Abstract

Motivated by the project uncertainties of complex realities brought by the fourth industrial revolution, Industry 4.0 (I4.0), researchers must look at Lean project management (LPM) soft skills as a new mindset to have a holistic view of customer needs and to improve value to the organization. In the digital transformation era, it is essential that Lean practitioners develop socio-technical thinking while also prioritizing interpersonal soft skills that directly affect their ability to solve problems in order for the company to grow sustainably. This paper aims to identify the critical soft skills (CSSs) to implement LPM in the I4.0 era and to investigate, from the perspective of organizations, the latent factors for LPM implementation that generate sustainable value. For this purpose, a mixed-method approach was used, combining literature review and a survey with 166 Brazilian professionals. This empirical study intends to set the CSSs from a practice perspective and explore the benefits they generate throughout the organization. Data analysis was conducted with descriptive statistics and factorial analysis. Research findings revealed convergences regarding the practitioners’ perception regarding the ten CSSs identified in the literature, and portray two latent factors, human and process factors, which can assist decision-makers in implementing LPM by offering a better perspective of the key factors that add sustainable value for companies in the digital transformation context. This study contributes to the debate on rethinking traditional skills, accentuates the need for adjustments, and proposes a socio-technical framework that can be used in a project manager’s routine to enable better Lean project execution, help with decision making, and increase the understanding and meeting of customer needs.

1. Introduction

Organizations need best practices that fit the current reality, which include new management methodologies and revisions of those already adopted. Today, project management is a strategic activity for any company that is crucial for gaining competitive advantage. However, according to [1], the model currently adopted must be reassessed, given that the reality in which projects are inserted has become much more uncertain, agile, and complex.

During the 1980s, it was understood that the success of a project revolved around meeting the goals of the deadline, cost, quality specifications, and scope [2,3]. As early as the 1990s, authors began to point out that success is no longer based on specific concepts, but rather in a multidimensional category that is perceived differently by all stakeholders involved [4]. Through this, we realize that project management today, in the age of digital transformation, must reflect this multidimensionality, that is, consider the requirements of all stakeholders and understand all aspects that can influence the project. Organizations must deploy new methodologies and practices in project management that are more consistent with reality, which seek better use of resources and internal capacity [5].

A comprehensive model that understands how work is actually performed knows how to deal with uncertainties and brings vital concepts to the activities of a project such as control, flow, and value generation, and constitutes a new way to manage projects [1]. According to [6], projects should be related to a structure that reduces production costs, increase efficiency/effectiveness, links project objectives to the company’s strategic goals, increases communication across the organization, and uses common resources to level usage.

These concepts are widely discussed in Lean methodology. Its application has been promoting improvements and reducing waste, mainly in the areas of production and manufacturing, where its application is widespread due to the high aggregation of value [7]. Once Lean methodology emphasizes the efficiency of the activities and project management effectiveness; this union develops a new approach that improves the projects’ performance [8] and guarantees the main objective of the organizations: the complete fulfillment of their stakeholders’ needs.

Lean approaches can be supported by digital technologies, such as the Internet of Things (IoT), Data Analytics, or autonomous robots to help the organization be more efficient, have less waste, be precise in production, and have faster times [9]. Many of the tools used in Lean approaches, such as Value Stream Mapping (VSM), the PDCA (Plan-Do-Check-Act) Cycle, and A3 thinking can be improved by digitalization, making them more easily accessible, integrated, and less dependent on manual inputs [10].

According to [11], the challenges and opportunities of the current market, coupled with the different problems that arise, demand solutions and methodologies that are also different, which ensure flexibility and agility in projects. This reality reveals that it is necessary to rethink how projects are conducted to manage the workflow better, control project processes, reduce activities that do not add value and, especially, emphasize those that deliver value to the customer. Given its proven results in production management, Lean methodology presents itself as a very suitable option for managing projects in this environment of high complexity and uncertainty, achieving promising results and success in projects [1].

The context of digital transformation has contributed to the ever-increasing challenges that organizations face. Digital transformation can be seen as a project in itself and, thus, demands the use of project management tools to achieve its results. Nonetheless, it is usually difficult to establish how project managers must deal with digital transformation [12]. One particularly critical aspect is the digital transformation team organization, since the digital transformation team must present various skills to support the process fully.

The Lean project management (LPM) approach emphasizes added value, decreases waste and unproductivity, and helps control project risks, costs, complexity, and time [13]. According to [14], to achieve such goals, LPM considers all of the people and processes involved in the project and simplifies them to meet the stakeholders’ needs in the shortest possible time, minimizing the stress of those involved. Also, according to the author, “any project worth doing is worth doing quickly”.

LPM can also be viewed as a set of technical and cultural tools that helps the organization attain higher operational efficiency. Although Lean technical skills are important, the cultural part of Lean philosophy is of utmost importance for dealing with more complex problems. Nonetheless, defining and training these Critical Soft Skills (CSSs) is a difficult task, given the complexity and need for innovative teaching methods [15]. This difficulty can lead to an incomplete comprehension of Lean philosophy within an organization, mitigating the added value of Lean initiatives [16].

LPM in I4.0 and digitalization processes have been studied by several authors [15,17,18,19], who find that aside from the technical facet, cultural and social aspects are crucial for LPM in this context. This encompasses a series of soft skills that Lean practitioners must have in order to successfully implement LPM in an organization [15,18,20,21]. Nonetheless, research on the need to identify which are the critical soft skills of LPM in the age of digital transformation is scarce [15]. Although theoretical studies can be useful in understanding these skills an empirical perspective is also needed, since the main challenges, in this case, are socio-cultural, given that the technical aspect of Lean practices is well documented. In this context, a more holistic view of Lean Digital Transformation is needed, one that encompasses the socio-technical nature of these processes. Thus, an increased interest has arisen in need for artifacts that help guide LPM [15,18,19] toward sustainable value. Therefore, the following research questions are posed:

RQ1: What are the CSSs for implementing LPM in the digital transformation era?

RQ2: From the organizations’ perspective, what are the latent factors for LPM implementation that generate sustainable value in the digital transformation era?

Within this context, the goals of this paper are: (i) to identify the CSSs for implementing LPM in the digital transformation era and (ii) to obtain the latent factors that order themselves into a framework to facilitate the socio-technical implementation of Lean, adding sustainable value in project management from the perspective of project managers in a developing country.

This research contributes to identifying CSSs for combining Lean methodology and project management in the I4.0, generating a new framework for LPM. Applying the proposed critical soft skills can contribute to developing a new organization’s mentality, focused on management by processes and people in all its axes. According to [22], practical strategies should be employed to develop new processes and new thinking focused on project management, increasing the company’s competitiveness. Also, according to the authors, a process- and project-aware organizational culture evolves in terms of continuous improvement, well-sustained processes, and successful projects.

Moreover, in today’s VUCA (volatile, uncertain, complex, and ambiguous) world, the proposed socio-technical framework for LPM, based on CSSs for I4.0 (e.g., agile mindset), can lead to the successful and sustainable delivery of value in projects. The management of risks and uncertainties is critical to the success of any project [23], so the implementation of an agility strategy, which can include the use of Lean thinking [24], is key to successfully navigating the complexities of I4.0 needs. Also, the integration of socio-technical aspects, leveraging both social and technical systems, also plays a crucial role in the success of projects, particularly in the context of sustainable development [25,26]. This integration can lead to improved efficiency and effectiveness in the delivery of projects. Thus, the novelty of this work is due to a proposal of a managerial artifact that combines CSS-based LPM, digital transformation, and sustainable value through an empirical study in a developing country.

The work is structured as follows: Section 2 presents a literature review on the themes of Lean Project Management, Digital Transformation, and Critical soft Skills for Industry 4.0. Section 3 presents the methodology employed, including the research workflow, survey details, and data analysis techniques used. In Section 4, the descriptive and inferential results extracted from the data analysis are shown. Finally, Section 5 presents the conclusions and implications, as well as a research agenda. Appendix A presents a list of abbreviations used throughout this work.

2. Literature Review

2.1. Link between Project Management and Lean Philosophy

According to the PMBOK Guide [27], a project is “a temporary effort undertaken to create a unique product, service, or result” that has a defined beginning and end. Technical problem-solving is an old view of projects that has been replaced by a new understanding in which projects are triggers for change, business development, and a starting point for companies to achieve their goals [28]. Therefore, Ref. [29] states that managing projects is based on planning, organizing, monitoring, and controlling everything that involves a project, seeking to achieve the goals according to the schedule, budget, and performance criteria established safely.

Given this, it is possible to realize that the concept of project management is based on project performance [30]; however, there are many uncertainties throughout a project, making it impossible for project management to be based on an illusion of certainty [1]. Therefore, from 1950 until today, project management methodology has greatly changed, and has been appropriating methods that seek to create more value for the end customer, reducing the use of resources and improving the processes involved in the project. Such methods are based on the Lean philosophy, which is widely used in industry and has proven to be a successful approach to conducting projects and product development, making them more efficient, elastic, and cost-effective [31].

The Lean methodology was perceived as a solution that suited complex realities, aiming to respond better to customer demands, reducing costs and waste with the speed that the customer requires [32]. In the early 1990s, “Lean was seen as a contradictory alternative to the traditional Fordist production model” [33], and there were still some limitations, mainly in how to deal with demand variability and with the human aspects that demanded high performance [34]. However, over the years, companies have increasingly applied Lean principles to see value in Lean principles [32]. Such principles are described in [35]: the generation of value to the final customer, the elimination of waste in the production system, and the management of the value stream, that is, the ability to flow the production. Soon, the model showed that through Lean thinking, it was possible to produce more with less [36].

According to [34], many have the old thought that Lean principles apply only to the factory floor, but this limited vision that restricts the methodology’s ability to achieve all the expected benefits needs to be replaced by a contemporary vision. A vision based on the application of Lean along the entire value chain, encompassing the entire operations network of organizations aiming to generate value for the end customer and grow sustainably [34,37].

According to [36], it is necessary to go beyond traditional project management concepts and explore Lean thinking to deal with the challenges of the current competitive context.

LPM is a combination of continuous improvement tools and socio-compartmental abilities, and to be effective it must be adopted from the shop floor to executive management [16]. It is expected that Lean practitioners develop and express a set of behaviors and values, such as openness to change, a continuous improvement mindset, and the ability to actively listen to their peers and subordinates [38]. These soft skills are as important as, if not more than, the technical tools of LPM.

Specifically in the Industry 4.0 digitalization context, LPM can be leveraged as a tool to increase the efficiency of digital initiatives, providing less waste of resources and improving decision-making and team engagement [9]. These advantages of LPM in the digitalization context can be perceived in several areas, such as supply chains, management, and services [9,39].

2.2. LPM and Digital Transformation

According to [40], “projects are temporary systems, and when these systems are structured to deliver products while maximizing their value and minimizing waste, they are considered Lean projects.” Project management encompasses the entire project, the operation and improvement of such production systems, and attempts to optimize the process and value-adding activities [41].

The Lean project management approach emphasizes added value, decreases waste and unproductivity, and helps control project risks, costs, complexity, and time [13]. According to [14], to achieve such goals, LPM considers all of the people and processes involved in the project and simplifies them to meet the stakeholders’ needs in the shortest possible time, minimizing the stress of those involved. Also, according to the author, “any project worth doing is worth doing quickly”.

The fact that the Lean methodology has been consolidated in manufacturing generates a false perception that it is only applied in this area and will not benefit other business processes [42]. However, as seen previously, its application covers several areas and its benefits can be widely reaped within organizations. According to [41], “LPM uses noble approaches in management methods seeking to create a flat structure in the organization that executes projects more efficiently”. The conventional project management approach may not bring as many advantages when the nature of projects is uncertain and complex, making agile/Lean methods better suited to environments with these characteristics [11].

The Lean methodology applies to project management to improve existing methods and standards, and its evolution will lead to Lean project management [43,44]. LPM has a holistic view of traditional project management, affecting how the project is controlled, optimized, and evaluated [41].

The main goal of LPM (through the above characteristics) is to improve the value of a project [8]. Ref. [40] points out that the LPM differs significantly from traditional project management, not only by optimizing activities that add value to the customer and reduce waste but also by being present in all phases of a project in the relationship between them and the people involved in each phase.

For the perception that the processes are efficient, the companies often do not see the need to apply Lean thinking. However, this thought forces a review of all business processes, reveals inefficiencies, and has already proven benefits in several processes [42]. Ref. [45] state that Lean “should be seen as a direction, not as a state to be reached after a certain time”, so all company processes should move in that direction. Ref. [37] states that Lean is a revolution, so it requires a change in the entire organization’s mindset, from the highest management levels to the operational level, including all business processes. Ref. [46] state that Lean thinking should integrate people, processes, and technology, promoting change and learning.

LPM practices can be suitably coupled with digital transformation to draw out synergies between both in a way that can largely improve organizational performance [47]. In this context, the success of both approaches depends on a set of critical soft skills [16,38,48,49], which encompass the socio-cultural aspects of both digital transformation and Lean philosophy.

To implement this thinking and enjoy its benefits, several critical soft skills will be presented on the following topic, requiring immersion in the principles and concepts established here, and the willingness to change all the practices previously used in organizations.

2.3. Critical Soft Skills for LPM in Industry 4.0 Era

Among the many critical success factors that can affect a project, there are the soft skills of the project team. Soft skills can be generally defined as personal attributes that enable someone to interact effectively and harmoniously with other people and shape how flexible and cooperative a person can be, directly affecting their ability to solve problems and make decisions in specific contexts [48,50]. In the PM context, soft skills such as communication, adaptability, flexibility, and a continuous growth mindset are highly desirable, especially in managers [49]. Even among soft skills, some can be more relevant than others, depending on the context. These are then defined as Critical Soft Skills (CSS). In the following paragraphs, CSSs for Lean in the context of digital transformation is presented.

The Lean approach requires planning, vision, and willingness to systematically change according to customer needs [51]. Ref. [46] state that Lean thinking must integrate people, processes, and technology, promoting change and learning. To implement this thinking and enjoy its benefits, it is necessary to immerse oneself in the principles and concepts discussed below.

Lean is a systematic and integrative method that involves doing things differently, separating non-value-added processes, creating a robust, truly Lean process, and reducing everything that does not add value to the end customer [13,42,52]. Problems such as wasted time, materials, redundant procedures, rework, lack of communication, and time spent waiting are realities that cannot exist, giving way to the search for solutions aimed at reducing costs and deadlines and increasing efficiency [9,36,53]. Therefore, the first CSS states the need to implement a culture of waste elimination in the company, simplifying all activities involved in the project.

From this basic pillar of Lean implementation, the following CSS is about implementing widely spread methodologies and concepts applied to LPM culture. The second CSS is based on fostering agile methodologies and quality management tools/concepts [54].

Ref. [43] states that Lean management and quality management overlap, as the quality management principles described in ISO 9000 are also principles of Lean management, such as customer focus, continuous improvement, and process approach [55]. Companies that choose to use methods with 5S, JIT, and total quality management (TQM) show improvements in their delivery times, productivity, and customer satisfaction [32].

The third CSS focuses on ensuring that the changes required throughout the project are fully executed. Ref. [14] states that all projects will undergo changes. The author points out that rigorous change management is essential for effective projects and delivering value to stakeholders. According to [42], many project managers see change as a problem, depriving themselves of its benefits. However, in contrast with this intrinsic thought of managers, this same author emphasizes that Lean thinking is to think outside the box, that is, to be open to review processes, even if they seem to be efficient, and to implement changes even if there is initially perceived of lack of tangible benefits [9].

Extending the focus of CSS to the behavioral sphere, the fourth factor focuses on encouraging the project team to go to the Gemba and develop a broad view of everything that happens on and impacts a project, what we call the “big picture view” [56]. Gemba is the Japanese word for the “real place” where things happen. Going to the Gemba is an allusion to the “go-see” principle, which consists of leaving your workplace and seeing for yourself the activity performed in the Gemba, following the processes, helping to identify the causes, and solving the problems that occur [57]. Going to the Gemba improves production processes, helps build relationships, ensures that everyone involved in the activity has the same view of the whole, and aids in decision making [57,58].

Ref. [59] emphasizes that only when leaders put themselves in the shoes of the employees where they perform their activities can they understand the problems and their root causes, contributing to an environment of process improvement and complex analysis of all factors that impact it.

Aiming to encompass all project stakeholders, the fifth CSS points to the need for the project team to involve the customer in all project phases [55]. According to [42], Lean thinking starts with the customer and the definition of value. Value is everything the customer is willing to pay for, and should be determined at the beginning of the project and described in terms of scope, cost, and schedule, based on an interactive dialog between the customer and supplier [60].

To deliver value to the customer, its purpose and constraints must be understood. In addition, it is necessary to provide what he wants, help him decide what he wants and the possible consequences of these desires [60]. According to [37], a solid understanding of what generates value for the customer is what moves a project forward, generating transparency, alignment, and reducing risks. Furthermore, [52] also reports that working directly with the customer and joining technical capabilities during project management generates innovation and speed in the project.

The sixth CSS involves a phase after the delivery of the project which is vital for the success of future projects. It is the sharing of knowledge obtained in each project, so those who succeed can have access to the positive and negative knowledge accumulated thus far [61]. Continuous improvement in TPS requires learning at the organizational level [46]. Establishing new ways of doing work through reusable, known, and visible standards means that the company is learning [62] and, consequently, applying the concept of knowledge management.

The author also points out that evolving through improvement and learning should be a character when using the Lean system, because an organization that learns and adapts improves its performance, generates value for stakeholders, and ensures its survival. The seventh CSS ensures that all factors are fully executed and disseminated. It deals with the need to ensure that communication flows well among all project stakeholders [54,61].

Ref. [36] reaffirms that the more people are involved in a project, the greater the complexity, so the need for effective communication becomes even more essential. Ref. [51] emphasizes that the human skills of communication, problem-solving, and teamwork are vital to the success of Lean projects.

The eighth CSS corroborates, and is a tool that ensures the propagation of clear and accessible communication to all, as it is based on the visual availability of the primary information related to projects within the company [10]. Visual management uses visual resources and tools/graphic representations to make information available in the workplace to facilitate the flow of information, make it accessible, and facilitate creative ideas [37,63].

Having information available to all team members at any time of the day ensures the flow of information, highlights problems, improves project planning and performance, reduces complexity, enables rapid decision-making, and breaks down internal functional barriers [36,37,40]. One way to ensure that visible information is constantly analyzed and addressed is the focus of the ninth CSS, which refers to holding regular agile meetings (known as obeyas) to manage smaller, achievable deliverables.

Ref. [64] approaches the tool called obeya, a Japanese term used to designate the word “big room”. This is a meeting room with visual resources which count on the presence of representatives of each discipline of the project with the objective that all have easy access to information, can make decisions, and solve operational problems [10,63,65]. The obeya is one of the visual tools that facilitates communication, the delegation of activities in the context of operations management, reduction of reworks and unnecessary discussions, efficiency throughout the project, and quality of the resulting product [46,65].

Finally, the tenth CSS comes as a link that unites all of the other factors toward a common theme: the encouragement by management for all employees to be engaged in the Lean theme. The implementation of the Lean methodology describes the cooperation between employees and leaders pursuing continuous improvement, working together as a team, and being engaged, leading to a better understanding of the overall project goals [12,36,59].

Such a culture of active participation and employee engagement is an enabler for the operator for sustainable and successful Lean operations, promoting increased employee confidence to face future challenges and strengthening teamwork [32]. In addition, the human skills of communication, teamwork, and cultural change are vital to the success of Lean management [51].

Lean is a transformation throughout the company; a corporate culture that preaches change in people’s skills and habits, requiring the engagement of the parties in the search for the formation of a dynamic mechanism aimed at generating value and reducing waste [66].

2.4. Research Gaps

Although the literature on LPM and digital transformation is useful in identifying the CSSs for LPM in digital transformation, there is still a need for empirical studies that not only relate LPM with CSSs in digital transformation but are able to translate this knowledge into managerial artifacts to help guide decision making [26], enabling managers and practitioners to better understand the challenges posed by digital transformation in the VUCA [23,24,25] world as well as use LPM practices to tackle them.

Thus, after the CSSs for implementing LPM in the digital transformation era are identified, this research intends to establish the latent factors for LPM in digital transformation so that it can be translated into a framework to help understand the socio-technical aspects of LPM in digital transformation.

3. Methodology

3.1. Research Steps

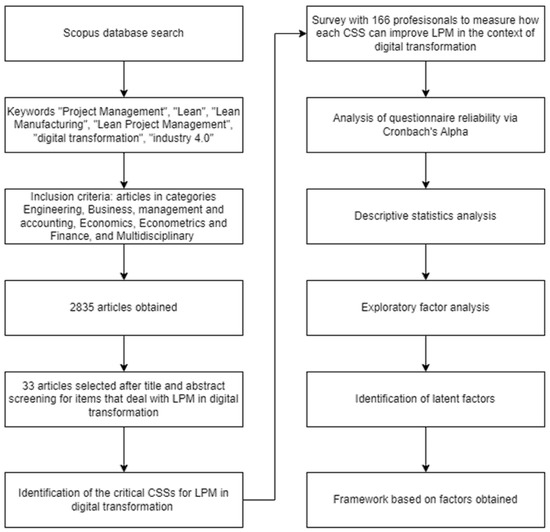

The steps of the research are shown in Figure 1 below:

Figure 1.

Research steps.

The first step of the research encompasses a narrative review to identify the CSSs and was performed in the Scopus database, using keywords related to: “Project Management”, “Lean”, “Lean Manufacturing”, “Lean Project Management”, “digital transformation” and “Industry 4.0”. As inclusion criteria, only articles published in Engineering, Business, management and accounting, Economics, Econometrics and Finance, Multidisciplinary areas were considered from a total of 2.835 articles to a bibliographic portfolio (BP) of 33 articles, selected after reading titles and abstracts and screening for the items that dealt with LPM in the context of digital transformation. Based on BP, CSSs were identified, as shown in the literature review. Hence, these were all of the articles that, to a certain extent, referred to factors of LPM implementation within digital transformation. In order to synthesize knowledge in a replicable and transparent way, a content analysis technique was used. It was based on the work of [21] through the following steps: (1) discussion and delimitation of the relevant material to be analyzed: 24 selected articles, (2) descriptive analysis of formal characteristics using Microsoft Excel worksheet, (3) selection of CSSs for LPM implementation in the context of digital transformation in an inductive way and (4) evaluation of the material according to the factors identifying how these CSSs can add value to Brazilian organizations. The literature review is summarized in Table 1.

Table 1.

Literature Review of Critical Soft Skills of Lean Project Management implementation in digital transformation.

From the identification of the CSSs, a quantitative analysis was conducted through an empirical study to analyze the agreement of project specialists regarding implementing these CSSs and the value they generate for the organization. To this end, a questionnaire was prepared with ten direct questions, each one referring to one of these CSSs. First, a pilot was applied to three experts with high experience and knowledge of LPM initiatives to examine content validity and test readability of the dimensions identified [68]. The pilot questionnaire provided a better refinement of the questions, ensuring clarity and objectivity in answering the questions that composed the web questionnaire [21].

3.2. Questionnaire Survey and Data Collection

The survey instrument was divided into two main sections: information about the respondent, and the value of CSSs in implementing the LPM. The profile of each respondent and their experience is detailed in the first section; considered a valid sample of respondents who have already been involved with projects in their organizations.

The second section focuses on evaluating whether the implementation of each variable, based on the literature, can really bring benefits (also found in the literature) to the organization. The questionnaire had closed-ended questions, and its answers were based on the Likert Scale from “Strongly Disagree” to “Strongly Agree” as the expected answer for each question. The five Likert levels are as follows: 1 = strongly disagree, 2 = disagree, 3 = indifferent, 4 = agree, 5 = strongly agree.

The web survey was sent from 1 March to 31 March 2021 to the most relevant and representative professional groups existing on LinkedIn®. After a period of four weeks of research, 199 experts agreed to participate. Of this total, 33 responses were excluded, totaling 166 valid responses representing a return of 83% and fitting the minimum sample size criteria of 120 respondents, which means at least five times the number of variables (24 items) analyzed [69]. In addition, this study also exceeds the minimum size of 119 respondents to cover the largest possible population (with a margin of error of 5 3% and α 5 5%), according to [70].

As in [68], the sample is considered non-probabilistic (convenience sampling) since the researcher does not know the probability that an element of the population should belong to the sample (Sekaran and Bougie, 2010) and that the sample audiences were selected according to the criteria of accessibility and availability [71].

3.3. Data Analysis

The statements present in the research instrument point directly to each of the variables found in the literature. The data obtained by applying the instrument are intended to confront these statements. Through this, we expected to generate a model that enables managers better to execute their projects within the digital transformation paradigm, meeting the client’s needs with excellence. In order to estimate the reliability of the questionnaire, Cronbach’s alpha coefficient was used, which is one of the most reliable measures used in organizational research. It aims to specify the extent to which the questionnaire items characterize a common concept and have an interrelationship with each other [72]. It is the average correlation between the questions in a questionnaire, expressed by a number ranging from 0 to 1; the higher the value, the more reliable the scale generated [73,74]. Cronbach’s alpha coefficient can be calculated as follows:

where is the number of items, is the variance associated with items i and is the variance associated with all items.

To determine the reliability, validity, and objectivity of the collected data, other tests were applied, for example, the Kaiser-Meyer-Olkin criterion (KMO) and Bartlett’s sphericity test. Based on these mentioned coefficients and with the objective of elaborating a final research product that is more summarized and applicable to the daily lives of managers, a multivariate data analysis method known as Factor Analysis was used. This method identifies strongly interrelated variables and proposes latent factors that summarize or explain the original set of variables with minimal loss of information, preserving the character of the original variable and simplifying the analysis [69]. With this, it is possible to compile the variables found in the literature into latent factors, which will be the product of a more straightforward understanding and application in the organizational context.

3.4. Reliability and Validity

Reliability and validity analyses were performed following some crucial steps proposed by [75]. First, the reliability of the questionnaire was verified by Cronbach’s alpha coefficient (α). According to [69], Cronbach’s alpha is a reliability coefficient that assesses the consistency of the entire scale, where the lower limit for the generally accepted Cronbach’s alpha is 0.70, although it may decrease to 0.60 in exploratory research. In the present study, the value of α = 0.7 will be adopted as the acceptable minimum, and α = 0.9 as the acceptable maximum, since an acceptable or good internal consistency is desired [76].

Moreover, as in previous studies [77,78], content analysis was also achieved as the dimensions and items identified were obtained from the narrative literature review. As in [75], construct validity was calculated with PCA, which uses OBLIMIN rotation, considering eigenvalues greater than 1 [69]. Factorability was examined by KMO test (which measures the sampling adequacy) (KMO > 0.50) and Bartlett’s sphericity test (significant at the 5% level) [79]. In addition, as suggested in previous studies [78], all dimensions are one-dimensional.

4. Results and Discussion

4.1. Descriptive Results

Table 2 shows the results concerning the first section of the questionnaire, where information about the respondent’s profile is presented. The main selection criterion of the sample in this one was the respondent’s involvement with a project in his/her organization. Based on this, the amount of experience and the position held in the organization was questioned, and it was possible to observe that more than half of the respondents held leadership positions within their organizations, contributing to a sample with greater relevance and credibility in the research context.

Table 2.

Respondents profile (n = 166).

Seeking to validate the second section of the research instrument, Cronbach’s alpha was calculated considering a value of 10 variables, finding a value of 0.828. On the scale presented by [80], this index is considered satisfactory to validate the research instrument, remaining between the acceptance criteria of 0.7 and 0.9 [69].

Seeking to analyze the behavior of each critical factor individually, Table 3 presents the relative frequency of each perception pointed out by the respondents, following the Likert scale.

Table 3.

Relative frequency of answer per question.

Table 3 indicates that all respondents considered the CSSs surveyed by the literature exposed in this paper as relevant to the successful implementation of LPM in organizations. In addition, it is noteworthy that all variables (except 9) did not obtain any “strongly disagree” answers, which further reinforces the foregoing paragraph. Furthermore, none of the variables achieved more than 7% in “disagree” or “indifferent” responses.

4.2. Inferential Results

The method of multivariate data analysis called Factor Analysis aims to analyze relationships between variables to identify among them a set with similar characteristics, that is, to form groups of variables that give rise to latent factors [69]. Thus, it was possible to identify two latent factors emerging from the variables found in the literature review, whose application by the manager within his projects brings considerable value to the organization. These values are described in Table 4, found in the researched literature.

Table 4.

Correlation Matrix. Correlations higher than 0.3 are highlighted in gray with bold text.

Initially, the correlation matrix between variables was generated, representing the intercorrelations between all variables [69]. These correlations are important to determine if factor analysis is suitable. It was noticed that there is a significant amount of correlations greater than 0.3 (highlighted in the table below), which according to [69], justifies the application of factor analysis.

Once the correlation matrix was obtained, the Bartlett’s test of sphericity was applied. According to [69], the Barlett’s test of sphericity is “a statistical test of the overall significance of all correlations in a correlation matrix. It provides the statistical probability that the correlation matrix has significant correlations between at least some of the variables, where the significance (sig) found should be less than 0.05.

Furthermore, according to [69], the KMO test is also used to quantify the degree of correlations between variables, where its results can be interpreted as follows:

- (1)

- Factorial loads in the range of ±0.30 to ±0.40 are considered to meet the minimum level for structure interpretation;

- (2)

- Loads of ±0.50 or greater are considered to be virtually significant;

- (3)

- Loads exceeding ±0.70 are considered indicative of a well-defined structure and are the goal of any factor analysis.

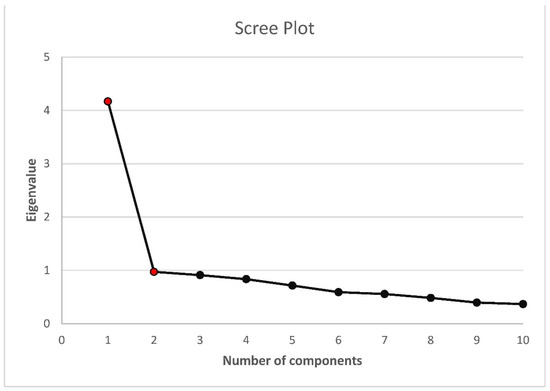

The principal component analysis method uses the criterion of the latent root, which according to [69], is a technique in which “any individual factor must explain the variance of at least one variable if it is to be maintained for interpretation. This criterion enables the determination of the number of latent factors, where only the factors that have a latent root greater than 1 can be considered significant and kept for interpretation. From the variables identified in the literature, 2 latent factors (marked in red) were extracted using the explained criterion, as can be seen in the Scree plot from Figure 2 below: The Scree plot shows the eigenvalues associated with the correlation matrix. The underlying logic for the scree plot is that if there exists a specific number of m major common factors, then there will be m relatively large eigenvalues, and the other eigenvalues will be small in comparison. These other eigenvalues can be considered noise or random influences [81].

Figure 2.

Eigenvalues for the latent root criterion.

According to [69], the criterion of variance percentage can be used to guarantee practical significance for the determining factors. This criterion is based on the specified cumulative percentage of total variance extracted by successive factors. The authors state that it is satisfactory when the number of factors extracted explains 60% of the total variance, but there is an additional variant for this criterion. For practical reasons, there may be a certain pre-specified commonality for each variable, so the researcher may include as many factors as he or she considers sufficient to represent the original variables adequately. The total variance presents the variance accounted for by the extracted factors prior to rotation. After rotation, the total amount of variance accounted for by the factors will be the same, but this variance will be redistributed across the two factors [81]. The total variance explained is shown in Table 5.

Table 5.

Total variance explained.

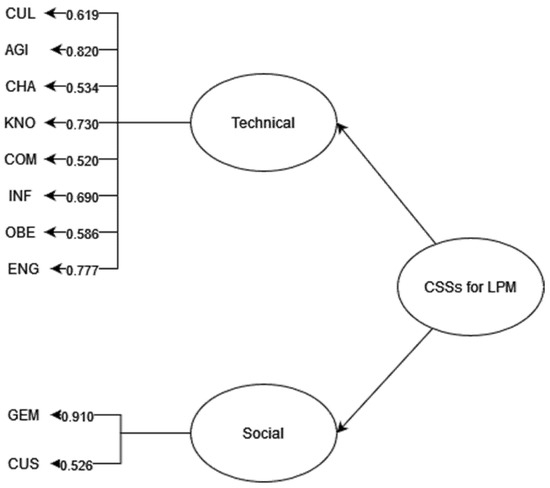

Ref. [69] address rotational methods that simplify the rows and columns of the factorial matrix to facilitate the rotated matrix interpretation. Whenever an oblique rotation is used, the rotated factor loading matrix is referred to as the pattern matrix. This is the matrix that should be the primary basis of interpretation. Its coefficients can be thought of as similar to standardized partial regression coefficients in which common factors predict measured variables (i.e., a factor loading is the standardized unit of increase in the measured variable for each standardized unit of increase in the common factor). Thus, these loadings represent the impact of the factor on the item controlling for the impact of other factors in the model on the same item [81]. This simplification involves making as many row and column values as close to zero as possible. Thus, we proceeded to the OBLIMIN rotation step of the matrix in question. The rotated matrix can be found in Appendix B. Figure 3 presents the graphical representation of factor structures, with the latent factors and the related variables.

Figure 3.

Graphical representation of exploratory factor analysis.

From the Factor Analysis, it was possible to subdivide the variables into two dimensions. Dimension 1 encompasses variables 1, 2, 3, 6, 7, 8, 9, and 10, where a strong connection to implementing the LPM through processes was identified. It can be inferred through this dimension that it is of great importance that organizations implement specific processes so that the LPM is working. These processes are change management, knowledge management, communication management, visual management, people management, and quality management. All of these processes are part of a combination of attitudes that an organization chooses to take so that Lean is developed and fully applied within the reality of projects.

From the variables related to Dimension 1, a strong connection with the need for the company to implement processes so that the Lean methodology could be added to process management was identified. From such processes, one can list: change management, knowledge management, communication management, visual management, people management, and quality management. All of these processes are part of a combination of attitudes that an organization chooses to take, so that Lean is developed and fully applied within the reality of projects.

As for dimension 2, which encompasses variables 4 and 5, there is a dependence on human relations for the variables to be employed. Such relationships are vital to the establishment of Lean methodology that [62] emphasizes that as people get used to and understand the new way of working, their mental model also begins to change.

Ref. [62] points out that a true Lean system is constantly adapting its technical and social systems for the sake of value generation, improved performance, and long-term survival. Building social and technical capabilities that fit the circumstances, using flexible processes/tools, and having people committed to controlling variations in their processes form a set of principles that encompass dimensions 1 and 2, the purpose of which is to ground Lean within project management.

Ref. [64] states that for an organization to become Lean and open to learning, it is essential to have a combination of processes, people, problem-solving, and long-term commitment. Ref. [66] reaffirms this thought by noting that Lean is a deep transformation of the corporate system; it is the construction of a cultural atmosphere focused on improvement. The company must build dynamic processes oriented to Lean thinking and tie this to cultivating people’s skills and habits, forming a new corporate culture. This process can also be called Lean sustainability.

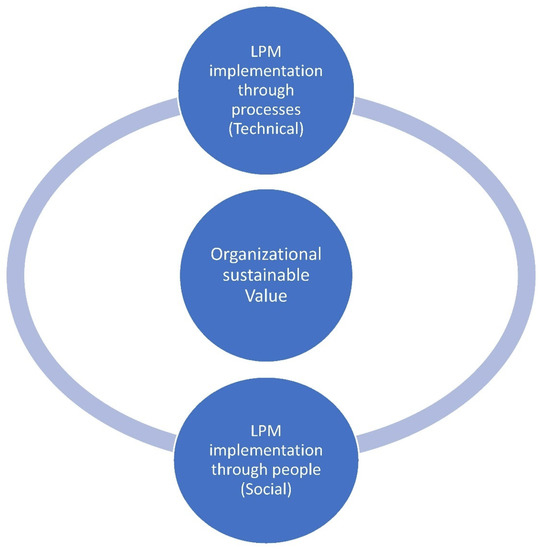

According to [66], Lean sustainability is defined as “the establishment of the long-term Lean implementation concept, the use of Lean for deep transformation, continuous optimization, and the effectuation of a Lean cultural atmosphere within the company. The union of dimensions 1 and 2 revealed after the factor analysis aims precisely to implement Lean in the long = term through people and processes, consolidating this methodology in the company and generating organizational value; therefore, Figure 4 below can be named Lean sustainability.

Figure 4.

Socio-technical Framework for Sustainable Value.

Ref. [82] already emphasized that “the management of a system requires knowledge of the interrelationships among all the sub-processes within the system and all those who work in it. Confirming this reasoning, Ref. [67] points out that Lean manufacturing is not a singular concept and cannot be tied only to continuous improvement processes, JIT, or employee involvement; but rather to the mutual support of various components to constitute the whole system.

Finally, inspired by [66], organization’s sustainability requires a Lean mindset when looking at everything that involves project management and, complementary to this, it must live, breathe and be Lean-oriented in all aspects, especially in the context of ongoing digital transformation.

LPM is a methodology aimed at lowering waste and increasing efficiency, adding value to the organization. Nonetheless, in the context of digital transformation in companies, it can be seen that the results point to a need to observe not only the development of technical and managerial skills, but also interpersonal soft skills so that the company grows in a sustainable way. The socio-technical characteristics of LPM in the digital age can be seen in both dimensions. Dimension 1 encompasses both purely process-related factors (such as factors 3 and 8) but shows that the manager needs to be able to motivate the team (expressed, for example, in factors 2 and 10) in order to achieve project goals. Dimension 2 can be seen as the dimension which encompasses the interpersonal relations of LPM in digital transformation, since it has both a factor (factor 4) regarding the interpersonal collaboration of the project team by going to the Gemba and a customer-centric factor (factor 5).

It can be seen that from the technical point of view of the processes that the most important CSSs are those related to the use of agile methodologies and the need to stimulate engagement in the adoption of Lean methodologies. This is consistent with the findings of [24,32,43,54,55,83] for other countries (e.g., USA, Canada, and Mexico), which show that an agile mindset and the use of agile practices are important pillars in LPM, and also with work that shows that engagement in LPM practices plays a vital role in the implementation of Lean practices [12,36,59].

Regarding the people aspect, the most important CSS is related to guaranteeing that the LPM teams go to the Gemba. Other research shows that the Gemba is an important tool in the so-called shop floor management in that managers can use it to view, interact and empathize with the professionals at more operational levels [54,58,59].

5. Conclusions

The purpose of this paper was to present critical soft skills for LPM implementation and highlight the sustainable value they can generate for organizations in the age of digital transformation. To achieve this goal, two latent factors were identified and structured in a socio-technical framework that aims to be a guideline for how to transform traditional project management into a Lean approach by eliminating waste, managing change initiatives, developing communication, knowledge, quality, and agile principles and creating different solutions for the old PM issues in a collaborative way. The proposed framework intends to implement system-wide Lean thinking throughout organizational culture, paving the way for successful digital projects. This socio-technical approach is particularly prone to adding value in companies that deal with digital transformation, since the Lean approach can both affect and be affected positively by digital tools. The latent factors identified and their composition show that soft skills are important both from the technical (process) and cultural (people) points of view. Furthermore, the CSSs affect all stakeholders, from the project leaders/managers to the customer.

5.1. Theoretical Implications

The contributions of this article are as follows. First, a thorough study of the existing literature was conducted by identifying ten critical factors for implementing LPM. Through survey research, these factors were validated by professionals working in the project management field in Brazil. Second, two latent factors, called “implementation through processes” and “implementation through people,” were identified in the principal component analysis. In parallel with establishing LPM in digital transformation through business processes and human resources, the company must develop a production process that will turn into selling products. The paper highlights the ever-increasing need to conjugate both technical and social aspects of LPM in view of the industry 4.0 paradigm [17]

5.2. Practical Implications

These factors can guide decision making at the strategic level and project leaders of organizations when it comes to implementing LPM toward digital transformation. Thirdly, this article shows a comprehensive theoretical framework that analyzes the existence of critical factors in the literature and practice for implementing LPM. The proposed framework can help managers to guide decision making in LPM implementation by prioritizing the development of critical soft skills, which will help LPM to succeed [15] and can also accelerate the transition to Industry 4.0

5.3. Suggestions for Further Research

Therefore, future studies are expected to be conducted more comprehensively, comparing critical and latent factors of LPM implementation in different countries to make the research more generalizable in a global scenario. It is also suggested that in future studies, the latent dimensions found in this paper are applied to a case study to verify the market response to research and to improve each latent factor further. The main limitations of this article are the delimitation of the survey to professionals working in Brazilian companies and a sample size that was conditioned by the number of respondents of the questionnaire distributed electronically. Although it presents the above limits, it is possible to consider this research as academically vital because it presents content that can serve as a source of future studies in synergy with the theme of project management, since leaders of organizations can, from the identified critical skills and latent factors, promote actions that prioritize them and assist the implementation of LPM.

Author Contributions

Conceptualization, B.F.L., J.V.N. and R.G.G.C.; Data curation, B.F.L., J.V.N. and R.G.G.C.; Formal analysis, B.F.L., J.V.N. and R.S.S.; Funding acquisition, R.G.G.C.; Investigation, B.F.L. and J.V.N.; Methodology, B.F.L., J.V.N., R.S.S. and R.G.G.C.; Project administration, J.V.N. and R.G.G.C.; Resources, B.F.L. and J.V.N.; Software, B.F.L., J.V.N., R.S.S. and R.G.G.C.; Supervision, J.V.N. and R.G.G.C.; Validation, J.V.N. and R.G.G.C.; Visualization, B.F.L., J.V.N. and R.S.S.; Writing—original draft, B.F.L. and J.V.N.; Writing—review & editing, R.S.S. and R.G.G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior–Brasil–CAPES [Finance Code 001]; Brazilian National Council for Scientific and Technological Development–CNPq [307173/2022-4]; Carlos Chagas Filho Foundation for Research Support of the State of Rio de Janeiro–FAPERJ [Grant number E-26/201.363/2021; E26/211.298/2021].

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Abbreviation table.

Table A1.

Abbreviation table.

| Abbreviation | Terms |

|---|---|

| CSS | Critical Soft Skills |

| LPM | Leal Project Management |

| VSM | Value Stream Mapping |

| PMBOK | Project Management Body of Knowledge |

| PM | Project Management |

| JIT | Just in Time |

| TQM | Total Quality Management |

| BP | Bibliographic Portfolio |

| KMO | Kaiser-Meyer-Olkin |

| PCA | Principal Component Analysis |

| PDCA | Plan, Do, Check, Act |

Appendix B

Table A2.

Rotated component matrix.

Table A2.

Rotated component matrix.

| Component | Factor | |

|---|---|---|

| 1 | 2 | |

| V1 | 0.619 | |

| V2 | 0.820 | |

| V3 | 0.534 | |

| V4 | 0.910 | |

| V5 | 0.526 | |

| V6 | 0.730 | |

| V7 | 0.520 | |

| V8 | 0.690 | |

| V9 | 0.586 | |

| V10 | 0.777 | |

| Extraction Method: Principal Component Analysis. Rotation Method: Oblimin with Kaiser Normalization. | ||

| a. Rotation converged in 6 iterations. | ||

References

- Howell, G.; Koskela, L. Reforming project management: The role of lean construction. J. Manag. 2000. Available online: http://usir.salford.ac.uk/9428/ (accessed on 12 December 2022).

- Shenhar, A.J.; Dvir, D.; Levy, O.; Maltz, A.C. Project success: A multidimensional strategic concept. Long Range Plan. 2001, 34, 699–725. [Google Scholar] [CrossRef]

- Todorović, M.L.; Petrović, D.Č.; Mihić, M.M.; Obradović, V.L.; Bushuyev, S.D. Project success analysis framework: A knowledge-based approach in project management. Int. J. Proj. Manag. 2015, 33, 772–783. [Google Scholar] [CrossRef]

- Koskela, L.; Howell, G. The underlying theory of project management is obsolete. IEEE Eng. Manag. Rev. 2008, 36, 22–34. [Google Scholar] [CrossRef]

- Gomes, J.; Romao, M. Improving project success: A case study using benefits and project management. Procedia Comput. Sci. 2016, 100, 489–497. [Google Scholar] [CrossRef]

- Perrotta, D.; Araujo, M.; Fernandes, G.; Tereso, A.; Faria, J. Towards the development of a methodology for managing industrialization projects. Procedia Comput. Sci. 2017, 121, 874–882. [Google Scholar] [CrossRef]

- Hines, P. Value Stream Management: Strategy and Excellence in the Supply Chain; Financial Times Management: Harlow, UK, 1999. [Google Scholar]

- Horman, M.; Kenley, R. The application of lean production to project management. In Proceedings of the 4th Annual International Group for Lean Construction, Birmingham, UK, 27–29 November 2018. [Google Scholar]

- Cifone, F.D.; Hoberg, K.; Holweg, M.; Staudacher, A.P. ‘Lean 4.0’: How can digital technologies support lean practices? Int. J. Prod. Econ. 2021, 241, 108258. [Google Scholar] [CrossRef]

- Dhamangaonkar, M.P. Digitalization of Lean Tools—Digital A3. Int. J. Sci. Res. Publ. 2020, 10, 967–973. [Google Scholar] [CrossRef]

- Fernandez, D.J.; Fernandez, J.D. Agile Project Management—Agilism versus Traditional Approaches. J. Comput. Inf. Syst. 2008, 49, 10–17. [Google Scholar]

- Guinan, P.J.; Parise, S.; Langowitz, N. Creating an innovative digital project team: Levers to enable digital transformation. Bus. Horiz. 2019, 62, 717–727. [Google Scholar] [CrossRef]

- Amran, T.G.; Saraswati, D.; Harahap, E.F. Evaluating Storage Tank Cap 10000L Manufacturer by Using Lean Project Management. In Proceedings of the 11th International Seminar on Industrial Engineering and Management: Technology and Innovation Challenges Towards Industry 4.0 Era, ISIEM 2018, Makassar, Indonesia, 27–29 November 2018; Institute of Physics Publishing: Bristol, UK, 2019; Volume 528. [Google Scholar]

- Leach, L.P. Lean Project Management: Eight Principles for Success; Advanced Projects: Cosby, UK, 2005. [Google Scholar]

- Lista, A.P.; Tortorella, G.L.; Bouzon, M.; Thürer, M.; Jurburg, D. Soft and hard skills development in lean management trainings. Int. J. Lean Six Sigma 2022, 13, 1137–1158. [Google Scholar] [CrossRef]

- DE Jesus, R.C.; Vieira, G.P.; DE Gouvêa, D.G.T.; Filho, E.D.J. O Impacto das Soft Skills na Gestão Lean no Setor de Facilities no Rio de Janeiro. In Proceedings of the Anais do XLI Encontro Nacional de Engenharia de Produção, Foz do Iguaçu, Paraná, Brazil, 18–21 October 2021. [Google Scholar] [CrossRef]

- Tortorella, G.; Fogliatto, F.S.; Kumar, M.; Gonzalez, V.; Pepper, M. Effect of Industry 4.0 on the relationship between socio-technical practices and workers’ performance. J. Manuf. Technol. Manag. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Agostinho, V.; Baldo, C.R. Assessment of the impact of Industry 4.0 on the skills of Lean professionals. Procedia CIRP 2021, 96, 225–229. [Google Scholar] [CrossRef]

- Nascimento, D.L.D.M.; Quelhas, O.L.G.; Caiado, R.; Tortorella, G.L.; Garza-Reyes, J.A.; Rocha-Lona, L. A lean six sigma framework for continuous and incremental improvement in the oil and gas sector. Int. J. Lean Six Sigma 2019, 11, 577–595. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Vergara, L.G.L.; Ferreira, E.P. Lean manufacturing implementation: An assessment method with regards to socio-technical and ergonomics practices adoption. Int. J. Adv. Manuf. Technol. 2017, 89, 3407–3418. [Google Scholar] [CrossRef]

- Lins, M.G.; Zotes, L.P.; Caiado, R. Critical factors for lean and innovation in services: From a systematic review to an empirical investigation. Total Qual. Manag. Bus. Excell. 2021, 32, 606–631. [Google Scholar] [CrossRef]

- Sousa, P.; Tereso, A.; Alves, A.; Gomes, L. Implementation of project management and lean production practices in a SME Portuguese innovation company. Procedia Comput. Sci. 2018, 138, 867–874. [Google Scholar] [CrossRef]

- Muniz, M.V.P.; Lima, G.B.A.; Caiado, R.G.G.; Quelhas, O.L.G. Bow tie to improve risk management of natural gas pipelines. Process Saf. Prog. 2018, 37, 169–175. [Google Scholar] [CrossRef]

- Bouchard, S.; Abdulnour, G.; Gamache, S. Agility and Industry 4.0 Implementation Strategy in a Quebec Manufacturing SME. Sustainability 2022, 14, 7884. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Lima, G.B.A.; Gaviáo, L.O.; Quelhas, O.L.G.; Paschoalino, F.F. Sustainability Analysis in Electrical Energy Companies by Similarity Technique to Ideal Solution. IEEE Lat. Am. Trans. 2017, 15, 675–681. [Google Scholar] [CrossRef]

- Batista, M.; Caiado, R.G.G.; Quelhas, O.L.G.; Lima, G.B.A.; Filho, W.L.; Yparraguirre, I.T.R. A framework for sustainable and integrated municipal solid waste management: Barriers and critical factors to developing countries. J. Clean. Prod. 2021, 312, 127516. [Google Scholar] [CrossRef]

- Project Management Institute. Guide to the Project Management Body of Knowledge (PMBOK Guide); Project Management Institute: Newtown Square, PA, USA, 2021. [Google Scholar]

- Andersen, E.S.; Jessen, S.A. Project maturity in organisations. Int. J. Proj. Manag. 2003, 21, 457–461. [Google Scholar] [CrossRef]

- International Project Management Association—IPMA. Individual Competence Baseline for Project Management; IPMA Standards: Nijkerk, The Netherlands, 2015. [Google Scholar]

- Radujković, M.; Sjekavica, M. Project Management Success Factors. In Proceedings of the Creative Construction Conference, CCC 2017, Primosten, Croatia, 19–22 June 2017; Hajdu, M., Skibniewski, M.E., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume 196, pp. 607–615. [Google Scholar]

- Lishner, I.; Shtub, A. Measuring the success of lean and agile projects: Are cost, time, scope and quality equally important? J. Mod. Proj. Manag. 2019, 7, 138–145. [Google Scholar]

- Bhamu, J.; Sangwan, K.S. Lean manufacturing: Literature review and research issues. Int. J. Oper. Prod. Manag. 2014, 34, 876–940. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World: The Story of Lean Production, Toyota’s Secret Weapon in the Global Car Wars That Is Now Revolutionizing World Industry; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Hines, P.; Holwe, M.; Rich, N. Learning to evolve—A review of contemporary lean thinking. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Sohi, A.J.; Hertogh, M.; Bosch-Rekveldt, M.; Blom, R. Does lean & agile project management help coping with project complexity? In Proceedings of the 29th IPMA World Congress WC2015, Panama City, Panama, 28 September–1 October 2015; Volume 226, pp. 252–259. [Google Scholar] [CrossRef]

- Melton, T. The benefits of lean manufacturing—What lean thinking has to offer the process industries. Chem. Eng. Res. Des. 2005, 83, 662–673. [Google Scholar] [CrossRef]

- van Dun, D.H.; Hicks, J.N.; Wilderom, C.P.M. Values and behaviors of effective lean managers: Mixed-methods exploratory research. Eur. Manag. J. 2017, 35, 174–186. [Google Scholar] [CrossRef]

- Freitag, A.E.B.; Santos, J.D.C.; Reis, A.D.C. Lean Office and digital transformation: A case study in a services company. Braz. J. Oper. Prod. Manag. 2018, 15, 588–594. [Google Scholar] [CrossRef]

- Ballard, G.; Howell, G.A. Lean project management. Build. Res. Inf. 2003, 31, 119–133. [Google Scholar] [CrossRef]

- Dabestani, R.; Baerz, A.M.; Azar, A.; Shahin, A. Proposing a model for evaluating lean project management performance using grounded theory. Int. J. Product. Qual. Manag. 2017, 22, 521. [Google Scholar] [CrossRef]

- Melton, T. To lean or not to lean? (that is the question!). Chem. Eng. 2004, 34–37. [Google Scholar]

- Reusch, P.J.A.; Reusch, P. How to develop lean project management? In Proceedings of the 2013 IEEE 7th International Conference on Intelligent Data Acquisition and Advanced Computing Systems, IDAACS 2013, Berlin, Germany, 12–14 September 2013; Volume 2, pp. 547–550. [Google Scholar]

- Coster, C.J.; van Wijk, S. “Lean project management—An exploratory research into lean project management in the Swedish public and private sector”. Master’s Thesis, Umeå School of Business and Economics, Umeå, Sweden, 2015. Available online: https://www.diva-portal.org/smash/get/diva2:850350/FULLTEXT01.pdf (accessed on 12 December 2022).

- Karlsson, C.; Ahlstrom, P. Assessing changes towards lean production. Int. J. Oper. Prod. Manag. 1996, 16, 24–41. [Google Scholar] [CrossRef]

- Liker, J.K.; Morgan, J.M. The Toyota Way Fieldbook: A Practical Guide for Implementing Toyota’s 4P; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Rossini, M.; Cifone, F.D.; Kassem, B.; Costa, F.; Portioli-Staudacher, A. Being lean: How to shape digital transformation in the manufacturing sector. J. Manuf. Technol. Manag. 2021, 32, 239–259. [Google Scholar] [CrossRef]

- Mabe, K.; Bwalya, K.J. Critical soft skills for information and knowledge management practitioners in the fourth industrial revolution. SA J. Inf. Manag. 2022, 24, 11. [Google Scholar] [CrossRef]

- Gulati, R.; Reaiche, C.H. Soft Skills: A Key Driver for Digital Transformation. In Proceedings of the ICDS 2020: The Fourteenth International Conference on Digital Society Soft, Valencia, Spain, 21–25 November 2020; pp. 40–43. [Google Scholar]

- Nagy, Z. The Importance of Soft Skills. In Soft Skills to Advance Your Developer Career; Apress: Berkeley, CA, USA, 2019; pp. 1–28. [Google Scholar] [CrossRef]

- Bhasin, S.; Burcher, P. Lean viewed as a philosophy. J. Manuf. Technol. Manag. 2006, 17, 56–72. [Google Scholar] [CrossRef]

- Melton, T. Agile project management for API projects: Get Agile—deliver faster. In Proceedings of the ISPE European Conference 2003, Madeira, Portugal, 26–30 July 2003. [Google Scholar]

- Kadarova, J.; Demecko, M. New approaches in Lean Management. In Proceedings of the 3rd Global Conference on Business, Economics, Management and Tourism, Rome, Italy, 26–28 November 2015; Volume 39, pp. 11–16. [Google Scholar] [CrossRef]

- Andriole, S.J. Skills and Competencies for Digital Transformation. IT Prof. 2018, 20, 78–81. [Google Scholar] [CrossRef]

- Venumuddala, V.R.; Kamath, R. Lean 4.0 for customer-centric digital transformation: Analysis through a work systems framework. SSRN Electron. 2021, 643, 1–11. [Google Scholar] [CrossRef]

- Warner, K.S.R.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Tyagi, S.; Choudhary, A.; Cai, X.M.; Yang, K. Value stream mapping to reduce the lead-time of a product development process. Int. J. Prod. Econ. 2015, 160, 202–212. [Google Scholar] [CrossRef]

- Samudio, M.; Alves, T.d.C.L.; Chambers, D. Employing the principle of “going and seeing” to construction. Lean Constr. J. IGLC Spec. Issue 2011, 41–53. [Google Scholar]

- Dombrowski, U.; Mielke, T. Lean Leadership-15 Rules for a sustainable Lean Implementation. Procedia CIRP 2014, 17, 565–570. [Google Scholar] [CrossRef]

- Ballard, G. The lean project delivery system: An update. Lean Constr. J. 2008, 5, 1–19. [Google Scholar]

- van Laar, E.; van Deursen AJA, M.; van Dijk JAG, M.; de Haan, J. The relation between 21st-century skills and digital skills: A systematic literature review. Comput. Human Behav. 2017, 72, 577–588. [Google Scholar] [CrossRef]

- Lander, E.; Liker, J.K. The Toyota Production System and art: Making highly customized and creative products the Toyota way. Int. J. Prod. Res. 2007, 45, 3681–3698. [Google Scholar] [CrossRef]

- Aas, T.H.; Alaassar, A. The Impact of Visual Performance Management on Decision-Making in the Entrepreneurial Process. Int. J. Innov. Manag. 2018, 22, 5. [Google Scholar] [CrossRef]

- Liker, J.K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2020. [Google Scholar]

- Aasland, K.; Blankenburg, D. An analysis of the uses and properties of the Obeya. In Proceedings of the 2012 18th International Conference on Engineering, Technology and Innovation, ICE 2012, Munich, Germany, 18–20 June 2012. [Google Scholar] [CrossRef]

- Zhang, B.; Niu, Z.W.; Liu, C.C. Lean Tools, Knowledge Management, and Lean Sustainability: The Moderating Effects of Study Conventions. Sustainability 2020, 12, 956. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Kruger, C.; Caiado, R.G.G.; Franca, S.L.B.; Quelhas, O.L.G. A holistic model integrating value co-creation methodologies towards the sustainable development. J. Clean. Prod. 2018, 191, 400–416. [Google Scholar] [CrossRef]

- Hair, J.F., Jr.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Análise Multivariada de Dados; Bookman: Porto Alegre, Brazil, 2009. [Google Scholar]

- Bartlett, J.E., II; Kotrlik, J.W.; Higgins, C.C. Determing appropriate sample size in survey research. Inf. Technol. Learn. Perform. J. 2001, 19, 43–50. [Google Scholar]

- Megliorini, E.; Weffort, E.F.J.; de Holanda, V.B. Amostragem. In Pesquisa Operacional Para Decisão em Contabilidade e Administração: Contabilometria; Atlas: São Paulo, Brazil, 2004; pp. 19–74. [Google Scholar]

- Tavakol, M.; Dennick, R. Making sense of Cronbach’s alpha. Int. J. Med. Educ. 2011, 2, 53–55. [Google Scholar] [CrossRef]

- Santos, J.R.A. Cronbach’s Alpha: A Tool for Assessing the Reliability of Scales. J. Ext. 1999, 37, 2. [Google Scholar]

- Da Hora, H.R.M.; Rego Monteiro, G.T.; Arica, J. Confiabilidade em Questionários para Qualidade: Um Estudo com o Coeficiente Alfa de Cronbach. Prod. Produção 2010, 11, 2. [Google Scholar] [CrossRef]

- Tarí, J.J.; García-Fernández, M. A proposal for a scale measuring innovation in a total quality management context. Total Qual. Manag. Bus. Excell. 2020, 31, 1703–1717. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Quelhas, O.L.G.; Nascimento, D.L.D.; Anholon, R.; Leal, W. Towards sustainability by aligning operational programmes and sustainable performance measures. Prod. Plan. Control 2019, 30, 413–425. [Google Scholar] [CrossRef]

- Saraph, J.V.; Benson, P.G.; Schroeder, R.G. An Instrument for Measuring the Critical Factors of Quality Management. Decis. Sci. 1989, 20, 810–829. [Google Scholar] [CrossRef]

- Xiong, J.J.; He, Z.; Ke, B.; Zhang, M. Development and validation of a measurement instrument for assessing quality management practices in hospitals: An exploratory study. Total Qual. Manag. Bus. Excell. 2016, 27, 465–478. [Google Scholar] [CrossRef]

- Blok, V.; Wesselink, R.; Studynka, O.; Kemp, R. Encouraging sustainability in the workplace: A survey on the pro-environmental behaviour of university employees. J. Clean. Prod. 2015, 106, 55–67. [Google Scholar] [CrossRef]

- George, D.; Mallery, P. IBM SPSS Statistics 27 Step by Step; Routledge: London, UK, 2021. [Google Scholar] [CrossRef]

- Fabrigar, L.R.; Wegener, D.T. Exploratory Factor Analysis. Understanding Statistics; Oxford University Press: Oxford, UK, 2011. [Google Scholar]

- Deming, W.E. Out of the Crisis; MIT Press: Cambridge, MA, USA, 1982. [Google Scholar]

- García-Alcaraz, J.L.; Flor-Montalvo, F.J.; Avelar-Sosa, L.; Sánchez-Ramírez, C.; Jiménez-Macías, E. Human Resource Abilities and Skills in TQM for Sustainable Enterprises. Sustainability 2019, 11, 6488. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).