Analysis of Five-Extraction Technologies’ Environmental Impact on the Polyphenols Production from Moringa oleifera Leaves Using the Life Cycle Assessment Tool Based on ISO 14040

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.1.1. Plant Material and Extraction Process

2.1.2. Chemicals

2.2. Determination of the Total Polyphenol Content (TPC)

2.3. Environmental Impact Assessment

2.3.1. Goal of the Study

2.3.2. Scope of the Study

2.3.3. Product Systems under Study

2.3.4. System Boundaries

2.3.5. System Functionality (Facts and Assumptions)

2.3.6. LCA Methodology, Impact Categories, and Data Requirements

3. Results and Discussion

3.1. Inventory Analysis (Inputs/Outputs)

3.2. Impact Assessment

3.2.1. System 1 (PEF)

3.2.2. System 2 (MAE)

3.2.3. System 3 (UAE)

3.2.4. System 4 (BW)

3.2.5. System 5 (C)

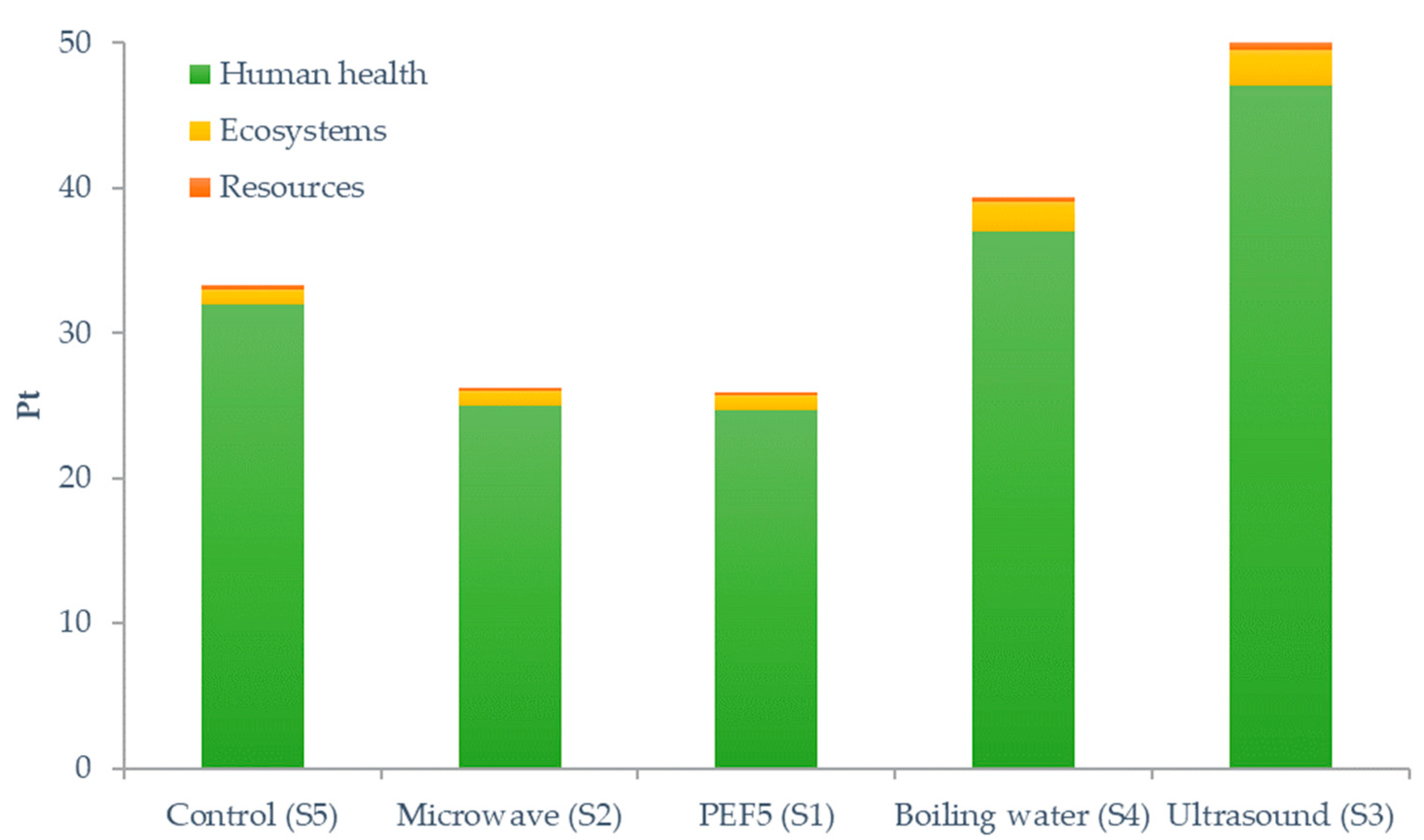

3.3. Comparison of the Environmental Performance of S1–S5 Systems

3.4. Comparison of the Environmental Performance of S1–S5 Systems: A Sensitivity Study

4. Conclusions and Recommendations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Teplova, V.V.; Isakova, E.P.; Klein, O.I.; Dergachova, D.I.; Gessler, N.N.; Deryabina, Y.I. Natural Polyphenols: Biological Activity, Pharmacological Potential, Means of Metabolic Engineering (Review). Appl. Biochem. Microbiol. 2018, 54, 221–237. [Google Scholar] [CrossRef]

- Lalas, S.I.; Athanasiadis, V.; Karageorgou, I.; Batra, G.; Nanos, G.D.; Makris, D.P. Nutritional Characterization of Leaves and Herbal Tea of Moringa oleifera Cultivated in Greece. J. Herbs Spices Med. Plants 2017, 23, 320–333. [Google Scholar] [CrossRef]

- Pandey, K.B.; Rizvi, S.I. Plant polyphenols as dietary antioxidants in human health and disease. Oxid. Med. Cell. Longev. 2009, 2, 270–278. [Google Scholar] [CrossRef]

- Pérez-Jiménez, J.; Neveu, V.; Vos, F.; Scalbert, A. Identification of the 100 richest dietary sources of polyphenols: An application of the Phenol-Explorer database. Eur. J. Clin. Nutr. 2010, 64, S112–S120. [Google Scholar] [CrossRef]

- Azmir, J.; Zaidul, I.S.M.; Rahman, M.M.; Sharif, K.M.; Mohamed, A.; Sahena, F.; Jahurul, M.H.A.; Ghafoor, K.; Norulaini, N.A.N.; Omar, A.K.M. Techniques for extraction of bioactive compounds from plant materials: A review. J. Food Eng. 2013, 117, 426–436. [Google Scholar] [CrossRef]

- Khoddami, A.; Wilkes, M.A.; Roberts, T.H. Techniques for analysis of plant phenolic compounds. Molecules 2013, 18, 2328–2375. [Google Scholar] [CrossRef]

- Talmaciu, A.I.; Volf, I.; Popa, V.I. A Comparative Analysis of the “Green” Techniques Applied for Polyphenols Extraction from Bioresources. Chem. Biodivers. 2015, 12, 1635–1651. [Google Scholar] [CrossRef]

- Liberal, Â.; Molina, A.K.; Pereira, C.; Dias, M.I.; Ferreira, I.C.F.R.; Barros, L. Chapter 4 Solid-liquid extraction of polyphenols. In Technologies to Recover Polyphenols from AgroFood By-products and Wastes, 1st ed.; Pintado, M.E., Saraiva, J.M.A., Alexandre, E.M., Eds.; Academic Press: London, UK, 2022; Volume 1, pp. 73–112. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Life cycle analysis of pistachio production in Greece. Sci. Total Environ. 2017, 595, 13–24. [Google Scholar] [CrossRef]

- Bartzas, G.; Vamvuka, D.; Komnitsas, K. Comparative life cycle assessment of pistachio, almond and apple production. Inf. Process. Agric. 2017, 4, 188–198. [Google Scholar] [CrossRef]

- Longo, S.; Mistretta, M.; Guarino, F.; Cellura, M. Life Cycle Assessment of organic and conventional apple supply chains in the North of Italy. J. Clean. Prod. 2017, 140, 654–663. [Google Scholar] [CrossRef]

- Iannone, R.; Miranda, S.; Riemma, S.; De Marco, I. Improving environmental performances in wine production by a life cycle assessment analysis. J. Clean. Prod. 2016, 111, 172–180. [Google Scholar] [CrossRef]

- Cellura, M.; Longo, S.; Mistretta, M. Life Cycle Assessment (LCA) of protected crops: An Italian case study. J. Clean. Prod. 2012, 28, 56–62. [Google Scholar] [CrossRef]

- Tsangas, M.; Gavriel, I.; Doula, M.; Xeni, F.; Zorpas, A.A. Life Cycle Analysis in the Framework of Agricultural Strategic Development Planning in the Balkan Region. Sustainability 2020, 12, 1813. [Google Scholar] [CrossRef]

- Mouron, P.; Nemecek, T.; Scholz, R.W.; Weber, O. Management influence on environmental impacts in an apple production system on Swiss fruit farms: Combining life cycle assessment with statistical risk assessment. Agric. Ecosyst. Environ. 2006, 114, 311–322. [Google Scholar] [CrossRef]

- Ferrara, C.; De Feo, G. Life Cycle Assessment Application to the Wine Sector: A Critical Review. Sustainability 2018, 10, 395. [Google Scholar] [CrossRef]

- Masuda, K. Measuring eco-efficiency of wheat production in Japan: A combined application of life cycle assessment and data envelopment analysis. J. Clean. Prod. 2016, 126, 373–381. [Google Scholar] [CrossRef]

- Sohn, J.; Bisquert, P.; Buche, P.; Hecham, A.; Kalbar, P.P.; Goldstein, B.; Birkved, M.; Olsen, S.I. Argumentation Corrected Context Weighting-Life Cycle Assessment: A Practical Method of Including Stakeholder Perspectives in Multi-Criteria Decision Support for LCA. Sustainability 2020, 12, 2170. [Google Scholar] [CrossRef]

- Bozinou, E.; Karageorgou, I.; Batra, G.; Dourtoglou, V.G.; Lalas, S.I. Pulsed electric field extraction and antioxidant activity determination of Moringa oleifera dry leaves: A comparative study with other extraction techniques. Beverages 2019, 5, 8. [Google Scholar] [CrossRef]

- Ho, S.; Mittal, G.S. High voltage pulsed electrical field for liquid food pasteurization. Food Rev. Int. 2000, 16, 395–434. [Google Scholar] [CrossRef]

- Wouters, P.C.; Alvarez, I.; Raso, J. Critical factors determining inactivation kinetics by pulsed electric field food processing. Trends Food Sci. Technol. 2001, 12, 112–121. [Google Scholar] [CrossRef]

- Jaeger, H.; Balasa, A.; Knorr, D. Food Industry Applications for Pulsed Electric Fields. In Electrotechnologies for Extraction from Food Plants and Biomaterials, 1st ed.; Lebovka, N., Vorobiev, E., Eds.; Springer: New York, NY, USA, 2009; Volume 1, pp. 181–216. [Google Scholar] [CrossRef]

- Chan, C.H.; Yusoff, R.; Ngoh, G.C.; Kung, F.W.L. Microwave-assisted extractions of active ingredients from plants. J. Chromatogr. A 2011, 1218, 6213–6225. [Google Scholar] [CrossRef]

- Chemat, F.; Fabiano-Tixier, A.S.; Vian, M.A.; Allaf, T.; Vorobiev, E. Solvent-free extraction of food and natural products. TrAC Trends Anal. Chem. 2015, 71, 157–168. [Google Scholar] [CrossRef]

- Chemat, F.; Tomao, V.; Virot, M. Chapter 5 Ultrasound-Assisted Extraction in Food Analysis. In Handbook of Food Analysis Instruments, 1st ed.; Otles, S., Ed.; CRC Press: Boca Raton, FL, USA, 2008; Volume 1, pp. 85–104. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 27 August 2021).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 27 August 2021).

- Hospido, A.; Davis, J.; Berlin, J.; Sonesson, U. A review of methodological issues affecting LCA of novel food products. Int. J. Life Cycle Assess. 2010, 15, 44–52. [Google Scholar] [CrossRef]

- Cucurachi, S.; Van Der Giesen, C.; Guinée, J. Ex-ante LCA of Emerging Technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Meullemiestre, A.; Turk, M.; Perino, S.; Fabiano-Tixier, A.S.; Abert-Vian, M. Review of Green Food Processing techniques. Preservation, transformation, and extraction. Innov. Food Sci. Emerg. Technol. 2017, 41, 357–377. [Google Scholar] [CrossRef]

- Briante, R.; La Cara, F.; Febbraio, F.; Patumi, M.; Nucci, R. Bioactive derivatives from oleuropein by a biotransformation on Olea europaea leaf extracts. J. Biotechnol. 2002, 93, 109–119. [Google Scholar] [CrossRef]

- Bobinaitė, R.; Pataro, G.; Lamanauskas, N.; Šatkauskas, S.; Viškelis, P.; Ferrari, G. Application of pulsed electric field in the production of juice and extraction of bioactive compounds from blueberry fruits and their by-products. J. Food Sci. Technol. 2015, 52, 5898–5905. [Google Scholar] [CrossRef]

- Pataro, G.; Carullo, D.; Ferrari, G. Effect of PEF pre-treatment and extraction temperature on the recovery of carotenoids from tomato wastes. Chem. Eng. Trans. 2019, 75, 139–144. [Google Scholar] [CrossRef]

- Hendrawan, Y.; Larasati, R.; Wibisono, Y.; Umam, C.; Sutan, S.M.; Choviya Hawa, L. Extraction of Phenol and Antioxidant Compounds from Kepok Banana Skin with PEF Pre-Treatment. IOP Conf. Ser. Earth Environ. Sci. 2019, 305, 012065. [Google Scholar] [CrossRef]

- Luengo, E.; Ãlvarez, I.; Raso, J. Improving Carotenoid Extraction from Tomato Waste by Pulsed Electric Fields. Front. Nutr. 2014, 1, 12. [Google Scholar] [CrossRef]

- Martín-García, B.; Tylewicz, U.; Verardo, V.; Pasini, F.; Gómez-Caravaca, A.M.; Caboni, M.F.; Dalla Rosa, M. Pulsed electric field (PEF) as pre-treatment to improve the phenolic compounds recovery from brewers’ spent grains. Innov. Food Sci. Emerg. Technol. 2020, 64, 102402. [Google Scholar] [CrossRef]

- Pataro, G.; Carullo, D.; Bakar Siddique, M.A.; Falcone, M.; Donsì, F.; Ferrari, G. Improved extractability of carotenoids from tomato peels as side benefits of PEF treatment of tomato fruit for more energy-efficient steam-assisted peeling. J. Food Eng. 2018, 233, 65–73. [Google Scholar] [CrossRef]

- Sukardi; Pulungan, M.H.; Purwaningsih, I.; Sita, P.F. Extraction of phenolic compounds from basil (Ocimum americanum L.) leaves with pretreatment using pulsed electric field (PEF). IOP Conf. Ser. Earth Environ. Sci. 2020, 475, 012056. [Google Scholar] [CrossRef]

- Grahl, T.; Märkl, H. Killing of microorganisms by pulsed electric fields. Appl. Microbiol. Biotechnol. 1996, 45, 148–157. [Google Scholar] [CrossRef]

- Álvarez, I.; Pagán, R.; Condón, S.; Raso, J. The influence of process parameters for the inactivation of Listeria monocytogenes by pulsed electric fields. Int. J. Food Microbiol. 2003, 87, 87–95. [Google Scholar] [CrossRef] [PubMed]

- Kotnik, T.; Rems, L.; Tarek, M.; Miklavcic, D. Membrane Electroporation and Electropermeabilization: Mechanisms and Models. Annu. Rev. Biophys. 2019, 48, 63–91. [Google Scholar] [CrossRef]

- Brodelius, P.E.; Funk, C.; Shillito, R.D. Permeabilization of cultivated plant cells by electroporation for release of intracellularly stored secondary products. Plant Cell Rep. 1988, 7, 186–188. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Barjoveanu, G.; Pătrăuțanu, O.-A.; Teodosiu, C.; Volf, I. Life cycle assessment of polyphenols extraction processes from waste biomass. Sci. Rep. 2020, 10, 13632. [Google Scholar] [CrossRef] [PubMed]

| System Number | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Targeted polyphenol extraction (g) | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Used Moringa oleifera leaves per extraction cycle (g) | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 |

| Yielded mass of polyphenols per extraction cycle (g) | 0.046 | 0.042 | 0.033 | 0.036 | 0.032 |

| Number of extraction cycles needed | 21.60 | 23.75 | 29.94 | 27.55 | 31.35 |

| Total mass of Moringa oleifera leaves (g) | 27.00 | 29.70 | 37.43 | 34.44 | 39.18 |

| H2O needs as solvent per extraction cycle (g) | 34.70 | 38.50 | 35.50 | 40.40 | 34.60 |

| Total mass of H2O (g) | 751.62 | 914.49 | 1062.87 | 1112.95 | 1084.64 |

| S1 | S2 | S3 | S4 | S5 | |

|---|---|---|---|---|---|

| Extraction duration (min) | 40 | 2 | 15 | 2 | 40 |

| Temperature start (°C) | 25 | 25 | 25 | 100 | 25 |

| Temperature end (°C) | 25 | 80 | 36 | 88 | 25 |

| ΔT (°C) | 0 | 55 | 11 | 12 | 0 |

| Total Pt | Electrical Grid (Pt) | Photovoltaic (Pt) | Moringa oleifera Leaves (DMPM) | |

|---|---|---|---|---|

| S5-Control (no sensitivity analysis) | 57.255323 | 26.461639 | – | 27.883349 |

| S5-Control (with sensitivity analysis) | 32.986533 | – | 2.192848 | 27.883349 |

| S1-PEF (with sensitivity analysis) | 26.718349 | – | 3.316455 | 19.211269 |

| S2-Microwave (with sensitivity analysis) | 26.818446 | – | 2.931145 | 21.127833 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pappas, V.M.; Samanidis, I.; Stavropoulos, G.; Athanasiadis, V.; Chatzimitakos, T.; Bozinou, E.; Makris, D.P.; Lalas, S.I. Analysis of Five-Extraction Technologies’ Environmental Impact on the Polyphenols Production from Moringa oleifera Leaves Using the Life Cycle Assessment Tool Based on ISO 14040. Sustainability 2023, 15, 2328. https://doi.org/10.3390/su15032328

Pappas VM, Samanidis I, Stavropoulos G, Athanasiadis V, Chatzimitakos T, Bozinou E, Makris DP, Lalas SI. Analysis of Five-Extraction Technologies’ Environmental Impact on the Polyphenols Production from Moringa oleifera Leaves Using the Life Cycle Assessment Tool Based on ISO 14040. Sustainability. 2023; 15(3):2328. https://doi.org/10.3390/su15032328

Chicago/Turabian StylePappas, Vasileios M., Iordanis Samanidis, Giorgos Stavropoulos, Vassilis Athanasiadis, Theodoros Chatzimitakos, Eleni Bozinou, Dimitris P. Makris, and Stavros I. Lalas. 2023. "Analysis of Five-Extraction Technologies’ Environmental Impact on the Polyphenols Production from Moringa oleifera Leaves Using the Life Cycle Assessment Tool Based on ISO 14040" Sustainability 15, no. 3: 2328. https://doi.org/10.3390/su15032328

APA StylePappas, V. M., Samanidis, I., Stavropoulos, G., Athanasiadis, V., Chatzimitakos, T., Bozinou, E., Makris, D. P., & Lalas, S. I. (2023). Analysis of Five-Extraction Technologies’ Environmental Impact on the Polyphenols Production from Moringa oleifera Leaves Using the Life Cycle Assessment Tool Based on ISO 14040. Sustainability, 15(3), 2328. https://doi.org/10.3390/su15032328