Government Subsidy Strategies for the New Energy Vehicle Power Battery Recycling Industry

Abstract

1. Introduction

2. Literature Review

2.1. Benefits of Power Battery Recycling

2.2. Game Theory in the Power Battery Recycling Industry

2.3. Government Subsidies for the Recycling Industry

3. Evolutionary Game Model for Both Recyclers and Consumers

3.1. Description of the Reality of the Situation

3.2. Model Assumptions

3.3. Constructing Evolutionary Game Models

- (a)

- Recycling companies

- (b)

- Consumers

4. Equilibrium Analysis of the Evolutionary Game

4.1. Expected Earnings

4.2. Evolutionary Stable Strategy Based on the Replicated Dynamic Function

4.3. Stability Analysis of the Equilibrium Strategy

- (a)

- Stability analysis of the recycling companies’ strategy

- (b)

- Stability analysis of the consumer’ strategy

- (c)

- Stability analysis of the hybrid strategy

4.4. Numerical Simulation

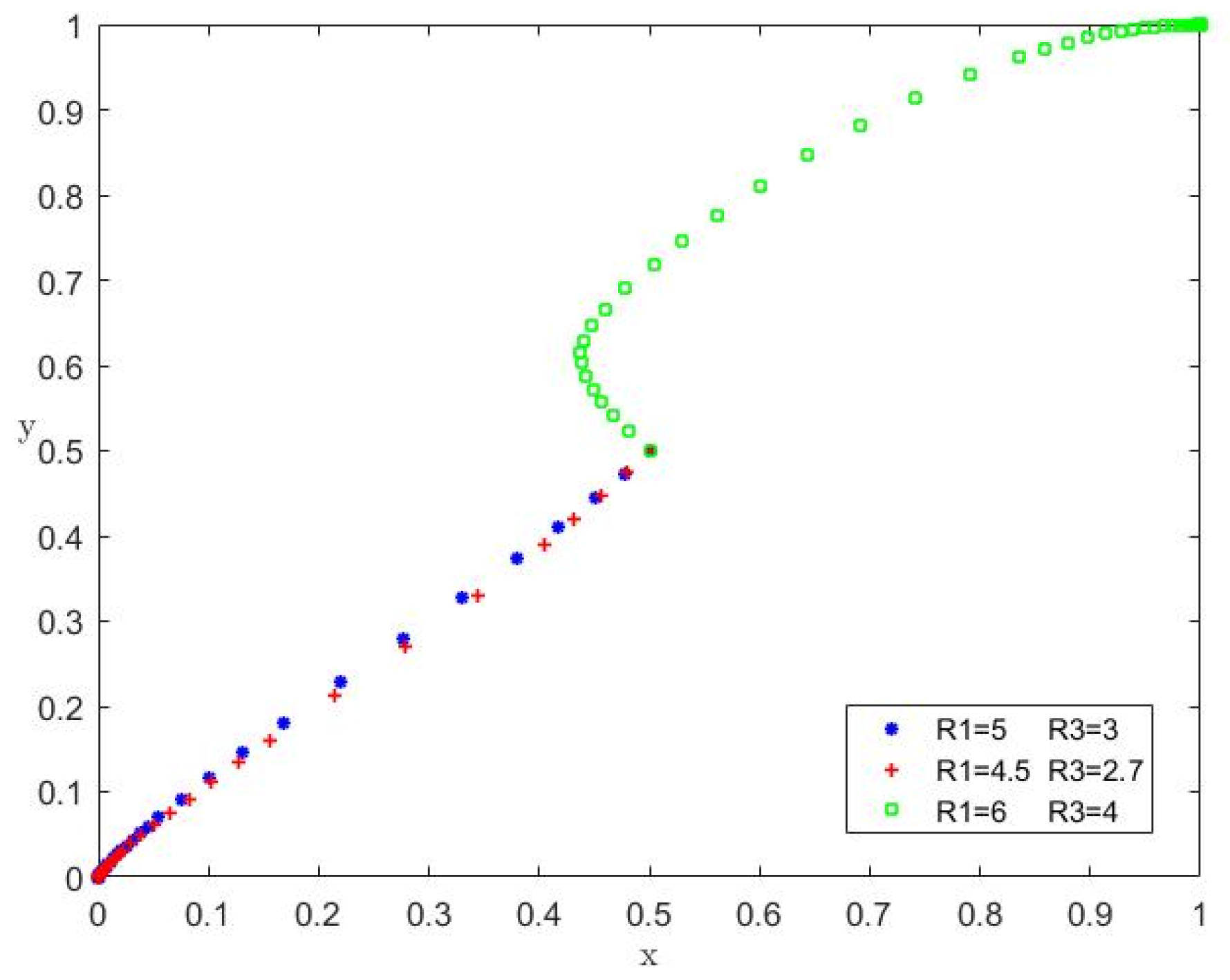

- (a)

- Impact of changes in R1 and R3 on evolutionary pathways

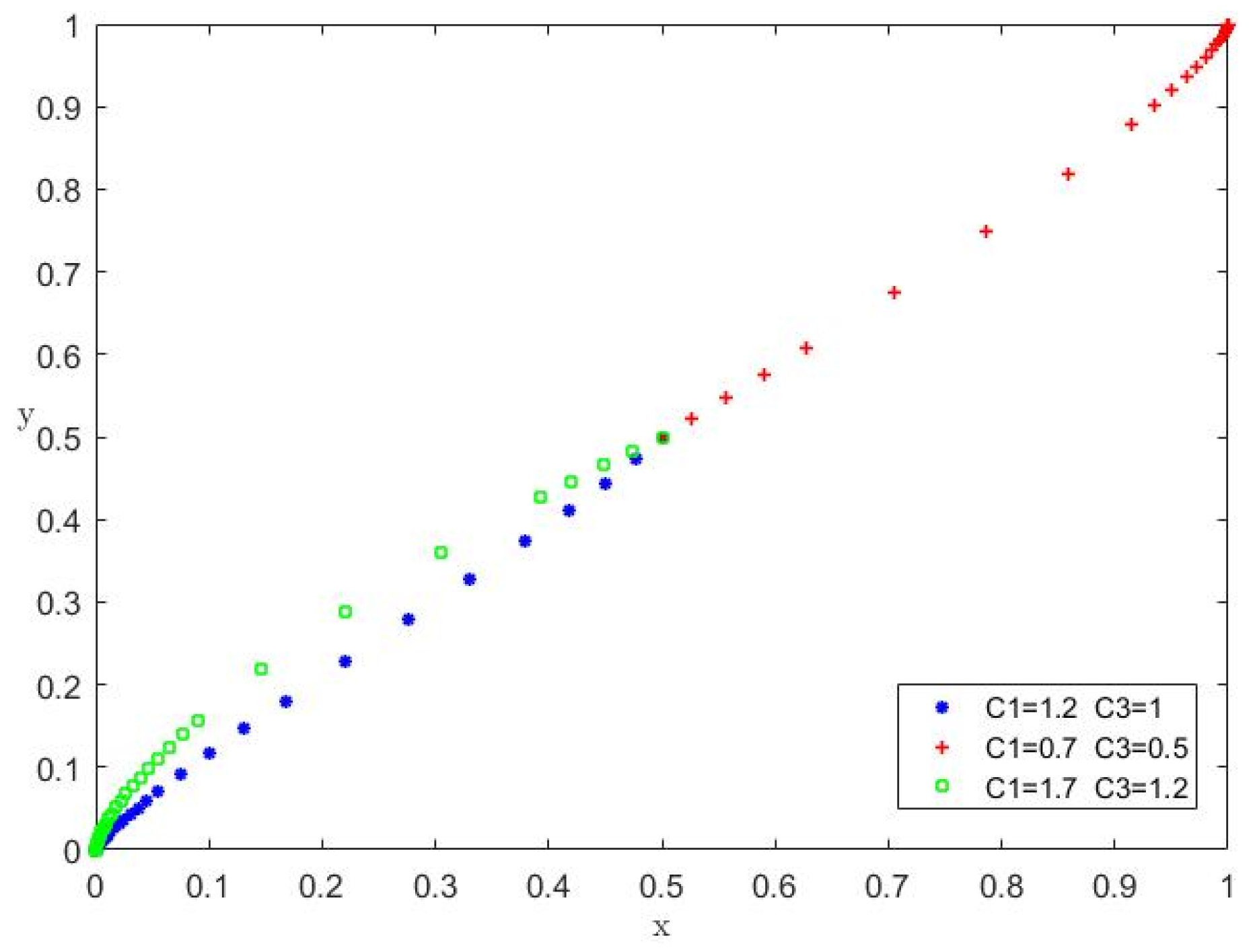

- (b)

- Impact of changes in C1 and C3 on evolutionary pathways

- (c)

- Impact of changes in R2 and R4 on evolutionary pathways

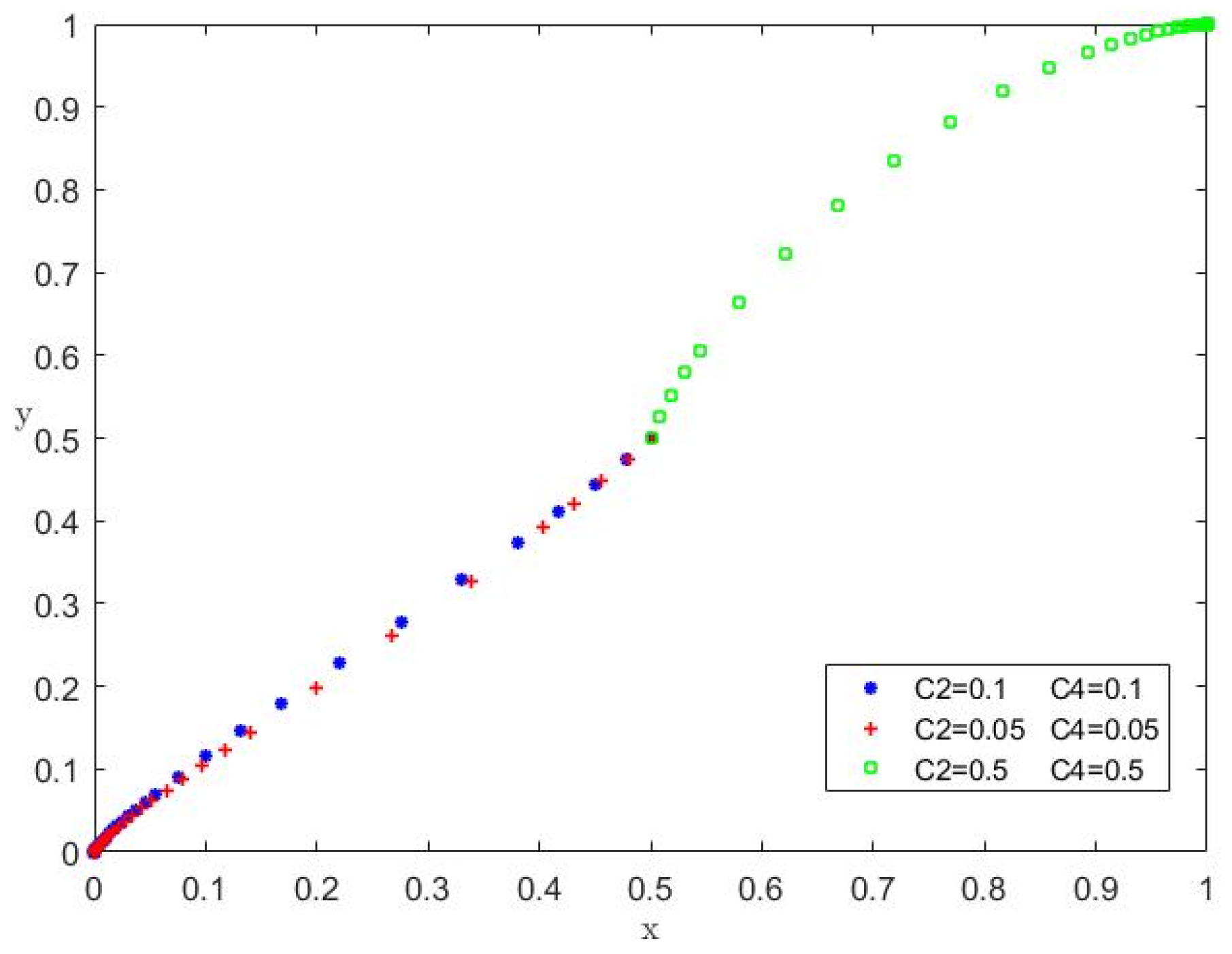

- (d)

- Impact of changes in C2 and C4 on evolutionary pathways

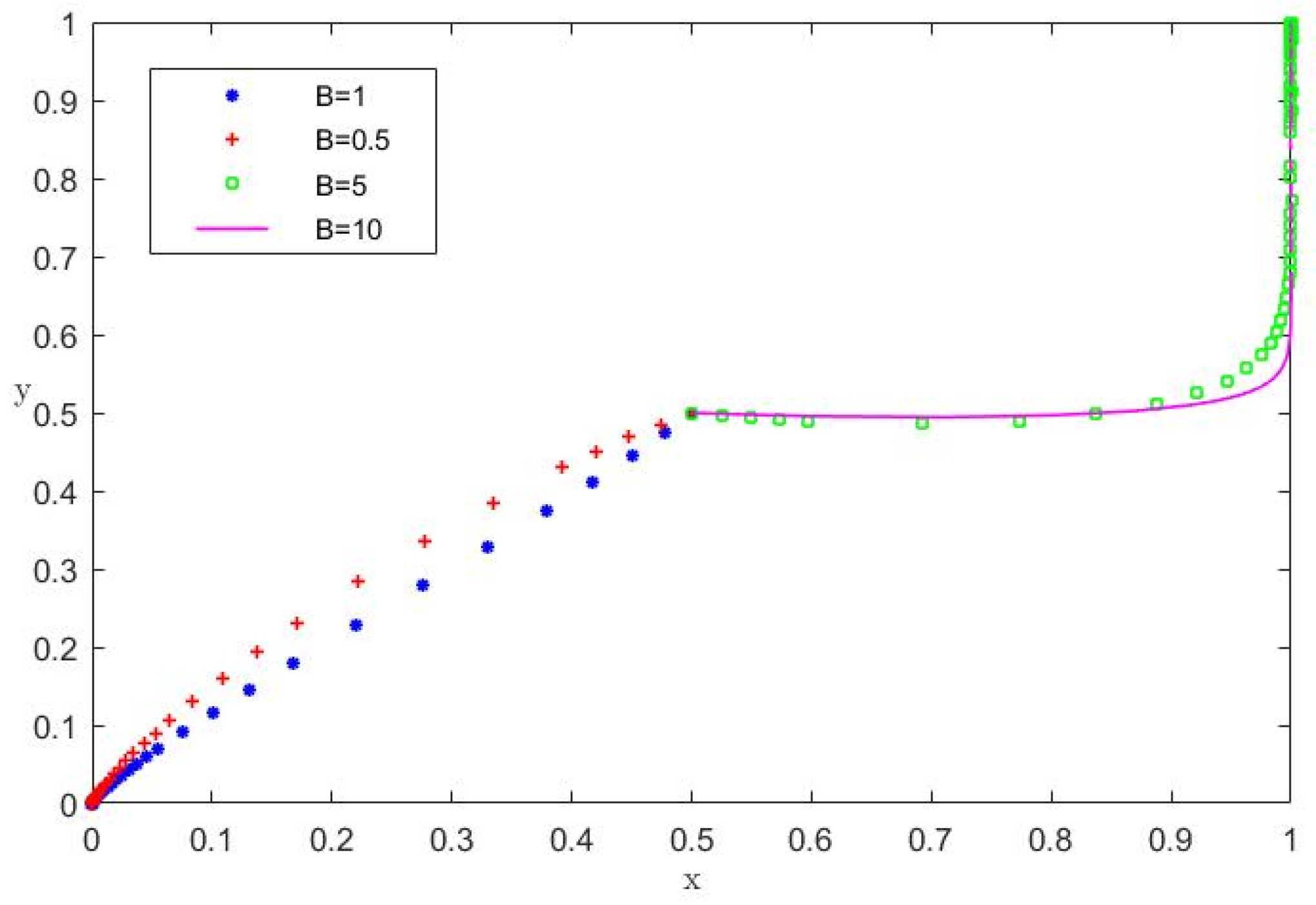

- (e)

- Impact of changes in B on evolutionary pathways

5. The Choice of Optimal Government Subsidy Strategy

5.1. Description of the Reality of the Situation

5.2. Three-Party Game Model

5.3. Analysis of the Optimal Subsidy Strategy

- (a)

- Subsidy policy analysis for scenario 1

- (b)

- Subsidy policy analysis for scenario 2

- (c)

- Subsidy policy analysis for scenario 3

- (d)

- Subsidy policy analysis for scenario 4

5.4. Case Study

6. Conclusions and Policy Recommendations

6.1. Conclusions

- (1)

- Under no government intervention, recycling companies and consumers cannot effectively recycle EoL power batteries. When the net benefit of positive behavior of one or both parties is smaller than the net benefit of negative behavior, the system eventually evolves to {recycling companies do not regulate recycling, consumers do not participate in recycling}.

- (2)

- Increasing the benefits of positive recycling, the costs of negative recycling, and indirect benefits of both parties, or decreasing the benefits of negative recycling and the costs of positive recycling of both parties, will facilitate the system to eventually evolve to {recycling companies regulate recycling, consumers participate in recycling}.

- (3)

- Government subsidies can promote recycling companies and consumers to actively recycle EoL power batteries. The government hopes to achieve the goal of optimal total social gain by employing subsidies. However, the government will only act if the net benefit to society is greater than the subsidy paid by the government. Therefore, this paper evaluates the effects of three subsidies: a single subsidy to recycling companies, a single subsidy to consumers, and a simultaneous subsidy to both recycling companies and consumers. The case study results show that the government’s subsidizing of recycling companies and consumers work best.

6.2. Policy Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Habib, K.; Hansdóttir, S.T.; Habib, H. Critical metals for electromobility: Global demand scenarios for passenger vehicles, 2015–2050. Resour. Conserv. Recycl. 2020, 154, 104603. [Google Scholar] [CrossRef]

- Xiong, S.; Ji, J.; Ma, X. Environmental and economic evaluation of remanufacturing lithium-ion batteries from electric vehicles. Waste Manag. 2020, 102, 579–586. [Google Scholar] [CrossRef] [PubMed]

- IEA Global Supply Chains of EV Batteries. Available online: https://www.iea.org/reports/global-supply-chains-of-ev-batteries (accessed on 14 August 2022).

- IEA Global EV Outlook 2022. Available online: https://www.iea.org/reports/global-ev-outlook-2022 (accessed on 14 August 2022).

- Ghosh, A.; Jha, J.K.; Sarmah, S.P. Optimal lot-sizing under strict carbon cap policy considering stochastic demand. Appl. Math. Model. 2017, 44, 688–704. [Google Scholar] [CrossRef]

- Pavlovic, J.; Marotta, A.; Ciuffo, B. CO2 emissions and energy demands of vehicles tested under the NEDC and the new WLTP type approval test procedures. Appl. Energy 2016, 177, 661–670. [Google Scholar] [CrossRef]

- Sun, S.; Zhao, G.; Wang, T.; Jin, J.; Wang, P.; Lin, Y.; Li, H.; Ying, Q.; Mao, H. Past and future trends of vehicle emissions in Tianjin, China, from 2000 to 2030. Atmos. Environ. 2019, 209, 182–191. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, K.; Hang, Z.; Zhou, D.; Zhou, Y.; Xu, Z. Waste battery-to-reutilization decisions under government subsidies: An evolutionary game approach. Energy 2022, 259, 124835. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y. An overview of recycling and treatment of spent LiFePO 4 batteries in China. Resour. Conserv. Recycl. 2017, 127, 233–243. [Google Scholar] [CrossRef]

- Gu, X.; Zhou, L.; Huang, H.; Shi, X.; Ieromonachou, P. Electric vehicle battery secondary use under government subsidy: A closed-loop supply chain perspective. Int. J. Prod. Econ. 2021, 234, 108035. [Google Scholar] [CrossRef]

- Hao, H.; Qiao, Q.; Liu, Z.; Zhao, F. Impact of recycling on energy consumption and greenhouse gas emissions from electric vehicle production: The China 2025 case. Resour. Conserv. Recycl. 2017, 122, 114–125. [Google Scholar] [CrossRef]

- Heymans, C.; Walker, S.B.; Young, S.B.; Fowler, M. Economic analysis of second use electric vehicle batteries for residential energy storage and load-levelling. Energy Policy 2014, 71, 22–30. [Google Scholar] [CrossRef]

- Natkunarajah, N.; Scharf, M.; Scharf, P. Scenarios for the Return of Lithium-ion Batteries out of Electric Cars for Recycling. Procedia Cirp 2015, 29, 740–745. [Google Scholar] [CrossRef]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.W.; Nenadic, N.G.; Gaustad, G. Environmental trade-offs across cascading lithium-ion battery life cycles. Int. J. Life Cycle Assess. 2017, 22, 66–81. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A.; Williams, B.; Ferry, M.; Eyer, J. Techno-Economic Analysis of PEV Battery Second Use: Repurposed-Battery Selling Price and Commercial and Industrial End-User Value; 0148-7191; National Renewable Energy Lab.(NREL): Golden, CO, USA, 2012.

- Lih, W.-C.; Yen, J.-H.; Shieh, F.-H.; Liao, Y.-M. Second use of retired lithium-ion battery packs from electric vehicles: Technological challenges, cost analysis and optimal business model. In Proceedings of the 2012 International Symposium on Computer, Consumer and Control, Taichung, Taiwan, 4–6 June 2012; pp. 381–384. [Google Scholar]

- Assunção, A.; Moura, P.S.; de Almeida, A.T. Technical and economic assessment of the secondary use of repurposed electric vehicle batteries in the residential sector to support solar energy. Appl. Energy 2016, 181, 120–131. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M. Energy and environmental benefits of circular economy strategies: The case study of reusing used batteries from electric vehicles. J. Energy Storage 2019, 25, 100845. [Google Scholar] [CrossRef]

- Nguyen-Tien, V.; Dai, Q.; Harper, G.D.J.; Anderson, P.A.; Elliott, R.J.R. Optimising the geospatial configuration of a future lithium ion battery recycling industry in the transition to electric vehicles and a circular economy. Appl. Energy 2022, 321, 119230. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, B.; Shen, M.; Wu, Y.; Qu, S.; Hu, Y.; Feng, Y. Environmental impact assessment of second life and recycling for LiFePO4 power batteries in China. J. Environ. Manag. 2022, 314, 115083. [Google Scholar] [CrossRef]

- Wanger, T.C. The Lithium future—Resources, recycling, and the environment. Conserv. Lett. 2011, 4, 202–206. [Google Scholar] [CrossRef]

- Song, J.; Yan, W.; Cao, H.; Song, Q.; Ding, H.; Lv, Z.; Zhang, Y.; Sun, Z. Material flow analysis on critical raw materials of lithium-ion batteries in China. J. Clean. Prod. 2019, 215, 570–581. [Google Scholar] [CrossRef]

- Feng, T.; Guo, W.; Li, Q.; Meng, Z.; Liang, W. Life cycle assessment of lithium nickel cobalt manganese oxide batteries and lithium iron phosphate batteries for electric vehicles in China. J. Energy Storage 2022, 52, 104767. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective. eTransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Miao, Y.; Liu, L.; Zhang, Y.; Tan, Q.; Li, J. An overview of global power lithium-ion batteries and associated critical metal recycling. J. Hazard. Mater. 2022, 425, 127900. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Muralidharan, N.; Sun, Y.-K.; Passerini, S.; Whittingham, M.S.; Belharouak, I. Energy and environmental aspects in recycling lithium-ion batteries: Concept of Battery Identity Global Passport. Mater. Today 2020, 41, 304–315. [Google Scholar] [CrossRef]

- Kaushal, R.K.; Nema, A.K.; Chaudhary, J. Strategic exploration of battery waste management: A game-theoretic approach. Waste Manag. Res. 2015, 33, 681–689. [Google Scholar] [CrossRef]

- Sun, Q.; Chen, H.; Long, R.; Li, Q.; Huang, H. Comparative evaluation for recycling waste power batteries with different collection modes based on Stackelberg game. J Environ. Manag. 2022, 312, 114892. [Google Scholar] [CrossRef]

- Zhang, C.; Tian, Y.-X.; Han, M.-H. Recycling mode selection and carbon emission reduction decisions for a multi-channel closed-loop supply chain of electric vehicle power battery under cap-and-trade policy. J. Clean. Prod. 2022, 375, 134060. [Google Scholar] [CrossRef]

- He, L.; Sun, B. Exploring the EPR system for power battery recycling from a supply-side perspective: An evolutionary game analysis. Waste Manag. 2022, 140, 204–212. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Tan, Z.; Li, Z. Analysis of cooperation equilibrium of participants in power battery recycling chains considering information barrier. Chin. J. Popul. Resour. Environ. 2022, 20, 159–167. [Google Scholar] [CrossRef]

- Yang, Y.; Okonkwo, E.G.; Huang, G.; Xu, S.; Sun, W.; He, Y. On the sustainability of lithium ion battery industry—A review and perspective. Energy Storage Mater. 2021, 36, 186–212. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.; Gong, B.; Zhang, X.; Li, H. Optimal policy for the recycling of electric vehicle retired power batteries. Technol. Forecast. Soc. Chang. 2022, 183, 121930. [Google Scholar] [CrossRef]

- Liu, K.; Wang, C. The impacts of subsidy policies and channel encroachment on the power battery recycling of new energy vehicles. Int. J. Low-Carbon Technol. 2021, 16, 770–789. [Google Scholar] [CrossRef]

- Ding, P.; Zhao, Z.; Li, X. Government subsidies in the power battery recycling industry. Ind. Manag. Data Syst. 2020, 120, 1059–1083. [Google Scholar] [CrossRef]

- Ma, W.M.; Zhao, Z.; Ke, H. Dual-channel closed-loop supply chain with government consumption-subsidy. Eur. J. Oper. Res. 2013, 226, 221–227. [Google Scholar] [CrossRef]

- Shao, L.; Yang, J.; Zhang, M. Subsidy scheme or price discount scheme? Mass adoption of electric vehicles under different market structures. Eur. J. Oper. Res. 2017, 262, 1181–1195. [Google Scholar] [CrossRef]

- Zhao, J.; Sun, N. Government subsidies-based profits distribution pattern analysis in closed-loop supply chain using game theory. Neural Comput. Appl. 2020, 32, 1715–1724. [Google Scholar] [CrossRef]

- Savaskan, R.C.; Bhattacharya, S.; Wassenhove, L. Closed-Loop Supply Chain Models with Product Remanufacturing. Manag. Sci. 2004, 50, 239–252. [Google Scholar] [CrossRef]

- Hu, L.; Wei, X.; Ma, J. Research on Power Battery Recovery Mode of New Energy Electric Vehicles in China under Circular Economy; IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 042029. [Google Scholar]

- MIIT, Interim Measures for the Management of New Energy Vehicle Power Battery Recycling. Available online: https://www.miit.gov.cn/zwgk/zcwj/wjfb/zh/art/2020/art_459b0eb972964f68930bb39be9e92688.html (accessed on 18 March 2022).

- Long, R.; Yang, J.; Chen, H.; Li, Q.; Fang, W.; Wang, L. Co-evolutionary simulation study of multiple stakeholders in the take-out waste recycling industry chain. J. Environ. Manag. 2019, 231, 701–713. [Google Scholar] [CrossRef]

- Friedman, D. On economic applications of evolutionary game theory. J. Evol. Econ. 1998, 8, 15–43. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, L.; Hua, H.; Liu, X.; Wu, H.; Yuan, Z. Assessment of end-of-life electric vehicle batteries in China: Future scenarios and economic benefits. Waste Manag. 2021, 135, 70–78. [Google Scholar] [CrossRef]

- Heydari, J.; Govindan, K.; Jafari, A. Reverse and closed loop supply chain coordination by considering government role. Transp. Res. Part D Transp. Environ. 2017, 52, 379–398. [Google Scholar] [CrossRef]

- Shao, Y.; Deng, X.; Qing, Q.; Wang, Y. Optimal battery recycling strategy for electric vehicle under government subsidy in China. Sustainability 2018, 10, 4855. [Google Scholar] [CrossRef]

| Recycling Companies | Consumers | |

|---|---|---|

| P | NP | |

| RR | ||

| UR | ||

| Point | ||

|---|---|---|

| 0 |

| Conditions | Point | Results | ||

|---|---|---|---|---|

| Scenario 1 | + | − | ESS | |

| + | + | Unstable point | ||

| + | + | Unstable point | ||

| + | − | ESS | ||

| Scenario 2 | + | − | ESS | |

| − | Saddle Point | |||

| − | Saddle Point | |||

| + | + | Unstable point | ||

| Scenario 3 | + | − | ESS | |

| − | Saddle Point | |||

| + | + | Unstable point | ||

| − | Saddle Point | |||

| Scenario 4 | + | − | ESS | |

| + | + | Unstable point | ||

| − | Saddle Point | |||

| − | Saddle Point |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, E.; Nie, J.; Wang, Y. Government Subsidy Strategies for the New Energy Vehicle Power Battery Recycling Industry. Sustainability 2023, 15, 2090. https://doi.org/10.3390/su15032090

Wang E, Nie J, Wang Y. Government Subsidy Strategies for the New Energy Vehicle Power Battery Recycling Industry. Sustainability. 2023; 15(3):2090. https://doi.org/10.3390/su15032090

Chicago/Turabian StyleWang, Enci, Jianyun Nie, and Yuhan Wang. 2023. "Government Subsidy Strategies for the New Energy Vehicle Power Battery Recycling Industry" Sustainability 15, no. 3: 2090. https://doi.org/10.3390/su15032090

APA StyleWang, E., Nie, J., & Wang, Y. (2023). Government Subsidy Strategies for the New Energy Vehicle Power Battery Recycling Industry. Sustainability, 15(3), 2090. https://doi.org/10.3390/su15032090