Liner-Shipping Network Design with Emission Control Areas: A Real Case Study

Abstract

1. Introduction

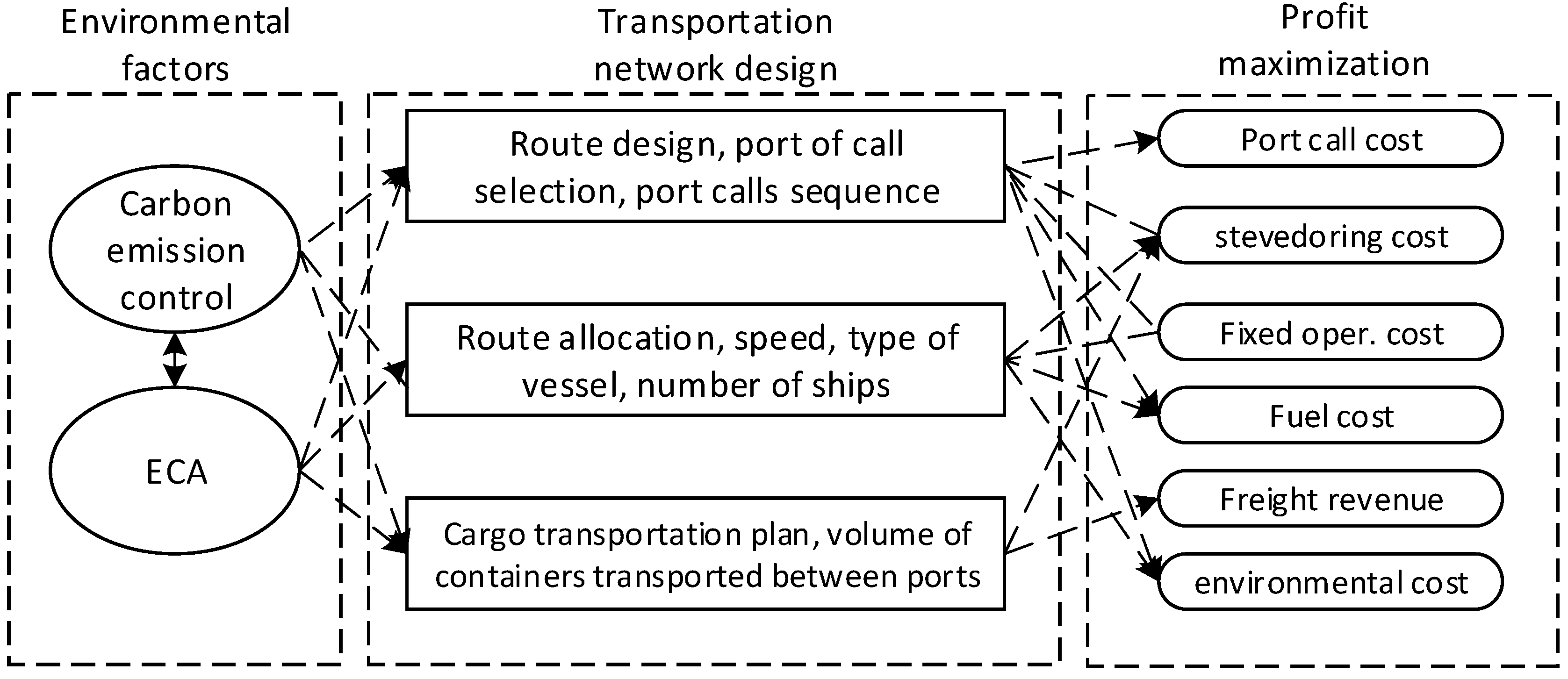

- The docking port, docking order, ship type, quantity, and speed are the decision variables. Considering environmental factors, how can a liner-transportation network optimization model be built?

- Liner-transportation network optimization is an NP-hard problem. What algorithm should be designed to solve the liner-transportation network optimization considering environmental factors?

- What is the impact of the ECA policy on shipping-company profits and transportation networks?

- The implementation of the ECA policy had little impact on the profits of shipping companies and transportation networks. Although the establishment of an emission control zone will increase the cost burden of shipowners to a certain extent, the impact of ECAs on the cost is relatively small compared to the total.

- The ECA policy has little influence on port attractiveness and competitiveness, and port cargo supply and demand, namely, port throughput, is the key factor in attracting ships.

- Freight rate fluctuation has the most significant impact on the shipping company’s profit and transportation network, followed by the impact of inter-port OD demand fluctuation. Increasing port cargo volume is key to increasing port attractiveness and competitiveness.

2. Literature Review

2.1. Liner Transport Network Optimization

2.2. Optimization Algorithm Design of Liner Transport Network

3. Model Specifications and Parameter Definition

- Description of the variables

- Decision variables

- Port-related parameters

- Ship-related parameters

4. Models

4.1. Route Operating Cost

- Total cargo transport between ports

- The connection between navigation speed, navigation time, and the number of vessels. Let the sailing time between ports be , equal to the voyage divided by the speed, and the expression is:

- Fleet costs

- Cost of carbon emissions

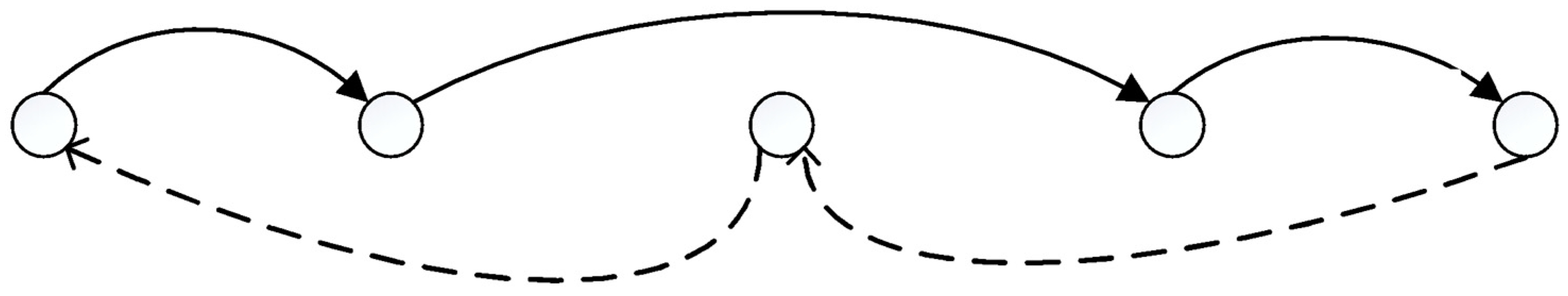

4.2. Route Design

4.3. Liner Transportation Network Design

- Capacity constraints

- 2.

- Minimum one leg of the route

- 3.

- Closed-loop route

- 4.

- Route allocation constraints

- 5.

- Cargo transportation and port-of-call constraints

- 6.

- Vessel capacity limit, with W being a very large positive number

- 7.

- Vessel speed constraint

5. Arithmetic Design

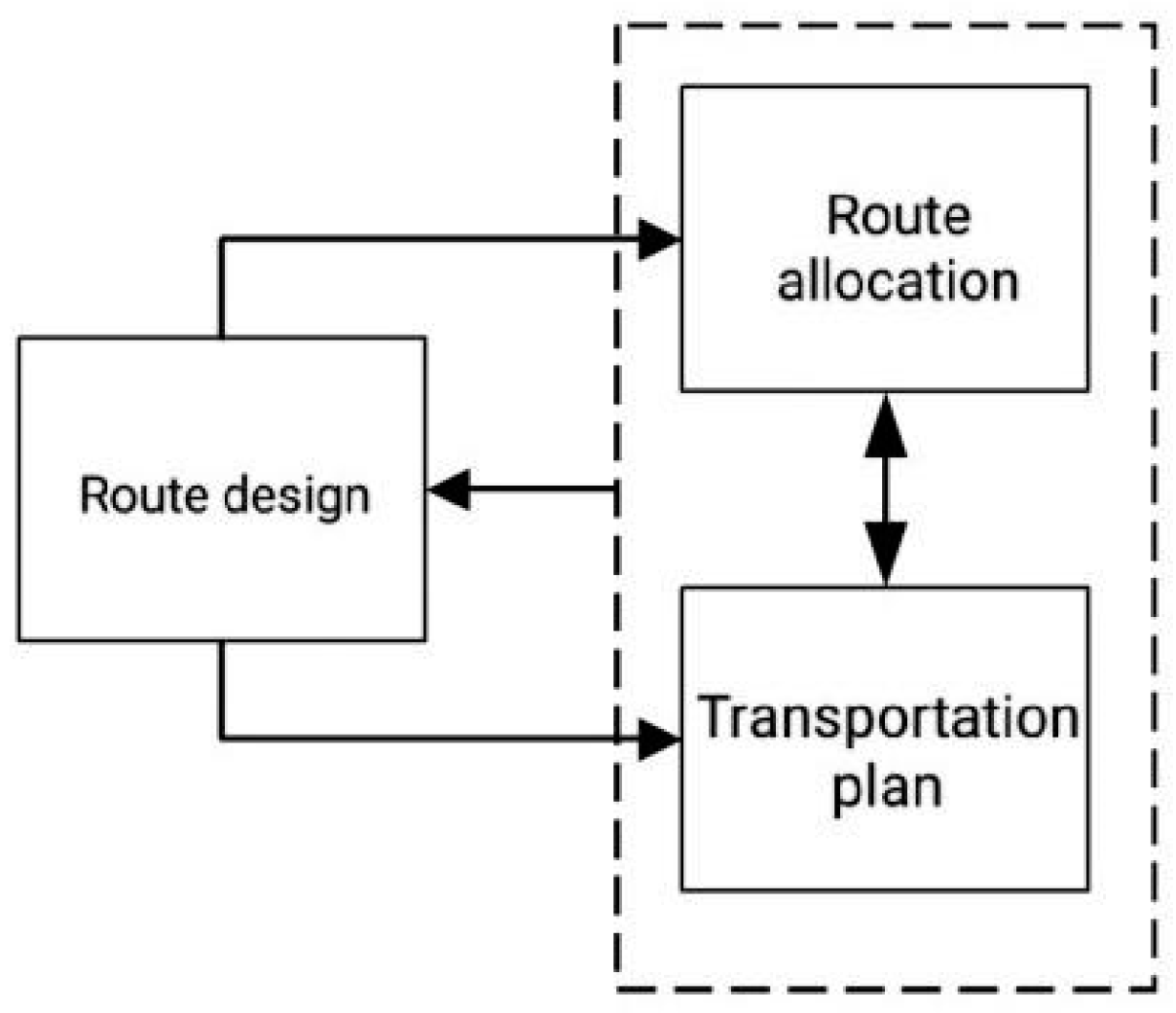

5.1. Overall Design of the Algorithm

5.2. Route Generation Model

5.3. Generation of Optimal Route Networks

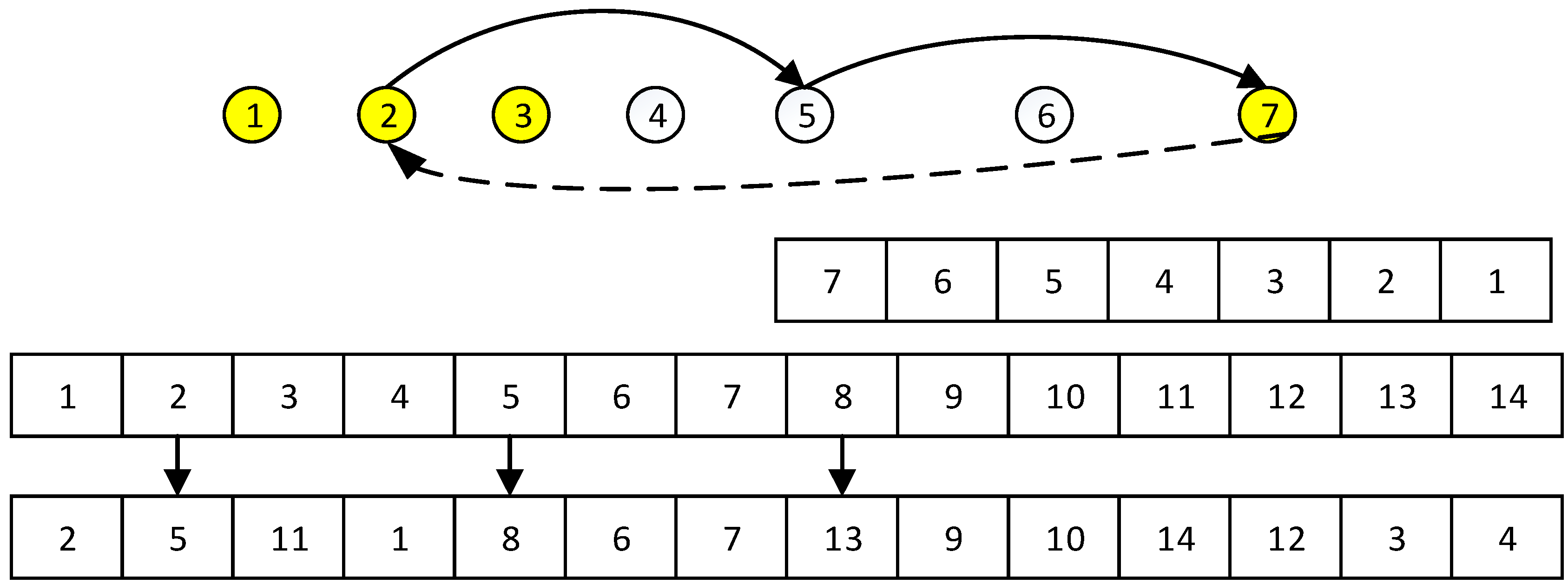

5.4. Coding of the Route Generation Model

6. Case Study

6.1. Data Collection

6.2. Analysis of Results

- (1)

- The thesis affirms that regarding the liner-shipping network optimization model that considers the environmental costs and the design of the heuristic algorithm based on empirical data, the validity of the model and algorithm can be proven through empirical calculations, which provide an effective solution for the liner network design of shipping companies. The overall better route design (port of call and sequence of port calls), route allocation (vessel type, fleet size, and speed inside and outside the ECAs region), and cargo transportation plan (cargo transport between ports) were obtained through calculations.

- (2)

- A comparison between DES-LSND and LSND shows that the LSND method is 5.02% more profitable and 10.79% less carbon-intensive than the DES-LSND method. With the carbon tax on international shipping and the successive introduction of increasingly stringent policies related to environmental protection in maritime transport, slow steaming has become a major trend, and represents a more effective method for shipping companies to adapt to environmental-protection requirements. It also shows that the LSND method proposed in this study considers the problem from the perspective of global optimization and can lead to a significant increase in the profitability of the route network compared to the route network obtained at design speed (DES-LSND). This is because the DES-LSND method uses the design-speed value; hence, the cost of each segment is fixed. Therefore, when market conditions change, the optimization results can only adjust the route network, and it is more difficult to obtain a globally optimal solution.

- (3)

- The comparison between ECA-LSND and LSND shows that slower steaming within the LSND emission control area (two speeds) is 2.24% more profitable and 0.34% more carbon-intensive than the single-speed strategy (one speed) of ECA-LSND. This further shows that when the market conditions (introduction of the ECA policy) change, the LSND approach takes a more holistic view of the problem and results in a significant increase in the profitability of the route network compared with the route network obtained with a single-speed strategy (ECA-LSND). This is because the ECA-LSND method uses a single-speed strategy inside and outside the ECAs, thus making it harder to obtain a globally optimal solution because the ship does not adjust its speed in response to the high price of the fuel that must be used in the ECAs, leading to an increase in fuel costs. These ECAs increase carbon emissions, which have a negative impact on marine environments. The ECA policy is mainly designed to reduce sulfur emissions, but it also leads to an increase in carbon emissions. This is also the reason why ECAs emission control areas are called SECA in many places, as well as the defect of the ECA policy.

- (4)

- Under the emission-control-area policy, it is the best sailing strategy for shipping companies to adopt different sailing speeds outside the ECAs and low sailing speeds within the ECAs. Ships entering ECAs using high-priced low-sulfur marine gas oil can minimize total costs and increase profits by slowing down [16]. As increasing attention is being paid to marine environmental protection, speed optimization inside and outside the ECAs will become increasingly important. Shipping companies must pay attention to the influence of ECAs and optimize the speed inside and outside ECAs when making sailing plans.

6.3. Sensitivity Analysis

6.3.1. Sensitivity Analysis of Emission-Control-Area Numbers

6.3.2. Analysis of OD Demand between Ports and Tariff Sensitivity

6.3.3. Sensitivity Analysis of Different Carbon Prices

6.3.4. Sensitivity Analysis of Different Fuel Prices

6.4. Management Implications

- With the introduction of the global maritime carbon tax and increasingly strict maritime-transport environmental-protection policies, low-speed navigation has become the trend of the times [14], and it is also a relatively effective way for shipping companies to deal with environmental protection.

- As increasing attention is being paid to marine environmental protection, speed optimization will become increasingly important. Shipping companies must pay attention to the influence of ECAs and optimize the speed inside and outside ECAs when making sailing plans [16]. For shipping companies, low-speed sailing in ECAs is the best strategy.

- The ECA policy system faces the dilemmas of port development and environmental protection. Studies show that the implementation of the ECA policy has little influence on the design of the ship transport network; therefore, ECAs have little influence on port competitiveness [30], and the supply and demand of port goods, namely, port throughput, is the key factor in attracting ships [35].

- The main function of ECAs is to reduce sulfur emissions, but this will lead to an increase in carbon emissions. These ECAs should be combined with carbon-emissions control policies. Only by implementing dual policies can the marine environment be better protected. At the same time, the development of the shipping market should also be considered when formulating policies to develop reasonable policies.

7. Conclusions

- This study proposes a liner-shipping network optimization model considering environmental costs, designs a heuristic algorithm based on empirical data, and proves the effectiveness of the model and algorithm through empirical calculations, providing an effective solution for the liner network design of shipping companies. Liner companies can use the model and algorithm proposed in this study to readjust and optimize the linear network when market conditions change, thus simultaneously preserving the market share and maximizing the profit of the liner network.

- The LSND method proposed in this study considers the problem from the perspective of global optimization and is more likely to yield globally optimized solutions than the other methods, and provides a new reference for solving liner transport network design problems.

- With the introduction of a global maritime carbon tax and increasingly strict maritime-transport environmental-protection policies, more and more attention has been paid to marine environmental protection, and speed optimization will become more and more important. Shipping companies must pay attention to the influence of ECAs and make overall optimization of ECA internal and external speed when formulating navigation plans. For shipping companies, low-speed sailing in ECA areas is the best sailing strategy [14].

- The impact of fluctuations in freight rates on shipping-company profits and transport networks is most significant, followed by the impact of OD demand between port fluctuations. The implementation of the ECA policy has had relatively little impact on shipping-company profits and transport networks [30]. When a policy regime balances port development and environmental protection, the key to increasing the attractiveness and competitiveness of ports is to increase the volume of port cargo [35].

- Low oil prices will have a negative impact on energy conservation and emission reduction [36]. Most shipping companies cut costs by sailing at lower speeds, but when oil prices drop, shipping companies choose to increase shipping speed, which can offset the cost of increased carbon emissions by increasing voyage profits or reducing ship investment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- John, B. Intergovernmental Panel on Climate Change Special Report on Global Warming of 1.5 °C Switzerland: IPCC. Popul. Dev. Rev. 2018, 45, 251–252. [Google Scholar]

- Fourth Greenhouse Gas Study 2020. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Fourth-IMO-Greenhouse-Gas-Study-2020.aspx (accessed on 10 November 2022).

- Marielle, C.; Erik, H.; David, P.; David, S.; Charlotte, V. Liner shipping network design. Eur. J. Oper. Res. 2019, 286, 1–20. [Google Scholar]

- Brouer, B.; Alvarez, J.; Plum, C.; Pisinger, D.; Sigurd, M. A base integer programming model and benchmark suite for liner-shipping network design. Transp. Sci. 2014, 48, 281–312. [Google Scholar] [CrossRef]

- Du, G.; Sun, C.; Weng, J. Liner shipping fleet deployment with sustainable collaborative transportation. Sustainability 2016, 8, 165. [Google Scholar] [CrossRef]

- Cheaitou, A.; Cariou, P. Greening of maritime transportation: A multi-objective optimization approach. Ann. Oper. Res. 2018, 273, 501–525. [Google Scholar] [CrossRef]

- Pierre, C.; Ali, C.; Rim, L.; Sadeque, H. Liner shipping network design with emission control areas: A genetic algorithm-based approach. Transp. Res. Part D Transp. Environ. 2018, 63, 604–621. [Google Scholar]

- Zhu, M.; Chen, M.; Kristal, M. Modelling the impacts of uncertain carbon tax policy on maritime fleet mix strategy and carbon mitigation. Transport 2018, 33, 707–717. [Google Scholar] [CrossRef]

- Branchini, R.; Armentano, V.; Morabitoc, R. Routing and fleet deployment in liner shipping with spot voyages. Transp. Res. Part C Emerg. Technol. 2015, 57, 188–205. [Google Scholar] [CrossRef]

- Gelareh, S.; Nickel, S.; Pisinger, D. Liner shipping hub network design in a competitive environment. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 991–1004. [Google Scholar] [CrossRef]

- Gelareh, S.; Pisinger, D. Fleet deployment, network design and hub location of liner shipping companies. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 947–964. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, S. Liner shipping service network design with empty container repositioning. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 695–708. [Google Scholar] [CrossRef]

- Ameln, M.; Fuglum, J.; Thun, K.; Andersson, H.; Stålhane, M. A new formulation for the liner shipping network design problem. Int.Trans. Oper. Res. 2019, 00, 1–22. [Google Scholar] [CrossRef]

- Xing, Y.; Yang, H.; Ma, X.; Zhang, Y. Optimization of ship speed and fleet deployment under carbon emissions policies for container shipping. Transport 2019, 34, 260–274. [Google Scholar] [CrossRef]

- Ma, W.; Hao, S.; Ma, D.; Wang, D.; Jin, S.; Qu, F. Scheduling decision model of liner shipping considering emission controlareas regulations. Appl. Ocean. Res. 2020, 106, 102416. [Google Scholar] [CrossRef]

- Zhen, L.; Hu, Z.; Yan, R.; Zhuge, D.; Wang, S. Route and speed optimization for liner ships under emission control policies. Transp. Res. Part C Emerg. Technol. 2020, 110, 330–345. [Google Scholar] [CrossRef]

- Xin, X.; Wang, X.; Ma, L.; Chen, K.; Ye, M. Shipping network design- infrastructure investment joint optimization model: A case study of West Africa. Marit. Policy. Manag. 2021, 1, 1–27. [Google Scholar] [CrossRef]

- Ma, W.; Ma, D.; Ma, Y.; Zhang, J.; Wang, D. Green maritime: A routing and speed multi-objective optimization strategy. J. Clean. Prod. 2021, 305, 127–179. [Google Scholar] [CrossRef]

- Gao, C.; Hu, Z. Speed Optimization for Container Ship Fleet Deployment Considering Fuel Consumption. Sustainability 2021, 13, 5242. [Google Scholar] [CrossRef]

- Zhuge, D.; Wang, S.; Wang, Z. Joint Bunkering Decision and Service Planning Problem in Liner Shipping with Sulfur Limits. Compendex 2022, 44, 1556–5068. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Sailing speed optimization for container-ships in a liner shipping network. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 701–714. [Google Scholar] [CrossRef]

- Song, D.; Li, D.; Drake, P. Multi-objective optimization for planning liner shipping service with uncertain port times. Transp. Res. Part E Logist. Transp. Rev. 2015, 84, 1–22. [Google Scholar] [CrossRef]

- Chuang, T.; Lin, C.; Kung, J.; Lin, M. Planning the route of container ships: A fuzzy genetic approach. Expert. Syst. Appl. 2010, 37, 2948–2956. [Google Scholar] [CrossRef]

- Plum, C.; Pisinger, D.; Sigurd, M. A service flow model for the liner shipping network design problem. Eur. J. Oper. Res. 2014, 235, 378–386. [Google Scholar] [CrossRef]

- Brouer, B.; Desaulniers, G.; Karsten, C. A Metaheuristic for the Liner Shipping Network Design Problem with Transit Time Restrictions. In Proceedings of the International Conference on Computational Logistics, ICCL 2015, Delft, The Netherlands, 23–25 September 2015. [Google Scholar]

- Karsten, C.; Brouer, B.; Desaulniers, G.; Pisinger, D. Time constrained liner shipping network design. Transp. Res. Part E Logist. Transp. Rev. 2017, 105, 152–162. [Google Scholar] [CrossRef]

- QinCheng, Q.; Wang, C. Container liner shipping network design with shipper’s dual preference. Comput. Oper. Res. 2021, 128, 105187. [Google Scholar]

- Ma, W.; Lu, T.; Ma, D.; Wang, D.; Qu, F. Ship route and speed multi-objective optimization considering weather conditions and emission control area regulations. Marit. Policy. Manag. 2020, 48, 1053–1068. [Google Scholar] [CrossRef]

- Wang, S.; Zhuge, D.; Zhen, L.; Lee, C. Liner shipping service planning under sulfur emission regulations. Transp. Sci. 2021, 55, 491–509. [Google Scholar] [CrossRef]

- Sheng, D.; Meng, Q.; Li, Z. Optimal vessel speed and fleet size for industrial shipping services under the emission control area regulation. Transp. Res. Part C Emerg. Technol. 2019, 105, 37–53. [Google Scholar] [CrossRef]

- Agarwal, R.; Ergun, Z. Ship Scheduling and Network Design for Cargo Routing in Liner Shipping. Transp. Sci. 2008, 42, 175–196. [Google Scholar] [CrossRef]

- Fagerholt, K.; Gausel, N.T.; Rakke, J.G.; Psaraftis, H.N. Maritime routing and speed optimization with emission control areas. Transp. Res. Part C Emerg. Technol. 2015, 52, 57–73. [Google Scholar] [CrossRef]

- Aldy, J.E.; Pizer, W.A. The competitiveness impacts of climate change mitigation policies. J. Assoc. Environ. Resour. Econ. 2015, 2, 565–595. [Google Scholar] [CrossRef]

- Yang, H.; Ma, X.; Xing, Y. Trends in CO2 emissions from china-oriented international marine transportation activities and policy implications. Energies 2017, 10, 980. [Google Scholar] [CrossRef]

- Cullinane, K.; Wang, Y. Determinants of port centrality in maritime container transportation. Transp. Res. Part E Logist. Transp. Rev. 2016, 95, 326–340. [Google Scholar]

- Mohamued, E.; Ahmed, M.; Pypacz, P.; Liczmańska-Kopcewicz, K.; Khan, M.A. Global Oil Price and Innovation for Sustainability: The Impact of R&D Spending, Oil Price and Oil Price Volatility on GHG Emissions. Energies 2021, 14, 1757. [Google Scholar]

| Name of Vessel | m | Bm (TEU) | (T/day) | (T/day) | (Kn/h) | (Kn/h) | (Kn/h) | (UDS/Day) | (UDS/Call) |

|---|---|---|---|---|---|---|---|---|---|

| XIN ZHANG ZHOU | 1 | 4253 | 139.5 | 6.33 | 18.2 | 11.34 | 25.15 | 9000 | 3001 |

| XIN WENZHOU | 2 | 4738 | 82 | 4.3 | 18 | 11.04 | 24.7 | 10,026 | 3344 |

| XIN YAN TIAN | 3 | 5668 | 202 | 7.81 | 17.7 | 12.05 | 26.7 | 11,994 | 4000 |

| COSCO THAILAND | 4 | 8501 | 250 | 10.47 | 18.6 | 12 | 26.6 | 17,989 | 6000 |

| XIN SHANGHAI | 5 | 9572 | 248.2 | 10.43 | 17.2 | 11.22 | 26.73 | 20,255 | 6204 |

| COSCO ASIA | 6 | 10,036 | 250 | 12.75 | 16.8 | 11.04 | 25.8 | 21,238 | 6505 |

| COSCO FAITH | 7 | 13,114 | 274.9 | 13.2 | 16.7 | 11 | 26.2 | 27,751 | 8500 |

| CSCLJUPITER | 8 | 14,074 | 262 | 14.51 | 16.1 | 11.18 | 26.62 | 29,783 | 9122 |

| CSCLPACIFIC OCEAN | 9 | 18,982 | 195.5 | 13.768 | 18 | 10 | 24.6 | 40,169 | 13,000 |

| COSCO SHIPPING VIRGO | 10 | 20,119 | 168 | 10.263 | 19 | 8.4615 | 22.5 | 42,575 | 13,040 |

| DKABG | CNQIN | CNSHA | CNNBO | CNXIA | CNYTN | HKHKG | JPTOK | JPOSK | SKBUS | USTAC | USVAN | USSEA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CNQIN | 0 | 448 | 540 | 920 | 1376 | 1362 | 1135 | 824 | 516 | 5146 | 5177 | 5127 |

| CNSHA | 448 | 0 | 243 | 623 | 1079 | 1065 | 1051 | 792 | 494 | 5124 | 5154 | 5105 |

| CNNBO | 540 | 243 | 0 | 544 | 1000 | 986 | 1062 | 832 | 542 | 5173 | 5203 | 5153 |

| CNXIA | 920 | 623 | 544 | 0 | 901 | 886 | 1374 | 1153 | 907 | 5538 | 5568 | 5518 |

| CNYTN | 1376 | 1079 | 1000 | 901 | 0 | 24 | 1752 | 1533 | 1330 | 5948 | 5974 | 5928 |

| HKHKG | 1362 | 1065 | 986 | 886 | 24 | 0 | 1738 | 1518 | 1316 | 5933 | 5959 | 5914 |

| JPTOK | 1135 | 1051 | 1062 | 1374 | 1752 | 1738 | 0 | 374 | 681 | 4316 | 4339 | 4297 |

| JPOSK | 824 | 792 | 832 | 1153 | 1533 | 1518 | 374 | 0 | 370 | 4592 | 4615 | 4573 |

| SKBUS | 516 | 494 | 542 | 907 | 1330 | 1316 | 681 | 370 | 0 | 4646 | 4676 | 4626 |

| USTAC | 5146 | 5124 | 5173 | 5538 | 5948 | 5933 | 4316 | 4592 | 4646 | 0 | 428 | 21 |

| USVAN | 5177 | 5154 | 5203 | 5568 | 5974 | 5959 | 4339 | 4615 | 4676 | 428 | 0 | 404 |

| USSEA | 5127 | 5105 | 5153 | 5518 | 5928 | 5914 | 4297 | 4573 | 4626 | 21 | 404 | 0 |

| DKABG | CNQIN | CNSHA | CNNBO | CNXIA | CNYTN | HKHKG | JPTOK | JPOSK | SKBUS | USTAC | USVAN | USSEA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CNQIN | 0.0 | 98.6 | 87.5 | 69.3 | 88.9 | 74.5 | 40.1 | 40.1 | 40.1 | 385.6 | 305.0 | 374.4 |

| CNSHA | 98.6 | 0.0 | 105.9 | 87.7 | 107.3 | 92.9 | 58.5 | 58.5 | 58.5 | 404.0 | 323.4 | 392.8 |

| CNNBO | 87.5 | 105.9 | 0.0 | 76.6 | 96.2 | 81.8 | 47.4 | 47.4 | 47.4 | 392.9 | 312.3 | 381.7 |

| CNXIA | 69.3 | 87.7 | 76.6 | 0.0 | 78.0 | 63.6 | 29.2 | 29.2 | 29.2 | 374.7 | 294.1 | 363.5 |

| CNYTN | 88.9 | 107.3 | 96.2 | 78.0 | 0.0 | 83.2 | 48.8 | 48.8 | 48.8 | 394.3 | 313.7 | 383.1 |

| HKHKG | 74.5 | 92.9 | 81.8 | 63.6 | 83.2 | 0.0 | 34.4 | 34.4 | 34.4 | 379.9 | 299.3 | 368.7 |

| JPTOK | 40.1 | 58.5 | 47.4 | 29.2 | 48.8 | 34.4 | 0.0 | 0.0 | 0.0 | 345.5 | 264.9 | 334.3 |

| JPOSK | 40.1 | 58.5 | 47.4 | 29.2 | 48.8 | 34.4 | 0.0 | 0.0 | 0.0 | 345.5 | 264.9 | 334.3 |

| SKBUS | 40.1 | 58.5 | 47.4 | 29.2 | 48.8 | 34.4 | 0.0 | 0.0 | 0.0 | 345.5 | 264.9 | 334.3 |

| USTAC | 385.6 | 404.0 | 392.9 | 374.7 | 394.3 | 379.9 | 345.5 | 345.5 | 345.5 | 0.0 | 418.4 | 6.0 |

| USVAN | 305.0 | 323.4 | 312.3 | 294.1 | 313.7 | 299.3 | 264.9 | 264.9 | 264.9 | 418.4 | 0.0 | 412.4 |

| USSEA | 374.4 | 392.8 | 381.7 | 363.5 | 383.1 | 368.7 | 334.3 | 334.3 | 334.3 | 6.0 | 412.4 | 0.0 |

| DKABG | CNQIN | CNSHA | CNNBO | CNXIA | CNYTN | HKHKG | JPTOK | JPOSK | SKBUS | USTAC | USVAN | USSEA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CNQIN | 0 | 122 | 147 | 250 | 374 | 371 | 309 | 224 | 140 | 1400 | 1400 | 1350 |

| CNSHA | 122 | 0 | 66 | 169 | 294 | 290 | 287 | 216 | 135 | 1400 | 1400 | 1350 |

| CNNBO | 147 | 66 | 0 | 148 | 272 | 268 | 287 | 225 | 147 | 1400 | 1400 | 1350 |

| CNXIA | 250 | 169 | 148 | 0 | 245 | 241 | 385 | 323 | 254 | 1550 | 1550 | 1500 |

| CNYTN | 374 | 294 | 272 | 245 | 0 | 7 | 200 | 250 | 347 | 1550 | 1550 | 1500 |

| HKHKG | 371 | 290 | 268 | 241 | 7 | 0 | 100 | 100 | 344 | 1550 | 1550 | 1500 |

| JPTOK | 309 | 286 | 289 | 374 | 477 | 473 | 0 | 100 | 178 | 1128 | 1129 | 1090 |

| JPOSK | 224 | 215 | 226 | 314 | 417 | 413 | 102 | 0 | 101 | 1200 | 1200 | 1160 |

| SKBUS | 140 | 134 | 147 | 247 | 362 | 358 | 185 | 101 | 0 | 1214 | 1216 | 1173 |

| USTAC | 1400 | 1394 | 1407 | 1507 | 1618 | 1614 | 1174 | 1249 | 1264 | 0 | 116 | 6 |

| USVAN | 1408 | 1402 | 1416 | 1515 | 1625 | 1621 | 1180 | 1256 | 1272 | 116 | 0 | 110 |

| USSEA | 1395 | 1389 | 1402 | 1501 | 1613 | 1609 | 1169 | 1244 | 1259 | 6 | 110 | 0 |

| DKABG | CNQIN | CNSHA | CNNBO | CNXIA | CNYTN | HKHKG | JPTOK | JPOSK | SKBUS | USTAC | USVAN | USSEA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CNQIN | 0 | 0 | 0 | 0 | 0 | 0 | 446 | 724 | 849 | 320 | 965 | 423 |

| CNSHA | 0 | 0 | 0 | 0 | 0 | 0 | 235 | 304 | 383 | 409 | 794 | 851 |

| CNNBO | 0 | 0 | 0 | 0 | 0 | 0 | 663 | 305 | 459 | 840 | 379 | 954 |

| CNXIA | 0 | 0 | 0 | 0 | 0 | 0 | 235 | 686 | 322 | 219 | 869 | 380 |

| CNYTN | 0 | 0 | 0 | 0 | 0 | 0 | 632 | 325 | 623 | 810 | 383 | 986 |

| HKHKG | 0 | 0 | 0 | 0 | 0 | 0 | 417 | 524 | 816 | 954 | 705 | 540 |

| JPTOK | 874 | 493 | 818 | 745 | 500 | 762 | 0 | 0 | 0 | 871 | 479 | 611 |

| JPOSK | 615 | 665 | 562 | 293 | 862 | 342 | 0 | 0 | 0 | 296 | 389 | 666 |

| SKBUS | 535 | 977 | 211 | 787 | 457 | 647 | 0 | 0 | 0 | 721 | 559 | 929 |

| USTAC | 556 | 473 | 651 | 691 | 427 | 958 | 505 | 917 | 696 | 0 | 0 | 0 |

| USVAN | 936 | 239 | 972 | 432 | 843 | 818 | 470 | 716 | 997 | 0 | 0 | 0 |

| USSEA | 584 | 997 | 726 | 235 | 826 | 632 | 587 | 584 | 916 | 0 | 0 | 0 |

| CNQIN: 1 | CNSHA: 2 | CNNBO: 3 | CNXIA: 4 | CNYTN: 5 | HKHKG: 6 | JPTOK: 7 | JPOSK: 8 | SKBUS: 9 | USTAC: 10 | USVAN: 11 | USEA: 12 |

| Method | LSND | DES-LSND | ECA-LSND |

|---|---|---|---|

| Port of call and order | 5-6-4-3-2-9-8-7-11-12-10-7-8-9-1-2-4-6-5 | 5-6-4-3-2-9-8-7-11-12-10-7-8-9-1-2-4-6-5 | 5-6-4-3-2-9-8-7-11-12-10-7-8-9-1-2-4-6-5 |

| Profit | 3,957,362.95 | 2,438,426.32 | 3,870,687.40 |

| Total cost | 1,686,897.72 | 1,851,594.22 | 1,722,952.43 |

| Fuel cost | 691414.00 | 847,338.83 | 689,188.20 |

| Carbon emission | 7839.08 | 10,382.49 | 7812.62 |

| In the ECA speed | 13.535 | 18.00 | 14.03 |

| ECA outside speed | 14.627 | 18.00 | 14.03 |

| Ship type | 8 | 8 | 8 |

| Ship number | 7 | 7 | 7 |

| DKABG | CNQIN | CNSHA | CNNBO | CNXIA | CNYTN | HKHKG | JPTOK | JPOSK | SKBUS | USTAC | USVAN | USSEA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CNQIN | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| CNSHA | 0 | 0 | 0 | 0 | 0 | 0 | 923 | 451 | 867 | 225 | 597 | 483 |

| CNNBO | 0 | 0 | 0 | 0 | 0 | 0 | 100 | 137 | 136 | 293 | 161 | 110 |

| CNXIA | 0 | 0 | 0 | 0 | 0 | 0 | 177 | 99 | 235 | 795 | 577 | 476 |

| CNYTN | 0 | 0 | 0 | 0 | 0 | 0 | 739 | 768 | 394 | 379 | 314 | 808 |

| HKHKG | 0 | 0 | 0 | 0 | 0 | 0 | 369 | 935 | 902 | 331 | 799 | 205 |

| JPTOK | 716 | 556 | 0 | 208 | 596 | 453 | 0 | 0 | 0 | 784 | 773 | 844 |

| JPOSK | 167 | 250 | 0 | 134 | 90 | 644 | 0 | 0 | 0 | 758 | 859 | 768 |

| SKBUS | 567 | 356 | 0 | 197 | 575 | 248 | 0 | 0 | 0 | 446 | 918 | 438 |

| USTAC | 652 | 312 | 0 | 782 | 584 | 804 | 457 | 380 | 354 | 0 | 0 | 0 |

| USVAN | 172 | 272 | 0 | 656 | 760 | 238 | 637 | 162 | 442 | 0 | 0 | 0 |

| USSEA | 494 | 575 | 0 | 538 | 481 | 350 | 791 | 279 | 825 | 0 | 0 | 0 |

| Method | Case 1 | Case 2 | LSND |

|---|---|---|---|

| Port of call and order | 5–6–4–3–2–9–8–7–11–12–10–7–8–9–1–2–4–6–5 | 5–6–4–3–2–9–8–7–11–12–10–7–8–9–1–2–4–6–5 | 5–6–4–3–2–9–8–7–11–12–10–7–8–9–1–2–4–6–5 |

| Profit | 21,280,885.56 | 2,733,597.50 | 3,957,362.95 |

| Total cost | 6,869,693.11 | 2,663,319.99 | 1,686,897.72 |

| Fuel cost | 1,360,256.79 | 862,967.65 | 691,414.00 |

| Carbon emission | 8416.53 | 13,697.90 | 7839.08 |

| In the ECA speed | 12.133 | 14.39 | 13.535 |

| ECA outside speed | 14.872 | 14.627 | |

| Ship type | 8 | 8 | 8 |

| Ship number | 7 | 7 | 7 |

| Method | Demand Is Reduced by 20% | Freight Rates Were Reduced by 20% | Invariant |

|---|---|---|---|

| Port of call and order | 5–6–4–3–2–9–8–7–11–12–10–7–8–9–1–2–4–6–5 | 5–4–2–9–8–7–11–12–7–8–9–1–2–4–5 | 5–6–4–3–2–9–8–7–11–12–10–7–8–9–1–2–4–6–5 |

| Profit | 2,854,323.595 | 2,978,286.01 | 3,957,362.95 |

| Fuel cost | 697,085.77 | 649,626.763 | 691,414.00 |

| Carbon emission | 7906.49 | 7279.2 | 7839.08 |

| In the ECA speed | 13.68 | 11.86 | 13.535 |

| ECA outside speed | 14.42 | 13.01 | 14.627 |

| Ship type | 8 | 8 | 8 |

| Ship number | 7 | 7 | 7 |

| Method | Carbon Prices 50.4 | Carbon Prices 63 | Carbon Prices 75.6 |

|---|---|---|---|

| Port of call and order | 5–6–4–3–2–9–8–7–11–12–7–8–9–1–2–4–5 | 5–6–4–3–2–9–8–7–11–12–10–7–8–9–1–2–4–6–5 | 5–4–3–2–9–8–7–11–12–7–8–9–1–2–4–5 |

| Profit | 4,021,694.133 | 3,957,362.95 | 3,866,976.2 |

| Fuel cost | 804,827.37 | 691,414 | 556,354.72 |

| Carbon emission | 8800.1011 | 7839.08 | 6634.17473 |

| In the ECA speed | 14.14 | 13.535 | 12.78 |

| ECA outside speed | 14.89 | 14.627 | 14.097 |

| Ship type | 8 | 8 | 8 |

| Ship number | 6 | 7 | 7 |

| Method | Lower Fuel Prices 20% | Lower Fuel Prices 10% | LSND | Increase in Fuel Prices 10% | Increase in Fuel Prices 10% |

|---|---|---|---|---|---|

| Port of call and order | 5–6–4–3–2–9–8–7–11-12–10–7–8–9–1–2–4–6–5 | 5–6–4–3–2–9–8–7–11-12–10–7–8–9–1–2–4–6–5 | 5–6–4–3–2–9–8–7–11-12–10–7–8–9–1–2–4–6–5 | 5–6–4–3–2–9–8–7–11-12–10–7–8–9–1–2–4–6–5 | 5–4–3–2–9–8–7–11–12–10–7–8–9–1–2–4–5 |

| Profit | 4,210,848.61 | 4,002,766.25 | 3,957,362.95 | 3,652,554.54 | 3,010,744.785 |

| Fuel cost | 606,727.61 | 626,287.67 | 691,414 | 722,529.43 | 741,462.76 |

| Carbon emission | 8219.19 | 8069.97 | 7839.08 | 6833.99 | 6962.50 |

| In the ECA speed | 14.27 | 12.37 | 13.53 | 11.78 | 11.96 |

| ECA outside speed | 14.66 | 14.77 | 14.63 | 13.45 | 12.21 |

| Ship type | 8 | 8 | 8 | 8 | 8 |

| Ship number | 6 | 7 | 7 | 7 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, X.; Tao, Q.; Wu, X. Liner-Shipping Network Design with Emission Control Areas: A Real Case Study. Sustainability 2023, 15, 3734. https://doi.org/10.3390/su15043734

Lan X, Tao Q, Wu X. Liner-Shipping Network Design with Emission Control Areas: A Real Case Study. Sustainability. 2023; 15(4):3734. https://doi.org/10.3390/su15043734

Chicago/Turabian StyleLan, Xiangang, Qin Tao, and Xincheng Wu. 2023. "Liner-Shipping Network Design with Emission Control Areas: A Real Case Study" Sustainability 15, no. 4: 3734. https://doi.org/10.3390/su15043734

APA StyleLan, X., Tao, Q., & Wu, X. (2023). Liner-Shipping Network Design with Emission Control Areas: A Real Case Study. Sustainability, 15(4), 3734. https://doi.org/10.3390/su15043734