Abstract

The classical solar chimney offers passive electricity and water production at a low operating cost. However, the solar chimney suffers from high capital cost and low energy output density per construction area. The high capital investment increases the levelized cost of energy (LCOE), making the design less economically competitive versus other solar technologies. This work presents a new noteworthy solar chimney design for high energy density and maximizing water production. This was achieved by integrating a cooling tower with the solar chimney and optimizing the operating mood. The new design operated day and night as a hybrid solar double-chimney power plant (HSDCPP) for continuous electricity and water production. During the daytime, the HSDCPP operated as a cooling tower and solar chimney, while during the night, it operated as a cooling tower. The annual energy output from the cooling towers and solar chimney (i.e., the HSDCPP) totaled 1,457,423 kWh. The annual energy production from the cooling towers alone was 1,077,134 kWh, while the solar chimney produced 380,289 kWh. The annual energy production of the HSDCPP was ~3.83-fold greater than that of a traditional solar chimney (380,289 kWh). Furthermore, the HSDCPP produced 172,344 tons of fresh water per year, compared with zero tons in a traditional solar chimney. This led to lower overall capital expenditures maximizing energy production and lower LCOE.

1. Introduction

The world has depended on fossil fuels for electricity generation for decades now. However, due to the discovery of the potential of renewable energy sources for power production, the focus recently has been on developing technologies for clean energy generation using renewable energy sources, such as the sun, wind, and water [1]. The newly found interest in clean energy was driven by the rapid increase in CO2 emissions, in addition to other greenhouse gases (GHG) caused using conventional sources (e.g., natural gas, coal, and oil) [2]. GHG emissions are the root cause of global warming that is led by climate change [3,4]. This creates an environmental problem that has many repercussions that impact the environment and the well-being of individuals [5,6]. Simultaneously, with industrial expansion and development in addition to rocketing world population numbers, the improved living standards for individuals have contributed to the incessant increase in their energy and water consumption, leading to continuous growth in energy and water demand [7]. As a result, countries are trying to encourage the penetration of renewable energy technologies in their grids by administrating new policies that incentivize the development of clean energy technologies [8], which is supported by environmental regulations that will strive to decrease GHG emissions.

Renewable energy sources vary in the maturity of the technology. Renewable resources such as wind power, solar energy, hydropower, tidal, biomass, and geothermal, are well-developed technologies that have reached or almost reached maturity [9]. Hence, they are commonly used. While in theory, solar energy is the best choice to invest in for electricity production [10], like other renewable resources, it still is economically challenging to depend on because of the production costs and sometimes the installed capacity cost. All the aforementioned factors have led the world to focus on an economically feasible technology that utilizes solar energy to produce electricity [11,12], prompting the design of the solar chimney power plant (SCPP).

Schlaich first tested the SCPP in Spain in the 1980s, with a design that could generate power with a range of 100–200 MW; the produced electrical power depended on the designed internal diameter of the chimney [13]. The optimized design of the SCPP of Schlaich consisted of three parts, a specified-diameter long chimney, the mechanical turbine that produces electricity, and the solar collector at the base. The chimney was designed so that the solar collector located at the base of the chimney could collect solar irradiation to heat the air trapped between the ground and the base collector above it. The velocity of the heated air would boost because of the increase in its pressure and density. The newly gained properties of the air would allow it to move upward toward the turbine in the chimney to convert its high content of kinetic and thermal energy to electrical energy.

Despite numerous published works of literature about the SCPP with different improvements on the mathematical modeling either by modifying the mathematical equations or by altering the layout and design of the chimney, challenges were still faced, including the high cost of construction, the low thermal efficiency, and the large, needed space for the power plant [14,15]. All the challenges were related to design aspects that have decreased the efficiency of the system and/or increased the cost of the SCPP; this is why in the last decade, studies conducted on the SCPP were oriented toward improving the efficiency and decreasing the cost [16,17].

Multiple papers have been published that focus on the improvement of numerical equations from a new perspective for the development of simulation models that provide a faultless representation of the solar chimney power plant dynamics. Some of these papers include Guo et al. [17], Maia et al. [18], Bilgen and Rheault [19], Jing et al. [20], Sangi et al. [21], Meng et al. [22], and Pastohr et al. [23]. Others studied the effect of the geometric characteristics of the chimney on electricity generated from the turbine, and the results were promising, such as the ones reported by Hamdan [24], Koonsrisuk et al. [25], Jing et al. [20], Saifi et al. [26], and Kasaeian et al. [27].

However, some papers took a different approach to efficiency amplification by focusing on the design aspects of the SCPP, more than the mathematical modeling. To start with, Zuo et al. [28] suggested the addition of a seawater desalination unit to the original design of the SCPP. In another paper, Zuo et al. [29] deduced that the addition of the desalination unit has resulted in more efficient utilization of the solar irradiation that experimentally resulted in a maximum solar irradiance utilization efficiency of 25%, which is a remarkable drop from the expected 55% efficiency of a large-scale system. Kiwan et al. [30,31] went a step farther and proposed integrating a photovoltaic system to yield higher power generation and another design to optimize the production of desalinated water and electricity concurrently. To increase the thermal efficiency of a Rankine cycle, Zandian and Ashjaee [32] used the model of the SCPP to integrate a cooling tower, and the thermal efficiency of a 250 MW power plant increased by 0.37%.

Some of the literature took interest in the materials of the collector as demonstrated in Chaichan and Kazem [33], where they chose three base materials to study, which were concrete, black concrete, and black pebbles; moreover they substituted the commonly used glass cover of the collector with transparent plastic material. The winning base material was black pebbles, which maximized the efficiency by 49.7%. Chantawong et al. [34] studied the design micro-geographically by considering the hot humid climate of Thailand when assessing the effect of the glazed double-glass panes of the collector on the thermal characteristics of the air in the SCPP, the results were favorable to hot regions. Ninic [35] showed that an SCPP with a 1000 m tall chimney increased the resultant work of the power plant by 62% by studying how the work and efficiency were influenced by the air humidity and atmospheric pressure as a function of the solar chimney’s height. Koonsrisuk and Chitsomboon [36] devised a mathematical model using measurements from an existing SCPP while taking into consideration different parameters to suggest a commercial SCPP that can be used in Thailand, and the results showed that a 200 m radius collector with a 400 m high chimney was the most economically feasible to use in that specific region. A prototype that studied the correlation between the chimney’s dimensions and the collector’s materials with the thermal response of the system was designed by Ghalamchi et al. [37], by fixing the collector’s height to 3 m and the diameter to 2 m; the heat transfer rates of the absorbers using different materials were studied, and the obtained results demonstrated that iron had a lower heat transfer rate than black aluminum, with a maximum temperature difference of 27 °C between the ambient air and the heated air inside the collector. The study’s significant outcome showed that the performance of the SCPP responded the most to the change in the chimney’s diameter.

Researchers have also suggested the integration of wind energy in the SCPP design; Li et al. [38] put forward a design that had a much higher power yield than the conventional SCPP design. The system included a wind tower (tornado type) placed at the chimney outlet. The suggested system with a 290 m tall chimney produced the same amount of power as a conventional SCPP with a 772 m high chimney if 15 m/s was the value of the reference wind speed. The innovative design generated 2.21 times a conventional SCPP’s power if both systems had a 290 m chimney at the reference wind speed. Researchers including [28,38] have also integrated wind energy in the design of the SCPP by adding it at the top of the chimney wind capturing devices for greater utilization of wind.

Fluri and Von Backstrom [39] inspected the behavior of the SCPP’s turbine by developing three different configurations to compare their efficiencies and energy production through a performance model that they developed. Different parameters were considered to study their impact on the performance of the turbine such as the turbine’s output torque, the aerodynamic losses, and various other losses; the model confirmed what other pieces of literature have proposed, which is that the total-to-total efficiency of the turbine was equal to 80%. Moreover, the efficiency of the turbine increased trivially when the diffuser area ratio decreased; contrastingly, it decreased notably when the diffuser ratio area increased. Another piece of literature that chose a numerical approach was the one published by Tingzhen et al. [40], which numerically analyzed the pattern of the airflow and heat transfer in the SCPP, in the presence of a porous layer that consisted of soil and gravel to act as an energy storage solution; their research work also included the impact of the solar radiation on the soil and gravel layer. The results of the study showed that when the solar radiation increased from 200 to 600 W/m2, the heat storage ratio of the energy storage layer decreased; when the solar radiation increased to 800 W/m2, the heat storage ratio increased; and as the solar radiation increased, another two factors inside the chimney are affected, the air velocity and relative static pressure, which increased and decreased, respectively.

The authors of [41] proposed a hybrid solar chimney-power plant (HSCPP) that had an increased efficiency of about 1.4 multiples compared with the traditional solar chimney-power plant by utilizing a seawater pool at the bottom of the chimney. The deployment feasibility study of the beforementioned HSCPP was investigated in [42,43]. An innovative design of an SCPP facilitating energy production at night by introducing cooling towers was proposed in [44]. The authors of [45] proposed integrating a photovoltaic system into an SCPP, which resulted in increased electricity production by over 30%. Higher electricity production was achieved in [46,47].

This work proposes a novel design of a hybrid solar double-chimney power plant (HSDCPP) that is designed to achieve high thermal efficiency and does not take up much land space. These two aspects have been proven to be essential in the literature review when implementing improvements on the basic design of the SCPP. This work’s novelty is integrating two types of renewable energy generation (solar chimney and cooling tower) into one system. The integration allowed the HSDCPP to operate continuously as an SCPP during the daytime while operating at night as a cooling tower. The novel design included two chimneys (co-centric) that operated jointly with the turbine, the collector, and the ten cooling towers (CT) channels; each had a turbine for extra generation of energy. Adding the second chimney as a cooling tower and fitting the first chimney with water sprinklers to work as a cooling tower at night boosted the performance of the design. The HSDCPP design maximized the output electrical power of the power plant while simultaneously increasing the production of distilled water, all the while having a low operating cost with a predetermined economical capital. The repercussions on the feasibility and operation of energy integration system implementation in the SCPP system are explored in this paper.

2. Materials and Methods

2.1. HSDCPP Description

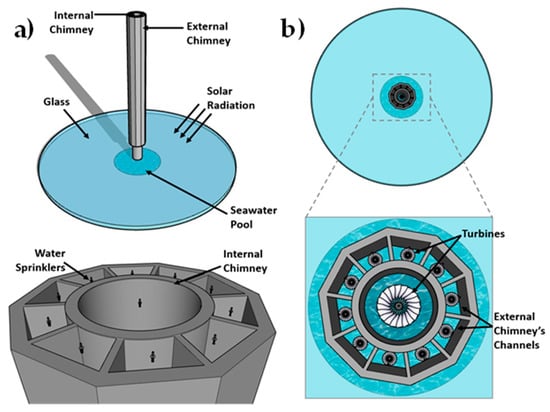

The structure of an HSDCPP mainly consisted of two chimneys (see Figure 1). The internal chimney with a collector, a bidirectional turbine, a base, and a pool of seawater to produce distilled water formed a traditional solar chimney (SCPP), while the external chimney, which was concentric with the internal chimney, performed as a cooling tower (CT).

Figure 1.

Diagram of the proposed HSDCPP design: (a) a three-dimensional view. (b) View from the top section; rwater is the radius of the seawater pool, and rbase is the radius of the base of the HSDCPP. (c) Daytime operation cross-sectional view, showing the internal and external cooling towers (CT). (d) Nighttime operation cross-sectional view.

Typically, the SCPP and CT are usually constructed and operated separately. The SCPP operates during the daytime based on the solar irradiation received from the sun. The process begins when the solar irradiation heats up the collector, and the temperature of the air under the collector increases; when air temperature increases, its density decreases. As the air expands under the collector, it moves over the seawater pool. Meanwhile, the water evaporates and results in increasing air humidity. So, the hot and moist air moves up toward the chimney; the air temperature at the entrance of the collector is lower than the temperature at the bottom of the chimney. Due to the temperature and pressure difference between the bottom of and outside the chimney (at the vent at the top of the chimney, where the temperature is equal to air temperature), the hot air moves up from the bottom of the chimney to the top of the chimney and moves out of the system. As the hot air moves in the chimney, its velocity increases and exchanges energy with the turbine blades that are located at the bottom of the chimney and condensate on the chimney’s inner walls, producing electricity. However, CT does not depend on solar irradiation. Its operation is based on spraying a mist of water at the top of the chimney where the hot and dry air is. When the air absorbs the water from the mist, it becomes cooler and heavier. It is a natural draft CT; the air drops toward the bottom of the chimney due to gravity. In addition, due to the temperature difference between inside and outside the chimney, the air accelerates toward the turbine at the bottom of the chimney and exits outside the chimney, moving the turbine to produce electricity. The proposed system combined two system designs that were developed previously, the hybrid solar chimney power plants, HSCPP [41,42,43] and the solar double-chimney power plant (SDCPP) [44] The use of a bidirectional turbine that can move in both directions depending on the operation of the system was the key design parameter for the HSCPP as it enabled the system to operate as an SCPP during the day and becomes idle at night to enable the system to operate as a CT. This ensured electrical generation throughout the whole day. One other proposed modification (design) was adding a second chimney structure around the original chimney, which would operate as 10 cooling towers in series, where each tower would be equipped with a turbine and water sprinklers, allowing for higher energy production as it would be operating both day and night. This design offered higher utilization of the system as it made use of the daily operation of the SCPP and the day-night operation of the cooling towers, which did not rely on solar radiation, maximizing the efficiency of the electricity generation of the plant.

In this work, the proposed method was to implement both the hybrid modification, which would allow for the main chimney to operate as a cooling tower at night using a bidirectional turbine, and the double modification, which would allow the second chimney structure to operate as a cooling tower all the time, resulting in a hybrid solar double-chimney power plant (HSDCPP). This design would further maximize both the electricity generation output and the distilled water amount of the power plant.

2.2. Mathematical Model

To be able to analyze and assess the behavior of the proposed system, a mathematical model was developed. This model utilized the mass and energy balance equations showcased in Figure 1 in detail in the Supplementary Materials. The program used for the simulations was developed in MATLAB R2018, and it made use of the built-in numerical functions of the program such as Genetic Algorithm methods, which allowed for accurate simulations of the performance of the proposed system. The program used an input file that contained data from a weather station as its starting point, which contained data on solar irradiation, ambient air temperature, wind velocity, and relative humidity. This file contained weather data that were sampled hourly for a whole year, which resulted in a total of 8760 data points. The program was split into two sub-programs. The first was for the main chimney simulations, which acted as a solar chimney during the day and a cooling tower at night. The other one was for the second chimney which acted as a cooling tower all the time. The total time taken for the program to process all the data was about 10 h. The computer used in the processing of the data had the following specifications: Intel i7-9700K 3.6 GHz CPU, Nvidia RTX 2070 SUPER GDDR6 8 GB GPU, G.SKILL TridentZ DDR4 3000 MHz 32 GB (8 GB × 4) RAM. The properties and physical dimensions of the HSCDPPs are showcased in the Supplementary Materials. The model was validated against a well-known prototype SCPP in the literature. The validated results are available in detail in the Supplementary Materials.

3. Results and Discussion

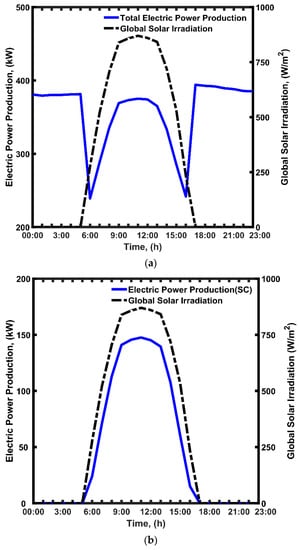

This study was conducted at Doha International Airport in Qatar (25°15′24.00″ N/51°33′32.39″ E). The annual weather data, which were accumulated hourly, were used to initiate the production of the total electricity and distilled water. In Table 1, the data of global horizontal solar irradiation, ambient temperature, wind velocity, and relative humidity for a day in September are represented. It can be noted that the first value of the solar radiation intensity of the representative day was 276 W/m2, recorded at 6:00, and the last value of the day was 233 W/m2, recorded at 16:00. Figure 2a displays the maximum and average values of the solar radiation intensity for all the year months.

Table 1.

The 24 h weather data on 22 September 2015, at Doha International Airport, Qatar.

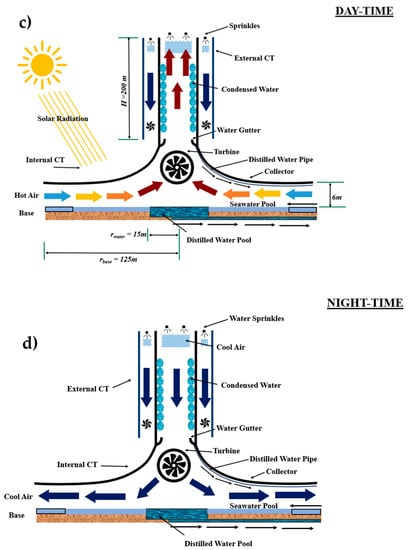

Figure 2.

Maximum, minimum, and average monthly weather data profiles for (a) solar irradiation, (b) temperature, and (c) relative humidity. The data shown are a full year of weather conditions taken from the Doha International Airport in Qatar.

The range of the average solar radiation values was from 250 W/m2 to 310 W/m2. In March, the maximum value of the year was recorded with an intensity close to 900 W/m2. The maximum solar radiation values did not vary significantly throughout the year; the values stayed within the range from 850 W/m2 to 890 W/m2. However, there was a significant difference between the maximum and average values. The maximum difference in summer accounted for 540 W/m2, and in winter, the maximum difference was equal to almost 650 W/m2. The solar radiation at the studied location suggests a promising location for the generation of electricity and distilled water from the HSDCPP.

From Table 1, it can be noticed that during the daytime, the temperature ranged between 30.9 °C and 36 °C, and they ranged between 31 °C and 34.7 °C during the night. Figure 2b shows the temperature profile in the summer months, where the average temperature was around 35 °C, and during the winter months, the average temperature ranged between 18 °C and 30 °C. The weather data also included readings of the wind speed, which is important to consider because the velocity of the wind directly affects the movement of the turbines that produce the electricity. In Table 1, the data showed that the wind speed ranged between 3.1 m/s and 9.3 m/s during the day and between 1.5 m/s and 8.8 m/s during the nighttime. During the operation of the HSDCPP as a CT, the relative humidity percentage (%RH) was critical to consider when analyzing the CT’s performance. Figure 2c shows the trend of the %RH during the year. The data showed that the average relative humidity ranged between 30% and 70%, where the lowest average %RH was in June and the highest was in January.

In the next sections, the investigation will focus on the influence of solar radiation, ambient temperature, wind speed, and %RH on the electric power produced. The HSDCPP design used the information provided by the weather station by exploiting the given data on the operation of the internal chimney when it is in SCPP mode during the day, and during the night when the inner chimney is operating in CT mode, in addition to the external ten channels, this will ensure 24-h electricity production.

3.1. HSDCPP Performance

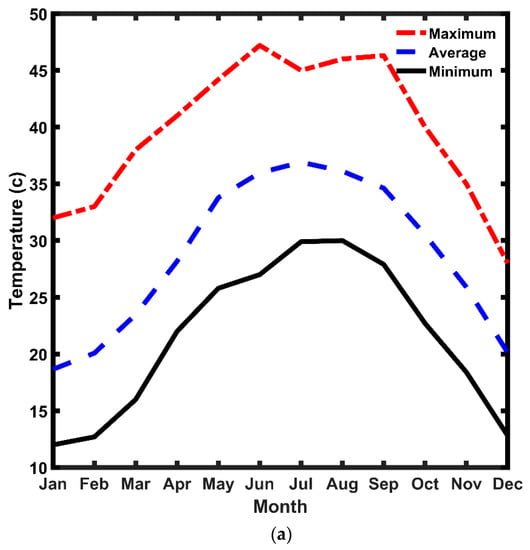

The HSDCPP system continuously generated electricity throughout a 24-h operation period, as shown in Figure 3a, where the total electric power produced from the system and the solar light intensity for one day are presented. As mentioned before, there were two main sources to generate electricity in the system, the internal chimney, which operated as an SCPP in the daytime and as a CT (internal CT) in the nighttime, and the external chimney, which operated as a CT (external CT) throughout the whole day. The electrical power produced from the SCPP and the CTs is presented in Figure 3b and Figure 3c, respectively.

Figure 3.

HSDCPP system performance: a representative day of the system operation with (a) the total electric power production and the global solar irradiation, (b) the electric power production from the solar chimney, (c) the electric power production from the cooling tower (internal and external), and (d) the distilled water generated and the global solar irradiation.

Starting with the internal chimney, during the operation of the system as an SCPP, electricity production started at 05:00 and gradually increased throughout the day reaching a maximum value of 175 kW produced in the period between 09:00 and 13:00, then gradually decreased back again until there was no electricity produced (0 kW) from the SCPP at 17:00. In addition, as shown in Figure 3b, the variation of the amount of electricity produced and the intercepted solar irradiation were directly related; as the solar intensity increased, the power produced from the SCPP increased, and once there was no solar radiation, no electricity production occurred.

The production of the internal chimney continued as a CT through the nighttime operation. As in the afternoon, when the solar intensity decreased, the bidirectional turbine’s blades turned in the opposite angular direction, resulting in operating the system as a CT. As shown in Figure 3c, the internal CT electricity production started around 16:00 and continued through the nighttime and in the early hours of the morning when the solar intensity was at its lowest levels. At 6:00, the solar irradiation increased, and the SCPP mode started again (the cycle of the electricity production process in the internal chimney between the SCPP and CT modes was repeated).

The external chimney operated as a CT continuously in parallel to the internal chimney. The structure and the outline of the external chimney supported the expansion of the operation of the CT, and consequently, the total produced electrical power from the HSDCPP was extremely increased. As shown in Figure 3c, the external CT continually produced electricity within a range of 210–230 kW in a 24-h operation period.

To sum up the operation of the proposed system, during the daytime, both the SCPP and external CT operated, while during the nighttime, both the CTs operated, resulting in high continuous power production throughout the whole day as shown in Figure 3a.

Furthermore, the HSDCPP system also produced distilled water. Figure 3d shows the daily water production of seawater desalination and the intercepted solar irradiation. As shown in the figure, distilled water production started from 05:00 to 17:00, which corresponded to the SCPP operation period, achieving the maximum value of 125 tons between 09:00 and 13:00.

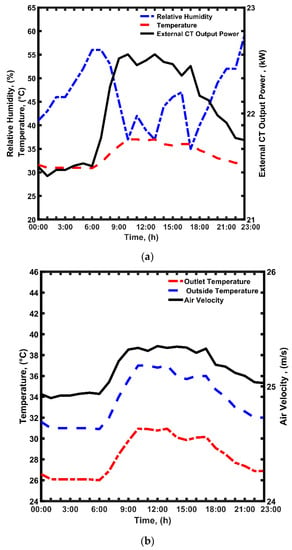

3.2. Operation of the External CT

As can be observed in Figure 4a, an indirect relationship can be concluded between the output power generated from the external cooling tower and the percentage of relative humidity (%RH) and/or the ambient temperature, making both the %RH and the ambient temperatures two parameters that affected the performance of the HSDCPP. From midnight until the beginning of the morning, from 24:00 until 06:00, the %RH increased from 41% to 56%; however, the ambient temperature decreased from 31.6 °C to 30.9 °C, and the insignificant increase in the ambient temperature led the output power to remain at 21.5 kW, despite the fluctuation of the power value during the time from 24:00 until 06:00. During the rest of the day, from 06:00 to 17:00, the %RH decreased from 56% to 35%, and the ambient temperature increased from 30.9 °C to 36 °C, causing the electrical output power to increase from 21.5 kW to 22.25 kW. However, the humidity fluctuation reflected directly on the electrical power produced. For example, the power production peaks (22.33 kW) at 10:00 and 13:00 correlated well with a low humidity value of 37%. However, the electricity production dropped down at 16:00, corresponding with the spike (47%) in the humidity. After dusk and during nighttime, the value of %RH increased from 35% to 59%, and the ambient temperature witnessed a drop from 36 °C to 32 °C; thus, the decline of the output electric power of the external CT was from 22.5 kW to 21.75 kW.

Figure 4.

(a) The outside temperature profile and the relative humidity profile effect on the external CT performance. (b) The outside temperature profiles and the water vapor velocity throughout the CT mode. The data presented were taken on 22 September.

The trends shown in Figure 4a were a result of the impact of the temperature gradient that was formed between the air inside each channel of the external CT and the air outside the channels. A pressure difference originated from the temperature gradient, which increased as the temperature gradient increased; this generated more dynamic power that could rotate the turbine’s blades because of the boost in the air’s velocity inside the chimney. This chain of circumstances of changes in the temperature, pressure, and velocity was what controlled the energy generated from the outer CT. The increase in the relative humidity percentage of the air outside the chimney spiked a different reaction from the CT as the more humid the air was, the less the power generated would be because the water amount that can be evaporated to obtain the desired cooling effect decreased. Because of the aerodynamic effect of the wind on the system, any changes in the wind’s speed and direction could cause an increase in the air’s kinetic energy inside the chimney, which could also cause an increase in the output of electric power.

The relation between the velocity of the air inside the chimney and the inlet and outlet temperatures is shown in Figure 4b. It can be noticed that the average air velocity and the outlet temperature were directly proportional. During the night, when the outlet temperature decreased, the air velocity also decreased, while during the day, the air velocity increased because the outlet temperature did. The prime operational parameter that was considered when studying power generation was the rotational speed of the turbine, and it was directly correlated with the average air velocity.

Figure 4b displays the temperature profiles of the air leaving the CT and the ambient temperature, and it shows that the CT mode was following the natural draft cooling profile. There was a 6 °C difference between the ambient temperature and the cool air vapor exiting the CT.

It has been established previously that the increase in the evaporation rate that is caused by the heat exchange between the ambient air and the air inside the channels of the CT will lead to higher power generation; this is because of the dynamic airflow that is created inside the CT channels that confirms the turbines’ blades’ continuous rotation.

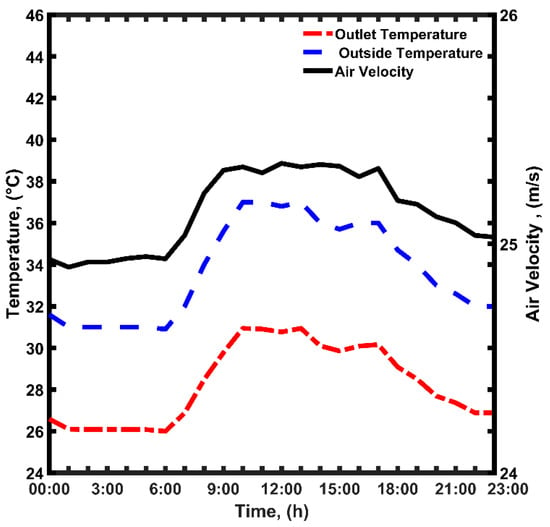

3.3. Operation of the Internal CT

As shown in Figure 5, the effect of the outside temperature and the relative humidity on the internal CT’s performance was analyzed. The internal CT offered only a nighttime operation; as a result, no output power was presented from 6:00 until 17:00. The study showed that the outside temperature and the relative humidity directly affected the amount of electrical power produced by the CT. For the outside temperature, it was directly proportional to the electrical power produced; the decrease in the outside temperature from 36 °C to 31 °C, from 17:00 till midnight, affected the output power as it decreased from 172 kW to 167 kW. However, as shown in Figure 5, the electrical power produced by the internal CT decreased from 172 kW to 167 kW when the relative humidity increased from 35% to 58%.

Figure 5.

The effect of the outside temperature and relative humidity on the internal CT’s performance.

These results were mainly justified by the fact that the cold air velocity inside the chimney increased when the outside air was hot (high temperature) and dry (low humidity) due to the temperature difference that resulted between the water vapor and the outside air, as shown in Figure 6. In contrast, when the outside air was humid, an increase in the water spraying that was required for cooling the inside air was expected; consequently, more water needed to be pumped, which resulted in a reduction in the efficiency of the CT system. That is why less electrical power was produced when the relative humidity was increased.

Figure 6.

The outside temperature profile and the outlet temperature profile effects on the water vapor velocity moving down the internal CT.

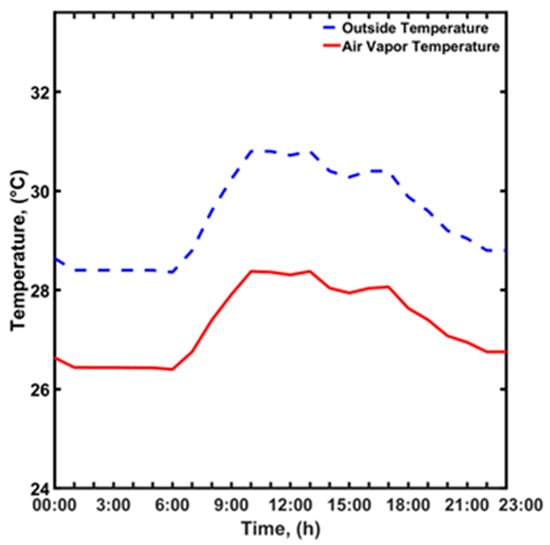

Both the outside air profile and the outlet air that exited from the bottom of the chimney profile had the same trend. However, due to the cooling effect inside the chimney, the inside air temperature levels were at lower values by 2 °C, as shown in Figure 7, when the internal chimney operated as a CT at nighttime.

Figure 7.

The inside and outside air’s temperature profiles during the internal chimney operation as a CT.

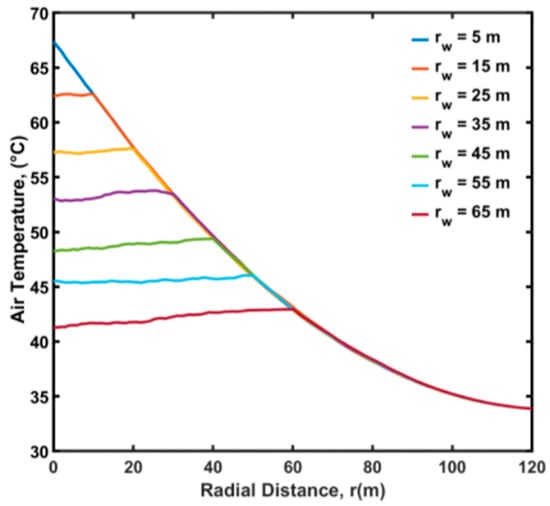

3.4. SCPP Performance

One of the key operating parameters which had a direct impact on the kinetic energy of the air inside the chimney was the developed temperature gradient that was generated between the ambient air and the air under the collector. It also directly impacted the output power generated from the system. As a result, an optimal selection of the radius of the water pool () resulted in the generation of a high-temperature gradient, thus increasing the energy output capacity. This was supported by similar results by Kiwan et al. [30]. Additionally, Toghraie et al. [48] demonstrated that although increasing the increased the SC’s output power, a significant decrease in the system performance was found. Particularly, increasing the at the same solar intensity improved production capacity but reduced efficiency by 35%, according to the same study. The pressure caused by the rise in , which raised both the airflow rate and temperature, was thought to be the key cause of the increase in power output. A substantial decrease in the observed efficiency was found because of the increased region of heat transfer, which resulted from increasing the at constant heat flux.

As seen in Figure 8, the temperature profile of the air under the collector was a function of the radial distance from the entrance to the solar chimney’s center. The reported air temperature inside the solar chimney showed an indirect relationship with the radius of the seawater pool (). Increasing the was accompanied by a significant decrease in the air temperature because the energy needed to evaporate the water increased. Increasing the air temperature, as previously mentioned, supported the hydrodynamic flow of air for electricity production. In other words, the had a direct effect on air temperature, thus increasing or decreasing the electrical power output.

Figure 8.

The generated temperature profile at different radiuses () of the seawater pool.

According to the previous analysis, the had a cap over which the benefit vs. power was contradictory. This could be attributed to the risk of excessive heat loss from the collector and from the ground to the soil storage at high values of . As a result, the airflow temperature in the collector would have an upper limit, with respect to the equilibrium between inlet solar radiation and heat loss. Consequently, an upper limit would be present for the temperature of the airflow in the collector in terms of the balance between the solar radiation in the SC inlet and the heat loss. From this analysis, it was found that the ideal range for the radius of the chimney was between 5 and 25 m, with 15 m being the most optimal choice in that range, which resulted in maximum power output while taking into consideration the costs of the collector.

Table 2 shows the monthly electrical power and desalinated water output from the proposed design for a full year. The lowest monthly electrical power (lowest value was in December, 27,887 kWh) and the lowest monthly desalinated water output (lowest value was in January, 10,231 tons) occurred during the winter season (November to February). This was because of the low solar irradiation intercepted during these months. On the contrary, the summer months saw a substantial rise in electrical power generated (up to 236,636 kWh found to be in July) and desalinated water (up to 19,382 tons found to be in July). By steadily raising the solar radiation intensity and atmospheric temperature, which are both optimal conditions for better SCPP activity, the output of electricity gradually increased.

Table 2.

HSDCPP monthly electrical power and distilled water production.

According to previous studies [44], a modified solar double chimney provided 2.3 times more generated electrical power and about two times more desalinated water than the conventional SCPP [29]. The 10 turbines in the secondary chimney contribution could result in a substantial rise in power and desalinated water generation. Table 2 also shows that the CT’s power output showed the lowest values in the winter months because of the low-temperature gradient and the high humidity. Importantly, the new proposed system generated more annual combined power (1457 MWh) than the traditional SCPP (380 MWh).

3.5. Performance Comparison

To compare the performance of the HSDCPP with similar design proposals available in the literature, the following work has been selected as shown in Table 3. The basic physical dimensions of the designs, along with the annual energy produced, are summarized in the table. The dimensions included are the height of the chimney, the diameter of the collector, and the diameter of the chimney. The work selected was either in Qatar or close to the Qatar region to have a fair comparison due to weather variations from one place to another. The table demonstrates the superiority of the HSDCPP in producing energy over all the work cited.

Table 3.

HSDCPP performance comparison with similar designs in the literature.

4. Conclusions

The HSDCPP showed superior performance in terms of energy and water production to the traditional solar chimney. With the same footprint, the HSDCPP outperformed, by 3.83 times (1,457,423 kWh), the annual electrical energy produced by the traditional solar chimney. Furthermore, the HSDCPP had an added value over the traditional solar chimney by producing 172,344 tons of fresh water annually. The HSDCPP can operate at different geographical locations and does not necessarily require operation at high solar radiation due to its dual functionality as a cooling tower and solar chimney. However, some of the drawbacks of the proposed design are that it needed a large area of land for the collector. Additionally, the HSDCPP needed a continuous supply of seawater. Furthermore, the performance of the HSDCPP was very dependent on weather conditions, particularly the dependency of the cooling towers on the humidity in the air. The cooling towers’ performance depended on the availability of hot and dry weather. Hence, winter times were detrimental to the performance of the cooling towers. The present design provided electricity for remote areas where the grid was not present and supplied arid areas with fresh water. Future work may include using artificial intelligence to select the best modes of operation between the cooling towers and the solar chimney as the cooling towers could work during the daytime in addition to nighttime. Furthermore, a detailed techno-economic assessment is warranted in the future to ensure the economic feasibility of the proposed design.

5. Patents

A provisional patent application has been filed with the USPTO.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/su15032729/s1, Figure S1: Energy balance environment. (a) is in the case of the SCPP mode, and (b) in the case of the CT mode; Figure S2: Model validation against the results obtained by [51]. Showing 24-h electrical power production; Table S1: Dimensions of the HSDCPP model. References [13,30,51,52,53,54,55,56,57,58] are cited in the Supplementary Materials.

Author Contributions

Conceptualization, E.A. and F.K.; methodology, E.A.; software, M.A.; validation, M.J., F.K.; formal analysis, M.A.; investigation, S.I.; resources, F.K.; data curation, E.A.; writing—original draft preparation, S.I. and E.A.; writing—review and editing, E.A. and F.A.; visualization, S.I. and M.J.; supervision, E.A. and F.A.; project administration, E.A. and F.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study is contained within the article.

Acknowledgments

The authors extend their appreciation to the MERG lab (www.MERG.live) for their support by providing data and guidance.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kannan, N.; Vakeesan, D. Solar energy for future world—A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Almomani, F.; Al Ketife, A.; Judd, S.; Shurair, M.; Bhosale, R.R.; Znad, H.; Tawalbeh, M. Impact of CO2 concentration and ambient conditions on microalgal growth and nutrient removal from wastewater by a photobioreactor. Sci. Total. Environ. 2019, 662, 662–671. [Google Scholar] [CrossRef] [PubMed]

- Judd, S.; Al Momani, F.; Znad, H.; Al Ketife, A. The cost benefit of algal technology for combined CO2 mitigation and nutrient abatement. Renew. Sustain. Energy Rev. 2017, 71, 379–387. [Google Scholar] [CrossRef]

- Al Ketife, A.M.; Al Momani, F.; El-Naas, M.; Judd, S. A technoeconomic assessment of microalgal culture technology implementation for combined wastewater treatment and CO2 mitigation in the Arabian Gulf. Process. Saf. Environ. Prot. 2019, 127, 90–102. [Google Scholar] [CrossRef]

- Brusseau, M.; Ramirez-Andreotta, M.; Pepper, I.; Maximillian, J. Environmental Impacts on Human Health and Well-Being. In Environmental and Pollution Science; Academic Press: Cambridge, MA, USA, 2019; pp. 477–499. [Google Scholar] [CrossRef]

- Filho, W.L.; Azeiteiro, U.; Alves, F. Climate Change and Health: An Overview of the Issues and Needs. In Climate Change and Health: Improving Resilience and Reducing Risks; Springer: Cham, Switzerland, 2016; pp. 1–11. [Google Scholar] [CrossRef]

- Mohsin, M.; Abbas, Q.; Zhang, J.; Ikram, M.; Iqbal, N. Integrated effect of energy consumption, economic development, and population growth on CO2 based environmental degradation: A case of transport sector. Environ. Sci. Pollut. Res. 2019, 26, 32824–32835. [Google Scholar] [CrossRef]

- Meckling, J.; Nahm, J. The politics of technology bans: Industrial policy competition and green goals for the auto industry. Energy Policy 2019, 126, 470–479. [Google Scholar] [CrossRef]

- Infield, D.; Freris, L. Renewable Energy in Power Systems; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Rypkema, H.A. Environmental Chemistry, Renewable Energy, and Global Policy. In Green Chemistry: An Inclusive Approach; Elsevier: Amsterdam, The Netherlands, 2017; pp. 19–47. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Carlucci, S.; Sen, H.; Sudhakar, K.; Hasanuzzaman, M.; Daneshazarian, R. Solar Chimney Power Plants: A Review of the Concepts, Designs and Performances. Sustainability 2022, 14, 1450. [Google Scholar] [CrossRef]

- Pradhan, S.; Chakraborty, R.; Mandal, D.; Barman, A.; Bose, P. Design and performance analysis of solar chimney power plant (SCPP): A review. Sustain. Energy Technol. Assess. 2021, 47, 101411. [Google Scholar] [CrossRef]

- Schlaich, J. The solar chimney: Electricity from the sun, Edition Axel Menges, Stuttgart, Germany, 1995.[2] ROBERT R. Span. Sol. Chimney Nears Complet. MPS Rev. 1981, 6, 21–23. [Google Scholar]

- Asayesh, M.; Kasaeian, A.; Ataei, A. Optimization of a combined solar chimney for desalination and power generation. Energy Convers. Manag. 2017, 150, 72–80. [Google Scholar] [CrossRef]

- Mehranfar, S.; Gharehghani, A.; Azizi, A.; Andwari, A.M.; Pesyridis, A.; Jouhara, H. Comparative assessment of innovative methods to improve solar chimney power plant efficiency. Sustain. Energy Technol. Assess. 2022, 49, 101807. [Google Scholar] [CrossRef]

- Abdelmohimen, M.A.; Algarni, S.A. Numerical investigation of solar chimney power plants performance for Saudi Arabia weather conditions. Sustain. Cities Soc. 2018, 38, 1–8. [Google Scholar] [CrossRef]

- Guo, P.; Li, J.; Wang, Y.; Wang, Y. Numerical study on the performance of a solar chimney power plant. Energy Convers. Manag. 2015, 105, 197–205. [Google Scholar] [CrossRef]

- Maia, C.; Ferreira, A.G.; Valle, R.M.; Cortez, M.F. Theoretical evaluation of the influence of geometric parameters and materials on the behavior of the airflow in a solar chimney. Comput. Fluids 2009, 38, 625–636. [Google Scholar] [CrossRef]

- Bilgen, E.; Rheault, J. Solar chimney power plants for high latitudes. Sol. Energy 2005, 79, 449–458. [Google Scholar] [CrossRef]

- Jing, H.; Chen, Z.; Li, A. Experimental study of the prediction of the ventilation flow rate through solar chimney with large gap-to-height ratios. Build. Environ. 2015, 89, 150–159. [Google Scholar] [CrossRef]

- Sangi, R.; Amidpour, M.; Hosseinizadeh, B. Modeling and numerical simulation of solar chimney power plants. Sol. Energy 2011, 85, 829–838. [Google Scholar] [CrossRef]

- Ming, T.; de Richter, R.K.; Meng, F.; Pan, Y.; Liu, W. Chimney shape numerical study for solar chimney power generating systems. Int. J. Energy Res. 2013, 37, 310–322. [Google Scholar] [CrossRef]

- Pastohr, H.; Kornadt, O.; Gürlebeck, K. Numerical and analytical calculations of the temperature and flow field in the upwind power plant. Int. J. Energy Res. 2004, 28, 495–510. [Google Scholar] [CrossRef]

- Hamdan, M.O. Analysis of a solar chimney power plant in the Arabian Gulf region. Renew. Energy 2011, 36, 2593–2598. [Google Scholar] [CrossRef]

- Koonsrisuk, A.; Lorente, S.; Bejan, A. Constructal solar chimney configuration. Int. J. Heat Mass Transf. 2010, 53, 327–333. [Google Scholar] [CrossRef]

- Saifi, N.; Settou, N.; Dokkar, B.; Negrou, B.; Chennouf, N. Experimental study and simulation of airflow in solar chimneys. Energy Procedia 2012, 18, 1289–1298. [Google Scholar] [CrossRef]

- Kasaeian, A.; Ghalamchi, M. Simulation and optimization of geometric parameters of a solar chimney in Tehran. Energy Convers. Manag. 2014, 83, 28–34. [Google Scholar] [CrossRef]

- Zuo, L.; Ding, L.; Chen, J.; Zhou, X.; Xu, B.; Liu, Z. Comprehensive study of wind supercharged solar chimney power plant combined with seawater desalination. Sol. Energy 2018, 166, 59–70. [Google Scholar] [CrossRef]

- Zuo, L.; Yuan, Y.; Li, Z.; Zheng, Y. Experimental research on solar chimneys integrated with seawater desalination under practical weather condition. Desalination 2012, 298, 22–33. [Google Scholar] [CrossRef]

- Kiwan, S.; Al-Nimr, M.; Salam, Q.I.A. Solar chimney power-water distillation plant (SCPWDP). Desalination 2018, 445, 105–114. [Google Scholar] [CrossRef]

- Kiwan, S.; Al-Nimr, M.; Salim, I. A hybrid solar chimney/photovoltaic thermal system for direct electric power production and water distillation. Sustain. Energy Technol. Assess. 2020, 38, 100680. [Google Scholar] [CrossRef]

- Zandian, A.; Ashjaee, M. The thermal efficiency improvement of a steam Rankine cycle by innovative design of a hybrid cooling tower and a solar chimney concept. Renew. Energy 2013, 51, 465–473. [Google Scholar] [CrossRef]

- Chaichan, M.T. Basement kind effects on air temperature of a solar chimney in Baghdad-Iraq weather. Int. J. Appl. Sci. 2011, 2, 12–20. [Google Scholar] [CrossRef]

- Chantawong, P.; Hirunlabh, J.; Zeghmati, B.; Khedari, J.; Teekasap, S.; Win, M.M. Investigation on thermal performance of glazed solar chimney walls. Sol. Energy 2006, 80, 288–297. [Google Scholar] [CrossRef]

- Ninic, N. Available energy of the air in solar chimneys and the possibility of its ground-level concentration. Sol. Energy 2006, 80, 804–811. [Google Scholar] [CrossRef]

- Koonsrisuk, A.; Chitsomboon, T. Mathematical modeling of solar chimney power plants. Energy 2013, 51, 314–322. [Google Scholar] [CrossRef]

- Ghalamchi, M.; Kasaeian, A.; Mirzahosseini, S.A.H. An experimental study on the thermal performance of a solar chimney with different dimensional parameters. Renew. Energy 2016, 91, 477–483. [Google Scholar] [CrossRef]

- Li, J.-Y.; Guo, P.; Wang, Y. Preliminary investigation of a novel solar and wind energy extraction system. Proc. Inst. Mech. Eng. Part A J. Power Energy 2012, 226, 73–85. [Google Scholar] [CrossRef]

- Fluri, T.; Von Backström, T. Performance analysis of the power conversion unit of a solar chimney power plant. Sol. Energy 2008, 82, 999–1008. [Google Scholar] [CrossRef]

- Tingzhen, M.; Wei, L.; Yuan, P. Numerical Analysis of the Solar Chimney Power Plant with Energy Storage Layer. In Proceedings of the ISES Solar World Congress 2007, Beijing, China, 18–21 September 2007; Volume 3, pp. 1800–1805. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Kafiah, F.; Tawalbeh, M.; Almomani, F.; Azzam, A.; Alzoubi, I.; Alkasrawi, M. Performance analysis of hybrid solar chimney–power plant for power production and seawater desalination: A sustainable approach. Int. J. Energy Res. 2021, 45, 17327–17341. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Almomani, F.; Ibrahim, S. A novel hybrid solar chimney power plant: Performance analysis and deployment feasibility. Energy Sci. Eng. 2022, 10, 3559–3579. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Almomani, F.; Ashraf, H.; Ibrahim, S. Dual-technology power plant as a potential solution for the clean water and electricity productions: Eritrea case study. Renew. Energy 2022, 201, 1050–1060. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Kafiah, F.; Almomani, F.; Tawalbeh, M.; Kiswani, S.; Khasawneh, A.; Ibrahim, D.; Alkasrawi, M. An innovative design of a solar double-chimney power plant for electricity generation. Energies 2021, 14, 6235. [Google Scholar] [CrossRef]

- Alkasrawi, M.; Abdelsalam, E.; Alnawafah, H.; Almomani, F.; Tawalbeh, M.; Mousa, A. Integration of Solar Chimney Power Plant with Photovoltaic for Co-Cooling, Power Production, and Water Desalination. Processes 2021, 9, 2155. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Almomani, F.; Alnawafah, H.; Alrashed, R. Triple-renewable energy system for electricity production and water desalination. Environ. Sci. Pollut. Res. 2022, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Abdelsalam, E.; Almomani, F.; Kafiah, F.; Almaitta, E.; Tawalbeh, M.; Khasawneh, A.; Habash, D.; Omar, A.; Alkasrawi, M. A New Sustainable and Novel Hybrid Solar Chimney Power Plant Design for Power Generation and Seawater Desalination. Sustainability 2021, 13, 12100. [Google Scholar] [CrossRef]

- Toghraie, D.; Karami, A.; Afrand, M.; Karimipour, A. Effects of geometric parameters on the performance of solar chimney power plants. Energy 2018, 162, 1052–1061. [Google Scholar] [CrossRef]

- Sangi, R. Performance evaluation of solar chimney power plants in Iran. Renew. Sustain. Energy Rev. 2012, 16, 704–710. [Google Scholar] [CrossRef]

- Asnaghi, A.; Ladjevardi, S.M. Solar chimney power plant performance in Iran. Renew. Sustain. Energy Rev. 2012, 16, 3383–3390. [Google Scholar] [CrossRef]

- Haaf, W.; Friedrich, K.; Mayr, G.; Schlaich, J. Solar Chimneys Part I: Principle and Construction of the Pilot Plant in Manzanares. Int. J. Sol. Energy 1983, 2, 3–20. [Google Scholar] [CrossRef]

- Islamuddin, A.; Al-Kayiem, H.H.; Gilani, S.I. Simulation of solar chimney power plant with an external heat source. IOP Conf. Ser. Earth Environ. Sci. 2013, 16, 12080. [Google Scholar] [CrossRef]

- Bansal, N.K.; Mathur, J.; Mathur, S.; Jain, M. Modeling of window-sized solar chimneys for ventilation. Build. Environ. 2005, 40, 1302–1308. [Google Scholar] [CrossRef]

- Kannan, R.; Selvaganesan, C.; Vignesh, M.; Ramesh Babu, B.; Fuentes, M.; Vivar, M.; Skryabin, I.; Srithar, K. Solar still with vapor adsorption basin: Performance analysis. Renew. Energy 2014, 62, 258–264. [Google Scholar] [CrossRef]

- Elminshawy, N.A.S.; Siddiqui, F.R.; Addas, M.F. Development of an active solar humidification-dehumidification (HDH) desalination system integrated with geothermal energy. Energy Convers. Manag. 2016, 126, 608–621. [Google Scholar] [CrossRef]

- Incropera, F.P.; Lavine, A.S.; Bergman, T.L.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Mathew, S. Wind Energy: Fundamentals, Resource Analysis and Economics; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Zuo, L.; Zheng, Y.; Li, Z.; Sha, Y. Solar chimneys integrated with sea water desalination. Desalination 2011, 276, 207–213. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).