Geothermal Characteristics and Productivity Potential of a Super-Thick Shallow Granite-Type Enhanced Geothermal System: A Case Study in Wendeng Geothermal Field, China

Abstract

1. Introduction

2. Site Characteristics

2.1. Geological Background

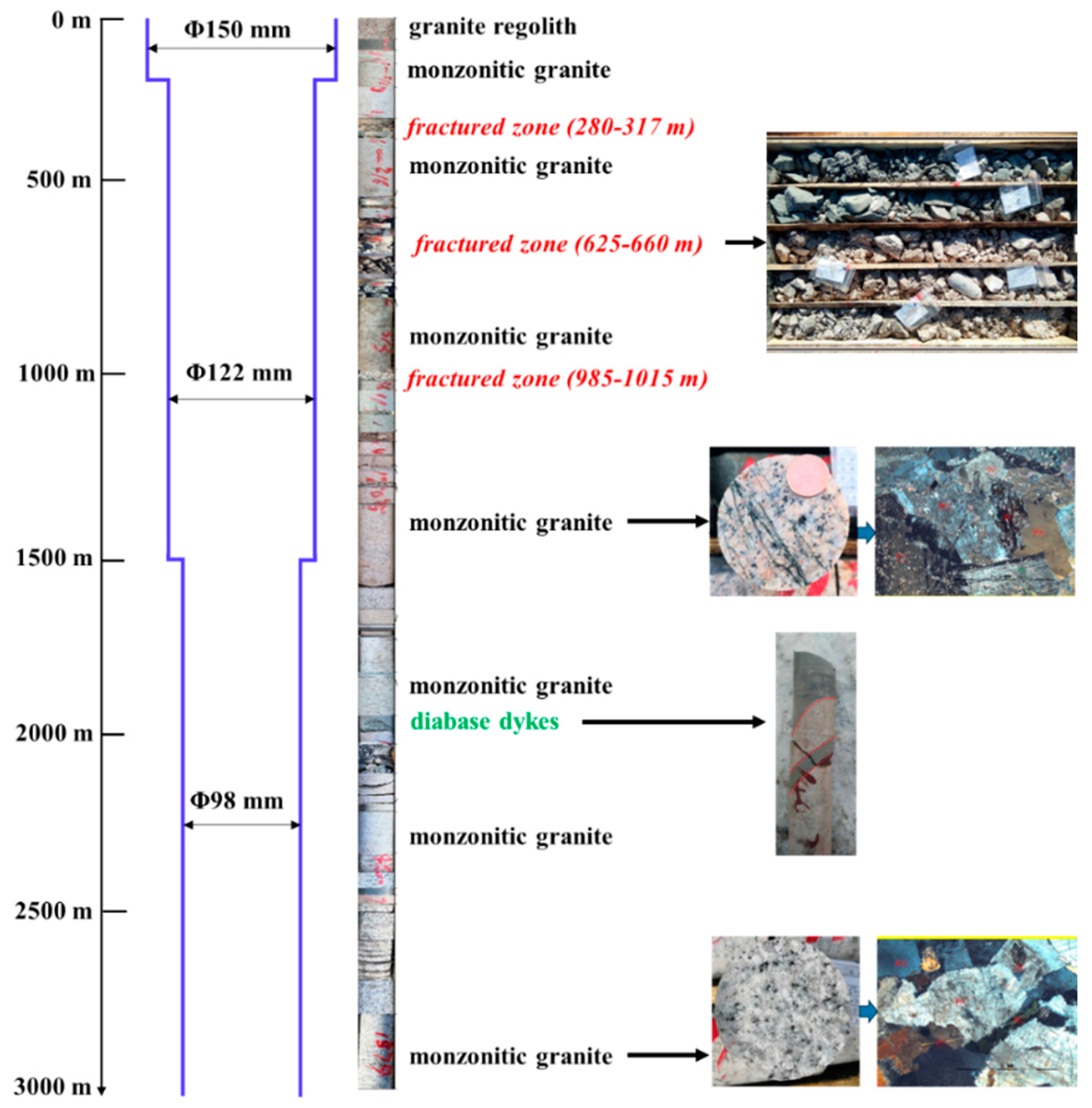

2.2. Strata and Lithology

3. Methods

3.1. Field and Lab Test

3.2. Hydraulic Fracturing Simulation

3.3. Thermal Extraction Simulation

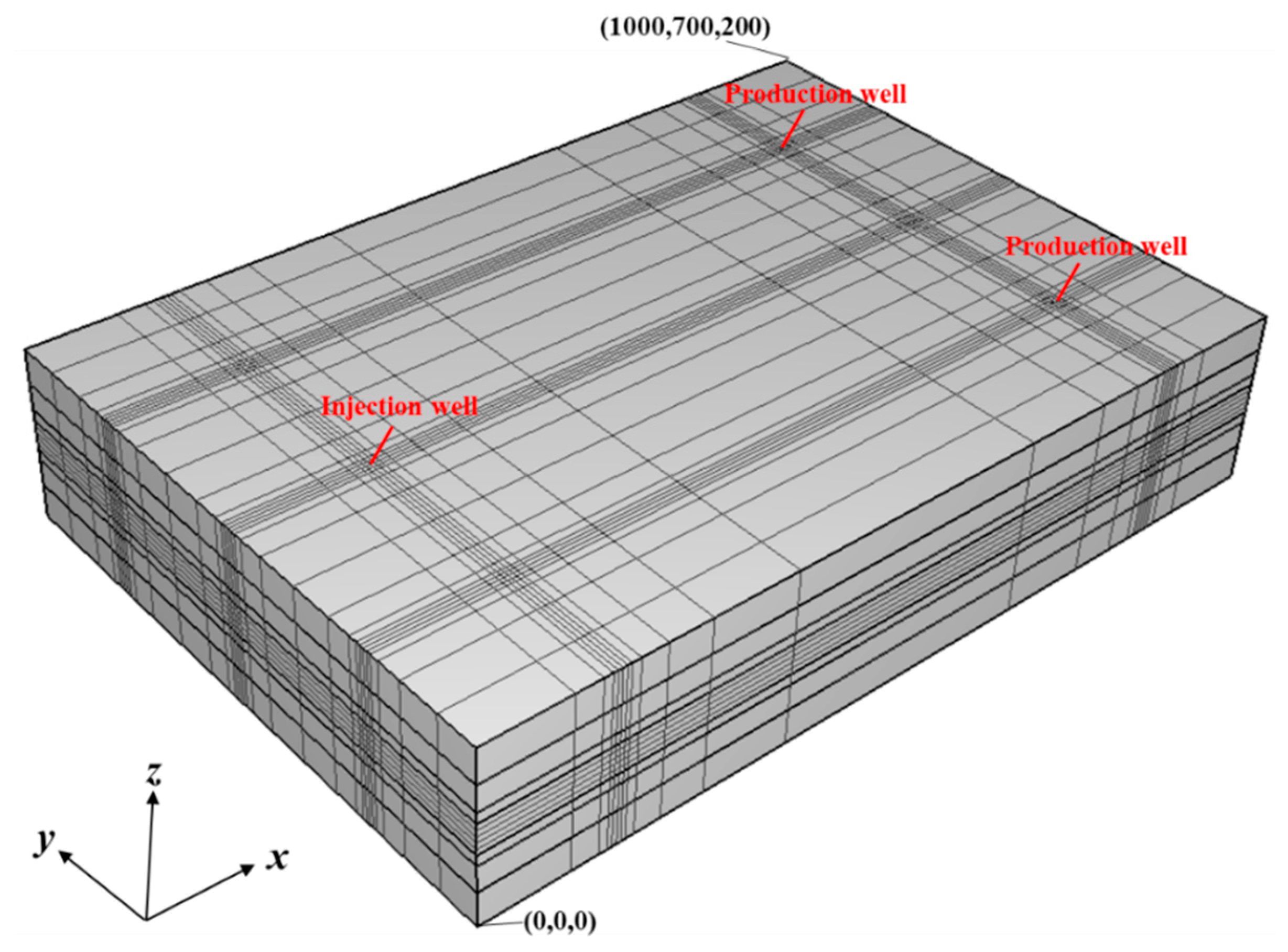

3.3.1. Numerical Model, Parameters, Initial and Boundary Conditions

3.3.2. Production Performance Indicators

4. Results

4.1. Geothermal Features

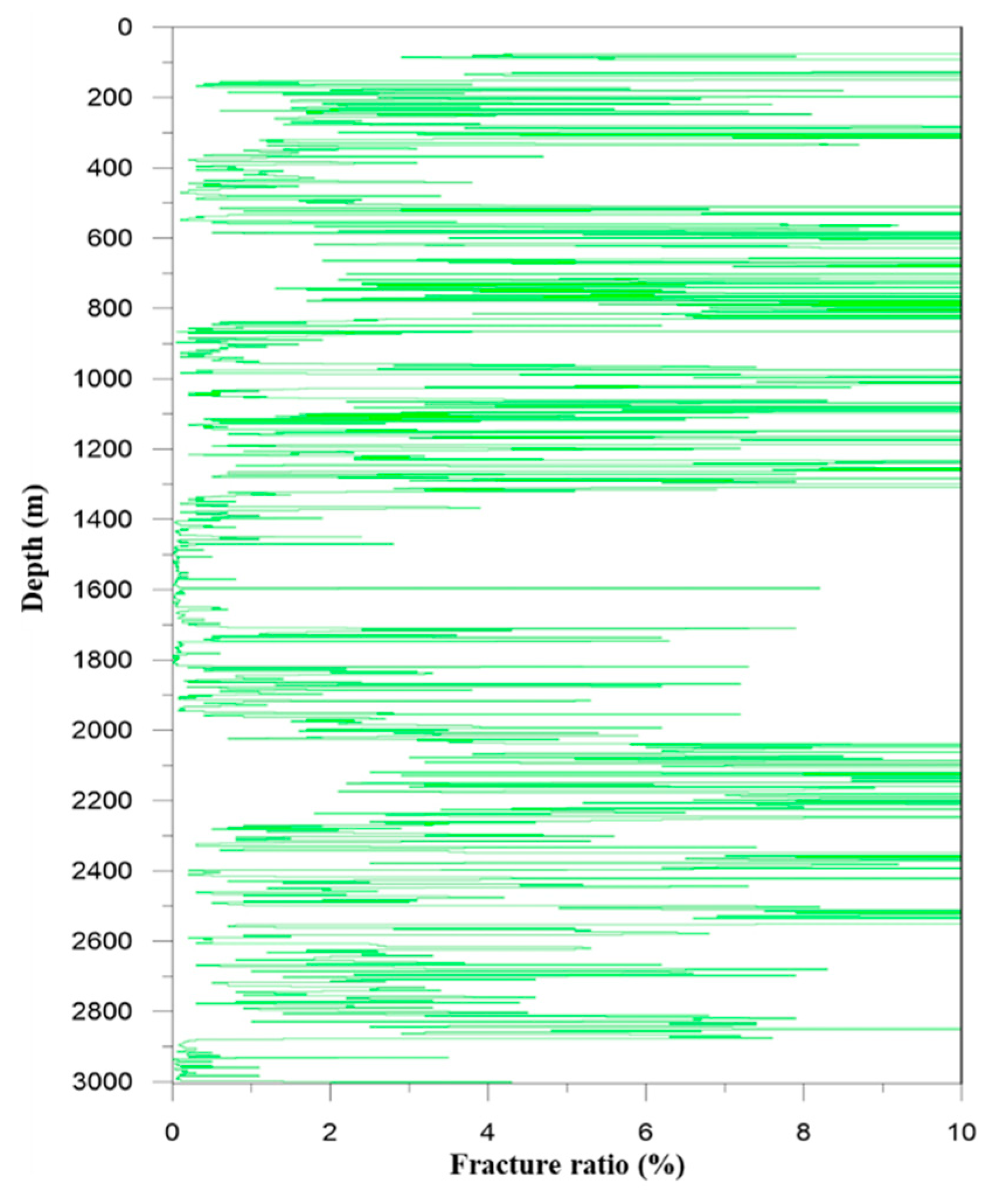

4.2. Stress State

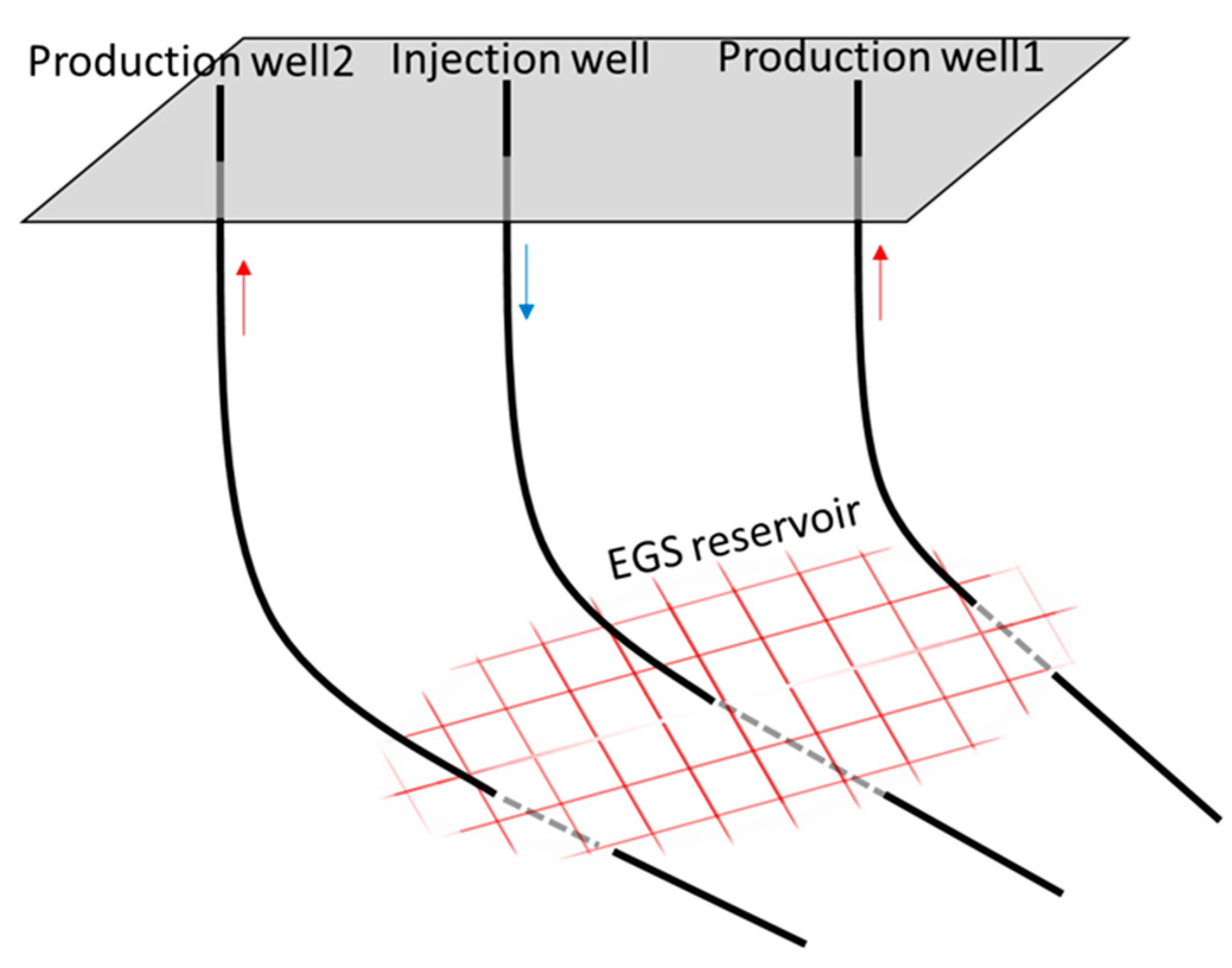

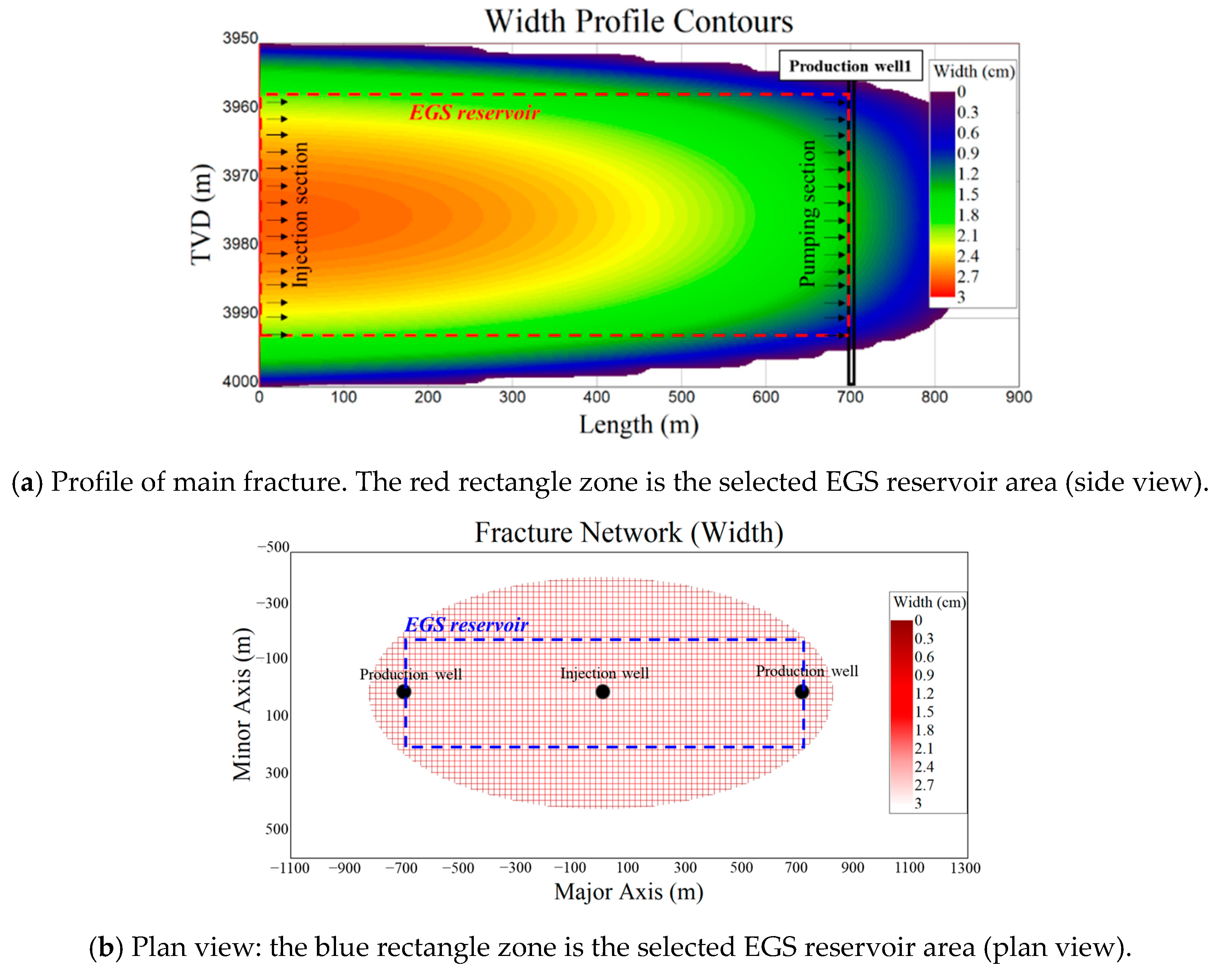

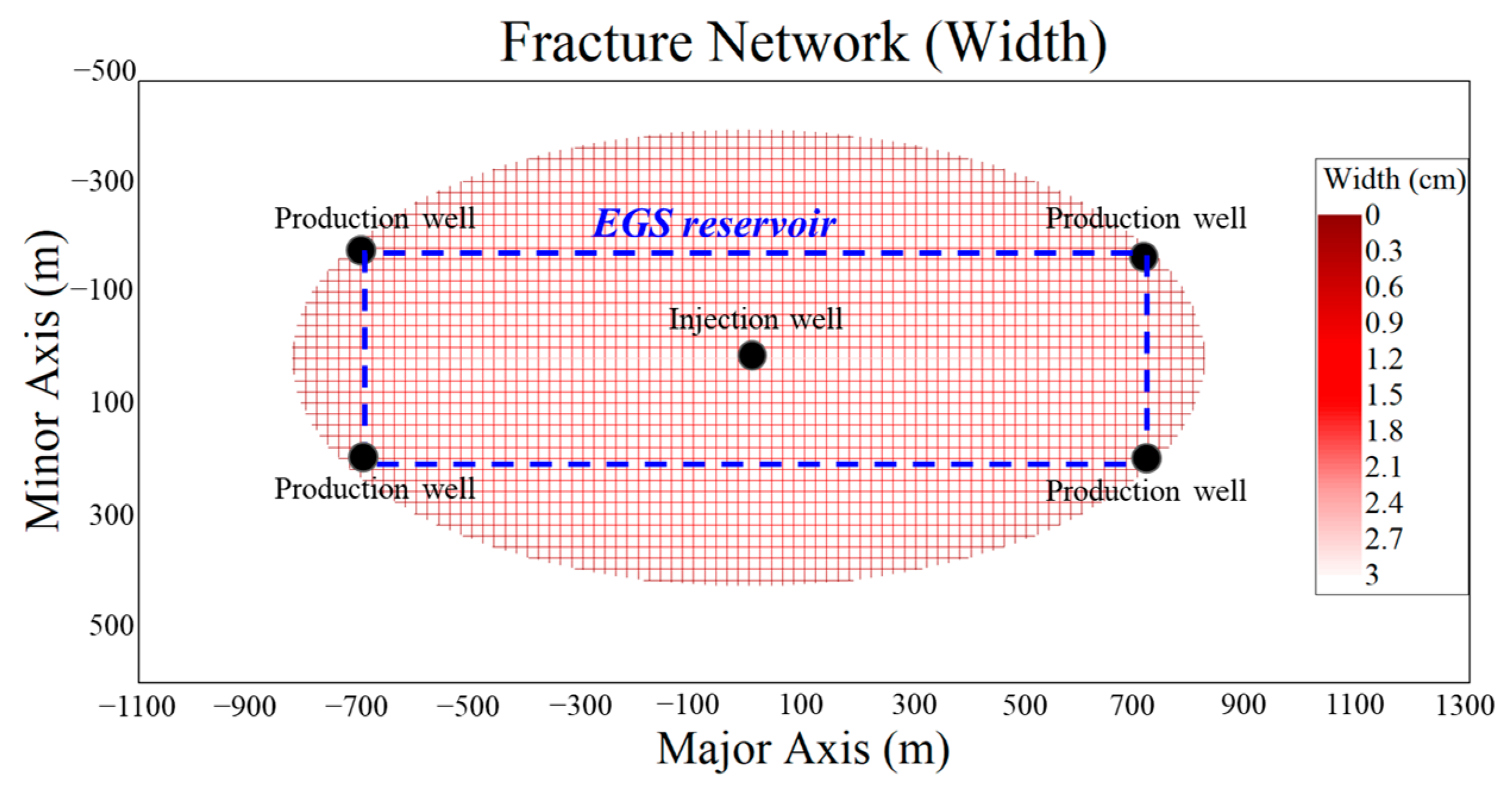

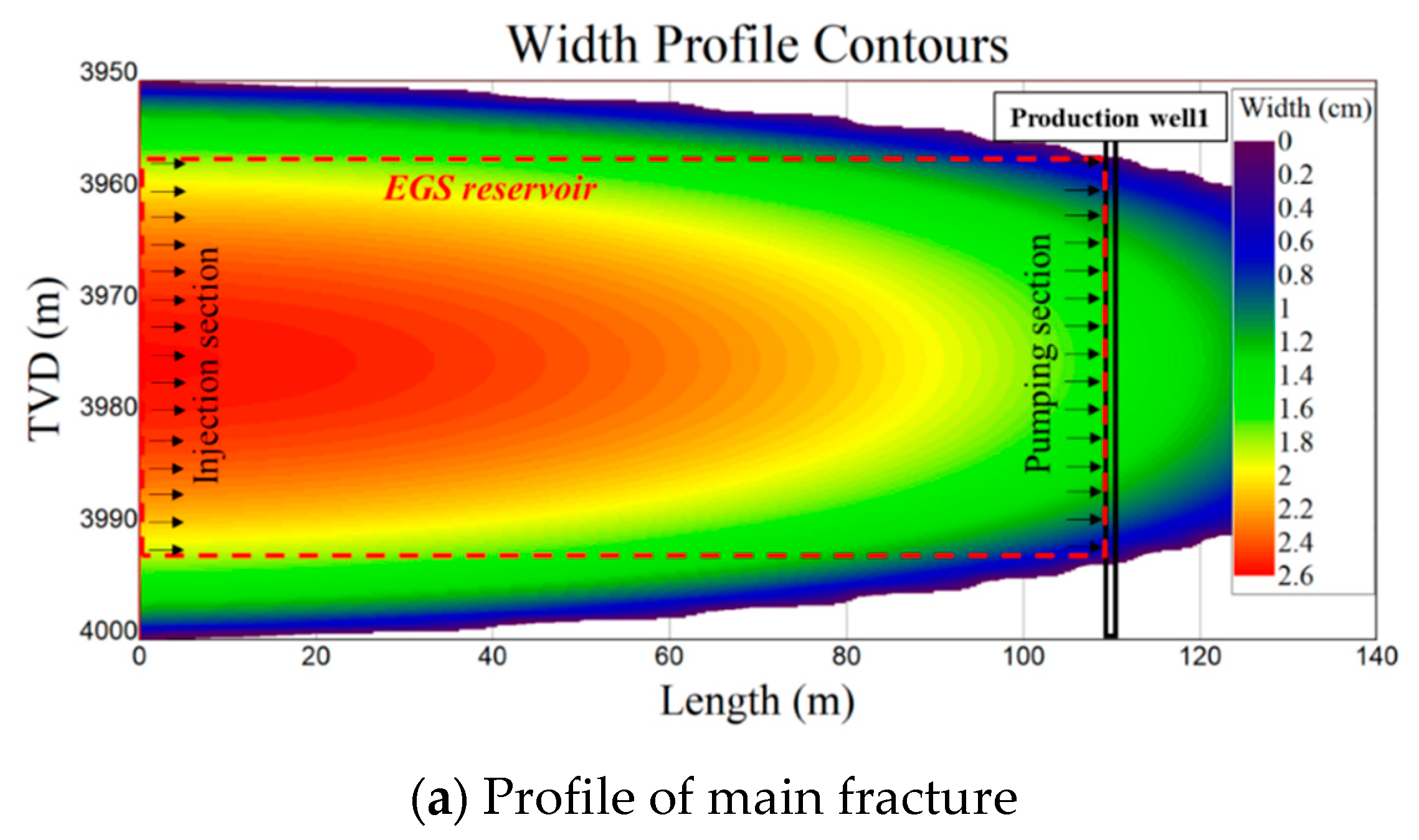

4.3. Stimulated Reservoir and Well Pattern

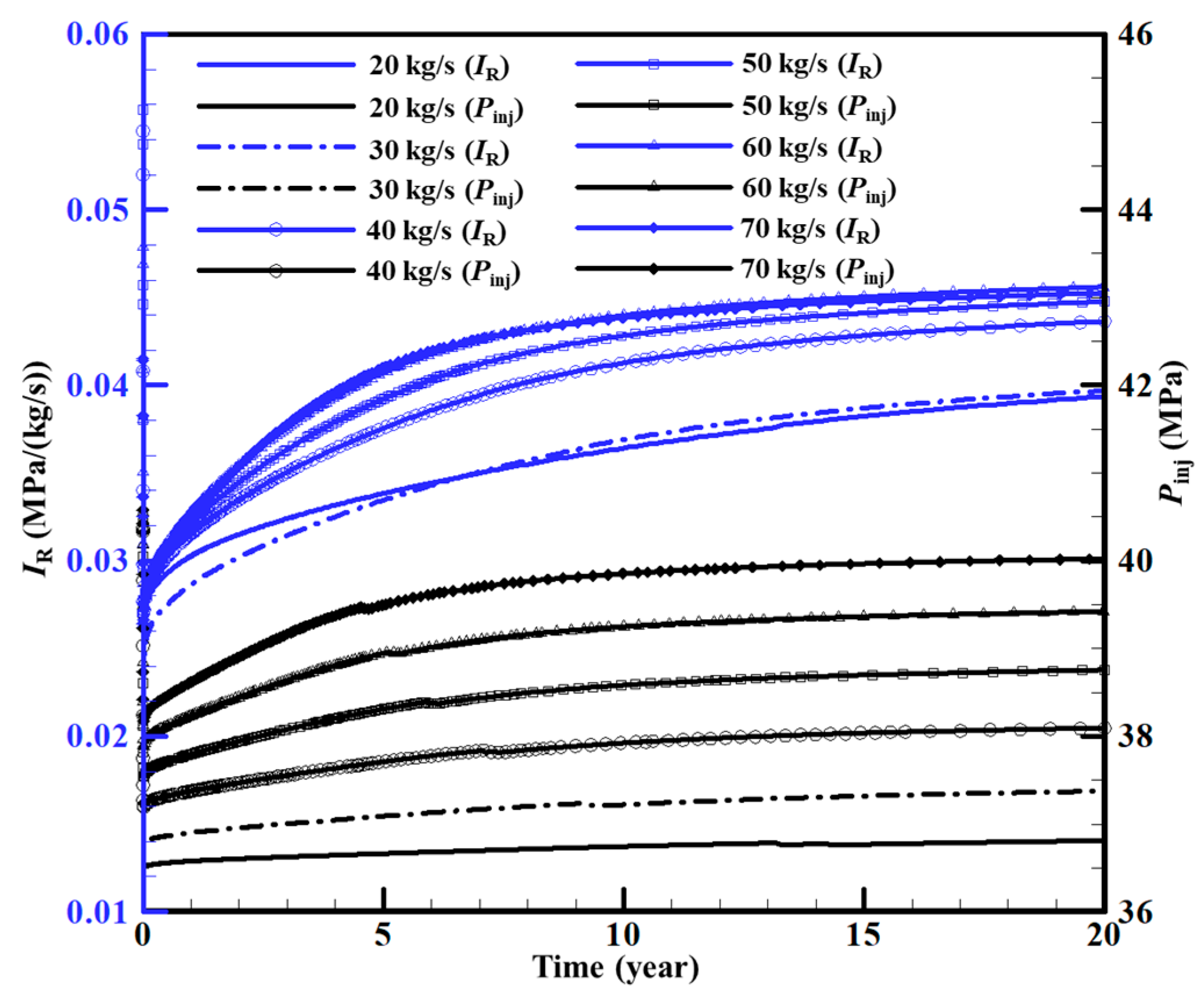

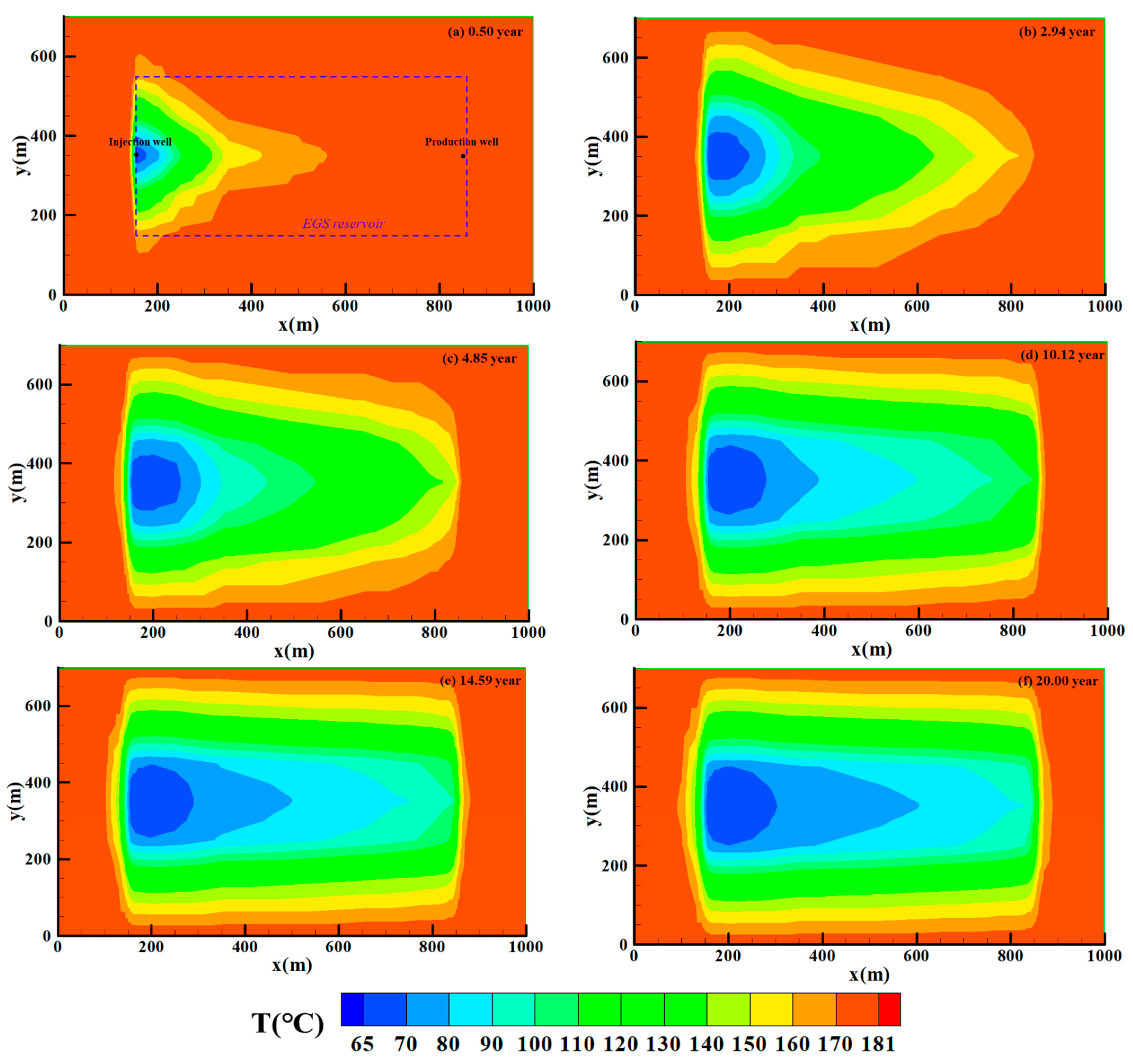

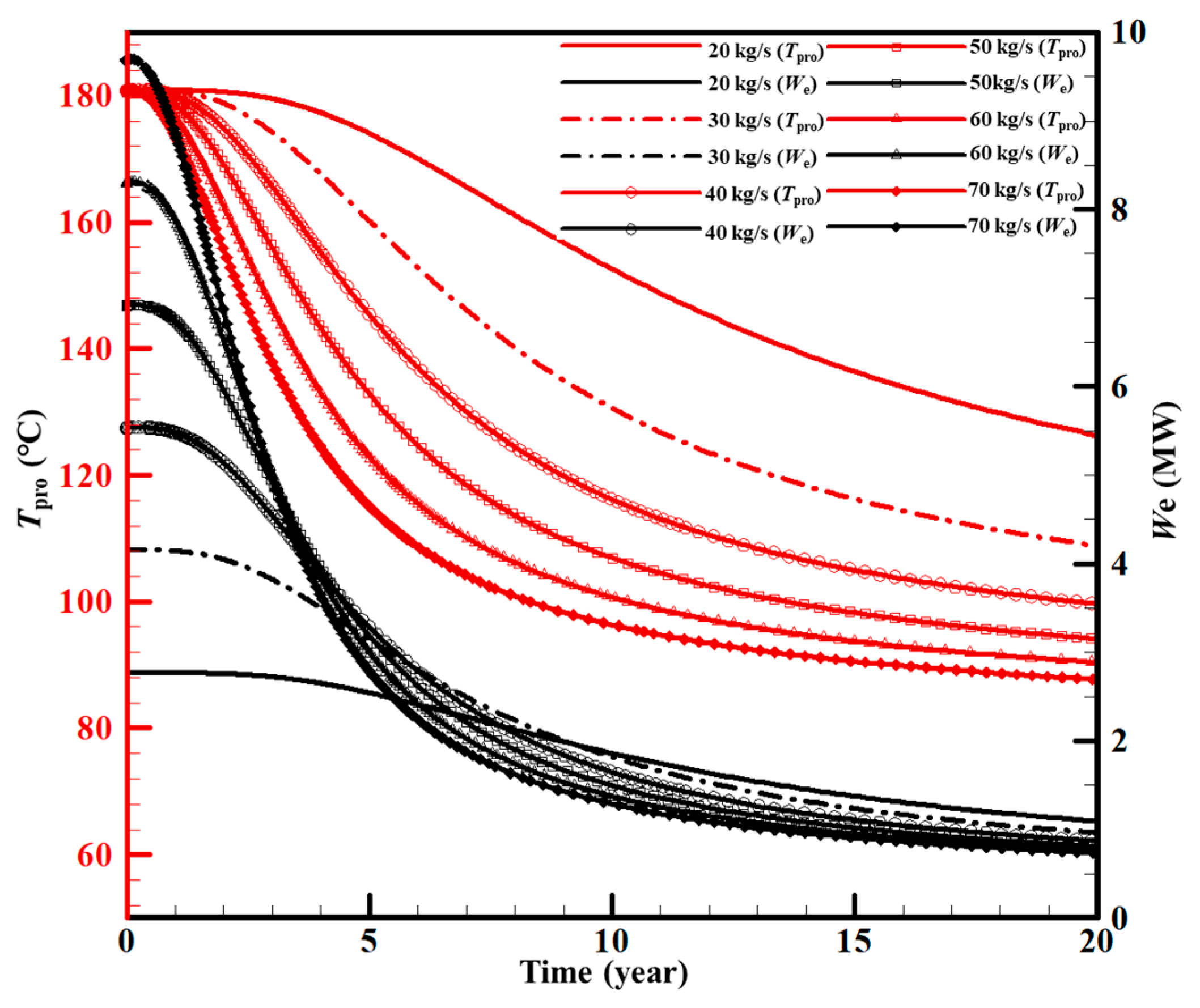

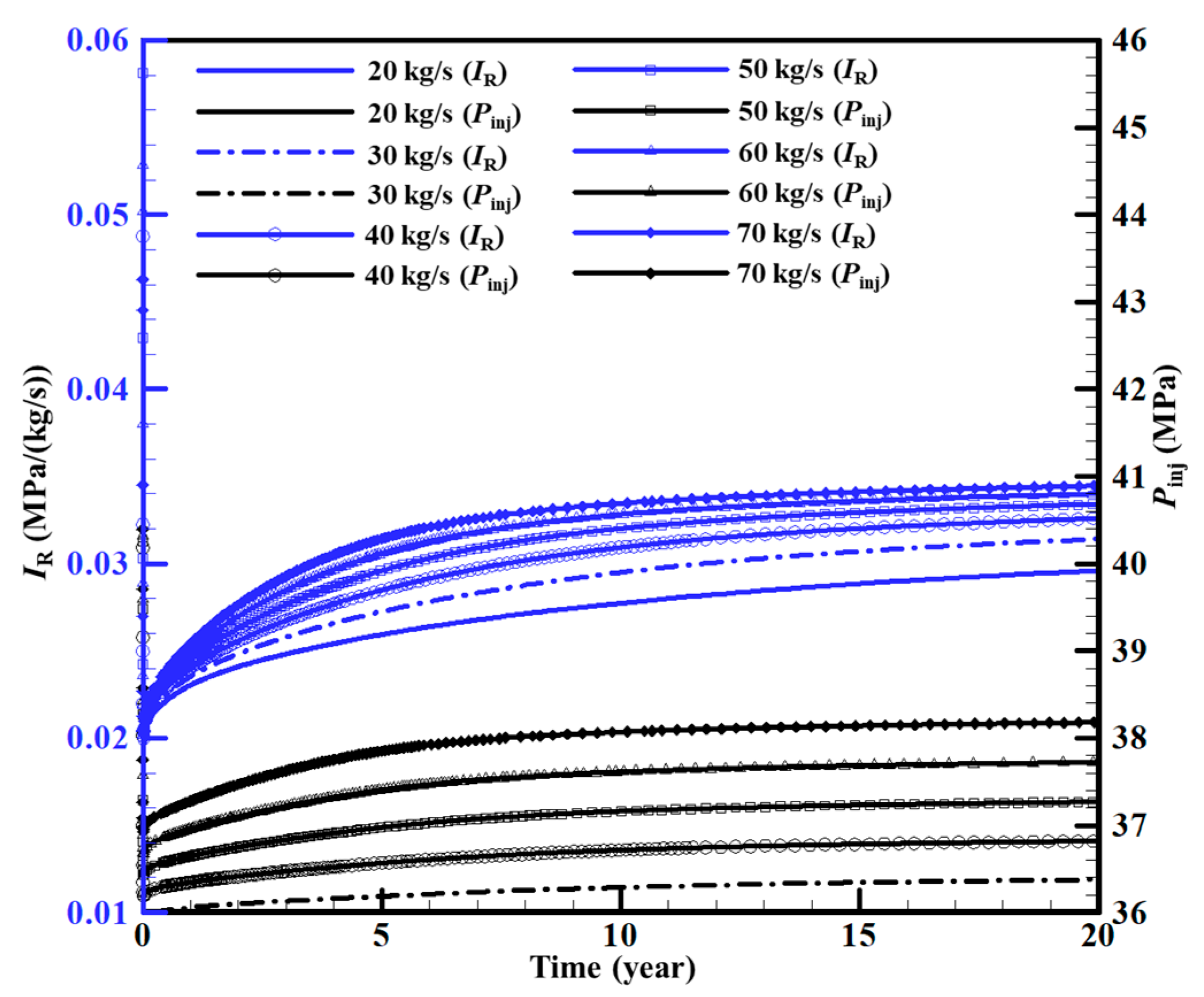

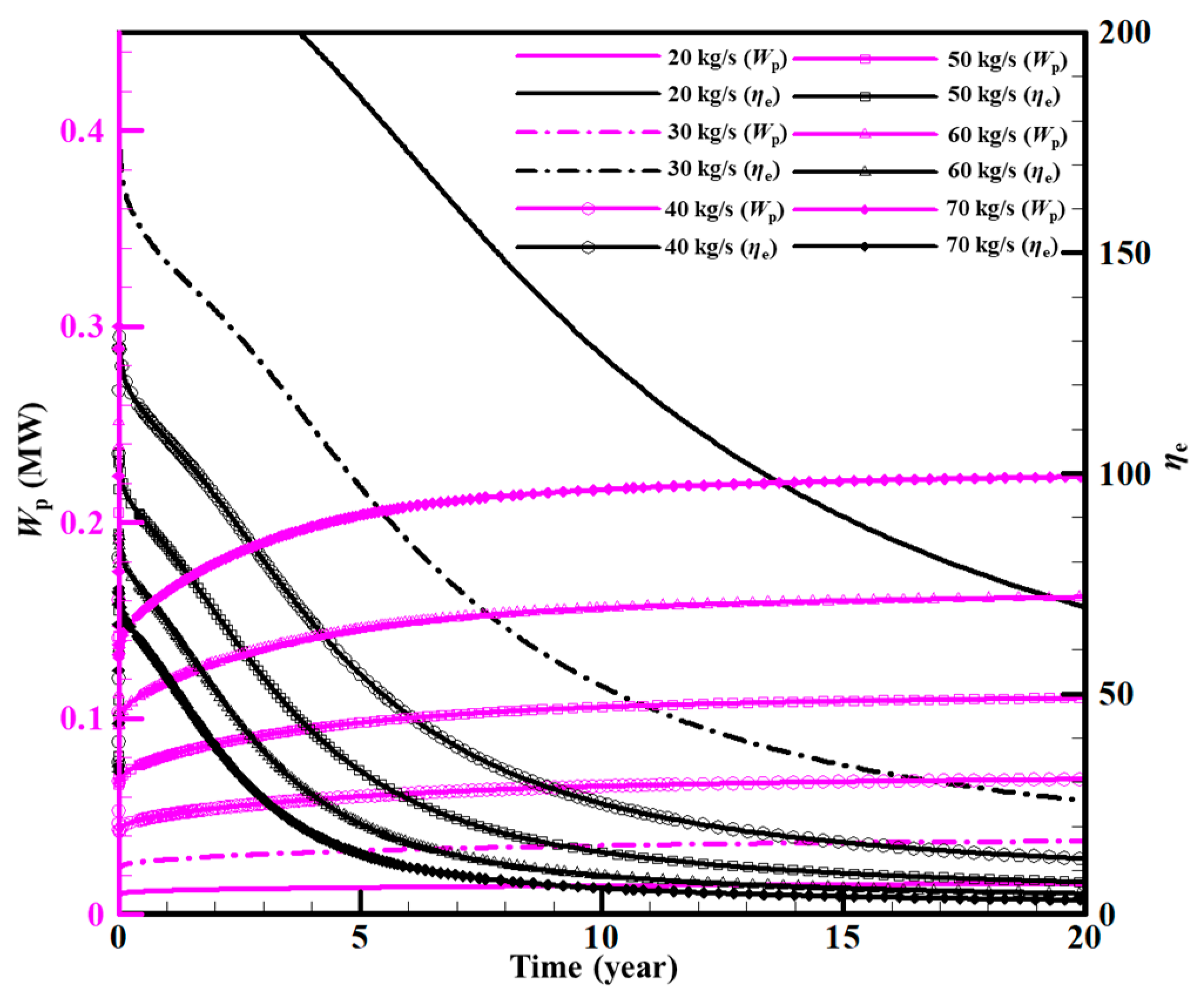

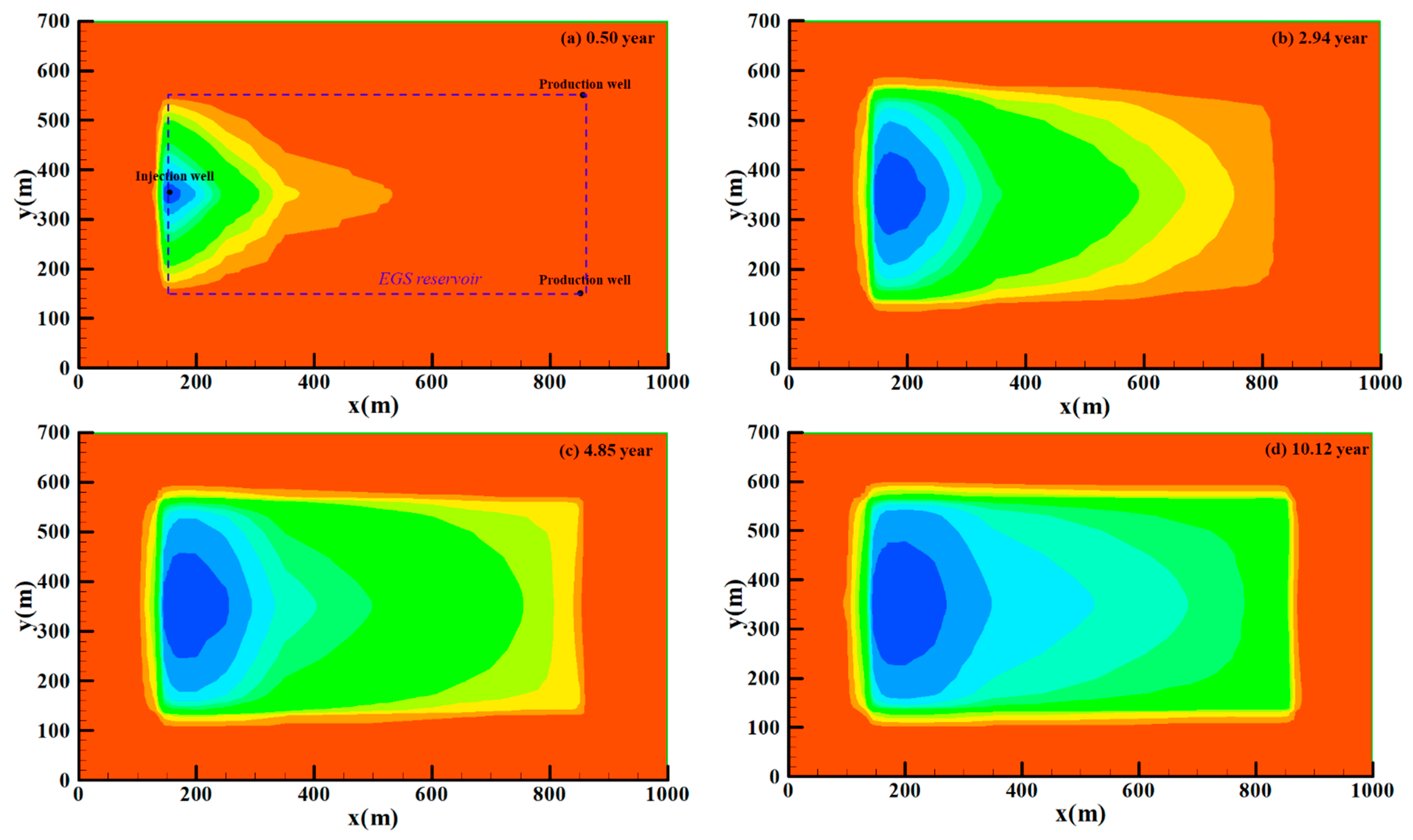

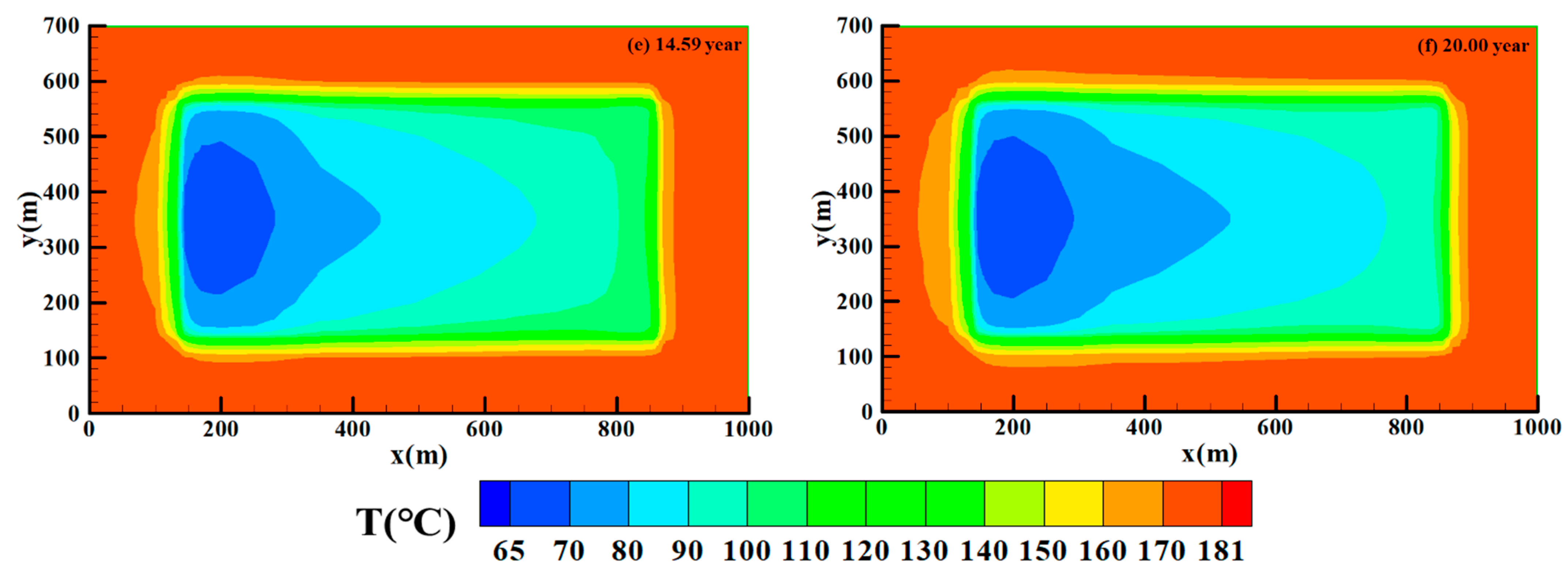

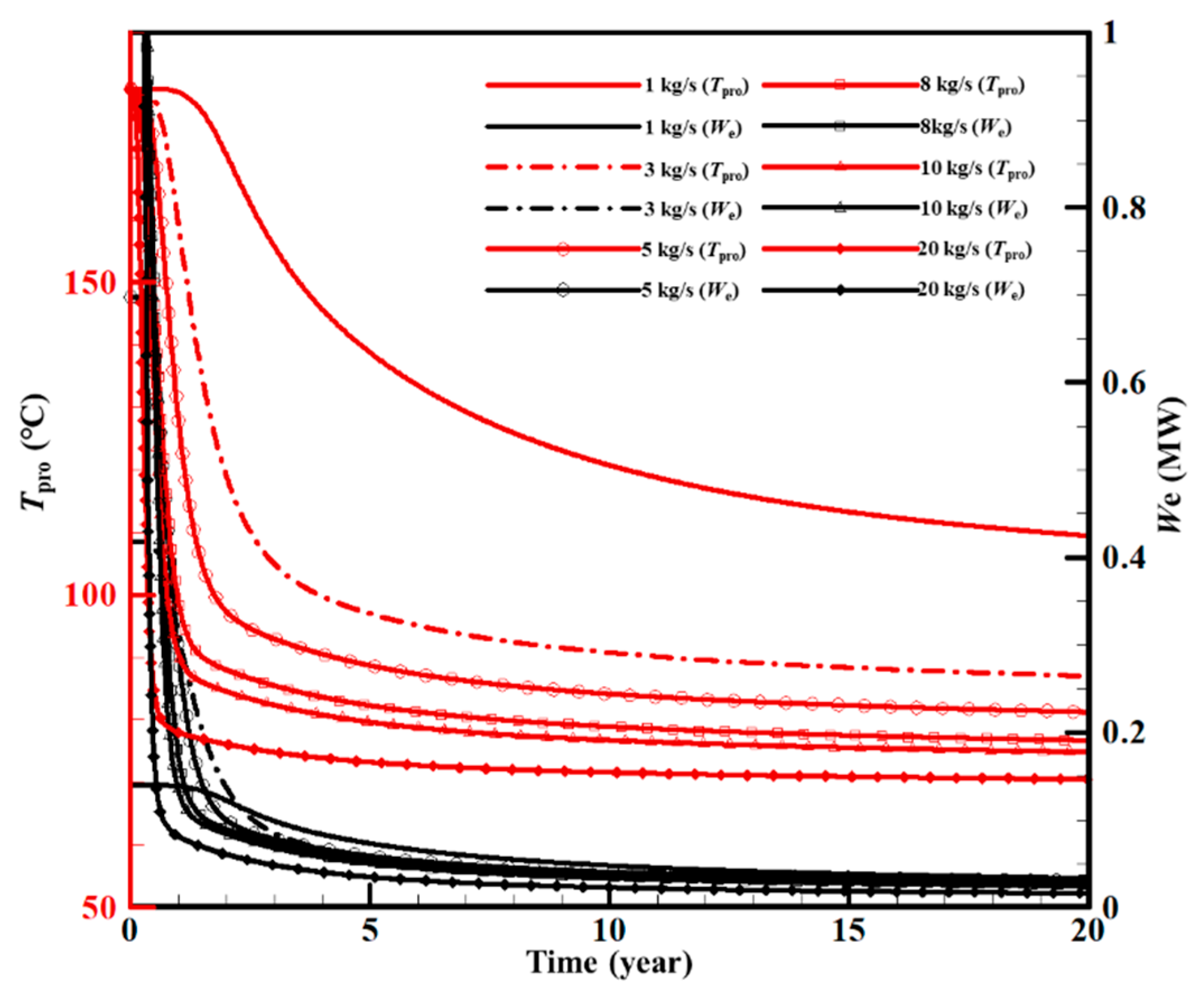

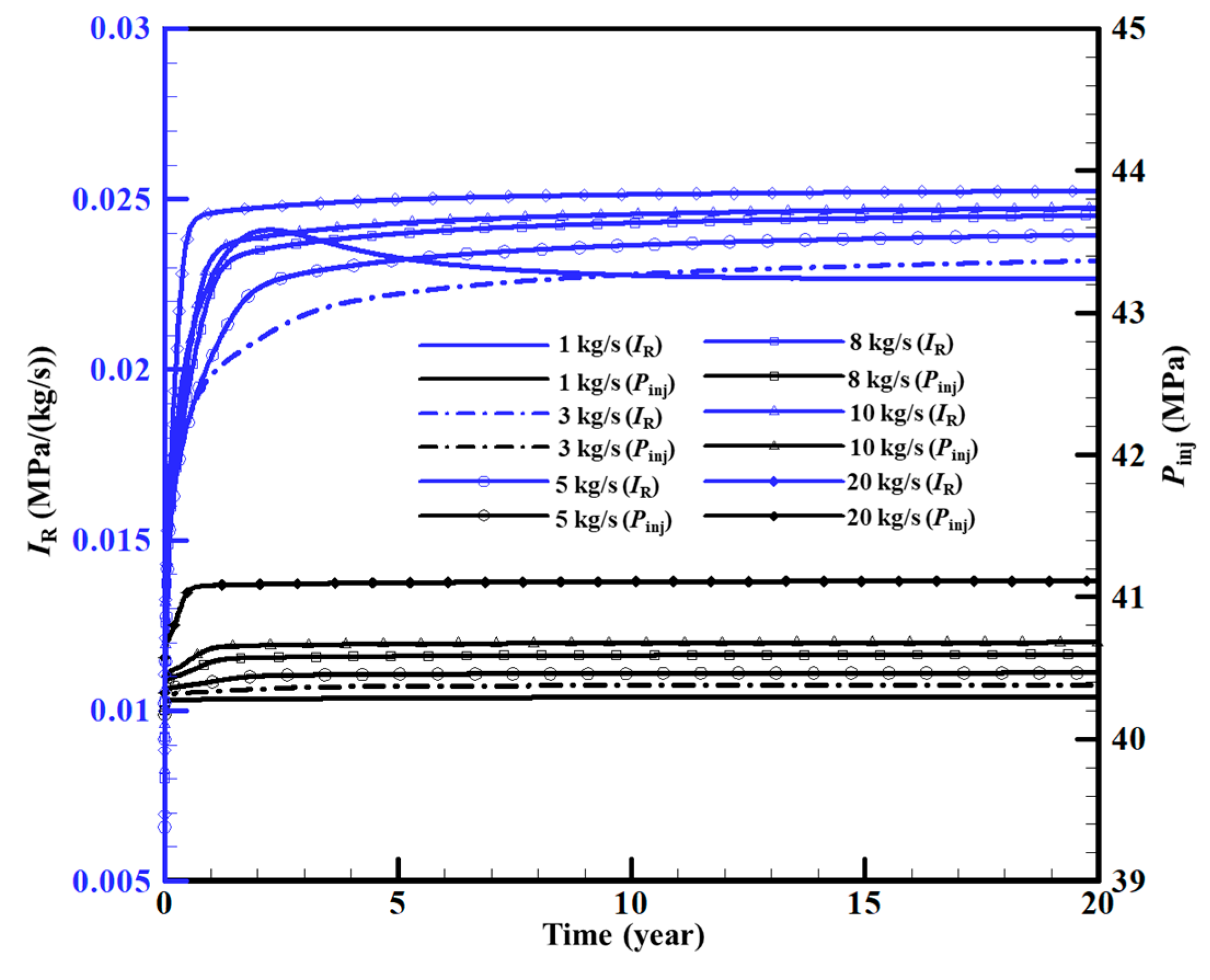

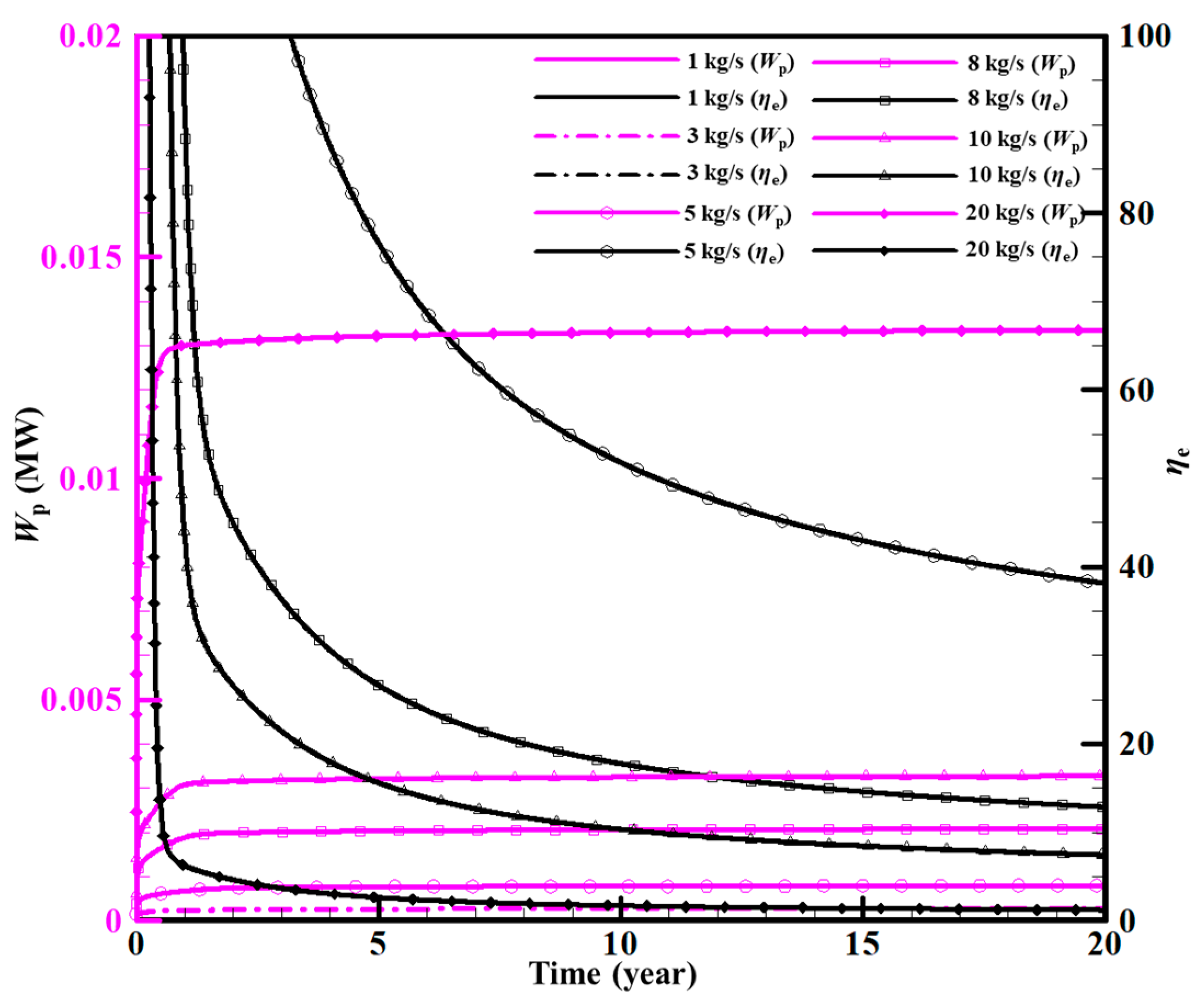

4.4. Heat Production Performance

5. Discussions

5.1. Influence of Well Pattern on Production Performance

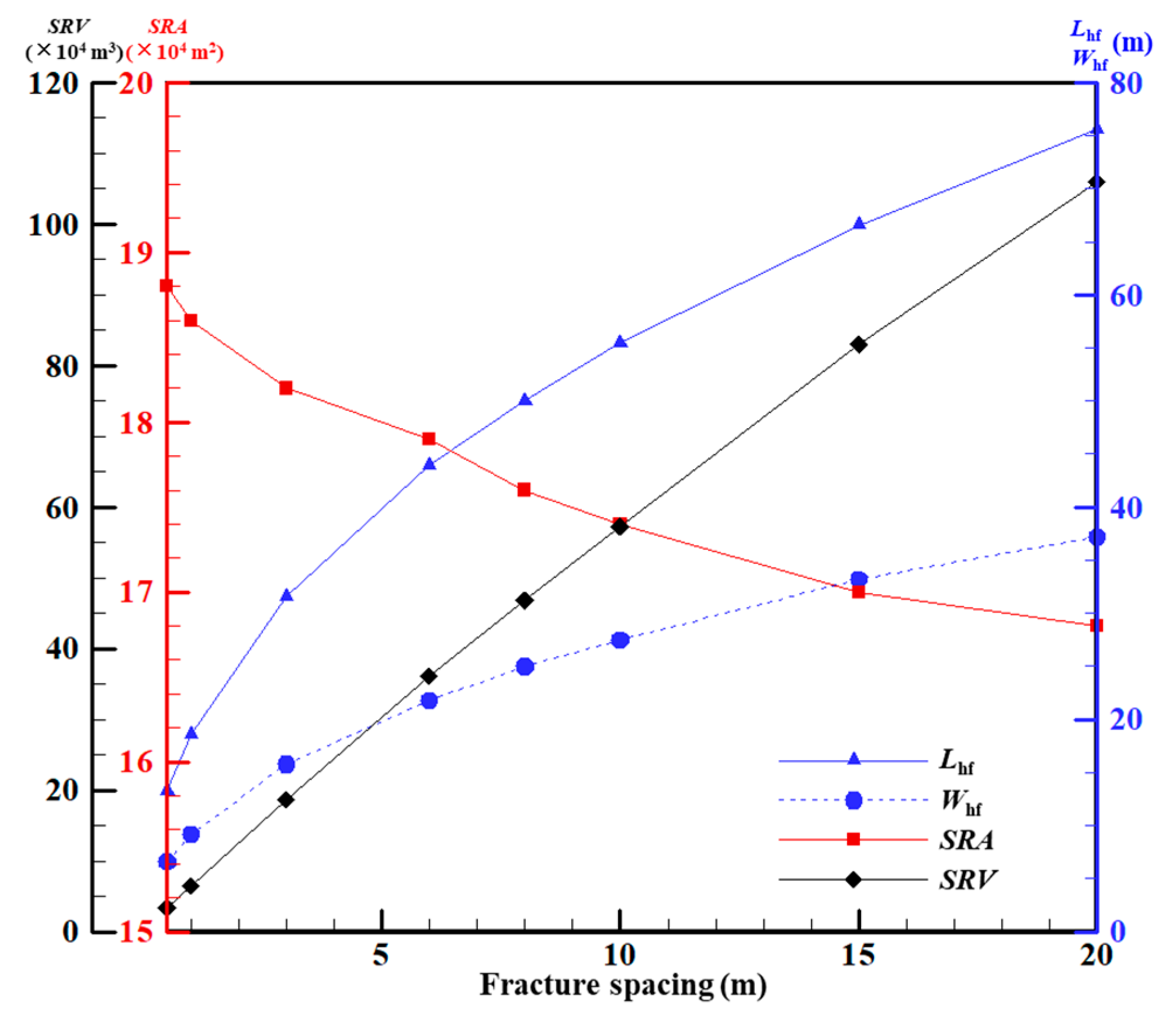

5.2. Influence of Fracture Spacing on Production Performance

5.3. Recommendations for EGS Operation

6. Conclusions

- (1)

- For Wendeng geothermal field, the average geothermal gradient is 36.8 °C/km between 0 m and 3000 m. It can be seen that the temperature of the super-thick shallow granite reservoir in Wendeng geothermal field is not as high as the ideal, and the temperature change of shallow strata is almost linear. The reason is that the lithology is uniform and there is no insulating cap layer to keep in the heat. The high thermal conductivity of granite rocks radiates heat from below into the atmosphere. The deep geothermal gradient greatly decreases because it is controlled by tectonic faults and belongs to a convective geothermal zone. Therefore, when choosing shallow high-temperature HDR reservoirs in such super-thick granite areas, attention should be paid to avoiding deep water-filled faults.

- (2)

- Wendeng geothermal field has high horizontal tectonic stress, which is conducive to forming a horizontal EGS reservoir after stimulation. The well-logging results show that there are also multiple fracture zones in the super-thick granite strata and the formation fracture ratio varies greatly at different depths. The selection of a target EGS reservoir should consider the influence of fracture spacing.

- (3)

- For naturally fractured formations with stress shielding, large well spacings should be maintained and reservoirs with overdeveloped natural fractures should not be selected. For the same created reservoir, the production performance of five-spot and triplet-well modes of production is different. The variation trends of each production indicator of the two modes are very similar, but the indicator value is different. The pressure indicator is more sensitive to the choice of well-layout mode than the temperature indicator. For the same reservoir, the power generation of the five-spot well mode is slightly improved over that of the triplet-well mode.

- (4)

- When selecting the target reservoir, formations with high temperatures, moderate natural fractures and high I -situ stress shielding are preferable. On this basis, a large volume of fracturing fluids should be injected to stimulate the reservoir, making the reservoir length as large as possible. If the desired large-scale reservoir is created, the five-point well mode is preferable.

- (5)

- For the potential target reservoir at depth of 4000 m in the Wendeng geothermal field, the optimal scenario for an EGS reservoir is Case 2. With the five-spot well mode, and a maximum injection rate between 60 kg/s and 80 kg/s, the power generation over a 20-year period is 8.32 MW~1.92 MW or 11.08 MW~1.74 MW, and the energy efficiency ranged from 176.5 to 25.8 or from 131.0 to 12.6. It can be seen that the Wendeng geothermal field also has an HDR-resource development potential after reasonable screening of target reservoirs and good targeted fracturing and thermal extraction design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tester, J.W.; Livesay, B.; Anderson, B.J.; Moore, M.C.; Bathchelor, A.S.; Nichols, K.; Petty, S.; Toksӧz, M.N.; Veatch, R.W. The Future of Geothermal Energy: Impact of Enhanced Geothermal Systems (EGS) on the United States in the 21st Century; An Assessment by an MIT-Led Interdisciplinary Panel; Massachusetts Institute of Technology: Cambridge, MA, USA, 2006. [Google Scholar]

- Zhao, Y.; Shu, L.F.; Chen, S.Y.; Zhao, J.; Guo, L.L. Optimization Design of Multi-Factor Combination for Power Generation from an Enhanced Geothermal System by Sensitivity Analysis and Orthogonal Test at Qiabuqia Geothermal Area. Sustainability 2022, 14, 7001. [Google Scholar] [CrossRef]

- Pollack, A.; Horne, R.; Mukerji, T. What are the challenges in developing enhanced geothermal systems (EGS)? Observations from 64 EGS sites. In Proceedings of the World Geothermal Congress, Reykjavik, Iceland, 1 April–1 October 2020; Volume 1. [Google Scholar]

- Zhang, Y.; Zhang, Y.J.; Zhou, L.; Lei, Z.H.; Guo, L.L.; Zhou, J. Reservoir stimulation design and evaluation of heat exploitation of a two-horizontal-well enhanced geothermal system (EGS) in the Zhacang geothermal field, Northwest China. Renew. Energy 2022, 183, 330–350. [Google Scholar] [CrossRef]

- Hofmann, H.; Babadagli, T.; Zimmermann, G. Hot water generation for oil sands processing from enhanced geothermal systems: Process simulation for different hydraulic fracturing scenarios. Appl. Energy 2014, 113, 524–547. [Google Scholar] [CrossRef]

- Lei, Z.H.; Zhang, Y.J.; Hu, Z.J.; Li, L.Z.; Zhang, S.Q.; Fu, L.; Yue, G.F. Application of Water Fracturing in Geothermal Energy Mining: Insights from Experimental Investigations. Energies 2019, 12, 2138. [Google Scholar] [CrossRef]

- Akdas, S.B.; Onur, M. Analytical solutions for predicting and optimizing geothermal energy extraction from an enhanced geothermal system with a multiple hydraulically fractured horizontal-well doublet. Renew. Energy 2022, 181, 567–580. [Google Scholar] [CrossRef]

- Zeng, Y.C.; Su, Z.; Wu, N.Y. Numerical simulation of heat production potential from hot dry rock by water circulating through two horizontal wells at Desert Peak geothermal field. Energy 2013, 10, 92–107. [Google Scholar] [CrossRef]

- Willis-Richards, J.; Wallroth, T. Approaches to the modeling of HDR reservoirs: A review. Geothermics 1995, 24, 307–332. [Google Scholar] [CrossRef]

- Hayashi, K.; Willis-Richards, J.; Hopkirk, R.J.; Niibori, Y. Numerical models of HDR geothermal reservoirs- a review of current thinking and progress. Geothermics 1999, 28, 507–518. [Google Scholar] [CrossRef]

- Wu, Y.S. The effective continuum method for modeling multiphase flow, multicomponent transport and heat transfer in fractured rock. In Dynamics of Fluids in Fractured Rock; Geophysical monograph 122; American Geophysical Union: Washington, DC, USA, 2000; pp. 299–312. [Google Scholar]

- Gelet, R.; Loret, B.; Khalili, N. A thermal-hydro-mechanical coupled model in local thermal non-equilibrium for fractured HDR reservoir with double porosity. J. Geophys. Res. 2012, 117, 1–23. [Google Scholar] [CrossRef]

- Mcdermott, C.I.; Randriamanjatosoa, A.R.; Tenzer, H.; Kolditz, O. Simulation of heat extraction from crystalline rocks: The influence of coupled processes on differential reservoir cooling. Geothermics 2006, 35, 321–344. [Google Scholar] [CrossRef]

- Suzuki, A.; Fomin, S.A.; Chugunov, V.A.; Niibori, Y.; Hashida, T. Fractional diffusion modeling of heat transfer in porous and fractured media. Int. J. Heat Mass Transf. 2016, 103, 611–618. [Google Scholar] [CrossRef]

- Patterson, J.R.; Cardiff, M.; Feigl, K.L. Optimizing geothermal production in fractured rock reservoirs under uncertainty. Geothermics 2020, 88, 101–906. [Google Scholar] [CrossRef]

- Cheng, W.L.; Wang, C.L.; Nian, Y.L.; Han, B.B.; Liu, J. Analysis of influencing factors of heat extraction from enhanced geo-thermal systems considering water losses. Energy 2016, 115, 274–288. [Google Scholar] [CrossRef]

- Shaik, A.R.; Rahman, S.S.; Tran, N.H.; Tran, T. Numerical simulation of Fluid-Rock coupling heat transfer in naturally fractured geothermal system. Appl. Therm. Eng. 2011, 31, 1600–1606. [Google Scholar] [CrossRef]

- Yuan, Y.L.; Xu, T.F.; Jiang, Z.J.; Feng, B. Prospects of power generation from the deep fractured geothermal reservoir using a novel vertical well system in the Yangbajing geothermal field, China. Energy Rep. 2021, 7, 4733–4746. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, X.; Sun, Z.; Huang, Z.; Liu, J.; Li, Y.; Xin, Y.; Yan, X.; Liu, W. Numerical simulation of the heat extraction in 3D-EGS with thermal-hydraulic-mechanical coupling method based on discrete fractures model. Geothermics 2018, 74, 19–34. [Google Scholar] [CrossRef]

- Yu, L.K.; Wu, X.T.; Hassan, N.S.; Wang, Y.D.; Ma, W.W.; Liu, G. Modified zipper fracturing in enhance d geothermal system reservoir and analyzed heat extraction optimization via orthogonal design. Renew. Energy 2020, 161, 373–385. [Google Scholar] [CrossRef]

- Jiang, H.Y.; Wang, S.X.; Kang, F.X.; Shi, M.; Fan, Z.H.; Zhang, L. Geological characteristics and resource potential of dry-hot pore ZKCW01 in Wendeng, Shandong province. Acta Geol. Sin. 2019, 93, 217–225. (In Chinese) [Google Scholar]

- Liu, C.H.; Sun, J.G.; Zheng, C.Q. Geochemical features and genesis of the Wendeng adamellitic rockbody, eastern Shandong province. Jilin Geol. 1995, 14, 51–58. (In Chinese) [Google Scholar]

- Meyer & Associates. Mayer Fracturing Simulators User’s Guide; Unicode Inc.: San Francisco, CA, USA, 2011. [Google Scholar]

- Lei, Z.H.; Zhang, Y.J.; Zhang, S.Q.; Fu, L.; Hu, Z.J.; Yu, Z.W. Electricity generation from a three-horizontal-well enhanced geothermal system in the Qiabuqia geothermal field, China: Slickwater fracturing treatments for different reservoir scenarios. Renew. Energy 2020, 145, 65–83. [Google Scholar] [CrossRef]

- Zeng, Q.D.; Yao, J. Numerical simulation of fracture network generation in naturally fractured reservoirs. J. Nat. Gas Sci. Eng. 2016, 30, 430–443. [Google Scholar] [CrossRef]

- Hu, X.C.; Banks, J.; Guo, Y.T.; Liu, W.V. Utilizing geothermal energy from enhanced geothermal systems as a heat source for oil sands separation: A numerical evaluation. Energy 2022, 238, 121676. [Google Scholar] [CrossRef]

- Zoback, M.D. Reservoir Geomechanics, 1st ed.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; p. 464. [Google Scholar]

- Dezayes, C.; Genter, A.; Valley, B. Structure of the low permeable naturally fractured geothermal reservoir at Soultz. Comptes Rendus Geosci. 2010, 342, 517–530. [Google Scholar] [CrossRef]

- Yoo, H.; Park, S.; Xie, L.; Kim, K.L.; Min, K.B.; Rutqvist, J.; Rinaldi, A.P. Hydro-mechanical modeling of the first and second hydraulic stimulations in a fractured geothermal reservoir in Pohang, South Korea. Geothermics 2021, 89, 101982. [Google Scholar] [CrossRef]

- Pruess, K.; Oldenburg, C.; Moridis, G. TOUGH2 User’s Guide, Version 2.0; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 1999.

- Warren, J.E.; Root, P.J. The Behavior of Naturally Fractured Reservoirs. Soc. Pet. Eng. 1963, 3, 245–255. [Google Scholar] [CrossRef]

- Garg, S.K.; Combs, J. A reformulation of USGS volumetric “heat in place” resource heat in place” resource estimation method. Geothermics 2015, 55, 150–158. [Google Scholar] [CrossRef]

- Hou, F.L. Critical under-ground stress of disked rock cores and the relation between the thickness of rock disk and under-ground stress. J. Wuhan Inst. Hydraul. Electr. Power 1985, 1, 37–48. (In Chinese) [Google Scholar]

- Ding, J.M.; Liang, G.P.; Guo, Q.L. Stress measurements in deep borehole along bohai coastal area in Shandong province-determination of the magnitude of principal stress. J. Seismol. (In Chinese). 1986, 5, 1–8. [Google Scholar]

- Mahmoodpour, S.; Singh, M.; Bär, K.; Sass, I. Impact of Well Placement in the Fractured Geothermal Reservoirs Based on Available Discrete Fractured System. Geosciences 2022, 12, 19. [Google Scholar] [CrossRef]

- Mahmoodpour, S.; Singh, M.; Turan, A.; Bär, K.; Sass, I. Hydro-Thermal Modeling for Geothermal Energy Extraction from Soultz-sous-Forêts, France. Geosciences 2021, 11, 464. [Google Scholar] [CrossRef]

| Parameters | Type | Values |

|---|---|---|

| Stress state | Shielding | Stress difference is 10 MPa Shielding thickness is 50 m |

| Mechanical parameters | Elastic modulus | 70 GPa |

| Poisson’s ratio | 0.16 | |

| Fracture toughness | 1.5 MPa·m1/2 | |

| Critical stress | 24 MPa | |

| Operation parameters | Pump rate | 16 m3/min |

| Injection volume | 50,000 m3 | |

| DFN | Fracture spacing | 20 m |

| Mesh Number | Production Temperature (°C) |

|---|---|

| 3300 | 121.3 |

| 6600 | 120.4 |

| 7850 | 119.9 |

| 8420 | 119.8 |

| 9250 | 119.8 |

| Items | Value |

|---|---|

| Matrix density | 2650 kg/m3 |

| Matrix porosity | 2% |

| Matrix permeability | 1 × 10−17 m2 |

| Fracture permeability | 0.21 × 10−8 m2 |

| Fracture spacing | 20 m |

| Heat conductivity | 3.52 W/(m·K) |

| Specific heat | 850 J/(kg·K) |

| Initial pore pressure | P = 4 × 107 – 10,000z (Pa) |

| Injection water temperature | 65 °C |

| Injection water specific enthalpy | 305.80 kJ/kg |

| Initial reservoir temperature | 181 °C |

| Productivity index | 5.4 × 10−12 m3 |

| Production bottom-hole pressure | 35 MPa |

| No. | “Broken Cake” Location | Thickness (m) | Pictures |

|---|---|---|---|

| 1 | 2109.54 m~2264.17 m | 244.63 |  |

| 2 | 2342.74 m~2386.90 m | 44.16 |  |

| 3 | 2501.44 m~2551.19 m | 49.75 |  |

| 4 | 2615.06 m~2622.29 m | 7.23 |  |

| 5 | 2838.98 m~2872.51 m | 33.53 |  |

| Results | Values |

|---|---|

| Lhf | 822.4 m |

| Whf | 410.5 m |

| Hf | 50.0 m |

| SRA | 675.0 × 104 m2 |

| SRV | 4600 × 104 m3 |

| Results | Values |

|---|---|

| Lhf | 139.1 m |

| Whf | 68.3 m |

| Hf | 50.0 m |

| SRA | 700.0 × 104 m2 |

| SRV | 123 × 104 m3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Guo, L.; Kang, F.; Wang, F.; Cao, Y.; Sun, Z.; Shi, M. Geothermal Characteristics and Productivity Potential of a Super-Thick Shallow Granite-Type Enhanced Geothermal System: A Case Study in Wendeng Geothermal Field, China. Sustainability 2023, 15, 3551. https://doi.org/10.3390/su15043551

Jiang H, Guo L, Kang F, Wang F, Cao Y, Sun Z, Shi M. Geothermal Characteristics and Productivity Potential of a Super-Thick Shallow Granite-Type Enhanced Geothermal System: A Case Study in Wendeng Geothermal Field, China. Sustainability. 2023; 15(4):3551. https://doi.org/10.3390/su15043551

Chicago/Turabian StyleJiang, Haiyang, Liangliang Guo, Fengxin Kang, Fugang Wang, Yanling Cao, Zhe Sun, and Meng Shi. 2023. "Geothermal Characteristics and Productivity Potential of a Super-Thick Shallow Granite-Type Enhanced Geothermal System: A Case Study in Wendeng Geothermal Field, China" Sustainability 15, no. 4: 3551. https://doi.org/10.3390/su15043551

APA StyleJiang, H., Guo, L., Kang, F., Wang, F., Cao, Y., Sun, Z., & Shi, M. (2023). Geothermal Characteristics and Productivity Potential of a Super-Thick Shallow Granite-Type Enhanced Geothermal System: A Case Study in Wendeng Geothermal Field, China. Sustainability, 15(4), 3551. https://doi.org/10.3390/su15043551