1. Introduction

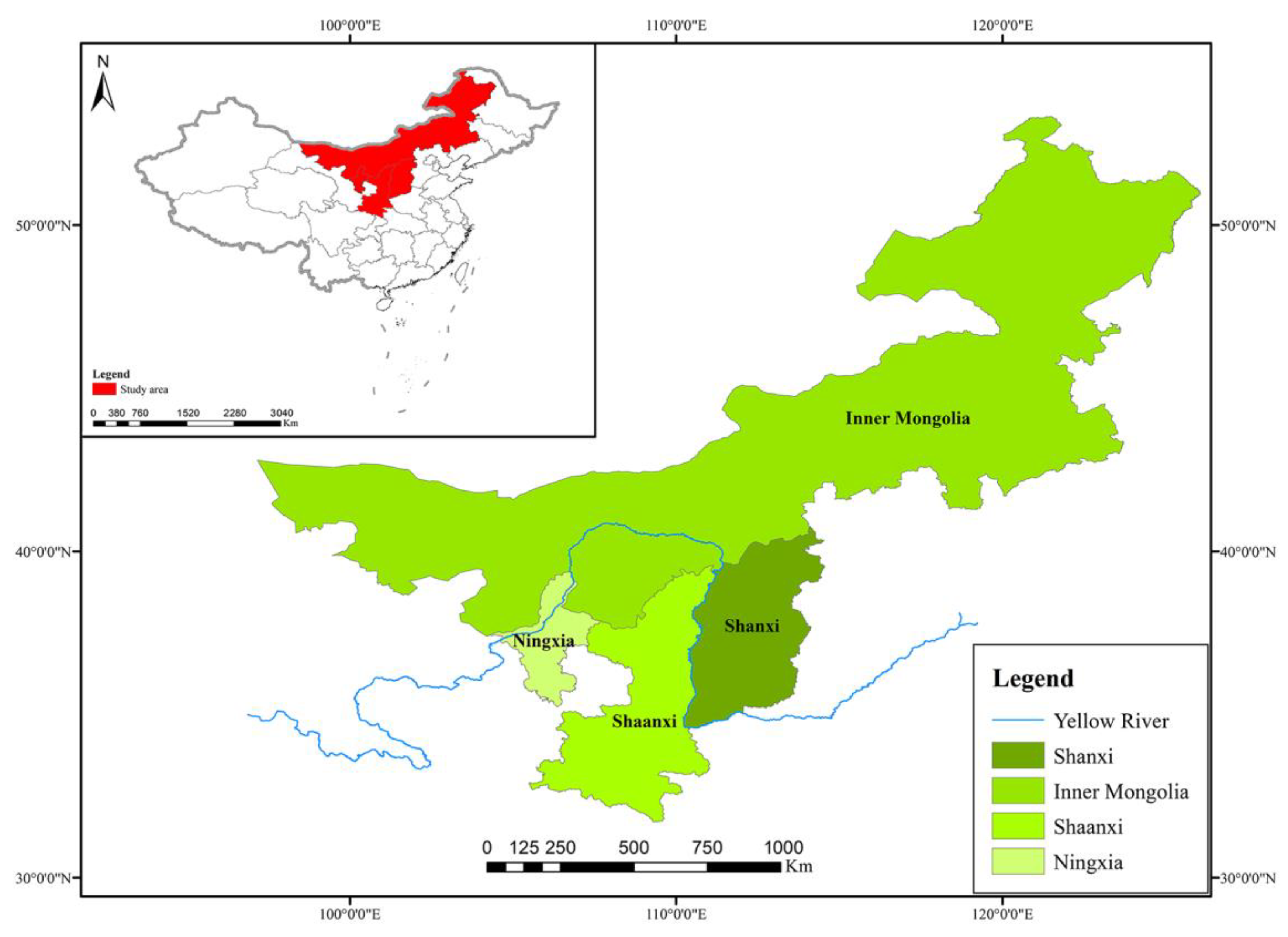

In the Outline of the Yellow River Basin’s Ecological Protection and High-quality Development Plan, the Chinese government pledged to optimize and adjust the layout of the regional economy and its productivity and to rationalize the division of labor in the upper, middle, and lower reaches of the Yellow River Basin on the premise of ecological protection. China made ecological protection and high-quality development in the Yellow River Basin part of its major national strategies. To realize high-quality development, it is important to undertake an industrial transfer and optimize the spatial layout of industries without exceeding the environmental capacity. The Yellow River Basin, especially the Great Bend of the Yellow River (the Bend), is a very special area, as shown in

Figure 1. It serves as a major base of clean energy in China. On the one hand, the Bend faces the important task of ensuring energy security. On the other hand, the Bend needs to solve a thorny issue in high-quality development; energy-intensive heavy industries are crowding out other industries in the regional industrial structure, and the fast development of the energy industry is leading to high and intense carbon emissions. To achieve sustainable development, it is necessary to transform the economic development mode to achieve energy conservation, emission reduction, and climate change adaptation [

1]. In the context of carbon peaking, it is urgent to study and answer the following question: How should the Bend reduce carbon emissions and achieve high-quality economic development by optimizing the regional industrial layout and guiding the orderly transfer of industries?

The spatial layout optimization of industries aims to reconfigure factor resources among various industries to achieve high-quality economic development. Industrial transfer is an important way to optimize the spatial layout of industries. It can spur the economic development of developed regions and energize the leap-forward development of developing regions. Since the reform and opening up, the southeastern coastal region of China has continued to attract international manufacturing industries due to its superior geographical location and labor cost advantages, laying the foundation for the development of manufacturing industries along the eastern coast [

2]. Many manufacturing enterprises are concentrated in the eastern coastal region, and its industrial scale and factor concentration have expanded, forming an apparent industrial gradient with the central and western regions [

3]. However, as land and labor costs continue to rise, the industrial transformation in the southeast coastal region is coming under enormous pressure. To alleviate the problem of over-concentration in industry, the Chinese government has introduced a series of policy measures, including the State Council’s Guidance on Undertaking Industrial Transfer in Central and Western Regions, the Catalogue of Industries Encouraged in Western Regions (2020 version), and the Guidance on Promoting the Orderly Transfer of Manufacturing Industries. The eastern region has successively transferred labor-intensive industries, mainly trade processing and some capital-intensive and technology-intensive industries, to the western region [

4]. However, the target carbon emission intensity across China is set based on the carbon emission intensity of each region. As a result, the central and western regions, which are rapidly industrializing, possess ample room for carbon emissions, owing to the large proportion of the heavy chemical industry in the regional industrial structure. Pollution-intensive industries tend to move from the east to the central and western regions [

5,

6]. The industrial transfer is accompanied by the transfer of carbon emissions, which poses a severe threat to the environment of the region receiving the transferred industry. To cope with this threat, the relevant provincial administrative regions (provinces) have been tightening environmental regulations, making carbon emissions a mandatory external constraint on economic development. While optimizing the spatial layout of industries through industrial transfers, these provinces are attempting to tap the spatial potential of the transfer of industries in batches, strictly limiting the transfer of high-energy-consuming and high-emission industries, and constructing a green and low-carbon industrial system, with the premise remaining within the constraints of resources and the environment.

The premise of industrial spatial layout optimization with a carbon peak target is to achieve carbon reduction through inter-industry and intra-industry reallocation of production factors while maintaining high-quality economic development. This paper establishes a research paradigm for optimizing the industrial spatial layout and high-quality development in carbon peaking. Using the framework of the existing theory of the industrial spatial layout and from the perspective of industrial transfer, the static agglomeration index, dynamic agglomeration index, industrial gradient coefficient, and low-carbon competitiveness index of each industry are measured to find industries with agglomeration advantages, competitive advantages, and low-carbon development advantages in each province and region at the national level. The different industrial types are further divided to identify the correct industrial spatial layout for each province and region in the Bend to reach the carbon peak. The research results lay a theoretical basis for realizing ecology-first high-quality green development in the Bend and provide a good reference for governments at all levels to formulate measures for the spatial layout optimization of industries in the context of carbon peaking.

2. Literature Review

Industrial transfer is the phenomenon of the migration of production factors from one region to another, which is conducive to optimizing the spatial layout of regional industries and realizing high-quality economic development. Domestic and foreign scholars extensively discussed industrial transfer and formed a relatively systematic theoretical basis, which mainly includes two theories: one is the theory of industrial transfer based on agglomeration, including external economies of scale “circular accumulation causality” theory, and “core-edge “theory [

7]; the other is the theory of industrial transfer based on comparative advantage, including the theory of the flying geese pattern [

8], the theory of product life cycle [

9], the theory of marginal industrial transfer, the eclectic theory of international production [

10], and the theory of gradient transfer. A new economic geography model has been constructed to illustrate the effects of the industrial transfer on regional economic development, which provides theoretical support for further adjustment and implementation of industrial transfer policies in China. The pressure on industrial development in China’s eastern coastal development regions is increasing, and the original comparative advantages of traditional industries are being lost. In contrast, the developing regions in central and western China are characterized by lower production costs, intensive labor resources, abundant factor resources, and the urgent need for industrial investment to drive development. Effective industrial transfer involves the transfer of industries that have lost their comparative advantages in eastern China to the western region in response to the needs of industrial development; this has become a critical path to optimize the spatial layout of regional industries. Industrial transfer has both positive and negative effects on regional economic development. Some scholars believe that the transfer of industries is conducive to optimizing the efficiency of resource allocation between regions and that industrial transfer promotes industrial restructuring and upgrading, technological progress in the receiving regions [

11], increased total factor productivity [

12,

13], reduction of energy consumption per unit in the transferring and receiving regions [

14], and economic growth in the transferring and receiving regions [

15,

16], thereby reducing regional differences in economic development. Some scholars have also pointed out that both international and regional industrial transfers in China inevitably have certain negative effects on the receiving region; for example, they do not lead to significant productivity growth in the receiving region [

17,

18]; the transferring region aggravates environmental pollution and resource consumption in the receiving region by transferring polluting enterprises [

19], and there are industrial transfer gradient traps and industrial upgrading blocking hysteresis effects [

20]. In particular, as the impact of the climate crisis continues to intensify, the issues of “carbon transfer” and “carbon leakage” [

21,

22,

23,

24] brought about by industrial relocation have attracted increasing attention.

Initially, due to international industrial transfer, domestic and international attention was attracted to the problem of “carbon transfer” and “carbon leakage” brought about by free trade between countries with different levels of economic development. Some scholars were the first to put forward the “pollution paradise” [

25,

26,

27,

28] hypothesis. This hypothesis suggests that developing countries will attract foreign direct investment by lowering environmental regulations early to enhance their economic development. At the same time, developed countries tend to transfer their highly polluting enterprises to developing countries, thus deteriorating the natural environment of developing countries, with these developing countries becoming “pollution havens” [

29,

30,

31] for developed countries. In contrast, some scholars have put forward the pollution halo hypothesis. This hypothesis argues that foreign-invested enterprises in developed countries usually face higher environmental regulation standards in their home countries and strict environmental requirements from governments and residents. These enterprises generally use more advanced pollution treatment technologies. When these enterprises enter the host country directly through foreign investment, the environmental pollution treatment technologies and environmental management systems they use will spread to the host country, which will help improve environmental sustainability. Li et al. [

32] demonstrated that industrial transfer is a critical factor in carbon transfer. In the actual situation in China, there is a net carbon transfer from foreign countries to China through international trade and a net carbon transfer from the eastern provinces to the central and western provinces through domestic trade, with the most significant net domestic carbon transfer into the northwest region and out of the eastern coastal region [

33]. Under the carbon peak target, reducing the net carbon transfer in the northwest region, represented by the Bend, in the process of undertaking industrial transfer while optimizing the spatial layout of industries and achieving high-quality economic development has become an urgent concern for governments at all levels.

Industrial transfer is manifested as a change in the spatial distribution of regional industrial activities over different periods. The direction and degree of industrial transfer are generally illustrated by comparing economic indicators of regional industries. There are significant differences in the identification methods of industrial transfer at home and abroad. Developed countries have perfect information on the location of enterprises and can directly judge the scale and direction of industrial transfer through location changes of enterprises [

34,

35]. In China, due to the lack of detailed data on changes in the geographical location of enterprises, indirect indicators are generally used to measure industrial transfer, such as location quotient based on industry share, absolute share index, Herfindahl index, industry gradient coefficient, static agglomeration index, dynamic agglomeration index, inter-regional input–output index [

36,

37,

38,

39], etc. By measuring the above indirect indicators, the transfer of industries into and out of regions can be judged, which is conducive to the optimization of the overall industrial spatial layout of China. The impact of market concentration on regional development has been studied [

40]. However, while the problem of carbon transfer is becoming increasingly severe, the relevant measurement indicators do not include the low-carbon competitiveness of industries, which may blindly transfer high-energy-consuming and high-emission industries to less developed regions, creating a double dilemma of an unreasonable industrial spatial layout and rapid growth of carbon emissions for less developed regions.

In summary, the existing literature is essential to the proposal presented in this paper, but there are still certain things that could be improved:

(1) As an underdeveloped area, the Bend is receiving a large quantity of high-energy-consuming and high-emission industries. The local industrial structure is becoming resource-intensive and capital-intensive, adding to the difficulty in structural adjustment and quality improvement. Additionally, the Bend shoulders the important task of ensuring national energy security. There are few reports focusing on the spatial layout of industries in the Bend.

(2) In existing research on the relationship between industrial transfers and carbon emissions, more attention has been paid to carbon transfer and carbon leakage brought about by industrial transfer in the receiving region. Less research has been conducted on the optimization of the industrial spatial layout under the carbon peak target, and no research paradigms have been proposed for the optimization of the industrial spatial layout and high-quality development in terms of carbon peaking.

(3) When studying the industrial spatial layout optimization, most existing studies analyze industrial agglomeration advantages and competitive advantages through industrial economic indicators and give suggestions for the industrial spatial layout. However, despite increasing research on climate issues, existing studies are less likely to include low-carbon competitiveness advantage indicators in industrial spatial layout optimization and less likely to analyze the advantages of low-carbon development of industries, thus leading to the transfer of industries to areas that may have already taken on more polluting industries.

Compared with the existing research, this paper makes the following contributions:

(1) In terms of research objects, the Bend is an underdeveloped region facing the dual dilemma of the transfer in of high-energy-consumption and high-pollution industries and the need for carbon reduction. In the context of carbon peaking, this paper analyzes the spatial layout optimization of industries in the Bend. The analysis will help the region to achieve high-quality economic development while reducing carbon emissions.

(2) In terms of research topics, a research paradigm for the industrial spatial layout optimization and high-quality development in the context of carbon peaking is proposed. Under the framework of the existing industrial spatial layout theory and from the perspective of industrial transfer, the static agglomeration index, dynamic agglomeration index, and industrial transfer gradient coefficient of each industry are used to analyze the agglomeration advantages and competitive advantages of each industry at the national scale and identify the dilemmas faced by developing industries. To this paradigm, industrial low-carbon competitiveness indices are added and, based on the agglomeration advantage, competitive advantage, and low-carbon development advantage of each industry, the ideal industrial spatial layout for each province and region in the Bend is derived, with the goal of reaching the carbon peak. This paradigm enriches research frameworks on industrial spatial layout.

(3) In terms of research conclusions, we concluded that all provinces and regions should vigorously develop “agglomeration” industries, especially energy-based industries, and that some provinces still have comparative advantages in energy-based industries in the national context of reaching the carbon peak, so they should not blindly restrict their development and engage in campaign-style “carbon reduction” or “apply the emergency brake.” At the same time, appropriate industrial policies should be formulated. Government guidance should be used to improve the capacity of industries, focusing on “potential” industries and appropriately designating “scale” industries using advanced technological transformation. The study findings have particular significance for governments at all levels in formulating measures for the industrial spatial layout optimization.

4. Results

4.1. Variation in Overall Regional Industrial Landscape

4.1.1. Static Agglomeration Indices of Resource-Intensive Industries

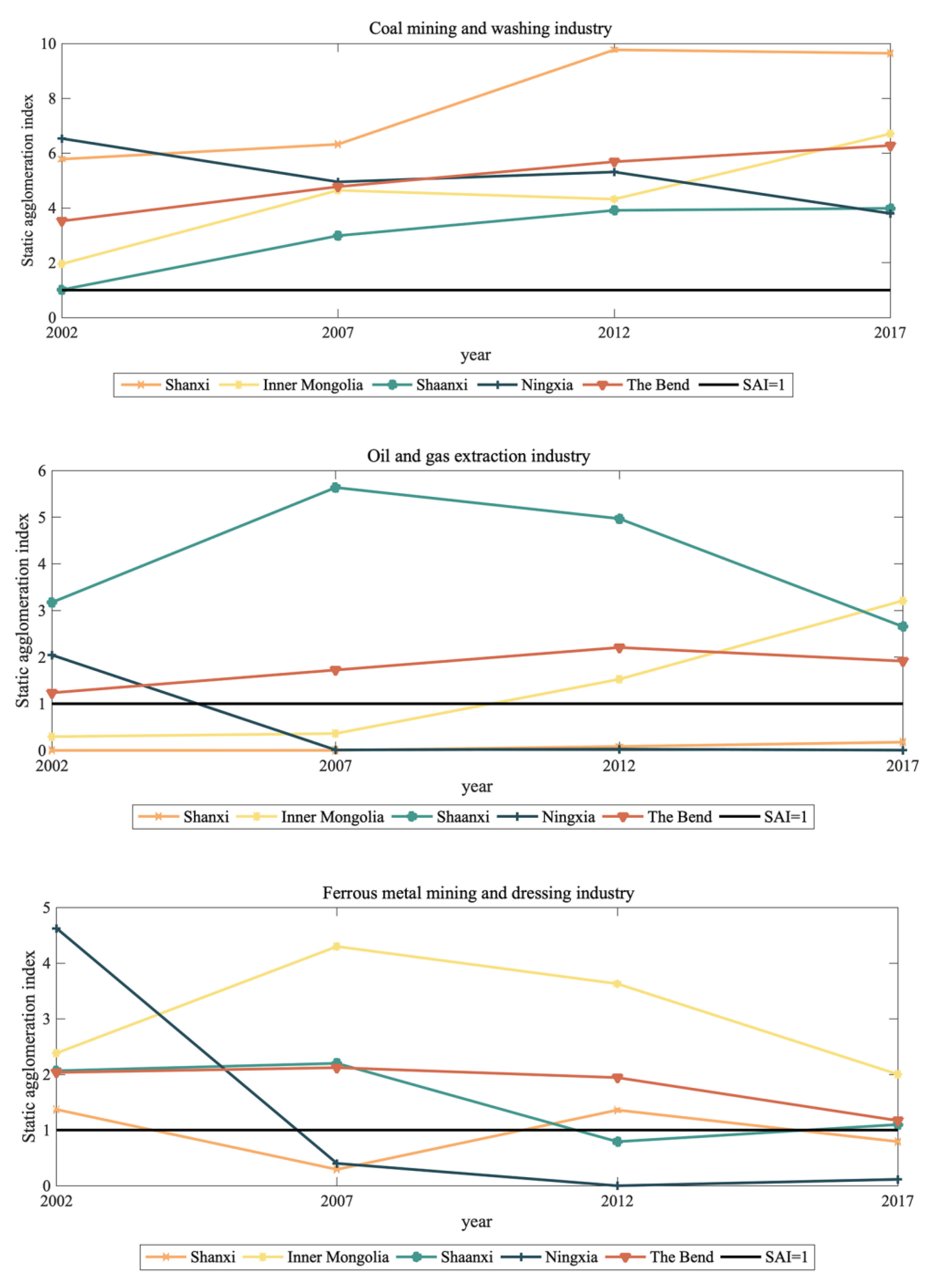

The static agglomeration indices of resource-intensive industries are shown in

Figure 2. Among the resource-intensive industries, the agglomeration level of coal mining and oil and gas extraction has steadily increased (except in Shanxi), with the coal mining industry showing the most significant increase, with the static agglomeration indices for Shanxi, Inner Mongolia, Ningxia, and Shaanxi being 9.64, 6.71, 3.99, and 3.80, respectively, in 2017. All regions possess solid industrial competitive advantages. This is because the Bend is a typical energy resource-rich region. The development of coal mining and oil and gas extraction aligns with the region’s comparative advantages. Additionally, the region is an essential strategic energy resource base for the country, and the agglomeration of the industries, as mentioned above, is crucial to ensuring national energy security. The clustering level of the ferrous metal mining and dressing industries and the non-ferrous metal mining and dressing industries in the provinces and districts shows a fluctuating downward trend, influenced by structural reform on the supply side, as well as significant downward pressure on the economy, weaker market demand, insufficient growth momentum, and a significant decline in the production capacity of the metal ore and non-ferrous metal mining and dressing industries. Aside from Ningxia, the provinces and regions do not have a comparative advantage in the chemical product manufacturing industry. In the ferrous metal smelting and rolling processing industries, Shanxi, Shaanxi, and Ningxia show a fluctuating upward trend. At the same time, the level of agglomeration in Inner Mongolia decreased from 2.08 in 2002 to 1.47 in 2017, with an evident trend of the industry turning outward. The chemical product manufacturing, metal smelting, and rolling processing industries are traditional high-energy-consuming industries. Compared with developed regions, the energy utilization rate in each province and region has slowly improved. The advantages of industrial development in each province and region are being lost due to the constraints of dual control of energy consumption.

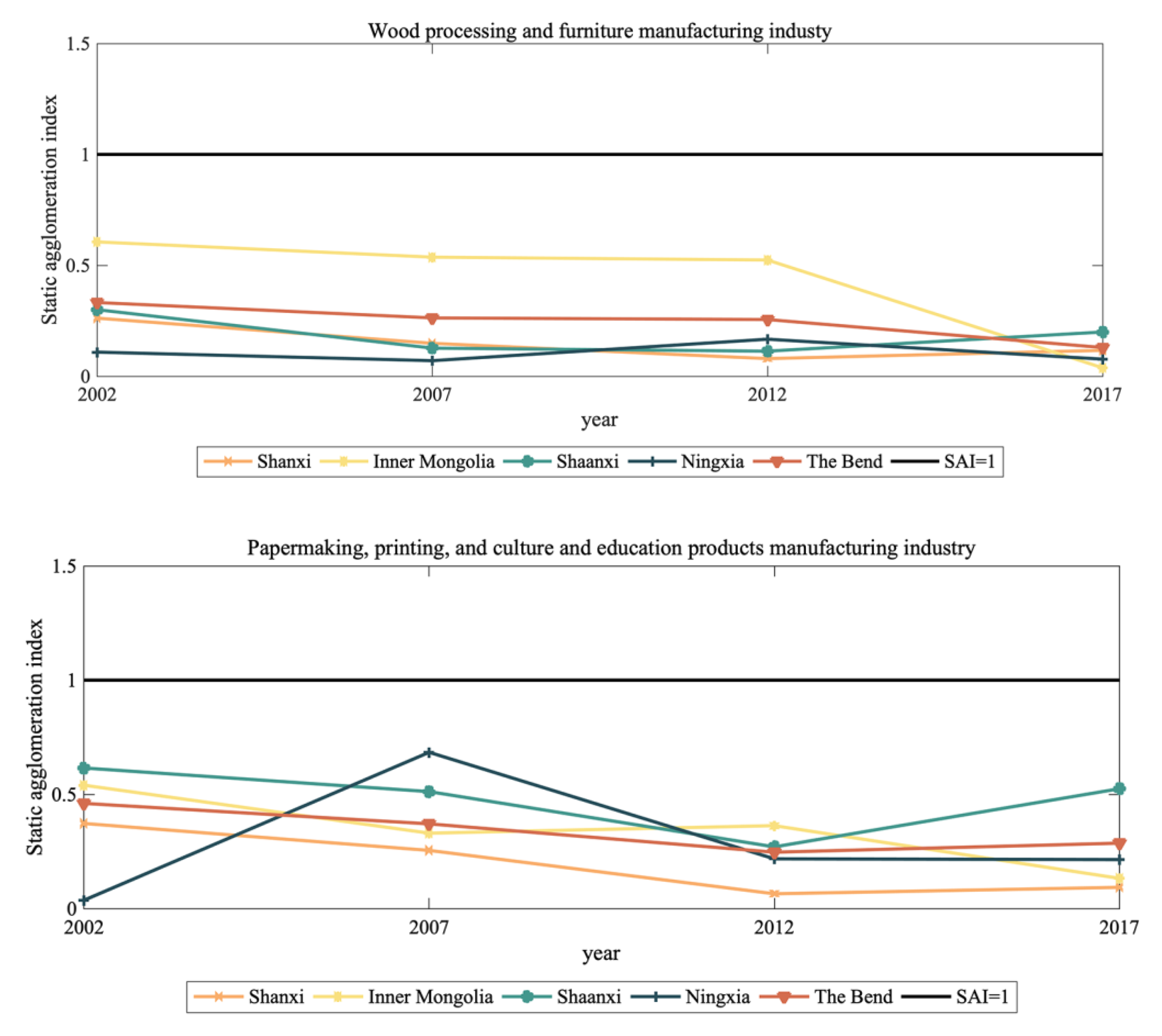

4.1.2. Static Agglomeration Indices of Labor-Intensive Industries

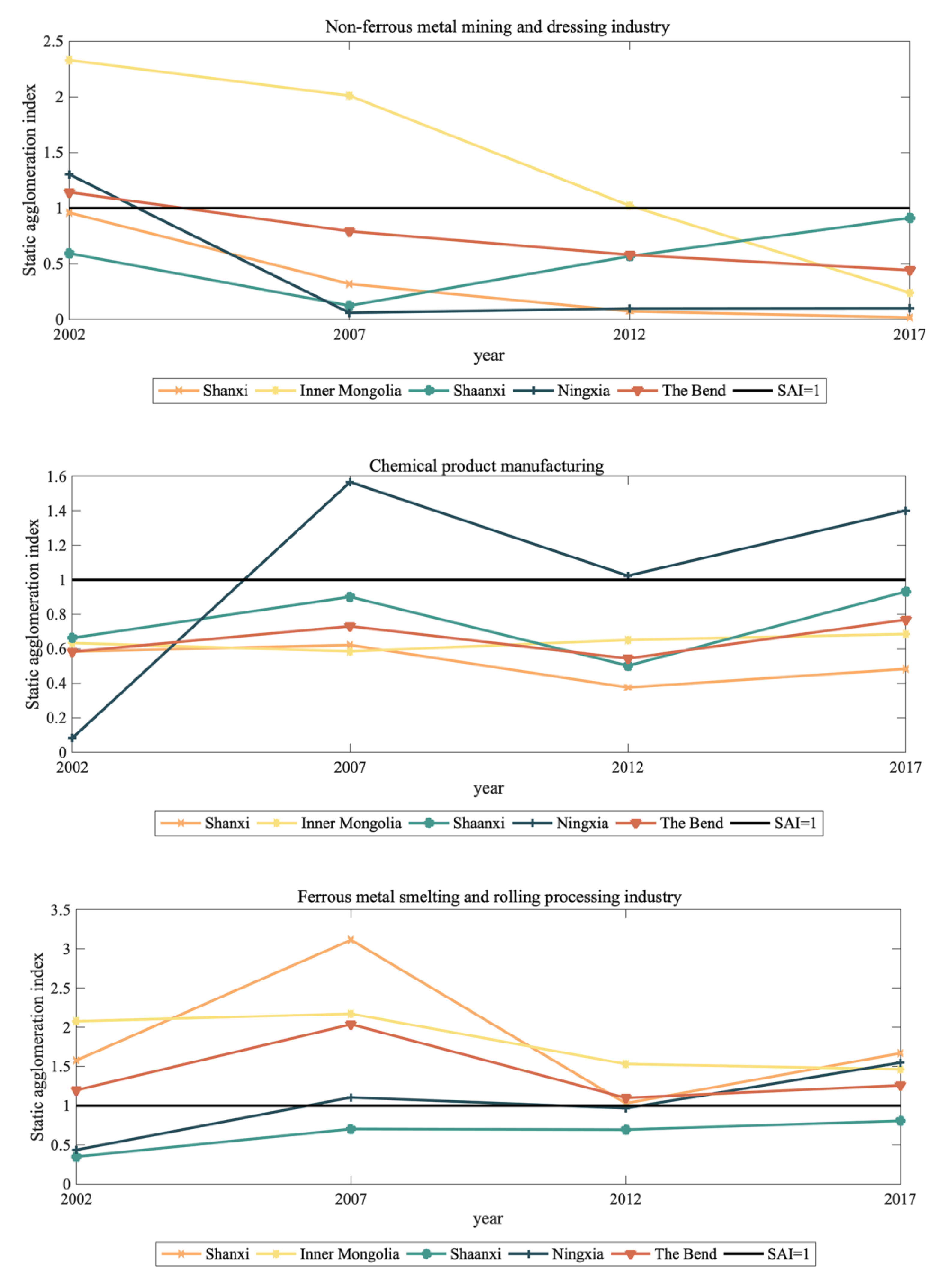

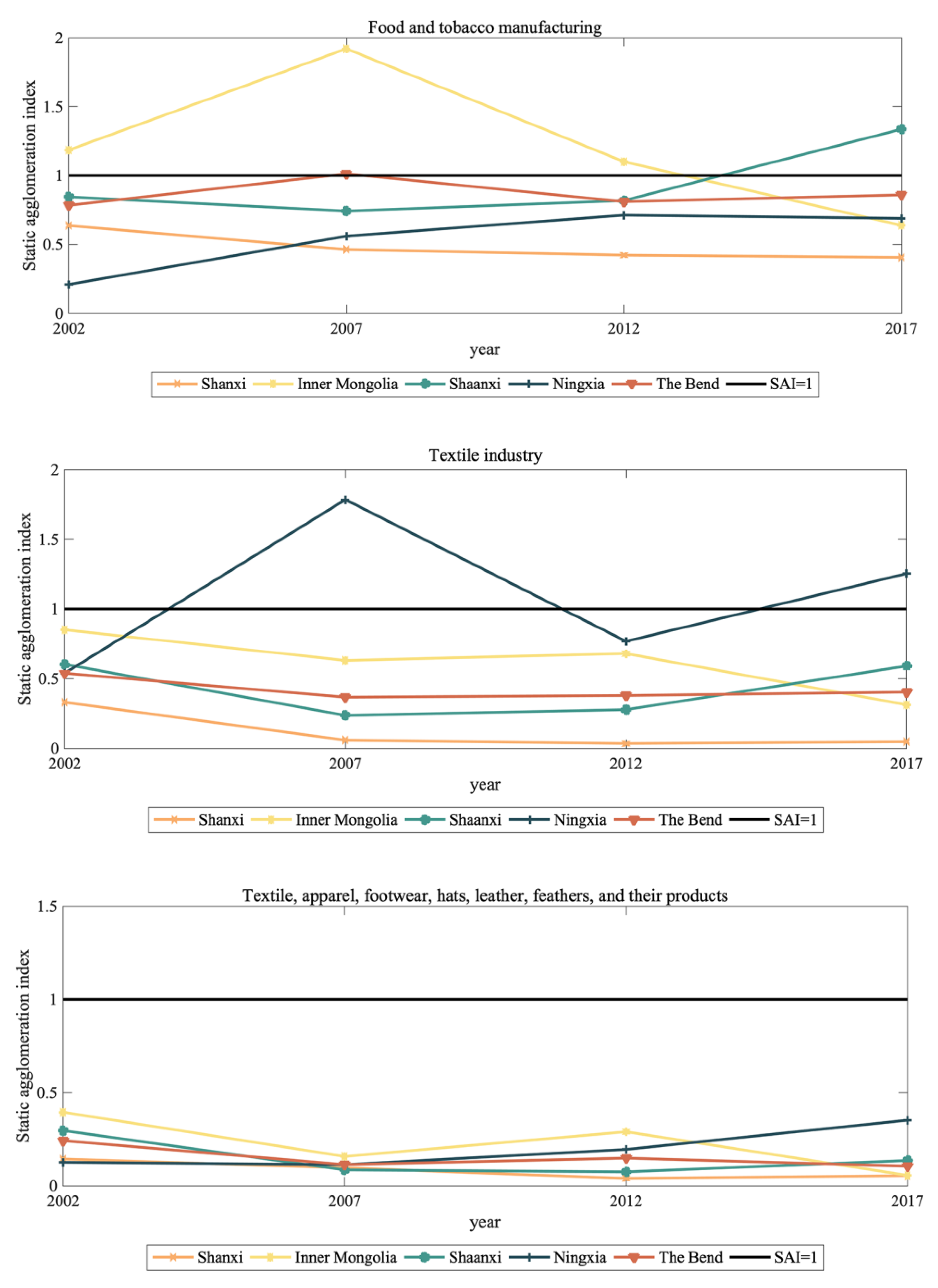

The changes in the static agglomeration indices of labor-intensive industries are shown in

Figure 3. Among the labor-intensive industries, Shaanxi and Ningxia’s food and tobacco manufacturing increased their agglomeration levels from 0.85 and 0.21 in 2002 to 1.34 and 0.69 in 2017, respectively. For the textile industry, Ningxia’s static agglomeration index rose from 0.54 in 2002 to 1.25 in 2016, while other regions showed a fluctuating downward trend. The provinces and regions do not have agglomeration advantages in apparel, footwear, hats, leather, and feathers and their products; wood processing and furniture manufacturing; or papermaking, printing, and culture and education product manufacturing. Overall, the region does not have a comparative advantage in labor-intensive industries. The reason for this is that the population of the provinces and regions is growing slowly and, compared with the sixth national census, in the seventh national census data from 2020, the populations of Shanxi and Inner Mongolia decreased by 796,500 and 657,200, respectively. The size of the labor force therefore declined significantly. Furthermore, with the rapid development of foreign trade-oriented manufacturing industries in the eastern coastal areas, the trend of population transfer out of the Bend has been accelerated, thus leading to a slower development of labor-intensive industries.

4.1.3. Static Agglomeration Indices of Capital-Intensive Industries

The changes in the static agglomeration indices of capital-intensive industries are shown in

Figure 4. Among the capital-intensive industries, oil processing, coking, and nuclear fuel processing; electricity, heat production, and supply; and gas production and supply all have substantial agglomeration advantages in each province and region. This is because the region is a distinctly energy resource-rich area. The provinces and regions are actively undertaking industrial transfer and vigorously developing their energy and raw material industries. In Inner Mongolia, for example, energy and raw material industries account for 82.1% of the added value of industries. The energy consumption of the six high-energy-consuming industries of electricity, chemicals, iron and steel, non-ferrous metals, petrochemicals and coking, and building materials accounts for 89.4% of the energy consumption of industries. The non-metallic mineral product industry, metal mineral product industry, and water production and supply industry show a clear trend of outward transfer, with the metal mineral product industry in Ningxia showing the most prominent outward transfer, with the agglomeration index dropping from 2.22 in 2002 to 0.19 in 2017. Due to geographical location and transportation, the non-metallic and metal mineral product industries in the Bend generally have a low utilization rate of resources. At the same time, their processing technology lags that of developed regions. Low-level, repetitive construction has led to severe economic losses and ecological problems. This has led to a declining industrial agglomeration in the non-metallic and metal mineral product industries. The declining agglomeration level of the water production and supply industry is mainly because the Bend consists of arid and semi-arid areas, where water resources are relatively scarce. Industrial development has a high demand for water resources, resulting in a declining agglomeration index.

4.1.4. Static Agglomeration Indices of Technology-Intensive Industries

The changes in the static agglomeration indices of technology-intensive industries are shown in

Figure 5. Except for electrical equipment manufacturing in Shaanxi, which has the advantage of agglomeration, other provinces and regions do not have comparative advantages in technology-intensive industries, and the level of industry agglomeration in most provinces and regions shows an apparent downward trend, with an evident trend of outward transfer. The reason for this is that the level of scientific and technological innovation capacity in each province and region is low and cannot support the development of technology-intensive industries. In the

China Regional Science and Technology Innovation Evaluation Report 2022, published by the China Academy of Science and Technology Development Strategy, Shaanxi, Ningxia, Shanxi, and Inner Mongolia ranked 9th, 18th, 22nd, and 27th in the country, respectively, in terms of the comprehensive science and technology innovation index. Furthermore, energy-intensive and capital-intensive industries are key industries in the region’s development and occupy significant human and material resources. The agglomeration and development of these industries have had a crowding-out effect on technology-intensive industries.

4.2. Industrial Transfer and Agglomeration by Province

The industrial transfer and agglomeration situations of each Bend province was analyzed using the dynamic agglomeration index () and the industrial gradient index (). That is, the situation of different industries in each province was determined based on the relationship between each index and 1. There are four possible situations: (1) If , the industry is agglomerated with a competitive advantage; (2) if , the industry is agglomerated without a competitive advantage; (3) if , the industry is being transferred out, with some technological and scale advantages; (4) if , the industry has neither agglomeration advantages nor regional competitive advantages. The four situations are denoted by , , , and , respectively.

Table 2 reports the industrial transfer and agglomeration situations in the Bend. Overall, the following industries are agglomerated with a competitive advantage in the Bend: coal mining and washing industry; food and tobacco manufacturing; textile industry; electrical equipment manufacturing; and computer, communications, and other electronic equipment manufacturing. These industries are primarily resource-intensive, labor-intensive, and technology-intensive industries. When it comes to the industrial transfer and agglomeration situations in each province, agglomeration is the dominant trend in industrial development in the Bend provinces. Shanxi, Inner Mongolia, Shaanxi, and Ningxia have 6, 8, 14, and 11 industries belonging to the agglomeration group, respectively, and 4, 2, 12, and 6 industries with regional competitive advantages, respectively. These industries are evenly distributed across the four industry categories. Specifically, Shaanxi has 12 agglomerated industries with regional competitive advantages: coal mining and washing; non-ferrous metal mining and dressing; ferrous metal smelting and rolling processing; food and tobacco manufacturing; textiles; wood processing and furniture manufacturing; papermaking, printing, and culture and education product manufacturing; non-metallic mineral products; general equipment manufacturing; electrical equipment manufacturing; special equipment manufacturing; and computer, communications, and other electronic equipment manufacturing. These industries span the four kinds of industries. As Shaanxi works to optimize its regional industrial layout through industrial transfer, the agglomeration and competitive advantages of technology-intensive industries are gradually increasing, in addition to the advantages of traditional industries, laying a good foundation for the transformation of the regional industrial structure. Inner Mongolia has two agglomerated industries with regional competitive advantages, namely, the coal mining and washing industry and the oil and gas extraction industry, both of which are resource-intensive industries. The development of these industries is crucial to safeguarding China’s energy security and industrial security. Ningxia has six agglomerated industries with regional competitive advantages, namely, the textile industry; apparel, footwear, hats, leather, and feathers and their products; electricity; heat production and supply industry; water production and supply industry; general equipment manufacturing; and electrical equipment manufacturing. These industries are basically evenly distributed across the four kinds of industries. However, technology- and capital-intensive industries are not highly developed and fail to lead the optimization of the regional industrial layout. Shanxi has four agglomerated industries with regional competitive advantages, namely, electricity; heat production and supply; gas production and supply; electrical equipment and equipment manufacturing; and computer, communications and other electronic equipment manufacturing. These industries are largely capital- and technology-intensive industries. In recent years, Shanxi has made great efforts to optimize its industrial structure, reshape the industrial spatial landscape, and actively promote industrial transformation. The spatial layout optimization of industries has been quite successful.

In summary, the above analysis of the industrial transfer and agglomeration situations of the Bend provinces reveals that industrial transfer has provided strong impetus and support for the spatial layout optimization of industries in each province and improved the level of industrial development to varying degrees. Judging by the development of specific industries, most provinces rely on their own resource endowments to vigorously develop resource-intensive, labor-intensive, and capital-intensive industries. To promote the overall coordinated development of the Bend and the comprehensive green transformation of the economy and society, all provinces in the Bend should further leverage their own resource endowments, enhance their technological innovation capabilities, promote the low-carbon and high-end development of industries, and accelerate the optimization of the spatial layout of industries.

4.3. Low-Carbon Competitiveness Index by Province

Table 3 lists the low-carbon competitiveness index of each industry. The smaller the

, the higher the low-carbon competitiveness of a region. On the whole, 12 industries in the Bend realized an

, including resource-intensive industries, labor-intensive industries, and technology-intensive industries. Industries with strong low-carbon competitiveness in the region should be vigorously encouraged in the context of carbon peaking.

When it comes to the low-carbon competitiveness of the industries in each province, Shanxi, Inner Mongolia, Shaanxi, and Ningxia have 10, 10, 17, and 12 industries with strong low-carbon competitiveness, respectively. These industries span the four types of industries. Concerning resource-intensive industries, all provinces except Ningxia have low-carbon competitiveness nationwide in coal mining and washing. Concerning oil and gas extraction, Inner Mongolia, Shaanxi, and Ningxia have low-carbon competitiveness. Concerning ferrous metal mining and dressing, Inner Mongolia and Shaanxi have low-carbon competitiveness. Concerning chemical product manufacturing and ferrous metal smelting and rolling processing, all provinces except Shaanxi do not have low-carbon competitiveness. This is because, by relying on the advantages of their resource endowments to undertake industrial transfer, the provinces have actively promoted the green transformation of the industries through technological transformation. Because the industrial layout is determined considering the environment, the development of resource-intensive industries does not have a significant impact on the environment. Concerning labor-intensive industries, Shanxi and Shaanxi have low-carbon competitiveness nationwide in food and tobacco manufacturing, while all provinces except Shanxi have low-carbon competitiveness in the textile industry. Shanxi, Shaanxi, and Ningxia have low-carbon competitiveness nationwide in apparel, footwear, hats, leather, and feathers and their products and in wood processing and furniture manufacturing. Shaanxi has low-carbon competitiveness nationwide in papermaking, printing, and culture and education product manufacturing. Concerning capital-intensive industries, there is a significant difference among the provinces in low-carbon competitiveness. In Ningxia, oil processing, coking, and nuclear fuel processing have low-carbon competitiveness. In Shaanxi, the non-metallic mineral product industry and metallic product industry have low-carbon competitiveness. In Shanxi, the gas production and supply industry has low-carbon competitiveness. In addition, all provinces have low-carbon competitiveness in water production and supply. Concerning technology-intensive industries, the low-carbon-competitive industries are distributed uniformly in each province. In Ningxia, all industries have low-carbon competitiveness. In addition, low-carbon competitiveness was observed in electrical equipment and equipment manufacturing and instrumentation manufacturing in Shanxi; general equipment manufacturing and computer, communications, and other electronic equipment manufacturing in Inner Mongolia; and general equipment manufacturing, special equipment manufacturing, transportation equipment manufacturing, and electrical equipment in Shaanxi.

After analyzing the low-carbon competitiveness indices of the Bend provinces, it was found that each province has some low-carbon-competitive industries. In the context of carbon peaking, these industries are key in the industrial transfer and the optimization of the industrial layout. The provincial governments should step up the promotion of investment in these industries and use them to lead low-carbon development in the region while optimizing the regional industrial layout.

4.4. Spatial Layout of Agglomerated Industries

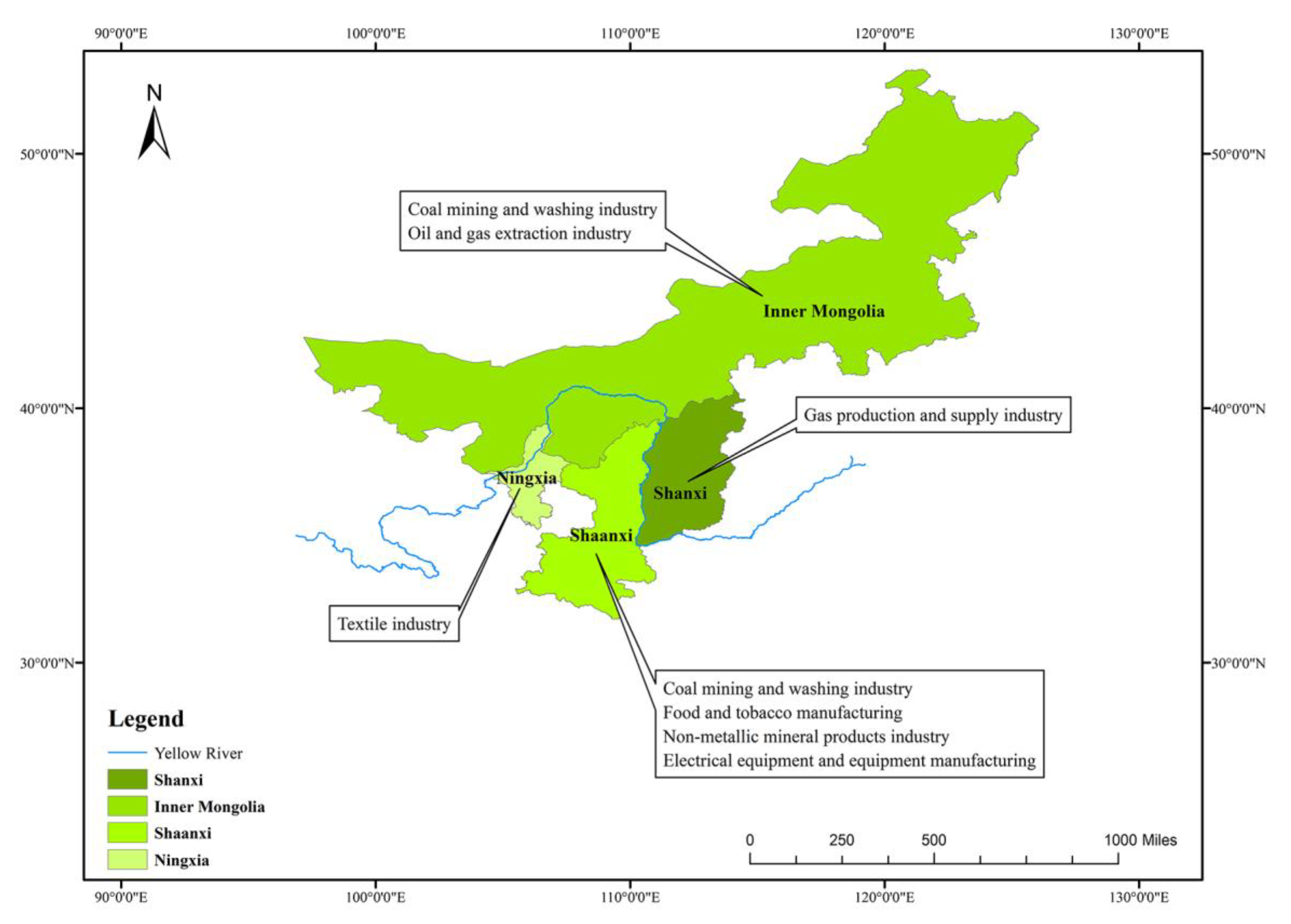

As shown in

Figure 6, the layout of the agglomerated industries in Inner Mongolia includes two resource-intensive industries: coal mining and washing and oil and gas extraction. Both industries remain in the agglomeration state and transfer-in state, feature technological and scale advantages, meet the industrial layout requirements in the context of carbon peaking, and boast nationwide above-average low-carbon competitiveness. These industries are in line with Inner Mongolia’s pursuit of a new ecology-first path toward green development and the vision of developing an important national base of energy and strategic resources. Therefore, we should develop energy resources, increase coal production promptly when the supply of renewable energy is insufficient, and promote the role of coal and oil in ensuring energy security. In Shaanxi, there are four key agglomerated industries: coal mining and washing, food and tobacco manufacturing, non-metallic mineral products, and electrical equipment manufacturing. These industries are distributed across resource-intensive industries, labor-intensive industries, capital-intensive industries, and technology-intensive industries. Hence, the agglomerated industries in Shaanxi are deployed diversely, with strong overall competitiveness. The above industries could be the focus of the industrial layout by virtue of their agglomeration advantages and strong competitiveness. The agglomeration of Shaanxi’s coal mining industry is crucial to ensuring national energy security. In the future, we should further promote the transformation of resource advantages into industrial advantages and the transformation of industrial advantages into innovation advantages, which will, in turn, drive the development of other industries. The food and tobacco processing industry is a typical labor-intensive industry. Its advantages of strong employment capacity, job development, and ease employment pressure should be promoted. Relying on the agglomeration and competitive advantages of the non-metallic mineral product industry, Shaanxi should vigorously develop high-tech industries, such as the electronic information, new energy, and new material sectors, and accelerate the pace of transformation and upgrading of the industrial structure. Electrical equipment manufacturing is the focus of the future transformation of Shaanxi’s industrial structure. We should take the opportunity to build a national (western) science and technology innovation center, strengthen cooperation with developed areas on the eastern coast, promote the industry’s agglomeration advantages, and enhance the internal dynamics of its transformation and upgrading. Ningxia’s “agglomerated” industrial layout includes only the textile industry; in the process of undertaking industrial transfer from the eastern region and anchoring advanced technology high value-added textile enterprises, the advantages of low labor costs, the creation of industrial clusters, and the cultivation of leading enterprises with a solid driving capacity should be promoted while pursuing digital upgrading to empower the industry to improve quality and efficiency, thereby promoting the high-quality development of the light industry and the textile industry. The only “agglomerated” industry in Shanxi is gas production and supply. Based on the advantages of Shanxi’s energy industry, we should accelerate the promotion of coalbed methane storage and production; build a clean, low-carbon, and efficient modern energy supply system; and promote the gas industry as a new strategic and pillar industry for the transformation and development of Shanxi’s resource-based economy.

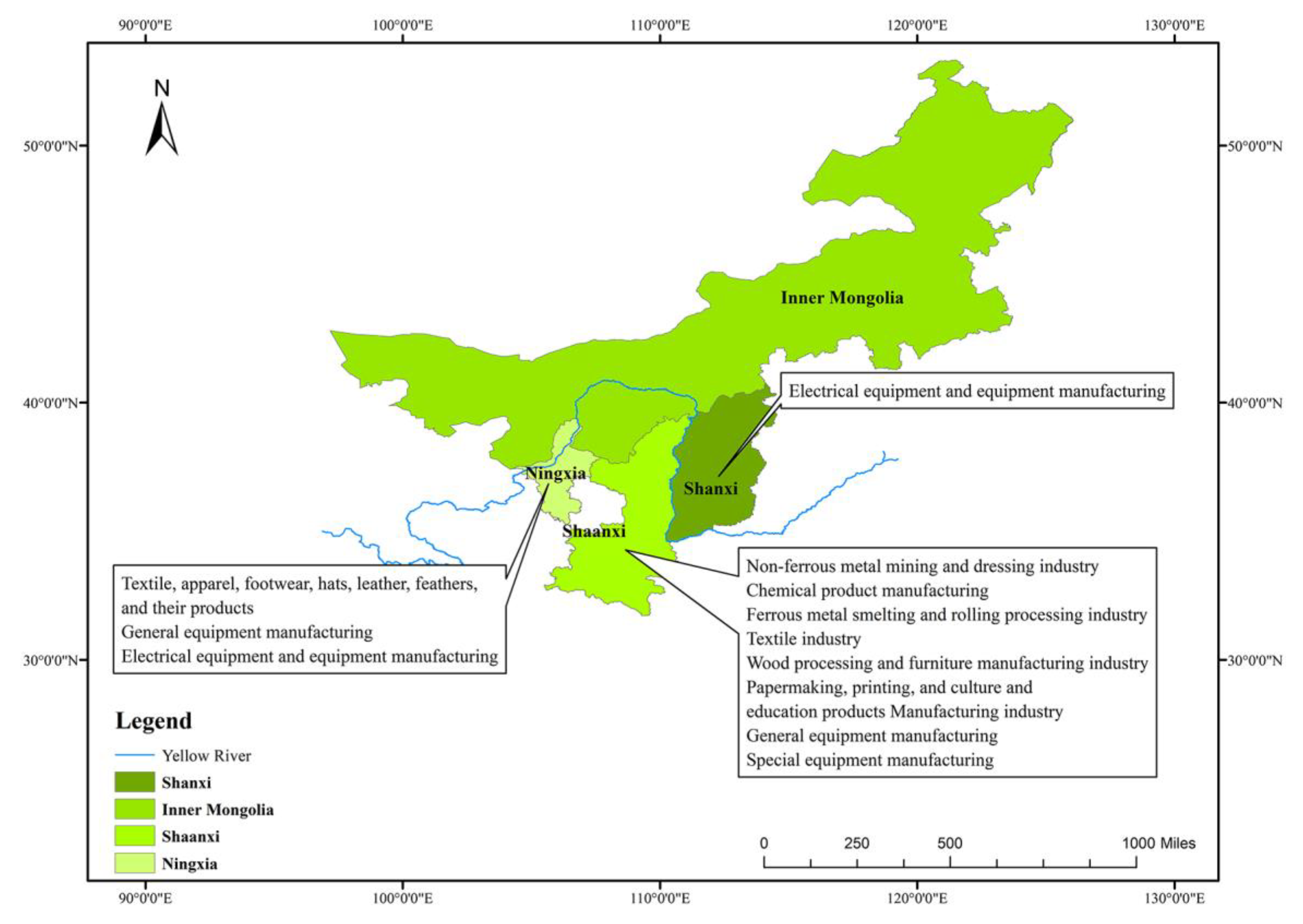

4.5. Spatial Layout of Promising Industries

Figure 7 presents the distribution of promising industries in the Bend provinces. The promising industries in Shaanxi cover resource-intensive industries, such as non-ferrous metal mining and dressing, chemical product manufacturing, and ferrous metal smelting and rolling processing; labor-intensive industries, such as textiles, wood processing and furniture manufacturing, and papermaking, printing, and culture and education product manufacturing; and technology-intensive industries, such as general equipment manufacturing and special equipment manufacturing. No capital-intensive industries are included as promising industries. Overall, the promising industries in Shaanxi are distributed rather evenly across resource-, labor-, and technology-intensive industries. Although Shaanxi’s non-metallic mineral extraction, chemical industry manufacturing, and metal smelting and rolling processing industries do not have agglomeration advantages, the industries are in a state of transfer. They have apparent low-carbon competitiveness advantages compared with the national low-carbon competitiveness index of the same industries, so, in the process of attracting industrial transfer, we should promote the green transformation and upgrading of these industries and their low-carbon development. The integration and development of labor-intensive industries with new-generation information technology and enhanced industrial intelligence should be promoted, as should the development of the general equipment manufacturing and special equipment manufacturing industries toward high-end equipment manufacturing clusters in the western region. Furthermore, more leading enterprises should be attracted to settle and build factories. In Shanxi, the promising industry is electrical equipment and equipment manufacturing. In Ningxia, there are three promising industries: apparel, footwear, hats, leather, and feathers and their products; general equipment manufacturing; and electrical equipment and equipment manufacturing. In these two provinces, the promising industries are mainly labor-intensive and technology-intensive. As the resource-based economies of Shanxi and Ningxia enter a period of decline, breakthroughs for future industrial transformation will occur through the development of labor-intensive and, partially, technology-intensive industries. Therefore, it is necessary to effectively change the mode of development; strengthen exchanges and cooperation with Beijing, Tianjin, Hebei, the Bohai Rim, and the Guangdong–Hong Kong–Macao Greater Bay Area; develop advanced sectors, such as science and technology; and attract talent from the areas mentioned above. In the context of the tremendous domestic cycle, it is vital to promote the transfer of technology-intensive industries to central cities, provincial sub-centers, and other areas with richly innovative sectors and solid industrial bases. Relying on the advantages of low labor costs in Shanxi and Ningxia, the gradual and orderly transfer of labor-intensive industries from the eastern regions should be undertaken to build a national base for the production of light industrial products and green food.

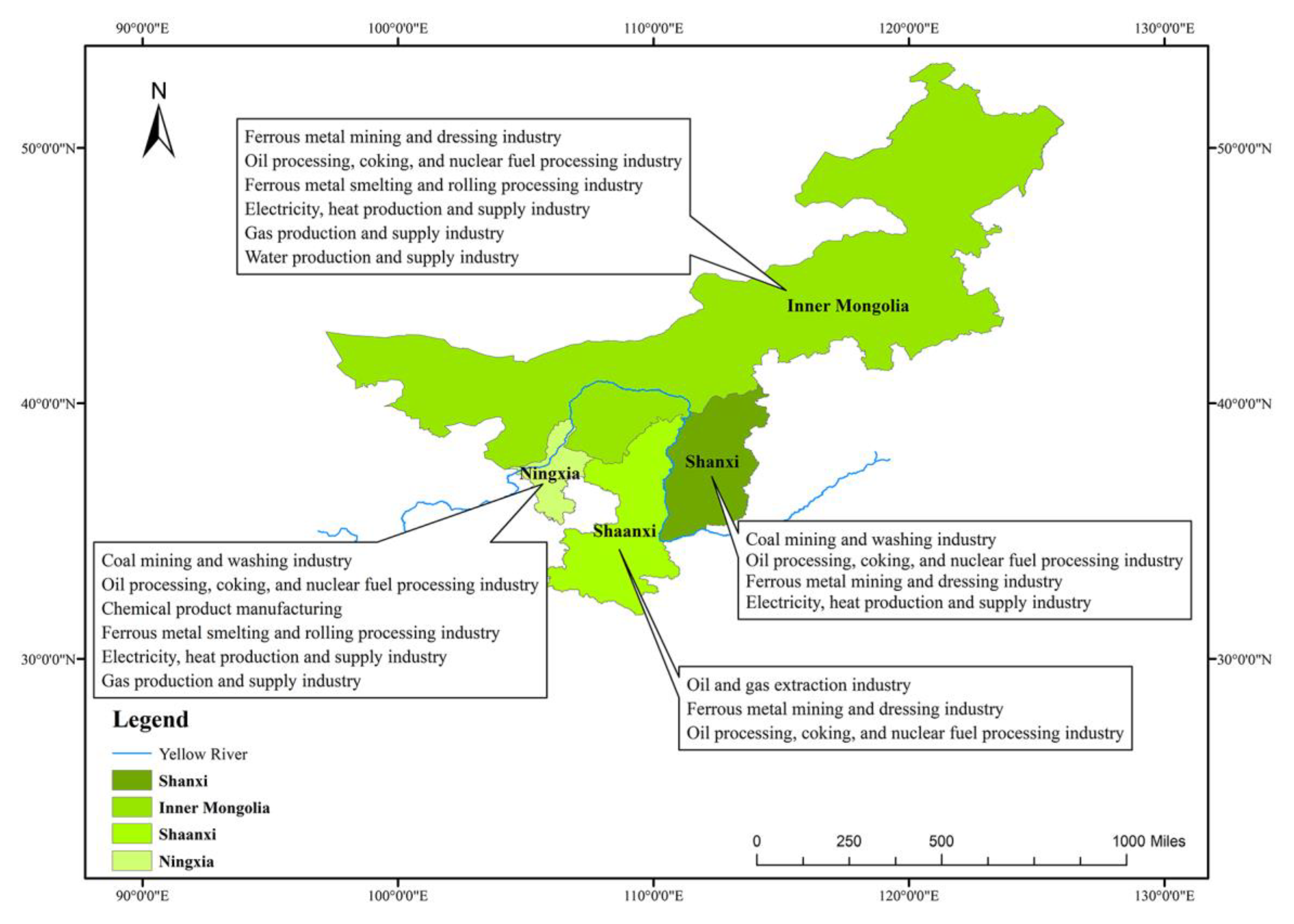

4.6. Spatial Layout of Scale Industries

Figure 8 shows the layout of scale industries in the Bend provinces. In Shanxi, four industries can be considered as scale industries: coal mining and washing; oil processing, coking, and nuclear fuel processing; ferrous metal smelting and rolling processing; and electricity, heat production, and supply. In Inner Mongolia, six industries fall into this category: ferrous metal mining and dressing; oil processing, coking, and nuclear fuel processing; ferrous metal smelting and rolling processing; electricity, heat production, and supply; gas production and supply; and water production and supply. In Shaanxi, three industries are scale industries: oil and gas extraction; ferrous metal mining and dressing; and oil processing, coking, and nuclear fuel processing. In Ningxia, seven industries can be regarded as scale industries: coal mining and washing; oil processing, coking, and nuclear fuel processing; chemical product manufacturing, ferrous metal smelting and rolling processing; electricity, heat production, and supply; gas production and supply; and water production and supply. Most of the above industries are resource- and capital-intensive. Their static agglomeration indices are all greater than 1. The greatest problem with the above industries in the regional development process is that they are more dependent on energy and must meet the requirements of the spatial layout of industries based on the carbon peak target. However, these industries also play an essential role in supporting regional economic growth. Therefore, under the carbon peak target, it is necessary to change the mode of industrial development and energy use to resolve the conflict between industrial layout and carbon emissions. We should accelerate the transformation of high-energy-consuming and high-polluting industries with applicable high-tech and advanced technologies, strengthen the dual control of total energy consumption and intensity, and promote the high-end, intelligent, and green development of traditional industries in order to use the scale effect to drive high-quality regional development. The single energy structure of the Bend is also the main reason for the uneven development of the industries, as mentioned above. Therefore, we should rely on the advantages of the regional resources, promote the development of renewable energy, and build a diversified energy supply. The low energy use efficiency of traditional industries in the region is the main reason for the low-carbon competitiveness of the industries. Therefore, we should attach great importance to the research, development, and innovation of key energy technologies, encourage enterprises to carry out independent innovation in the energy field, continuously promote the improvement of the energy use efficiency of resource-intensive industries and capital-intensive industries, and reduce the impact of carbon emission constraints on industrial development.

6. Conclusions and Policy Suggestions

6.1. Conclusions

This paper establishes a research paradigm for optimizing the industrial spatial layout and high-quality development in the context of carbon peaking. From the perspective of industrial transfer, this paper utilizes the static agglomeration index (), dynamic agglomeration index (), industrial gradient coefficient (), and low-carbon competitiveness index () to analyze industrial agglomeration, competitive advantage, and low-carbon advantage. On this basis, the paper summarizes the difficulties in the industrial development of each province in the Bend and optimizes their industrial layout.

(1) Among the resource-intensive industries, the coal mining and washing industry has the highest static agglomeration indices. The indices of the other industries fluctuated significantly. In labor-intensive industries, the agglomeration advantage of most industries was weakened in the provinces. In capital-intensive industries, obvious agglomeration trends were observed in oil processing, coking, and nuclear fuel processing and electricity, heat production, and supply. As for technology-intensive industries, the static agglomeration indices declined to different degrees in the sample period, reflecting an apparent trend of industrial transfer-out.

(2) The agglomerated and competitive industries in the Bend are concentrated in resource-intensive, labor-intensive, and technology-intensive industries. Technology-intensive industries are developing slowly and face an unreasonable pattern of industrial layout. There is a significant gap between the provinces in terms of agglomerated and competitive industries.

(3) Resource-intensive industries in the Bend boast obvious low-carbon competitiveness compared to industries in other regions of China. These industries are the focus of industrial layout in the context of carbon peaking and reflect the comparative advantages of the region in resource endowments. The provinces differ markedly in the low-carbon competitiveness of labor-, capital-, and technology-intensive industries.

(4) There are not many agglomerated industries in the Bend provinces, but these industries appear in every kind of industry. They are the focal points in the future industrial layout of the Bend. The promising industries are mostly resource-intensive, labor-intensive, and capital-intensive and should be further exploited by the provinces. Scale industries are concentrated in resource-intensive and capital-intensive industries, which are the traditionally advantageous industries. The provinces should properly develop scale industries in the pursuit of carbon peaking.

6.2. Governmental Actions

When relying on industrial transfer to optimize the spatial layout of industries in the Bend, the provinces should take the bearing capacity of the resources and the environment, the ecological and environmental capacities, and the carbon peaking and carbon neutral targets as important bases and exploit the guiding role of the government according to the competitive advantages of industries in each province and region. The government should establish innovative institutional mechanisms, improve the policy system, guide the reasonable and orderly transfer of industries, and create an industrial development pattern with excellent regional division of labor and linkage development.

(1) The government should promote the transformation of resource advantages into industrial advantages. Under the condition that industrial, energy, and carbon emission policies are met, governments should support high-energy-consuming industries that meet the requirements of ecological and environmental zoning and the requirements of environmental protection, energy efficiency, safe production, and other standards, driving them to cluster in areas with advantages in clean energy in the Bend. The government should control the industrial transfer from the eastern region in an orderly manner, relying on the advantages of the “agglomerated” industrial layout of the coal mining industry and oil and gas mining industry in Inner Mongolia and Shaanxi to build a nationally important energy and chemical industry and resource processing base to ensure national industrial and energy security. At the same time, the government should support the development of succession and alternative industries in resource-based areas and promote the transformation and upgrading of these areas.

(2) The government should undertake the development of industries with advantages and characteristics according to local conditions. Based on the layout of “agglomerated” and “potential” industries in each province and region, and according to the competitive advantages of each province and region, the development of key industries should be promoted. The government should guide the transfer of labor-intensive industries to Ningxia and Shaanxi and a labor-intensive industrial base focusing on the textile industry. The transfer of technology-intensive industries to the central cities, provincial sub-centers, and other areas in the Bend that are rich in innovation factors and have solid industrial bases should be promoted, and regional high-technology industrial bases should be constructed. The government should guide the transfer of productive service industries, such as software development, information services, and industrial design, in synergy with technology-intensive industries. The advantages of Shaanxi’s rich energy resources and industrial base should be exploited, guiding the transfer of non-metallic mineral production, chemical product manufacturing, metal smelting, and rolling processing industry to Shaanxi in order to build an open highland and energy and raw materials base in the inland region.

(3) The government should promote the transformation and development of high-carbon industries. The industrial distribution of the provinces and regions is concentrated in resource-intensive and capital-intensive industries, and development patterns of significant carbon emissions and high emission intensity still exist. In the context of carbon peaking, the relationship between regional economic development and carbon emissions must be balanced, and the blind development of high-energy-consuming and high-emission projects must be curbed. For the production and supply of electricity and heat, based on the development of regional clean energy in the Bend, the government should build a clean, low-carbon, safe, and efficient energy system with new energy as its mainstay; actively develop wind, photovoltaic, and hydrogen energy, energy storage, and other industrial clusters; promote renewable energy substitution to achieve results on the ground; and accelerate the transformation of the power system from thermal power to new energy. For chemical product manufacturing, metal smelting, and rolling processing and petroleum, coking products, and nuclear fuel processing, we should strengthen the “double control” of total carbon emissions and intensity, promote the national trading of carbon emission targets in crucial industries, and use market mechanisms to reduce carbon emissions. The government should utilize electricity price regulation, strictly control electricity consumption by high-energy-consuming enterprises on the demand side, establish a sound energy-saving monitoring system, and dynamically adjust the energy consumption of vital high-energy-consuming projects. Following the government’s policy of controlling “too-high-energy” projects, financial institutions should avoid financing “too-high-energy” projects that fail to pass the energy-saving review and environmental assessment and do not meet national green development requirements, thereby acting as gatekeepers and ensuring green development.

(4) The government should improve the institutional mechanisms to support industrial transfer. This includes improving the industrial transfer service system and the national industrial transfer information platform and continuing to hold industrial transfer docking activities to promote precise industrial docking. Several typical cooperation models for industrial transfer should be selected to promote model innovation and application. The government should strengthen the tracking and evaluation of industrial transfer, build an evaluation index for regional industrial transfer, and scientifically evaluate the effectiveness of industrial transfer. The Catalogue of Industries Encouraging Foreign Investment and the Guidance Catalogue for Industrial Development and Transfer should be revised in due course. The government can establish a national platform for industrial integration and cooperation and guide financial institutions to create innovative financial products that support industrial transfer cooperation, as well as study and support localities in setting up industrial transfer funds based on risk control and adherence to market orientation. The regions should be supported in training skilled personnel in line with the industries to be promoted, and an assistance program should be launched to construct a regional human resources market in the Bend.