Experimental Study on Fan Aerodynamic Noise Variation Characteristics under Non-Proportional Variation Law

Abstract

1. Introduction

2. Fan Noise Source

2.1. Aerodynamic Noise

2.2. Mechanical Noise and Electromagnetic Noise

3. Experimental Device

3.1. Experimental System Setup

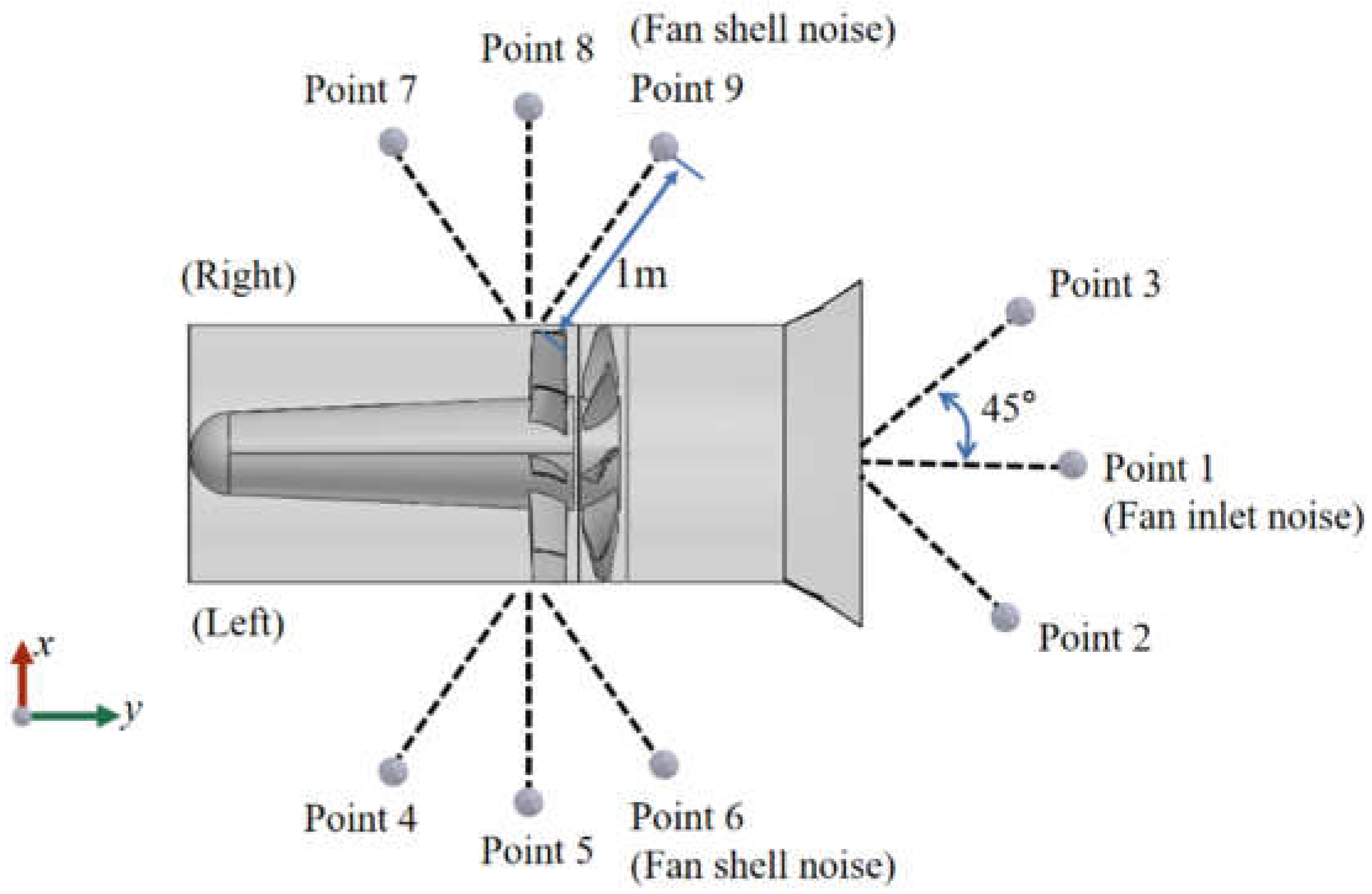

3.2. Measurements and Conditions

4. Results and Discussion

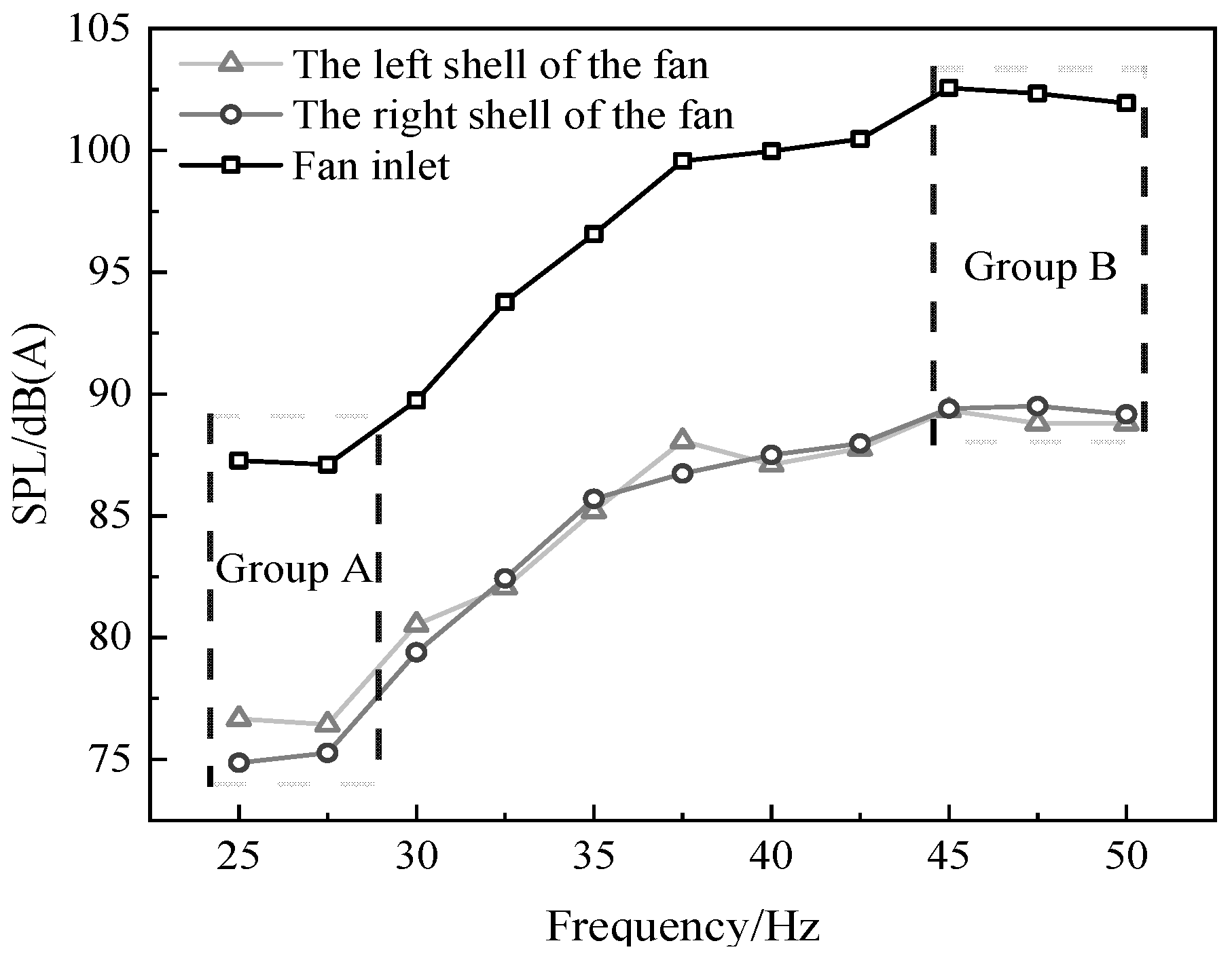

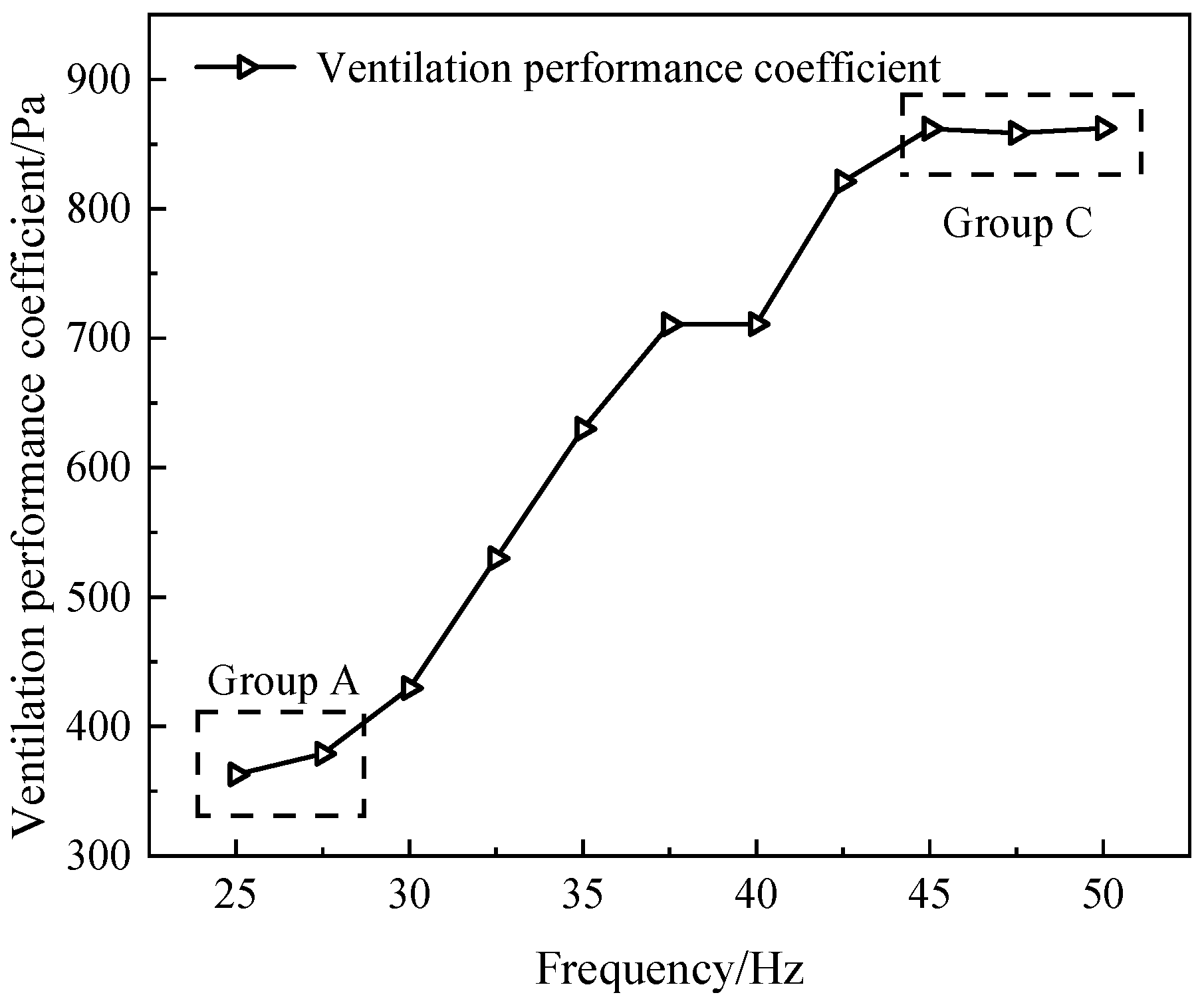

4.1. SPL and Air Volume Flowrate, Power Consumption

4.2. Noise Variation Characteristics at Typical OC

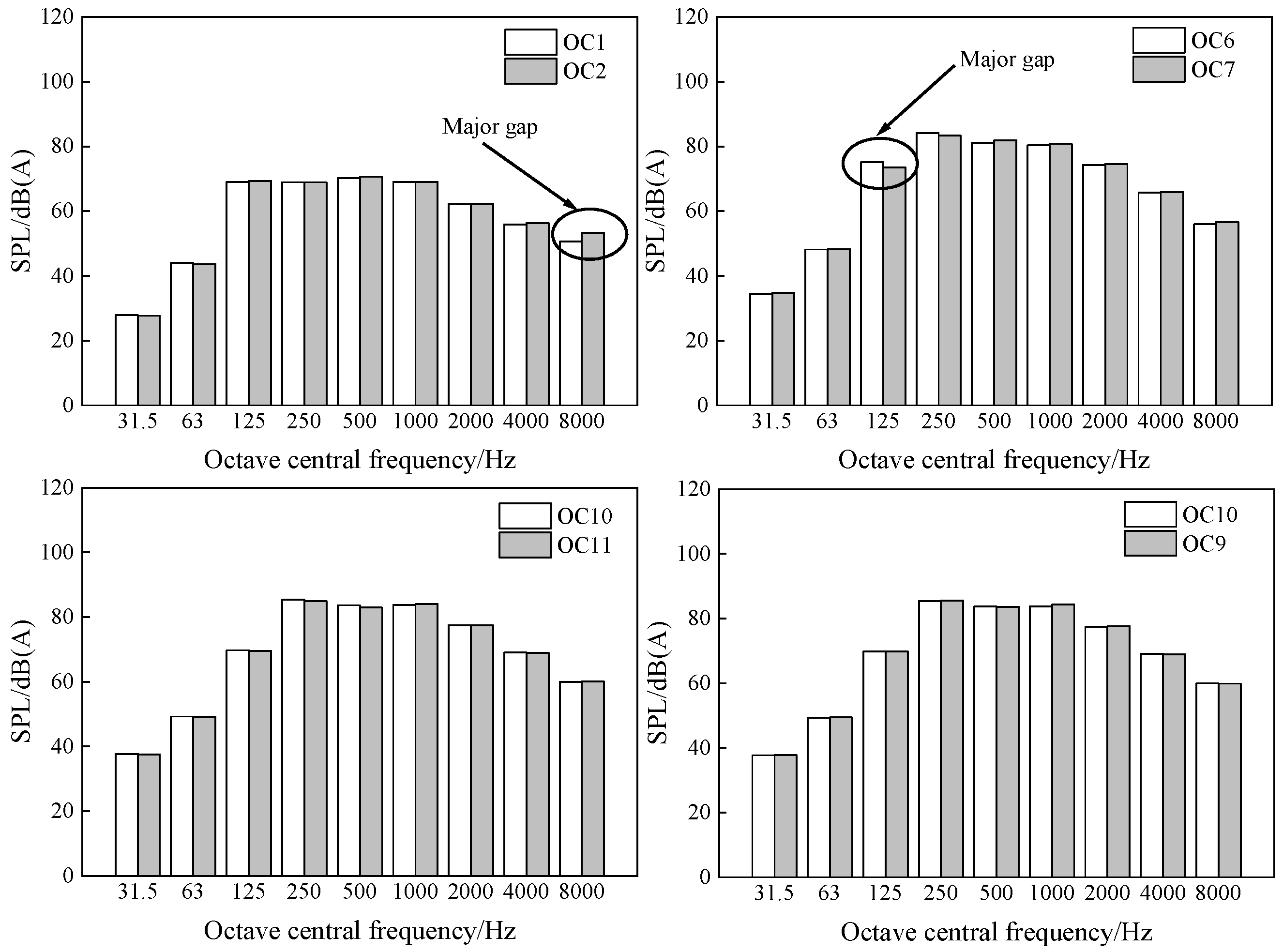

4.3. Sound Spectrum Characteristics at Typical OC

4.3.1. Spectrum Characteristics of Fan Inlet

4.3.2. Spectrum Characteristics of Fan Shell

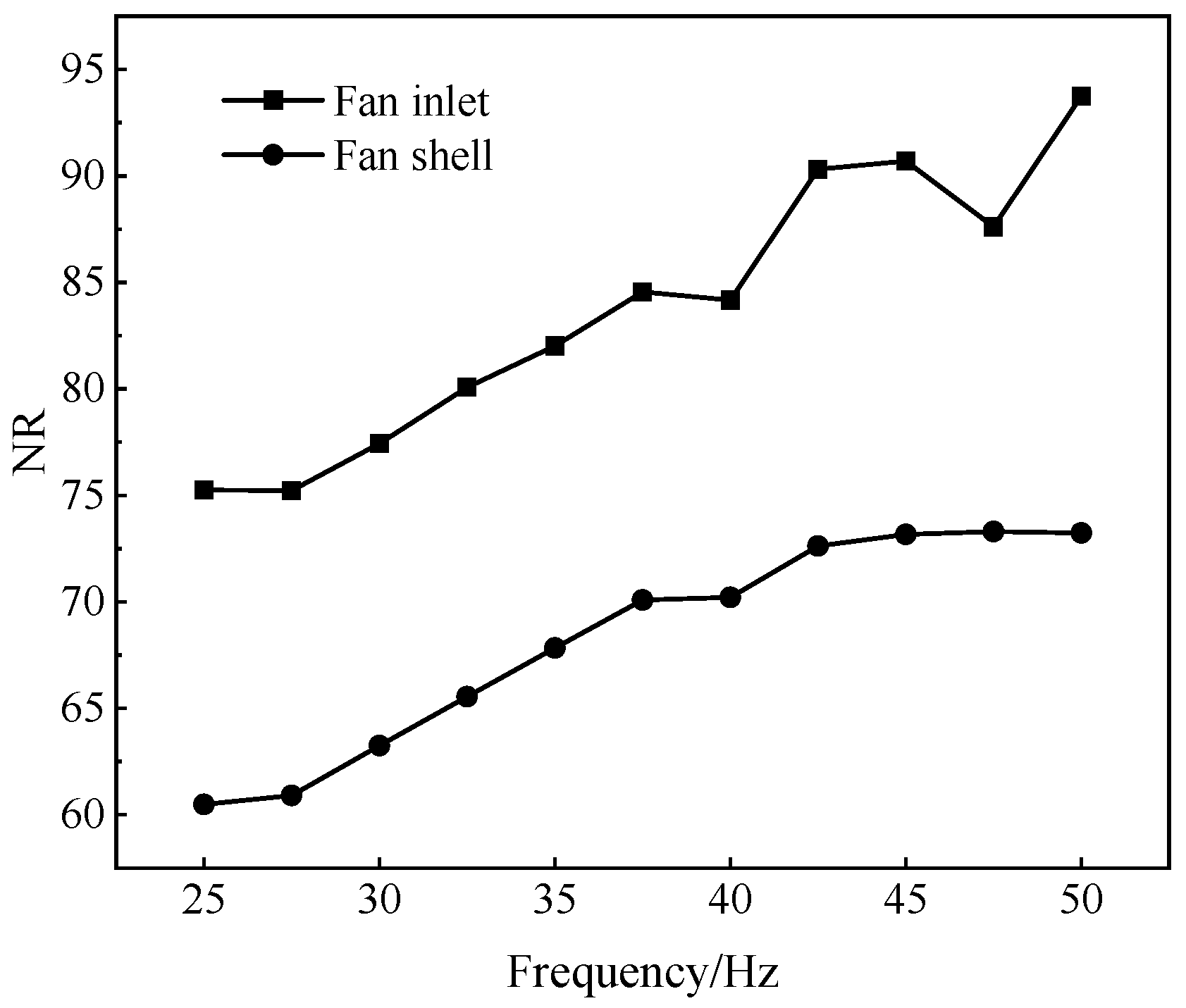

4.4. Noise Evaluation and High-Risk Area Division

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y. Development of ventilation methods for mountain-crossing tunnels during construction. Tunn. Constr. 2010, 30, 569–572. [Google Scholar]

- Wang, Y. The selection and optimization of ventilation scheme for railway tunnel construction. Chin. J. Undergr. Space Eng. 2015, 11, 359–366. [Google Scholar]

- Heinemann, T.; Becker, S. Axial Fan Performance under the Influence of a uniform ambient flow field. Int. J. Rotating Mach. Vol. 2018, 2018, 6718750. [Google Scholar] [CrossRef]

- Sarraf, C.; Nouri, H.; Ravelet, F.; Bakir, F. Experimental study of blade thickness effects on the overall and local performances of a controlled vortex designed axial-flow fan. Exp. Therm. Fluid Sci. 2011, 35, 684–693. [Google Scholar] [CrossRef]

- Venter, S.; Kröger, D. The effect of tip clearance on the performance of an axial flow fan. Energy Conver. 1992, 33, 89–97. [Google Scholar] [CrossRef]

- Sheng, Y.; Zhang, L.; Wang, Y.; Fang, L. Explore energy saving operation strategy: Indoor VOCs removal performance of silica gel rotor in Clean-Air Heat Pump system at low regeneration air temperature. Energy Build. 2019, 202, 109379. [Google Scholar] [CrossRef]

- Chen, S.; Wang, H.; Yang, C.; Li, X.; Jia, T. Experimental investigation of a mine main fan with variable frequency adjustment and the non-equal law between flowrate-ratio and power-ratio. J. Hunan Univ. Sci. Technol. 2016, 31, 1–7. [Google Scholar]

- Sheng, Y.; Zhang, Y.; Zhang, G. Simulation and energy saving analysis of high temperature heat pump coupling to desiccant wheel air conditioning system. Energy 2015, 83, 583–596. [Google Scholar] [CrossRef]

- Maaloum, A.; Kouidri, S.; Bakir, F.; Rey, R. Effect of inlet duct contour and lack thereof on the noise generated of an axial flow fan. Appl. Acoust. 2003, 64, 999–1010. [Google Scholar] [CrossRef]

- Ito, T.; Minorikawa, G.; Fan, Q. Experimental research for performance and noise of small axial fan. Int. J. Fluid Mach. Syst. 2009, 2, 136–146. [Google Scholar] [CrossRef]

- Jang, C.; Fukano, T.; Furukawa, M. Effects of the tip clearance on vortical flow and its relation to noise in an axial flow fan. JSME Int. J. Ser. B 2003, 46, 356–365. [Google Scholar] [CrossRef]

- Sanjose, M.; Moreau, S. Direct noise prediction and control of an installed large low-speed radial fan. Eur. J. Mech. B Fluids 2017, 61, 235–243. [Google Scholar] [CrossRef]

- Grace, S.; Logue, M. Comparison of two low-order models for the prediction of fan broadband noise. J. Sound Vib. 2018, 431, 304–327. [Google Scholar] [CrossRef]

- Posson, H.; Moreau, S.; Roger, M. Broadband noise prediction of fan outlet guide vane using a cascade response function. J. Sound Vib. 2011, 330, 6153–6183. [Google Scholar] [CrossRef]

- Hu, B.; OuYang, H.; Wu, Y. Numerical prediction of the interaction noise radiated from an axial fan. Appl. Acoust. 2013, 74, 544–552. [Google Scholar] [CrossRef]

- Zanon, A.; De Gennaro, M.; Kuehnelt, H.; Giannattasio, P. Assessment of the broadband noise from an unducted axial fan including the effect of the inflow turbulence. J. Sound Vib. 2018, 429, 18–33. [Google Scholar] [CrossRef]

- Luo, B.; Chu, W.; Zhang, H. Tip leakage flow and aeroacoustics analysis of a low-speed axial fan. Aerosp. Sci. Technol. 2020, 98, 105700. [Google Scholar] [CrossRef]

- Scheit, C.; Karic, B.; Becker, S. Effect of blade wrap angle on efficiency and noise of small radial fan impellers—A computational and experimental study. J. Sound Vib. 2012, 331, 996–1010. [Google Scholar] [CrossRef]

- Bizjan, B.; Milavec, M.; Širok, B.; Trenc, F.; Hočevar, M. Energy dissipation in the blade tip region of an axial fan. J. Sound Vib. 2016, 382, 63–72. [Google Scholar] [CrossRef]

- Krömer, F.; Moreau, S.; Becker, S. Experimental investigation of the interplay between the sound field and the flow field in skewed low-pressure axial fans. J. Sound Vib. 2019, 442, 220–236. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, B. Application of variable-frequency variable-voltage in highway tunnel ventilation control. J. Chang. Univ. 2006, 4, 71–74. [Google Scholar]

- Fan, S.; Chen, S.; Wu, Z.; Wu, S.; Chen, Y.; Liu, D.; Yao, Y.; Huang, J. Analysis of droplet size distribution and selection of spray parameters based on the fractal theory. J. Clean. Prod. 2022, 371, 133315. [Google Scholar] [CrossRef]

- Wang, S.; Sheng, M.; Hu, D. Energy-saving analysis and calculation of HV frequency conversion retrofitting for fan and pump. Electr. Power Autom. Equip. 2011, 31, 117–120. [Google Scholar]

- Li, Y.; Li, C.; Yang, J. Analysis on the influence of different adjustment modes on economy of induced draft fan. J. Eng. Therm. Energy Power 2021, 36, 39–43. [Google Scholar]

- Li, Y.; Shi, H. The Aerodynamic noise of analysis of the fan. Fluid Mach. 2000, 2, 20–22. [Google Scholar]

- Wu, X.; Li, Z. Principle of ventilator blade noise and methods to cut it down. Chin. J. Turbomach. 2001, 4, 11–13. [Google Scholar]

- Han, J.; Wang, Q. Noise analysis and reduction of mine ventilator. Coal Technol. 2016, 35, 265–267. [Google Scholar]

- GB/T 2888-2008; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Methods of Noise Measurement for Fans Blowers Compressors and Roots Blowers. Standards Press of China: Beijing, China, 2008.

- Cui, X. The performance assessment of aerodynammic noise in axial flow fans. Fluid Mach. 1994, 22, 19–21. [Google Scholar]

- Cen, Y.; Deng, Y.; Liu, X. Risk of hearing loss in noise-exposed workers: A retrospective cohort study. Chin. J. Public Health 2016, 32, 642–645. [Google Scholar]

- Wang, D.; Dai, X.; Chen, W. Study on the association between occupational noise exposure and cardiovascular diseases. Chin. J. Ind. Hyg. Occup. Dis. 2021, 39, 555–557. [Google Scholar]

- Tan, J.; Huang, X. Discussion about the noise rating number. Tech. Acoust. 2008, 2, 240–243. [Google Scholar]

| OC | Group A | Group B | Group C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| supply frequency (Hz) | 25 | 27.5 | 30 | 32.5 | 35 | 37.5 | 40 | 42.5 | 45 | 47.5 | 50 |

| Classification of Aerodynamic Noise | Range of Frequency/Hz | SPL Range/dB |

|---|---|---|

| Laminar vortex shedding noise | 0~1840 | 37~78 |

| Laminar boundary layer noise | 2600~8700 | |

| Turbulence vortex shedding noise | 1800~6800 | 50~110 |

| Turbulence boundary layer noise | 0~9000 | 40~87 |

| OC | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fan rotational speed/(r·min−1) | 853 | 825 | 915 | 1016 | 1116 | 1223 | 1208 | 1312 | 1409 | 1465 | 1480 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Chen, S.; Lei, Z.; Zhu, Z.; Chen, Y. Experimental Study on Fan Aerodynamic Noise Variation Characteristics under Non-Proportional Variation Law. Sustainability 2023, 15, 2025. https://doi.org/10.3390/su15032025

Dong X, Chen S, Lei Z, Zhu Z, Chen Y. Experimental Study on Fan Aerodynamic Noise Variation Characteristics under Non-Proportional Variation Law. Sustainability. 2023; 15(3):2025. https://doi.org/10.3390/su15032025

Chicago/Turabian StyleDong, Xiangyang, Shiqiang Chen, Zhenlin Lei, Zhulong Zhu, and Yihan Chen. 2023. "Experimental Study on Fan Aerodynamic Noise Variation Characteristics under Non-Proportional Variation Law" Sustainability 15, no. 3: 2025. https://doi.org/10.3390/su15032025

APA StyleDong, X., Chen, S., Lei, Z., Zhu, Z., & Chen, Y. (2023). Experimental Study on Fan Aerodynamic Noise Variation Characteristics under Non-Proportional Variation Law. Sustainability, 15(3), 2025. https://doi.org/10.3390/su15032025