Influence of Coarse Grain Content on the Mechanical Properties of Red Sandstone Soil

Abstract

:1. Introduction

2. Triaxial Shear Test

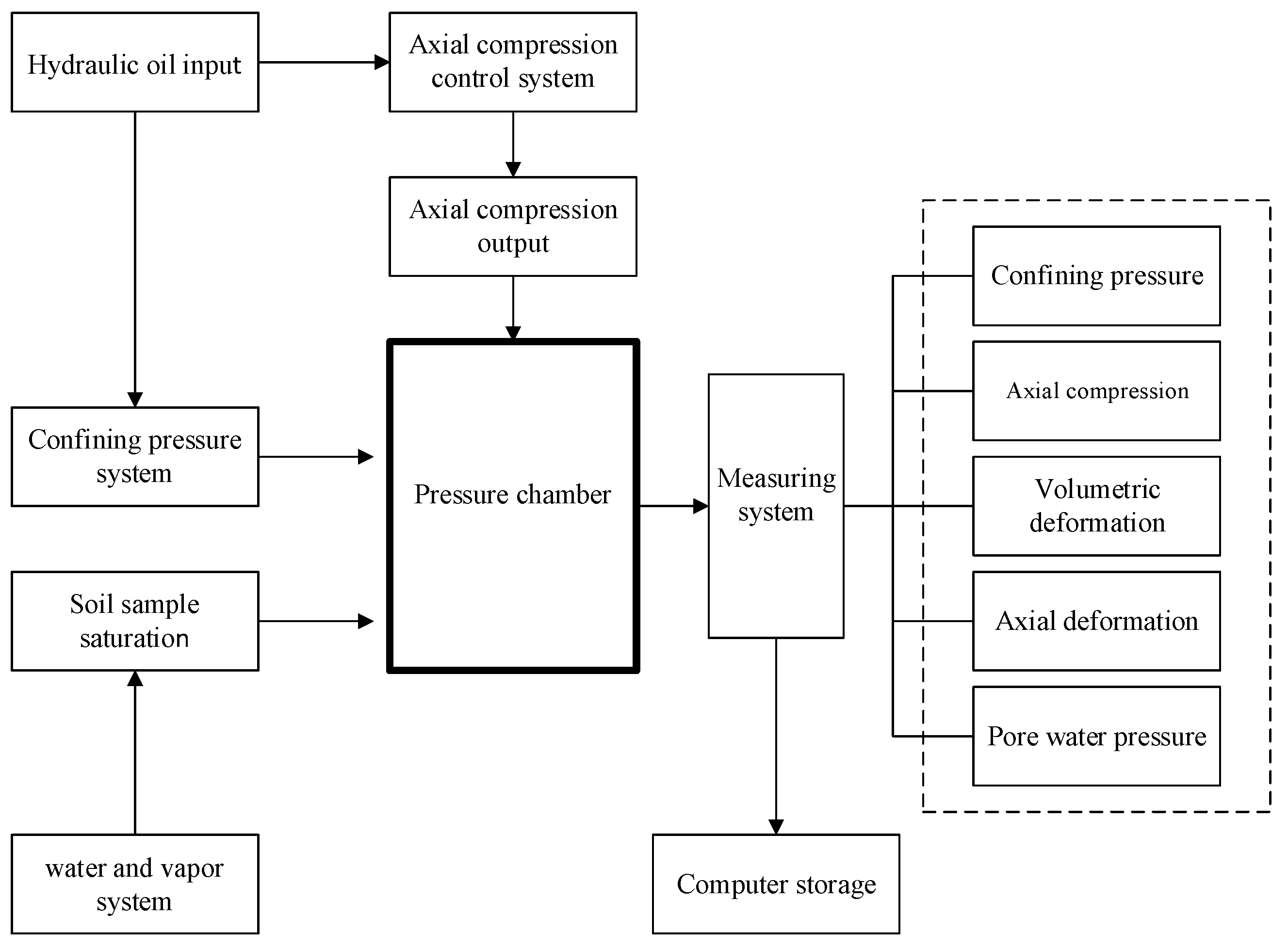

2.1. Test Instrument

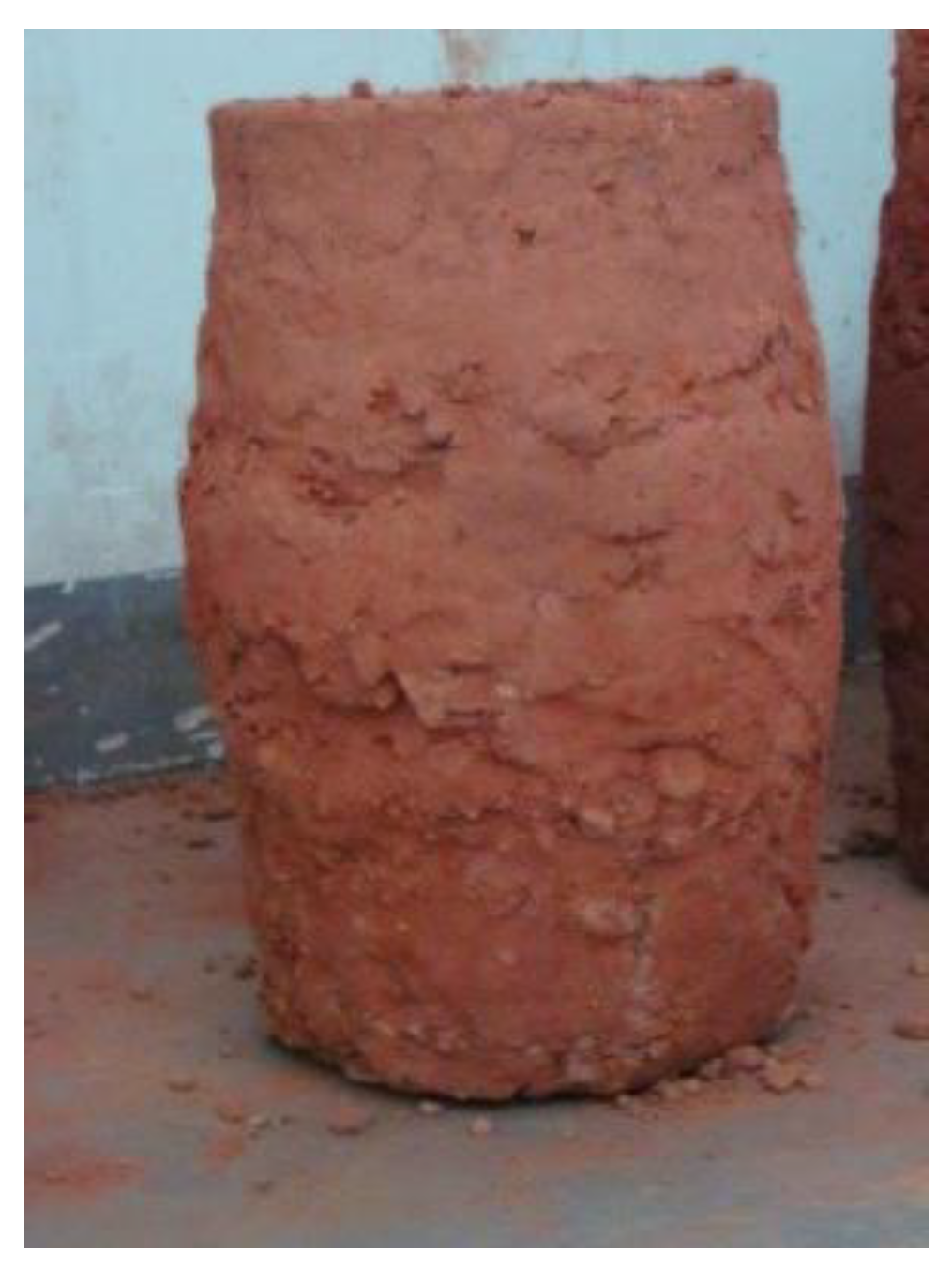

2.2. Sample Preparation

2.3. Test Loading Scheme

3. Test Results and Analysis

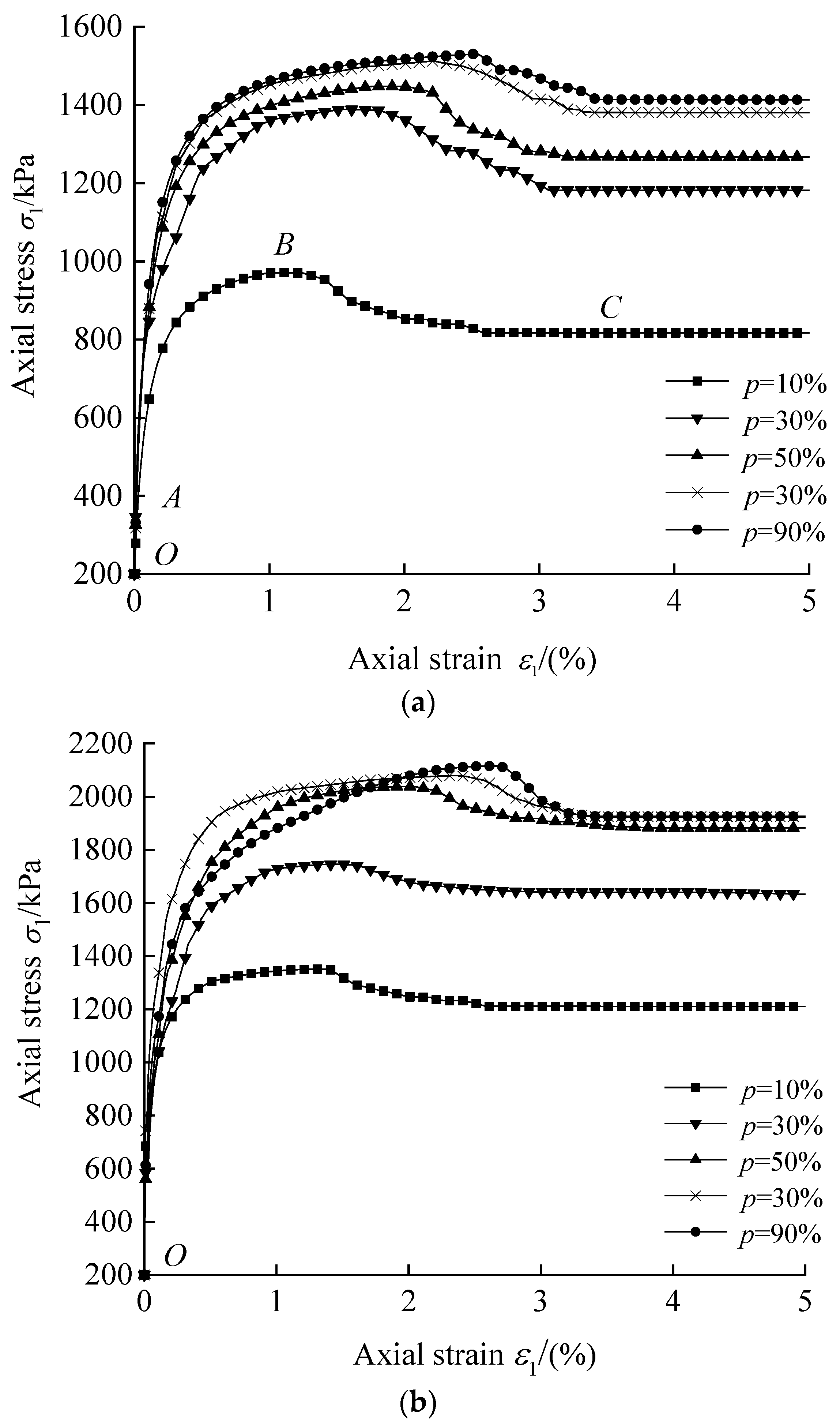

3.1. Stress–Strain Relationship Analysis of Coarse-Grained Soil

3.2. The Effect of Coarse Grain Content on the Deviation Stress of Static Failure

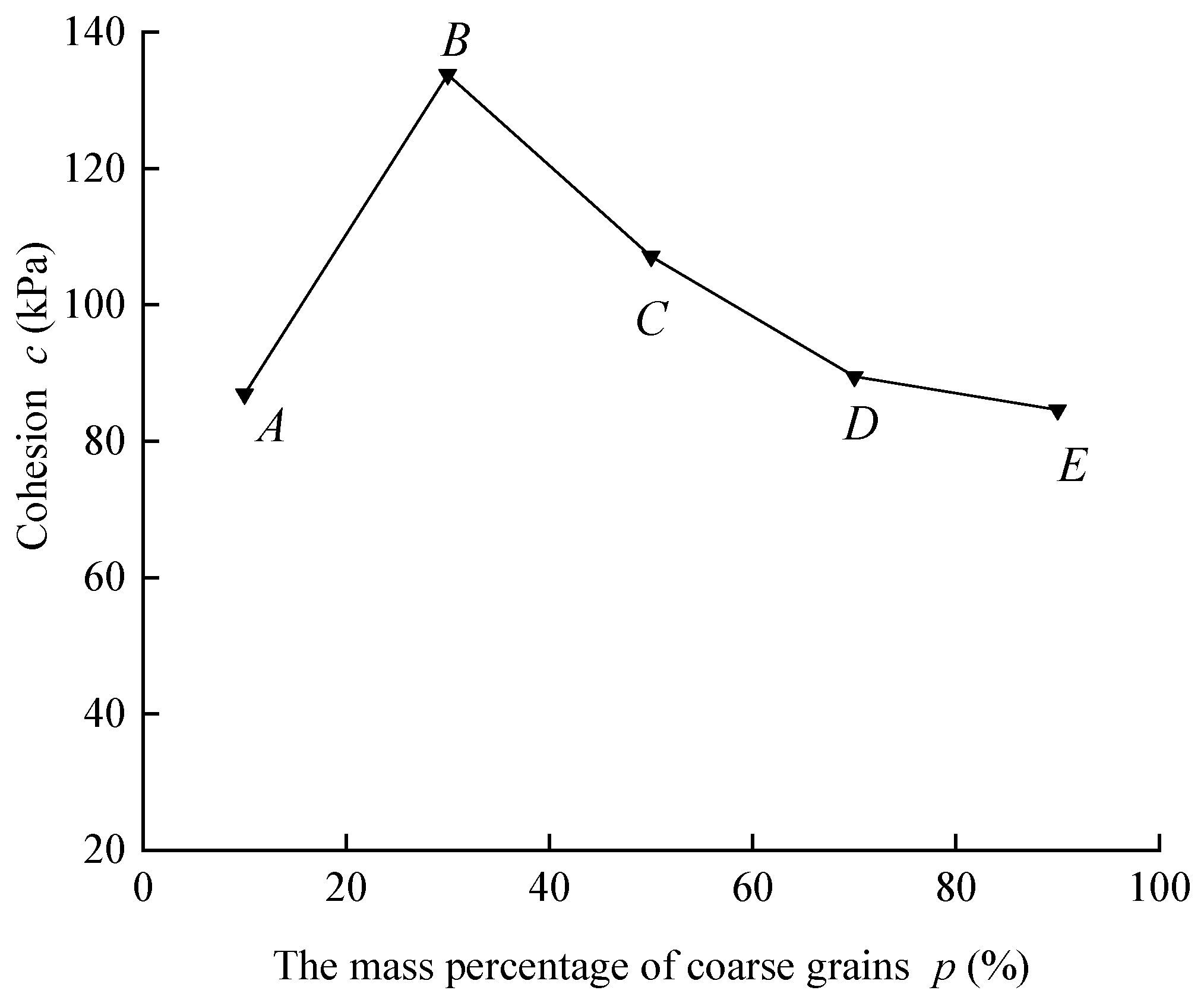

3.3. The Influence of Coarse Grain-Content on Cohesion and Internal Friction

3.4. The Influence of Coarse Grain Content on the Elastic Modulus

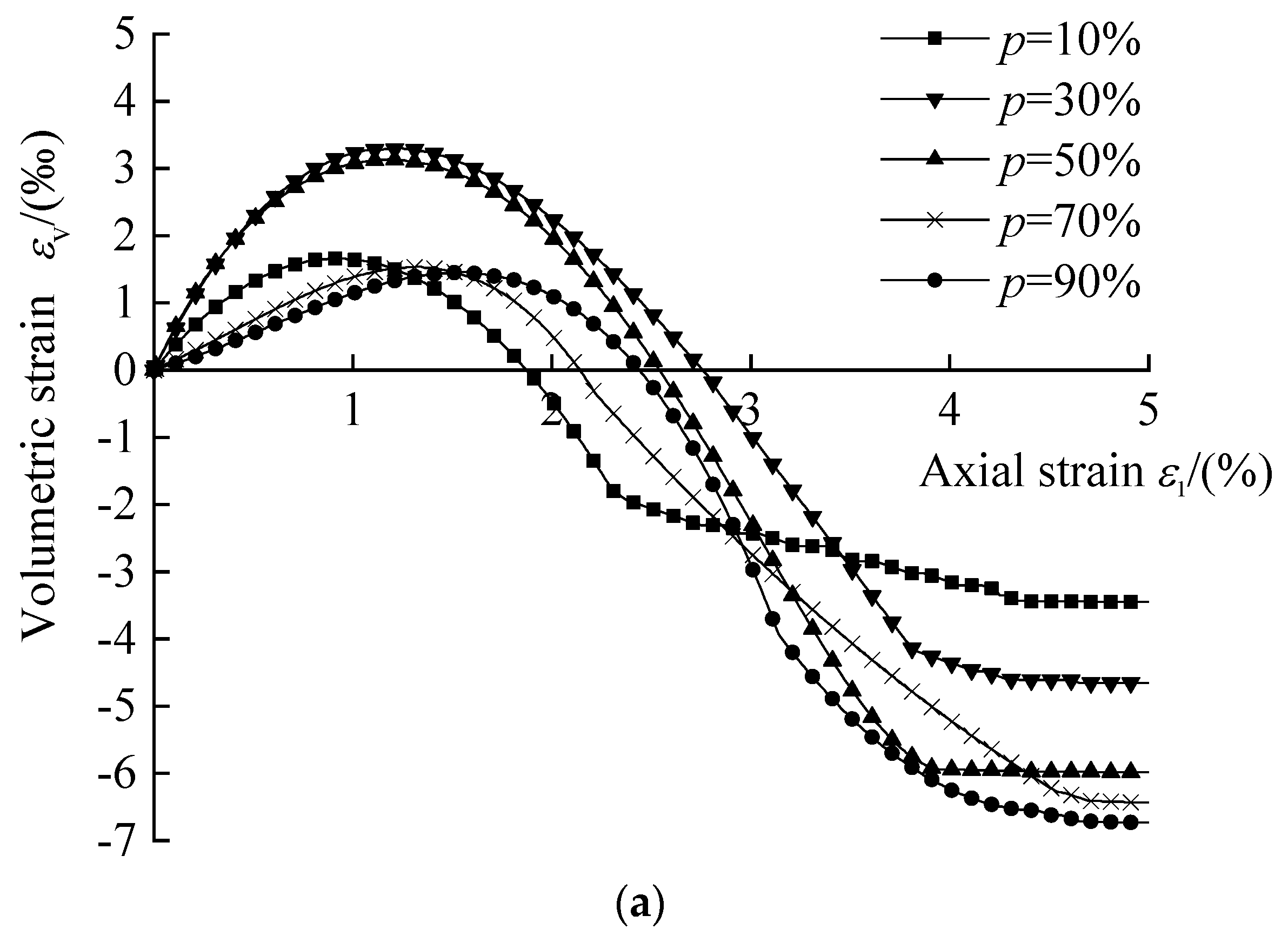

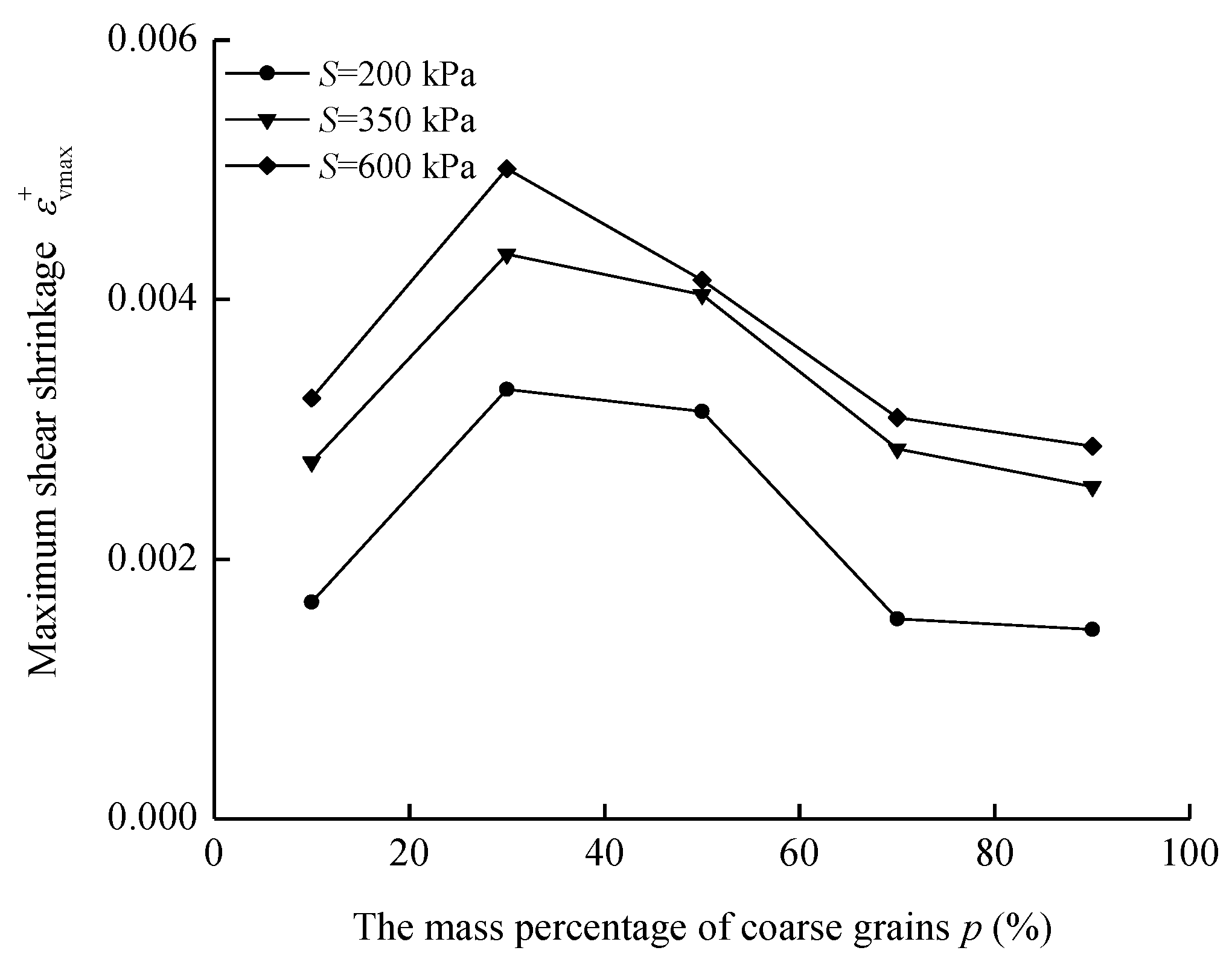

3.5. The Influence of Coarse-Grain Content on Shear Volume Change

4. Influence Mechanism Analysis of Coarse Grain Content

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zou, J.; Li, J.; Lei, R.; Wang, S. Experimental research on applicability of weathered red sandstone soil to roadbed filling. Road Mater. Pavement Des. 2021, 23, 2167–2177. [Google Scholar] [CrossRef]

- Zhai, B.; Leng, W.; Xu, F.; Zhang, S.; Ye, X.; Leng, H. Critical dynamic stress and shakedown limit criterion of coarse-grained subgrade soil. Transp. Geotech. 2020, 23, 100354. [Google Scholar] [CrossRef]

- Ye, Y.; Cai, D.; Yao, J.; Wei, S.; Yan, H.; Chen, F. Review on Dynamic Modulus of Coarse-grained Soil Filling for High-speed Railway Subgrade. Transp. Geotech. 2020, 27, 100421. [Google Scholar] [CrossRef]

- Chen, X.B.; Zhang, J.S.; An, G.F. Test study of red stone granular soil’s rheological property in road embankment engineering. J. Cent. South Univ. Sci. Technol. 2007, 38, 154–159. [Google Scholar]

- Peng, B.; Wu, J.Q.; Liu, L.H.; Pan, J.P.; Wen, S.J. Experimental research on influence of different moisture content on static compaction deformation characteristics of red sandstone soil. Yangtze River 2016, 7, 91–96. [Google Scholar]

- Wu, E.; Zhu, J.; Guo, W.; Zhang, Z. Effect of Gradation on the Compactability of Coarse-Grained Soils. KSCE J. Civ. Eng. 2020, 24, 356–364. [Google Scholar] [CrossRef]

- Wen, R.; Tan, C.; Wu, Y.; Wang, C. Grain size effect on the mechanical behavior of cohesionless coarse-grained soils with the discrete element method. Adv. Civ. Eng. 2018, 2018, 4608930. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, S.; Feng, T.; Yi, B.; Liu, J. Research on reuse of silty fine sand in backfill grouting material and optimization of backfill grouting material proportions. Tunn. Undergr. Space Technol. 2022, 130, 104751. [Google Scholar] [CrossRef]

- Bagherzadeh-Khalkhali, A.; Mirghasemi, A.A. Numerical and experimental direct shear tests for coarse-grained soils. Particuology 2009, 7, 83–91. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Q.; Liu, E.; Liu, X.; Zhang, G.; Song, B. Dynamic properties of frozen silty soils with different coarse-grained contents subjected to cyclic triaxial loading. Cold Reg. Sci. Technol. 2019, 157, 64–85. [Google Scholar] [CrossRef]

- Liu, X.; Zou, D.; Liu, J.; Zheng, B. Predicting the small strain shear modulus of coarse-grained soils. Soil Dyn. Earthq. Eng. 2021, 141, 106468. [Google Scholar] [CrossRef]

- Wei, K.M.; Zhu, S. An elastoplastic constitutive model for coarse-grained soils. Iran. J. Sci. Technol. Trans. Civ. Eng. 2014, 38, 285. [Google Scholar] [CrossRef]

- Rakhimzhanova, A.K.; Thornton, C.; Minh, N.H.; Fok, S.C.; Zhao, Y. Numerical simulations of triaxial compression tests of cemented sandstone. Comput. Geotech. 2019, 113, 103068. [Google Scholar] [CrossRef]

- Voznesensky, E.A.; Funikova, V.V.; Babenko, V.A. Deformability properties of model granular soils under true triaxial compression conditions. Mosc. Univ. Geol. Bull. 2013, 68, 253–259. [Google Scholar] [CrossRef]

- Wang, J.; Song, Z.; Zhao, B.; Liu, X.; Liu, J.; Lai, J. A study on the mechanical behavior and statistical damage constitutive model of sandstone. Arab. J. Sci. Eng. 2018, 43, 5179–5192. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.N.; Zhu, S. An Elastoplastic Model for Coarse Grained Soils Obeying Lade’s Dilatancy Rule. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2014; Volume 850, pp. 381–386. [Google Scholar] [CrossRef]

- Babenko, V.; Funikova, V.; Voznesensky, E. The effect of deviatoric deformation on the compressibility of coarse-grained soil. In Proceedings of the International Multidisciplinary Scientific GeoConference: SGEM 2013, Albena, Bulgaria, 16–22 June 2013. [Google Scholar] [CrossRef]

- Zhang, H.Q.; Zhao, F.; Cheng, S.Q.; Zhang, Y.Q.; Gou, M.J.; Jing, H.J.; Zhi, H.F. Study of sericite quartz schist coarse-grained soil by large-scale triaxial shear tests. Front. Phys. 2020, 508, 551232. [Google Scholar] [CrossRef]

- Seo, M.W.; Kim, B.J.; Ha, I.S. Comparison of shear strength of coarse materials measured in large direct shear and large triaxial shear tests. J. Korean Geoenviron. Soc. 2009, 10, 25–34. [Google Scholar]

- Guo, Q.G. Engineering Characteristics of Coarse-Grained Soil and Its Application; The Yellow River Water Conservancy Press: Zhengzhou, China, 1998. [Google Scholar]

- National Railway Administration of the People’s Republic of China. Code for Soil Test of Railway Engineering; China Railway Publishing House: Beijing, China, 2010. [Google Scholar]

- Zhou, J.; Niu, Y.; Zhou, Y.; Zhang, J.; Zhao, C. The Ball-Surface Normal Contact Experiment Research and Numerical Simulation of Coarse Grained Soil. In Proceedings of the GeoShanghai 2018 International Conference: Fundamentals of Soil Behaviours, Shanghai, China, 27–30 May 2018; Springer: Singapore, 2018; pp. 856–872. [Google Scholar] [CrossRef]

- Zhang, J.M.; Zhang, L.; Jiang, G.S.; Wang, R. Research on particle crushing of calcareous sands under triaxial shear. Rock Soil Mech. 2008, 29, 2789–2793. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, J.; Ye, X.; Gu, C.; Cai, Y. Experimental study on particle breakage of carbonate gravels under cyclic loadings through large-scale triaxial tests. Transp. Geotech. 2021, 30, 100632. [Google Scholar] [CrossRef]

- Wu, X.L.; Shi, B.X.; Liu, S.C.; Xu, W.; Chang, W.K. Large-scale triaxial test of rockfill material considering particle breakage. Sci. Technol. Eng. 2022, 22, 749–756. [Google Scholar]

- Kong, X.; Ning, F.; Liu, J.; Zou, D.; Zhou, C. Scale effect of rockfill materials using super-large triaxial tests. Chin. J. Geotech. Eng. 2019, 41, 255–261. [Google Scholar]

- Xu, J.; Han, W.X.; Wu, Y.D.; Yi, L.L.; Sun, C. Effect of Coarse Grain Content on the Mechanical Properties of Sand and MudstoneFillers. Water Power 2020, 46, 117–123. [Google Scholar]

- Chen, A.J. The Influence of Particle Gradation on Strength and Deformation Characteristics otCoarse-grained Soil. J. Hunan Inst. Eng. (Nat. Sci. Ed.) 2017, 27, 75–82. [Google Scholar] [CrossRef]

- Peng, B.; Yang, J.Y.; Wu, J.Q.; Wen, S.J.; Pan, J.Q. Impact of Coarse Grain Content on Static Compaction Deformation Characteristics of Red Sandstone Soil. Highway 2015, 60, 1–9. [Google Scholar]

| Natural Moisture Content (%) | Natural Density (g/cm3) | Specific Gravity Gs | Plastic Limit WP (%) | Liquid Limit WL (%) | Plasticity Index Ip | Void Ratio e |

|---|---|---|---|---|---|---|

| 7.9 | 2.05 | 2.58 | 21.5 | 33.3 | 11.8. | 0.39 |

| The Mass Percentage of Coarse Grains p (%) | Maximum Dry Density (g/cm3) | Optimum Moisture Content (%) |

|---|---|---|

| 10 | 1.894 | 9.32 |

| 30 | 2.185 | 8.63 |

| 50 | 1.956 | 5.34 |

| 70 | 1.908 | 4.01 |

| 90 | 1.867 | 3.45 |

| The Mass Percentage of Coarse Grains p (%) | Cohesion c/(kPa) | Angle of Internal Friction φ (°) |

|---|---|---|

| 10 | 86.9 | 31.1 |

| 30 | 133.8 | 36.2 |

| 50 | 107.1 | 40.5 |

| 70 | 89.5 | 42.4 |

| 90 | 84.6 | 43.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zhang, Y.; Yang, Y.; Yang, B.; Huang, B.; Ji, X. Influence of Coarse Grain Content on the Mechanical Properties of Red Sandstone Soil. Sustainability 2023, 15, 3117. https://doi.org/10.3390/su15043117

Chen J, Zhang Y, Yang Y, Yang B, Huang B, Ji X. Influence of Coarse Grain Content on the Mechanical Properties of Red Sandstone Soil. Sustainability. 2023; 15(4):3117. https://doi.org/10.3390/su15043117

Chicago/Turabian StyleChen, Junhua, Yanjiang Zhang, Yanxin Yang, Bai Yang, Bocheng Huang, and Xinping Ji. 2023. "Influence of Coarse Grain Content on the Mechanical Properties of Red Sandstone Soil" Sustainability 15, no. 4: 3117. https://doi.org/10.3390/su15043117

APA StyleChen, J., Zhang, Y., Yang, Y., Yang, B., Huang, B., & Ji, X. (2023). Influence of Coarse Grain Content on the Mechanical Properties of Red Sandstone Soil. Sustainability, 15(4), 3117. https://doi.org/10.3390/su15043117