Vertical-Longitudinal Coupling Effect Investigation and System Optimization for a Suspension-In-Wheel-Motor System in Electric Vehicle Applications

Abstract

1. Introduction

- A UEMF model is established and used as an internal excitation of the suspension-in-wheel-motor system (SIWMS). The electro-mechanical mechanism of UEMF and its effect on vehicle vertical–longitudinal dynamics are comprehensively studied under various road conditions.

- A RTRF model that can capture the transient tire–road contact patch and tire belt deformation is proposed to accurately describe the vertical–longitudinal coupling effect of the road–tire–motor system. The RTRF model is then incorporated into the SIWMS model for better modelling accuracy.

- A comprehensive evaluation system is proposed to describe the vertical–longitudinal dynamics of IWMD EVs. The ride comfort and handling performance are improved by optimizing the key parameters of the SIWMS.

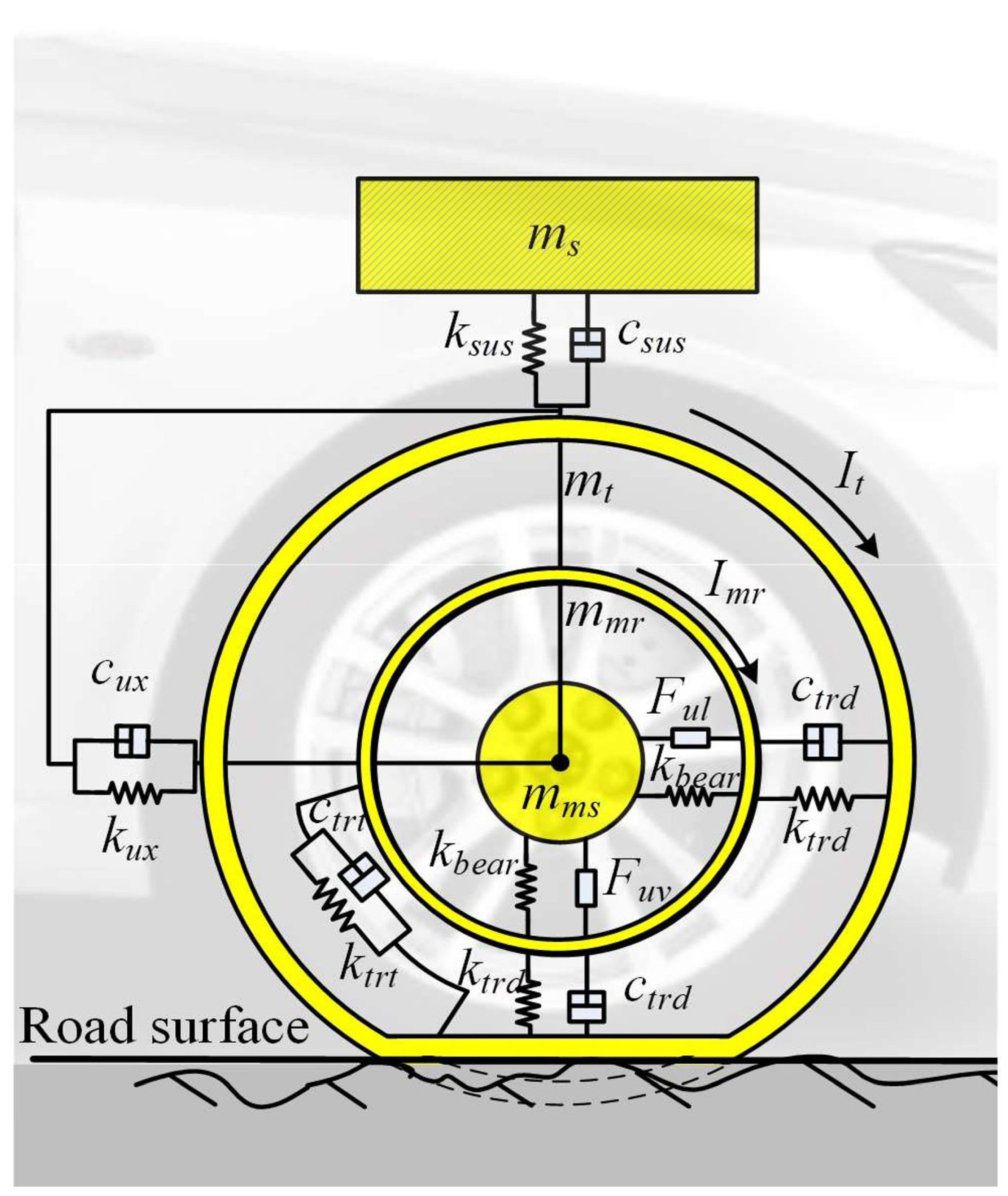

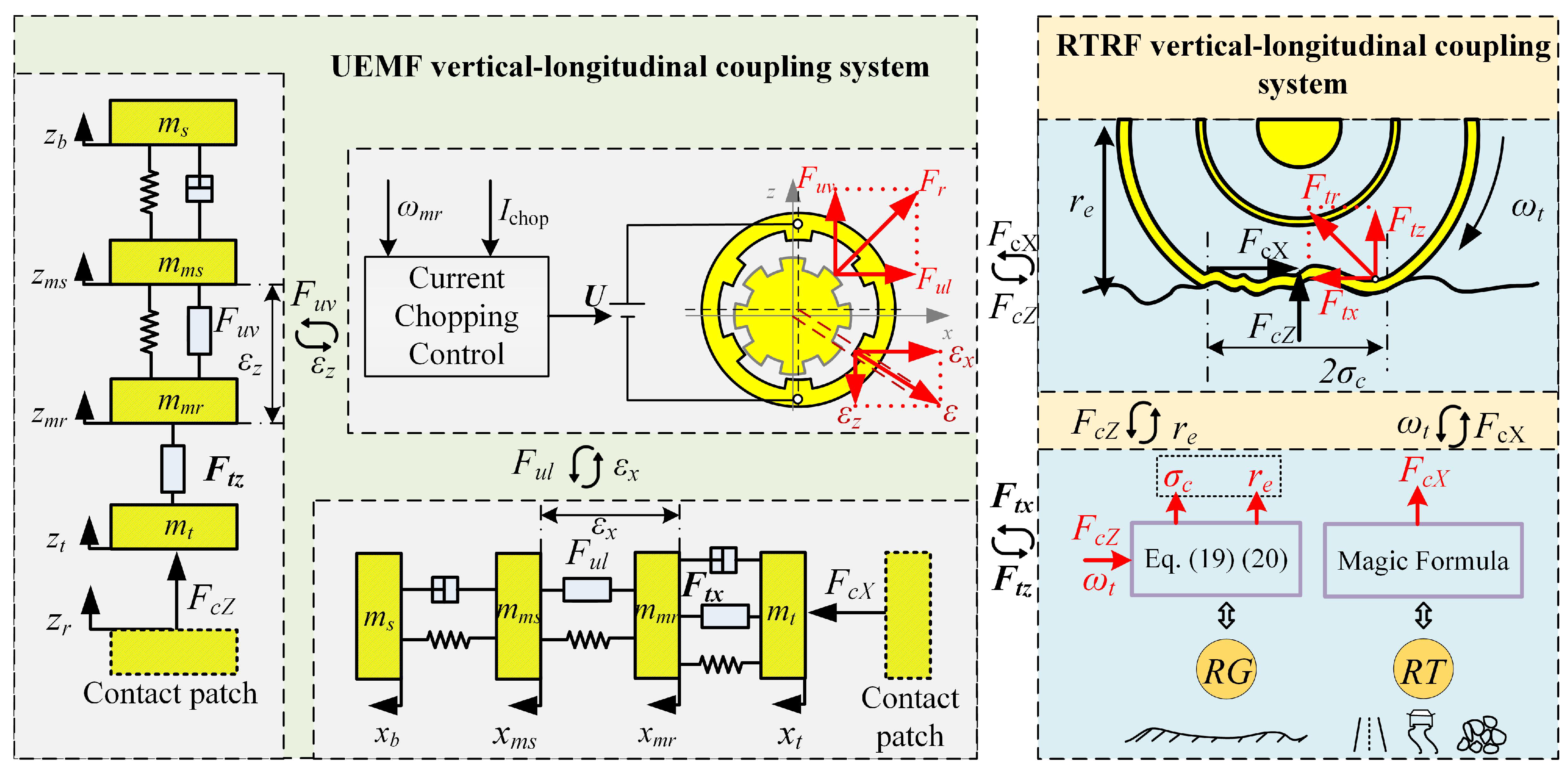

2. The Quarter-SIWMS Model

2.1. The Excitation Source Model

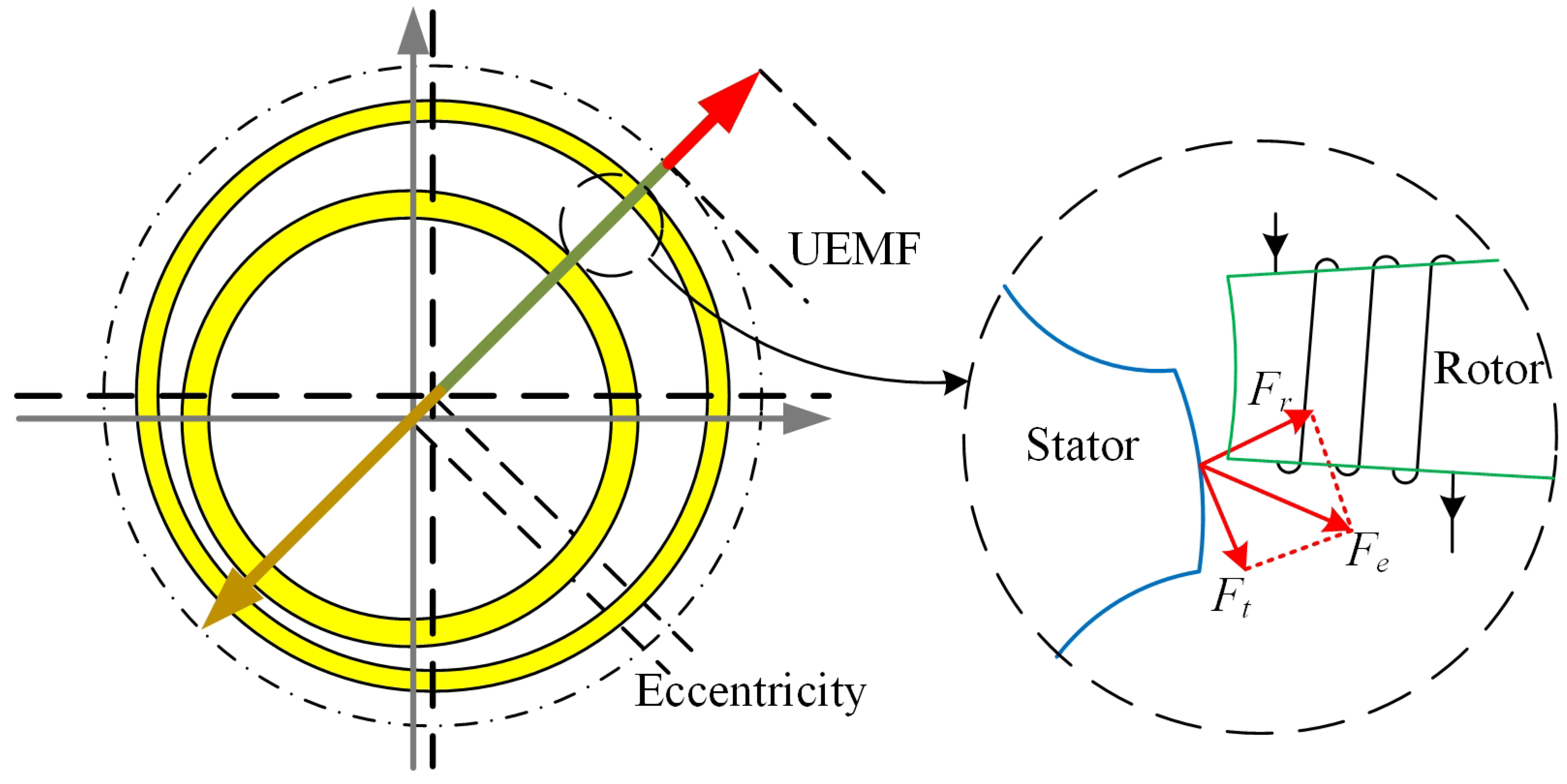

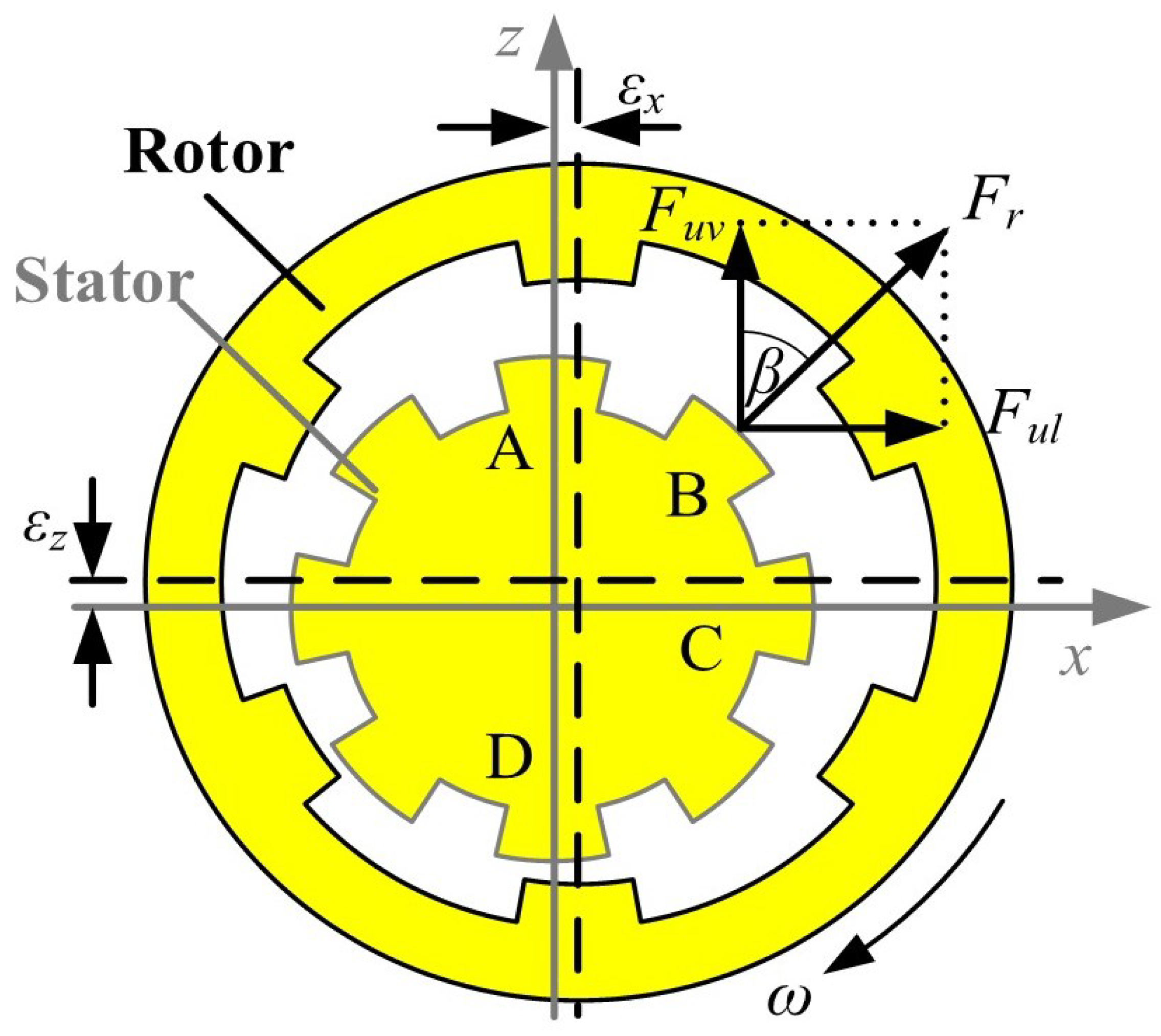

2.1.1. The UEMF Model

2.1.2. Road Inputs Model

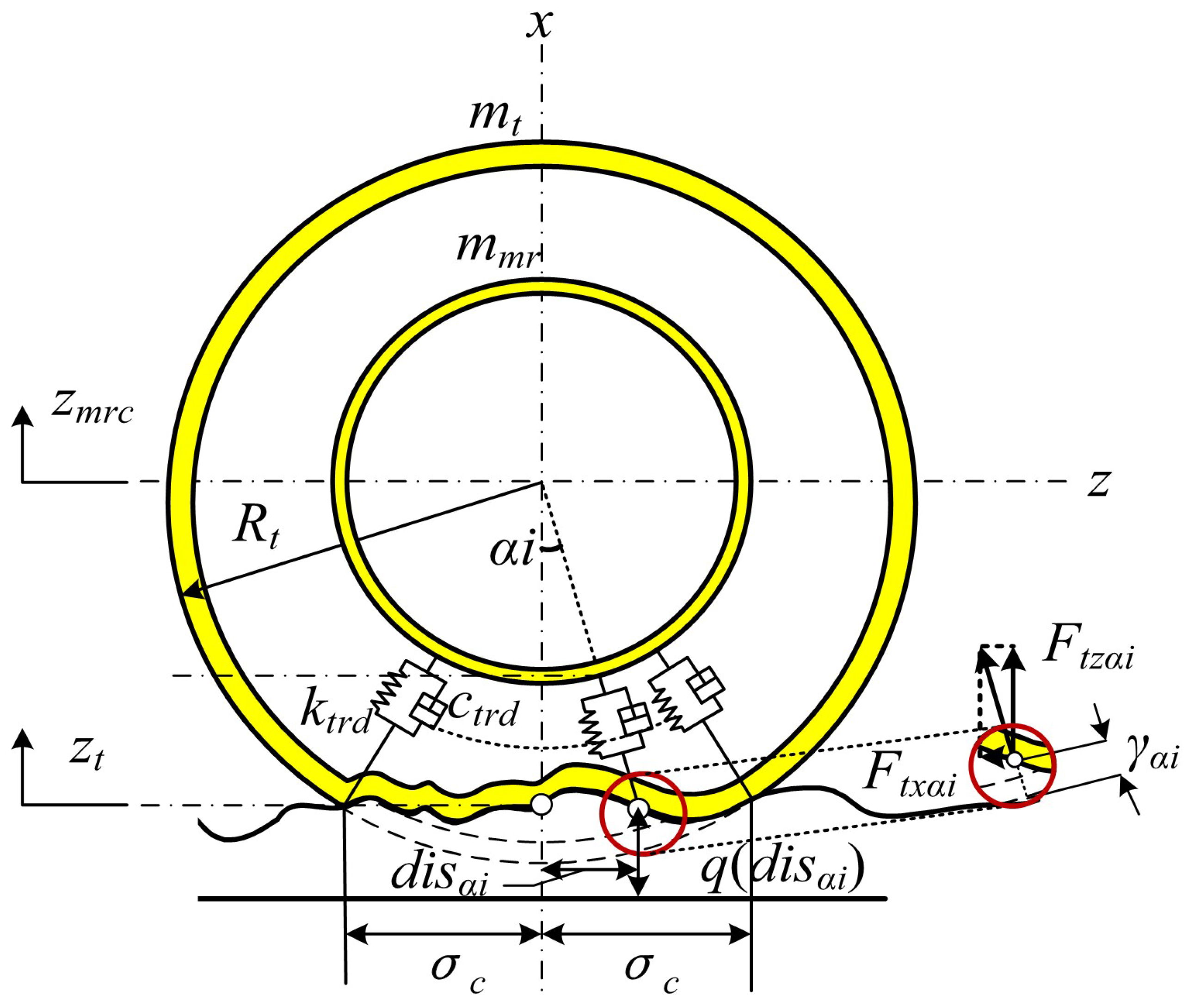

2.2. RTRF Model

2.2.1. Road–Tire Force

2.2.2. Tire–Rotor Force

2.3. NTDC Model

3. Simulation and Verification of the Quarter-SIWMS Model

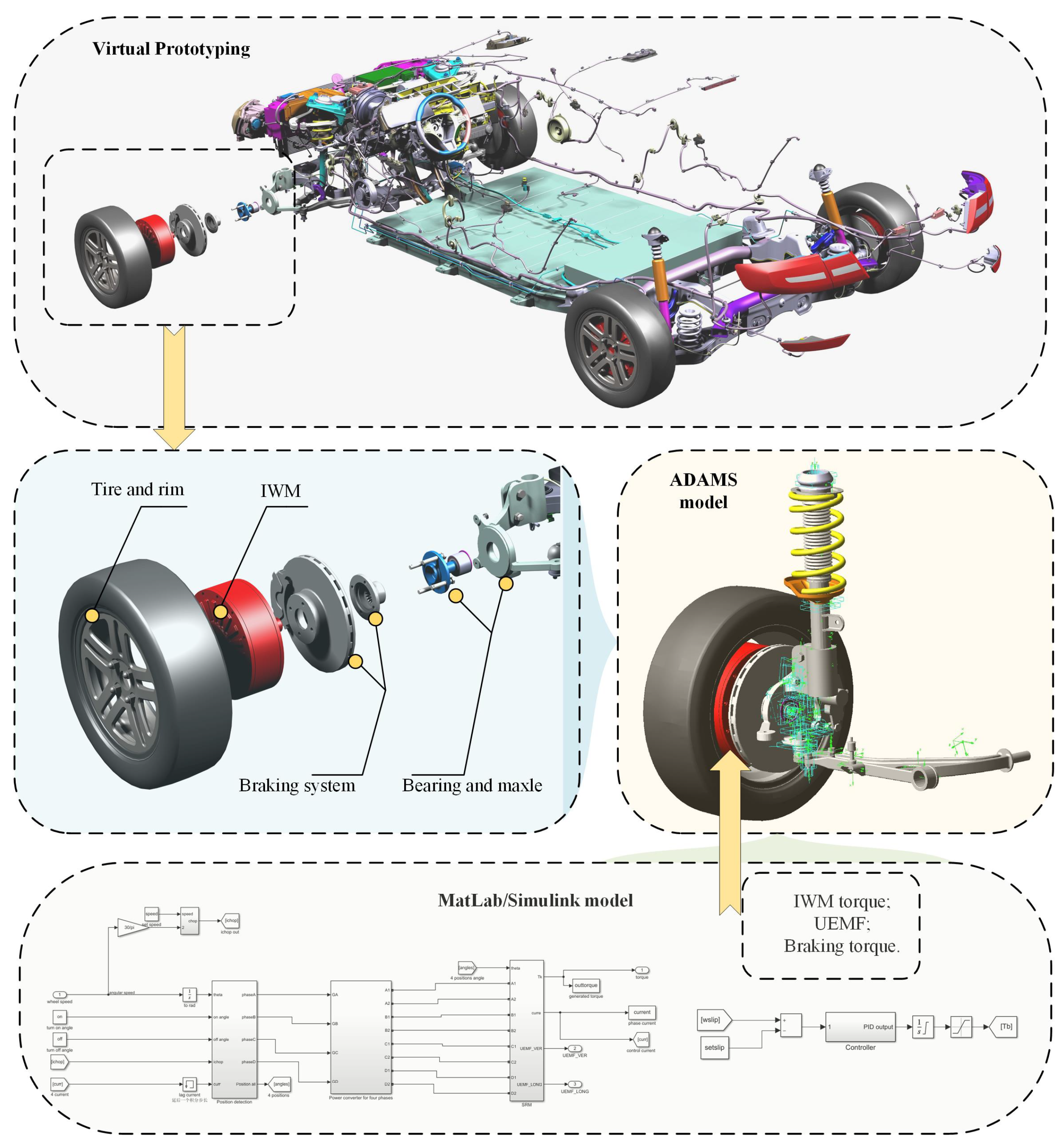

3.1. SIWMS Simulation Model

3.2. Brake Control System

3.3. Vertical–Longitudinal Dynamics Evaluation Indexes

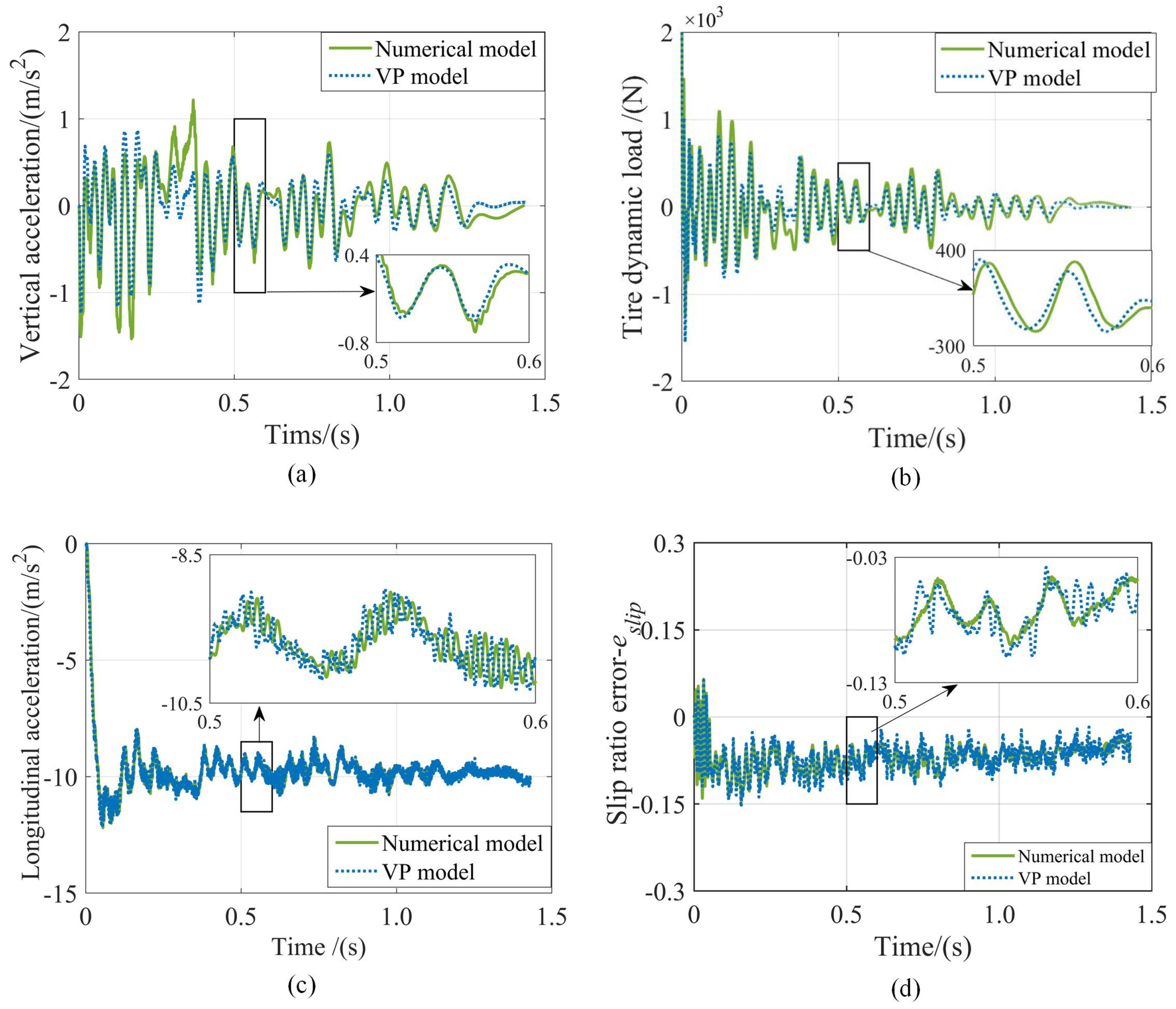

3.4. Virtual Prototype Validation for the SIWMS

4. UEMF Effects and SIWMS Optimization

4.1. Analysis of UEMF Effects

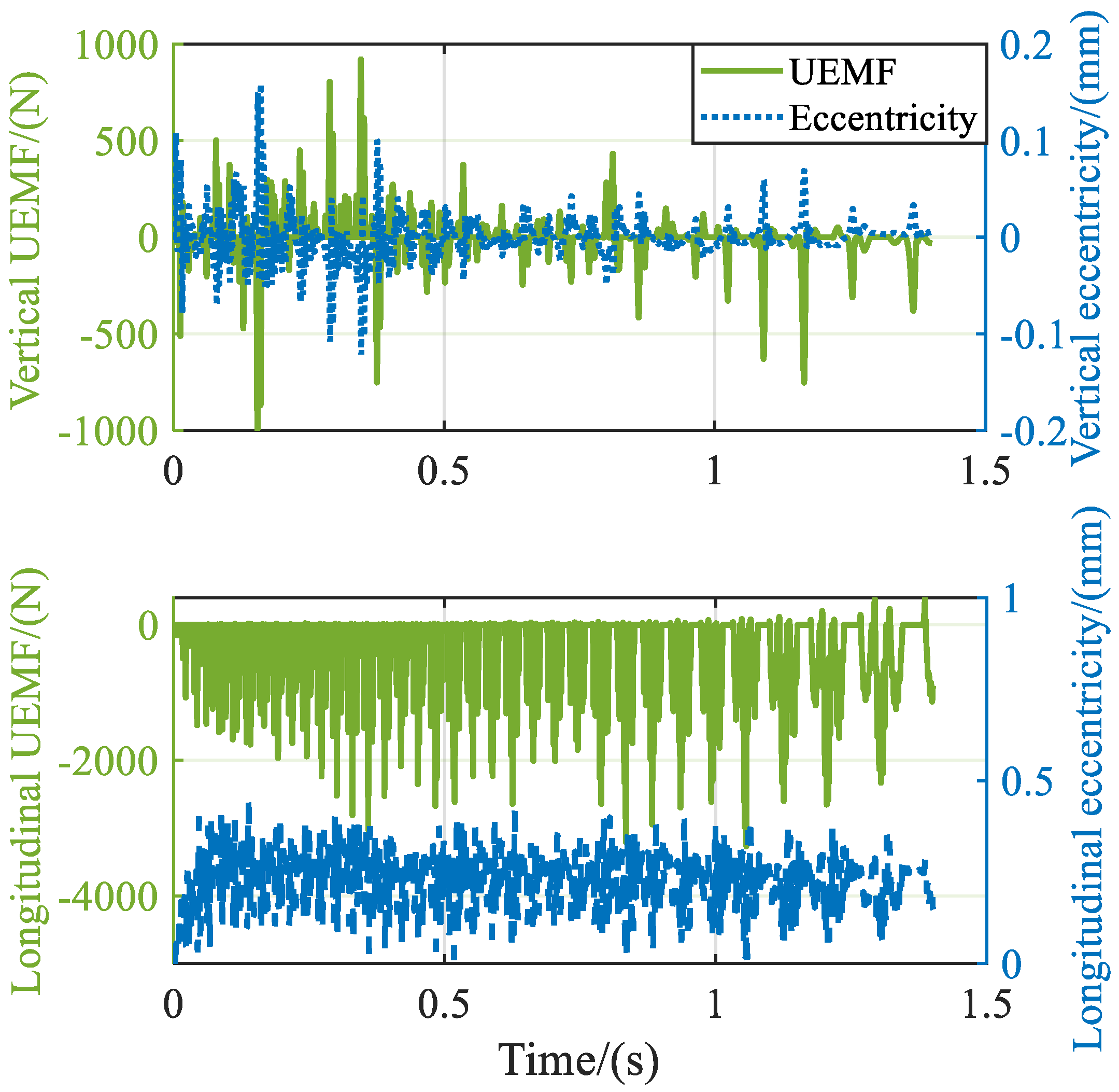

4.1.1. Relationship between UEMF and Eccentricity

4.1.2. UEMF Effects

4.2. Sensitivity Analysis and Optimization

4.2.1. Sensitivity Analysis

4.2.2. Multi-Objective Optimization of Key Parameters

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Z.; Taghavifar, H.; Du, H.; Qin, Y.; Dong, M.; Gu, L. In-wheel motor vibration control for distributed-driven electric vehicles: A review. IEEE Trans. Transp. Electrif. 2021, 7, 2864–2880. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Z.; Wang, Z.; Deng, J.; Dorrell, D. Chassis coordinated control for full X-by-wire vehicles—A review. Chin. J. Mech. Eng. 2021, 34, 1–25. [Google Scholar] [CrossRef]

- He, S.; Fan, X.; Wang, Q.; Chen, X.; Zhu, S. Review on Torque Distribution Scheme of Four-Wheel In-Wheel Motor Electric Vehicle. Machines 2022, 10, 619. [Google Scholar] [CrossRef]

- Bilgin, B.; Liang, J.; Terzic, M.V.; Dong, J.; Rodriguez, R.; Trickett, E.; Emadi, A. Modeling and analysis of electric motors: State-of-the-art review. IEEE Trans. Transp. Electrif. 2019, 5, 602–617. [Google Scholar] [CrossRef]

- Wu, J.; Wang, Z.; Zhang, L. Unbiased-estimation-based and computation-efficient adaptive MPC for four-wheel-independently-actuated electric vehicles. Mech. Mach. Theory 2020, 154, 104100. [Google Scholar] [CrossRef]

- Dukalski, P.; Będkowski, B.; Parczewski, K.; Wnęk, H.; Urbaś, A.; Augustynek, K. Dynamics of the vehicle rear suspension system with electric motors mounted in wheels. Eksploat. i Niezawodn. 2019, 21, 125–136. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, X.; Zhao, F.; Gerada, D.; Li, L. Improvements on Permanent Magnet Synchronous Motor by Integrating Heat Pipes Into Windings for Solar Unmanned Aerial Vehicle. Green Energy Intell. Transp. 2022, 1, 100011. [Google Scholar] [CrossRef]

- Islam, R.; Husain, I. Analytical model for predicting noise and vibration in permanent-magnet synchronous motors. IEEE Trans. Ind. Appl. 2010, 46, 2346–2354. [Google Scholar] [CrossRef]

- Smith, A.; Dorrell, D. Calculation and measurement of unbalanced magnetic pull in cage induction motors with eccentric rotors. Part 1: Analytical model. IEE Proc.-Electr. Power Appl. 1996, 143, 193–201. [Google Scholar] [CrossRef]

- Dukalski, P.; Będkowski, B.; Parczewski, K.; Wnęk, H.; Urbaś, A.; Augustynek, K. Analysis of the influence of motors installed in passenger car wheels on the torsion beam of the rear axle suspension. Energies 2022, 15, 222. [Google Scholar] [CrossRef]

- Carmeli, M.S.; Dezza, F.C.; Mauri, M. Electromagnetic vibration and noise analysis of an external rotor permanent magnet motor. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Taormina, Italy, 23–26 May 2006; pp. 1028–1033. [Google Scholar]

- Wang, Y.y.; Yang, F.n. SRM representative parameters effect on in-wheel motored vehicle performance. In Proceedings of the 2017 2nd IEEE International Conference on Intelligent Transportation Engineering (ICITE), Singapore, 1–3 September 2017; pp. 36–41. [Google Scholar]

- Li, J.; Cho, Y. Dynamic reduction of unbalanced magnetic force and vibration in switched reluctance motor by the parallel paths in windings. Math. Comput. Simul. 2010, 81, 407–419. [Google Scholar] [CrossRef]

- Qin, Y.; He, C.; Shao, X.; Du, H.; Xiang, C.; Dong, M. Vibration mitigation for in-wheel switched reluctance motor driven electric vehicle with dynamic vibration absorbing structures. J. Sound Vib. 2018, 419, 249–267. [Google Scholar] [CrossRef]

- Xu, B.; Xiang, C.; Qin, Y.; Ding, P.; Dong, M. Semi-active vibration control for in-wheel switched reluctance motor driven electric vehicle with dynamic vibration absorbing structures: Concept and validation. IEEE Access 2018, 6, 60274–60285. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Z.; Yuan, K.; Zhang, Y. Comprehensive analysis and optimization of dynamic vibration-absorbing structures for electric vehicles driven by in-wheel motors. Automot. Innov. 2019, 2, 254–262. [Google Scholar] [CrossRef]

- Shieh, M.Y.; Chiou, J.S.; Liu, M.T. Design of immune-algorithm-based adaptive fuzzy controllers for active suspension systems. Adv. Mech. Eng. 2014, 6, 916257. [Google Scholar] [CrossRef]

- Sunwoo, M.; Cheok, K.C.; Huang, N. Model reference adaptive control for vehicle active suspension systems. IEEE Trans. Ind. Electron. 1991, 38, 217–222. [Google Scholar] [CrossRef]

- Chen, S.A.; Wang, J.C.; Yao, M.; Kim, Y.B. Improved optimal sliding mode control for a non-linear vehicle active suspension system. J. Sound Vib. 2017, 395, 1–25. [Google Scholar] [CrossRef]

- Badri, P.; Amini, A.; Sojoodi, M. Robust fixed-order dynamic output feedback controller design for nonlinear uncertain suspension system. Mech. Syst. Signal Process. 2016, 80, 137–151. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Z.; Zhang, L.; Dorrell, D.G. Braking/steering coordination control for in-wheel motor drive electric vehicles based on nonlinear model predictive control. Mech. Mach. Theory 2019, 142, 103586. [Google Scholar] [CrossRef]

- Mao, Y.; Zuo, S.; Wu, X.; Duan, X. High frequency vibration characteristics of electric wheel system under in-wheel motor torque ripple. J. Sound Vib. 2017, 400, 442–456. [Google Scholar] [CrossRef]

- Li, T.; Zhang, S.; Xiao, G.; Wang, M.; Zhong, H.; Feng, J. Brake Instability Dynamic Model and Active Control Strategy for a Multiunit Articulated Rubber-Wheel Autonomous Rail Rapid Transit System. Sustainability 2022, 14, 14531. [Google Scholar] [CrossRef]

- Kambe, H.; Koumura, S. Reduction of longitudinal vibration by side-view arrangement of suspension. Veh. Syst. Dyn. 2008, 46, 161–173. [Google Scholar] [CrossRef]

- Zuo, S.; Duan, X.; Wu, X. Modeling and analysis of rigid ring coupling model of electric wheel. Nat. Sci. 2014, 42, 1578–1585. [Google Scholar]

- Wang, Z.; Wang, Y.; Zhang, L.; Liu, M. Vehicle stability enhancement through hierarchical control for a four-wheel-independently-actuated electric vehicle. Energies 2017, 10, 947. [Google Scholar] [CrossRef]

- Zhao, W.; Qin, X. Study on mixed H2/H∞ robust control strategy of four wheel steering system. Sci. China Technol. Sci. 2017, 60, 1831–1840. [Google Scholar] [CrossRef]

- Wu, J.; Cheng, S.; Liu, B.; Liu, C. A human-machine-cooperative-driving controller based on AFS and DYC for vehicle dynamic stability. Energies 2017, 10, 1737. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Hu, M.; Yang, Z.; Fu, C. Longitudinal–vertical comprehensive control for four-wheel drive pure electric vehicle considering energy recovery and ride comfort. Energy 2021, 236, 121417. [Google Scholar] [CrossRef]

- Song, L.; Li, J.; Wei, Z.; Yang, K.; Hashemi, E.; Wang, H. Longitudinal and Lateral Control Methods from Single Vehicle to Autonomous Platoon. Green Energy Intell. Transp. 2023, 100066. [Google Scholar] [CrossRef]

- Qin, Y.; Zhao, Z.; Wang, Z.; Li, G. Study of longitudinal–vertical dynamics for in-wheel motor-driven electric vehicles. Automot. Innov. 2021, 4, 227–237. [Google Scholar] [CrossRef]

- Xing, C.; Zhu, Y.; Wu, H. Electromechanical Coupling Braking Control Strategy Considering Vertical Vibration Suppression for Vehicles Driven by In-Wheel Motors. IEEE/ASME Trans. Mechatron. 2022, 27, 5701–5711. [Google Scholar] [CrossRef]

- Ricciardi, V.; Ivanov, V.; Dhaens, M.; Vandersmissen, B.; Geraerts, M.; Savitski, D.; Augsburg, K. Ride blending control for electric vehicles. World Electr. Veh. J. 2019, 10, 36. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, L.; Gao, W.; Zhan, Z. Electromechanical coupling mechanism and control strategy for in-wheel-motor-driven electric vehicles. IEEE Trans. Ind. Electron. 2018, 66, 4524–4533. [Google Scholar] [CrossRef]

- Deur, J.; Asgari, J.; Hrovat, D. A 3D brush-type dynamic tire friction model. Veh. Syst. Dyn. 2004, 42, 133–173. [Google Scholar] [CrossRef]

- Besselink, I.; Schmeitz, A.; Pacejka, H. An improved Magic Formula/Swift tyre model that can handle inflation pressure changes. Veh. Syst. Dyn. 2010, 48, 337–352. [Google Scholar] [CrossRef]

- Zegelaar, P.; Pacejka, H. Dynamic tyre responses to brake torque variations. Veh. Syst. Dyn. 1997, 27, 65–79. [Google Scholar] [CrossRef]

- Gipser, M. FTire: A physically based application-oriented tyre model for use with detailed MBS and finite-element suspension models. Veh. Syst. Dyn. 2005, 43, 76–91. [Google Scholar] [CrossRef]

- Xue, X.; Cheng, K.W.E.; Lin, J.; Zhang, Z.; Luk, K.; Ng, T.W.; Cheung, N.C. Optimal control method of motoring operation for SRM drives in electric vehicles. IEEE Trans. Veh. Technol. 2010, 59, 1191–1204. [Google Scholar] [CrossRef]

- Anwar, M.; Husain, I. Radial force calculation and acoustic noise prediction in switched reluctance machines. IEEE Trans. Ind. Appl. 2000, 36, 1589–1597. [Google Scholar] [CrossRef]

- Jokinen, T.; Hrabovcova, V.; Pyrhonen, J. Design of Rotating Electrical Machines; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Zhu, W.; Pekarek, S.; Fahimi, B.; Deken, B.J. Investigation of force generation in a permanent magnet synchronous machine. IEEE Trans. Energy Convers. 2007, 22, 557–565. [Google Scholar] [CrossRef]

- Ito, T.; Akatsu, K. Electromagnetic force acquisition distributed in electric motor to reduce vibration. IEEE Trans. Ind. Appl. 2016, 53, 1001–1008. [Google Scholar] [CrossRef]

- Krishnan, R. Switched Reluctance Motor Drives: Modeling, Simulation, Analysis, Design, and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Ebrahimi, B.M.; Faiz, J.; Roshtkhari, M.J. Static-, dynamic-, and mixed-eccentricity fault diagnoses in permanent-magnet synchronous motors. IEEE Trans. Ind. Electron. 2009, 56, 4727–4739. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Z.; Xiang, C.; Hashemi, E.; Khajepour, A.; Huang, Y. Speed independent road classification strategy based on vehicle response: Theory and experimental validation. Mech. Syst. Signal Process. 2019, 117, 653–666. [Google Scholar] [CrossRef]

- Qin, Y.; Wei, C.; Tang, X.; Zhang, N.; Dong, M.; Hu, C. A novel nonlinear road profile classification approach for controllable suspension system: Simulation and experimental validation. Mech. Syst. Signal Process. 2019, 125, 79–98. [Google Scholar] [CrossRef]

- Rajamani, R. Vehicle Dynamics and Control; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Soares, C.M.; Martins, J.; Rodrigues, H.; Ambrosio, J.A.; Pina, C.; Soares, C.M.; Pereira, E.; Folgado, J. III European Conference on Computational Mechanics: Solids, Structures and Coupled Problems in Engineering: Book of Abstracts; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Canudas-de Wit, C.; Tsiotras, P.; Velenis, E.; Basset, M.; Gissinger, G. Dynamic friction models for road/tire longitudinal interaction. Veh. Syst. Dyn. 2003, 39, 189–226. [Google Scholar] [CrossRef]

- Ding, X.; Wang, Z.; Zhang, L.; Liu, J. A Comprehensive vehicle stability assessment system based on enabling tire force estimation. IEEE Trans. Veh. Technol. 2022, 71, 11571–11588. [Google Scholar] [CrossRef]

- Kindt, P.; Sas, P.; Desmet, W. Measurement and analysis of rolling tire vibrations. Opt. Lasers Eng. 2009, 47, 443–453. [Google Scholar] [CrossRef]

- Wang, H.; Al-Qadi, I.L.; Stanciulescu, I. Simulation of tyre–pavement interaction for predicting contact stresses at static and various rolling conditions. Int. J. Pavement Eng. 2012, 13, 310–321. [Google Scholar] [CrossRef]

- Mousseau, C.; Laursen, T.; Lidberg, M.; Taylor, R. Vehicle dynamics simulations with coupled multibody and finite element models. Finite Elem. Anal. Des. 1999, 31, 295–315. [Google Scholar] [CrossRef]

- Maurice, J.; Berzeri, M.; Pacejka, H. Pragmatic tyre model for short wavelength side slip variations. Veh. Syst. Dyn. 1999, 31, 65–94. [Google Scholar] [CrossRef]

- Ozerem, O.; Morrey, D. A brush-based thermo-physical tyre model and its effectiveness in handling simulation of a Formula SAE vehicle. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2019, 233, 107–120. [Google Scholar] [CrossRef]

- Guo, Z.; Wu, W.; Yuan, S. Longitudinal-vertical dynamics of wheeled vehicle under off-road conditions. Veh. Syst. Dyn. 2022, 60, 470–490. [Google Scholar] [CrossRef]

- Tuononen, A.; Hartikainen, L.; Petry, F.; Westermann, S. Parameterization of in-plane rigid ring tire model from instrumented vehicle measurements. In Proceedings of the 11th International Symposium on Advanced Vehicle Control (AVEC’12), Seoul, Republic of Korea, 9–12 September 2012; pp. 9–12. [Google Scholar]

- Albers, A.; Zingel, C.; Zehetner, J.; Meitz, K. Influence of Low-Frequency Powertrain-Vibrations on Driveability-Assessments; Technical Report, SAE Technical Paper; SAE: Warrendale, PA, USA, 2010. [Google Scholar]

- Guiggiani, M. The Science of Vehicle Dynamics; Springer: Pisa, Italy; Cham, The Netherlands, 2014; p. 15. [Google Scholar]

- Song, Z.; Li, J.; Wei, Y.; Xu, L.; Ouyang, M. Interaction of in-wheel permanent magnet synchronous motor with tire dynamics. Chin. J. Mech. Eng. 2015, 28, 470–478. [Google Scholar] [CrossRef]

- Jiang, R.; Wang, D. Optimization of Vehicle Ride Comfort and Handling Stability Based on TOPSIS Method; Technical report; SAE Technical Paper; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

| Road Type | * | |||

|---|---|---|---|---|

| Dry asphalt | 1.28 | 23.99 | 0.52 | 0.17 |

| Dry cement | 1.20 | 25.17 | 0.54 | 0.16 |

| Wet asphalt | 0.86 | 33.82 | 0.35 | 0.13 |

| Cobblestone | 0.40 | 33.71 | 0.12 | 0.14 |

| Snow | 1.20 | 94.13 | 0.06 | 0.06 |

| Ice | 0.05 | 306.39 | 0 | 0.03 |

| Parameters | Value | Parameters | Value | Parameters | Value |

|---|---|---|---|---|---|

| Effective rolling radius | Vertical sidewall stiffness | IWM and vehicle parameters | |||

| 0.3160 m | 8.5352 × 10 m s2 | 1800.39 N·s/m | |||

| 0.3164 m | 8.81 × 104 s | 2.5 × 104 N/m | |||

| −9.3972 × 10 m | 1.4389 × 105 N/m | 3.2 × 104 N/m | |||

| −9.3972 × 10 m | 4.5090 × 106 N/m2 | 1.8 × 103 N·s/m | |||

| −3.0346 × 10 m | 2.08 × 107 N/m | ||||

| Contact patch | Tire parameters | 5.3 × 10 N/m | |||

| 1.478 × 10 m | 0.546 kg·m2 | 9.5 kg | |||

| −5.6829 × 10 m/N | 0.417 kg·m2 | 22.5 kg | |||

| 0.015 N·s/m | 6.15 kg | 332 kg | |||

| Magic Formula | 510 N·s/m | ||||

| B | 20.2937 | 1.8 × 106 N/m | |||

| C | 1.9655 | 5.1 × 104 N/m | |||

| E | 0.8613 | 20 × N·s/m | |||

| Response Variables | Numerical Model | VP Model | Error |

|---|---|---|---|

| RVA/(m/s2) | 0.4353 | 0.4157 | 4.71% |

| RTDL/(N) | 296.5 | 282.6 | 4.92% |

| LAFR/(m/s2) | 10.77 | 11.03 | 2.36% |

| SNR/(%) | 31.17 | 32.55 | 4.24% |

| With UEFM | Without UEMF | Percentage of Degradation | With UEFM | Without UEMF | Percentage of Degradation | ||

|---|---|---|---|---|---|---|---|

| ISO-A and Dry asphalt | ISO-B and Dry asphalt | ||||||

| RVA (m/s2) | 0.4353 | 0.4325 | 0.65 | RVA (m/s2) | 0.9081 | 0.8935 | 1.63 |

| RTDL (N) | 296.5 | 295.3 | 0.41 | RTDL (N) | 631.2 | 622.2 | 1.45 |

| LAFR (%) | 10.77 | 10.66 | 1.03 | LAFR (%) | 12.82 | 12.27 | 4.48 |

| SNR (%) | 31.17 | 30.67 | 1.63 | SNR (%) | 36.58 | 34.61 | 5.69 |

| ISO-A and Cobblestone | ISO-B and Cobblestone | ||||||

| RVA (m/s2) | 0.4764 | 0.4734 | 0.63 | RVA (m/s2) | 0.9413 | 0.931 | 1.11 |

| RTDL (N) | 321.8 | 320.5 | 0.41 | RTDL (N) | 700.3 | 687.3 | 1.89 |

| LAFR (%) | 6.937 | 6.796 | 2.07 | LAFR (%) | 10.26 | 9.72 | 5.56 |

| SNR (%) | 31.49 | 30.76 | 2.37 | SNR (%) | 37.22 | 34.79 | 6.98 |

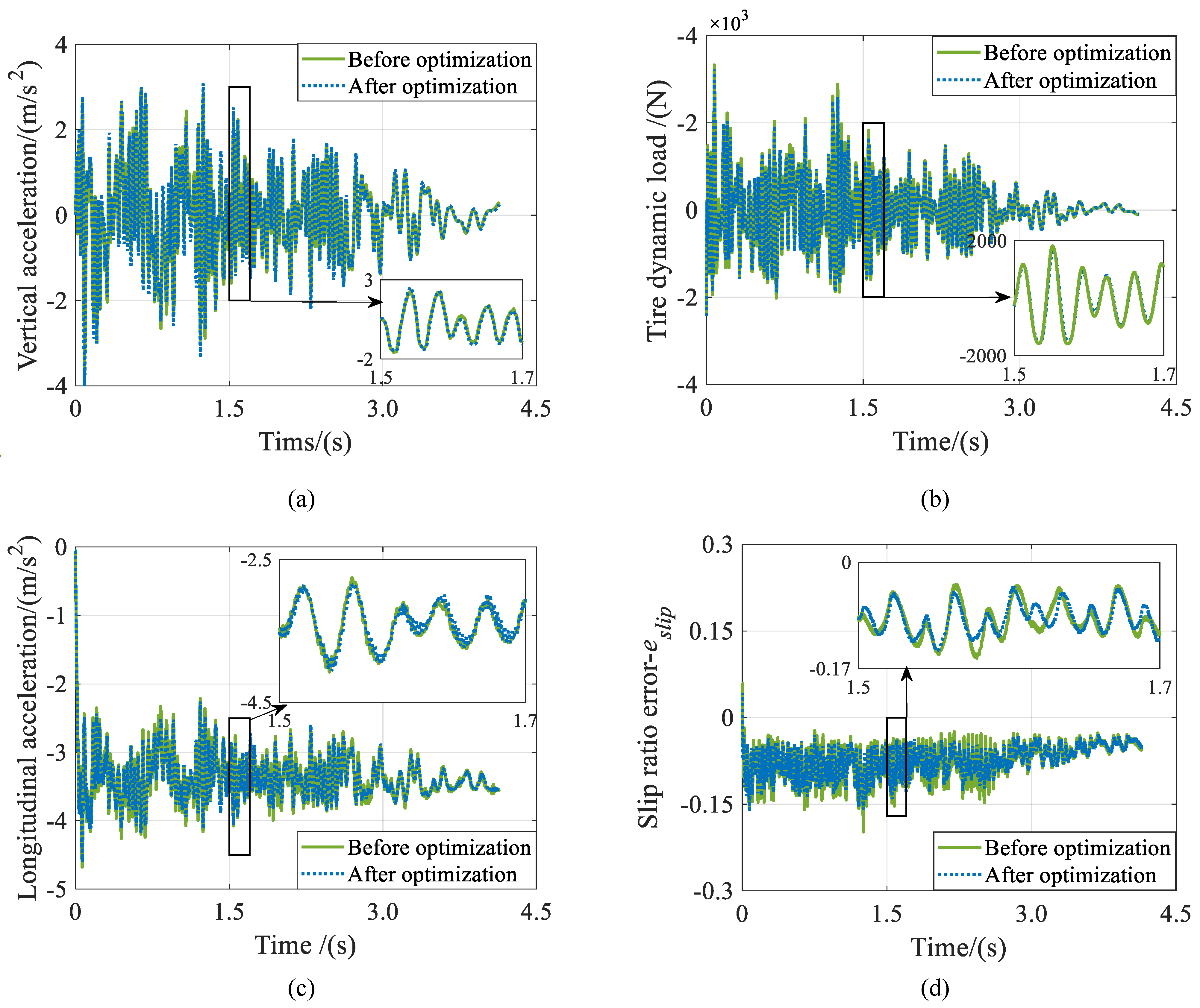

| RVA (m/s2) | RTDL (N) | LAFR (%) | SNR (%) | |

|---|---|---|---|---|

| Before optimization | 0.9423 | 700.3 | 10.26 | 37.22 |

| After optimization | 0.9147 | 674.6 | 9.74 | 34.94 |

| Optimization results | 2.93% ↓ | 3.67% ↓ | 5.07 % ↓ | 6.13% ↓ |

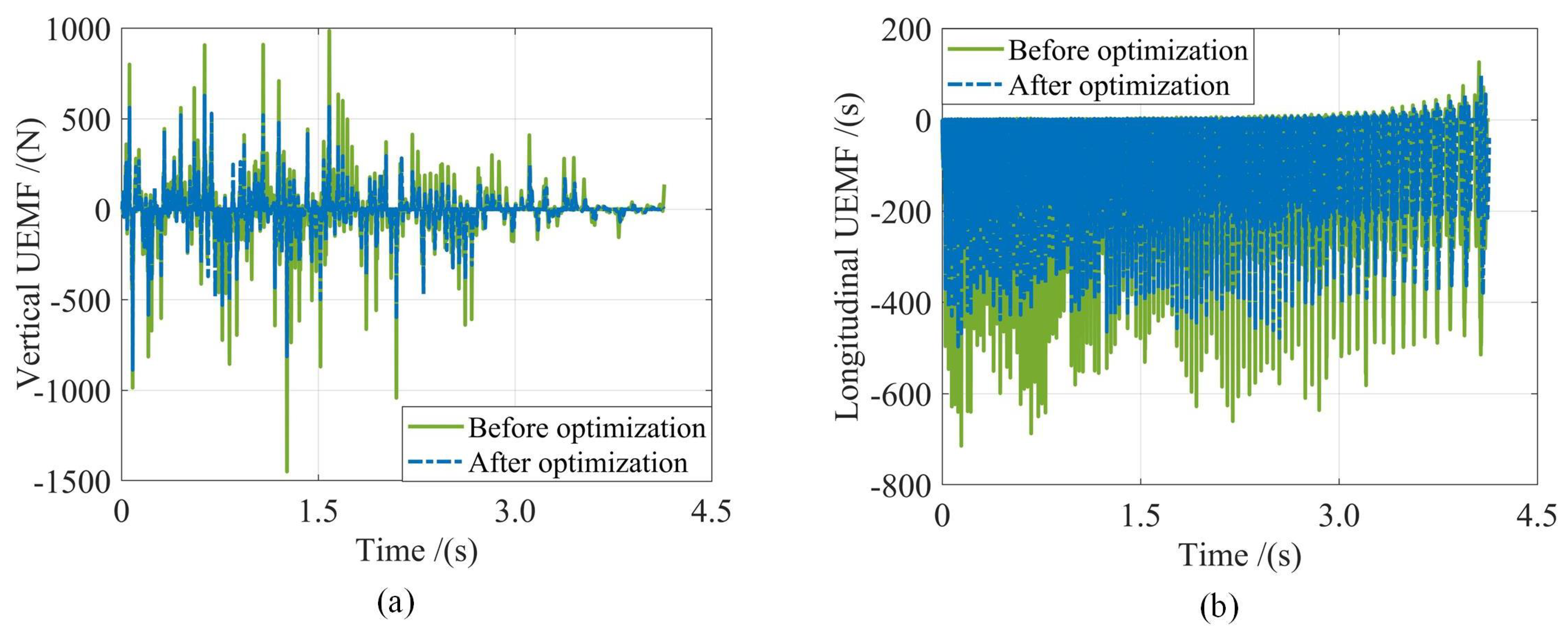

| RMS | Vertical UEMF (N) | Longitudinal UEMF (N) |

|---|---|---|

| Before optimization | 117.95 | 171.01 |

| After optimization | 77.02 | 133.06 |

| Optimization results | 34.7% ↓ | 22.2% ↓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Zhang, L.; Wu, J.; Gu, L.; Li, S. Vertical-Longitudinal Coupling Effect Investigation and System Optimization for a Suspension-In-Wheel-Motor System in Electric Vehicle Applications. Sustainability 2023, 15, 4168. https://doi.org/10.3390/su15054168

Zhao Z, Zhang L, Wu J, Gu L, Li S. Vertical-Longitudinal Coupling Effect Investigation and System Optimization for a Suspension-In-Wheel-Motor System in Electric Vehicle Applications. Sustainability. 2023; 15(5):4168. https://doi.org/10.3390/su15054168

Chicago/Turabian StyleZhao, Ze, Lei Zhang, Jianyang Wu, Liang Gu, and Shaohua Li. 2023. "Vertical-Longitudinal Coupling Effect Investigation and System Optimization for a Suspension-In-Wheel-Motor System in Electric Vehicle Applications" Sustainability 15, no. 5: 4168. https://doi.org/10.3390/su15054168

APA StyleZhao, Z., Zhang, L., Wu, J., Gu, L., & Li, S. (2023). Vertical-Longitudinal Coupling Effect Investigation and System Optimization for a Suspension-In-Wheel-Motor System in Electric Vehicle Applications. Sustainability, 15(5), 4168. https://doi.org/10.3390/su15054168