1. Introduction

Over recent decades, the greenhouse effect and consequent climate change have predominantly arisen due to the excessive release of anthropogenic CO

2 emissions. Furthermore, the continued utilization of fossil fuels in industrial processes is anticipated to lead to further escalation of CO

2 emissions in the forthcoming years [

1]. The concentration of CO

2 in the atmosphere was equal to 422.04 ppm on 27 July 2023, and this value increased by 0.80% compared to 27 July 2022 [

2]. In light of the imperative to attain carbon emissions reduction targets, the technology of CO

2 capture has garnered significant attention.

Ammonia-containing solvents are employed for CO

2 capture nowadays. However, these solvents degrade over time, leading to equipment corrosion and challenging regeneration after CO

2 capture [

3]. Solid adsorbents and significantly activated carbons have been identified as promising alternatives to overcome these drawbacks [

4].

Presently, there is a considerable and noteworthy focus on activated carbons synthesized from biomass and biomass waste [

5]. These materials have become the subject of significant scientific interest due to their versatile applications, including gas adsorption [

6,

7], solution adsorption [

7,

8], catalytic functionalities [

9,

10,

11], and supercapacitor capabilities [

12,

13], among others.

Commercial avocado applications prioritize the valuable pulp, neglecting the stone and peel, which end up in landfills. Avocado stones account for about 26% of the fruit’s weight and are generated at centralized facilities [

14]. Despite their starch content, the stones are unsuitable as livestock feed due to high polyphenol levels, causing bitterness and potential toxicity. In Mexico, 5% of avocados undergo processing for guacamole, creating 20,000 tons of waste [

15]. The potential of avocado waste as an eco-friendly adsorbent or precursor for activated carbon remains underexplored [

15]. Exploring diverse avocado waste applications can offer cost-effective, environmentally friendly materials addressing environmental challenges.

The recent literature highlights the use of avocado stones as a sustainable raw material for producing activated carbons, which serve as effective adsorbents for various solutions. For phenol removal, avocado stones were physically activated using CO

2 at 900 °C [

16]. Additionally, ZnCl

2 activation in a microwave oven was applied to remove resorcinol and 3-aminophenol from water [

17]. Activated carbon produced from avocado stones exhibited a high adsorption capacity for blue 41 dye after activation with H

3PO

4 [

18]. Furthermore, for fluorine ion sorption from water, avocado stones were activated using either N

2 or CO

2 at temperatures ranging from 600 to 1000 °C [

19]. Another approach involves sulfuric acid activation at 100 °C, resulting in a material suitable for adsorbing Cr(VI) ions from water [

20]. However, all of the activated carbons obtained from avocado stones, as mentioned above, exhibited mesoporous characteristics with low surface area and pore volume. Even with activation by H

2SO

4, the surface area was only 14 m

2/g, and the pore volume was 0.0323 cm

3/g [

20].

Other realistic applications related to CO2 adsorption on the activated carbon could include the following:

Indoor Air Quality: Activated carbon filters are commonly used in heating, ventilation, and air conditioning systems to remove CO2 and other volatile organic compounds from indoor air. This helps improve indoor air quality and ensures a healthier environment in buildings.

Gas Purification: Activated carbon can be used to purify gases, including CO2, by adsorbing impurities and contaminants. This is crucial in industries such as natural gas processing, biogas upgrading, and hydrogen production, where high-purity gases are required.

Respiratory Protection: Activated carbon is used in respiratory protection devices, such as gas masks and respirators, to adsorb CO2 and other toxic gases, providing a safe breathing environment for workers in hazardous conditions.

Beverage Carbonation: Activated carbon is used in the beverage industry to remove CO2 from water, allowing for the production of carbonated beverages like soda and sparkling water.

Air Separation: Activated carbon can be used in air separation processes to selectively adsorb CO2 from the air, facilitating the production of high-purity nitrogen or oxygen for industrial applications.

Biogas Upgrading: Activated carbon is employed in the upgrading of biogas (produced from organic waste) by adsorbing CO2 and impurities, resulting in a cleaner and more valuable fuel source.

Energy Storage: Activated carbon can be used in energy storage devices, such as supercapacitors and batteries, to improve their performance by enhancing the adsorption and release of CO2 ions in certain types of carbon-based electrode materials.

Water Treatment: Activated carbon is often used in water treatment processes to remove CO2 and other dissolved gases, as well as organic contaminants, making the water safe for consumption or industrial use.

We present here a novel method for producing activated carbons from avocado seeds, enabling the creation of microporous sorbents. According to our knowledge, we have demonstrated, for the first time, the feasibility of employing sulfuric acid as an activator for avocado seeds, resulting in the production of microporous materials with a relatively high surface area. The objective was to emphasize the utilization of H

2SO

4 as an activator and to devise an activation method that could yield higher textural parameters in contrast to the methodology delineated in reference [

20], where H

2SO

4 was similarly employed as an activating agent.

The primary objective of this research was to comprehensively examine the influence of both the isotherm type and the method utilized for extracting its parameters on the predictive outcomes within the models. To achieve this, a meticulous analysis was conducted employing a selection of two two-parameter isotherms (Langmuir, Freundlich) and four three-parameter isotherms (Sips, Toth, Radke-Prausnitz, and UNILAN), coupled with five distinct error functions. All of these selections were thoughtfully chosen to address this pertinent matter.

There are works discussing the utility of mathematical adsorption equilibrium models. However, these calculations often rely on a single error function, typically the sum of squares of errors (SSE) [

21,

22]. In our study, we introduce computations that consider five different error functions, revealing that the widely used SSE method does not perform effectively in this particular type of mathematical modeling.

4. Results and Discussion

The average particle size after grinding the avocado stone was 18 μm.

Figure 1 shows an SEM image of a representative particle of dry avocado seed powder. The spherical shape was observed.

The elemental composition of starting material was determined using the EDX method. Avocado seeds contained, in addition to carbon: oxygen (21%), magnesium (0.5%), phosphorus (0.3%), chlorine (0.5%), potassium (0.3%), and calcium (0.3%). The XRD spectrum of the avocado stones after drying is shown in

Figure 2.

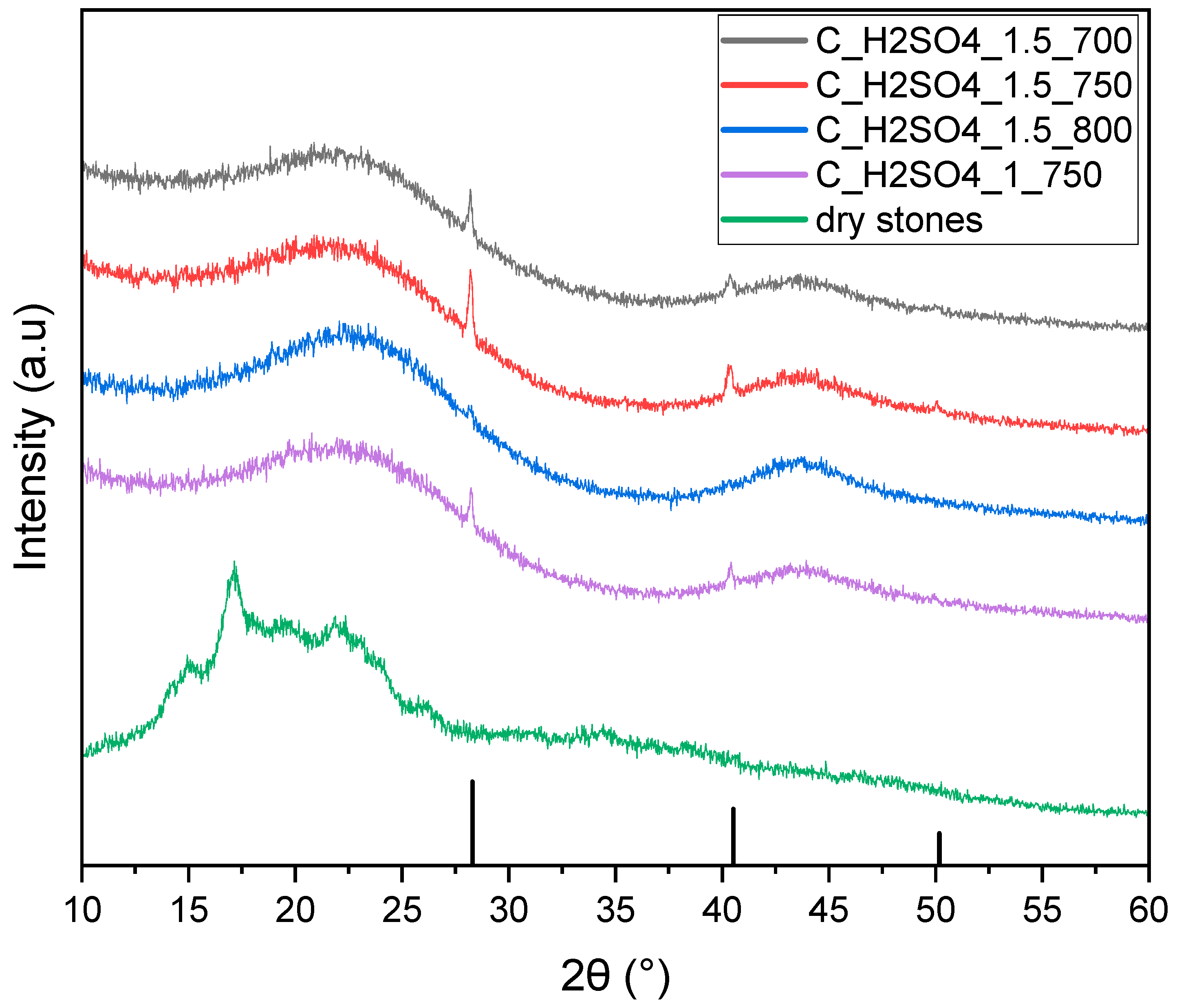

The graphitic structure and the purity of activated carbons were analyzed by the XRD method.

Figure 2 shows the XRD patterns of the samples. Two broad peaks cantered at about 2θ = 23 and 43° were observed. The broad peaks indicated a highly disordered carbon structure, which is typical for activated carbons. The observed diffractogram peak positions and their respective widths at half height exhibited remarkable congruence, underlining the similarity of the structure and degree of disorder among the investigated carbon materials.

Two sharp peaks at diffraction angles of 28.3° and 40.5° were observed in the diffraction pattern of all activated carbons. A third small peak was present at 2θ = 50.2° for the C_H2SO4_1.5_750. The peaks were identified as corresponding to KCl (JCPDS 04-0587). Both potassium and chlorine were present in the starting material. KCl peaks were absent on the XRD spectrum of dry seeds. Most likely, KCl crystallization occurred as a result of a series of reactions that occurred during carbonization combined with chemical activation. Based on the different heights of the KCl peaks, it can be assumed that the formation of KCl depends on both the temperature and the amount of sulfuric acid.

The yield of activated carbons depended strongly on the amount of sulfuric acid used (

Table 1). At a mass ratio of avocado to acid equal to 1, the yield was 21%. Increasing the amount of acid to 1.5 caused the yield to drop by about half. The temperature of carbonization combined with activation in the range of 700 to 800 °C did not affect the production yield of activated carbon.

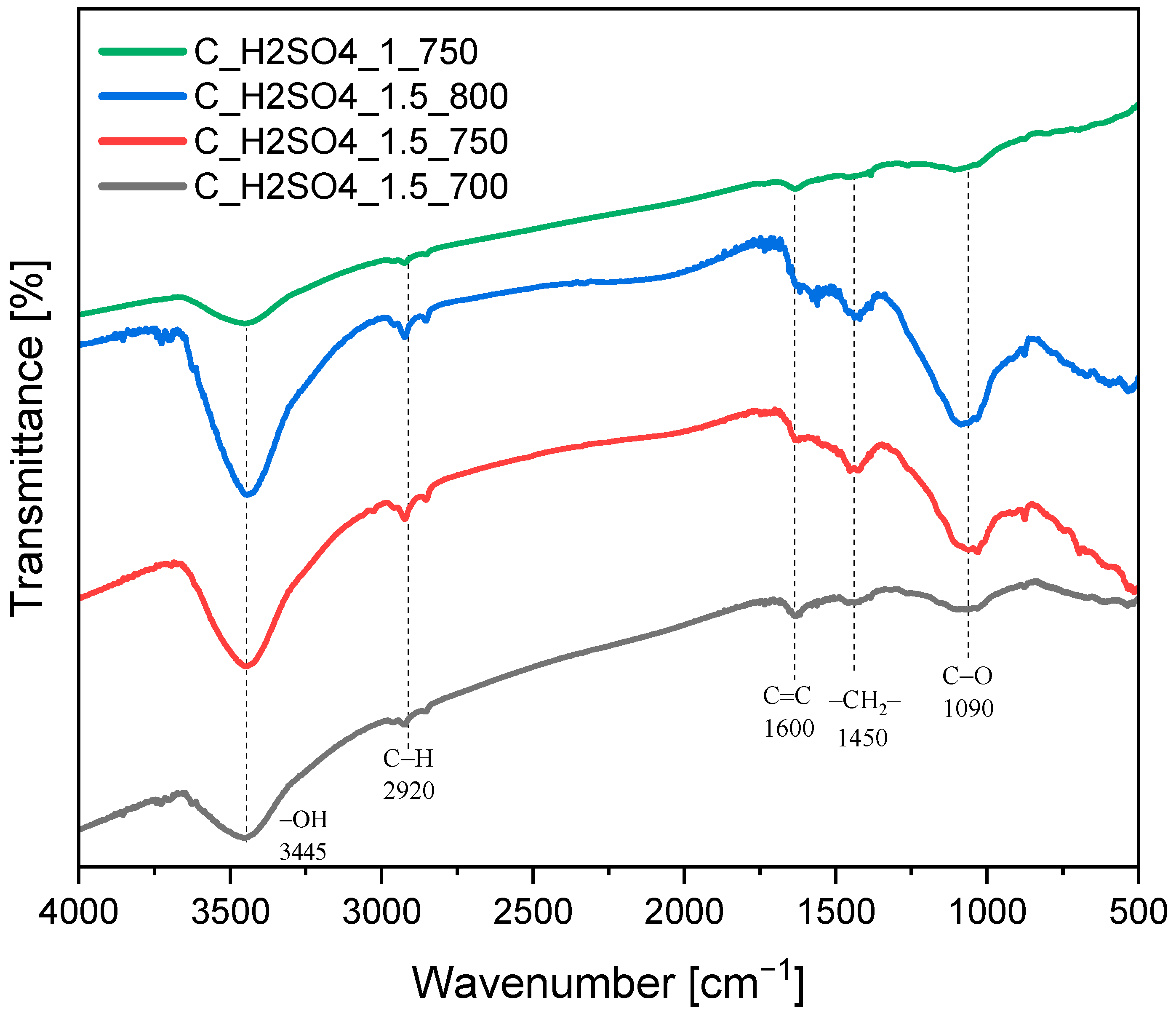

The FTIR spectrum provides valuable insights into the types and amounts of functional groups on the carbon’s surface, which can influence its adsorption properties. Typical functional groups found on activated carbons were observed (

Figure 3). The O-H stretching vibrations were observed in the range of 3200–3600 cm

−1. Aliphatic C-H stretching vibrations were identified at approximately 2920 cm

−1. Carbon–carbon (C-C) bonds, typical for activated carbons, were observed at 1600 cm

−1. At 1450 cm

−1, stretching vibrations of the CH2 groups were also detected. Bands at 1090 cm

−1, associated with C-O stretching vibrations, indicated the presence of various oxygen-containing functional groups, including ethers, alcohols, and phenolic groups.

Polar functional groups on the activated carbon surface, such as hydroxyl (-OH), are crucial for CO2 adsorption. CO2 molecules can form weak chemical bonds (such as hydrogen bonding) with these polar groups, enhancing their adsorption capacity.

Isotherms of nitrogen adsorption at 77 K are depicted in

Figure 4. All of the isotherms exhibit a swift rise at low p/p

0 pressure values, suggesting that the activated carbons derived from avocado stones and activated by H

2SO

4 are microporous materials. Notably, hysteresis loops for all samples appear exceedingly narrow, occasionally even imperceptible, without adequate magnification. The presence of these hysteresis loops indicates the coexistence of mesopores alongside the micropores.

All of the nitrogen adsorption isotherms depicted in

Figure 1 can be classified as type I according to the IUPAC classification or, more precisely, type Ia [

33]. This pattern is indicative of an ordered microporous material. The slight hysteresis loops observed in the examined coals were of the H4 type, which is associated with the presence of slit-like mesopores [

34].

The data presented in

Table 2 confirm the conclusions drawn from the figure. They indicate the presence of micropores (approximately 80% of all pores) and mesopores. The specific surface area of the adsorbents ranged from 538 to 636 m

2/g. The highest surface area, total pore volume, and micropore volume were observed for the material carbonized at the temperature of 750 °C with the ratio of activator to carbon source equal to 1.5 (C_H2SO4_1.5_750). Changes in the carbonization temperature and the ratio of the activator to the carbon source led to a decrease in the textural parameters.

Analyzing the effect of temperature on textural properties, it was found that the highest values for specific surface area, pore volume and micropores were obtained for the average temperature carbonization combined with activation, i.e., 750 °C. A lower temperature (700 °C) was too low for the development of sufficient porosity. At the higher temperature (800 °C), the porous structure that formed was partially degraded. Reducing the amount of activating agent, i.e., sulfuric acid, led to a decrease in the values of textural parameters. Too low an amount of activating agent did not allow sufficient development of the porous structure.

On the basis of values from the

Table 3, we can assume that the Rouquerol criteria have been met and the BET equation can be applied for these activated carbons.

Figure 5 shows the pore size distribution determined by the DFT method based on nitrogen adsorption measurements. The method allows for determining the content of pores with diameters in the range of 0.3–30 nm. However, no significant pore volume with diameters larger than 2 nm was observed. Therefore, in

Figure 5, on the

x-axis, a range up to 3 is presented. The highest pore volume was observed for small micropores in the range of 0.3–0.6 nm.

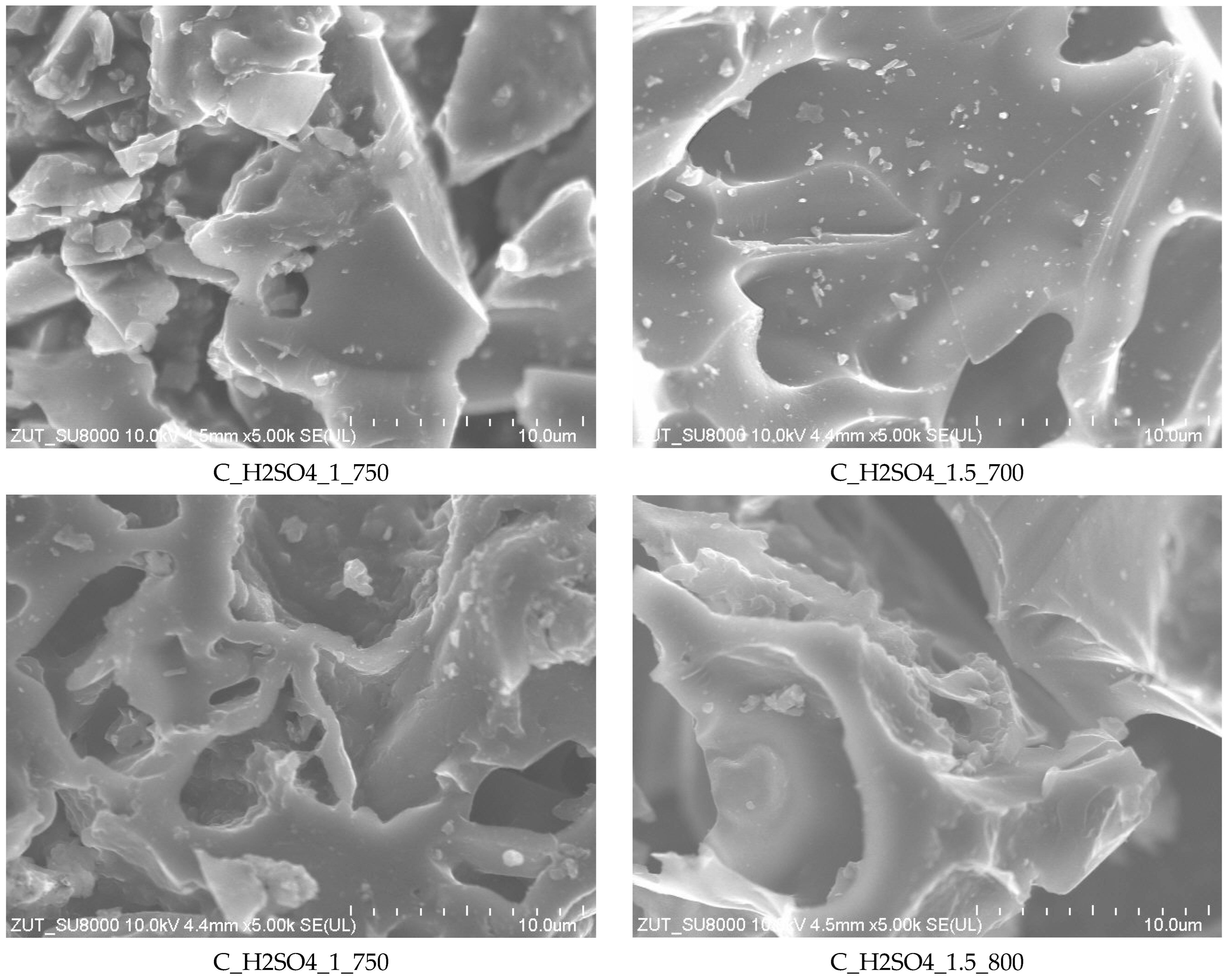

Figure 6 shows SEM images of the obtained activated carbons Their morphology was very similar and significantly different from the starting material. The SEM images show macropores that serve as the initial conduits within porous materials, and they frequently bifurcate into smaller structures known as mesopores. These mesopores, in turn, exhibit a branching pattern, further subdividing into even smaller entities called micropores. This hierarchical arrangement of pores plays a crucial role in determining the material’s overall surface area and its capacity for various adsorption processes.

Activated carbons were tested for their CO

2 adsorption capabilities. The experiments were conducted at a temperature of 0 °C and a pressure to 1 bar. The results are depicted in

Figure 7. For all of the activated carbons, the CO

2 adsorption isotherms at 0 °C exhibited a similar pattern, showing rapid growth at low pressures followed by a more gradual increase at higher pressures.

Table 2 lists textural parameters of activated carbons prepared from avocado stones and activated by H

2SO

4 and CO

2 adsorption at a temperature of 0 °C and pressure of 1 bar..

The highest CO2 adsorption, under a pressure of 1 bar, was achieved using activated carbon obtained at a temperature of 750 °C, with a mass ratio of H2SO4 to avocado seed equal to 1.5. The adsorption of carbon dioxide on C_H2SO4_1.5_750 was equal to 3.78 mmol/g.

Table 4 presents a summary of CO

2 adsorption outcomes for activated carbons derived from diverse carbon sources. While our CO

2 adsorption results may not claim the top position, they remain competitive when juxtaposed with outcomes from alternative materials.

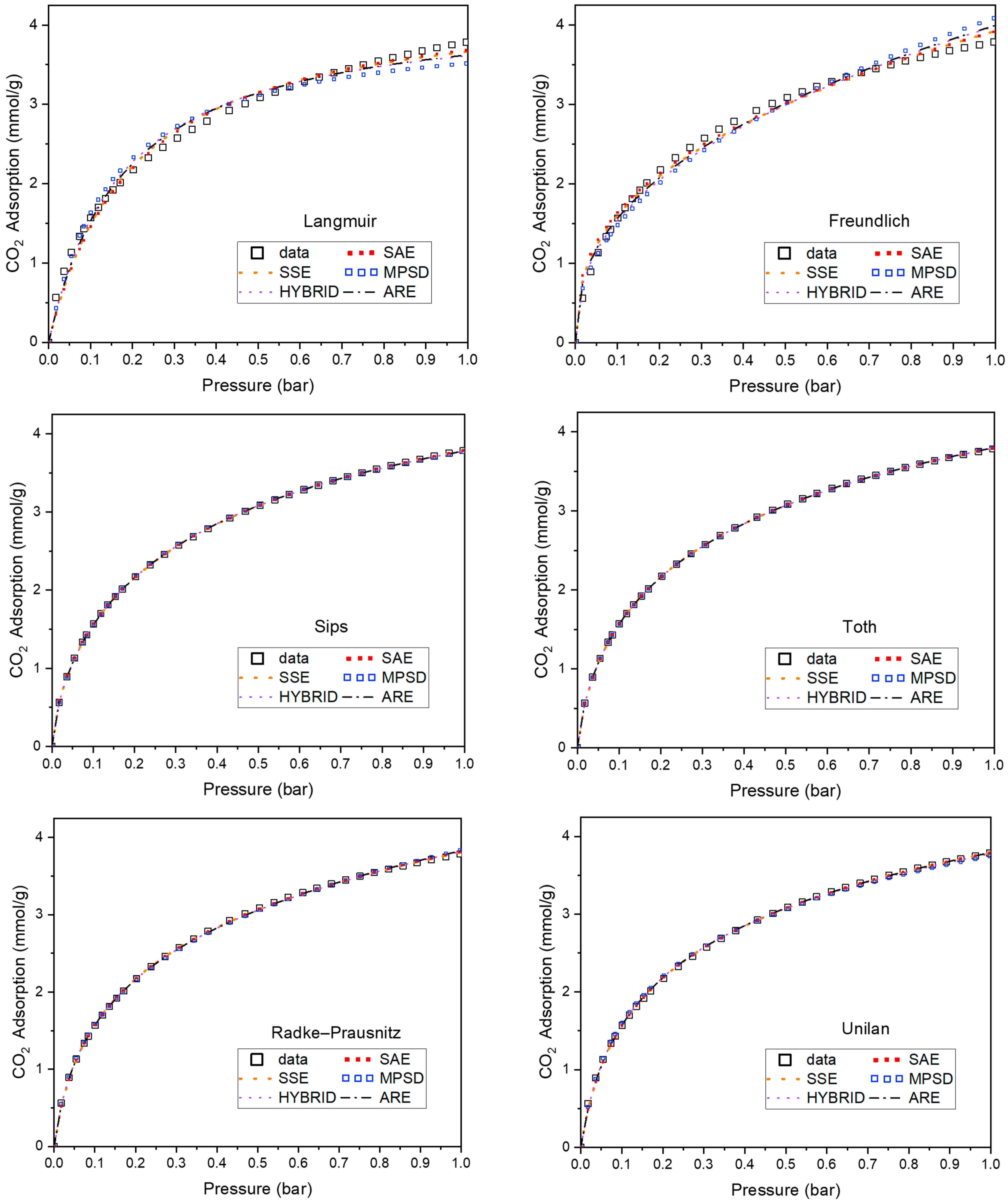

Experimental data of CO

2 adsorption isotherms (

Figure 7) were analyzed using the Langmuir, Freundlich, Sips, Toth, Radke–Prausnitz, and UNILAN equations. The parameters of these isotherm models were determined through non-linear regression analysis. To assess the quality of the model fit to the experimental data, the following error methods were employed: SSE, SAE, ARE, MPSD, HYBRID and SNE. The detailed results are presented in

Table 5,

Table 6,

Table 7,

Table 8,

Table 9 and

Table 10.

Table 5 displays the Langmuir isotherm constants obtained through non-linear regression for C_H2SO4_1.5_800, C_H2SO4_1.5_750, C_H2SO4_1.5_700, and C_H2SO4_1_750 using different error functions. The derived values of constants q

mL and b

L for each material are found to exhibit similarity. However, it is noteworthy that the error magnitudes are relatively high. SNE ranged from 3.6664 to 4.6744. This observation indicates that the Langmuir isotherm does not serve as an optimal model for accurately describing carbon dioxide adsorption on carbons activated by H

2SO

4. In light of the sum of normalized errors (SNE) analysis, it is apparent that the parameter sets yielding the most favorable overall Langmuir fit are based on the ARE.

Table 6 presents the Freundlich isotherm constants acquired via non-linear regression for the experimental conditions denoted as C_H2SO4_1.5_800, C_H2SO4_1.5_750, C_H2SO4_1.5_700, and C_H2SO4_1_750. Various error functions were employed during the regression analysis to assess the goodness-of-fit of the model to the experimental data. The determined values of the Freundlich constants, b

F and n

F, for each studied material, display a degree of similarity. Nevertheless, it is essential to acknowledge that the associated error magnitudes are relatively elevated. The SNE ranges from 3.4679 to 4.4975, which signifies that the Freundlich isotherm model does not provide an optimal fit for precisely characterizing the process of carbon dioxide adsorption on carbons produced from avocado seeds activated by H

2SO

4. The analysis of SNE reveals that among the investigated parameter sets, the HYBRID approach yields the most favorable overall fit for both C_H2SO4_1.5_750 and C_H2SO4_1.5_800 in the context of the Freundlich isotherm model. On the other hand, for C_H2SO4_1.5_700 and C_H2SO4_1_750, the ARE error function demonstrates superior performance in achieving an optimal fit. These findings suggest that different error functions may be more suitable for specific adsorbent systems, emphasizing the significance of selecting appropriate error metrics tailored to the unique characteristics of the adsorption process under investigation.

Table 7 presents the Sips isotherm constants that were determined through non-linear regression, employing a diverse range of error functions. The derived constants, qm

S, b

S, and n

S, exhibit similarity across all error functions, indicating consistent adsorption behavior across the adsorbents studied. The error magnitudes are relatively low. SNE ranged from 2.7578 to 4.4812. The SNE values for C_H2SO4_1.5_750 and C_H2SO4_1_750 adsorbents are the lowest compared to other models, highlighting the Sips equation’s efficacy in providing a reasonable approximation to the optimum parameter set. The ARE error function provides the most favorable overall fit for both of these materials. For the other two sorbents, the HYBRID error function proves to be more suitable. These results underscore the importance of employing specific error metrics tailored to the characteristics of individual adsorbent systems. Based on the findings, it is recommended to utilize the Sips isotherm equation for the analysis of experimental data for C_H2SO4_1.5_750 and C_H2SO4_1_750 due to its consistently good fit regardless of the chosen error function. This conclusion is corroborated by the excellent agreement between the experimental adsorption isotherm and the Sips equation model, further supporting the suitability of the Sips model for describing the adsorption process in the study of these materials.

Table 8 presents the Toth isotherm constants obtained through non-linear regression for C_H2SO4_1.5_800, C_H2SO4_1.5_750, C_H2SO4_1.5_700, and C_H2SO4_1_750, employing different error functions. The derived values of qm

T, b

T and n

T for each material show a degree of similarity. However, it is important to note that the associated error magnitudes are the highest, with SNE values ranging from 3.8325 to4.7586. This finding suggests that the Toth isotherm model is the least suitable for accurately describing carbon dioxide adsorption on carbons activated by H

2SO

4. The analysis of SNE indicates that the parameter sets yielding the most favorable overall Toth fit are based on the HYBRID.

Table 9 presents the Radke–Prausnitz isotherm constants obtained through non-linear regression for activated carbons produced from avocado stones activated by H

2SO

4, utilizing different error functions. Each material exhibits a noticeable degree of similarity in the determined values of constants q

mRP, b

RP and n

RP. However, it is pertinent to acknowledge that the associated error magnitudes are relatively low, with SNE values ranging from 3.1571 to 4.2494. These findings collectively indicate that the Radke–Prausnitz isotherm model does not serve as an optimal representation for accurately describing carbon dioxide adsorption on carbons activated by H

2SO

4. The observed high SNE values suggest that the model does not adequately capture the complexity of the adsorption process under investigation. In light of the SNE analysis, it becomes evident that the parameter sets leading to the most favorable overall Radke–Prausnitz fit are those based on the ARE.

Table 10 presents the UNILAN isotherm constants determined through non-linear regression, employing a diverse range of error functions. The derived constants, q

mU, b

U, and s, demonstrate a remarkable degree of similarity across all error functions, indicating consistent adsorption behavior across the studied adsorbents. It is noteworthy that the error magnitudes associated with the UNILAN model are relatively low, with SNE values ranging from 3.0383 to 4.6702. Particularly, for the C_H2SO4_1.5_700 and C_H2SO4_1_750 adsorbents, the SNE values are the lowest compared to other models, highlighting the UNILAN equation’s efficacy in providing a reasonable approximation to the optimum parameter set. The analysis reveals that the ARE error function yields the most favorable overall fit for both the C_H2SO4_1.5_750 and C_H2SO4_1.5_800 materials. Conversely, for the other two sorbents (C_H2SO4_1.5_700 and C_H2SO4_1.5_700), the SSE error function demonstrates greater suitability. Based on these findings, it is recommended to employ the UNILAN isotherm equation for the analysis of experimental data concerning the _H2SO4_1.5_700 and C_H2SO4_1_750 materials due to its consistent good fit regardless of the chosen error function. This conclusion is further supported by the excellent agreement between the experimental adsorption isotherm and the UNILAN equation model, reaffirming the suitability of the Sips model for accurately describing the adsorption process in the study of these materials.

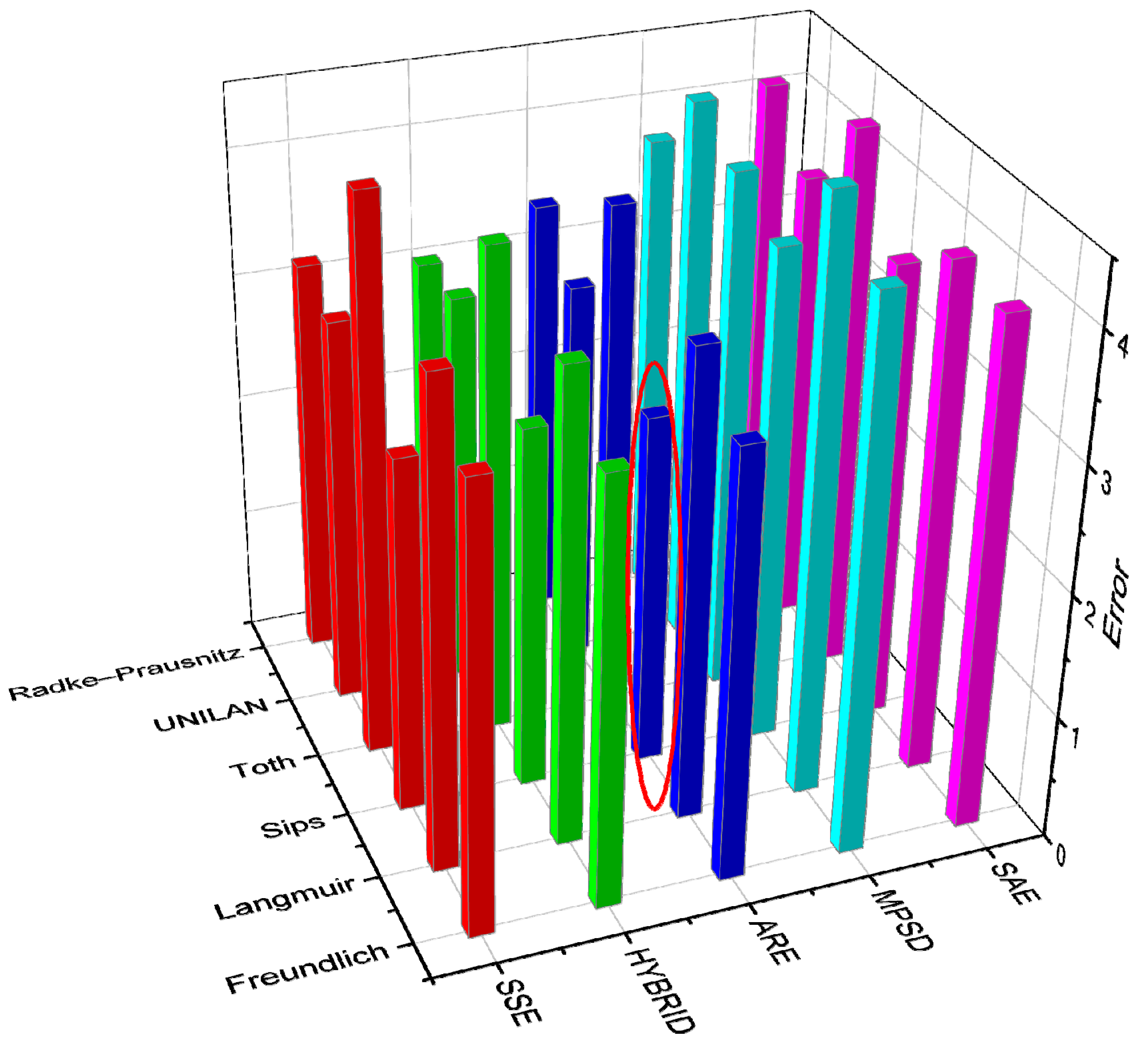

Figure 8 shows the analysis of adsorption isotherms and the error function used for the calculations of the best CO

2 sorbent, i.e., C_H2SO4_1.5_750.

It was found that the Sips equation described the adsorption data in the best way. The most appropriate error function was ARE.

Figure 9 presents the results of model fitting for CO

2 adsorption on C_H2SO4_1.5_750 at 0 °C using different error functions for the following models: Langmuir, Freundlich, Sips, Toth, Radke–Prausnitz, and UNILAN. It is evident that the Langmuir and Freundlich models are significantly inferior, while the Sips model performs the best.

The CO

2 adsorption investigations over C_H2SO4_1.5_750 at higher temperatures i.e., 10, 20, and 30 °C, were performed (

Figure 10). An increase in the CO

2 adsorption temperature leads to a decrease in CO

2 adsorption, indicating the physical nature of CO

2 adsorption on C_H2SO4_1.5_750.

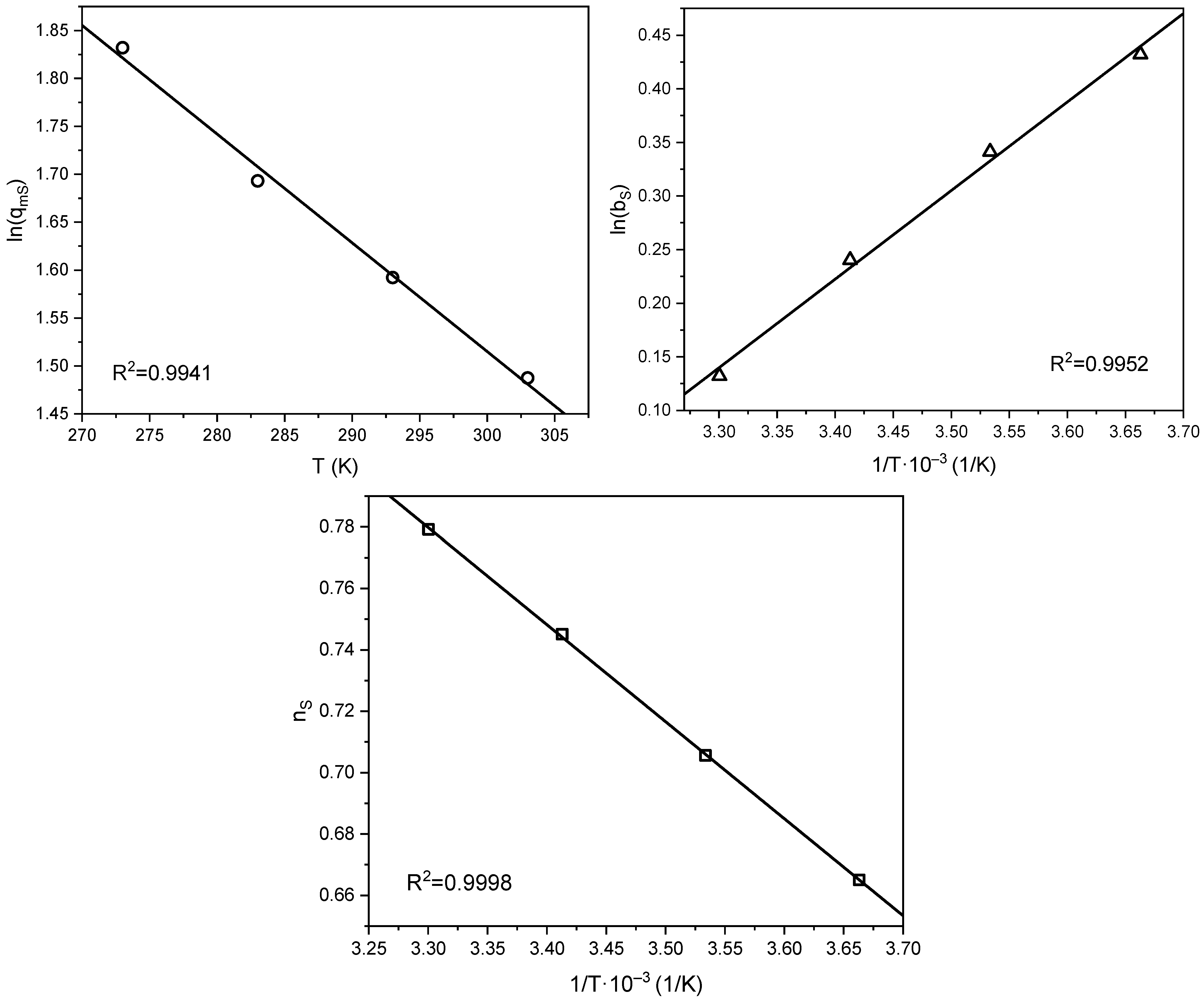

It was found that the adsorption data presented in

Figure 10 can be described by the Sips equation.

The Sips model coefficients for different temperatures for C_H2SO4_1.5_750 are presented in

Table 11. The maximum adsorption value (q

mS) decreases with an increase in temperature. This also confirms the physical nature of CO

2 adsorption over C_H2SO4_1.5_750.

The coefficients within the Sips Equation (4) exhibit temperature dependency described by Equations (15)–(17):

By plotting ln(qmS) vs. T, ln(bS) vs. 1/T and nS vs. 1/T, linear functions are supposed to be obtained.

The functions depicted in

Figure 11 exhibit a linear course. R-squared for each function yielded a value greater than 0.99. This confirms that the Sips equation accurately describes CO

2 adsorption, not only at 0 °C but also within the temperature range of 0 °C to 30°.

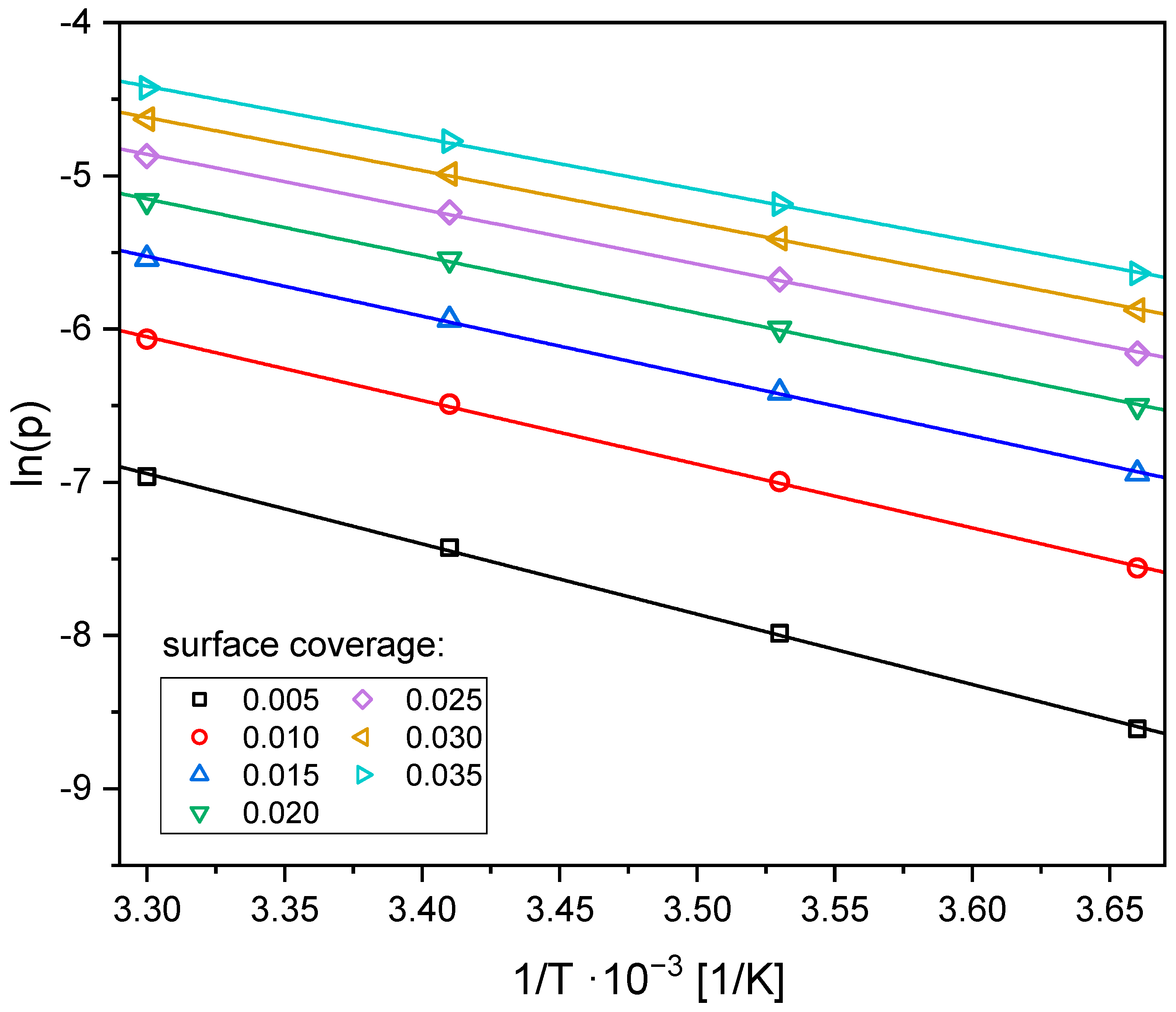

The value of the isosteric heat of adsorption (Q

iso) is essential for characterizing the interactions between the adsorbent and the adsorbate, providing information on the adsorption strength. A higher Q

iso value indicates a stronger interaction between the adsorbate and the adsorbent. However, it also results in a higher cost of regeneration. The isosteric heat of adsorption was calculated using Equation (14). To determine the pressure values for a given degree of surface coverage, the Sips Equation (4) was transformed appropriately (18).

where θ, the degree of surface coverage, is defined as (19):

Parameter values in the Sips equation (q

mS, b

S, n

S) are derived from

Table 11. Isosteric graphs, i.e., the relationship between ln(p)

θ and 1/T for temperatures in the range of 0–30 °C are presented in

Figure 12. On the basis of the values of the slope coefficients of the drawn straight lines, the values of the isosteric heat of adsorption for C_H2SO4_1.5_750 were calculated depending on the degree of coverage (14).

The values of the isosteric heat of CO

2 adsorption for C_H2SO4_1.5_750 as a function of the degree of surface coverage are shown in

Figure 13.

The values of isosteric heat ranged from 28 to 38 kJ/mol for surface coverages from 0.035 to 0.005. These values definitely confirm the physical nature of CO2 sorption on activated carbons. The isosteric heat of adsorption decreased with surface coverage. The greater the surface coverage, the weaker the interaction between carbon dioxide and activated carbons. Carbon dioxide is bound to the surface of activated carbons by van der Waals forces and can be easily desorbed. The isosteric heat of CO2 adsorption on the tested material was low, which makes C_H2SO4_1.5_750 a potentially useful CO2 sorbent.