Waste Generation Predictions and On-Site Waste Management: A Danish Perspective

Abstract

1. Introduction

2. Literature Review

2.1. Construction Waste Quantification Methods

2.2. Waste Generation Rate (WGR)

| Study | Country/Year | Focus | Key Findings | Applied Waste Quantification Calculation |

|---|---|---|---|---|

| [3] | Thailand 2009 | Waste management and calculation of CWG. |

| The quantity of construction waste material: Qx = A × Gav ×Px = Qp × Px |

| [25] | Andalusia 2011 | Identification of CWs, with a focus on packaging waste, remains, and soil. |

| The expected volume of CW: CW = ∑CWSBEj = ∑CWBei = ∑CWpi + ∑CWRi + ∑CWsi |

| [17] | China 2013 | Calculation of the WGA by weight. |

| Calculation of the overall WG: WG = ∑Mi × ri + W0 Calculation of the WGA: WGA = WG/GFA |

| [26] | China 2014 | Estimating WGA with a focus on demolition and construction waste. |

| The average WGA (tons/m2): W = CW + DW = CA.Gc + DA.Gd Demolition waste: DW = DWr + DWnr Construction waste: CW = CW r + CW nr |

| [27] | Brazil 2015 | Identifying CW and estimating the accuracy of a regression model. |

| - |

| [11] | Hong Kong 2016 | Approximating CWG using S-curve models. |

| - |

| [28] | China 2016 | Waste management with a focus on waste collection, transportation, utilisation options, and landfill planning. |

| The amount of waste generated for each type of material: Gx= ∑ GFAij × WGRijx |

| [4] | USA 2019 | Identification of CW of each waste stream using waste-hauling tickets. |

| WGA in kg per m2 of built-up area per waste stream was estimated using: WGRi = WGi/TBA; The total WGA was estimated using: WGR = ∑ WGRi + W0 |

| [29] | China 2019 | Forecasting CW using average WGR. The gross floor area of buildings determined using image recognition technology and Google Earth. Calculating the total weight of waste generated. |

| The total construction and demolition waste: TG = ∑ WGRij × GFAij |

| [12] | USA 2020 | Calculation of CW with a focus on concrete and drywall waste. |

| The CW generation estimate for the entire project: CWEstimated = ∑Purchased;SectionA − ∑ Needed, SectionA The backbone of the proposed model was: CW∑Estimated − CW∑Reused − CW∑Recycled = CWLandfilled |

| [22] | Brazilian 2020 | Fuzzy set theory was used to estimate CWG. |

| - |

| [30] | Russia 2021 | An artificial neural network was utilised to estimate the amount of weekly waste generated. |

| −1A + T1B |

| [34] | China 2011 | Calculation of WGR by conducting on-site waste sorting and weighing in four construction projects. |

| The WGRs of different waste materials: WGRji = |

| [33] | China 2015 | Identification of mass density functions of WGRs at project level based on CW per turnover of 5764 projects. |

| The WGR per turnover: WGR = |

| [23] | Malaysia 2016 | Calculation of WGR using the number of trucks, the truck size, and the amount of waste. |

| The WGR formula: WGR(k) = ([total waste disposed(m3)] × [waste(k) composition (%)] × [waste(k) density (tm−3)])/Floor area (m2) |

| [35] | Hong Kong 2020 | Calculation of weekly WGR based on project progress. |

| The WGR formula (per week) was: ri% = wi/W × 100% |

| [21] | Vietnam 2020 | The WGR was calculated based on construction and demolition waste (CDW) layout, image analysis, and interviews to reveal CDW flows. |

| Total CDW weight: W = ∑Wi = ∑V/S × D × Ci × Bi Formula for the WGR of each CDW component: WGR = Wi/A |

| [36] | Hong Kong 2021 | The impacts of prefabrication on waste minimisation. |

| |

| [37] | Vietnam 2021 | The calculation of WGR for construction and demolition activities in residential buildings. |

small demolition sites: 353 kg/m2; large demolition sites: 204 kg/m2; small construction sites: 2.88 kg/m2; large construction sites: 62.8 kg/m2. | The estimated total concrete waste amount (kg): EW = EWC + EWD = WGRC × FAC + WGRD × FAD |

| [24] | China 2021 | Identification of WGRs. |

| The WGRs at different stages: WGRji = |

3. Methods

3.1. Literature Collection

3.2. Quantitative Data Collection

3.3. Qualitative Data Collection

4. Results and Discussion

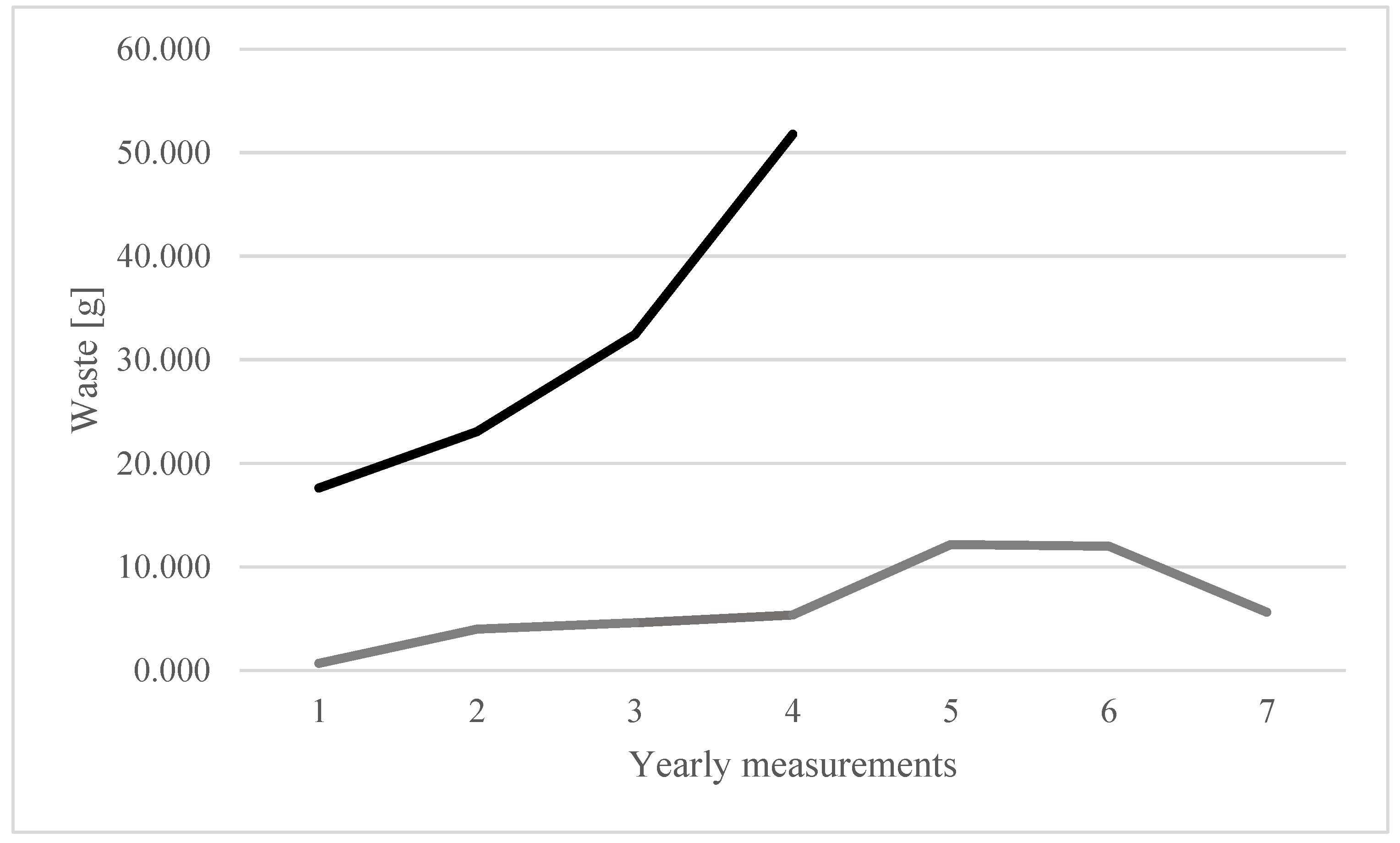

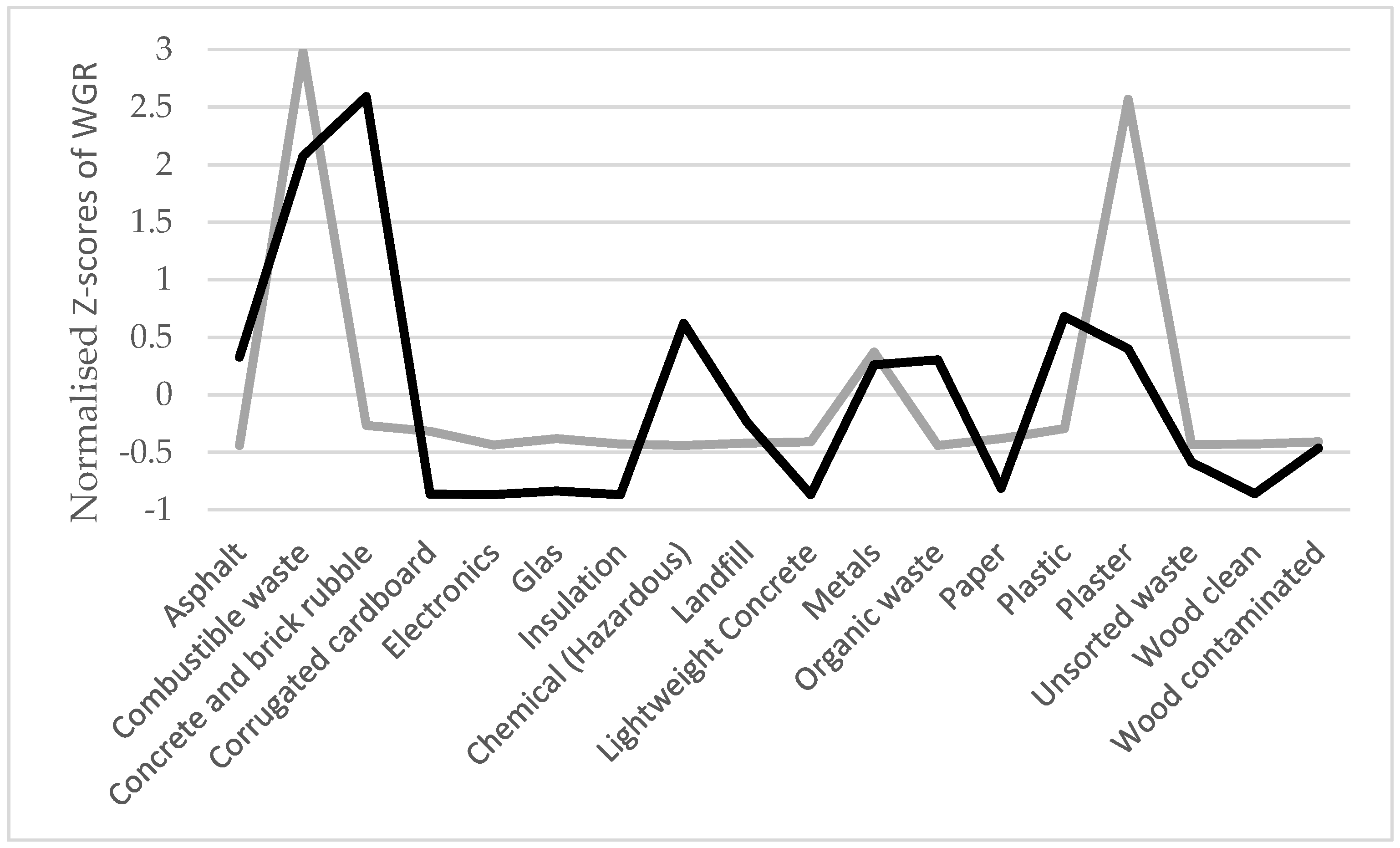

| Case I | Case II | |

|---|---|---|

| Mean WGR per fraction: | 242.76 tons | 1146.45 tons |

| Standard deviation in WGRs: | 551.85 tons | 1312.312 tons |

4.1. The Applicability of the WGR Approximations

- The quality of the 3D model for extracting the correct quantities.

- The processing or prefabrication degree of the used material. The processing degree of the delivered materials expresses the degree to which production is carried out off or on site. Moving activities away from the site of course reduces the on-site WGR, while the off-site waste generation is increased.

- The actual quantities delivered to site, i.e., the amounts ordered by the contractors, taking expected dwindling and waste into account.

- The WGR at the fraction level, which once again depends on numerous country- and project-specific static and dynamic factors. In other terms, using a mean value for the WGR oversimplifies the approximation, because it does not consider the actual variability of waste generation and the factors affecting it.

4.2. Waste Sorting

4.3. General Waste Behaviour

4.4. Organisational Factors Affecting Waste Management

5. Limitations

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hao, J.; Chen, Z.; Zhang, Z.; Loehlein, G. Quantifying Construction Waste Reduction through the Application of Prefabrication: A Case Study in Anhui, China. Environ. Sci. Pollut. Res. 2021, 28, 24499–24510. [Google Scholar] [CrossRef] [PubMed]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish Model for Quantification and Management of Construction Waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef] [PubMed]

- Kofoworola, O.F.; Gheewala, S.H. Estimation of Construction Waste Generation and Management in Thailand. Waste Manag. 2009, 29, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Bakchan, A.; Faust, K.M. Construction Waste Generation Estimates of Institutional Building Projects: Leveraging Waste Hauling Tickets. Waste Manag. 2019, 87, 301–312. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Li, H.; Wong, C.T.C. An Application of Bar-Code System for Reducing Construction Wastes. Autom. Constr. 2002, 11, 521–533. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L. Trend of the Research on Construction and Demolition Waste Management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef]

- Wang, Z.; Li, H.; Yang, X. Vision-Based Robotic System for on-Site Construction and Demolition Waste Sorting and Recycling. J. Build. Eng. 2020, 32, 101769. [Google Scholar] [CrossRef]

- Janani, R.; Kaveri, V. A Critical Literature Review on Reuse and Recycling of Construction Waste in Construction Industry. Mater. Today Proc. 2020, 37, 3077–3081. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Zeng, S.X.; Ng, W.C.Y. Towards Adoption of Prefabrication in Construction. Build. Environ. 2007, 42, 3642–3654. [Google Scholar] [CrossRef]

- Srinivas, H. Waste Management: Fact Sheet. Available online: http://www.gdrc.org/uem/waste/waste-factsheet.html (accessed on 3 January 2023).

- Lu, W.; Peng, Y.; Chen, X.; Skitmore, M.; Zhang, X. The S-Curve for Forecasting Waste Generation in Construction Projects. Waste Manag. 2016, 56, 23–34. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F.; Faust, K.M. 4D-BIM to Enhance Construction Waste Reuse and Recycle Planning: Case Studies on Concrete and Drywall Waste Streams. Waste Manag. 2020, 116, 79–90. [Google Scholar] [CrossRef]

- Guerra, B.C.; Bakchan, A.; Leite, F.; Faust, K.M. BIM-Based Automated Construction Waste Estimation Algorithms: The Case of Concrete and Drywall Waste Streams. Waste Manag. 2019, 87, 825–832. [Google Scholar] [CrossRef]

- Eurostat. Generation of Waste by Waste Category, Hazardousness and NACE Rev. 2 Activity; Eurostat: Luxembourg, 2021. [Google Scholar]

- Li, J.; Ding, Z.; Mi, X.; Wang, J. A Model for Estimating Construction Waste Generation Index for Building Project in China. Resour. Conserv. Recycl. 2013, 74, 20–26. [Google Scholar] [CrossRef]

- OECD. Environmental Performance Reviews: Denmark—Chapter 4. Waste, Materials Management and the Circular Economy; OECD: Paris, France, 2019. [Google Scholar]

- Bergsdal, H.; Bohne, R.A.; Brattebø, H. Projection of Construction and Demolition Waste in Norway. J. Ind. Ecol. 2008, 11, 27–39. [Google Scholar] [CrossRef]

- Katz, A.; Baum, H. A Novel Methodology to Estimate the Evolution of Construction Waste in Construction Sites. Waste Manag. 2011, 31, 353–358. [Google Scholar] [CrossRef]

- Nagapan, S.; Rahman, I.A.; Asmi, A.; Adnan, N.F. Study of Site’s Construction Waste in Batu Pahat, Johor. Procedia Eng. 2013, 53, 99–103. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Waste Generation, Composition, and Handling in Building-Related Construction and Demolition in Hanoi, Vietnam. Waste Manag. 2020, 117, 32–41. [Google Scholar] [CrossRef]

- Maués, L.M.F.; do Nascimento, B.D.M.O.; Lu, W.; Xue, F. Estimating Construction Waste Generation in Residential Buildings: A Fuzzy Set Theory Approach in the Brazilian Amazon. J. Clean. Prod. 2020, 265, 121779. [Google Scholar] [CrossRef]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Construction and Demolition Waste Generation Rates for High-Rise Buildings in Malaysia. Waste Manag. Res. 2016, 34, 1224–1230. [Google Scholar] [CrossRef]

- Bao, Z.; Lee, W.M.W.; Lu, W. Implementing On-Site Construction Waste Recycling in Hong Kong: Barriers and Facilitators. Sci. Total Environ. 2020, 747, 141091. [Google Scholar] [CrossRef]

- Hu, R.; Chen, K.; Chen, W.; Wang, Q.; Luo, H. Estimation of Construction Waste Generation Based on an Improved On-Site Measurement and SVM-Based Prediction Model: A Case of Commercial Buildings in China. Waste Manag. 2021, 126, 791–799. [Google Scholar] [CrossRef] [PubMed]

- Llatas, C. A Model for Quantifying Construction Waste in Projects According to the European Waste List. Waste Manag. 2011, 31, 1261–1276. [Google Scholar] [CrossRef] [PubMed]

- Ding, T.; Xiao, J. Estimation of Building-Related Construction and Demolition Waste in Shanghai. Waste Manag. 2014, 34, 2327–2334. [Google Scholar] [CrossRef] [PubMed]

- Parisi Kern, A.; Ferreira Dias, M.; Piva Kulakowski, M.; Paulo Gomes, L. Waste Generated in High-Rise Buildings Construction: A Quantification Model Based on Statistical Multiple Regression. Waste Manag. 2015, 39, 35–44. [Google Scholar] [CrossRef]

- Wu, H.; Duan, H.; Zheng, L.; Wang, J.; Niu, Y.; Zhang, G. Demolition Waste Generation and Recycling Potentials in a Rapidly Developing Flagship Megacity of South China: Prospective Scenarios and Implications. Constr. Build. Mater. 2016, 113, 1007–1016. [Google Scholar] [CrossRef]

- Yu, B.; Wang, J.; Li, J.; Zhang, J.; Lai, Y.; Xu, X. Prediction of Large-Scale Demolition Waste Generation during Urban Renewal: A Hybrid Trilogy Method. Waste Manag. 2019, 89, 1–9. [Google Scholar] [CrossRef]

- Huang, J.; Koroteev, D.D. Artificial Intelligence for Planning of Energy and Waste Management. Sustain. Energy Technol. Assess. 2021, 47, 101426. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H.; Li, J.; Hao, J.J.L.; Mi, X.; Ding, Z. An Empirical Investigation of Construction and Demolition Waste Generation Rates in Shenzhen City, South China. Waste Manag. 2011, 31, 680–687. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the Generation and Flows of Construction and Demolition Waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Lu, W.; Chen, X.; Peng, Y.; Shen, L. Benchmarking Construction Waste Management Performance Using Big Data. Resour. Conserv. Recycl. 2015, 105, 49–58. [Google Scholar] [CrossRef]

- Xu, J.; Lu, W.; Ye, M.; Webster, C.; Xue, F. An Anatomy of Waste Generation Flows in Construction Projects Using Passive Bigger Data. Waste Manag. 2020, 106, 162–172. [Google Scholar] [CrossRef]

- Lu, W.; Lee, W.M.W.; Xue, F.; Xu, J. Revisiting the Effects of Prefabrication on Construction Waste Minimization: A Quantitative Study Using Bigger Data. Resour. Conserv. Recycl. 2021, 170, 105579. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Financial and Economic Evaluation of Construction and Demolition Waste Recycling in Hanoi, Vietnam. Waste Manag. 2021, 131, 294–304. [Google Scholar] [CrossRef]

- Brinkmann, S.; Tanggaard, L. Kvalitative Metoder—En Grundbog, 3rd ed.; Hans Reitzels Forlag: Copenhagen, Denmark, 2020; ISBN 978-87-412-7726-4. [Google Scholar]

- Tanggaard, L.; Brinkmann, S. Interviewet: Samtalen Som Forskningsmetode. In Kvalitative metoder: En Grundbog; Hans Reitzels Forlag: København, Denmark, 2020; pp. 33–64. ISBN 978-87-412-7726-4. [Google Scholar]

- Gubrium, J.F.; Holstein, J.A. Narrative Practice and the Transformation of Interview Subjectivity. In The SAGE Handbook of Interview Research: The Complexity of the Craft; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2012; pp. 27–44. [Google Scholar]

- Rose, K.; Webb, C. Analyzing Data: Maintaining Rigor in a Qualitative Study. Qual. Health Res. 1998, 8, 556–562. [Google Scholar] [CrossRef]

- Hsieh, H.F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case Research in Operations Management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Wyke, S.; Lund Jensen, R.; Svidt, K. Design Rationale Documentation and Exchange in the Danish AEC Industry. In Proceedings of the 38th International Conference of CIB W78, Luxembourg, 13–15 October 2021; pp. 549–557. [Google Scholar]

- Wyke, S.; Lindhard, S.M.; Larsen, J.K. Using Principal Component Analysis to Identify Latent Factors Affecting Cost and Time Overrun in Public Construction Projects. Eng. Constr. Archit. Manag. 2023. ahead-of-print. [Google Scholar] [CrossRef]

| Case I | Case II | |

|---|---|---|

| Project type: | New build | Reconstruction and new build |

| Construction period: | 2013–2023 | 2010–2019 |

| Contract type: | Prime contracts | Prime contracts |

| Contract sum: | USD 832 M | USD 1238 B |

| Waste disposal centre: | 2015–2021 | 2013–2016 |

| Invoices (waste removal): | 1895 | 16,656 |

| Total tones waste handled: | 4370 | 20,636 |

| Study | Waste Generation Rate | Case I (Generated: 4370 tons) | Case II (Generated: 20,636 tons) |

|---|---|---|---|

| 3 | WGR = 21.38 kg/m2 | CW = 170,000 m2 × 21.38 kg/ m2 = 3634 tons | CW = 440,000 m2 × 21.38 kg/m2 = 9407 tons |

| 25 | WGR = 0.1388 m3/m2 | CW = 170,000 m2 × 0.1388 m3/m2= 23.6 m3 | CW = 440,000 m2 × 0.1388 m3/m2= 61.1 m3 |

| 17 | WGR = 40.7 kg/m2 | CW = 170,000 m2 × 40.7 kg/m2 = 6919 tons | CW = 440,000 m2 × 40.7 kg/m2 = 17,908 tons |

| 4 | WGR = 69.31 kg/m2 | CW = 170,000 m2 × 69.31 kg/m2 = 11,783 tons | CW = 440,000 m2 × 69.31 kg/m2 = 30,496 tons |

| 12 | WGRconcrete = 18.1 to 29.2 kg/m2 | CWconcrete = 170,000 m2 × 18.1 to 29.2 kg/m2 = [3077, 4964] tons; Actual = 95 tons | CWconcrete = 440,000 m2 × 18.1 to 29.2 kg/m2 = [7964, 12848] tons; Actual = 4546 tons |

| 34 | WGR = 3.275 to 8.791 kg/m2 | CW = 170,000 m2 × 3.275 to 8.791 kg/m2 = [557, 1494] tons | CW = 440,000 m2 × 3.275 to 8.791 kg/m2 = [1441, 1494] tons |

| 33 | WGR = 15,000 kg/ mHK$ | CW = 832 million USD × 15,000/(7.84) kg/million USD = 1592 tons | CW = 1238 million USD × 15,000/(7.84) kg/million USD = 2369 tons |

| 23 | WGR = 98,8 kg/m2 | CW = 170,000 m2 × 98.8 kg/m2 = 16,796 tons | CW = 440,000 m2 × 98.8 kg/m2 = 43,472 tons |

| 21 | WGRconstruction = 1030 kg/m2 WGRdemolition = 318 kg/m2 | CW = 170,000 m2 × 1030 kg/m2 = 175,100 tons | CW = 440,000 m2 × 1030 kg/m2 + 30,000 m2 × 318 kg/m2 = 462,740 tons |

| 37 | WGRconstruction = 62.8 kg/m2 WGRdemolition = 204 kg/m2 | CW = 170,000 m2 × 62.8 kg/m2 = 10,676 tons | CW = 440,000 m2 × 62.8 kg/m2 + 30,000 m2 × 204 kg/m2 = 33,752 tons |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindhard, S.M.; Wyke, S.; Mahami, H.; Vaezzadeh, S.S.; Svidt, K. Waste Generation Predictions and On-Site Waste Management: A Danish Perspective. Sustainability 2023, 15, 4207. https://doi.org/10.3390/su15054207

Lindhard SM, Wyke S, Mahami H, Vaezzadeh SS, Svidt K. Waste Generation Predictions and On-Site Waste Management: A Danish Perspective. Sustainability. 2023; 15(5):4207. https://doi.org/10.3390/su15054207

Chicago/Turabian StyleLindhard, Søren Munch, Simon Wyke, Hadi Mahami, Seyyed Saeed Vaezzadeh, and Kjeld Svidt. 2023. "Waste Generation Predictions and On-Site Waste Management: A Danish Perspective" Sustainability 15, no. 5: 4207. https://doi.org/10.3390/su15054207

APA StyleLindhard, S. M., Wyke, S., Mahami, H., Vaezzadeh, S. S., & Svidt, K. (2023). Waste Generation Predictions and On-Site Waste Management: A Danish Perspective. Sustainability, 15(5), 4207. https://doi.org/10.3390/su15054207