1. Introduction

Textile materials are dyed using various dyestuffs [

1,

2] and methods [

3,

4,

5] to add aesthetic and commercial value to the product. Until the discovery and commercialization of synthetic dyestuffs, these processes were carried out only with natural dye extracts [

6]. With the introduction of synthetic dyes into our lives, we moved away from natural dyes. This was due to our rapid access to synthetic dyes. With the increasing use of synthetic dyes, a large amount of water is used in the textile sector and disposal of this water polluted with the chemicals used [

7] also mixes into the environment and causes significant pollution [

8].

‘Synthetic dyes’ are part of the major chemical pollutants category in terms of textile waste [

9]. ‘Synthetic dyes’ are the primary source of waste from the textile industry [

10] and one of the causes of environmental pollution [

11]. In recent years, although the use of some heavy metals such as [

12] iron, titanium oxide, and derivatives [

13] was restricted due to their environmental hazards, synthetic dyes continue to cause severe damage, particularly to groundwater [

3] and also to the environment [

14]. Synthetic dyes and chemicals not only pollute the environment during the production of textile materials, but also adversely affect human health during their use [

15], and even discarded synthetic dyed textiles after their use also cause environmental pollution [

5]. In this context, natural dyes have gradually started to gain importance in the market because they are biodegradable and do not cause health risks; therefore, can be easily used without as many environmental concerns [

16,

17]. Due to all these adverse effects of synthetic dyes, the world today is entering significantly into a trend of returning to nature and natural processes [

18], and the level of awareness about environmentalist approaches is increasing. Restricting the use of chemicals [

19] and treatment of wastewater [

20], reducing the use of plastics [

21] and recycling waste [

22], and increasing the use of environmentally friendly and biodegradable natural materials [

23] are just some of the steps taken to protect the environment.

Natural dye plants [

24] are generally annual or biennial plants that do not have adverse effects on human and environmental health [

25], and do not cause environmental pollution during production, during use, and when they become waste after use [

18,

26]. Natural dyes are used not only in the coloring of textiles but also in many other fields [

27] such as pharmacy [

28], cosmetics [

29], food [

30], and packaging [

31]. The cost of dyeing with natural dyes is almost the same as dyeing with synthetic dyes [

32]. In addition, the light, washing, and rubbing fastness [

33] of the obtained products are better than synthetic dyes and inks.

Natural dyestuffs are generally classified into four main categories [

34]: plant, fungal, animal, and mineral-sourced natural dyestuffs. Dyestuffs obtained from flowers [

35], leaves [

36], bark/peel [

37,

38], roots [

39], seeds [

40], and fruits [

41] of plants are called galenic natural dyestuffs.

The mordanting operation is generally performed in order to color the textile surfaces obtained from natural fibers. Mordanting is a process that increases the affinity between the textile surface and the dyestuff [

42]. It increases the retention of the dyestuff to the fibers and the absorption ability of the fibers. It also provides brighter and more permanent color. In natural dyeing, substances such as potassium aluminum sulfate, soda, sodium sulfate, sodium carbonate, copper sulfate, aluminum sulfate [

43], and tannin [

44] are generally utilized.

MAUT “Multi-Attribute Utility Theory”

Multiple Criteria Decision Making (MCDM) is shortly defined as selecting the right alternative by solving multiple and conflicting criteria [

45,

46]. Today, there are more than 70 [

47] MCDM. One of these methods is the MAUT Method [

48]. MAUT is also defined as Multi-attribute Value Theory (MAVT) basically [

49]. The method is based on ranking a set of alternatives and selecting the best one among them. The MAUT method is used to find the most suitable alternative based on both qualitative and quantitative criteria. This method aims to find the most beneficial alternative by making subjective data calculable. Although the MAUT method seems to have a disadvantage in that it requires a lot of sensitive input data, it is also quite advantageous in finding a solution by considering many uncertainties [

50].

The recently used multi-criteria decision-making method, utility theory (MAUT), was started to be applied by Ralph L. Keeney in 1974 in his paper “Multiplicative Utility Functions” [

51]. After Keeney, James S. Dyer et al. in 1992 published “Multiple Criteria Decision Making, Multiattribute Utility Theory”: In their writing named “The Next Ten Years”, they found the different research topics and developments exciting for management science [

52]. In 1999, Tim Bedford and Roger Cooke in their paper, “A new generic model for applying MAUT” [

53], presented the Theory and Methodology of a new generic model for applying MAUT. Subsequently, many researchers applied the MAUT method to ranking and selection prioritization studies [

54,

55]. Studies on natural dyeing generally give CıeLab values, light, washing, and friction fastness with color efficiency values. The relationship between these values is interpreted depending on variables such as the amount of dyestuff or mordant. In this study, the results of light and washing fastness and color efficiency of fabrics dyed according to the amount of mordant and different dyestuffs are interpreted; however, in this interpretation, a statistical analysis was used based on the MAUT method from MCDM methods. At the same time, the MAUT Method is used to rank the recipes in terms of light and washing fastness. The MAUT Method has not been utilized for such a rating in the literature.

2. Materials and Methods

2.1. Material

In this research, Alanya silk woven in a plain weave was used with 100% silk fiber. Fabric weight is 136 g/m2, weft density is 11.4 cm, and warp density is 16.3 cm. Quercus aegilops L. was used as mordant, and crocus sativus, Helichrysum arenarium, and Glycyrrhiza glabra L. extracts were used as natural dyes. The selected dyestuff plants are plants that grow naturally in many regions of Alanya and can be easily reached by the people of Alanya. Acorn, which is selected as a mordant plant, also grows naturally in many regions of Alanya. It is selected as a mordant material because it is a plant with a high proportion of tannin. Tannin has been used as a binder in natural dyeing in the past.

2.2. Method

By applying the MAUT method to the data obtained as a result of light and washing fastnesses, the most suitable dye plant and mordant amount were determined according to the binder Quercus aegilops L. mordant. According to the MAUT Method, the test results of the fabrics dyed with Quercus aegilops L. mordant were determined as the criteria of the problem, and the options belonging to mordant rates were determined as alternatives. For the application, tests were carried out using 5 different concentrations of Quercus aegilops L. mordant (3%, 5%, 10%, 15%, 20%) and 3 plant extracts for a total of 15 different dyes and the appropriate recipe alternative from different concentrations of Quercus aegilops L. mordant, which provides the binding of the color in the dyeing of Alanya silk, was selected according to the MAUT method.

Sericin Removal: The silk fabric was pretreated and dried for 60′ to remove sericin in a bath prepared with 1 g/L soap and 2 g/L sodium carbonate with 98 °C and 1/50 Flotte ratio [

32]. Color coordinates, whiteness, yellowness, brightness and K/S values of untreated and pretreated silk fabrics are given in

Table 1.

Preparing extract:Quercus aegilops L. as a natural mordant, and crocus sativus,

Helichrysum arenarium, and

Glycyrrhiza glabra L. as the dyestuffs of the study, were boiled separately in distilled water for 1 h each, then filtered and cooled [

35].

Mordanting:Quercus aegilops L. mordant was prepared at 3%, 5%, 10%, 15%, 15%, and 20% concentration according to the material weight. When the Flotte with a Flotte ratio of 1/100 reached the boiling temperature, the fabric was added, and the process was carried out by stirring for 60′. After 24 h keeping it in this bath, it was dried without washing [

34].

Dyeing: The dyeing was carried out using 100% of the plant, so mL of the extracts corresponding to 1 g of plant per 1 g of sample was added to the dye bath by calculating the ratio and proportion method. The Flotte was prepared as 1/100 at 30 °C and it was brought to boiling temperature in 20 min, then the previously mordanted and dried sample was placed in the dye bath. Dyeing was performed by boiling at 100 °C for 60 min. The samples were kept in the dye bath for 24 h, washed 3 times, and dried [

26].

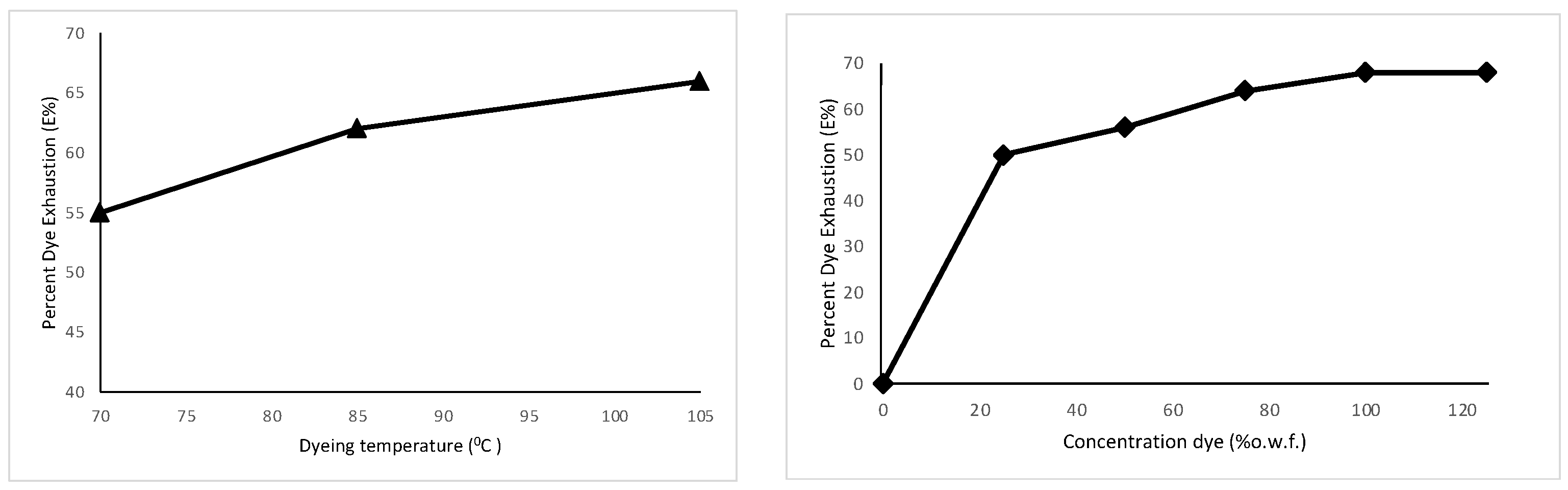

Effect of dye temperature and dye concentration on exhaustion are given in

Figure 1:

Color Measurement: Color measurements of the dyed samples were performed with a Datacolor Spectra Flash 600 plus reflectance spectrophotometer using a Datamaster computer program according to the CIE L*a*b system. Color measurements were made using a D65 light source with a 10° observer [

56]. Equation (1) was used to calculate color values according to the CIELab system [

57].

In the above formula, L* is lightness–darkness, a* is redness–greenness, and b* is yellowness–blueness values.

K/S Values: The color of the dyed samples was evaluated with color strength (K/S) calculated using the Kubelka–Munk equation (Equation (2)). R is the reflectance value of the fiber at the wavelength at maximum absorption, K is the absorption coefficient, and S is the scattering coefficient [

34].

Fastnesses: The washing fastnesses of the test samples was carried out in a washing fastness test machine (Gyrowash Washer Tester) according to ISO 105-C06 [

58] standard and the evaluation was carried out with reflectance spectrophotometer according to ISO A05 [

59] standard. Light fastnesses were applied in a light fastness tester (Solarbox 1500E) according to TS 1008 EN ISO 105-B02 standard [

60] and the total color difference (ΔE*) between the untested sample and the test samples was evaluated in a spectrophotometer.

MAUT Method solution stages: In this study, MAUT (Multi-Attribute Utility Theory), defined as “Multi-Attribute Utility Theory”, is used in multi-criteria decision-making methods that focus on ranking and selecting from a set of alternatives.

The main purpose of the MAUT method is that in every decision problem, there is a real-valued utility function U defined over the set of feasible alternatives, and the decision maker chooses the largest feasible one [

61]. The steps given below are followed when applying the MAUT method:

Step 1: The set of alternatives subject to the decision problem (an) and the attributes/criteria (xm) that will help in selecting the alternatives should be determined.

Step 2: Weight values (wi) are assigned or calculated, which ensures that the criteria are evaluated correctly, and priorities are set. The sum of all wi values must equal to 1, see Equation (3).

Step 3: Data values for the criteria are entered or their values are calculated. In this calculation, while quantitative values obtained from experimental results are for quantitative criteria, assigning specified values is carried out for qualitative criteria (xm).

Step 4: The calculated values are placed in the decision matrix, and the normalization process is started. In the normalization process, the best and worst values for each criterion are first determined; the best value is assigned a value of 1, the worst value is assigned a value of 0, and the following Equation (4) is used to calculate the other values within this range:

The terms used in this equation are shown below.

: Best value for criteria

: Worst value for criteria

X: Current benefit value in the calculated row

Step 5: Immediately after the normalization process, utility values are determined. The utility function Equation (5) is as follows [

62]:

3. Result and Discussion

Codes for dye plant and mordant concentration are given in

Table 2:

The codes used for the information of total color differences (ΔE*), K/S values, washing (color change and staining), and light fastness of the samples dyed with crocus sativus, Helichrysum arenarium and Glycyrrhiza glabra L. extracts evaluated by spectrophotometer are given below.

ΔE: Color Difference Compared to Dyeing without Mordant

ΔE Y: Washing Fastness (Color Change)

ΔE 1: Washing Fastness (Staining) Wool

ΔE 2: Washing Fastness (Staining) Polyacrylonitrile

ΔE 3: Washing Fastness (Staining) Polyester

ΔE 4: Washing Fastness (Staining) Polyamide

ΔE 5: Washing Fastness (Staining) Cotton

ΔE 6: Washing Fastness (Staining) Acetate

ΔE I: Light Fastness

K/S: Color Yield (Kubelka–Munk) (Absorption coefficients/Scattering coefficients)

L, a, b, C, and h values obtained by dyeing Alanya silk with crocus sativus,

Helichrysum arenarium, and

Glycyrrhiza glabra L. plants using

Quercus aegilops L. mordant are given altogether in

Table 3.

Within the framework of the data obtained in

Table 3, it was determined that the color became darker, the red nuance of the color increased, and the brightness decreased, in general, as the amount of mordant increased in the dyeings with crocus sativus,

Helichrysum arenarium, and

Glycyrrhiza glabra L. It was determined that the color of dyeing without mordant was lighter and brighter than dyeing with mordant.

The ΔE differences and color yield results obtained after washing and light fastnesses by dyeing Alanya silk with crocus sativus,

Helichrysum arenarium, and

Glycyrrhiza glabra L. plants using

Quercus aegilops L. mordant are given altogether in

Table 4.

The data given in

Table 5 show the decrease and increase in ΔE differences depending on the change in the amount of mordant.

While the biggest color difference compared to mordant-free dyeing was obtained from dyeing with the crocus sativus plant, it was determined that the colors made with Helichrysum arenarium were the closest to mordant-free dyeing. The sample with the highest color change after washing was obtained from dyeing with the highest concentration of the crocus sativus plant and Quercus aegilops L. mordant. The lowest color difference after washing is generally seen in the dyeings made with Glycyrrhiza glabra L. There was no significant difference between the mordants in terms of staining on Acetate, Cotton, Polyamide, Polyester, Polyacrylonitrile, and Wool, and staining was realized at rates too low to be visible to the eye. When we look at the color difference values obtained as a result of light fastness, the highest color differences were obtained from the dyes made with the crocus sativus plant, and the lowest color differences were obtained from the dyes made with the Helichrysum arenarium plant. When we examined the dyeings in terms of color yield, it was concluded that there was no significant difference between the dyeings made with Helichrysum arenarium and Glycyrrhiza glabra L., but the color yields of the dyeings made with crocus sativus were low.

According to the data obtained in

Table 6 and

Table 7, it was determined that the dyes made with crocus sativus and

Glycyrrhiza glabra L. were darker than the dyeing without mordant. In general, it was determined that the red and yellow color nuances increased at low rates in the dyeings. In addition, it was determined that all dyeings were more vivid than the dyeing without mordant.

Application of the MAUT Method in the Light of the Data Obtained

Step 1: First of all, the alternatives (an) subject to the decision problem and the attributes/criteria (xm) that will help in selecting the alternatives were determined. In this study, the criteria were determined by using standard tests (light and washing fastness test results and color yield (K/S)) and the alternatives were dyeing recipes using five different concentrations (3%, 5%, 10%, 15%, 15%, and 20%) of Quercus aegilops L. mordant with crocus sativus, Helichrysum arenarium, and Glycyrrhiza glabra L. plants, which also grow in Alanya region.

Thus, while rows were created for a total of 15 different alternatives with three dyestuffs × 5 mordant concentrations, the matrix for the recipe was designed using nine different criteria columns and the matrix was constructed for the start and solution.

Step 2: The values of the criteria are calculated. In this calculation, quantitative values obtained from the experimental results and read from the device are used for quantitative criteria, and their values are written in the cell places corresponding to the rows and columns in the matrix (

xm). The data set of the best and worst values of the criteria is determined under the criteria and written as rows. The values are given in

Table 8 below.

Step 3: The calculated values are placed in the decision matrix and the normalization process is started. In the normalization process, the best and worst values for each criterion are first determined, the best value is assigned a value of one, the worst value is assigned a value of zero, and

Table 9 below is created to calculate the other values within this range:

Step 4: Weight values (w

i) are assigned, which ensure that the criteria are evaluated correctly and priorities are set. The sum of all w

i values must equal to one. At this stage, by accepting the weights of the criteria as equal (1/9 = 0.111), the operations were performed on the values given in

Table 10.

At this stage, the MAUT method will be ranked by giving equal values to the criterion weights

wi. The weighted normalization values of the data are given in

Table 11.

According to the results of the calculations made up to this stage, the decision stage is reached. If the weights are taken equal (1/9 = 0.11), our recommendation for the best dyeing recipe is C-4 dyeing with

Glycyrrhiza glabra L. at 15%

Quercus aegilops L. concentration. It is seen that the top 3 best dyeings with

Glycyrrhiza glabra L. are in this group. The results are given in

Figure 2 below.

4. Conclusions

MCDM methods are taking their place in research with a new method every day. Controversial solutions are presented as to which method is reliable, which method is suitable for use, which method to choose, or which experiment is reproducible.

In this study, Alanya silk fabric was mordanted in five different concentrations (3%, 5%, 10%, 15%, and 20%) with Quercus aegilops L., which is a natural mordant, and dyed separately with crocus sativus, Helichrysum arenarium, and Glycyrrhiza glabra L. plants. According to the results of the MAUT method applied to the fastness results obtained from the dyes, the plant that gave the best three results was Glycyrrhiza glabra L. It was observed that the dyeings with the crocus sativus plant had the five worst dyes in terms of fastness properties.

According to the results of the obtained method, the recommended dyeing recipe in terms of fastness and color yield in the dyeing with the crocus sativus,

Helichrysum arenarium, and

Glycyrrhiza glabra L., where color tones close to each other are obtained, is given in

Table 12.