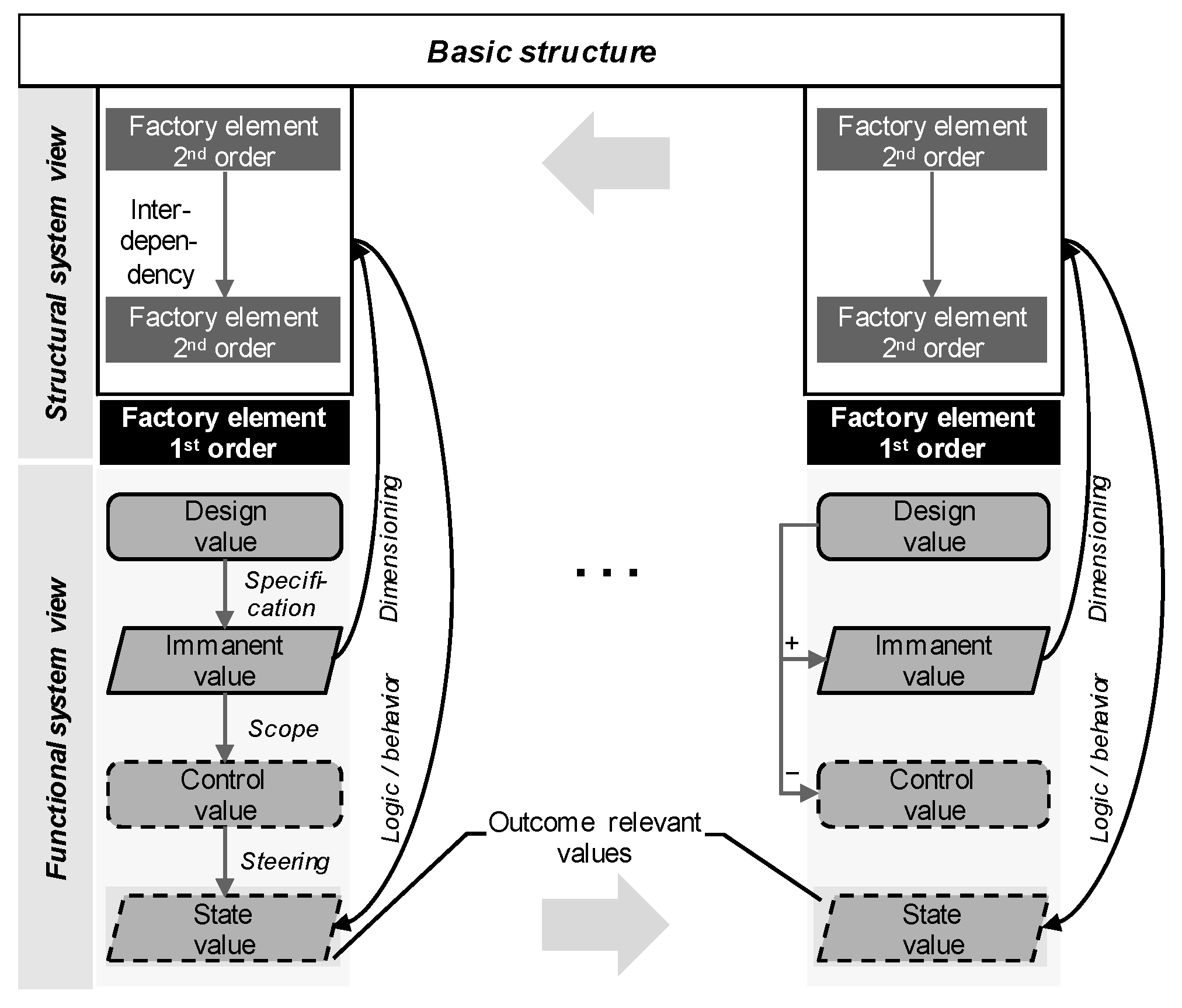

Aligning the factory life cycle along economic and environmental targets requires an awareness about the possibilities for influencing and controlling the factory system as a prerequisite. Based on control loops in the context of factory planning in the narrow sense and manufacturing in the broader sense [

23,

49], an integrated control loop of factory planning and operation has been developed (

Figure 2). The integrated control loop serves as a basic model for this section. It is based on the premise that there is a gradual merging of planning and operation towards a life cycle-oriented factory planning. Instead of a reactive adaptation of the factory, a proactive planning of the factory life cycle must be made. This integrated control loop emphasizes the cascading nature of decisions from planning to operation and therefore enables a more precise understanding of the relationship between factory planning and factory operation for the derivation of relevant system values.

Factory planning is regarded as a control element that sets factory planning targets and makes design decisions accordingly based on corporate targets (outer command variable). In addition, disturbances in the form of planning risks and target drivers need to be accounted for. Therefore, these decisions either involve structural planning to ensure a long-term development capability or incremental planning for short-term elimination of disturbances [

49]. The result of structural and incremental planning are concepts that serve as actuators for implementing the decisions. They affect the factory as a controlled system and its operation, resulting in regulating variables that are monitored in controlling. Their actual values are influenced by changed requirements or disturbances in factory operation (operational disturbances and process drivers). If a control deviation occurs and command variables are not met, the target-actual difference initiates another adjustment of the factory.

The cascading nature of decisions in life cycle-oriented factory planning results from an additional inner control loop. Production management functions as an additional control element. A joint controlling mechanism ensures that decisions in both phases are aligned. With this regard, the control element of production management takes action first. Thereby, the control deviation is determined based on the targets set by factory planning (inner command variable). Only once the predefined scope for action in factory operation has been exhausted by measures in production management, factory planning has to become active. Factory planning then creates the necessary conditions in the factory system for compensating the control deviation.

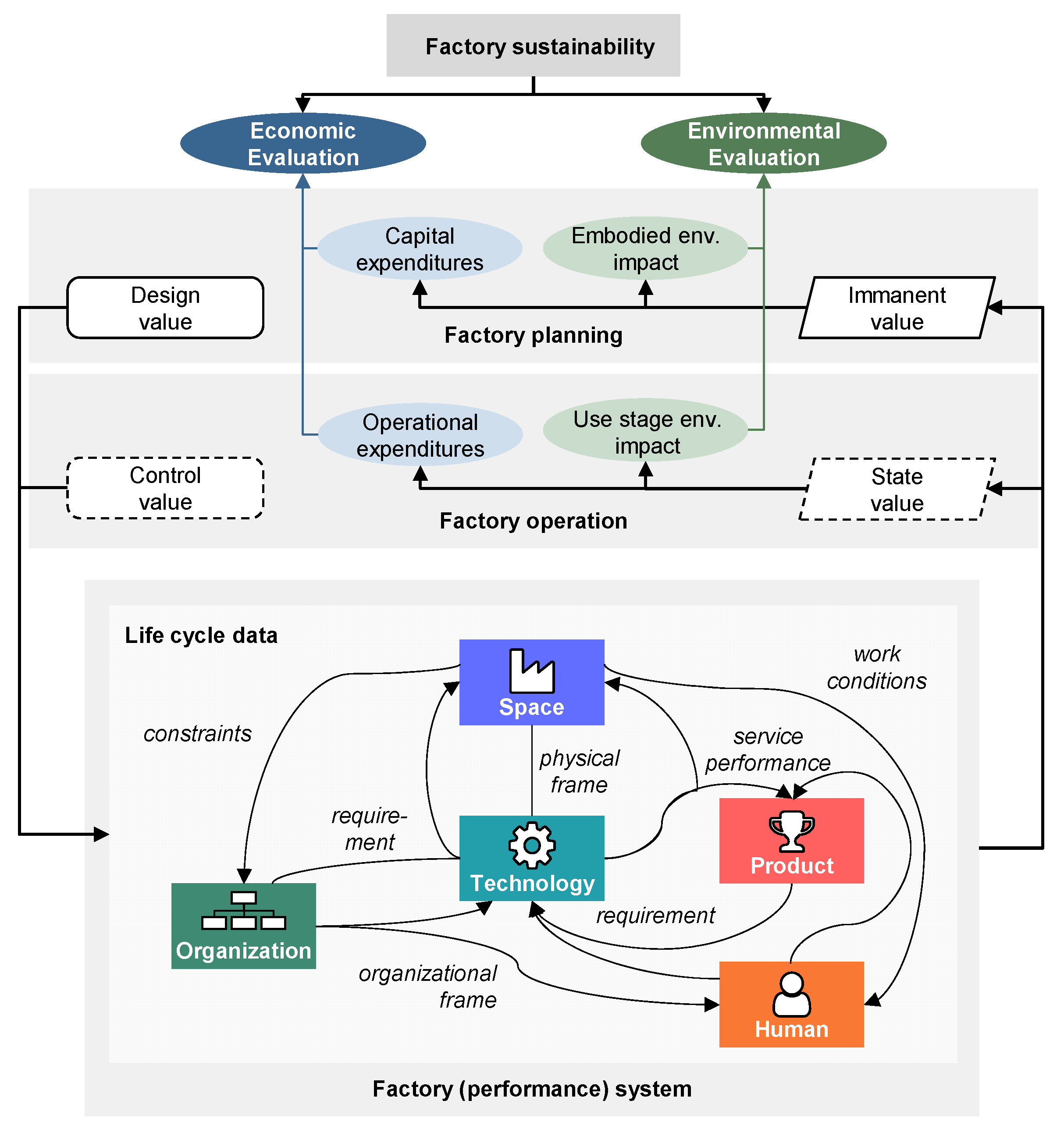

The next step towards the systemic understanding of factory life cycle evaluation is to relate the control elements from the integrated control loop to the outcome values for economic and environmental life cycle evaluation of factory systems. The relations between the economic and environmental outcome values, the planning- and operation-specific actuating and regulating variables as well as the regulated factory (performance) are illustrated in

Figure 3.

The fundament of life cycle-oriented factory planning is the performance system of a factory as the source of the life cycle data, consisting of the individual factory elements of the design fields explained in

Section 2. Both factory planning and production management can influence the performance system through design or control values as actuating variables. Decisions in factory planning, which are made by means of design values, determine the dimension of the factory system and thus determine the immanent values as an intermediate variable. They form the basis for calculating the outcome values, capital expenditures and embodied environmental impacts in factory planning. At the same time, the scope of factory operation is set and can be further regulated by production management based on control values. As the only regulating variable of the control loop, state values result from factory operation. They determine the outcome values, operating costs and use stage environmental impacts.

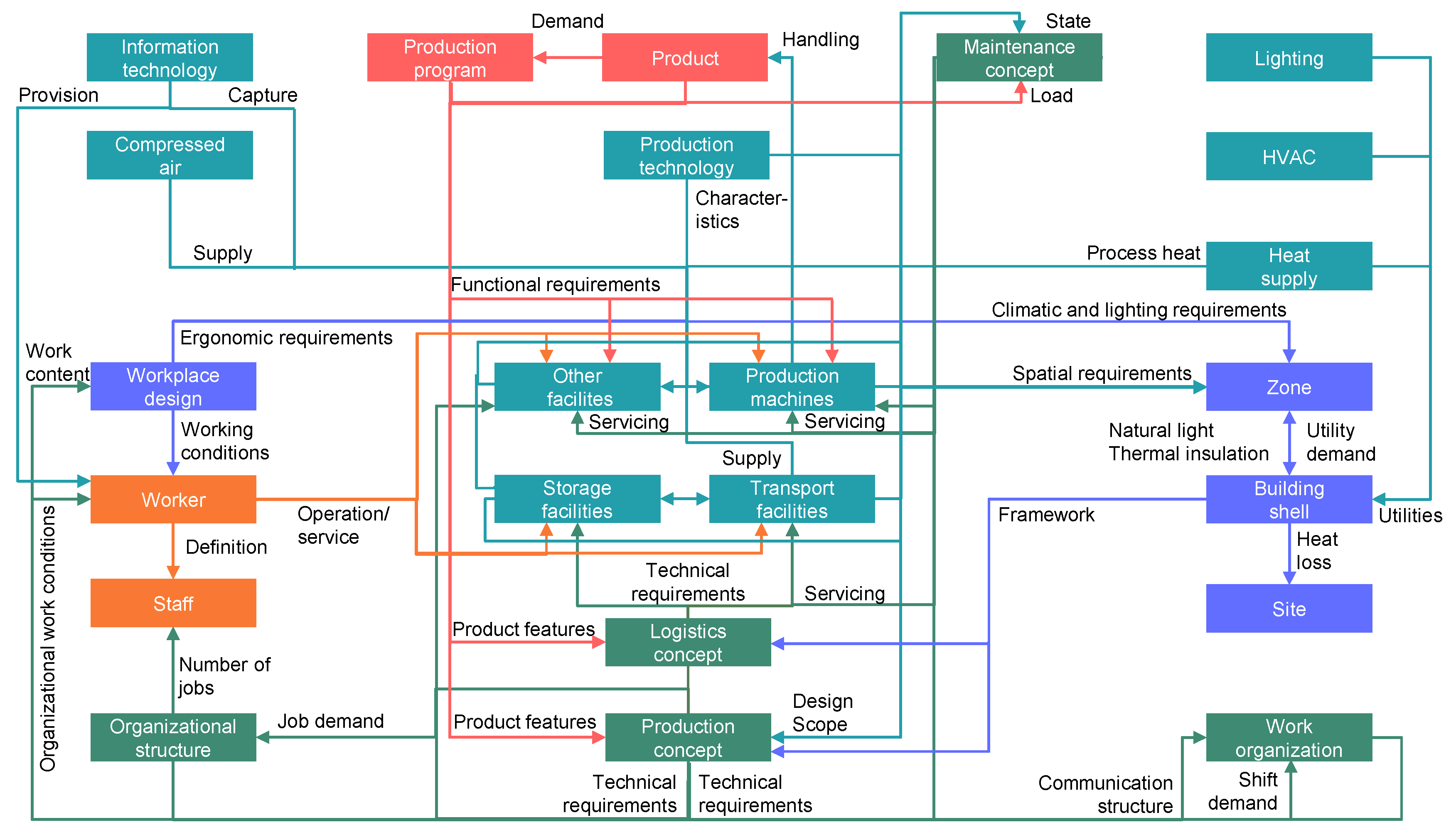

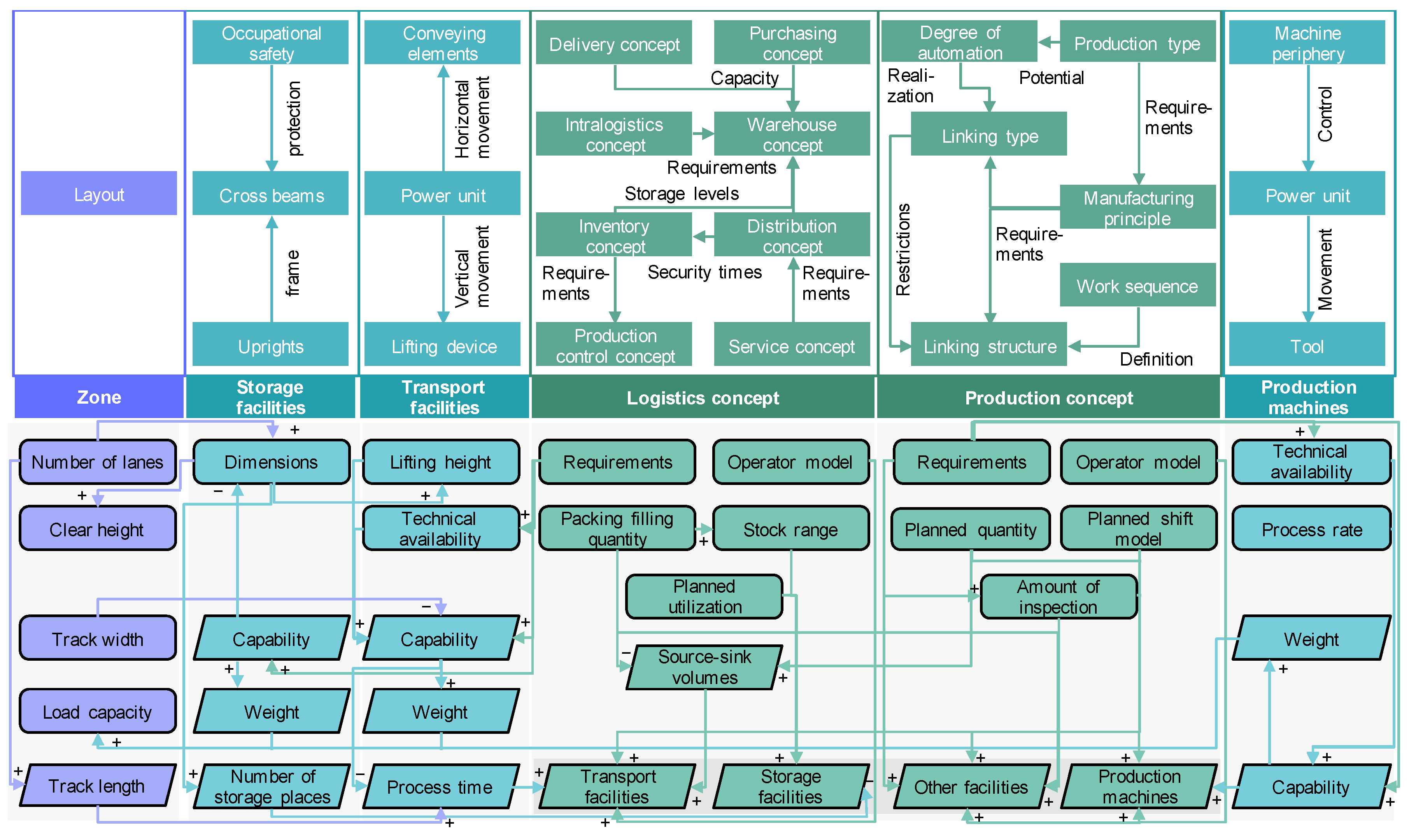

Corrective action must be taken if the state values do not correspond to the targets set by management. In the case of major deviations, a structural change is usually required, so factory planning must intervene. In order for factory planners to be able to knowingly and purposefully influence the outcome values with the help of factory planning measures, it is necessary to deepen the comprehensive understanding of the factory performance system. In

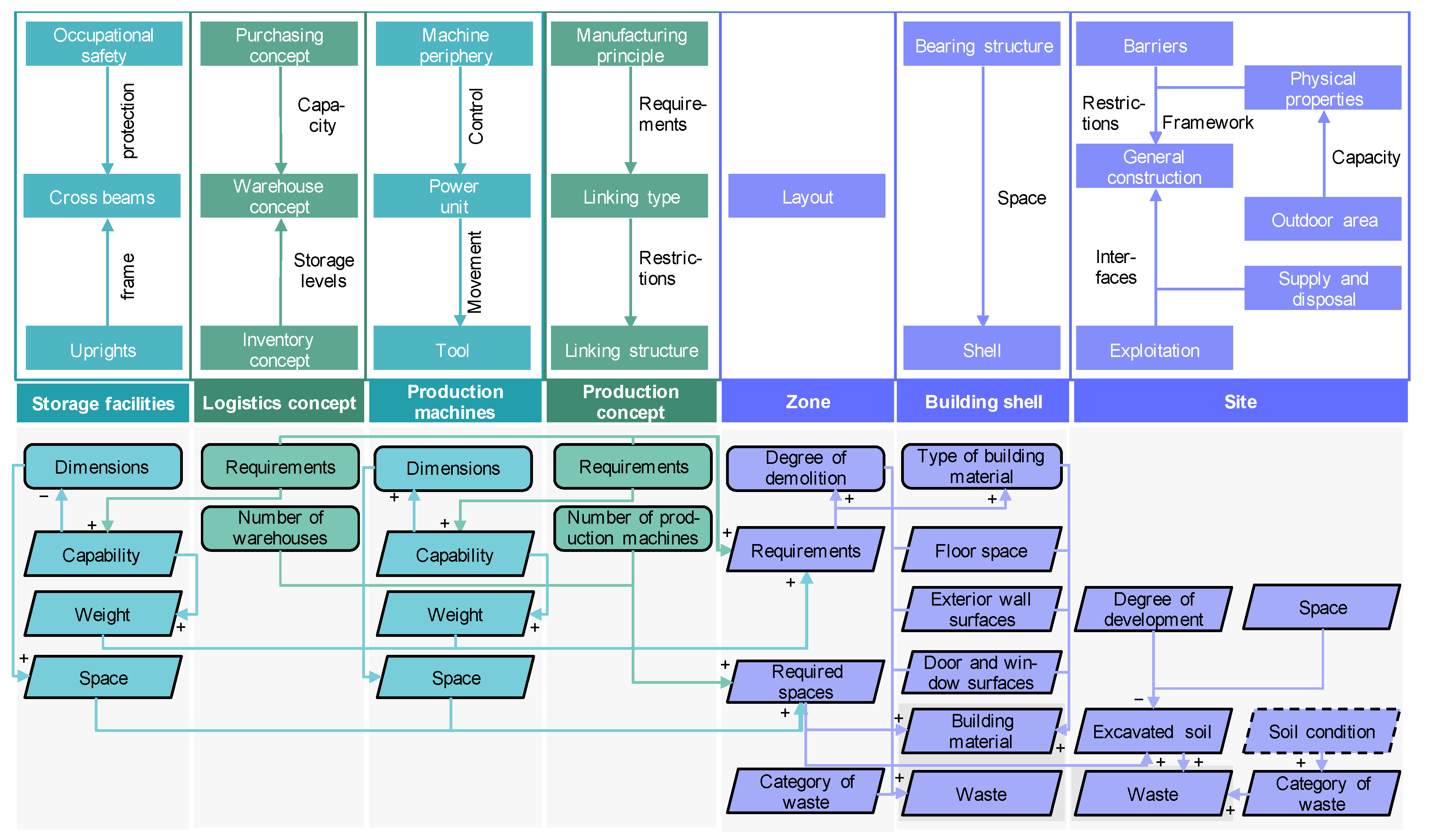

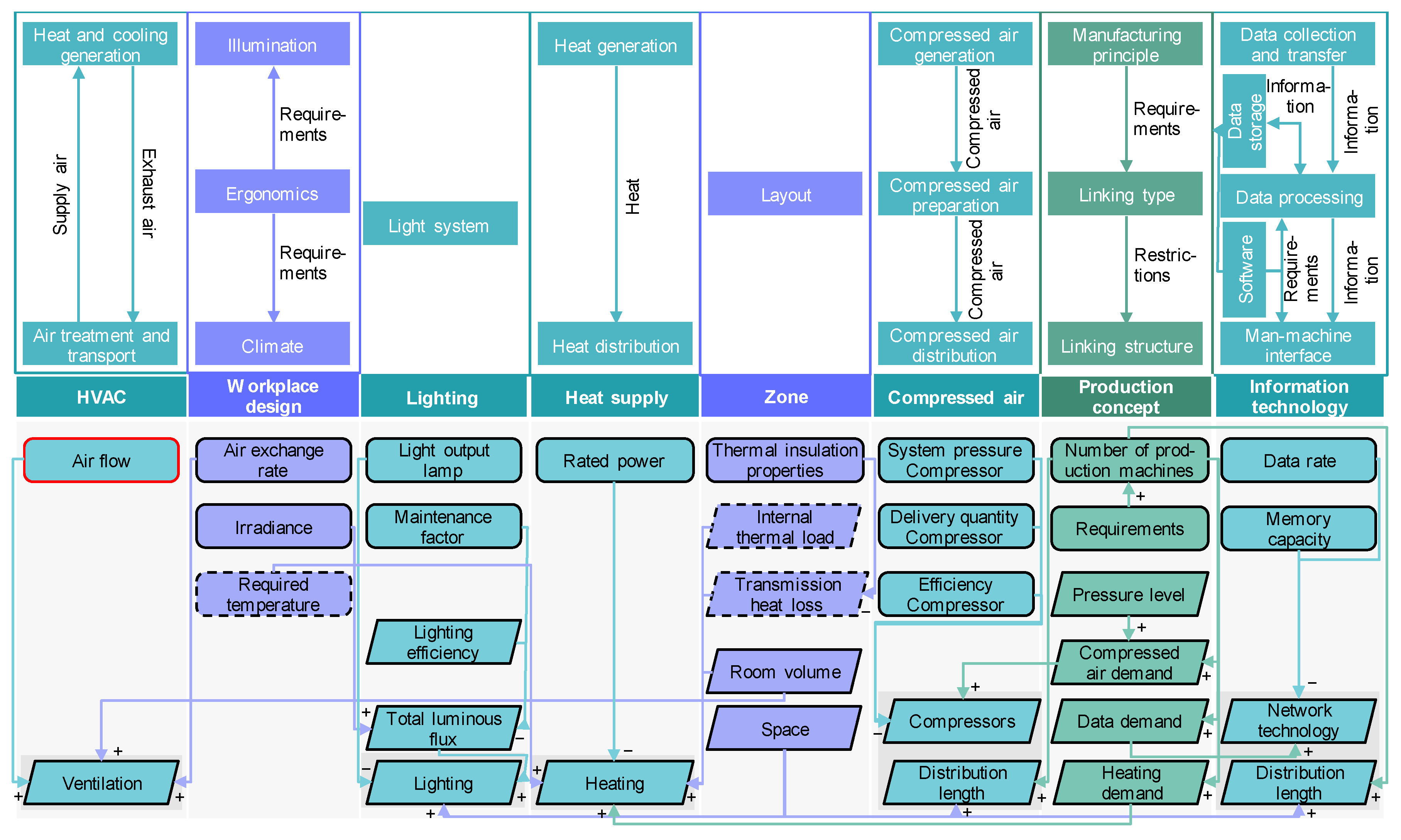

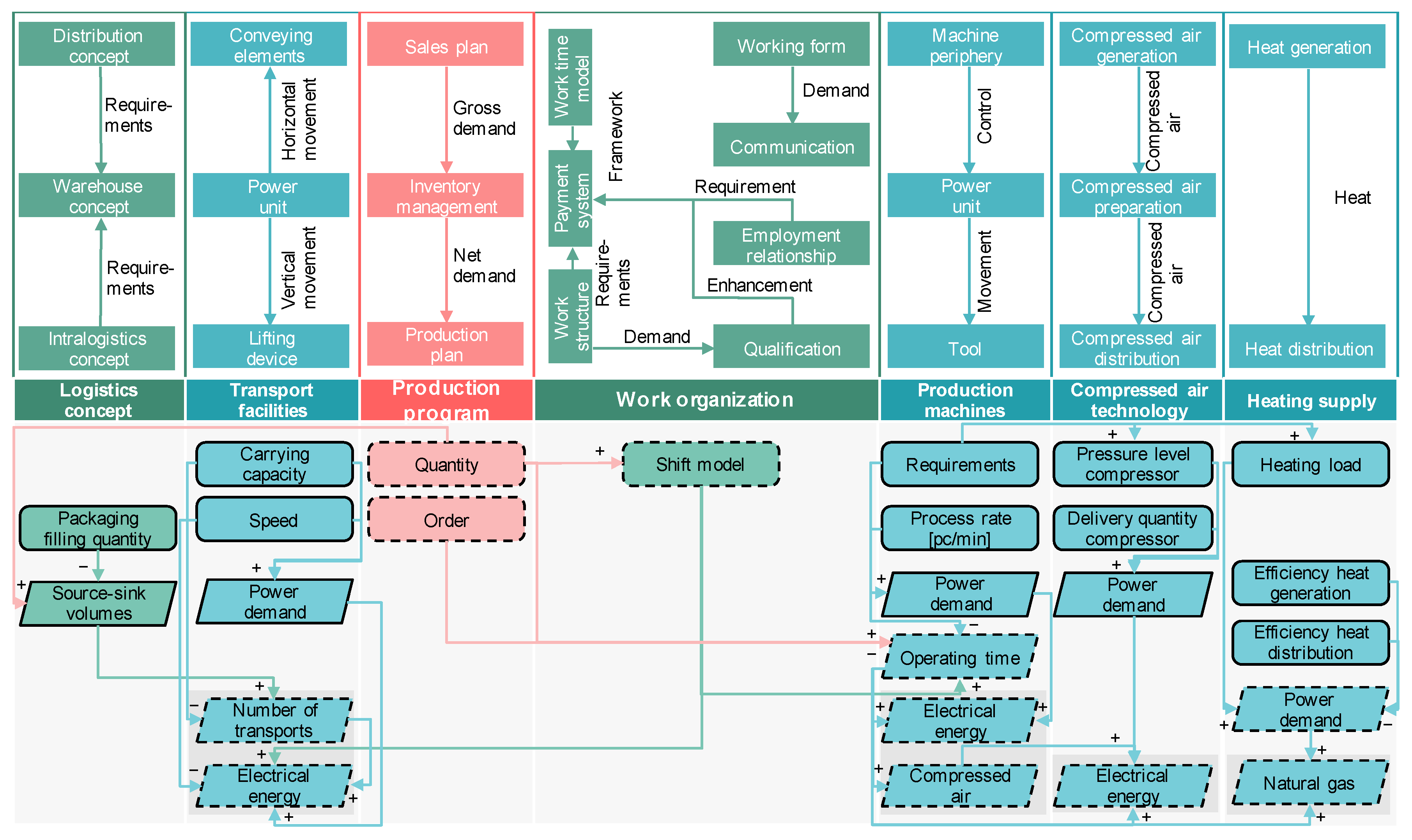

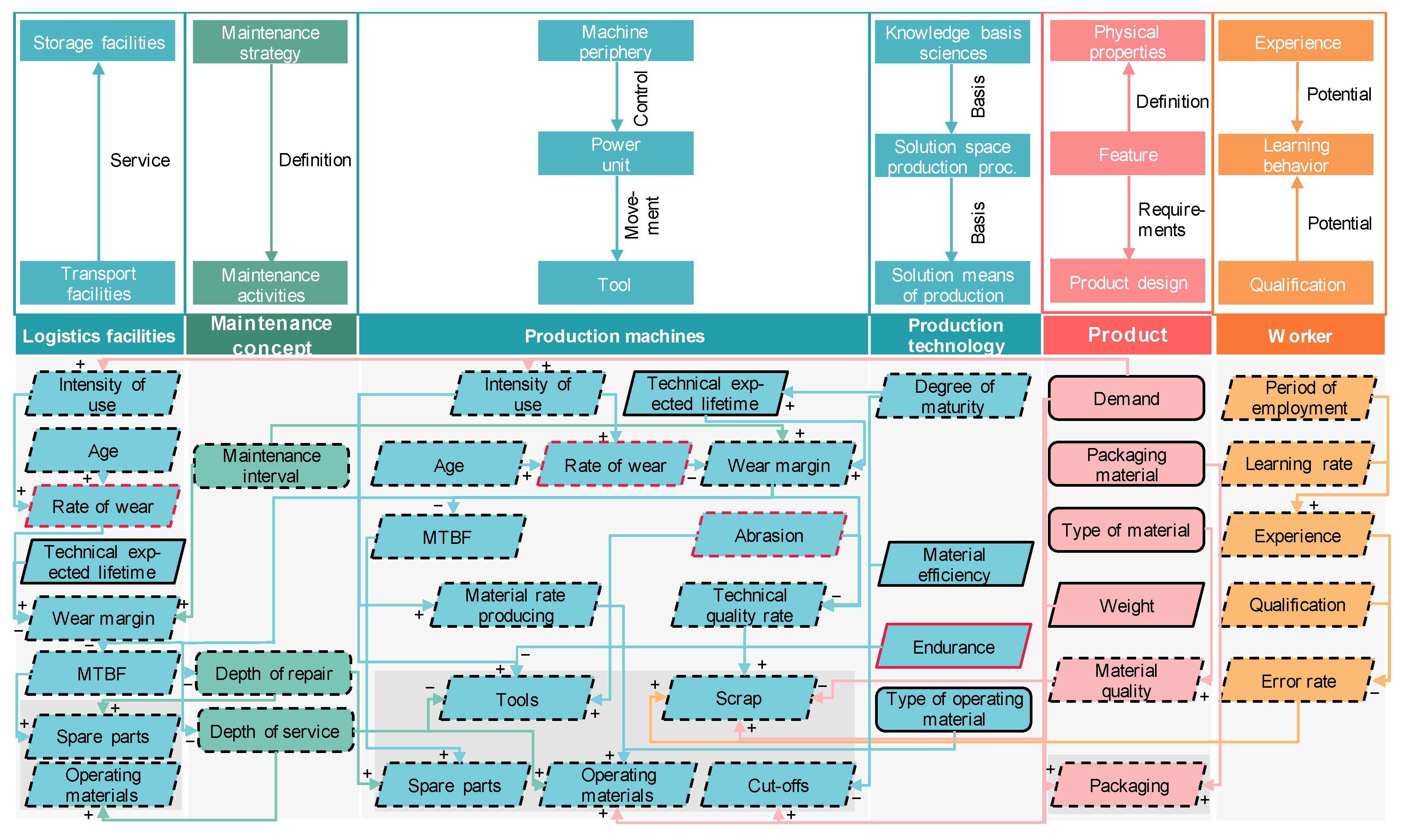

Figure 4, the interdependencies between the design fields are further broken down based on the associated factory elements (see color scheme in

Figure 3). It gives an overview of the main functional interdependencies between factory elements in factory planning and operation. The interpretation of the relationships indicate that interdependencies essentially originate from operation so that life cycle perspective must be maintained. The requirements for the concepts developed in factory planning result partly from the future interaction in operation (e.g., transport facilities servicing storage facilities).

Since value creation of the product represents the central task of a factory, the technical elements directly involved in value creation occupy a central position. In this context, production technology determines the performance potential of the factory and its production machines. The product itself is the origin of all activities in factory planning and operation and therefore takes on a superordinate role by setting the central requirements for technology, organization and space.

Organization and space, located at the outer edge in

Figure 4, represent the spatial and organizational framework of a factory. Specifically, the organizational concepts receive the product requirements as an input and plan the process facilities accordingly. Based on the planning results, further requirements are passed on to the elements of space. Here, the factory element zone functions as an aggregating element for the individual requirements (e.g., load-bearing capacity, climate conditions) and realizes them decentrally. For example, zones in production and logistics areas differ significantly in terms of those requirements.

As already indicated, the TBS are responsible for providing energy and media supply for design fields’ space and technology in line with the set requirements. The factory element workplace design defines the working conditions at the workplace depending on the work content planned in the production and logistics concept and the resulting specifications. The workers ultimately carry out the work at the process facilities within the basic conditions of factory operation defined by the organization (e.g., shift model).

Based on the functional interdependencies between the factory elements, a connection between possible factory planning measures and the outcome values can be established. Therefore, the factory elements contributing directly to the outcome values of the LCC and LCA have to be identified, which form the basis for the impact path model in

Section 4. As an inherent part of a factory, each factory element contains the previously identified system values with the respective shapes (see

Figure 3).

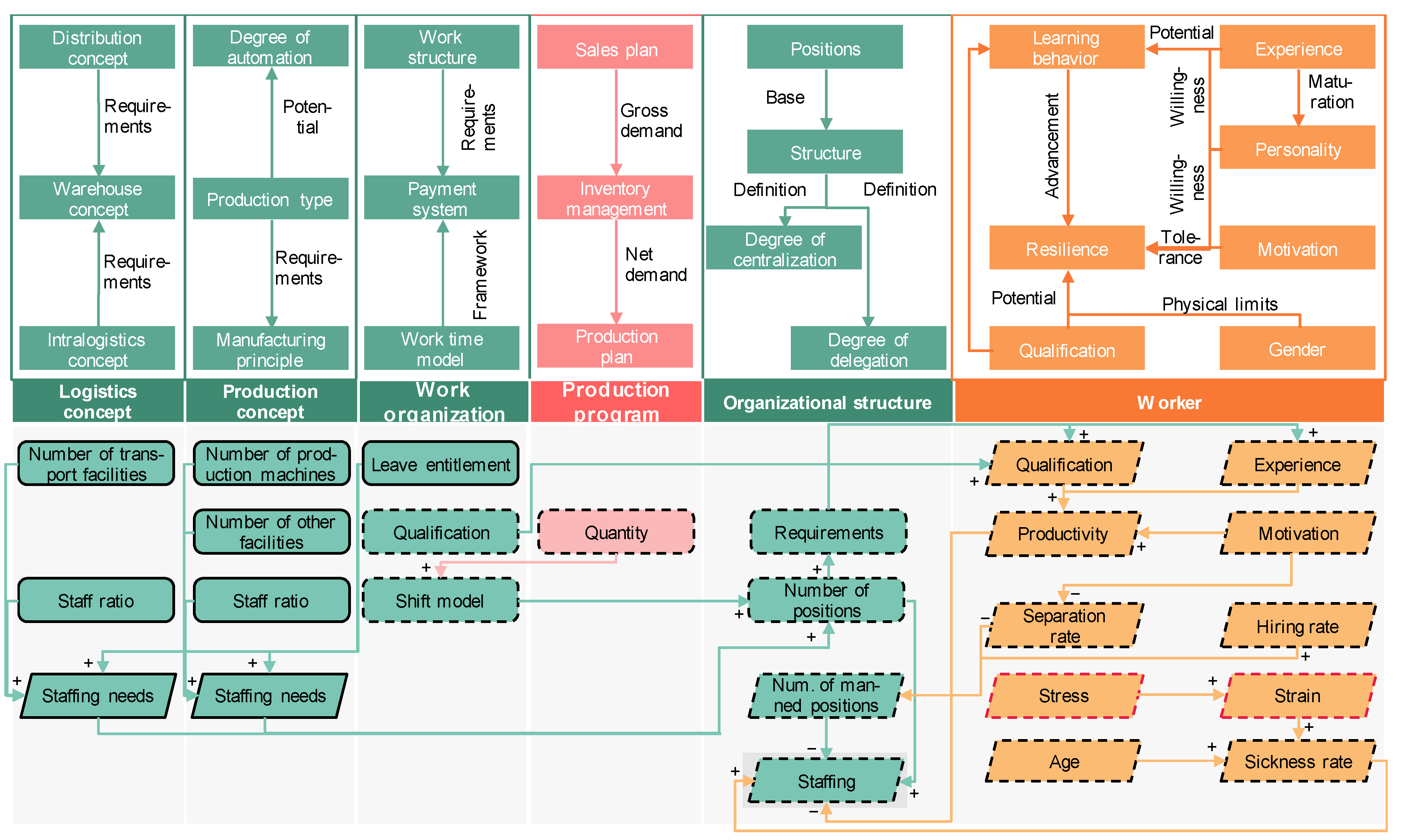

Consequently,

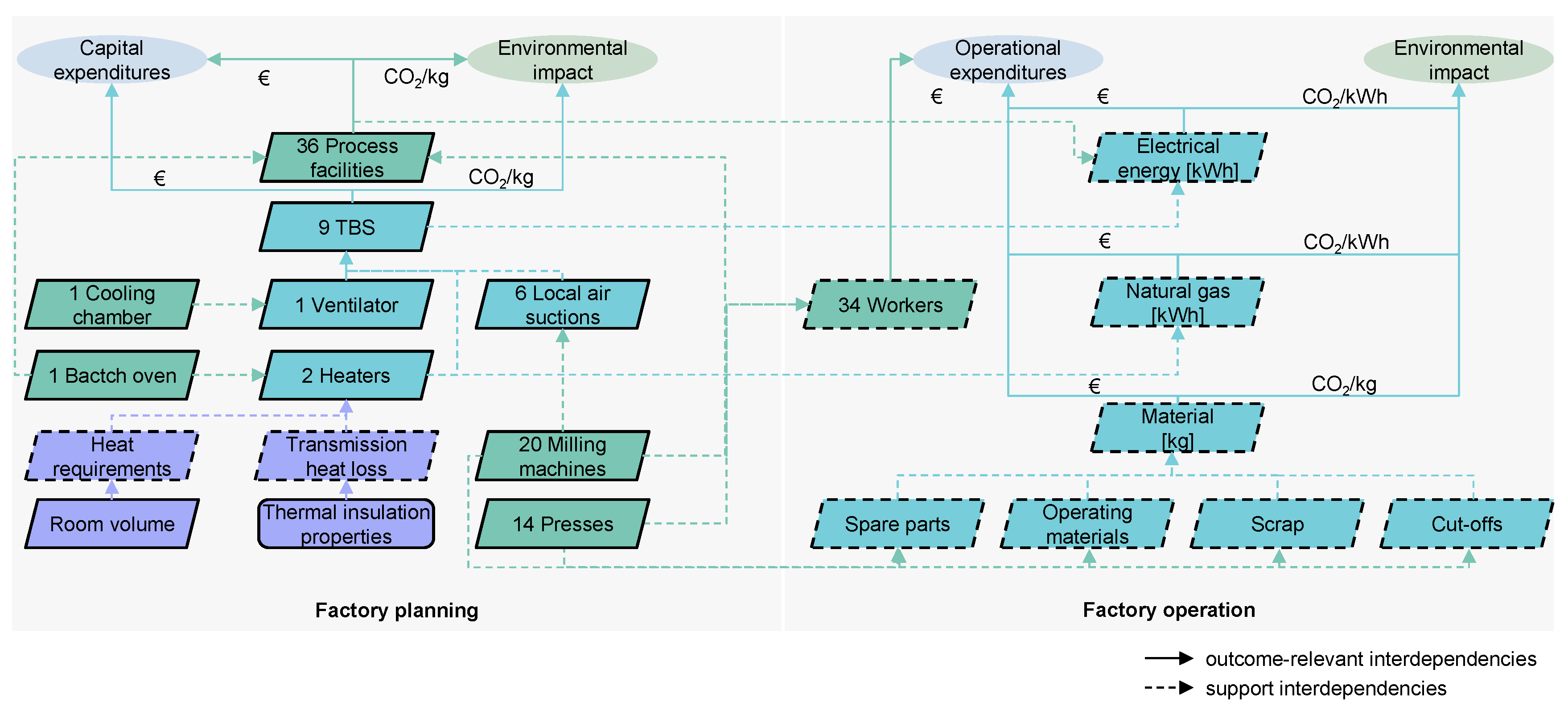

Figure 5 illustrates the interdependencies of the relevant factory elements with the outcome values. Thereby,

Figure 5 is divided into the fields of factory planning (top section) and operation (bottom section) in line with the performance measurement system presented before. For the application of LCC and LCA in factory planning, staffing, asset, material and energy demands have to be determined. The material and energy demands are listed in both fields, whereas the asset and staffing demands are only displayed once in-between planning and operation. Staffing demand in factory planning represents the planning effort and will be neglected in the further course of the paper. In factory operation, it represents the executing staff. Furthermore, the asset demand contributes to either capital or operating expenditures, depending on the selected operator model (purchase, rental, etc.).

The physical elements are in the center of

Figure 5. The spatial elements are located exclusively in planning and cause embodied material and energy demands during realization or dismantling of a factory. Technical elements are responsible for the outcome values in planning as well as in operation. In addition, the organization functions as a connecting element and coordinates the demands both in planning and in operation.

In the course of operation, the technical elements require operating materials and spare parts. Production machines additionally have tooling demands and waste is generated through scrap and cut-offs. The regular demand for production material is not considered, since it enters the factory as raw material and leaves again as a finished product after value creation, thus it is not emitted to the environment. Therefore, only packaging waste of the product is accounted for. The product passes performance requirements for the organizational concepts of actuators. The concepts give dimension to the process facilities based on the product requirements. This results in a certain asset demand, which, in turn, largely determines the staffing and space demands. The latter must be covered by the spatial elements, whose reconstruction or creation during factory realization generates embodied material and energy demands. These are already incurred at the time of acquisition of the technical elements. In the subsequent factory operation, all technical elements consume energy for service provision. The most relevant energy forms are electricity and natural gas for process heat or space heat supply.

As a result, the technical and spatial elements as well as staffing have direct influences on the outcome values and represent the starting point for the development of a knowledge base for later applications of LCC and LCA in the context of factory planning. With the help of the created system understanding for factory life cycle evaluation, the contribution of the system values of the respective factory elements to the corresponding outcome values is to be analyzed next.

5. Exemplary Application of the Impact Path Model in a Brownfield Planning Project

The case study demonstrates the conceptual results by showing how the impact path model can be used as a knowledge base in factory planning. A brownfield factory planning project is considered, where three different planning variants are qualitatively examined. The product portfolio of the factory comprises composite bending plates for various application scenarios such as automotive, sports and running prostheses. Various production and logistics concepts are conceivable for the production of the bending plates. The process chain of the composite bending plates starts with cutting and stacking of semi-finished products, which is followed by consolidation in a press. Afterwards, the bending plates undergo a heat treatment and a finalizing machining process. Resin transfer molding (RTM) and prepreg pressing are equally qualified for the consolidation step, however, they require different semi-finished products and processing times. Currently, pure composite plates are produced. Despite technological superiority and an existing production technology for hybrid bending plates (i.e., metal-fiber laminates), a switch from pure composite bending plates has yet been postponed due to higher material costs. A comparative analysis of the production costs and further details about the case study can be found in Rothe et. al. [

68].

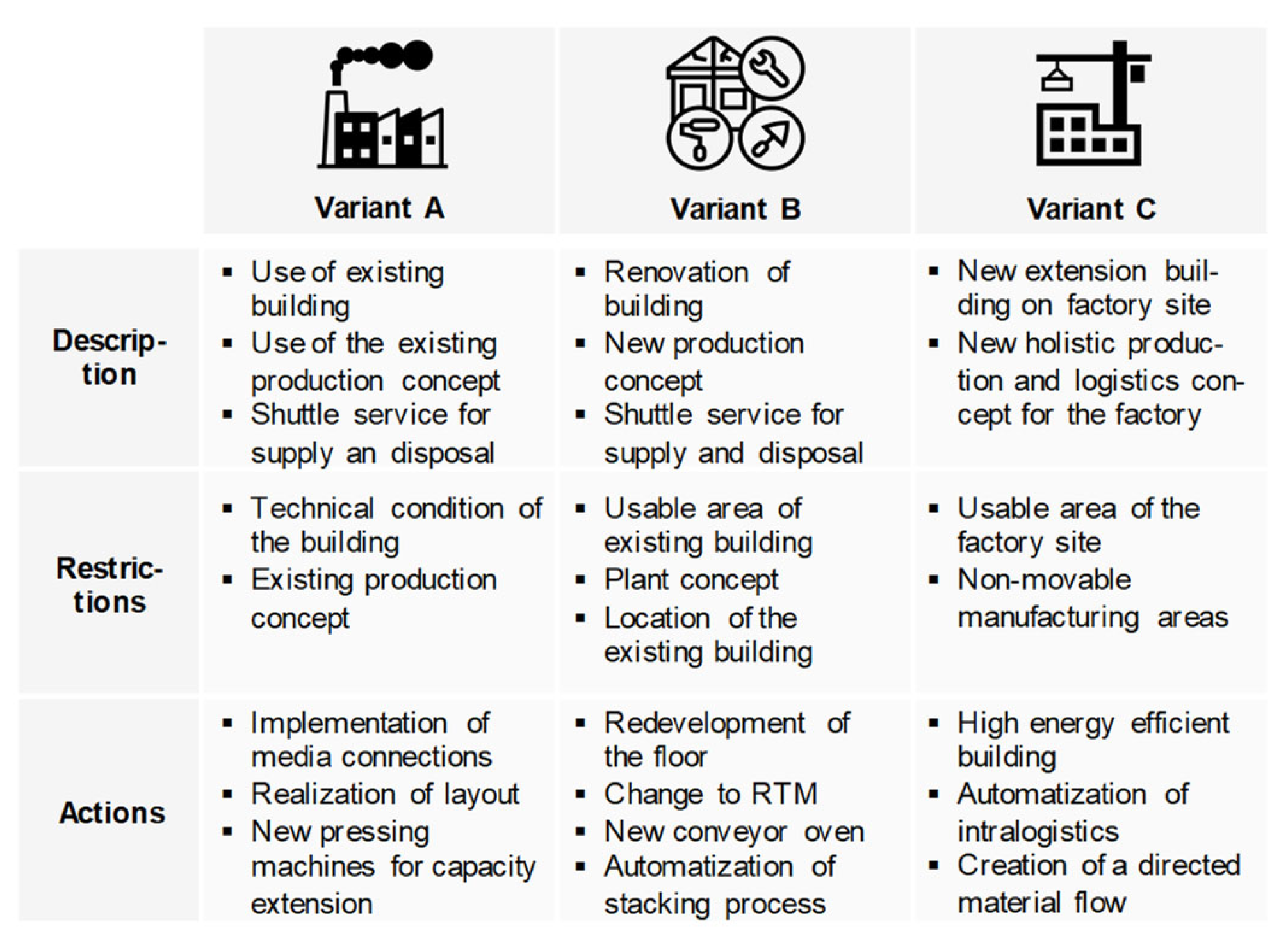

In light of a vast growth forecast for the demand of bending plates for running prostheses, the manufacturing company has made a decision to position itself more strongly in this field. In order to integrate development and production more closely, the company is considering relocating the production of bending plates back to its headquarters. Space utilization at the current production facility is very high, so a reorganization of the factory must be carried out first in order to clear the necessary space for the relocation. Considerations show that by moving spaces in the layout, one factory building can be emptied. The building is not ideally suited from a logistical perspective, as it is located on the outer edge of the factory site, standalone and separated from the main building. The supply of raw material and pickup of finished products will require shuttle transports, leading to an undirected flow of materials on site. Alternatively, an expansion area on site is available for the production of the bending plates. Eventually, three different planning variants emerged, which are summarized in

Figure 14.

Planning variant “A” plans the integration of production into the emptied building based on the existing concepts and without any additional reconstruction of the building. Prepreg pressing is used, as RTM was not considered in the past due to the high acquisition costs. For automotive and skis, each product family runs on its own press, whereas workshop production is used for prosthesis. The concept will be continued and expanded accordingly due to the necessary capacity expansion. From the building perspective, only the required media connections are installed, and the layout is implemented with corresponding markings on the building floor.

In order to increase the degree of freedom in factory planning, renovation of the building is proposed in planning variant “B”. Specifically, the building floor is upgraded. This provides the basis for using a conveyor oven instead of a batch oven. Furthermore, a production technology switch from prepreg pressing to RTM is planned. This is expected to eliminate the cooling chamber for semi-finished products and reduce processing times. Because of the expected increase in production quantities, transitions to line production and automation of the stacking process are also planned for the prostheses. Restrictions remain due to the dimensions and location of the existing building.

In planning variant “C”, an extension building on site is planned for the production concept described in planning variant “B”. The layout of the building zones is designed without any restrictions and the building shell meets the latest energy efficiency standards. The shape of the building is constrained by the factory site, but the required space is available next to the main production building, where central logistics is also located. The existing material flow in the main building is extended orthogonally. The extension building is ideally integrated through a holistic logistics concept with tugger trains, complemented by automated intralogistics using AGVs if possible.

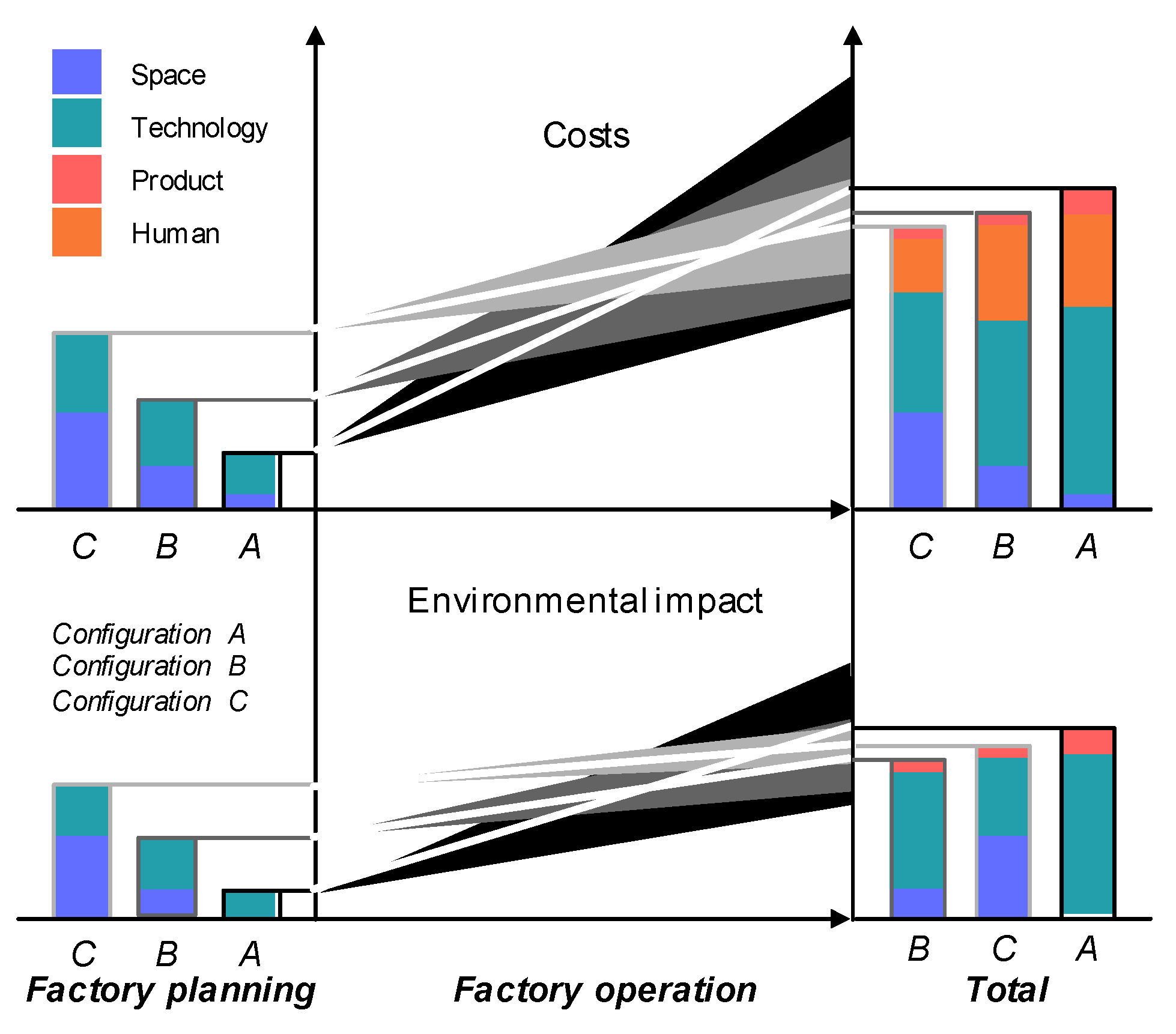

The impact path model was used to derive the relevant data for the economic and environmental evaluation of the planning variants over a length of 10 years.

Figure 15 shows exemplarily the impact paths for planning variant “A”, which illustrates how the individual system values are combined into the outcome values in planning and operation. The dashed arrows represent a selection of the interdependencies discussed in detail in the previous section. The solid arrows symbolize the outcome-relevant interdependencies. In factory planning, the acquisition and implementation of the technical and spatial factory elements entail capital expenditures and embodied emissions. Other environmental impacts are not considered in this case study. In factory operation, the material and energy demands are factorized depending on the evaluation dimension (e.g., unit price or the CO2 factor). Material demands for the bending plates are included in the considerations, except for scrap material and cut-offs.

In factory planning, the capital expenditure and embodied emissions can be quantified rather precisely at the end of the planning process. At the latest, during preparation for realization of the factory, when the exact configuration and properties of the factory elements are known. At the beginning of the concept phase, this is still an estimate, which is subject to uncertainties and becomes more precise with a detailing requirements profile as the planning process progresses. In contrast, the operating costs and use stage emissions in factory operation are dependent on the dynamics of the operating procedure and the associated changes of state of the process facilities. In the example of planning variant “A”, a total demand for electrical energy of 1,154,370 kWh can be statically calculated for the process facilities and TBS while taking assumptions into account (e.g., 5-day operation, three-shift model). Since the operation phase becomes more relevant with an increasing period of consideration of the factory life cycle, the focus should be placed on the corresponding dynamics in the LCC and LCA. These dynamics are qualitatively outlined in

Figure 16 as a beam in factory operation and are reinforced by the occurrence of change drivers and disturbances. An exact quantitative assessment of the confidence interval is only feasible with the envisioned forecasting model, which will enable a directionally reliable evaluation of the planning variants over the factory life cycle to support decision making in factory planning.

Based on the data recorded with the impact path model and static calculation of the outcome values, a linear progression in factory operation and an overall outcome value of the individual planning variants are obtained for the following comparison. Planning variants B and C are advantageous from a factory life cycle perspective. Economically, variant C stands out in particular because of the integrated logistics concept and the associated optimized operating costs for process facilities and personnel. For the supply of production in variants A and B, a shuttle service has to be established, leading to an undirected material flow. By automating the stacking process in the course of the higher production quantities, a part of the operating costs can be compensated. Furthermore, the asset demand can be reduced by switching to RTM and line production while eliminating the need for a cold storage of semi-finished products. To achieve this, part of the process facility has to be replaced, which also entails modernization. As a result, there is less downtime, higher energy efficiency and an improved quality rate. For this reason, variant B is most advantageous from an environmental point of view for the given period of the life cycle. However, because of the high efficiency standard of the new extension building, the consumption of the TBS is significantly lower in variant C. Therefore, the new building outweighs the other planning variants from an environmental point of view over a longer period of the life cycle. The higher embodied environmental impact is to be compensated due to lower overall energy demand of variant C.