A Combinatorial Optimization Strategy for Performance Improvement of Stratum Ventilation Considering Outdoor Weather Changes and Metabolic Rate Differences: Energy Consumption and Sensitivity Analysis

Abstract

:1. Introduction

1.1. Research Tools and Methods

1.2. Organization of the Manuscript

2. Methodology

2.1. Evaluation Indices of Ventilation Performance

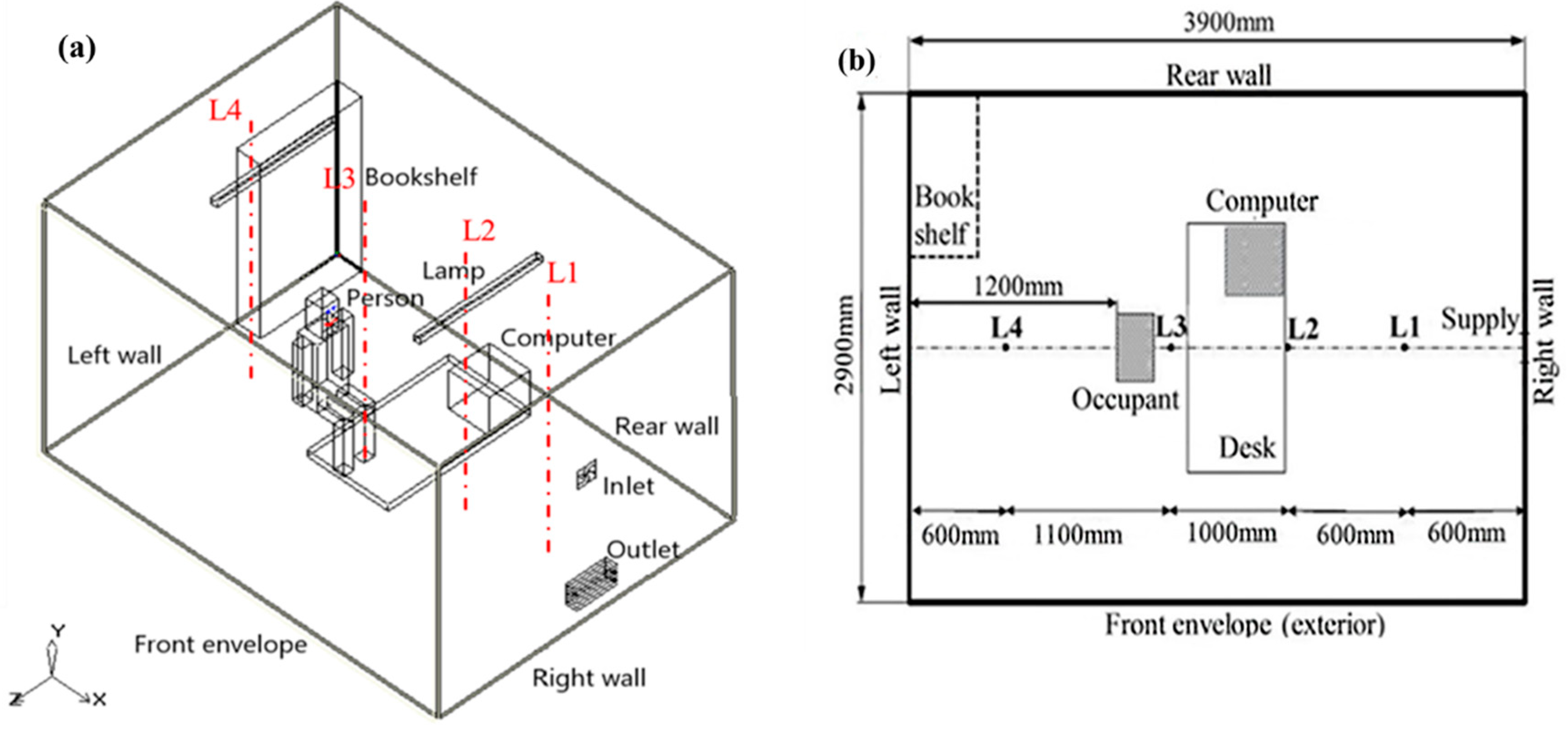

2.2. Experiment

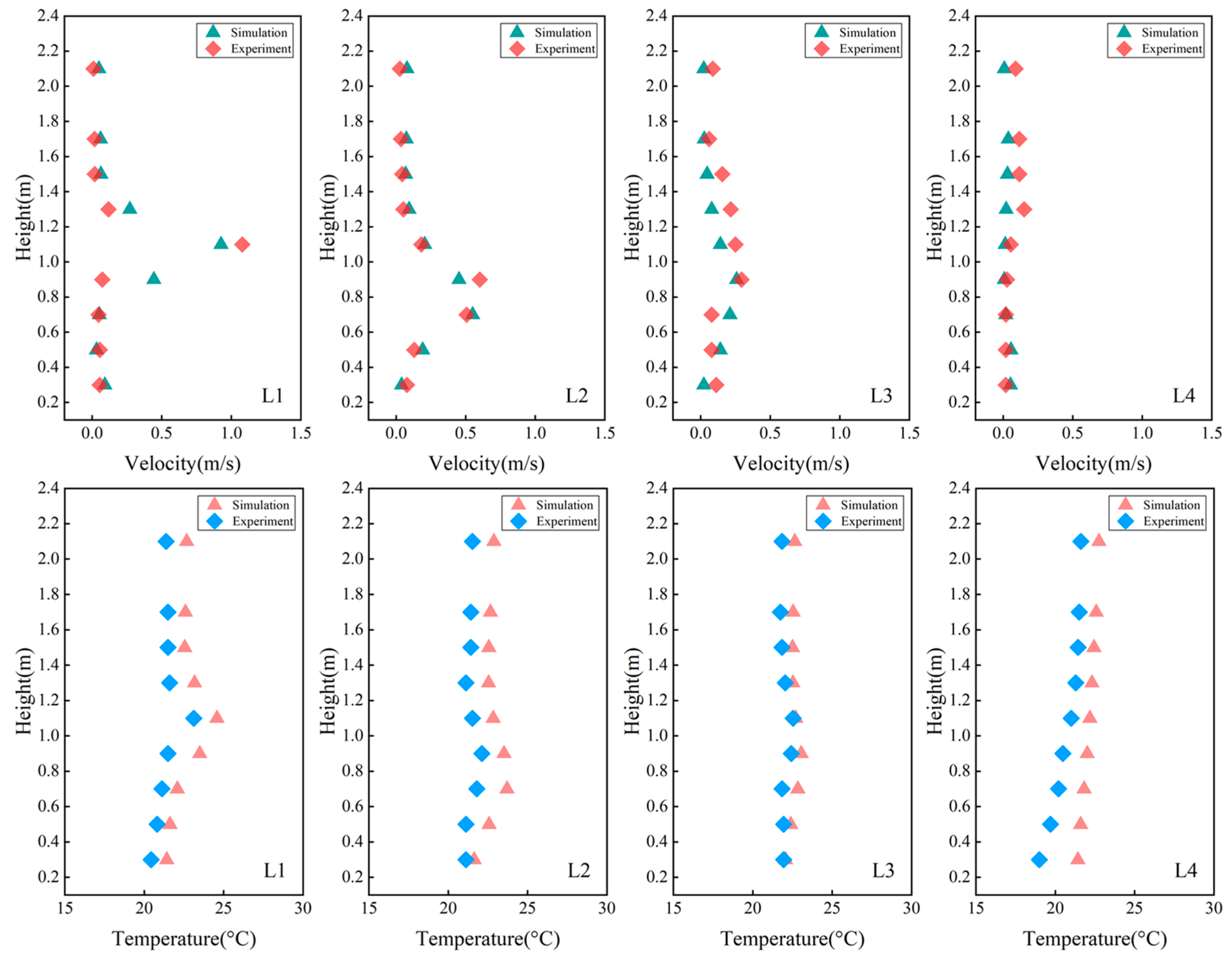

2.3. CFD Simulation

2.4. Response Surface Modeling

2.5. Pareto-Based Combinatorial Optimization Model

3. Results and Discussion

3.1. Validation of CFD Simulation

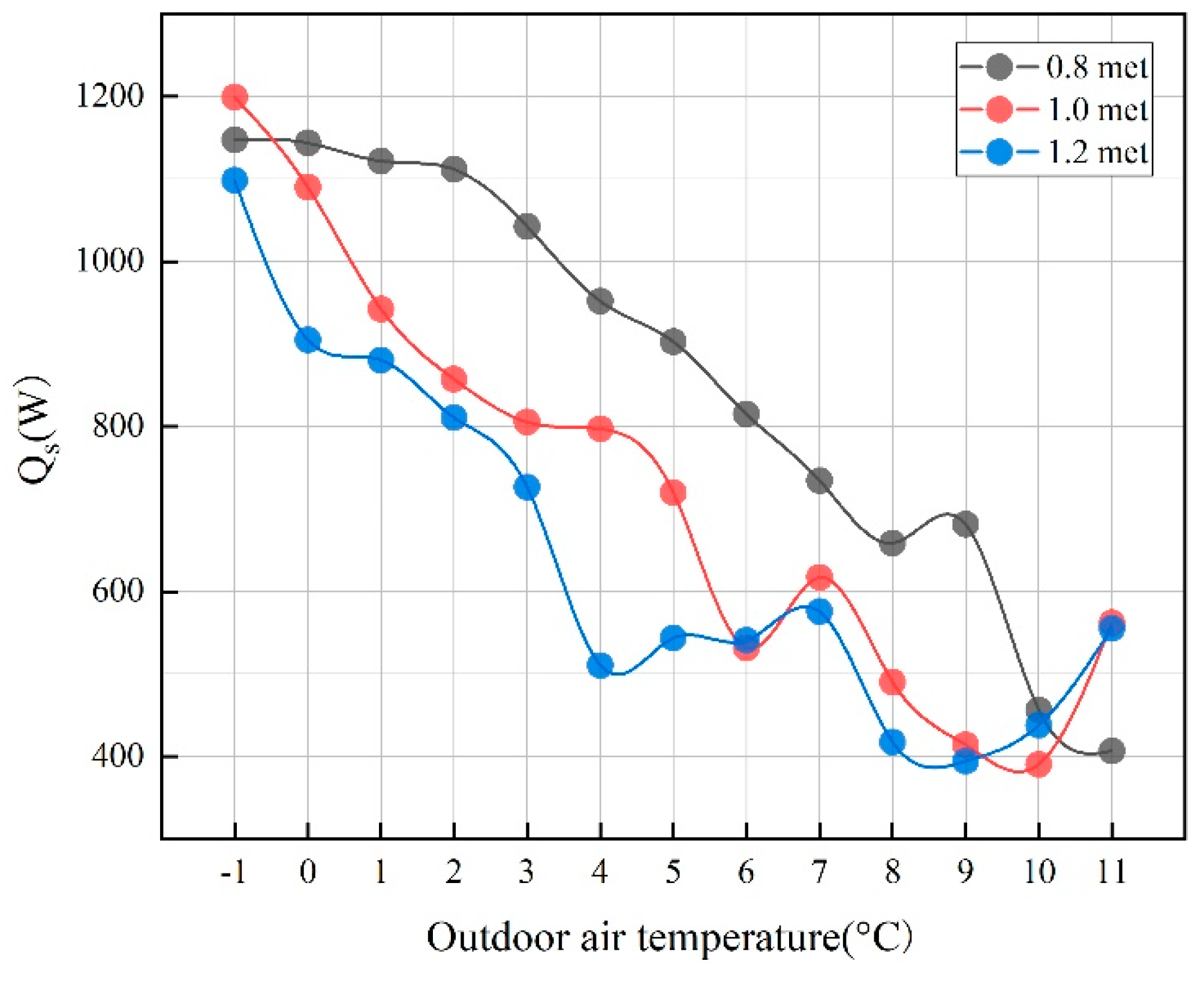

3.2. Combinatorial Optimization Modeling

3.3. Combinatorial Optimization Strategy Optimization and Analysis

3.4. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature and Abbreviations

| Age of occupant (year) | |

| The nude body surface area (m2) | |

| Positional parameter | |

| B is diagnosis of burn (present = 1, absent = 0) | |

| The basal metabolism (w) | |

| The basal metabolic rate (w/m2) | |

| Specific heat (J/kgK) | |

| , | Coefficients of the response |

| , | surface model |

| Height of occupants (cm) | |

| The mean absolute error betweenpredictions and observations | |

| Variation index | |

| Prediction of the RSM | |

| Air density (kg/m3) | |

| Relative operational energyconsumption (W) | |

| The nude body surface area (m2) | |

| Sex (male = 1, female = 0) | |

| CFD simulations | |

| The standard deviation of thejth indicator | |

| , | Interval random numbers |

| Outdoor air temperature | |

| Supply air temperature (°C) | |

| , | Normalized random positive number |

| Supply air velocity (m3/s) | |

| Supply air flow rate (l/s) | |

| Weight coefficient | |

| , | Expressions of parents |

| , | Expressions of children |

| Normalized design parameter | |

| , | The minimal and maximal original values of the design parameter |

| CFD | Computational fluid dynamics |

| CRITIC | Criteria importance though intercriteria correlation method |

| DV | Displacement ventilation |

| FCE | Fuzzy comprehensive evaluation |

| MV | Mixing ventilation |

| PMV | Predicted mean vote |

| PPD | Predicted percentage dissatisfied |

| SV | Stratum ventilation |

| TOPSIS | The technique for order preference by similarity to ideal solution |

| NSGA-II | Non-dominated sorting genetic algorithm-II |

| RSM | Response surface model |

References

- Staveckis, A.; Borodinecs, A. Impact of impinging jet ventilation on thermal comfort and indoor air quality in office buildings. Energy Build. 2021, 235, 163–170. [Google Scholar] [CrossRef]

- Wu, J.; Hou, Z.; Shen, J.; Lian, Z.W. A method for the determination of optimal indoor environmental parameters range considering work performance. J. Build. Eng. 2021, 35, 101976. [Google Scholar] [CrossRef]

- Li, S.; Li, Z. Requirements of HVAC for Green Building. Constr. Conserv. Energy 2011, 39, 20–24. [Google Scholar]

- Lin, Y.J.P.; Lin, C.L. A study on flow stratification in a space using displacement ventilation. Int. J. Heat Mass Transf. 2014, 73, 67–75. [Google Scholar] [CrossRef]

- Amai, H.; Novoselac, A. Experimental study on air change effectiveness in mixing ventilation. Build. Environ. 2016, 109, 101–111. [Google Scholar] [CrossRef]

- Chludzinska, M. An indoor environment evaluation by gender and age using an advanced personalized ventilation system. Build. Serv. Eng. Res. Technol. 2017, 5, 505–521. [Google Scholar]

- Lin, Z.; Zhou, T.T.; Tang, C.F. Stratum ventilation: A conceptual introduction. In Proceedings of the 10th International Conference on Indoor Air Quality and Climate, Beijing, China, 4–9 September 2005; pp. 3260–3264. [Google Scholar]

- Zhang, S.; Lin, Z.; Ai, Z.T.; Huan, C.; Cheng, Y.; Wang, F.H. Multi-criteria performance optimization for operation of stratum ventilation under heating mode. Appl. Energy 2019, 239, 969–980. [Google Scholar] [CrossRef]

- Fong, M.L.; Lin, Z.; Fong, K.F.; Chow, T.T.; Yao, T. Evaluation of thermal comfort conditions in a classroom with three ventilation methods. Indoor Air 2011, 3, 231–239. [Google Scholar] [CrossRef]

- Luis, A.R.; Cesar, C. Numerical study and optimization of air-conditioning systems grilles used in indoor environments. Int. J. Energy Environ. Eng. 2021, 12, 787–804. [Google Scholar]

- Zhang, L.N.; Mao, Y.H.; Tu, Q.; Wu, X.G.; Tan, L.Y. Effects of Supply Parameters of Stratum Ventilation on Energy Utilization Efficiency and Indoor Thermal Comfort: A Computational Approach. Math. Probl. Eng. 2021, 2021, 1–16. [Google Scholar] [CrossRef]

- Wang, C.H.; Liu, J.J.; Yu, C.W.; Xie, D. Numerical analysis for the optimization of multi-parameters stratum ventilation and the effect on radon dispersion. J. Build. Eng. 2022, 62, 39–47. [Google Scholar] [CrossRef]

- Diana, I.; John, B.; Dominik, W.; Biljana, M.; Max, C.; Felix, C. Quantifying the potential for climate change mitigation of consumption options. Environ. Res. Lett. 2020, 15, 093001. [Google Scholar]

- Ehsan, E.; Zainab, K.; Muhammad, Z.T.; Zhang, H.X.; Xing, L.R. Extreme weather events risk to crop-production and the adaptation of innovative management strategies to mitigate the risk: A retrospective survey of rural Punjab, Pakistan. Tecnovation 2022, 117, 102255. [Google Scholar]

- Sanna, M.; Annela, A.K. Social impacts of climate change mitigation policies and their implications for inequality. Clim. Policy 2019, 19, 827–844. [Google Scholar]

- Ehsan, E.; Zainab, K. Estimating smart energy inputs packages using hybrid optimization technique to mitigate environmental emissions of commercial fish farms. Appl. Energy 2022, 326, 119602. [Google Scholar]

- Bai, Y.; Wan, T.C. The SPA-TOPSIS-Based evaluating approach on thermal sensation model at different vane angles in UFAD–DV system. Arab. J. Sci. Eng. 2021, 46, 1787–1802. [Google Scholar] [CrossRef]

- Wan, T.C.; Bai, Y.; Wu, L.L.; He, Y.E. Multi-criteria decision making of integrating thermal comfort with energy utilization coefficient under different air supply conditions based on human factors and 13-value thermal comfort scale. J. Build. Eng. 2021, 39, 102249. [Google Scholar] [CrossRef]

- Frankenfield, D.C.; Muth, E.R.; Rowe, W.A. The Harris-Benedict studies of human basal metabolism: History and limitations. J. Am. Diet. Assoc. 1998, 98, 439–445. [Google Scholar] [CrossRef]

- Rao, Z.; Wu, X. Difference between predictive and measured resting energy expenditure in healthy subjects. Chin. J. Tissue Eng. Res. 2010, 14, 8707–8711. [Google Scholar]

- Hasson, R.E.; Howe, C.A.; Jones, B.L.; Freedson, P.S. Accuracy of four resting metabolic rate prediction equations: Effects of sex, body mass index, age, and race/ ethnicity. J. Sci. Med. Sport 2011, 14, 344–351. [Google Scholar] [CrossRef]

- DuBois, D. A formula to estimate approximate surface area, if height and weight are known. Arch. Int. Med. 1916, 17, 63–71. [Google Scholar]

- Ireton-Jones, C.; James, D.J. Improved equations for predicting energy expenditure in patients: The Ireton Jones Equations. Nutr. Clin. Pract. 2005, 17, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Lin, Z.; Ai, Z.; Wang, F.; Cheng, Y.; Huan, C. Effects of operation parameters on performances of stratum ventilation for heating mode. Build. Environ. 2019, 145, 55–66. [Google Scholar] [CrossRef]

- Arnaud, L.; Mathias, C.; Benjamin, K.; Olivier, L.M. Optimization principle and application of forced ventilation in railway tunnels based on improved TOPSIS theory and CFD simulations. Adv. Mech. Eng. 2021, 235, 168781402110176. [Google Scholar]

- Liang, S.S.; Li, B.Z.; Tian, X.; Cheng, Y.; Liao, C.H.; Zhang, J.H.; Liu, D. Determining optimal parameter ranges of warm supply air for stratum ventilation using Pareto-based MOPSO and cluster analysis. J. Build. Eng. 2021, 37, 102145. [Google Scholar] [CrossRef]

- Talib, R.; Nassif, N. Heating Ventilation and Air Conditioning Systems Performance Optimization Using a Two-Level Optimization Ap-proach. ASHRAE Trans. 2021, 1, 505–513. [Google Scholar]

- Jung, D.H.; Kim, H.J.; Kim, J.; Lee, T.S. Design Optimization of Proportional Plus Derivative Band Parameters Used in Greenhouse Ventila-tion by Response Surface Methodology. Ecol. Restor. 2020, 38, 187–200. [Google Scholar]

- Turkane, S.D.; Chouksey, S.K. Application of response surface method for optimization of stabilizer dosages in soil stabilization. Innov. Infrastruct. Solut. 2022, 7, 106. [Google Scholar] [CrossRef]

- UNE-EN ISO 7730-2006; Ergonomics of the Thermal Environment-Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Standard Organization: Brussels, Belgium, 2006; pp. 1–25.

- ASHRAE. Thermal Environmental Conditions for Human Occupancy, ASHRAE Standard 55-2013; American Society of Heating, Refrigerating and Air-conditioning Engineers: Atlanta, Georgia, 2017. [Google Scholar]

- Cheng, Y.; Fong, M.L.; Yao, T.; Lin, Z.; Fong, K.F. Uniformity of stratum ventilated thermal environment and thermal sensation. Indoor Air 2014, 24, 521–532. [Google Scholar] [CrossRef]

- Chen, H.; Moshfegh, B.; Cehlin, M. Computational investigation on the factors influencing thermal comfort for impinging jet ventilation. Build. Environ. 2013, 66, 29–41. [Google Scholar] [CrossRef]

- Yang, W.X. Analysis on Operational Regulation of Heat Metering Systems; Tianjin University: Tianjin, China, 2012. [Google Scholar]

- Li, Y.; Miao, Y.; Bao, J.H. AIRPAK simulation research on residential indoor air quality. Sci. Total Environ. 2014, 472, 1137–1144. [Google Scholar]

- Mao, N.; Hao, J.Y.; He, T.B.; Song, M.J.; Xu, Y.J.; Deng, S.M. PMV-based dynamic optimization of energy consumption for a residential task/ambient air conditioning system in different climate zones. Renew. Energy 2019, 142, 41–54. [Google Scholar] [CrossRef]

- Ren, F.; Du, J.; Cai, Y.F. Solidification performance analysis of bionic spider web vertical latent heat system based on response surface method optimization. J. Energy Storage 2022, 55, 122–134. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Z.; Shi, J. Optimization Design of the Integral Inertial Particle Separator Based on Response Surface Method. J. Appl. Fluid Mech. 2020, 13, 133–145. [Google Scholar] [CrossRef]

- Design Expert Version 8.0.6. User’s Guide; Stat-Ease Inc: Minneapolis, MN, USA, 2007.

- Mulay, A.; Rathod, V.K. Ultrasound-assisted synthesis of ethyl hexanoate using heterogeneous catalyst: Optimization using Box-Behnken design. J. Indian Chem. Soc. 2022, 99, 100573. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, H.L. Thermal Comfort of The Patients and Its Influence about Evaluating of Thermal Environment. Refrig. Air Cond. 2015, 29, 505–508. (In Chinese) [Google Scholar]

- Ali, P.; Konstadinos, H. Security/stability-based Pareto optimal solution for distribution networks planning implementing NSGAII/FDMT. Energy 2020, 192, 116644. [Google Scholar]

- Scherbakov, A.; Butyrin, A.; Stativa, E.; Larkina, A.; Verbova, N. Structural optimization of a mobile rope transport system hydro pipe based on pareto-optimal solutions. Transp. Res. Procedia 2022, 63, 1489–1497. [Google Scholar] [CrossRef]

- Federico, P.; Elisa, B.; Loris, V. A multi-objective optimization approach for FE model updating based on a selection criterion of the pre-ferred Pareto-optimal solution. Structures 2021, 33, 916–934. [Google Scholar]

- Joshua, C.; Laura, M.; James, T. Comparison of genetic algorithm to particle swarm for constrained simulation-based optimization of a geothermal power plant. Adv. Eng. Inform. 2014, 1, 81–90. [Google Scholar]

- Jia, F.; Lichti, D. A comparison of simulated, genetic algorithm and particle swarm optimization in optimal first-order design of indoor tells networks. In Proceedings of the ISPRS Annals of Photogrammetry, Remote Sensing and Spatial Information Sciences, Wuhan, China, 18–22 September 2017. [Google Scholar]

- Shi, H.T.; Li, Y.F.; Jiang, Z.N.; Zhang, J. Comprehensive power quality evaluation method of microgrid with dynamic weighting based on CRITIC. Meas. Control. 2021, 54, 5–6. [Google Scholar] [CrossRef]

- Behzadian, M.; Otaghsara, S.K.; Yazdani, M.; Ignatius, J. A state-of the-art survey of TOPSIS applications. Expert Syst. Appl. 2012, 17, 51–69. [Google Scholar] [CrossRef]

- Kannan, S.; Baskar, S.; McCalley, J.D.; Murugan, P. Application of NSGA-II algorithm to generation expansion planning. IEEE Trans. Power Syst. 2008, 24, 454–461. [Google Scholar] [CrossRef]

- Pan, B.H.; Liu, S.R.; Xie, Z.J.; Shao, Y.; Li, X.; Ge, R.C. Evaluating operational features of three unconventional intersections under heavy traf-fic based on CRITIC method. Sustainability 2021, 113, 4098. [Google Scholar] [CrossRef]

- Gilani, S.; Montazeri, H.; Blocken, B. CFD simulation of stratified indoor environment in displacement ventilation: Validation and sensi-tivity analysis. Build. Environ. 2016, 95, 299–313. [Google Scholar] [CrossRef]

- Melikov, A.; Popiolek, Z.; Silva, M.C.G.; Care, I.; Sefker, T. Accuracy limitations for low velocity measurements and draft assessment in rooms. HVAC R Res. 2007, 13, 971–986. [Google Scholar] [CrossRef]

- Davardoost, F.; Kahforoushan, D. Evaluation and investigation of the effects of ventilation layout, rate, and room temperature on pollu-tion dispersion across a laboratory indoor environment. Environ. Sci. Pollut. Res. 2019, 26, 5410–5421. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, Y.; Cheng, Y.; Huang, P.; Oladokun, M.O.; Lin, Z. Response-surface-model based system sizing for nearly/net zero energy buildings under uncertainty. Appl. Energy 2018, 228, 1020–1031. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, T.X.; Wan, T.C. Multi-criteria performance dynamic optimization for heating operation of stratum ventilation considering different metabolic rates. Arab. J. Sci. Eng. 2022, 14, 542–554. [Google Scholar] [CrossRef]

- Ahmed, F.; Abdul, A.M.S.; Mohd, A.Z.M.R.R.; Yee, K.C.; Shaik, F.; Che, H.D.S.; Mohd, S.M.A.A.; Kheimi, M. Design, Modelling and Optimization of a Novel Concentrated Solar Powered (CSP) Flash Desalination System Involving Direct Heating and Pressure Modulation Using Response Surface Methodology (RSM). Sustainability 2022, 14, 11558. [Google Scholar] [CrossRef]

- Aminia, R.; Ghaffarianhoseinib, A.; Berardi, U. Numerical investigation of indoor thermal comfort and air quality for a multi-purpose hall with various shading and glazing ratios. Therm. Sci. Eng. Prog. 2021, 22, 2–13. [Google Scholar] [CrossRef]

| Cases | Design Parameters | Design Responses | ||||||

|---|---|---|---|---|---|---|---|---|

| M (m) | Ts (°C) | VS (m3/s) | Tout (°C) | PMV (−) | QS (W) | ΔT (°C) | LMAA (s) | |

| 1 | 0.8 | 25 | 0.03 | 5 | 0.0649 | 541.532 | 2.5712 | 769.264 |

| 2 | 1 | 28 | 0.04 | −1 | 0.333 | 1046.91 | 3.5101 | 654.23 |

| 3 | 1.2 | 28 | 0.04 | 5 | 1.24 | 784.959 | 2.1234 | 640.965 |

| 4 | 1 | 25 | 0.04 | 5 | 0.52 | 766.451 | 1.7568 | 625.036 |

| 5 | 1 | 28 | 0.04 | 11 | 1.52 | 669.344 | 1.4474 | 642.562 |

| 6 | 1 | 25 | 0.05 | −1 | 0.001 | 1246.03 | 2.1721 | 441.689 |

| 7 | 1 | 25 | 0.05 | 11 | 1.12 | 740.993 | 0.5249 | 463.341 |

| 8 | 1 | 22 | 0.04 | 11 | 0.678 | 486.173 | 0.3126 | 562.581 |

| 9 | 1.2 | 25 | 0.05 | 5 | 0.812 | 1007.87 | 1.2172 | 524.109 |

| 10 | 1 | 22 | 0.03 | 5 | 0.066 | 487.035 | 1.8743 | 686.5 |

| 11 | 1 | 28 | 0.05 | 5 | 1.02 | 1118.72 | 1.836 | 445.451 |

| 12 | 1.2 | 22 | 0.04 | 5 | 0.368 | 688.597 | 1.4861 | 608.267 |

| 13 | 0.8 | 25 | 0.05 | 5 | 0.246 | 987.914 | 1.527 | 523.726 |

| 14 | 1 | 25 | 0.03 | −1 | −0.241 | 676.224 | 3.415 | 778.392 |

| 15 | 1 | 22 | 0.05 | 5 | 0.062 | 873.651 | 0.8011 | 420.369 |

| 16 | 0.8 | 28 | 0.04 | 5 | 0.608 | 843.966 | 2.1915 | 637.416 |

| 17 | 1.2 | 25 | 0.03 | 5 | 0.762 | 509.577 | 2.3996 | 779.837 |

| 18 | 1 | 22 | 0.04 | −1 | −0.495 | 868.951 | 2.2121 | 539.563 |

| 19 | 1 | 28 | 0.03 | 5 | 0.79 | 605.119 | 2.5352 | 809.483 |

| 20 | 1 | 25 | 0.03 | 11 | 1.11 | 418.016 | 1.3184 | 790.363 |

| 21 | 0.8 | 25 | 0.04 | 11 | 0.8 | 569.038 | 1.191 | 637.09 |

| 22 | 1.2 | 25 | 0.04 | −1 | 0.262 | 967.845 | 2.6326 | 626.56 |

| 23 | 0.8 | 25 | 0.04 | −1 | −0.448 | 949.983 | 3.001 | 622.618 |

| 24 | 0.8 | 22 | 0.04 | 5 | −0.153 | 668.043 | 1.3934 | 643.663 |

| 25 | 1.2 | 25 | 0.04 | 11 | 1.289 | 558.365 | 0.79253 | 626.245 |

| Thermal Comfort | Energy Consumption | |||

|---|---|---|---|---|

| PMV | ΔT | LMAA | Qs (W) | |

| p | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| R2 | 0.9981 | 0.9737 | 0.9321 | 0.9967 |

| Adjusted R2 | 0.9968 | 0.9684 | 0.9185 | 0.9944 |

| Predicted R2 | 0.9939 | 0.9584 | 0.8921 | 0.9890 |

| MAE | 0.0199 | 0.1145 | 22.2441 | 9.2019 |

| SD | 0.0316 | 0.1493 | 31.95 | 16.57 |

| Cases | M (m) | Tout (°C) | Ts (°C) | Vs (m3/s) | PMV (−) | Qs (W) | ΔT (°C) | LMAA (s) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 23.809 | 0.049 | 0.000 | 1097.297 | 1.830 | 465.727 |

| 2 | 1 | 1 | 22.000 | 0.030 | −0.360 | 572.066 | 2.520 | 735.531 |

| 3 | 1 | 1 | 22.000 | 0.050 | −0.278 | 1047.268 | 1.513 | 436.319 |

| 4 | 1 | 1 | 22.000 | 0.030 | −0.360 | 572.045 | 2.520 | 735.532 |

| 5 | 1 | 1 | 22.005 | 0.041 | −0.314 | 832.519 | 1.969 | 571.627 |

| 6 | 1 | 1 | 23.194 | 0.030 | −0.219 | 592.288 | 2.705 | 747.693 |

| 7 | 1 | 1 | 24.655 | 0.038 | 0.025 | 819.877 | 2.545 | 648.324 |

| 8 | 1 | 1 | 25.045 | 0.030 | 0.001 | 623.389 | 2.990 | 766.703 |

| 9 | 1 | 1 | 22.866 | 0.034 | −0.235 | 677.758 | 2.468 | 689.160 |

| 10 | 1 | 1 | 24.157 | 0.032 | −0.089 | 652.224 | 2.768 | 732.412 |

| 11 | 1 | 1 | 22.000 | 0.050 | −0.278 | 1047.307 | 1.514 | 436.318 |

| 12 | 1 | 1 | 23.778 | 0.050 | 0.001 | 1114.776 | 1.788 | 454.553 |

| 13 | 1 | 1 | 22.601 | 0.039 | −0.241 | 800.363 | 2.163 | 607.879 |

| 14 | 1 | 1 | 23.765 | 0.044 | −0.046 | 959.720 | 2.090 | 544.624 |

| 15 | 1 | 1 | 22.550 | 0.037 | −0.255 | 760.017 | 2.235 | 631.330 |

| 16 | 1 | 1 | 24.463 | 0.045 | 0.066 | 1013.103 | 2.138 | 534.000 |

| 17 | 1 | 1 | 22.485 | 0.050 | −0.204 | 1054.084 | 1.612 | 448.439 |

| 18 | 1 | 1 | 24.228 | 0.047 | 0.049 | 1061.194 | 1.994 | 499.604 |

| 19 | 1 | 1 | 22.830 | 0.046 | −0.174 | 972.448 | 1.860 | 509.321 |

| 20 | 1 | 1 | 23.304 | 0.041 | −0.130 | 880.623 | 2.148 | 578.282 |

| 21 | 1 | 1 | 24.022 | 0.043 | −0.016 | 942.211 | 2.179 | 562.061 |

| 22 | 1 | 1 | 22.283 | 0.045 | −0.259 | 929.338 | 1.827 | 519.210 |

| 23 | 1 | 1 | 23.011 | 0.049 | −0.124 | 1068.139 | 1.705 | 457.217 |

| 24 | 1 | 1 | 24.545 | 0.041 | 0.045 | 917.108 | 2.338 | 590.643 |

| 25 | 1 | 1 | 23.039 | 0.042 | −0.161 | 893.107 | 2.066 | 563.491 |

| 26 | 1 | 1 | 22.310 | 0.031 | −0.319 | 596.877 | 2.527 | 726.537 |

| 27 | 1 | 1 | 24.458 | 0.045 | 0.064 | 1009.037 | 2.144 | 536.157 |

| 28 | 1 | 1 | 24.061 | 0.030 | −0.111 | 619.351 | 2.814 | 749.363 |

| 29 | 1 | 1 | 25.045 | 0.030 | 0.001 | 623.389 | 2.990 | 766.703 |

| 30 | 1 | 1 | 22.005 | 0.039 | −0.322 | 786.119 | 2.068 | 600.845 |

| Tout (°C) | −1 | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ts (°C) | 24.60 | 24.62 | 24.02 | 23.48 | 23.11 | 22.05 | 22.01 | 22.00 | 22.00 | 22.00 | 22.00 | 22.00 | 22.01 |

| Vs (m3/s) | 0.049 | 0.046 | 0.042 | 0.042 | 0.032 | 0.048 | 0.050 | 0.049 | 0.050 | 0.047 | 0.050 | 0.050 | 0.048 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Y.; Wei, Z. A Combinatorial Optimization Strategy for Performance Improvement of Stratum Ventilation Considering Outdoor Weather Changes and Metabolic Rate Differences: Energy Consumption and Sensitivity Analysis. Sustainability 2023, 15, 2804. https://doi.org/10.3390/su15032804

Bai Y, Wei Z. A Combinatorial Optimization Strategy for Performance Improvement of Stratum Ventilation Considering Outdoor Weather Changes and Metabolic Rate Differences: Energy Consumption and Sensitivity Analysis. Sustainability. 2023; 15(3):2804. https://doi.org/10.3390/su15032804

Chicago/Turabian StyleBai, Yan, and Zhuo Wei. 2023. "A Combinatorial Optimization Strategy for Performance Improvement of Stratum Ventilation Considering Outdoor Weather Changes and Metabolic Rate Differences: Energy Consumption and Sensitivity Analysis" Sustainability 15, no. 3: 2804. https://doi.org/10.3390/su15032804

APA StyleBai, Y., & Wei, Z. (2023). A Combinatorial Optimization Strategy for Performance Improvement of Stratum Ventilation Considering Outdoor Weather Changes and Metabolic Rate Differences: Energy Consumption and Sensitivity Analysis. Sustainability, 15(3), 2804. https://doi.org/10.3390/su15032804